1. Introduction

The progress made in additive manufacturing has allowed for many materials to be transformed into useful devices with the most ecological and economical procedures known to mankind as of yet [

1]. Indeed, this technology, a legitimate child of Industry 4.0, and one of its main driving forces, is proving very useful in printing hybrid materials and also smart systems, which are materials with built-in sensing abilities [

2] as shown recently. Certainly, the concept of embedding sensing elements into structural components has often been used for monitoring purposes, with recent examples of circular PZT (lead zirconate titanate (Pb[Zr(x)Ti(1-x)]O

3)) patches incorporated in concrete cylinders reported in [

3]. In that study, vibration measurements from the embedded PZT patch were successfully correlated with measurements from accelerometers mounted on the cylinder’s surface. Since such measurements are useful for detecting increased stiffness of concrete due to aging, one may speak of concrete cylinders with integrated monitoring capabilities. At the same time, other studies attempted to evaluate problems from integrating sensing elements in various (mainly composite) materials. In [

4], piezoceramic flexible patches (PFP) inside glass fiber reinforced plastic (GFRP) specimens produced heat during their operation thus reducing the sensing performance of the specimens. Again [

5] concluded that integrating fiber Bragg grating (FBG) and strain gages via a hand lay-up process in sandwich composite material (with cork agglomerate core and fiberglass and epoxy resin skins) caused altered behavior in tensile, bending and creep tests.

Consequently, using 3D-printing techniques to embed low-power, passive sensing elements (thus avoiding self-heat problems [

4]) of limited dimensions into structural components, is the next step for creating smart materials with sensing capabilities. Many types of sensors and sensing systems can be 3D-printed nowadays and their numbers and applications are constantly rising [

6,

7]. It is easy to predict that many structural components and devices and even larger structures will be enabled with built-in, ab initio embedded sensors, providing monitoring of structural data, or health status. The applications of such systems start from the biomedical device industry, with their wearable sensors trends [

8], and finish up to smart aerospace materials endowed with sensing abilities [

9]. A key application of embedded sensors regards the nondestructive condition monitoring of structures, and mainly of joints between structural members or components.

In the past, different joint types were evaluated usually by dismantling the associated components and either testing them under static loading or inspecting them using traditional nondestructive testing and evaluation (NDT and E) techniques. For instance, in [

10], butt joint structures on composite fuselage frames were inspected during static loading by means of acoustic emission (AE) techniques. Indices such as the amplitude and accumulative energy of the recorded AE signals were evaluated over a testing period, in order to identify five different damage stages along with the corresponding damage style of the specimen. A similar principle of (tensile stress) loading along with a multi-parameter analysis of multiple AE features was used for monitoring carbon-fiber reinforced polymer composite single-lap shear joints in [

11]. In both studies, the monitored specimens were extracted from the structure and tested separately, meaning that normal operation of the structure had to be suspended. In [

12], adhesively bonded sandwich joints (used in aircraft interior fittings, ceilings, bulkheads) were reviewed and commented upon with respect to possible defects potentially causing reduced structural strength. Inspection of such joints was carried out by X-ray tomography, ultrasonic resting and, interestingly, low-frequency vibrational testing. In principle, such methods may be used when the structure is “off duty” for inspection purposes. Adhesive joints have also been considered for inspection in [

13] using the Single-Leg Bending (SLB) test. Obviously, this is an “off duty” mixed-mode (tensile and shear stress) testing procedure, which evaluates the structural condition of joints based on the strain energy release rate in tension and shear. For metal plate-like structures, nondestructive assessment of single-lap adhesive joints was carried out via ultrasonic guided wave propagation [

14], again during the time interval that the structure was “off duty” for inspection purposes. Other examples based on “off duty” inspection include [

15] where a composite pick-up truck box involving adhesively bonded composite joints was diagnosed by means of pulsed thermography methodologies, and [

16] with CFRP-epoxy adhesive single-lap joints inspected by means of eddy current pulse-compression thermography. These are two examples of NDT and E techniques traditionally used for detecting defects in parts/components which have been adapted for monitoring of joints in structures. A nice overview of such NDT and E techniques may be found in [

17].

The current study aims at introducing a vibration-based framework for monitoring joints in structures with composite members, based on measurements from embedded (via 3D-printing) sensing elements in them. The sensing ability thereby induced aims at limiting the use of dedicated equipment (amplifiers, accelerometers, piezoelectric sensors, 3D laser microscopes etc.), as found in AE [

10] and other NDT and E [

17] or traditional vibration-testing [

18] methods. Furthermore, the framework aims at using data potentially resulting from normal structure operation, in order to minimize the “off duty” inspection time of the monitored structure. Finally, with respect to test data evaluation/analysis, the framework aims at introducing techniques which do not require excessive time [

19] or a significant level of expertise from the user [

19,

20] to yield accurate results. To this end, the current study extends the use of the contactless damage diagnosis principle [

19] from a single slab to more complex structures formed by in-series connected slabs and characterized by more challenging dynamics. Embedding sensing elements via 3D-printing in a structural member means that (even) contactless transmission and recording of signals can be obtained via the principle proposed in [

19]. The added benefit is that the use of equipment such as amplifiers, accelerometers and piezoelectric sensors may be minimized. On the other hand, all joints should be monitored, even though only one of the slabs involved incorporates the 3D-printed sensing element. For this reason, the contactless diagnosis principle in [

19] (presented therein for a single slab) is now upgraded with respect to data evaluation techniques. Specifically, a novel approach for estimating damping values for a given mode is postulated. It undertakes the principle of the empirical procedure found in [

20], but achieves enhanced accuracy and applicability to noisy signals, while requiring less time and user-expertise than system identification techniques [

19]. Several test runs are conducted with structures formed by two or three composite slabs connected in series with bolted joints. These structures have been tested with either firmly fastened or failing joints. It is shown that specific frequency shifting and/or damping alteration patterns for given modes may be distinguished and associated to specific failing joints.

The rest of the paper is organized as follows:

Section 2 presents the fabrication of composite slabs via 3D-printing, the method for incorporating sensing elements during 3D-printing of slabs, the test structures resulting from connecting slabs in-series, the testing protocol used for the experiments and the procedure for damping factor estimation. In

Section 3, the experimental data along with results on detection and identification of failing joints are shown and commented upon. Finally,

Section 4 presents some concluding remarks.

2. Materials and Methods

2.1. Slab 3D-Printing, Assembly of Structures and Data Recording Setup

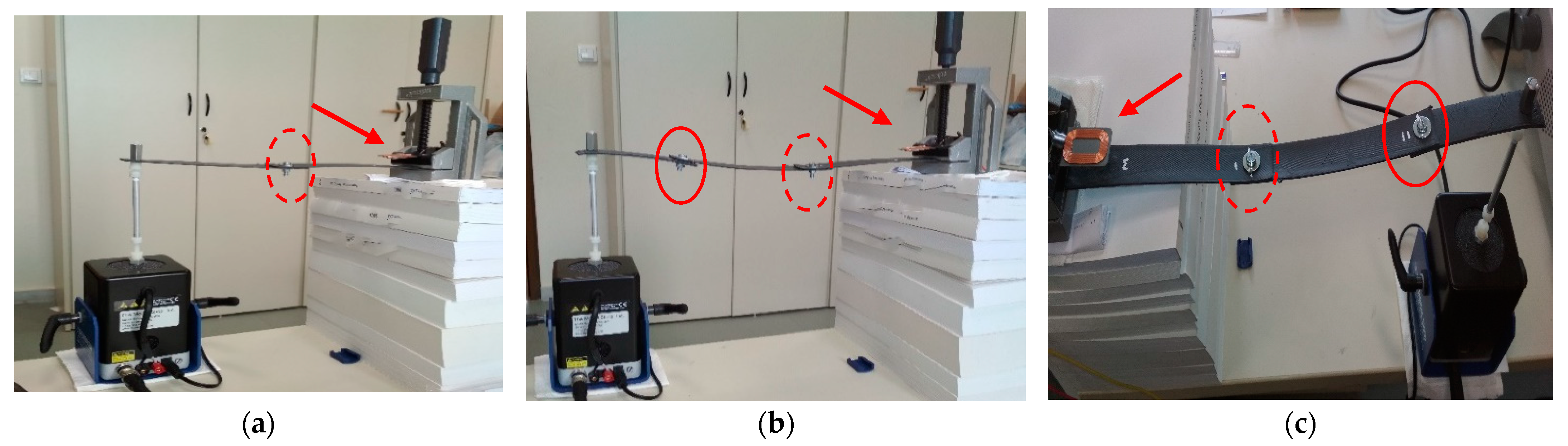

Rectangular slabs were prepared as in [

19]. Briefly, the printer (CTC i3, Zhuhai Electronic Ltd., Zhuhai City, Guangdong, China) operated in fused deposition modeling (FDM) mode, had a single nozzle with a diameter of 0.4 mm, and used a polymer filament of 1.75 mm. The filament was a short carbon fiber reinforced PET-G polymer (CFRP) by 20 wt% (NEEMA3D™ Carbon: plus) of NEEMA3D™, Petroupolis, Greece. According to the manufacturer’s specifications, the filament’s Young’s modulus and Yield Strength were equal to E = 3800 MPa and 52.5 MPa, respectively. The printing temperature was set at 225 °C. Two slabs each measuring 170 × 25 × 3 mm

3 were printed, one of which incorporated a 2826MB Metglas

® magnetoelastic (20 μm) strip of 25 × 5 mm

2, as sensing element. Another shorter slab (110 × 25 × 3 mm

3) without sensing element was also printed. As described in [

19], a sliced 3D design file was created for the considered slabs, and used in Pronterface

® software driving the 3D printer in Fused Deposition Mode (

Figure 1a). The sensing element was easily incorporated during 3D-printing of slabs, by pausing the FDM printer once the desired layer height had been reached, so as to attach the strip with epoxy adhesive (

Figure 1b). In the current case, 3D-printing of the slab in

Figure 1b was temporarily halted when the slab’s thickness was equal to 1.75 mm. Then, the strip was attached and subsequently covered by successive material layers until obtaining the final slab thickness of 3 mm (

Figure 1c).

Two structures were formed by either two or three slabs connected in series with 5 mm bolts and washers, as shown in

Figure 2. Since this study investigates the feasibility of modifying the framework in [

19] for detecting and identifying failing joints, it seemed evident not to consider structures of complex geometry and numerous joints at this (initial) stage. Therefore, two basic structures were investigated: The first (most basic) one was used to verify that in case of issues with failing joints, the framework proposed in [

19] in a suitably modified form, could detect the problem. The second structure should additionally allow for using the proposed framework to identify the joint that is failing. As seen in

Figure 2, each joint between two slabs is formed with 5 mm bolts. This allowed for easily switching between a normal (tight) joint condition to a failing (loose) one after each test run. Hence, failing or normal conditions for a given joint were easily replicated, without having to dismantle the structure. Note that, the aim was to assess the operational condition of joints (fit for purpose, or not), rather than to pick up particular defects (i.e., breakage of adhesive film between surfaces, delamination problems) leading to compromised operation. This macroscopic approach, in turn, means that the proposed monitoring framework could be applicable to various kinds of joints (adhesive, bolted, etc.).

The structure with two slabs involves only one bolted joint and is referred to as structure-A (

Figure 2a), whereas that with three slabs and, hence, two bolted joints is referred as structure-B (

Figure 2b). Both structures are clamped as cantilevers at one end, whereas the free end is vibrated by means of a mini-exciter with integrated power amplifier (K2004E01, The Modal Shop, Cincinnati, USA). The latter is capable of producing various profiles of vibratory force/motion (triangular, sinusoidal, pulse-like, etc.) supplied by an external waveform generator (SDG 5122, SIGLENT). Structure-A measures 300 mm, and the bolted join (referred to as J1 and indicated by red dashed ellipsis in

Figure 2a) is located 150 mm from the clamped end. Structure-B measures 400 mm and the two joints are located 150 mm (J1, indicated in

Figure 2b by a red dashed ellipsis) and 300 mm (J2, indicated in

Figure 2b by a red solid ellipsis) from the clamped end, respectively. In both structures, the slab involving the sensing element (MetGlas

® strip) is the one at the clamped end, as shown in

Figure 2c.

As in [

19], the response of the vibrating structure is translated into electrical signals created by induction to a low-cost reception coil (Vishay IWAS) placed at 20 mm above the slab incorporating the sensing element, as shown in

Figure 2c. According to the principle explained in [

19], the vibrational loading provokes changes in the magnetoelastic strip’s magnetization, which, in turn, causes induction of electrical signals in the reception coil circuits. Hence, this is a passive data transmission setup, in the sense that, unlike for instance [

21,

22], no excitation coil is used. All such signals were recorded by means of a conventional digital oscilloscope at 1 MHz. Note that the coil’s distance of 20 mm from the slab was defined by a trial-and-error process. In other words, the coil’s position comes from a trade-off obtained via an empirical process for recording signal output with principal frequency components of magnitude +20 to +30 dB over those of the noise layer.

2.2. Testing Procedure

As explained in

Section 2.1, the structure under test (structure-A or -B) is clamped at one end, whereas the other (free) end is attached to a stinger, i.e., a thin aluminum rod connected to the mini-exciter and shown on the left in

Figure 2. Tests involve vibrating structure-A and -B at normal and at failing joint conditions. Normal joint conditions involve firmly fastened joints, obtained in the current case by applying a torque of up to 8 N/m. They are referred to as NJ-A for structure-A and NJ-B for structure-B. Failing joint conditions correspond to fastening the bolt using almost zero torque. Hence, even though the bolt bears contact with the washer, it is difficult to visually detect whether the joint is loose or not. For the same reason, the word “failing” is used (i.e., still operating in a substandard manner) and not “failed” (as for disrupted) joints. Failing J1 joint is referred to as FJ1-A or -B, for structure-A (

Figure 2a) or structure-B (

Figure 2b), respectively. On the other hand, only structure-B involves failing joints J2, which is a condition referred to as FJ2-B.

With respect to testing at failing joint conditions, structure-A may, obviously, be tested with only one failing joint (FJ1-A). Structure-B was tested with either J1 (FJ1-B) or J2 (FJ2-B) in failing condition. Test cases with two simultaneously failing joints (FJ1-B and FJ2-B) were not considered, since, in real life, identifying the first failing joint should call for applying remedial action to revert to a condition with tightly fastened joints. Note that, irrespectively of the location of the failing joint, excitation is always provided at the same point. This has not always been the case in structural vibration testing in the past. Since the excitation position does not have to be defined according to the location of the monitored joint, the current framework could be used with vibration data recorded from normal operation/loading of the structure.

As explained in

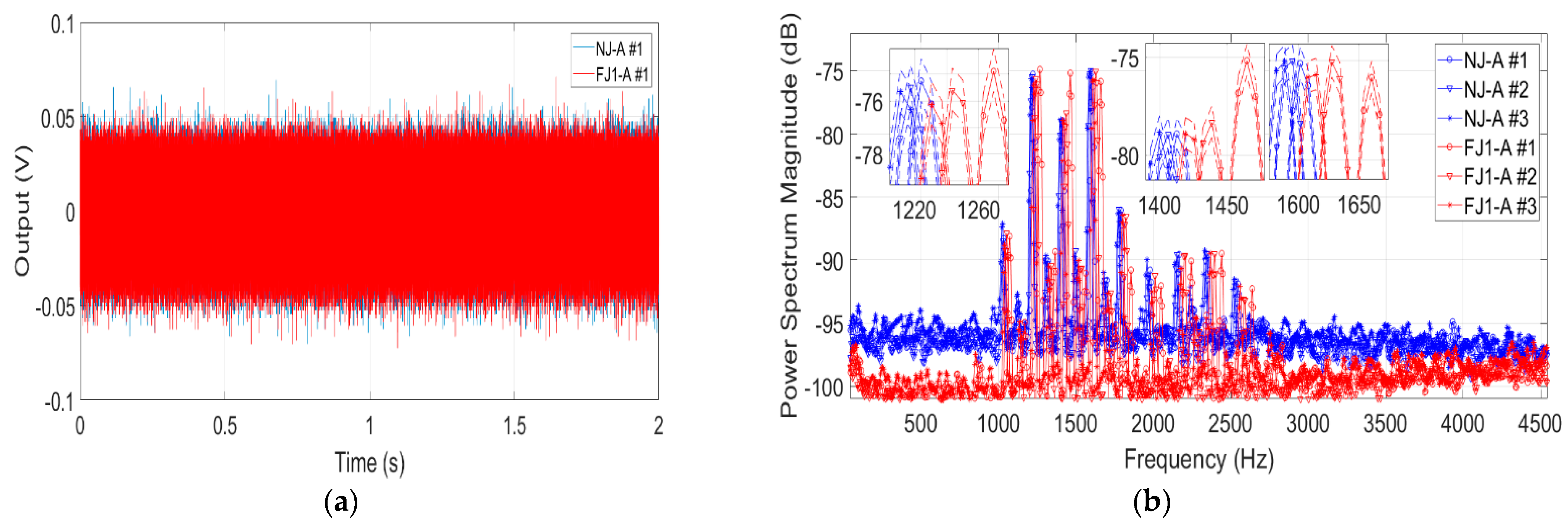

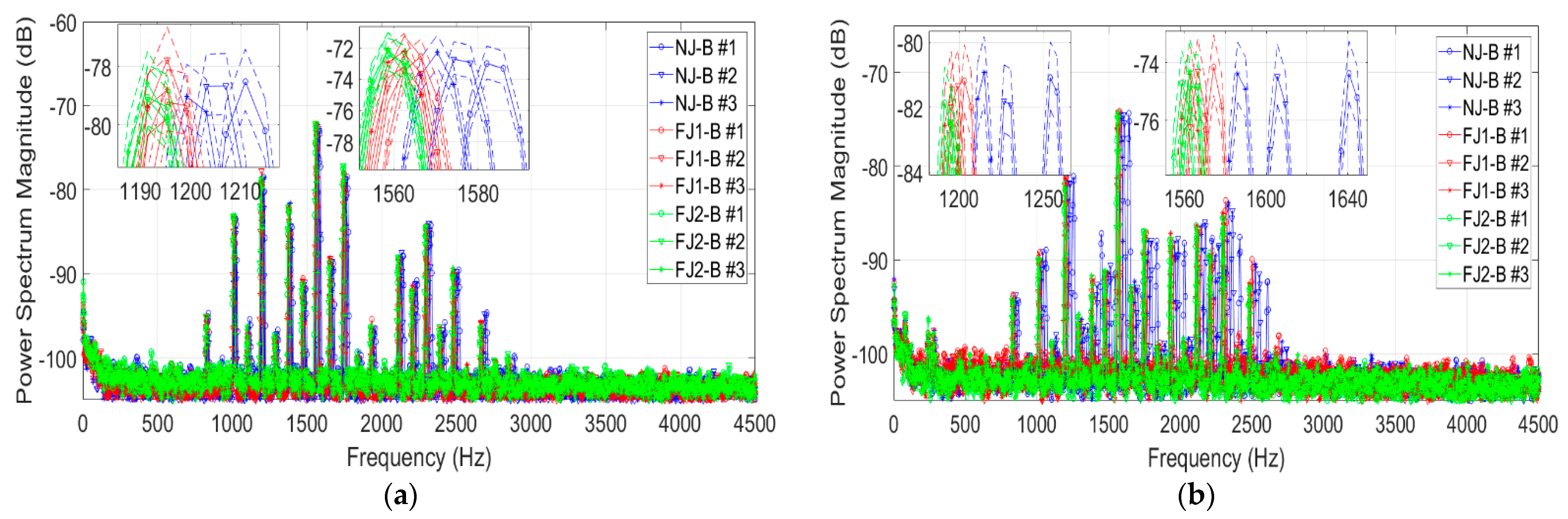

Section 2.1, the starting point for producing a vibratory force from the mini-exciter is the definition of an initial suitable profile in the waveform generator. This is then used for driving the mini-exciter, which theoretically produces a force/motion profile matching the characteristics of the supplied waveform. In practice, this profile is somewhat different due to mechanical constraints (inertia of stinger and various internal parts, possibility of saturating actuators), bandwidth limitations of the exciter’s armature response, parasitic loading from the stinger’s off-centered motion during its operation etc. With respect to the profile of the initial waveform, a repetitive triangular form was preferred to pulses or perfect sinusoids. The reason is that loading profiles produced in several real-life cases rarely correspond to pulses or perfect sinusoids, with examples involving loading from people walking on the surface (not at a marching pace), or from operating machinery with rotating parts (internal combustion engines, for instance). On the other hand, with respect to selecting the waveform’s frequency, the aim was to produce mechanical force/motion of low amplitude and frequencies corresponding to those from operation of machinery with rotating parts. Initially, tests were intended to be performed at 20–40 Hz, which is roughly the case of an internal combustion engine rotating quite slowly at 1200–2400 rpm. Following tests with the waveform generator, it soon became clear that frequency components of 50 Hz of quite significant magnitude were always present, even for triangular waveforms of 20 Hz. This meant that testing at frequencies over 50 Hz was the only dependable scenario. In practice, selecting a frequency of 80 Hz for the triangular waveform means that the mini-exciter should be ultimately producing mechanical force at somewhat lower frequencies (due to reasons stated at the beginning of this paragraph), which would roughly correspond to an engine turning at mid-range (4000–4500 rpm).

Hence, a triangular excitation profile at 80 Hz and 600 or 800 mVpp was selected in the waveform generator in order to drive the exciter. Note that, when a test was completed, the excitation input provided to the structure by the exciter was not recorded. Only output data recorded by the reception coil are used for detecting and identifying failing joints. This also means that, in principle, even test data from normal operation of the structure may be used for such monitoring purposes. All recorded signals underwent power spectrum analysis via the Welch method, with results presented in

Section 3.

2.3. Second-Order Approximation Procedure for Damping Factor Estimation

There are two issues, which require further investigation before attempting to adapt the contactless diagnosis principle of [

19] to the current application. First, the possibility of a failing joint quite far from the sensing element, which was not a problem in [

19] since only one slab was involved; second, a significant variability in dynamics (following occurrence of a failing joint) of a structure formed from a group of slabs as opposed to dynamics of a single (continuous) slab. When system testing and recording of experimental data is completed, examination of the data frequency content usually leads to analyzing the most prominent modes, approximately corresponding to the most visible peaks in the plots (as already verified via finite element analysis in [

19]). According to [

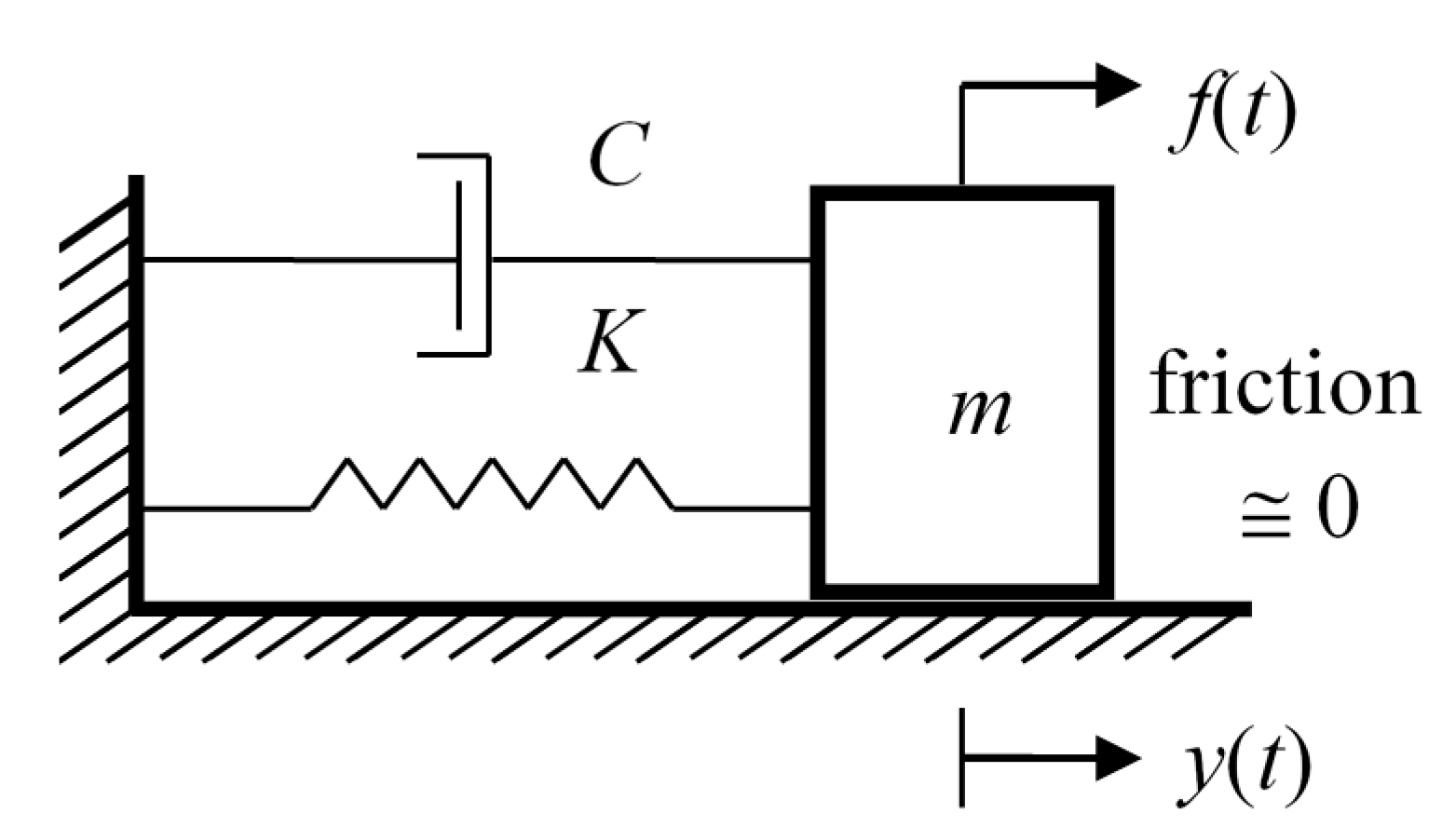

20], chapter 10, such peaks in Frequency Response Function (FRF) plots may be attributed to complex pairs of system poles with very low values of damping factors. In essence, mapping peaks to pairs of lightly damped poles means that the response of the linear system is due to the superposition of responses of elementary under-damped second order systems. In other words, this principle is similar to partial fraction expansion (see [

23], p. 61) usually performed in linear systems, with higher order systems decomposed to a series of first and second order systems for calculating the system response signal.

Thus, for such cases [

20] proposes an empirical method to estimate the value of damping factor

ζ for such pairs of lightly damped poles, based on the value

ωn of the mode’s frequency, its peak magnitude in dB, and the half-power frequency values. These are two frequency values for which the mode’s magnitude reaches 70.7% of its peak, before (

ωnb) and after (

ωna) frequency

ωn. Using this set of points, the unknown damping factor value is computed as equal to 0.5 × (

ωna −

ωnb)/

ωn (see [

20] for further details). This method is nicely suited to data characterized by low noise-to-signal ratio, but hardly suitable for many real-life noisy signals. In such cases, only peaks of modes of lightly damped pole pairs may be visible over the underlying noise in plots. Then, half-power frequencies

ωnb and

ωna cannot be easily defined, since they are masked by the noise. Another issue is that very often the excitation input is not available. This is typically the case of recorded system responses not resulting from a dedicated experiment, but rather from system operation in typical real-life conditions. Then, for such output only systems, only power spectrum plots of the output signal may be available for estimation.

Therefore, a modification of this procedure is postulated in order to circumvent the noise masking effects. Each monitored peak of magnitude Mn and frequency ωn is still considered as resulting from a lightly damped complex pair of poles. Let the group of q spectrum points with frequencies be defined as [ω1, ω2, …, ωn, … ωq] and let [M1, M2, …, Mn, …, Mq] be the group of the associated magnitudes. Spectrum points ωi and Mi with i = 1…q and I ≠ n, are all points preceding and following the peak [ωn, Mn] of interest, that are still visible over the noise layer in spectrum plots. The effort, now, is to identify the second order system producing a peak that matches the monitored one at all points ωi and Mi with i = 1…q. This second-order approximation procedure is formulated as an iterative nonlinear optimization problem, as follows:

Create the power spectrum plot of recorded data, define the value of resonant frequency ωn of the mode under examination, as well as the set of spectrum points [ωi, Mi], i = 1…q on either side of ωn, which can be distinguished over the noise;

Choose a set of parameters, namely the static gain A and damping factor ζ, for the trivial second order system with transfer function {A∙ωn2/(s2 + 2∙ζ∙ωn∙s + ωn2)}, obtain its discrete time counterpart and estimate the power spectrum (using the same settings as in step 1) of the output to a given periodic input (preferably white noise);

Focusing on frequencies

ωi,

i = 1…

q (see step 1), compute the quantity:

at the

k-th iteration, with

Mi the magnitude of the power spectrum estimate of the second order system at

ωi;

Go back to step 2, pick up a new set of A and ζ, and proceed to the next iteration by repeating steps 3 and 4, until a value of k for which r(k) becomes minimal is reached. Then, store the value for damping factor ζ, which corresponds to that of the considered (and monitored) mode.

This minimization procedure may be carried out by means of relevant nonlinear least squares routines, readily available in most software packages. For instance, in MATLAB® one may use the command lsqnonlin.m for this purpose. During testing of the second-order approximation, simulations were carried out with higher order linear systems, which were driven with periodic input usually of triangular or sawtooth forms. Use of the second-order approximation procedure led to quite accurate results when dealing with modes with damping factor values lower than 10−3.

Finally, note that, as its name suggests, this procedure is intended as a means of approximating the true dynamics associated to a mode. In other words, it may not be used as a substitute for stochastic system identification procedures, which, as also demonstrated in [

19], are extremely effective in capturing the

global system dynamics. The only problem with system identification procedures is that identifying an effective and accurate system model requires significant user expertise and time for choosing the correct model structure. Hence, for a given set of signals, when rapid evaluation of a specific mode is necessary, then one may proceed with [

20] or the currently presented second-order approximation procedure.