Effect of Sawdust Particle Size on Physical, Mechanical, and Energetic Properties of Pinus durangensis Briquettes

Abstract

1. Introduction

2. Materials and Methods

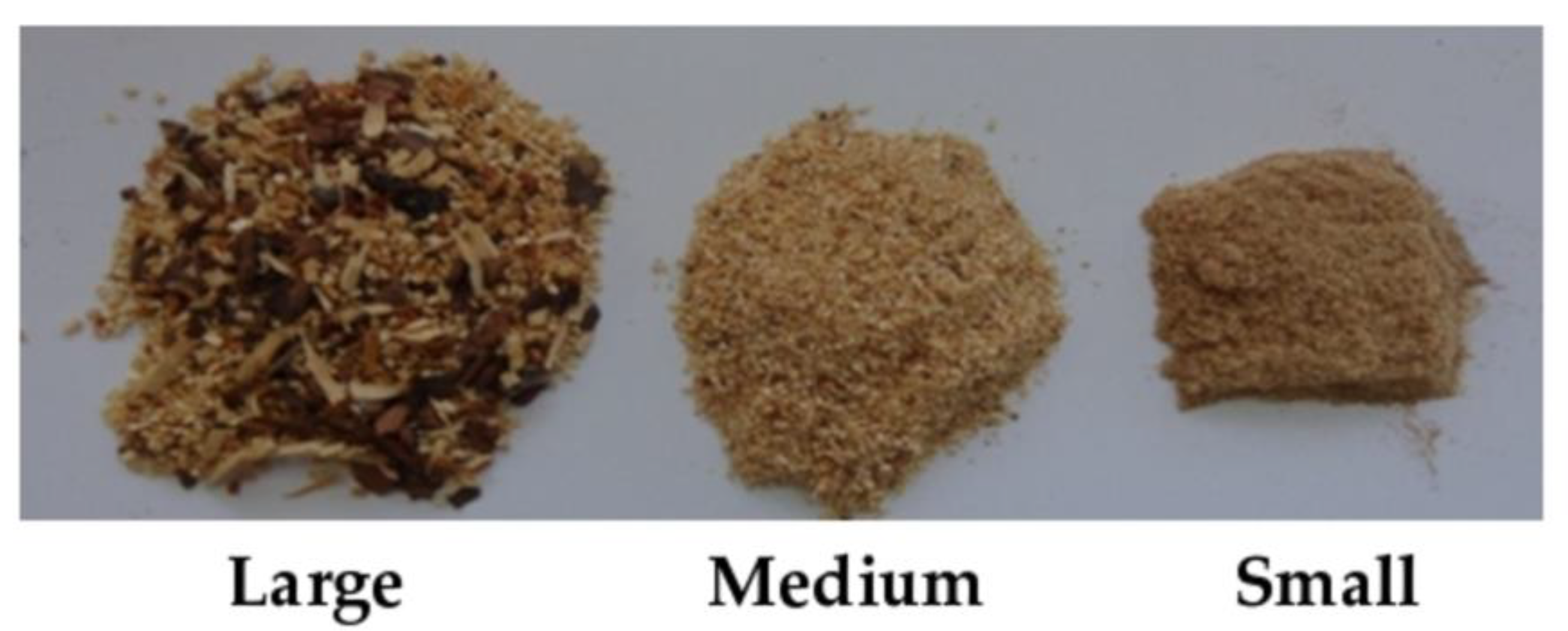

2.1. Timber Collection, Conditioning, and Determination of Sawdust Granulometric Distribution

2.2. Treatment, Preparation, and Conditioning of Briquettes

2.3. Determination of Briquette Quality

2.4. Statistical Analysis

2.5. Determination of Optimal Mixes

3. Results

3.1. Physical Properties

3.2. Mechanical Properties

3.3. Energy Properties

3.4. Determination of Optimal Mixes

4. Discussion

4.1. Particle Density

4.2. Volumetric Swelling

4.3. Compression Resistance

4.4. Impact Resistance Index (IRI)

4.5. Gross Calorific Value

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Fregoso-Madueño, J.N.; Goche-Télles, J.R.; Rutiaga-Quiñones, J.G.; González-Laredo, R.F.; Bocanegra-Salazar, M.; Chávez-Simental, J.A. Alternative uses of sawmill industry waste. Rev. Chapingo Ser. Ciencias For. Ambient. 2017, 23, 243–260. [Google Scholar] [CrossRef]

- Ayala-Mendivil, N.; Sandoval, G. Bioenergía a partir de residuos forestales y de madera. Madera y Bosques 2018, 24, 1–14. [Google Scholar] [CrossRef]

- SEMARNAT. Anuario Estadístico de la Producción Forestal; SEMARNAT: Mexico City, Mexico, 2016. [Google Scholar]

- Villela-Suárez, J.M.; Aguirre-Calderón, O.A.; Treviño-Garza, E.J.; Vargas-Larreta, B. Availability of forest residues and potential for energy production in temperate forests in El Salto, Durango. Madera Bosques 2018, 24, 1–18. [Google Scholar] [CrossRef]

- Cruz-Contreras, C. Residuos Generados del Aprovechamiento Maderable en el Estado de Durango. Bachelor’s Thesis, Universidad Autónoma de Chapingo, Texcoco, Mexico, 2012. [Google Scholar]

- Nájera-Luna, J.A.; Adame-Villanueva, G.H.; Méndez-González, J.; Vargas-Larreta, B.; Cruz-Cobos, F.; Hernández, F.J.; Aguirre-Calderón, C.G. Rendimiento de la madera aserrada en dos aserraderos privados de El Salto, Durango, México. Investig. Cienc. 2012, 20, 11–23. [Google Scholar]

- Arroyo-Vinueza, J.S.; Reina-Guzmán, W.S. Aprovechamiento del recurso biomasa a partir de los desechos de madera para una caldera de vapor. Ingenius. Rev. Cien. Tec. 2016, 16, 20–29. [Google Scholar] [CrossRef]

- Gwenzi, W.; Ncube, R.S.; Rukuni, T. Development, properties and potential applications of high-energy fuel briquettes incorporating coal dust, biowastes and post-consumer plastics. SN Appl. Sci. 2020, 2, 1–14. [Google Scholar] [CrossRef]

- Díaz-Artigas, I.J.; Díaz-Concepción, A.; Rodríguez-Piñero, A.J.; Alfonso-Álvarez, A.; Tamayo-Mendoza, J.E. Briquetas energeticas con aserrín y corteza de pino. Ing. Energética 2020, 41, 1–6.10. [Google Scholar]

- Chaloupková, V.; Ivanova, T.; Ekrt, O.; Kabutey, A.; Herák, D. Determination of particle size and distribution through image-based macroscopic analysis of the structure of biomass briquettes. Energies 2018, 11, 331. [Google Scholar] [CrossRef]

- Brožek, M. The effect of moisture of the raw materialon the properties briquettes for energy use. Acta Univ. Agric. Silvic. Mendelianae Brun. 2016, 64, 1453–1458. [Google Scholar] [CrossRef]

- Kers, J.; Kulu, P.; Aruniit, A.; Laurmaa, V.; Križan, P.; Šooš, L.; Kask, Ü. Determination of physical, mechanical and burnig characteristics of polymeric waste material briquettes. Est. J. Eng. 2010, 16, 307–316. [Google Scholar] [CrossRef]

- Nurek, T.; Gendek, A.; Roman, K.; Dąbrowska, M. The impact of fractional composition of the mechanical properties of agglomerated logging residues. Sustainability 2020, 12, 6120. [Google Scholar] [CrossRef]

- Maharani, R.; Yutaka, T.; Yajima, T.; Minoru, T. Scrutiny on physical properties of sawdust from tropical commercial wood species: Effects of different mills and sawdust’s particle size. Indones. J. For. Res. 2010, 7, 20–32. [Google Scholar] [CrossRef][Green Version]

- Tumuluru, J.S.; Fillerup, E. Briquetting characteristics of woody and herbaceous biomass blends: Impact on physical properties, chemical composition, and calorific value. Biofuels Bioprod. Biorefining 2020, 14, 1105–1124. [Google Scholar] [CrossRef]

- Berastegui-Barranco, C.; Ortega-Rodríguez, J. Elaboración de biocombustibles sólidos densificados a partir de tres biomasas residuales, tres tipos de bioaglomerante y carbón mineral del departamento de Córdoba. Ingeniare. Rev. Chil. Ing. 2017, 25, 643–653. [Google Scholar] [CrossRef]

- Gutiérrez-Pulido, H.; de la Vara-Salazar, R. Análisis y diseño de experimentos, 2nd ed.; Mc Graw Hill/Interamericana Editores S.A. de C.V.: Mexico City, Mexico, 2008. [Google Scholar]

- Niño, A.; Arzola, N.; Araque, O. Experimental study on the mechanical properties of biomass briquettes from a mixture of rice husk and pine sawdust. Energies 2020, 13, 1060. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Tabil, L.G.; Song, Y.; Iroba, K.L.; Meda, V. Impact of process conditions on the density and durability of wheat, oat, canola, and barley straw briquettes. Bioenerg. Res. 2015, 8, 388–401. [Google Scholar] [CrossRef]

- Križan, P.; Svátek, M.; Matúš, M.; Beniak, J.; Lisý, M. Determination of compacting pressure and pressing temperature impact on biomass briquettes density and their mutual interactions. In Proceedings of the 14th International Multidisciplinary Scientific GeoConference SGEM 2014, Albena, Bulgaria, 19–25 June 2014. [Google Scholar]

- Lela, B.; Barišić, M.; Nižetić, S. Cardboard/sawdust briquettes as biomass fuel: Physical-mechanical and thermal characteristics. Waste Manag. 2015, 47, 236–245. [Google Scholar] [CrossRef]

- Liu, H.; Liu, G.; Li, L.; Liu, Y.; Peng, S.; Hu, D.; Dong, Z. Optimization of the manufacturing process of Pinus rigida briquette by response surface methodology. J. For. Eng. 2016, 1, 93–99. [Google Scholar]

- Huko, D.; Kamau, D.N.; Ogola, W.O. Effects of varying particle size on mechanical and combustion characteristics of mango seed shell cashew nut shell composite briquettes. Int. J. Eng. Sci. Invent. 2015, 4, 32–39. [Google Scholar]

- Mitchual, S.J.; Katamani, P.; Afrifa, K.A. Fuel characteristics of binder free briquettes made at room temperature from blends of oil palm mesocarp fibre and Ceiba pentandra. Biomass Convers. Biorefinery 2019, 9, 541–551. [Google Scholar] [CrossRef]

- Nurek, T.; Gendek, A.; Roman, K. Forest residues as a renewable source of energy: Elemental composition and physical properties. BioRes 2018, 14, 6–20. [Google Scholar] [CrossRef]

- Nurek, T.; Gendek, A.; Roman, K.; Dąbrowska, M. The effect of temperature and moisture on the chosen parameters of briquettes made of shredded logging residues. Biomass and Bioenergy 2019, 130, 105368. [Google Scholar] [CrossRef]

- Ortíz-Torres, L. Producción de Biocombustibles Sólidos de Alta Densidad en España; Boletín del CIDEU; Universidad de Vigo: Vigo, Spain, 2008. [Google Scholar]

- UNE-EN 17827-2. Biocombustibles Sólidos. Determinación de la Distribución de Tamaño de Partícula para Combustibles sin Comprimir. Parte:2 Método del Tamiz Vibratorio con Abertura de Malla Inferior o Igual a 3.15 mm; Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2016. [Google Scholar]

- Maradiaga-Rodriguez, W.D.; Evangelista, A.W.; Sette, C.R.; Alves-Júnior, J.; Fernández da Silva, M. Producción de briquetas con residuos de cáscara de piñón manso (Jatropha curcas) y bagazo de caña de azúcar. Bosque 2017, 38, 527–533. [Google Scholar] [CrossRef][Green Version]

- Borowski, G.; Hycnar, J.J. Utilization of fine coal waste as a fuel briquettes. Int. J. Coal Prep. Util. 2013, 33, 194–204. [Google Scholar] [CrossRef]

- ASTM D143-83. Standard Methods of Testing Small Clear Specimens of Timber; American Society of Testing Material (ASTM): West Conshohocken, PA, USA, 1994. [Google Scholar]

- ASTM D440-86. Standard Test Method of Drop Shatter Test for Coal; American Society of Testing Material (ASTM): West Conshohocken, PA, USA, 1998. [Google Scholar]

- Richards, S.R. Physical testingof fuel briquettes. Fuel 1990, 25, 89–100. [Google Scholar] [CrossRef]

- UNE-EN 14918. Biocombustibles Sólidos. Determinación del Poder Calorífico; Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2011. [Google Scholar]

- UNE-EN 17225-3. Biocombustibles Sólidos. Especificaciones y Clases de Combustibles. Parte 3: Clases de Briquetas de Madera; Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2014. [Google Scholar]

- Camps, M.M.; Marcos, M.F. Los Biocombustibles, 2nd ed.; Mundi-Prensa Libros: Madrid, Spain, 2008. [Google Scholar]

- de Souza, F.; do Vale, A.T. Energy density of lignocellulosic biomass briquettes and its relationship with briquetting parameters. Pesqui. Florest. Bras. 2016, 36, 405–413. [Google Scholar] [CrossRef]

- Antwi-Boasiako, C.; Acheampong, B.B. Strength properties and calorific values of sawdust-briquettes as wood-residue energy generation source from tropical hardwoods of different densities. Biomass Bioenergy 2016, 85, 144–152. [Google Scholar] [CrossRef]

- Saptoadi, H. The best biobriquette dimension and its particle size. Asian J. Energy Environ. 2008, 9, 161–175. [Google Scholar]

- Ndindeng, S.A.; Mbassi, J.E.G.; Mbacham, W.F.; Manful, J.; Graham-Acquaah, S.; Moreira, J.; Dossou, J.; Futakuchi, K. Quality optimization in briquettes made from rice milling by-products. Energy Sustain. Dev. 2015, 29, 24–31. [Google Scholar] [CrossRef]

- Bello, R.S.; Onilude, M.A. Physico-mechanical characteristics of high density briquettes produced from composite sawdust. J. Appl. Sci. Environ. Manag. 2020, 24, 779–787. [Google Scholar] [CrossRef]

- Huanca-Ríos, L.V. Evaluación del proceso de producción de briquetas a partir de residuos de dos maderas de la zona de Iquitos, Loreto. Bachelor’s Thesis, Forest Engineering, Universidad Nacional Agraria La Molina, Lima, Peru, 2017. [Google Scholar]

- Ramírez-Ramírez, M.A.; Carrillo-Parra, A.; Ruíz-Aquino, F.; Pintor-Ibarra, L.F.; González-Ortega, N.; Orihuela-Equihua, R.; Carrillo-Ávila, N.; Luján-Álvarez, C.; Rutiaga-Quinones, J.G. Valorization of briquettes fuel using Pinus spp. sawdust from five regions of Mexico. BioResources 2021, 16, 2249–2263. [Google Scholar] [CrossRef]

- Mendoza-Martinez, C.L.; Sermyagina, E.; de Cassia-Oliveira, C.A.; Vakkilainen, E.; Cardoso, M. Production and characterization of coffee-pine wood residue briquettes as an alternative fuel for local firing systems in Brazil. Biomass Bioenergy 2019, 123, 70–77. [Google Scholar] [CrossRef]

- Plíštil, D.; Brožek, M.; Malaták, J.; Roy, A.; Hutla, P. Mechanical characteristics of standard fuel briquettes on biomass basis. Res. Agric. Eng. 2005, 51, 66–72. [Google Scholar] [CrossRef]

- Mitchual, S.J.; Frimpong-Mensah, K.; Darkwa, N.A. Effect of species, particle size and compacting pressure on relaxed density and compressive strength of fuel briquettes. Int. J. Energy Environ. Eng. 2013, 4, 1–6. [Google Scholar] [CrossRef]

- Sette, C.R., Jr.; Santiago Hansted, A.L.; Novaes, E.; Fonseca e Lima, P.A.; Rodrigues, A.C.; Rodrigues de Souza Santos, D.; Minoru Yamaji, F. Energy enhancement of the eucalyptus bark by briquette production. Ind. Crop. Prod. 2018, 122, 209–213. [Google Scholar] [CrossRef]

- Melin, S. Quality Certification and Standards for Solid Biofuels; Wood Pellet Association of Canada: Revelstoke, BC, Canada, 2011. [Google Scholar]

- Carrilo-Parra, A.; Contreras- Ortiz, E.; Garza-Ocañas, F.; Ngangyo-Heya, M.; Rutiaga-Quiñones, J.G. Efecto de la intemperización y proceso en las características físicas, mecánicas y energéticas de briquetas. Rev. Mex. Ciencias For. 2018, 9, 496–513. [Google Scholar] [CrossRef][Green Version]

- Zakari, I.Y.; Ismalia, A.; Sadiq, U.; Nasiru, R. Investigation on the effects of addition of binder and particle size on the high calorific value of solid biofuel briquettes. J. Nat. Sci. Res. 2013, 3, 30–35. [Google Scholar]

- Oke, P.K.; Olugbade, T.O.; Olaiya, G.N. Analysis of the effect of varying palm kernel particle sizes on the calorific value of palm kernel briquette. Br. J. Appl. Sci. Technol. 2016, 14, 1–5. [Google Scholar] [CrossRef]

| Treatment with Sample | Sawdust Size | ||

|---|---|---|---|

| Large (%) | Medium (%) | Small (%) | |

| T0 | 12 | 71 | 17 |

| T1 | 100 | 0 | 0 |

| T2 | 0 | 100 | 0 |

| T3 | 0 | 0 | 100 |

| T4 | 33 | 33 | 33 |

| T5 | 67 | 33 | 0 |

| T6 | 67 | 0 | 33 |

| T7 | 0 | 67 | 33 |

| T8 | 0 | 33 | 67 |

| T9 | 33 | 67 | 0 |

| T10 | 33 | 0 | 67 |

| Treatment with Sample | Physical Properties (Size) | Proximate Analysis Values | |||||

|---|---|---|---|---|---|---|---|

| Weight (g) | Diameter (mm) | Length (mm) | Moisture Content (%) | Volatile Material (%) | Ash (%) | Fixed Carbon (%) | |

| T0 | 39.79 (0.08) | 33.23 (0.08) | 46.06 (0.34) | 5.12 (0.01) | 82.86 (0.01) | 0.56 (0.02) | 11.46 (0.01) |

| T1 | 39.5 (0.21) | 33.46 (0.11) | 48.78 (0.50) | 5.78 (0.04) | 79.14 (0.40) | 1.22 (0.15) | 13.87 (0.28) |

| T2 | 40.17 (0.78) | 33.37 (0.14) | 46.48 (0.55) | 6.56 (0.11) | 81.57 (0.20) | 0.73 (0.05) | 11.14 (0.07) |

| T3 | 39.92 (0.06) | 33.05 (0.05) | 45.97 (0.36) | 5.21 (0.06) | 83.40 (0.13) | 0.36 (0.02) | 11.03 (0.20) |

| T4 | 39.67 (0.13) | 33.15 (0.08) | 46.52 (0.34) | 5.69 (0.03) | 81.91 (0.36) | 0.91 (0.04) | 11.48 (0.37) |

| T5 | 39.17 (0.09) | 33.25 (0.09) | 46.93 (0.46) | 5.41 (0.07) | 81.95 (0.22) | 0.73 (0.04) | 11.91 (0.27) |

| T6 | 39.29 (0.07) | 33.23 (0.11) | 46.18 (0.31) | 6.27 (0.05) | 82.97 (0.12) | 0.47 (0.04) | 10.29 (0.12) |

| T7 | 39.76 (0.15) | 33.15 (0.05) | 47.28 (0.31) | 6.62 (0.02) | 81.07 (0.04) | 1.11 (0.07) | 11.20 (0.02) |

| T8 | 39.76 (0.10) | 33.13 (0.08) | 47.21 (0.22) | 5.81 (0.01) | 83.05 (0.11) | 0.55 (0.04) | 10.60 (0.16) |

| T9 | 39.23 (0.10) | 33.28 (0.10) | 47.11 (0.42) | 6.52 (0.03) | 82.01 (0.03) | 0.90 (0.03) | 10.57 (0.02) |

| T10 | 39.33 (0.11) | 33.25 (0.11) | 48.25 (0.41) | 6.01 (0.13) | 82.51 (0.16) | 0.44 (0.01) | 11.04 (0.26) |

| Treatment (Mixture) | Particle Density (g cm−3) | Volumetric Swelling (%) | Compression Resistance (N mm−2) | Impact Resistance Index (%) | Gross Calorific Value (MJ kg−1) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | Std. | Mean | Std. | Mean | Std. | Mean | Std. | Mean | Std. | ||||||

| T0 (12-71-17) | 1.00 | 0.01 | b * | 1.86 | 0.78 | b | 29.06 | 1.63 | bc | 76.67 | 20.00 | ab | 19.93 | 0.26 | c |

| T1 (100-0-0) | 0.92 | 0.01 | f | 2.01 | 1.49 | b | 18.45 | 1.05 | e | 53.33 | 6.67 | c | 21.63 | 0.13 | a |

| T2 (0-100-0) | 0.99 | 0.02 | c | 3.75 | 1.17 | a | 26.13 | 3.61 | bcd | 100.00 | 51.64 | a | 20.11 | 0.04 | bc |

| T3 (0-0-100) | 1.01 | 0.01 | a | 3.00 | 0.45 | a | 37.09 | 2.51 | a | 99.73 | 0.37 | a | 19.48 | 0.15 | d |

| T4 (33-33-33) | 0.99 | 0.01 | bc | 1.63 | 0.99 | bc | 28.06 | 2.79 | bcd | 93.33 | 13.33 | a | 19.53 | 0.09 | d |

| T5 (67-33-0) | 0.96 | 0.01 | e | 0.96 | 0.61 | c | 24.53 | 2.89 | bcd | 60.00 | 8.16 | bc | 20.51 | 0.32 | abc |

| T6 (67-0-33) | 0.98 | 0.01 | cd | 1.57 | 0.86 | bc | 29.24 | 1.88 | bc | 76.67 | 20.00 | a, b | 19.44 | 0.22 | d |

| T7 (0-67-33) | 0.97 | 0.01 | d | 3.95 | 1.21 | a | 23.35 | 1.31 | cde | 106.67 | 48.99 | a | 19.82 | 0.04 | c |

| T8 (0-33-67) | 0.98 | 0.01 | d | 3.45 | 0.75 | a | 25.66 | 2.57 | bcd | 86.67 | 16.33 | a | 19.35 | 0.18 | d |

| T9 (33-67-0) | 0.96 | 0.01 | e | 1.77 | 1.07 | bc | 22.71 | 3.33 | de | 93.33 | 56.37 | a | 20.99 | 0.13 | ab |

| T10 (33-0-67) | 0.94 | 0.01 | f | 2.99 | 1.18 | a | 23.48 | 1.06 | cde | 73.33 | 13.33 | abc | 19.54 | 0.10 | d |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zepeda-Cepeda, C.O.; Goche-Télles, J.R.; Palacios-Mendoza, C.; Moreno-Anguiano, O.; Núñez-Retana, V.D.; Heya, M.N.; Carrillo-Parra, A. Effect of Sawdust Particle Size on Physical, Mechanical, and Energetic Properties of Pinus durangensis Briquettes. Appl. Sci. 2021, 11, 3805. https://doi.org/10.3390/app11093805

Zepeda-Cepeda CO, Goche-Télles JR, Palacios-Mendoza C, Moreno-Anguiano O, Núñez-Retana VD, Heya MN, Carrillo-Parra A. Effect of Sawdust Particle Size on Physical, Mechanical, and Energetic Properties of Pinus durangensis Briquettes. Applied Sciences. 2021; 11(9):3805. https://doi.org/10.3390/app11093805

Chicago/Turabian StyleZepeda-Cepeda, Christian Osvaldo, José Rodolfo Goche-Télles, Celina Palacios-Mendoza, Oswaldo Moreno-Anguiano, Víctor Daniel Núñez-Retana, Maginot Ngangyo Heya, and Artemio Carrillo-Parra. 2021. "Effect of Sawdust Particle Size on Physical, Mechanical, and Energetic Properties of Pinus durangensis Briquettes" Applied Sciences 11, no. 9: 3805. https://doi.org/10.3390/app11093805

APA StyleZepeda-Cepeda, C. O., Goche-Télles, J. R., Palacios-Mendoza, C., Moreno-Anguiano, O., Núñez-Retana, V. D., Heya, M. N., & Carrillo-Parra, A. (2021). Effect of Sawdust Particle Size on Physical, Mechanical, and Energetic Properties of Pinus durangensis Briquettes. Applied Sciences, 11(9), 3805. https://doi.org/10.3390/app11093805