Abstract

Due to the environmental pollution threatening human life, clean water accessibility is one of the major global issues. In this context, in literature, there are many portable water disinfection systems utilizing ultraviolet (UV) radiation. UV water disinfection systems employ piezoelectric-based electric power along with UV light-emitting diode (LED) sources. This paper elaborates on the detailed design and parametric optimization of a portable UV disinfection system. The proposed system aims to generate piezoelectric harvesting-based electrical power simply by shaking, and the generated power is then used to supply UV-LEDs for water disinfection. To this end, overall system parameters along with a physical-mathematical model of mechanical, electrical and biochemical aspects of the system are fully developed. Moreover, the main design parameters of the developed model are derived for optimal operation of the system by employing Genetic Algorithm (GA). Finally, optimal design parameters were identified for three different cost scenarios. The model can further be improved for practical implementation and mass production of the system.

1. Introduction

Environmental pollution has been threatening human life with the increase of industrial areas and population. Although sufficient and clean water accessibility is recognized as a human right by the UN General Assembly [1], 785 million people lack even a basic drinking-water service. Even microbiologically polluted drinking water causes 485,000 diarrheal deaths each year [2]. Thus, the improvement of effective water treatment systems as well as innovative approaches, particularly for inactivation of pathogenic microorganisms in water, is of great importance for human well-being and prosperity [3].

Over the last decades, various water cleaning methods have been developed to overcome this problem. The most common one is chemical water disinfection, also known as conventional disinfection. However, the systems based on chemical water disinfection have some disadvantages, such as inefficiency to destroy some specific microorganisms, difficulties in the storage or transportation of chemical ingredients, harmful sediments that remain after the chemical process, the corrosive effects of chemical reactions on the system (need for maintenance). As an alternative, another method is using ultraviolet (UV) disinfection to have microbiologically clean water. Many studies have shown that UV radiation can influentially kill and deactivate pathogenic microorganisms [4,5]. Therefore, UV disinfection has several advantages compared to chemical water disinfection, including lack of chemical addition and harmful disinfection by-products formation, as well as its effectiveness on chemical-resistant bacteria [6]. In literature, there are many water disinfection systems utilizing UV radiation and they can be evaluated in two different aspects: electrical power source and UV light source.

Certain UV water disinfection systems use photovoltaic panels [7,8], and the electric network as an electrical power source. Photovoltaic-panel-powered systems typically require photovoltaic (PV) cells-based solar energy which makes them fragile and so unsuitable for extreme conditions. Battery-powered systems have a very limited lifetime due to the capacity of battery cells, or size and weight constraints of the battery. Furthermore, batteries may not be stable in extreme temperature conditions and they can pollute the water [9]. Therefore, UV water disinfection systems powered by electrical battery cannot be used effectively in the field. In this regard, piezoelectricity may pave the way for powering portable UV disinfection systems. Piezoelectricity could be an effective energy harvesting mechanism for powering portable UV water disinfection systems. It may simply generate the required energy by applying mechanical stress, for example, simply shaking or vibrating by the user [10]. Various piezoelectricity energy harvesters have been developed and tested so far, such as a walking charger based on piezo-electric material [11], lead–zirconate–titanate (PZT) material, the Quick Pack (QP) actuator, the macro-fiber composite (MFC) for recharging batteries [12], and piezoelectric energy harvesters based on vibration [13]. To some extent, even natural vibrations can be used to supply the required power for UV water disinfection systems.

On the other hand, the type of the UV light source also plays a critical role in UV water disinfections. Generally, UV water disinfection systems may use UV mercury lamp [14], or concentrated sunlight [15] or UV light-emitting diode (LED) [16]. UV mercury lamp-based systems have some disadvantages, including large physical size, narrowband radiation, toxic ingredients (mercury) and high energy consumption [17]. Sunlight-powered water disinfection systems require continuous sunlight, and should be large in physical size to generate the required energy levels. Besides, the optical components of these systems are fragile and inappropriate for harsh environments. On the contrary, UV-LED source-based water disinfection systems provide not only a wide UV radiation spectrum in order to attain higher disinfection performance, but also consume less power with their relatively smaller physical size. Therefore, UV water disinfection systems employing piezoelectric-based electric power along with UV-LED sources may provide sustainability and portability, as well as efficiency. A patent owned by one of the authors has been filed recently for such a system design [18]. The proposed system generates its power using piezoelectric harvesting-based electrical power generated simply by user shaking.

This paper elaborates on the design and parametric optimization of the system in [18]. It is intended to have optimal design parameters of the system for possible mass production. The proposed design has three distinctive sub-systems, namely, mechanical sub-system, piezoelectricity-based energy harvesting sub-system, UV-LED disinfection sub-system. Then, from the design and optimization point of view, the system is quite complicated, and involves a mixture of geometrical, physical and biochemical parameters. Therefore, the design parameters of each sub-system are determined first, and necessary physical-mathematical models are developed. In this way, the overall system parameters and the mathematical model of the system are developed. Finally, objective function (OF) is formulated, and optimal design parameters are identified for optimal operation of the system. To this end, Genetic Algorithm (GA) is employed in single- and multi-objective optimizations [19,20]. The following are the major contributions of the paper:

- To the knowledge of the authors, the proposed piezoelectric-powered portable UV-LED water disinfection system is the first reported in the literature. This has been proven by the filed patent search where only a high-level design of the system is presented.

- The work elaborates the system design, including mechanical, electrical and chemical aspects and/or sub-systems.

- The paper develops the mathematical-physical model of the overall system in the form of objective functions (OF) and provides an optimal design for any targeted parameters by employing Genetic Algorithms (GA).

The remainder of this paper is structured as follows. Section 2 briefly describes the operation of the proposed system along with the sub-systems. Section 3 develops mathematical-physical models of the proposed system, and formulated sub-systems in detail. Section 4 presents a derivation of objective functions (OF) based on the results of formulations in Section 3, and implementation of GA for optimal parameter settings. Section 5 presents some of the results and discussions. Finally, conclusions are drawn in Section 6.

2. Operation of the Disinfection System

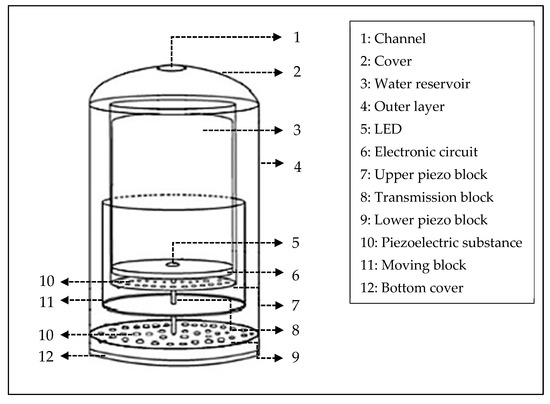

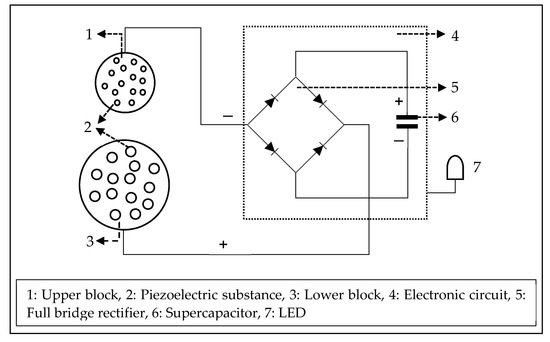

A general system overview of the piezoelectric-powered portable UV-LED water disinfection system is already presented in [18]. Apart from this, here, operation of the system is presented briefly. The proposed system, basically, is a portable water storage system (just like a canteen) that can be used for disinfecting drinking water without any battery or external power unit as well as any chemical component (eco-friendly design). The system comprises three main components, body, moving block and drinking glass. The body consists of two interwoven hollow cylinders. The outer cylinder functions as the shell of the system while the inner cylinder is simply a placeholder for the drinking glass. Moreover, there are two piezoelectric blocks for energy harvesting—one on the inner sole of the shell and the other on the outer sole of the inner cylinder. The moving block is free-running and is embedded tightly in between the hollow cylinders. Finally, the drinking glass is placed inside the inner cylinder for storing the drinking water. A technical drawing illustrating the main components of the system is shown in Figure 1. The system starts operation by shaking, i.e., shaking up and down by the user. Meanwhile, the bottom of the moving part hits the piezoelectric blocks with which mechanical energy is simply converted into electrical energy. The generated electrical energy is continuously stored in a supercapacitor which is an integral part of the piezoelectric energy harvester. The voltage level of the supercapacitor is displayed to the user so that they can stop shaking at a pre-defined voltage charging level (max) of the supercapacitor. Once the voltage level is reached, the required energy is ready for use, and the user can press the button to ignite UV-LED radiation for the disinfection process. The disinfection continues until the voltage level of the supercapacitor reaches the pre-defined level. Shown in Figure 2 is a simple diagram of the electronic circuit of the system. The following section describes the physical-mathematical model of this flow, and concludes with the optimal design parameters.

Figure 1.

Illustration of the main components [18].

Figure 2.

A simple diagram of the electronic circuit of the system.

3. Modeling of the System

Before describing the system, it is necessary to briefly mention the modeling considerations. Firstly, the system is assumed to be watertight. Another assumption is that the piezoelectric ceramics have identical properties in terms of the thickness and diameter. In addition, system performance degradation due to the lifecycle of the ceramics is neglected. It is also assumed that the UV-LEDs are expected to radiate at the desired energy level. Moreover, the variations on the performance of piezoelectric ceramics and UV-LEDs in different temperature and humidity conditions are ignored. Furthermore, during the conversion of mechanical energy to electrical energy, the piezoelectric ceramics are expected to work with maximum efficiency. On the other hand, the moving block used in the system is expected to be operated without any friction. For this reason, the forces of friction have not been taken into account.

The disinfection system is composed of three sub-systems: mechanical system, piezoelectric energy harvesting system, UV-LED disinfection system. The mechanical system represents entire-system mechanics as well as the generating of electrical energy by transferring the user’s hand shaking into the piezoelectric energy harvester.

3.1. Mechanical System

The mechanical system consists of various mechanical parts, and the most critical component is the moving block as illustrated in Figure 1. It simply applies a continuous force to the piezoelectric blocks by user shaking. This results in energy harvesting by the piezoelectric blocks. As mentioned in the previous section, two piezoelectric blocks are used for energy harvesting. One is located at the bottom of the moving block while the other is placed on the moving block. It is worth noting that it is unnecessary to define the dimension of the piezoelectric blocks as it does not directly affect the performance of the system. Then, the force induced () can be given simply by mass of the moving block () and shaking acceleration () as

where it is important to note that the system is independent from the forces of gravity because the moving block becomes motionless while shaking the system. In this case, user’s hand balances the force, and hence, only the shaking acceleration holds.

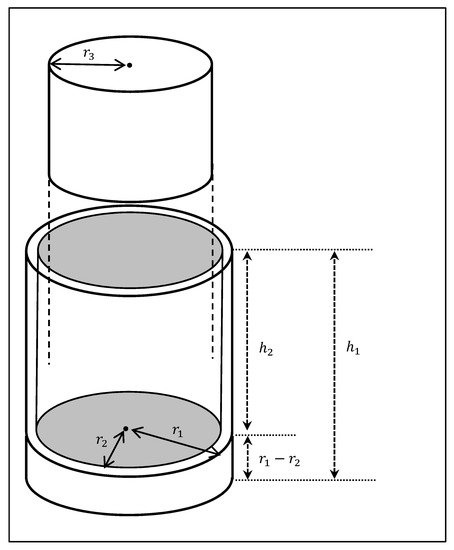

Furthermore, the term can also be calculated by using the outer–inner radius of the block ( ), the height of the block (), as well as the material density of the block () as follows

where, as shown Figure 3, is the height of the lower block which can be expressed as

Figure 3.

The dimensions of the lower and upper blocks.

After substituting Equation (3) in Equation (2), the term can be calculated by

The range of acceleration can be estimated experimentally. To this end, a mobile accelerometer application may work well. For this purpose, a water bottle (1.5 kg) and a smartphone (0.18 kg) in combination were shaken up and down while the application recorded the acceleration continuously. The mean value and standard deviation of the acceleration were calculated in order to estimate the approximate range of the acceleration. Base radius of the transparent drinking glass is also important for the UV radiation dosage. It should be slightly smaller than the inner radius of the moving block. Overall, considering the typical size of similar water storage systems (for example, a canteen), Table 1 shows some typical values and the ranges of the mechanical system parameters.

Table 1.

Mechanical System Parameters.

3.2. Piezoelectric Energy Harvesting System

Vibrations are quite typical in energy harvesting. The piezoelectric energy harvester is naturally capable of transforming mechanical energy, such as vibrations, into electrical energy [21,22]. Various piezoelectric energy harvesters have been developed [23,24,25]. Piezoelectric energy harvesters are quite appropriate for portability, and thus for environmentally friendly (eco-friendly) applications. Therefore, the proposed system uses a piezoelectric energy harvester. It is simply composed of piezoelectric blocks, a full-wave bridge rectifier, and a supercapacitor. This structure can also be evaluated by using more complex electronic components such as over-voltage protection circuit, IC full-wave bridge rectifier, filters, etc. However, the presented version of the electrical system is quite functional and available.

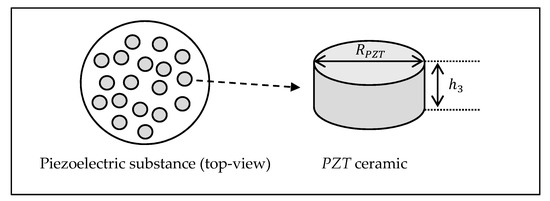

In the system, the piezoelectric blocks are subjected to mechanical pressure while the moving block moves up and down with user shaking. In every hit of the moving block, the piezoelectric materials generate certain amounts of AC signal [26]. Next, the AC signal is rectified by a full-wave bridge rectifier (with two additional diodes for reverse voltage), and the DC signal is stored in the supercapacitor. The supercapacitor must operate in a wide range of temperatures, and it should have a high charge–discharge efficiency as well as long lifetime [27]. In this regard, the supercapacitors which are classified in IEC/EN 62391-1 Class 2 as an energy storage component could be an appropriate choice for piezoelectric energy harvesting application. Here, the minimum voltage () and energy capacity () of the supercapacitor can be determined with respect to the optimization result. After a short examination on relevant piezoelectric materials in the market, Navy Type II PZT circular shape ceramics (PZT ceramic) were found to be quite appropriate for this system [28]. Therefore, the following model uses the specifications of this ceramic. The thickness () and the diameter () of the PZT ceramics can be used in modeling of the system (Figure 4). Moreover, the number of PZT ceramic () to be used as well as the shake frequency () should be taken into account. The shake frequency () in the acceleration tests was around 6 Hz. However, the size and weight of the smartphone and water bottle pair may be slightly smaller than the targeted size of the system. Then the range of the shake frequency must be a little bit smaller. Overall, Table 2 lists the range of the parameters for the piezoelectric harvesting system.

Figure 4.

The diameter and thickness of the lead–zirconate–titanate (PZT) ceramic.

Table 2.

Piezoelectric Energy Harvester Parameters.

Mathematical modeling of a piezoelectric energy harvester was already developed in [29]. Following the derivations along with lower frequency operation of the proposed system, the output (mechanical) power of the piezoelectric energy harvester can be simplified to

where is the transducer damping factor, is the resonant angular frequency, is the shaking angular frequency (), is the amplitude of the sinusoidal shaking (in voltage) [30]. Other parameters in Equation (5) can be given as follows:

where is the frequency constant (2040), and

where is the piezoelectric charge constant (24.8).

3.3. UV-LED Disinfection System

UV disinfection is a well-known technique that neutralizes or kills harmful microorganisms with UV-C band radiation. UV-C beams prevent harmful activations of microorganisms by damaging protein structures such as DNA, RNA, enzymes [31,32]. Typically, DNA/RNA protein structures have an absorption range of 200–300 nm with a peak around 260 nm [33]. However, some of the microorganisms have DNA repair mechanisms [34]. The DNA repair mechanism can be destroyed by breaking the repairing enzymes with more absorbable UV radiation [35,36]. For all these, the energy dose () plays a critical role, and it is defined by the Bunsen–Roscoe reciprocity law as follows [37].

In the proposed system, two UV-LEDs at two different wavelengths, 255 nm and 280 nm, are employed. The lower is for DNA and RNA disinfection, while the higher is for breaking DNA–RNA repair enzymes. Based on the standards for UV mercury lamp-based (254 nm) UV water disinfection [38], the bounds of the most appropriate dosage can be estimated roughly within a safety margin of 15%. The list of the microorganisms and estimated dosages are well-documented for water disinfection systems in [4]. Then, UV-LED power consumption () and UV-LED flux power () can be estimated accordingly, as shown in Table 3. The ranges could still be improved based on experimentation.

Table 3.

UV-LED Parameters.

4. Optimization

The system presented in the previous sections aims to generate electricity using human arm motion via a piezoelectric energy harvester and then use the generated energy for UV water disinfection. Then, human arm dynamic can be considered as an input while successful disinfection of certain amount of water, or corresponding UV dosage, could be the output (disinfection performance). However, from the user’s point of view, as well as mass production, the cost of the system is also an output parameter for the targeted disinfection performance. In fact, there may be many other parameters in the optimal design of the system. The goal of this section is to demonstrate the applicability of the optimization with some major parameters described above.

4.1. Feasible Objective Functions (OFs)

4.1.1. Shake Duration

From the user’s point of view, the first objective function (OF) could be the shake duration (). This helps to estimate the optimal shake duration for typical values of all design parameters. The OF can be derived based on the mechanical aspects as well as the energy harvesting and the targeted disinfection performance of the system. Firstly, since identical PZT ceramics are used in the system, the harvested energy can be written as

where is the number of PZT ceramics and is the shake duration.

Next, the dissipated energy can be written as

where is the average power of UV-LED, is the duration of the disinfection process, which also corresponds to in Equation (8). Thus, based on Equation (8), can be calculated in terms of the predefined UV dosage along with UV-LEDs flux power () via

where is the UV dose given in Table 3. Therefore, Equation (10) can be re-written as

Using Equations (9) and (12), and inserting the power in Equation (5), the shake duration can be calculated as follows

In the system, the amount of the harvested energy is directly proportional to the shake duration. Therefore, it is expected to have equal amounts of the harvested and dissipated energy in ideal conditions. Then, by expanding the terms using Equations (1)–(7), the power, , can be obtained as

The shake duration can be then written as

4.1.2. Cost of the System

The cost of the system is highly dependent on two main components, UV-LEDs and PZT ceramic. Besides, these components have a major role both in piezoelectric energy harvesting and UV disinfection. The next OF, the cost of the system, can then be derived based on the market price variability of these components. Firstly, considering market prices of PZT Navy Type II ceramic of $4–5, the cost of the ceramic can be formulated, as a linear function of the number of ceramics (), as follows

Next, the market price of UV-LED is highly dependent on the flux power () of UV-LEDs which was discussed in the previous section. As per the dosages given in Table 3, and considering the market prices of UV-LEDs of $9–50, the cost of two UV-LEDs (one UV-LED per each band) can be given as

Then, the overall cost of the system can be given as

4.2. Solution Method

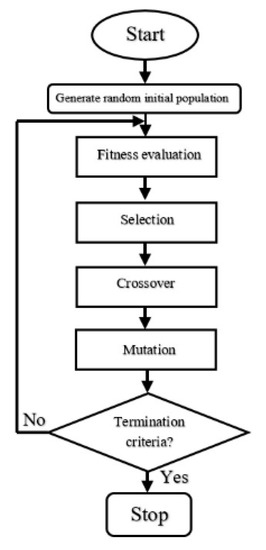

Genetic Algorithm (GA) is utilized in optimizations. GA simply focuses on minimizing the OF with the constraints of the input parameters [39]. GA optimization has a process flow as shown in Figure 5. The first step is the generation of initial populations. Initial populations (chromosomes) are selected randomly depending on the constraints. The second step is fitness evaluation where the OF is evaluated using each chromosome, and results are scaled. Then, the evaluated chromosomes are selected to create the new generation regarding their fitness performance. There are a few selection methods available, and the stochastic uniform selection is utilized in this study. It provides diversity in the population and so it prevents inadequate preterm convergence [40]. Next, the crossover process begins following the selection of fittest parent chromosomes. The crossover is employed to interchange some of chromosomes to create a new-generation offspring. Finally, mutation starts to change chromosomes randomly. Both the crossover and the mutation are executed with regards to the constraints of the parameters. All processes are executed repeatedly until the targeted termination criteria. In the optimization process, MATLAB 2020a Global Optimization Tool is used. GA optimization parameters are presented in Table 4.

Figure 5.

GA optimization flowchart.

Table 4.

Genetic Algorithm (GA) Optimization Parameters.

5. Results and Discussion

Firstly, single-objective optimization is performed using GA. In this case, the cost of the system is ignored, and the shake duration is taken as the OF. The minimum shake duration along with the optimal set of the parameters are determined based on the range of the constraints of the input parameters. Shown in Figure 6 is the variation of fitness value in GA optimization.

Figure 6.

GA optimization process.

The best fitness value of is found to be 15.34 in the 375th generation. Then, GA optimization helps to generate the optimal values of the design parameters (the first nine parameters in the table) along with the derived parameters (the last five parameters in the table), as shown in Table 5.

Table 5.

Optimal System Parameters (Objective Function (OF): Shake Duration).

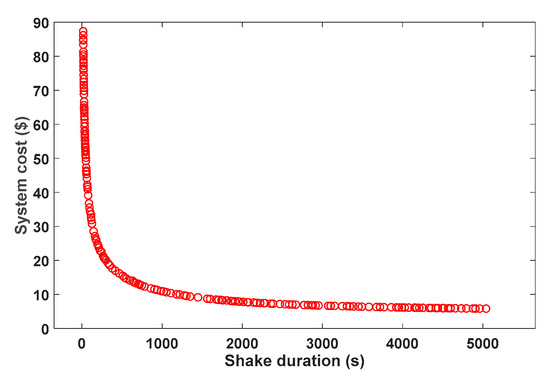

It should be noted that the piezoelectric harvester generates 42.19 of electrical energy within a shaking duration of 15.34 . Then, the stored energy is dissipated by the UV-LEDs within 27.9 to achieve the target disinfection performance. This optimal set of parameters may give an idea of the cost of the system. However, it would be better to optimize the cost and shake duration together. Next, multiple-objective optimization is applied by including the cost of the system. In this case, both objective functions (the shake duration and the cost) need to be solved together. Therefore, the shake duration and the cost are considered as the main criteria for the cost scenarios. Having considered various user expectations as well as the variability of the component cost in the market, there may be three different cost scenarios (low, typical or moderate, high). By inspecting the range of the cost and the shake duration, it is found that there are 175 different pairs of cost and shake duration. Among these pairs, a threshold value for the cost is determined for the low, moderate and high scenarios, respectively. More specifically, the low-cost scenario corresponds to the pairs with the lowest cost and the highest shake duration, whereas the high-cost scenario corresponds to the pairs with the lowest cost and the lowest shake duration. Besides, the moderate cost scenario corresponds to the mean value of the costs. The multi-objective GA optimization is shown in Figure 7 where all these pairs are considered. Then, the optimal values of the design parameters are derived as listed in Table 6. It should be noted that both the shake duration and the cost ranges present variability, and extreme values might indicate lower and upper parametric bounds. For more applicable values in between the extreme values, some more parameters need to be considered, and further fine-tuning would be possible.

Figure 7.

Multi-objective GA optimization for the shake duration and the cost.

Table 6.

Optimal System Parameters for Three Cost Scenarios.

6. Conclusions

In this study, the design and optimization of a piezoelectric-powered portable UV-LED water disinfection system were presented. Operation of the proposed system was described based on the filed patent of the first named author. Physical-mathematical models of mechanical, electrical and biochemical components of the system were fully developed from the design point of view. Then, the models were used in optimization of the design parameters. The results of single and multi-objective optimization employing Genetic Algorithm (GA) were presented. Finally, the design parameters were derived for three different cost scenarios. The cost of the system and the shake duration were taken as critical design parameters. For the three cost scenarios, optimal shake duration was quite diverse, ranging from 5040 s to 15.4 s. However, it should be noted that the impact of some other parameters both on the cost and the shake duration might also be considered. This paper elaborates on the full theoretical design and modeling of the system, and the realization of the system might require further engineering work.

Author Contributions

Conceptualization, methodology, D.E.Ş., Y.D., A.K. and M.D.; investigation, visualization, writing—original draft preparation, D.E.Ş. and Y.D.; validation, writing—review and editing, A.K. and M.D.; supervision, A.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available on request from the authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- United Nations General Assembly. The Human Right to Water and Sanitation; United Nations General Assembly: New York, NY, USA, 2010. [Google Scholar]

- WHO | Progress on Sanitation and Drinking-Water. Available online: http://www.who.int/water_sanitation_health/publications/9789241563956/en/ (accessed on 31 December 2020).

- Song, K.; Mohseni, M.; Taghipour, F. Application of Ultraviolet Light-Emitting Diodes (UV-LEDs) for Water Disinfection: A Review. Water Res. 2016, 94, 341–349. [Google Scholar] [CrossRef] [PubMed]

- Hijnen, W.A.M.; Beerendonk, E.F.; Medema, G.J. Inactivation Credit of UV Radiation for Viruses, Bacteria and Protozoan (Oo)Cysts in Water: A Review. Water Res. 2006, 40, 3–22. [Google Scholar] [CrossRef] [PubMed]

- Belosevic, M.; Craik, S.A.; Stafford, J.L.; Neumann, N.F.; Kruithof, J.; Smith, D.W. Studies on the Resistance/Reactivation of Giardia Muris Cysts and Cryptosporidium Parvum Oocysts Exposed to Medium-Pressure Ultraviolet Radiation. FEMS Microbiol. Lett. 2001, 204, 197–203. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Mori, M.; Hamamoto, A.; Takahashi, A.; Nakano, M.; Wakikawa, N.; Tachibana, S.; Ikehara, T.; Nakaya, Y.; Akutagawa, M.; Kinouchi, Y. Development of a New Water Sterilization Device with a 365 Nm UV-LED. Med. Bio. Eng. Comput. 2007, 45, 1237–1241. [Google Scholar] [CrossRef]

- Saraceno, D. Solar Powered Portable Water Purifier. U.S. Patent US10/065,999, 8 March 2005. [Google Scholar]

- Lifschitz, E.L. Portable Water Purifier with Ultraviolet Light Source. World Intellectual Property Organization PCT/US1999/018355, 24 February 2000. [Google Scholar]

- Aurbach, D.; Weissman, I.; Zaban, A.; Dan, P. On the Role of Water Contamination in Rechargeable Li Batteries. Electrochim. Acta 1999, 45, 1135–1140. [Google Scholar] [CrossRef]

- Horiuchi, S.; Tsutsumi, J.; Kobayashi, K.; Kumai, R.; Ishibashi, S. Piezoelectricity of Strongly Polarized Ferroelectrics in Prototropic Organic Crystals. J. Mater. Chem. C 2018, 6, 4714–4719. [Google Scholar] [CrossRef]

- Mehrotra, U. Walking Charger Using Piezo-Electric Material. Int. J. Technol. Res. Eng. 2016, 4, 57–60. [Google Scholar]

- Sodano, H.A.; Inman, D.J.; Park, G. Comparison of Piezoelectric Energy Harvesting Devices for Recharging Batteries. J. Intell. Mater. Syst. Struct. 2005, 16, 799–807. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, J.-H.; Kim, J. A Review of Piezoelectric Energy Harvesting Based on Vibration. Int. J. Precis. Eng. Manuf. 2011, 12, 1129–1141. [Google Scholar] [CrossRef]

- Cassassuce, F.V.; Arce, I.B.; Zamudio, O.R. UV Water Purification System. U.S. Patent US11/418,857, 22 April 2008. [Google Scholar]

- Lantis, R.; Phelan, J.P.; Phelan, A. Method and Apparatus for Solar-Based Water Disinfection. U.S. Patent US13/108,523, 23 October 2012. [Google Scholar]

- Yanke, R.D. Ultraviolet Light Purification Drinking System. U.S. Patent US14/691,639, 29 October 2015. [Google Scholar]

- Vilhunen, S.; Särkkä, H.; Sillanpää, M. Ultraviolet Light-Emitting Diodes in Water Disinfection. Environ. Sci. Pollut. Res. 2009, 16, 439–442. [Google Scholar] [CrossRef]

- Şala, D.E. Piezoelectric Powered Portable Water Disinfection System with Ultroviole Light. Turkish Patent Institute 2019/22118, 28 December 2020. (pending). [Google Scholar]

- Nabavi, S.; Zhang, L. MEMS Piezoelectric Energy Harvester Design and Optimization Based on Genetic Algorithm. In Proceedings of the 2016 IEEE International Ultrasonics Symposium (IUS), Tours, France, 18–21 September 2016; pp. 1–4. [Google Scholar]

- Hsieh, J.-C.; Lin, D.T.W.; Lin, C.-L. The Development and Optimization of an Innovative Piezoelectric Energy Harvester on the Basis of Vapor-Induced Vibrations. Mech. Syst. Signal Process. 2019, 131, 649–658. [Google Scholar] [CrossRef]

- Chopra, I. Review of State of Art of Smart Structures and Integrated Systems. AIAA J. 2002, 40, 2145–2187. [Google Scholar] [CrossRef]

- Sriramdas, R.; Pratap, R. Scaling and Performance Analysis of MEMS Piezoelectric Energy Harvesters. J. Microelectromechanical Syst. 2017, 26, 679–690. [Google Scholar] [CrossRef]

- He, X.; Teh, K.S.; Li, S.; Dong, L.; Jiang, S. Modeling and Experimental Verification of an Impact-Based Piezoelectric Vibration Energy Harvester with a Rolling Proof Mass. Sens. Actuators A Phys. 2017, 259, 171–179. [Google Scholar] [CrossRef]

- Zhao, Y.; Fan, H.; Ren, X.; Long, C.; Liu, G.; Liu, Z. Lead-Free Bi5−xLaxTi3FeO15 (x = 0, 1) Nanofibers toward Wool Keratin-Based Biocompatible Piezoelectric Nanogenerators. J. Mater. Chem. C 2016, 4, 7324–7331. [Google Scholar] [CrossRef]

- Ren, X.; Fan, H.; Zhao, Y.; Liu, Z. Flexible Lead-Free BiFeO3/PDMS-Based Nanogenerator as Piezoelectric Energy Harvester. ACS Appl. Mater. Interfaces 2016, 8, 26190–26197. [Google Scholar] [CrossRef]

- Zhang, T.; Liao, Y.; Zhang, K.; Chen, J. Theoretical Analysis of the Dynamic Properties of a 2-2 Cement-Based Piezoelectric Dual-Layer Stacked Sensor under Impact Load. Sensors 2017, 17, 1019. [Google Scholar] [CrossRef]

- Uno, M.; Tanaka, K. Accelerated Charge–Discharge Cycling Test and Cycle Life Prediction Model for Supercapacitors in Alternative Battery Applications. IEEE Trans. Ind. Electron. 2012, 59, 4704–4712. [Google Scholar] [CrossRef]

- USA Military Standard. Piezoelectric Ceramic Material and Measurements Guidelines for Sonar Transducers. MILSTD-1376B 1995. [Google Scholar]

- Williams, C.B.; Yates, R.B. Analysis Of A Micro-Electric Generator For Microsystems. In Proceedings of the International Solid-State Sensors and Actuators Conference—TRANSDUCERS ’95, Stockholm, Sweden, 25–29 June 1995; Volume 1, pp. 369–372. [Google Scholar]

- APC International, Ltd. Piezoelectric Ceramics: Principles and Applications; APC International, Ltd.: Mackeyville, PA, USA, 2011; ISBN 978-0-615-56503-3. [Google Scholar]

- Boyce, J.M. Modern Technologies for Improving Cleaning and Disinfection of Environmental Surfaces in Hospitals. Antimicrob. Resist. Infect. Control 2016, 5, 1–10. [Google Scholar] [CrossRef]

- Chatterley, C.; Linden, K. Demonstration and Evaluation of Germicidal UV-LEDs for Point-of-Use Water Disinfection. J. Water Health 2010, 8, 479–486. [Google Scholar] [CrossRef] [PubMed]

- Würtele, M.A.; Kolbe, T.; Lipsz, M.; Külberg, A.; Weyers, M.; Kneissl, M.; Jekel, M. Application of GaN-Based Ultraviolet-C Light Emitting Diodes–UV LEDs–for Water Disinfection. Water Res. 2011, 45, 1481–1489. [Google Scholar] [CrossRef]

- Oguma, K.; Katayama, H.; Mitani, H.; Morita, S.; Hirata, T.; Ohgaki, S. Determination of Pyrimidine Dimers InEscherichia Coli and Cryptosporidium Parvum during UV Light Inactivation, Photoreactivation, and Dark Repair. Appl. Environ. Microbiol. 2001, 67, 4630–4637. [Google Scholar] [CrossRef] [PubMed]

- Sommer, R.; Lhotsky, M.; Haider, T.; Cabaj, A. UV Inactivation, Liquid-Holding Recovery, and Photoreactivation of Escherichia Coli O157 and Other Pathogenic Escherichia Coli Strains in Water. J. Food Prot. 2000, 63, 1015–1020. [Google Scholar] [CrossRef] [PubMed]

- Kalisvaart, B.F. Re-Use of Wastewater: Preventing the Recovery of Pathogens by Using Medium-Pressure UV Lamp Technology. Water Sci. Technol. 2004, 50, 337–344. [Google Scholar] [CrossRef]

- Murata, Y.; Osakabe, M. The Bunsen–Roscoe Reciprocity Law in Ultraviolet-B-Induced Mortality of the Two-Spotted Spider Mite Tetranychus Urticae. J. Insect Physiol. 2013, 59, 241–247. [Google Scholar] [CrossRef]

- NSF International Standard/American National Standard for Drinking Water Treatment Units. NSF/ANSI 55: Ultraviolet Microbiological Water Treatment Systems; NSF International: Ann Arbor, MI, USA, 2018. [Google Scholar]

- Yusup, N.; Zain, A.M.; Hashim, S.Z.M. Evolutionary Techniques in Optimizing Machining Parameters: Review and Recent Applications (2007–2011). Expert Syst. Appl. 2012, 39, 9909–9927. [Google Scholar] [CrossRef]

- Kumar, M.; Husain, M.; Upreti, N.; Gupta, D. Genetic Algorithm: Review and Application. International Journal of Information Technology and Knowledge Management. 2010, 451–454. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).