The Use of Chemical Sensors to Monitor Odour Emissions at Municipal Waste Biogas Plants

Abstract

1. Introduction

2. Materials and Methods

Study Methodology

| PID Sensor | Range | Resolution | Response Time (RT) t90 (s) * | Odour Threshold (OT) (ppm) |

|---|---|---|---|---|

| Volatile organic compounds (VOCs) Ionization energy (IE) 10.6 eV | 0–1000 ppm | 10 ppb (0.01 ppm) | 15 | based on main components ** |

| Electrochemical Sensor | Range | Resolution | Response Time (RS) t90 (s) * | Odour Threshold (OT) (ppm) |

| Ammonia (NH3) | 0–100 ppm | 1 ppm | 60 | 5.2 [14] |

| Hydrogen sulphide (H2S) | 0–100 ppm | 0.1 ppm | 35 | 0.0081 [45] |

| Methanethiol (CH3SH) | 0–10 ppm | 0.1 ppm | <35 | 0.00393 [45] |

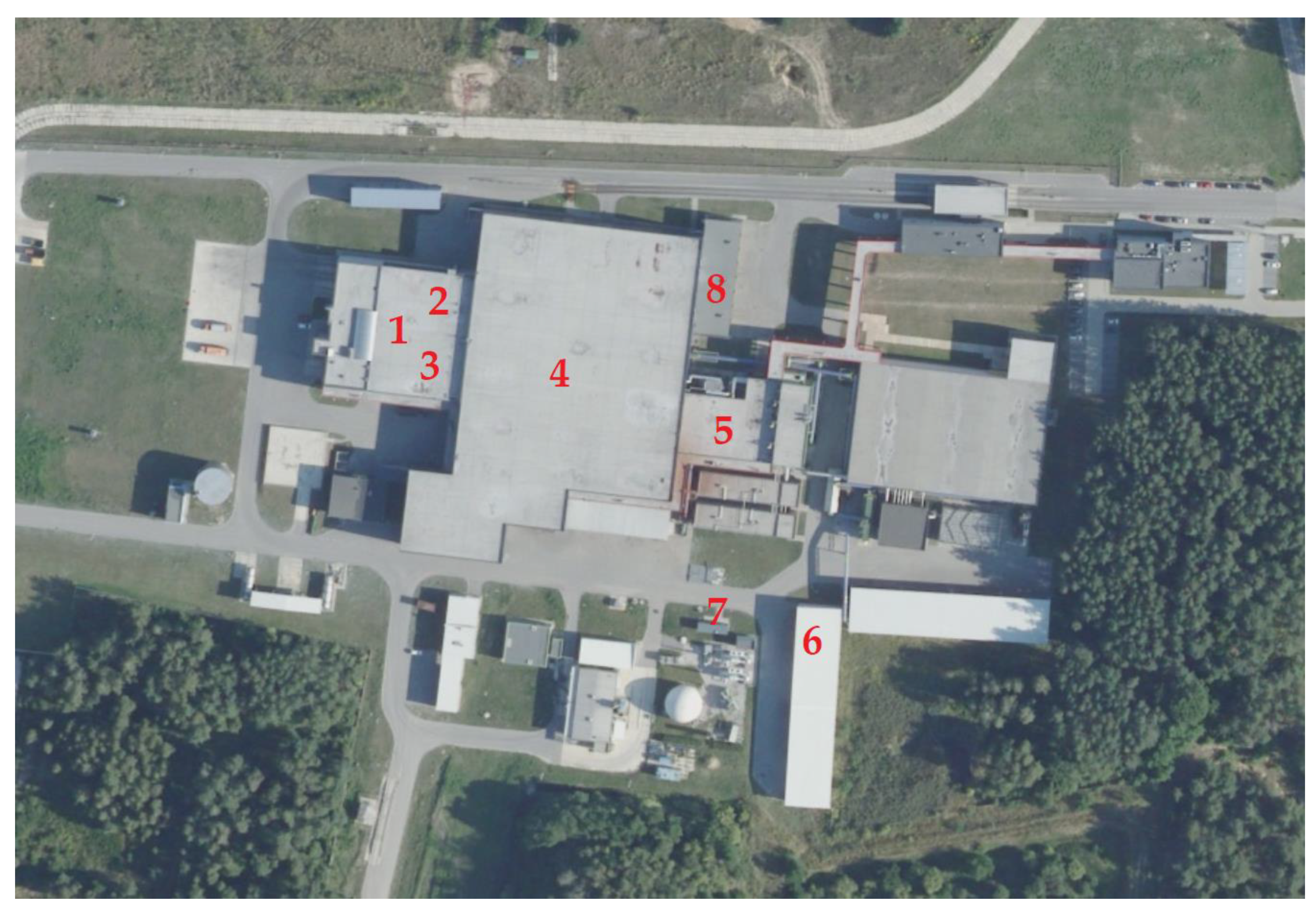

| Mark of Measurement Point | Biogas Plant | ||

|---|---|---|---|

| Biała Podlaska | Promnik | Wólka Rokicka | |

| 1 | Waste storage plant (inside the hall) | ||

| 2 | Mixed waste storage *** | ||

| 3 | Selectively collected waste storage *** | ||

| 4 | Mechanical treatment | ||

| 5 | Fermentation preparation *** | ||

| 6 | Oxygen stabilization *** | ||

| 7 | Technological wastewater pumping station | ||

| 8 | Biofilter *** | Digestate dewatering | Biofilter *** |

3. Results and Discussion

4. Conclusions

- The article presents a practice, in the form of a chemical sensor method, and a tool, in the form of a portable gas detector, for monitoring odorant emission from biogas plants processing municipal waste.

- Measurement research by means of the analyzed method and device can facilitate future activities related to the minimization of odour emissions and can aid in finding the relationships between odorant emissions and the type of treated waste, technological processes, and technological regime.

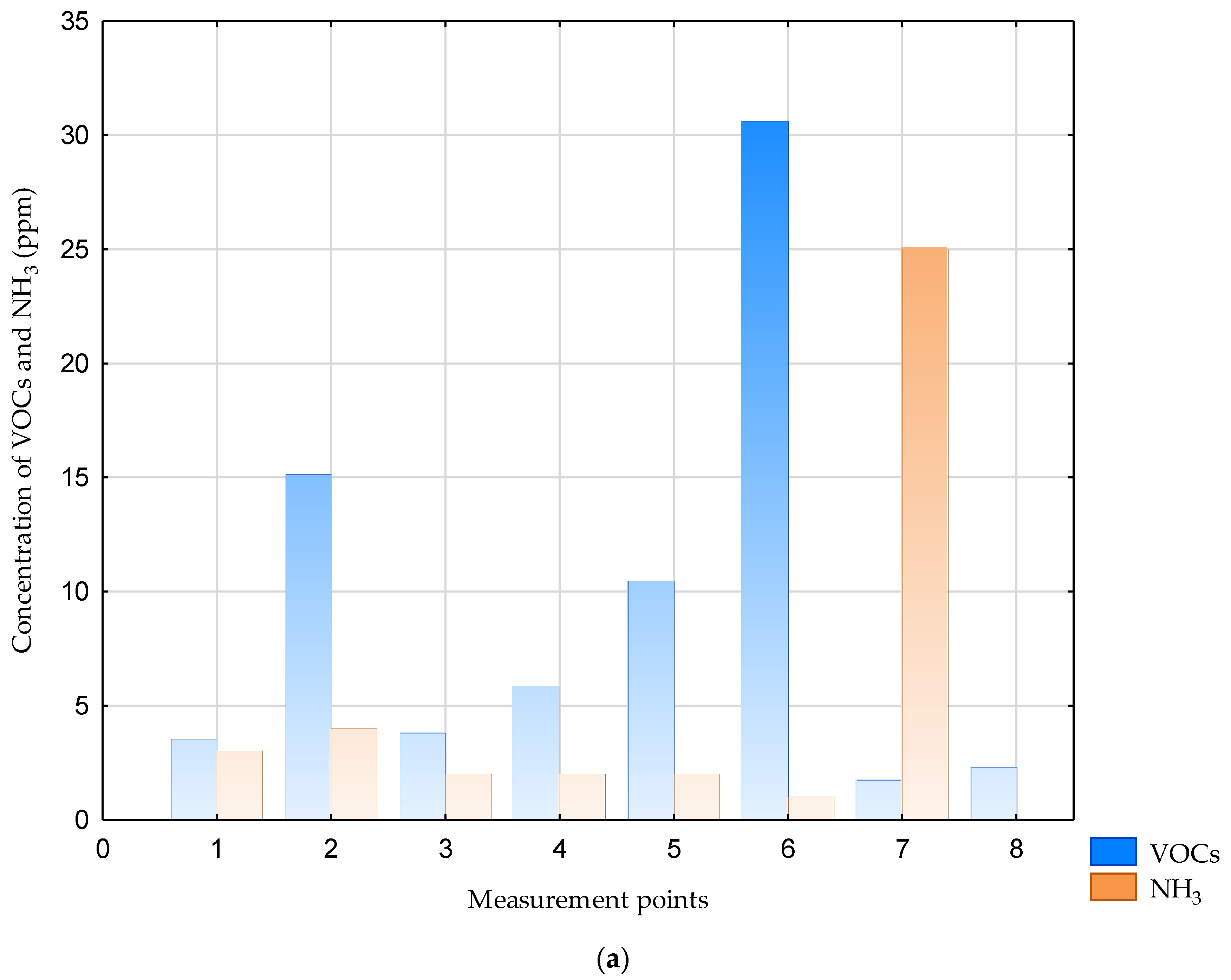

- In the analyzed studies, the highest concentrations of odorants were associated with oxygen stabilization of digestate (both VOC and NH3 concentrations) and with technological wastewater generated at biogas plants (mainly NH3 concentrations). For this reason, special attention should be paid to the encapsulation of biological processes and all wastewater-related operations, and proper exploitation of the pumping station.

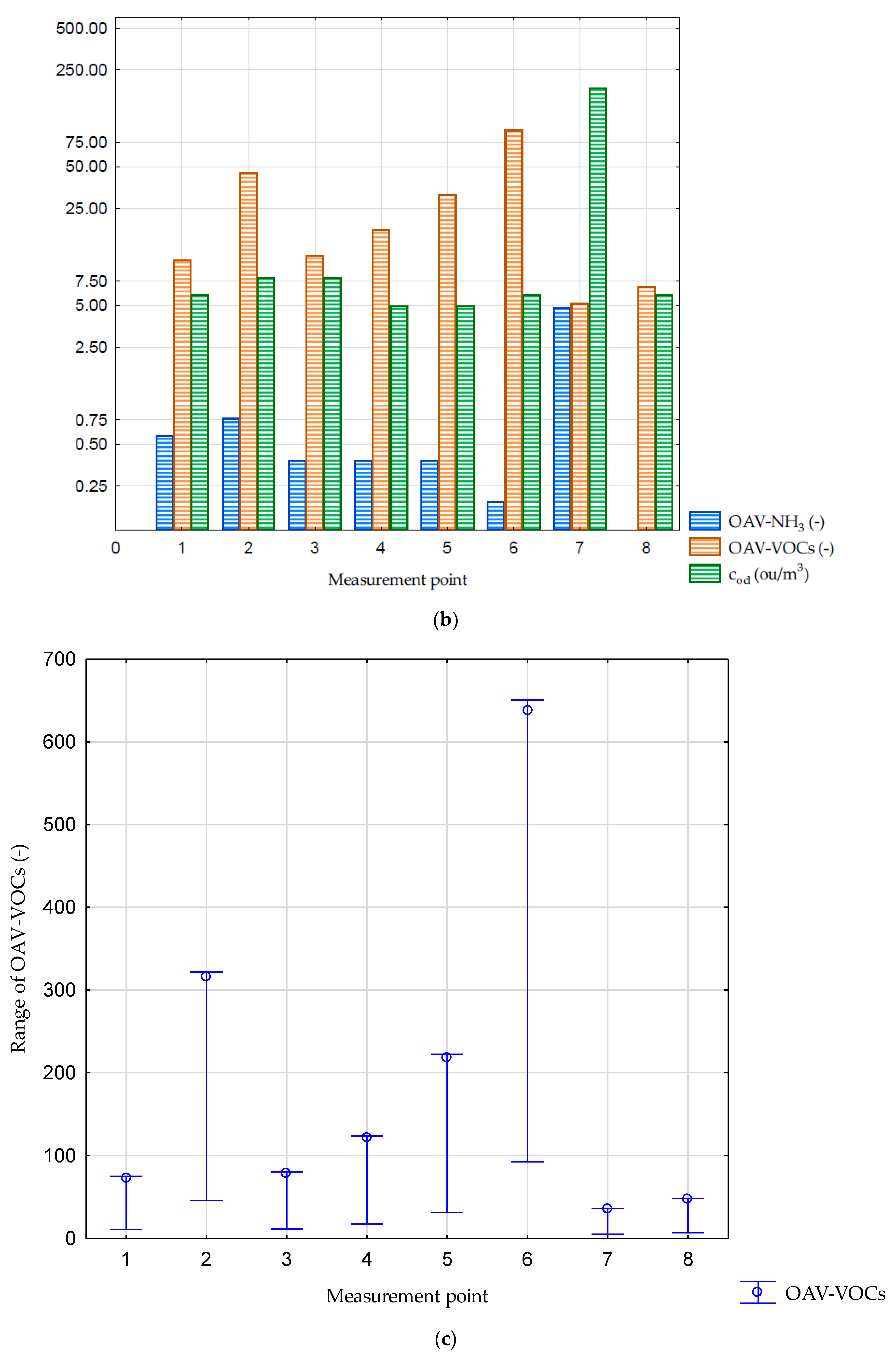

- The portable gas detector can be used to control technological processes in municipal waste biogas plants by measuring the odorant concentrations and calculating the odour activity value (OAV). Thanks to this result, it is possible to plan the activities aimed at minimizing the odour nuisance related to the presence of specific compounds (groups of compounds) in the mixture of process gases. In all analyzed biogas plants, the highest OAV level was determined for VOCs. This indicates the need for VOC monitoring in line with the requirement of Best Available Techniques for waste treatment [52]. The OAV for VOCs can be determined taking into account the predominant components in the VOC mixture. In the case of process gases emitted at the analyzed biogas plants processing municipal waste, the dominance of toluene is very clear, followed by phenol and styrene.

- At the analyzed waste biogas plants, the highest odour concentration concerns the places for which the highest OAV values were determined—either for VOCs, or for NH3, or both. These places were the technological wastewater pumping station and the oxygen stabilization process.

- The analysis of the correlations between VOC and NH3 concentrations shows only a slight connection between these parameters. In many parts of the analyzed technological lines, VOC and NH3 emissions occurred alternately and the concentrations of both the dominant odorants changed. This was confirmed by the OAV analysis, which indicated that only at the technological wastewater pumping station was a similar contribution of NH3 and VOCs to the overall odour of a complex odour mixture observed.

- An unquestionable disadvantage of the analyzed device representing the chemical sensor method is the relatively small range of chemical compound determination. For low odorant concentrations, the use of the device may be unreliable. The device is also sensitive to high humidity. The manufacturer declares a permissible humidity level of 95%, which means limiting the possibility of measurements (e.g., in the line supplying processed air to deodorizing installation or in the tunnel for aerobic stabilization of digestate).

- Further work should be carried out to clarify the correlation between individual odorant characteristics for the treatment of municipal waste.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. The impact of technological processes on odorant emissions at municipal waste biogas plants. Sustainability 2020, 12, 5457. [Google Scholar] [CrossRef]

- Gostelow, P.; Parsons, S.; Stuetz, R. Odour measurements for sewage treatment works. Water Res. 2001, 35, 579–597. [Google Scholar] [CrossRef]

- Tsai, C.-J.; Chen, M.-L.; Ye, A.-D.; Chou, M.-S.; Shen, S.-H.; Mao, I.-F. The relationship of odor concentration and the critical components emitted from food waste composting plants. Atmos. Environ. 2008, 42, 8246–8251. [Google Scholar] [CrossRef]

- Rincón, C.A.; De Guardia, A.; Couvert, A.; Wolbert, D.; Le Roux, S.; Soutrel, I.; Nunes, G. Odor concentration (OC) prediction based on odor activity values (OAVs) during composting of solid wastes and digestates. Atmos. Environ. 2019, 201, 1–12. [Google Scholar] [CrossRef]

- Gallego, E.; Roca, F.J.; Perales, J.F.; Sanchez, G.; Esplugas, P. Characterization and determination of the odorous charge in the indoor air of a waste treatment facility through the evaluation of volatile organic compounds (VOCs) using TD-GC/MS. Waste Manag. 2012, 32, 2469–2481. [Google Scholar] [CrossRef] [PubMed]

- Szulczyński, B.; Wasilewski, T.; Wojnowski, W.; Majchrzak, T.; Dymerski, T.; Namieśnik, J.; Gębicki, J. Different ways to apply a measurement instrument of E-nose type to evaluate ambient air quality with respect to odour nuisance in a vicinity of municipal processing plants. Sensors 2017, 17, 2671. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. Odour Emissions of municipal waste biogas plants—Impact of technological factors, air temperature and humidity. Appl. Sci. 2020, 10, 1093. [Google Scholar] [CrossRef]

- Borowik, P.; Adamowicz, L.; Tarakowski, R.; Siwek, K.; Grzywacz, T. Odor detection using an E-nose with a reduced sensor array. Sensors 2020, 20, 3542. [Google Scholar] [CrossRef]

- Wasilewski, T.; Migoń, D.; Gębicki, J.; Kamysz, W. Critical review of electronic nose and tongue instruments prospects in pharmaceutical analysis. Anal. Chim. Acta 2019, 1077, 14–29. [Google Scholar] [CrossRef]

- Rincón, C.A.; De Guardia, A.; Couvert, A.; Le Roux, S.; Soutrel, I.; Daumoin, M.; Benoist, J.C. Chemical and odor characterization of gas emissions released during composting of solid wastes and digestates. J. Environ. Manag. 2019, 233, 39–53. [Google Scholar] [CrossRef]

- Grzelka, A.; Sówka, I.; Miller, U. Methods for assessing the odor emissions from livestock farming facilities. Inżynieria Ekol. 2018, 19, 56–64. [Google Scholar] [CrossRef][Green Version]

- Muñoz, R.; Sivret, E.C.; Parcsi, G.; Lebrero, R.; Wang, X.; Suffet, I.M.; Stuetz, R.M. Monitoring techniques for odour abatement assessment. Water Res. 2010, 44, 5129–5149. [Google Scholar] [CrossRef] [PubMed]

- Belgiorno, V.; Naddeo, V.; Zarra, T. Odour Impact Assessment Handbook 2013; Belgiorno, V., Naddeo, V., Zarra, T., Eds.; Wiley: Chichester, UK, 2013. [Google Scholar]

- Kośmider, J.; Mazur-Chrzanowska, B.; Wyszyński, B. Odory [Odours]; PWN: Warszawa, Poland, 2012. [Google Scholar]

- Sówka, I.; Skrętowicz, M.; Sobczyński, P.; Zwoździak, J. Estimating odour impact range of a selected wastewater treatment plant for winter and summer seasons in Polish conditions using CALPUFF model. Int. J. Environ. Pollut. 2014, 54, 242. [Google Scholar] [CrossRef]

- Capelli, L.; Sironi, S.; Del Rosso, R.; Céntola, P.; Grande, M.I. A comparative and critical evaluation of odour assessment methods on a landfill site. Atmos. Environ. 2008, 42, 7050–7058. [Google Scholar] [CrossRef]

- Bax, C.; Sironi, S.; Capelli, L. How can odors be measured? An overview of methods and their applications. Atmosphere 2020, 11, 92. [Google Scholar] [CrossRef]

- Blazy, V.; De-Guardia, A.; Benoist, J.C.; Daumoin, M.; Guiziou, F.; Lemasle, M.; Wolbert, D.; Barrington, S. Correlation of chemical composition and odor concentration for emissions from pig slaughterhouse sludge composting and storage. Chem. Eng. J. 2015, 276, 398–409. [Google Scholar] [CrossRef]

- Fang, J.; Zhang, H.; Yang, N.; Shao, L.; He, P. Gaseous pollutants emitted from a mechanical biological treatment plant for municipal solid waste: Odor assessment and photochemical reactivity. J. Air Waste Manag. Assoc. 2013, 63, 1287–1297. [Google Scholar] [CrossRef]

- Schiavon, M.; Martini, L.M.; Corrà, C.; Scapinello, M.; Coller, G.; Tosi, P.; Ragazzi, M. Characterisation of volatile organic compounds (VOCs) released by the composting of different waste matrices. Environ. Pollut. 2017, 231, 845–853. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. Olfactometric testing as a method for assessing odour nuisance of biogas plants processing municipal waste. Arch. Environ. Prot. 2020, 46, 60–68. [Google Scholar] [CrossRef]

- Zhu, Y.-L.; Zheng, G.-D.; Gao, D.; Chen, T.-B.; Wu, F.-K.; Niu, M.-J.; Zou, K.-H. Odor composition analysis and odor indicator selection during sewage sludge composting. J. Air Waste Manag. Assoc. 2016, 66, 930–940. [Google Scholar] [CrossRef]

- Laor, Y.; Parker, D.; Pagé, T. Measurement, prediction, and monitoring of odors in the environment: A critical review. Rev. Chem. Eng. 2014, 30, 139–166. [Google Scholar] [CrossRef]

- Parker, D.B.; Koziel, J.A.; Cai, L.; Jacobson, L.D.; Akdeniz, N.; Bereznicki, S.D.; Lim, T.T.; Caraway, E.A.; Zhang, S.; Hoff, S.J.; et al. Odor and odorous chemical emissions from animal buildings: Part 6. odor activity value. Trans. ASABE 2012, 55, 2357–2368. [Google Scholar] [CrossRef]

- Wu, C.; Liu, J.; Yan, L.; Chen, H.; Shao, H.; Meng, T. Assessment of odor activity value coefficient and odor contribution based on binary interaction effects in waste disposal plant. Atmos. Environ. 2015, 103, 231–237. [Google Scholar] [CrossRef]

- Di, Y.; Liu, J.; Liu, J.; Liu, S.; Yan, L. Characteristic analysis for odor gas emitted from food waste anaerobic fermentation in the pretreatment workshop. J. Air Waste Manag. Assoc. 2013, 63, 1173–1181. [Google Scholar] [CrossRef]

- Guclu, G.; Sevindik, O.; Kelebek, H.; Selli, S. Determination of volatiles by odor activity value and phenolics of cv. Ayvalik early-harvest olive oil. Foods 2016, 5, 46. [Google Scholar] [CrossRef]

- Hayes, J.; Stevenson, R.; Stuetz, R. The impact of malodour on communities: A review of assessment techniques. Sci. Total. Environ. 2014, 500–501, 395–407. [Google Scholar] [CrossRef]

- Wiśniewska, M. Methods of assessing odour emissions from biogas plants processing municipal waste. J. Ecol. Eng. 2020, 21, 140–147. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. The importance of the microclimatic conditions inside and outside of plant buildings in odorants emission at municipal waste biogas installations. Energies 2020, 13, 6463. [Google Scholar] [CrossRef]

- Bontempelli, G.; Comisso, N.; Toniolo, R.; Schiavon, G. Electroanalytical sensors for nonconducting media based on electrodes supported on perfluorinated ion-exchange membranes. Electroanalysis 1997, 9, 433–443. [Google Scholar] [CrossRef]

- Cao, Z.; Buttner, W.J.; Stetter, J.R. The properties and applications of amperometric gas sensors. Electroanalysis 1992, 4, 253–266. [Google Scholar] [CrossRef]

- Szulczyński, B.; Gębicki, J. Currently commercially available chemical sensors employed for detection of volatile organic compounds in outdoor and indoor air. Environments 2017, 4, 21. [Google Scholar] [CrossRef]

- Rezende, G.C.; Le Calvé, S.; Brandner, J.J.; Newport, D. Micro photoionization detectors. Sens. Actuators B Chem. 2019, 287, 86–94. [Google Scholar] [CrossRef]

- Capelli, L.; Sironi, S.; Del Rosso, R. Electronic noses for environmental monitoring applications. Sensors 2014, 14, 19979–20007. [Google Scholar] [CrossRef] [PubMed]

- Font, X.; Artola, A.; Sánchez, A. Detection, composition and treatment of volatile organic compounds from waste treatment plants. Sensors 2011, 11, 4043–4059. [Google Scholar] [CrossRef]

- Moreno, A.; Arnaiz, N.A.; Font, R.; Carratalá, A. Chemical characterization of emissions from a municipal solid waste treatment plant. Waste Manag. 2014, 34, 2393–2399. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Council directive 1999/13/EC of 11 March 1999 on the limitation of emissions of volatile organic compounds due to the use of organic solvents in certain activities and installations. Offic. J. Eur. Commun. 1999, L 085, 1–24. [Google Scholar]

- Cheng, Z.; Sun, Z.; Zhu, S.; Lou, Z.; Zhu, N.; Feng, L. The identification and health risk assessment of odor emissions from waste landfilling and composting. Sci. Total. Environ. 2019, 649, 1038–1044. [Google Scholar] [CrossRef] [PubMed]

- Orzi, V.; Riva, C.; Scaglia, B.; D’Imporzano, G.; Tambone, F.; Adani, F. Anaerobic digestion coupled with digestate injection reduced odour emissions from soil during manure distribution. Sci. Total. Environ. 2018, 621, 168–176. [Google Scholar] [CrossRef] [PubMed]

- Jia, C.; Cao, K.; Valaulikar, R.; Fu, X.; Sorin, A.B. Variability of Total Volatile Organic Compounds (TVOC) in the indoor air of retail stores. Int. J. Environ. Res. Public Health 2019, 16, 4622. [Google Scholar] [CrossRef] [PubMed]

- Standard EN 13725: 2003. Air Quality-Determination of Odour Concentration by Dynamic Olfactometry; CEN: Brussels, Belgium, 2003. [Google Scholar]

- Rassia, S.T. Statistical analysis. In SpringerBriefs in Public Health; Springer Science and Business Media: Berlin/Heidelberg, Germany, 2017; pp. 53–63. [Google Scholar]

- Kelley, K.; Darku, F.B.; Chattopadhyay, B. Sequential accuracy in parameter estimation for population correlation coefficients. Psychol. Methods 2019, 24, 492–515. [Google Scholar] [CrossRef] [PubMed]

- Amoore, J.E.; Hautala, E. Odour as an aid to chemical safety: Odor thresholds compared with threshold limit values and vol-atilities for 214 industrial chemicals in air and water dilution. J. Appl. Toxicol. 1983, 3, 272–290. [Google Scholar] [CrossRef]

- Gębicki, J.; Dymerski, T.; Namieśnik, J. Investigation of air quality beside a municipal landfill: The fate of malodour com-pounds as a model VOC. Environments 2017, 4, 7. [Google Scholar] [CrossRef]

- Leonardos, G.; Kendall, D.; Barnard, N. Odor threshold determinations of 53 odorant chemicals. J. Air Pollut. Control. Assoc. 1969, 19, 91–95. [Google Scholar] [CrossRef]

- DHHS. Criteria for a Recommended Standard: Occupational Exposure to Phenol; DHHS (NIOSH) Publication: Spokane, WA, USA, 1976; pp. 76–196. [Google Scholar]

- Conti, C.; Guarino, M.; Bacenetti, J. Measurements techniques and models to assess odor annoyance: A review. Environ. Int. 2020, 134, 105261. [Google Scholar] [CrossRef] [PubMed]

- Toledo, M.; Gutiérrez, M.; Siles, J.; Martín, M. Full-scale composting of sewage sludge and market waste: Stability monitoring and odor dispersion modeling. Environ. Res. 2018, 167, 739–750. [Google Scholar] [CrossRef] [PubMed]

- Toledo, M.; Gutiérrez, M.; Siles, J.; Martín, M. Odor mapping of an urban waste management plant: Chemometric approach and correlation between physico-chemical, respirometric and olfactometric variables. J. Clean. Prod. 2019, 210, 1098–1108. [Google Scholar] [CrossRef]

- European Union. Commission implementing decision (EU) 2018/1147 of 10 August 2018 establishing best available tech-niques (BAT) conclusions for waste treatment, under Directive 2010/75/EU of the European parliament and of the council. Off. J. Eur. Union 2018, 208, 38–90. [Google Scholar]

| Biogas Plant | Ti (°C) | To (°C) | RHi (%) | RHo (%) |

|---|---|---|---|---|

| Biała Podlaska | 21.3 | 20.1 | 47.8 | 50.2 |

| Promnik | 20.1 | 16.6 | 63.1 | 56.6 |

| Wólka Rokicka | 26.0 | 25.3 | 49.3 | 40.7 |

| Biogas Plant Location | VOC-NH3 | OAV-NH3-cod | OAV-VOCs-cod | ||||||

|---|---|---|---|---|---|---|---|---|---|

| r | rho | taub | r | rho | taub | r | rho | taub | |

| Biała Podlaska | 0.995 | 0.737 | 0.617 | 0.999 | 0.934 | 0.890 | 0.995 | 0.885 | 0.794 |

| Promnik | 0.149 | −0.160 | −0.154 | 0.927 | 0.613 | 0.490 | 0.415 | 0.461 | 0.34 |

| Wólka Rokicka | −0.307 | −0.220 | −0.189 | 0.990 | 0.544 | 0.459 | −0.307 | −0.346 | −0.276 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. The Use of Chemical Sensors to Monitor Odour Emissions at Municipal Waste Biogas Plants. Appl. Sci. 2021, 11, 3916. https://doi.org/10.3390/app11093916

Wiśniewska M, Kulig A, Lelicińska-Serafin K. The Use of Chemical Sensors to Monitor Odour Emissions at Municipal Waste Biogas Plants. Applied Sciences. 2021; 11(9):3916. https://doi.org/10.3390/app11093916

Chicago/Turabian StyleWiśniewska, Marta, Andrzej Kulig, and Krystyna Lelicińska-Serafin. 2021. "The Use of Chemical Sensors to Monitor Odour Emissions at Municipal Waste Biogas Plants" Applied Sciences 11, no. 9: 3916. https://doi.org/10.3390/app11093916

APA StyleWiśniewska, M., Kulig, A., & Lelicińska-Serafin, K. (2021). The Use of Chemical Sensors to Monitor Odour Emissions at Municipal Waste Biogas Plants. Applied Sciences, 11(9), 3916. https://doi.org/10.3390/app11093916