RBS Channeling MATLAB Application for Automated Measurement Control and Evaluation for 6MV Tandetron Accelerator

Abstract

1. Introduction

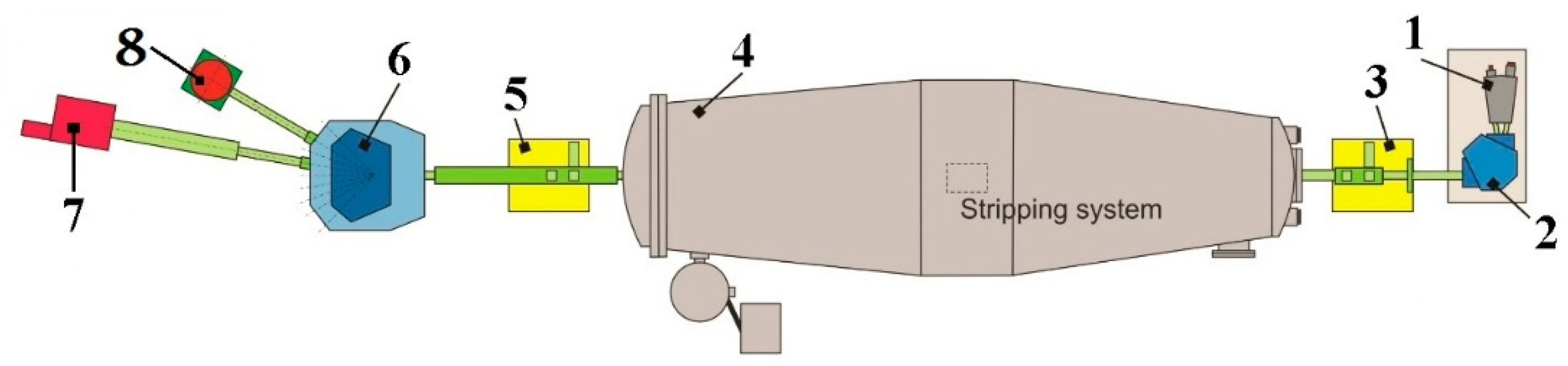

1.1. Accelerator and Ion Beam Analysis

1.2. Motivation

2. Preliminaries

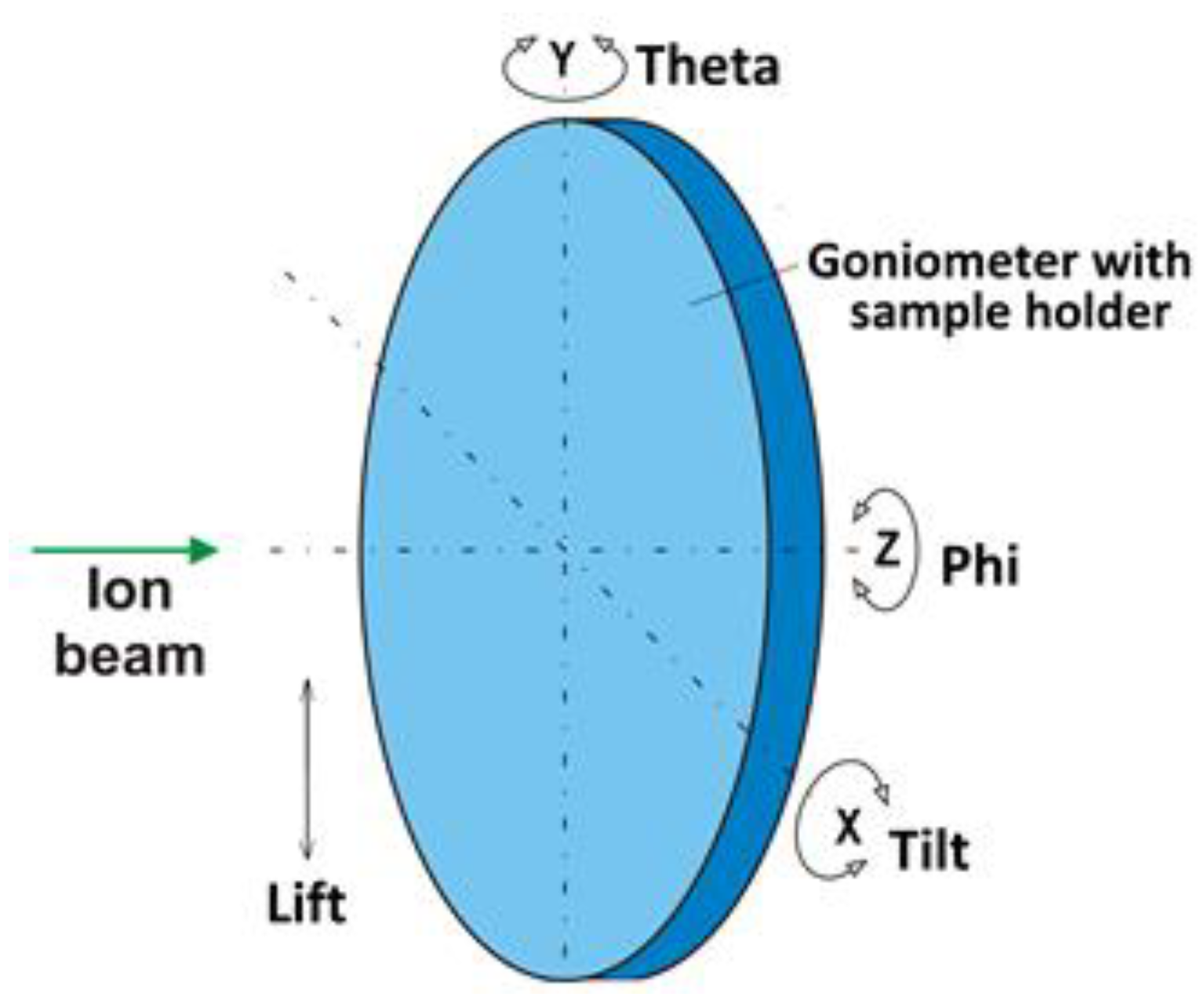

2.1. RBS/C Measurement Procedure

2.2. Issues

- Mechanical backslash of the goniometer could have negative influence on the accuracy of the measurement.

- Measured data are processed manually (which is time consuming); ARGUS doesn’t support an automatic mode for the measurements.

- An evaluation module for RBS/C in ARGUS is not available (not even an automated one).

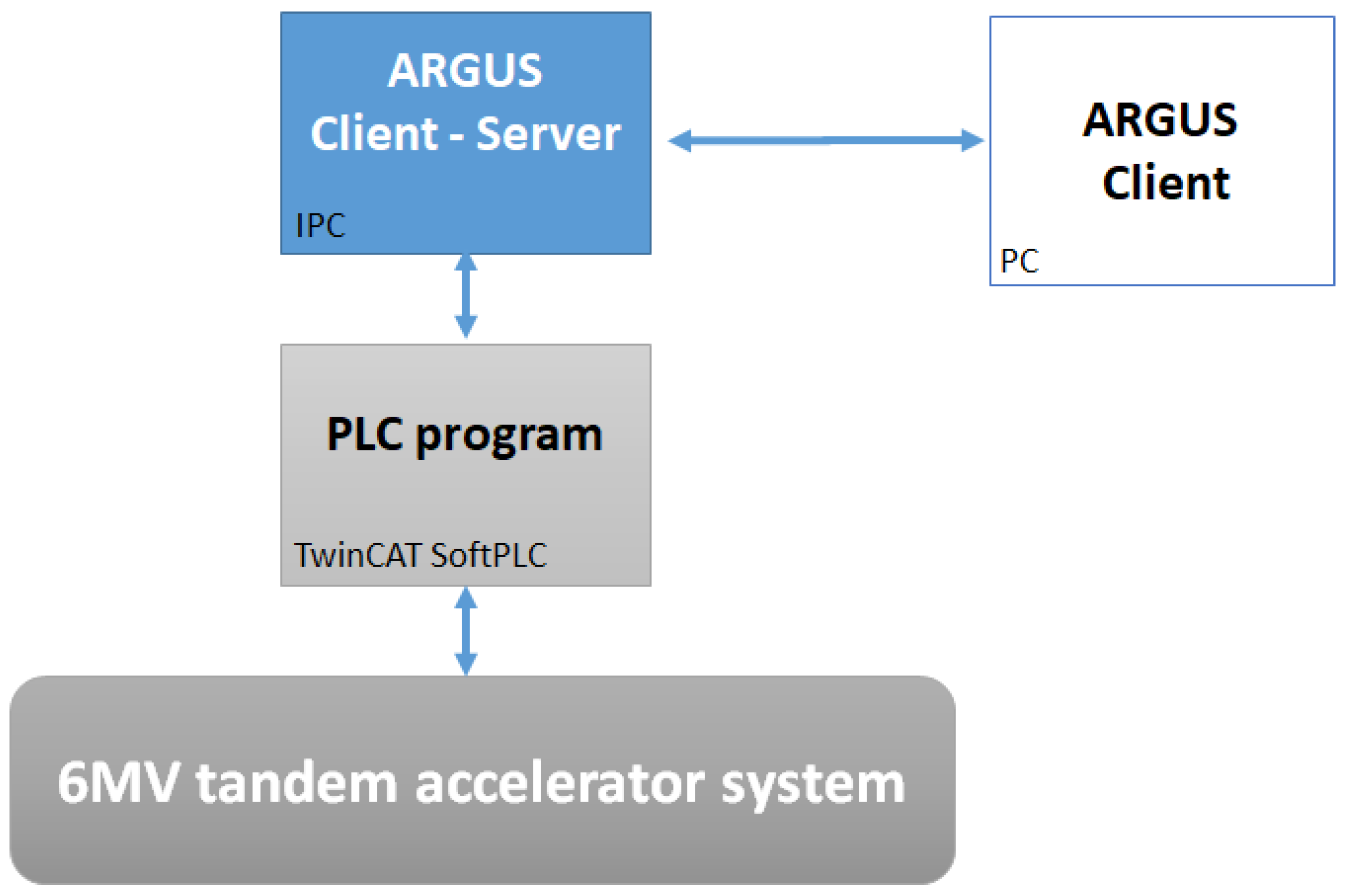

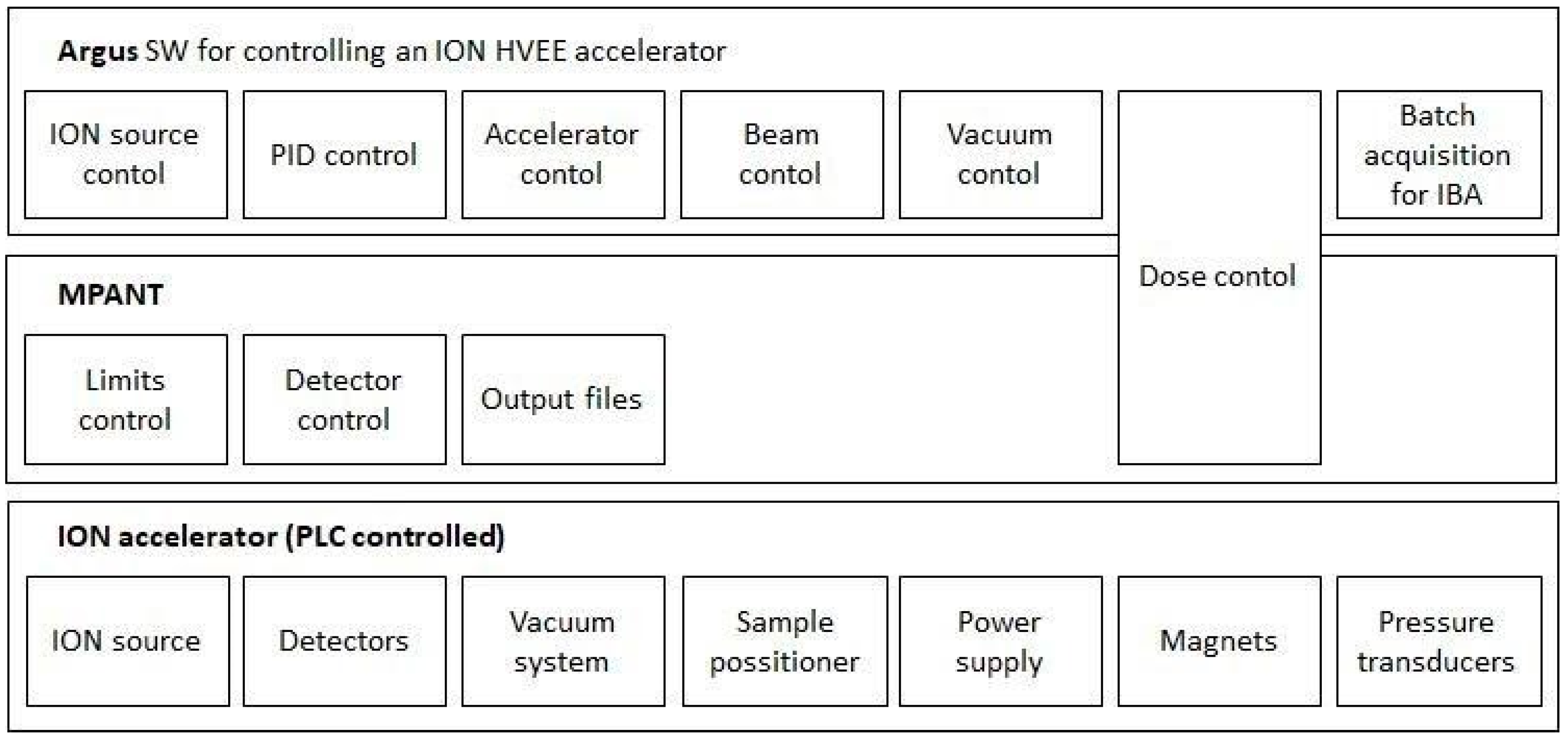

3. Software and Experiment

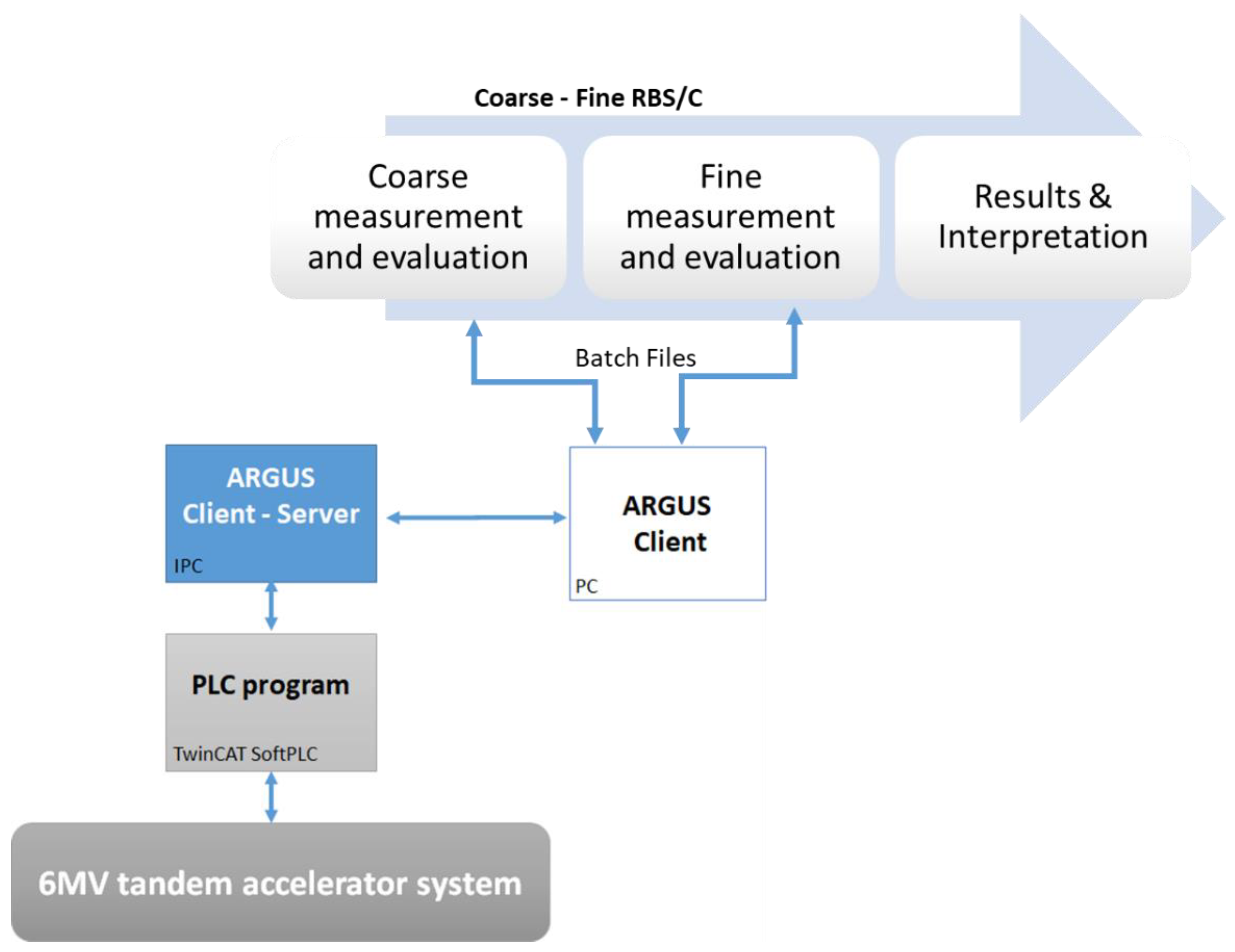

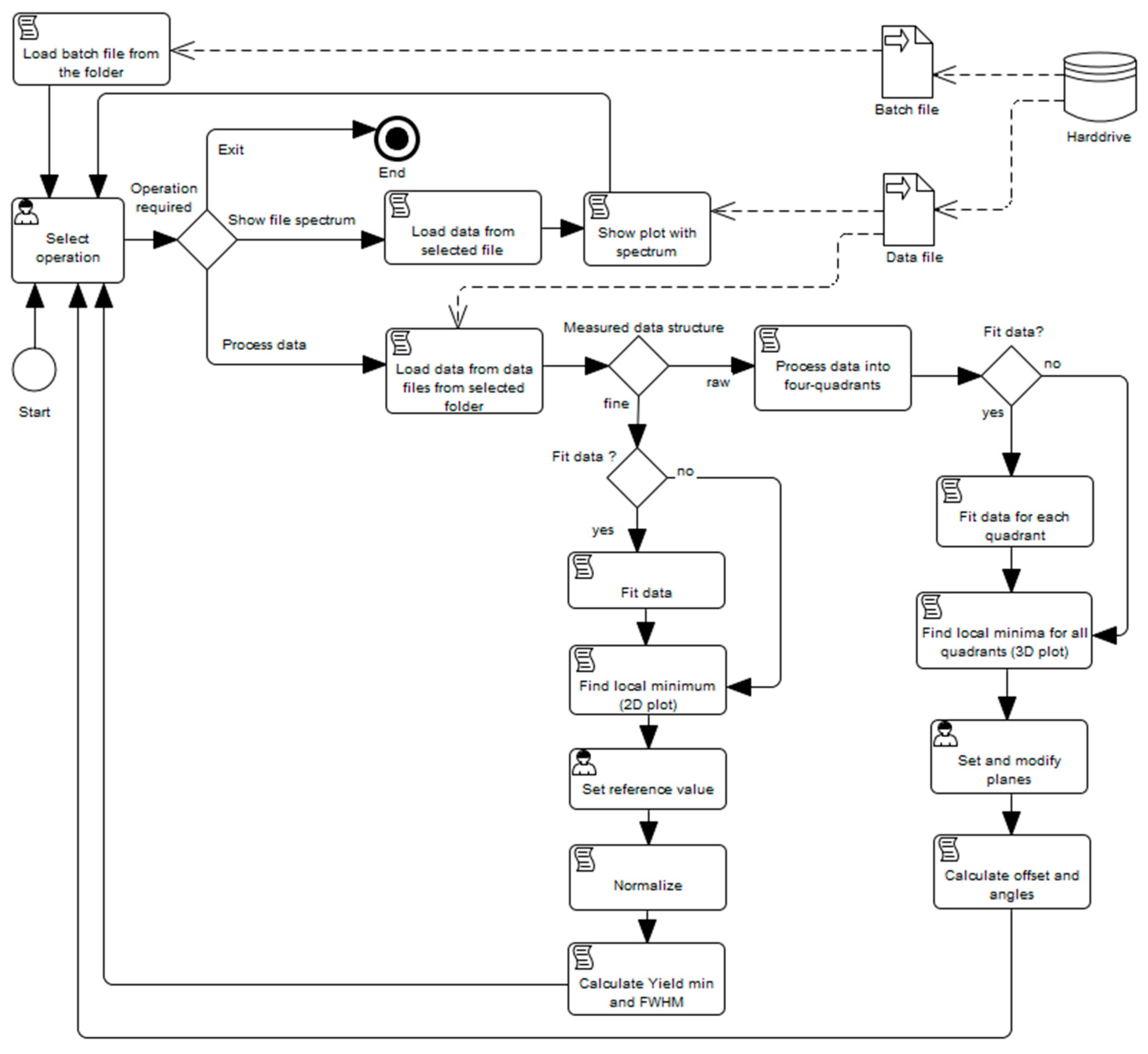

3.1. Design and Architecture

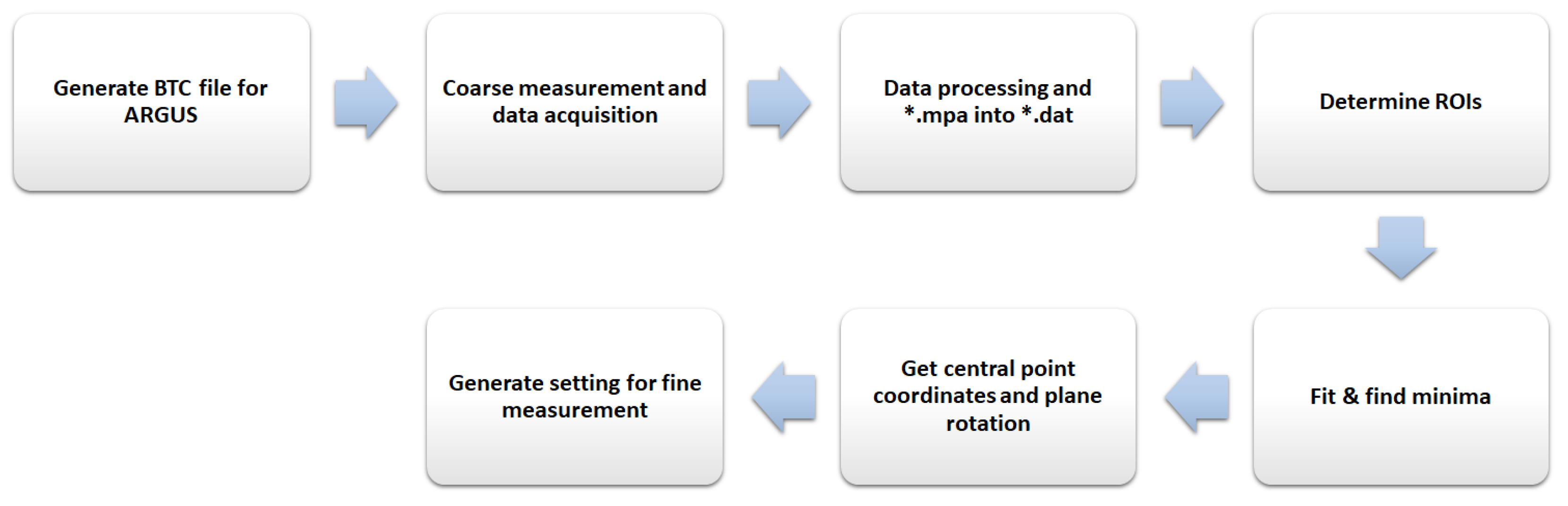

- Data extraction from * mpa files into * dat files while data processing.

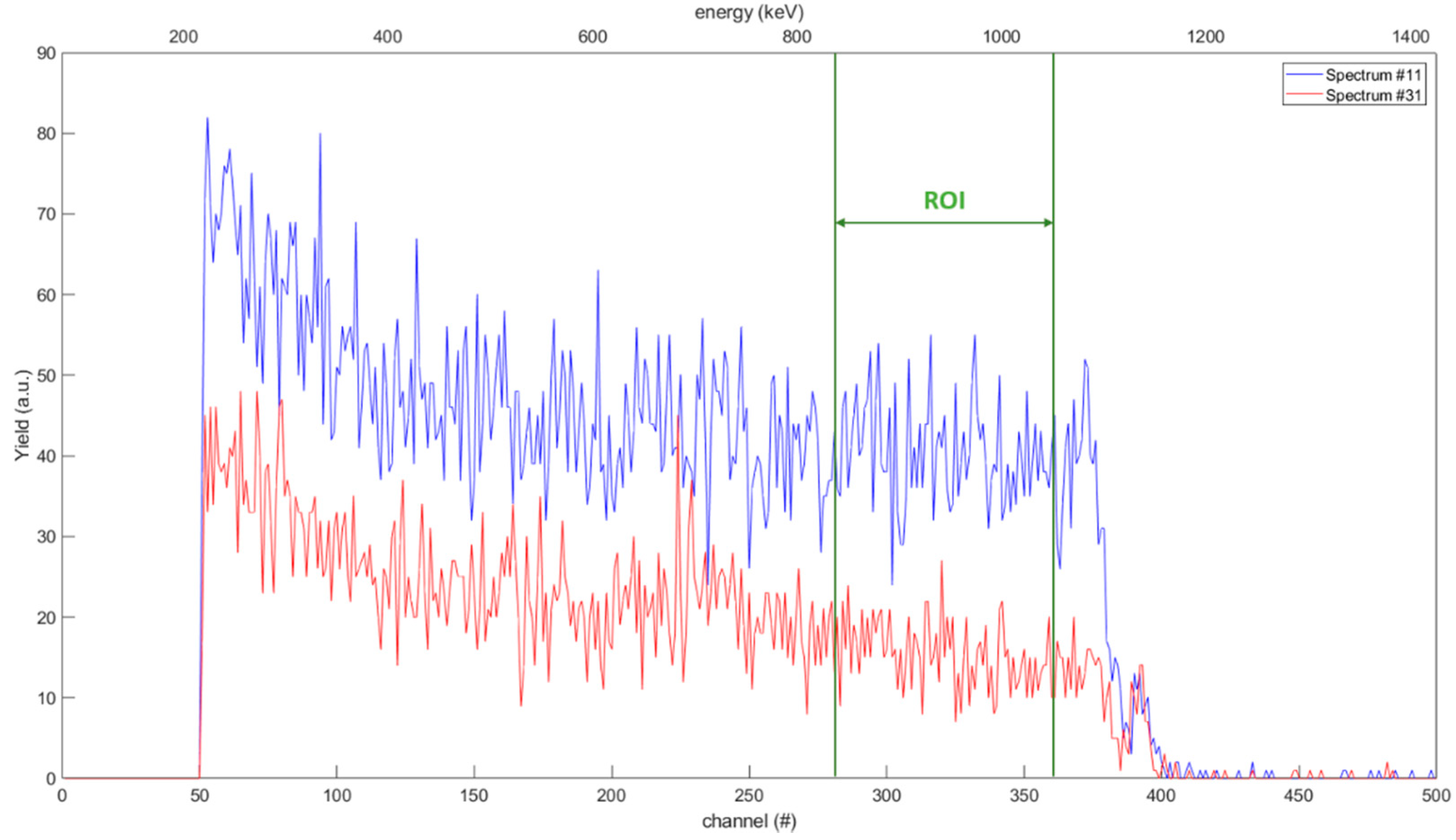

- Setting region of interests for measured RBS spectra.

- Fitting the data and locate minima.

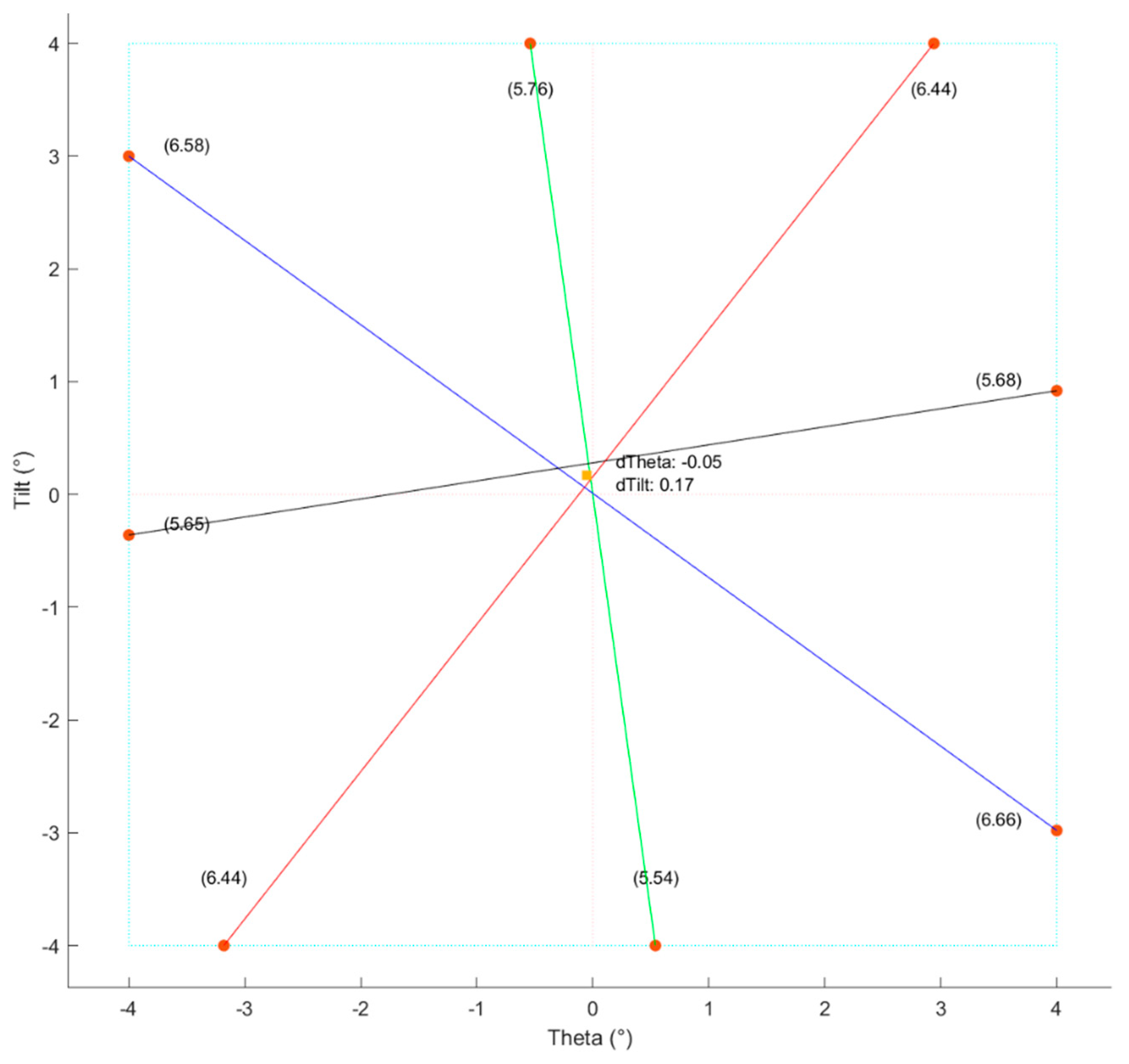

- Determining planar axes rotation and getting coordinates of the axial axis (offset).

- Generating control configuration (BTC files) for fine measurement.

3.2. RBS/C Measurement

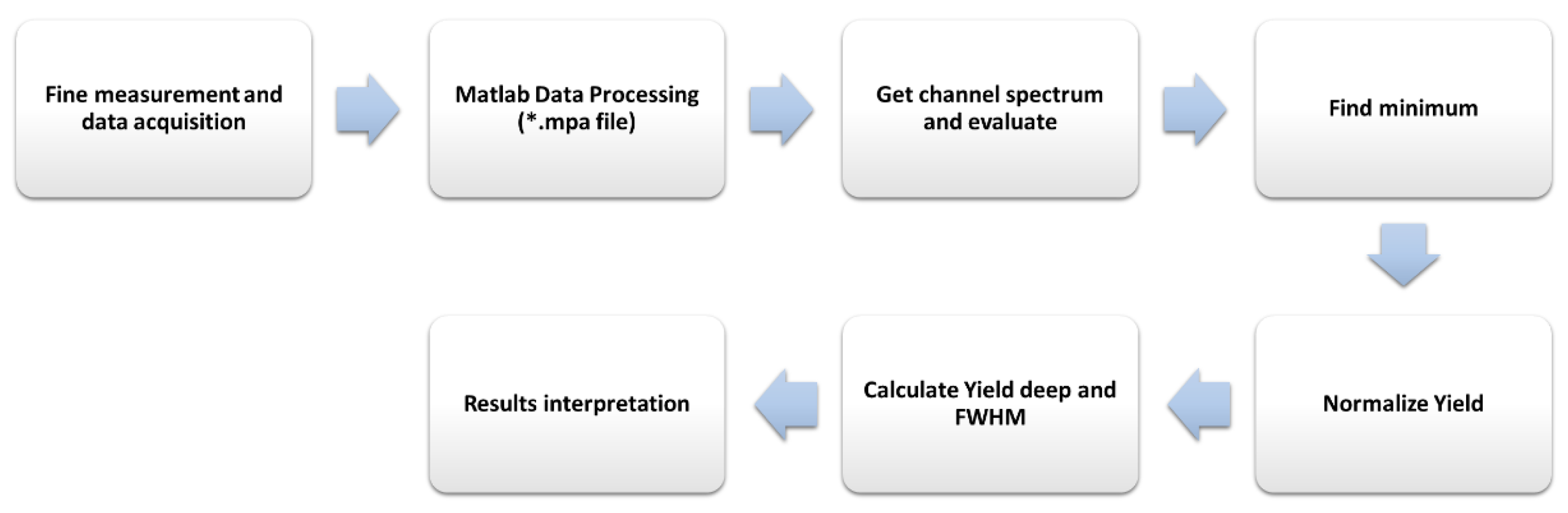

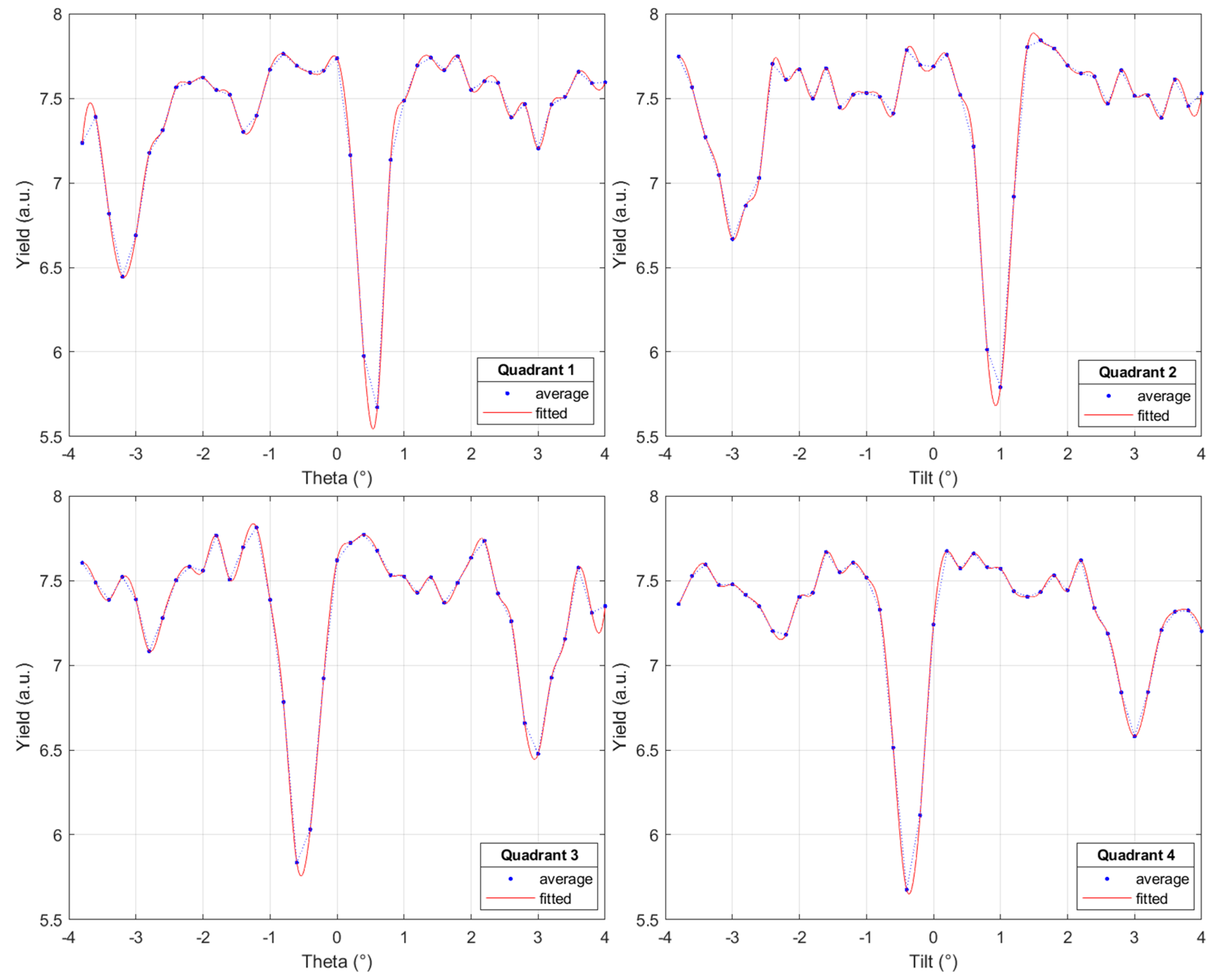

3.3. Coarse and Fine Evaluation

3.4. Implemented Features for Automated Measurement and Analysis

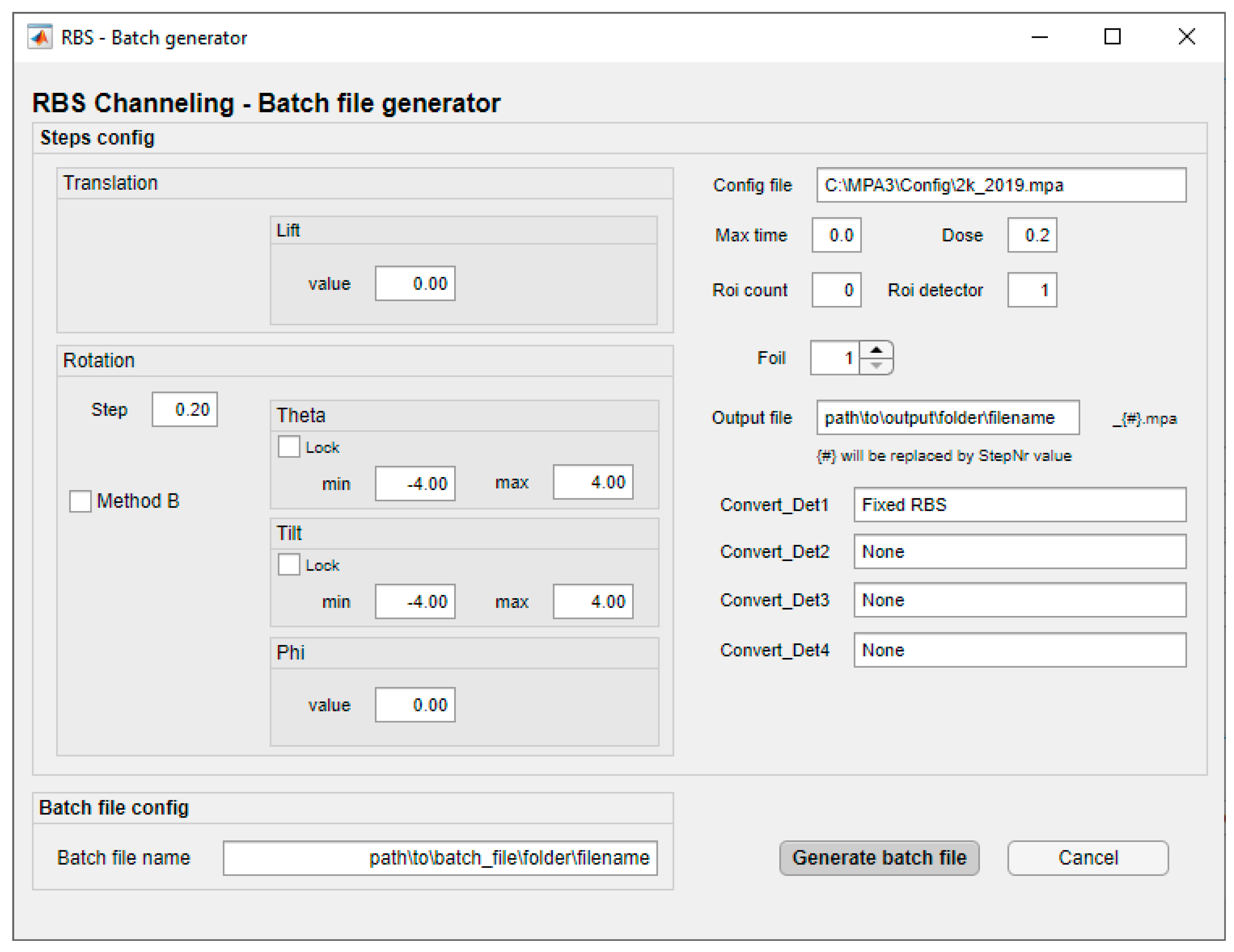

3.4.1. Batch File Generator (BFG)

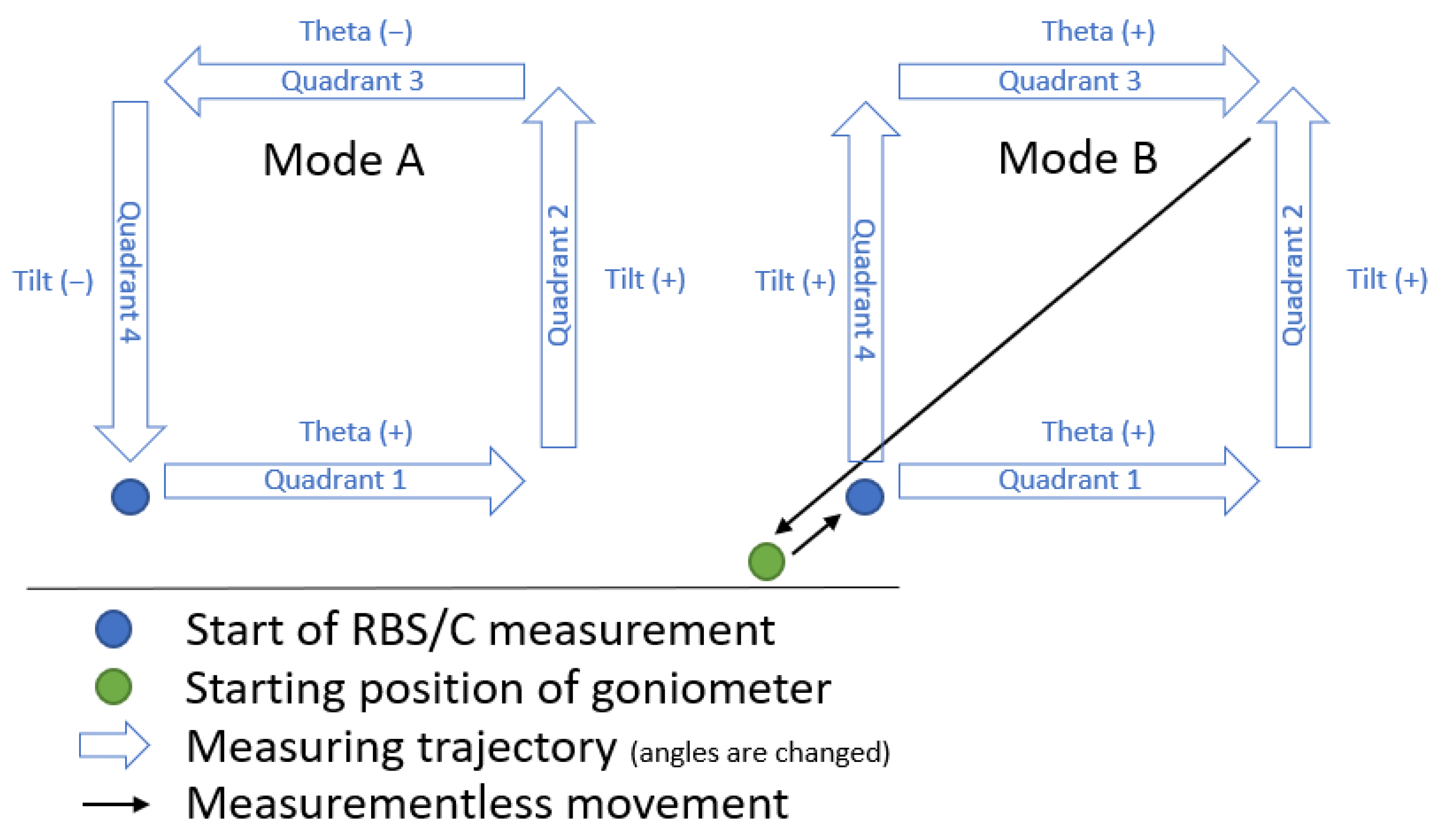

- mode A; The measurement starts in the first step by increasing the theta angle (quadrant 1). When the angle reaches its maximum, increasing of the tilt angle is performed (quadrant 2). Then, the theta angle is decreasing (quadrant 3) down to its minimum. The last movement is performed in quadrant 4, when the tilt angle is decreasing down to its minimum.

- mode B; Before the measurement starts, the goniometer is moved into the starting position and in the step after that into the first measuring position. The measurement is performed from the lowest to the highest angle incrementally.

3.4.2. Load and Convert Data Function

3.4.3. Analysis Features and Evaluation Tools Demonstrated in Experiment: 4He+ Beam Directed on a Si (100)

4. Results and Discussion

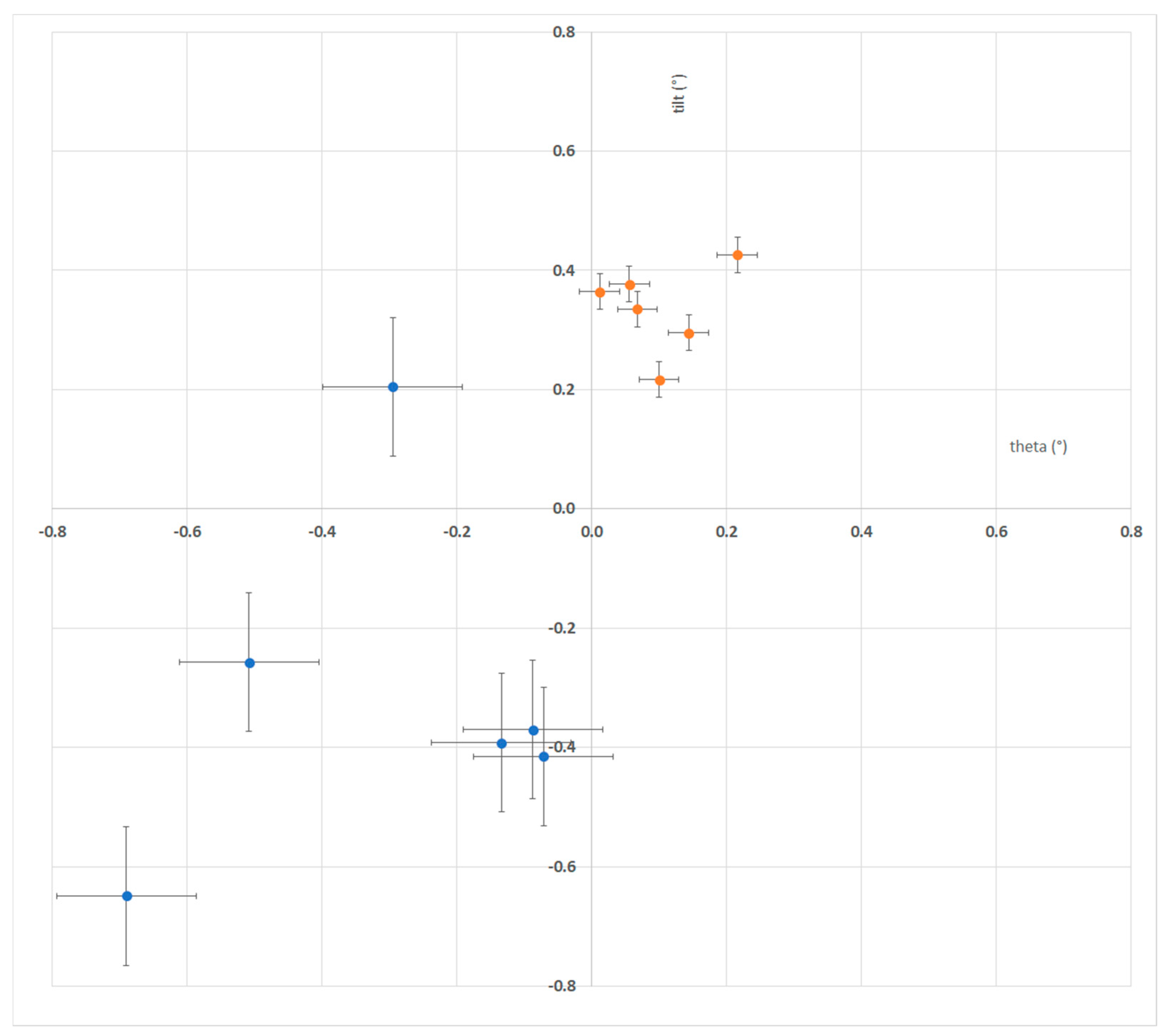

- In Figure 18 there are scattered intersections of planar axes (calculated based on the intersection positions of main axes of the crystallographic planes displayed in Figure 16 and their distance from the origin of coordinate system), where we can see the dispersion of points for both modes of generating steps.

- We calculated the dispersion for the intersection points of planes as it is shown in Table 3.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chu, W.-K.; Mayer, J.W.; Nicolet, M.A. Backscattering Spectrometry; Academic Press: New York, NY, USA, 1978. [Google Scholar]

- Feldman, L.C.; Mayer, J.W.; Picraux, S.T.A. Materials Analysis by Ion Channeling: Submicron Crystallography; Academic Press: Cambridge, MA, USA, 1982. [Google Scholar]

- Wijesundera, D.; Ma, K.; Wang, X.; Liu, B.; Liu, J.R.; Chu, W.K. A geometric procedure for improved Rutherford backscattering channeling analysis of materials. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2009, 267, 1948–1951. [Google Scholar] [CrossRef]

- Motapothula, M.R.; Breese, M.B. A study of small impact parameter ion channeling effects in thin crystals. Eur. Phys. J. B 2017, 91, 1–12. [Google Scholar] [CrossRef]

- Yamamoto, Y. Automatic Beam Alignment for Channeling Measurements in Rutherford Backscattering Spectrometry; North-Holland Publishing Company: Tokyo, Japan, 1981; pp. 171–176. [Google Scholar]

- Podaru, N.C.; Klein, M.; Hoef, F.; Mous, D.J.W. Versatile 500 kV air-insulated medium current ion implanter. In Proceedings of the 24th International Conference on the Application of Accelerators in Research and Industry (CAARI 2016), Fort Worth, TX, USA, 30 October–4 November 2016; pp. 68–69. [Google Scholar]

- Noga, P.; Dobrovodsky, J.; Vana, D.; Beno, M.; Zavacka, A.; Muska, M.; Halgas, R.; Minarik, S.; Riedlmajer, R. A new ion-beam laboratory for materials research at the Slovak University of Technology. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2017, 409, 264–267. [Google Scholar] [CrossRef]

- He, J.; Lee, J.; Li, M.; Wang, Z.; Liu, C.; Fu, D. Computerized Control and Operation of Rutherford Backscattering/Channeling for an in situ Ion Beam System and Its Application for Measurement of Si(001) and ZnO(001). Chin. Phys. Lett. 2011, 28, 012901. [Google Scholar] [CrossRef]

- Rauhala, E.; Barradas, N.P.; Fazinic, S.; Mayer, M.; Szilágyi, E.; Thompson, M. Status of ion beam data analysis and simulation software. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2006, 244, 436–456. [Google Scholar] [CrossRef]

- David-Bosne, E.; Wahl, U.; Correia, J.; Lima, T.; Pereira, A.V.A.L. A generalized fitting tool for analysis of two-dimensional channeling patterns. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2020, 462, 102–112. [Google Scholar] [CrossRef]

- Zhang, S.; Nordlund, K.; Djurabekova, F.; Zhang, Y.; Velisa, G.; Wang, T.S. Simulation of Rutherford backscattering spectrometry from arbitrary atom structures. Phys. Rev. E 2016, 12, 043319. [Google Scholar] [CrossRef] [PubMed]

- Stremy, M.; Cuninka, P.; Noga, P. Encouraging scientific thinking and fostering scientific careers in the environment of the Slovak University of Technology in Bratislava. In Proceedings of the 15th IEEE International Conference on Emerging eLearning Technologies and Applications (ICETA), Starý Smokovec, Slovakia, 26–27 October 2017; pp. 445–450. [Google Scholar]

- Burducea, I.; Straticiuc, M.; Ghiță, D.G.; Moșu, D.V.; Călinescu, C.I.; Podaru, N.C. A new ion beam facility based on a 3 MV Tandetron™ at IFIN-HH, Romania. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2015, 359, 12–19. [Google Scholar] [CrossRef]

- High Voltage Engineering, (H. V. E. E. B.V.) Operating manual for ARGUS Accelerator System Control. A-4-35-000-ARGUS, rev. 1.0, Amersfoort 2015. Available online: www.highvolteng.com (accessed on 11 March 2021).

- Biri, S.; Vajda, I.K.; Hajdu, P.; Rácz, R.; Csík, A.K.Z.; Perduk, Z.; Rajta, F.K.A.I. The Atomki Accelerator Centre. Eur. Phys. J. Plus 2021, 137, 247. [Google Scholar] [CrossRef]

- Han, J.; An, Z.; Zheng, G.; Bai, F.; Li, Z.; Wang, P.; Liao, X.; Liu, M.; Chen, S.; Zhang, M.S.A.J. An ion beam facility based on a 3 MV tandetron accelerator in Sichuan University, China. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2018, 418, 68–73. [Google Scholar] [CrossRef]

- Gurbich, A.F.; Bokhovko, M.V. Calibration of 3 MV Tandetron™ accelerator over nominal energy range. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2019, 459, 81–83. [Google Scholar] [CrossRef]

- Create Standalone Application from MATLAB—MATLAB & Simulink. MathWorks. Available online: https://www.mathworks.com/help/compiler/create-and-install-a-standalone-application-from-matlab-code.html (accessed on 11 March 2021).

- Tilli, M.; Motooka, T.; Airaksinen, V.; Franssila, S.; Paulasto-Krockel, M.; Lindroos, V. Handbook of Silicon Based MEMS Materials and Technologies, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2015; ISBN 978-0-323-29965-7. [Google Scholar]

- Malovcova, V.; Bezak, P.; Dobrovodsky, J. Rutherford Backscattering Spectrometry system in channeling regime. In Book of Abstracts of the 27th Joint Seminar, Proceedings of the Development of Materials Science in Research and Education (DMS-RE 2017), Kezmarske Zlaby, Slovakia, 4–8 September 2017, 1st ed.; Slovak Society for Industrial Chemistry: Bratislava, Slovakia, 2017; p. 30. [Google Scholar]

- Jozwik, P.; Nowicki, L.; Ratajczak, R.; Stonert, A.; Mieszczynski, C.; Turos, A.; Morawiec, K.; Alves, K.L.A.E. Monte Carlo simulations of ion channeling in crystals containing dislocations and randomly displaced atoms. J. Appl. Phys. 2019, 126, 195107. [Google Scholar] [CrossRef]

- Horvath, D.; Stremy, M.; Bezak, P. RBS/C for Tandetron Accelerators with ARGUS Control Software, MATLAB Central File Exchange. 2021. Available online: https://www.mathworks.com/matlabcentral/fileexchange/90087 (accessed on 9 April 2021).

| Axis of Rotation | Notation in Argus | Notation in MATLAB |

|---|---|---|

| X-Rotation (tilt-horizontal) | tiltPos = X-Tilt | Tilt |

| Y-Rotation (azimuthal) | thetaPos = theta | Theta |

| Z-Rotation (incoming beam) | PhiPos = phi | Phi |

| Parameter | Value | Description | |

|---|---|---|---|

| StepNr | 11 | Step identifier | |

| PhiPos | 0.00 | Sample holder rotation | |

| ThetaPos | −2.20 | Horizontal axe | |

| TiltPos | −4.00 | Vertical axe | |

| LiftPos | 0.00 | Sample holder vertical shift | |

| FoilPos | 1 | Foil identifier (for detector R2) | |

| ConfigFile | …/config.mpa | Configuration file for a multichannel analyzer | |

| MaxTime | 0 | Time limit | A measurement stops if one of these values is reached. Zero is ignored. |

| Dose | 0.20 | Dose limit (µC) | |

| RoiCounts | 0 | Integral limit | |

| RoiDetector | 1 | Detector identifier | |

| OutputFile | …/data_11.mpa | A file, where measured spectrum is saved. | |

| Convert_Det1 | Fixed RBS | Define, which detector is used to measure a spectrum under the specific Det. | |

| Convert_Det2 | None | ||

| Convert_Det3 | None | ||

| Convert_Det4 | None | ||

| Mode | Dispersion | |

|---|---|---|

| Theta Angles | Tilt Angles | |

| mode A | 0.253 ± 0.103 | 0.284 ± 0.116 |

| mode B | 0.072 ± 0.029 | 0.073 ± 0.030 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stremy, M.; Horvath, D.; Vana, D.; Kebisek, M.; Gaspar, G.; Bezak, P.; Riedlmajer, R. RBS Channeling MATLAB Application for Automated Measurement Control and Evaluation for 6MV Tandetron Accelerator. Appl. Sci. 2021, 11, 3817. https://doi.org/10.3390/app11093817

Stremy M, Horvath D, Vana D, Kebisek M, Gaspar G, Bezak P, Riedlmajer R. RBS Channeling MATLAB Application for Automated Measurement Control and Evaluation for 6MV Tandetron Accelerator. Applied Sciences. 2021; 11(9):3817. https://doi.org/10.3390/app11093817

Chicago/Turabian StyleStremy, Maximilian, Dusan Horvath, Dusan Vana, Michal Kebisek, Gabriel Gaspar, Pavol Bezak, and Robert Riedlmajer. 2021. "RBS Channeling MATLAB Application for Automated Measurement Control and Evaluation for 6MV Tandetron Accelerator" Applied Sciences 11, no. 9: 3817. https://doi.org/10.3390/app11093817

APA StyleStremy, M., Horvath, D., Vana, D., Kebisek, M., Gaspar, G., Bezak, P., & Riedlmajer, R. (2021). RBS Channeling MATLAB Application for Automated Measurement Control and Evaluation for 6MV Tandetron Accelerator. Applied Sciences, 11(9), 3817. https://doi.org/10.3390/app11093817