Integrating Gear Shifting Preference into Personalized Shift-Scheduling Calibration

Abstract

1. Introduction

2. Related Work

2.1. Particle Swarm Optimization (PSO)

- Generate a number of particles, . Each individual in the particle swarm has a position vector of d dimensions.

- With regard to the ith individual .

- 3.

- For particle , the velocity and position are updated according to the following rules:where w is the weight factor, l and g are the velocity parameters, and t is the number of iteration.

- 4.

- When the termination requirements are satisfied, stop the optimization; otherwise, repeat the previous steps.

2.2. Wasserstein Distance (WD)

2.3. Kolmogorov-Smirnov Test

2.4. Driver Model

2.5. Automatic Transmission Vehicle Model (ATVM)

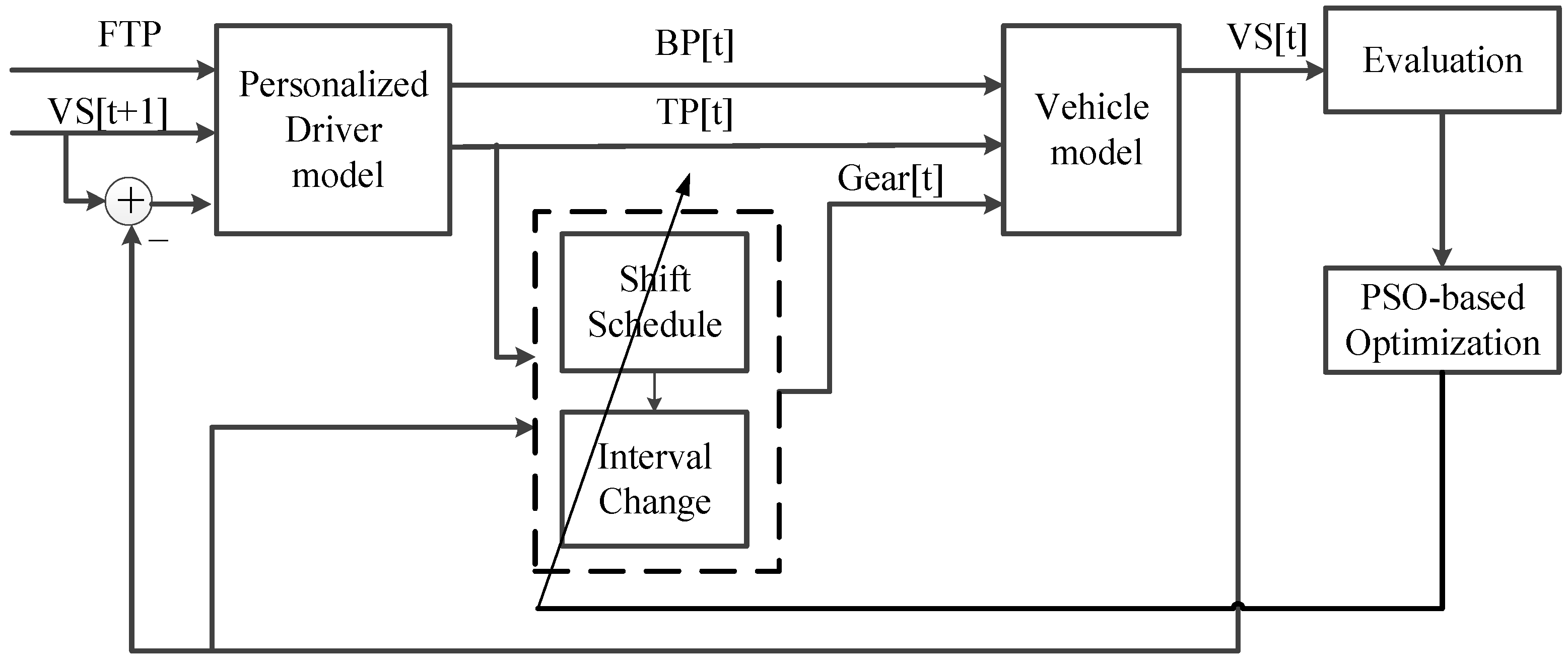

3. The Proposed Scheme for Preference Integration and Automated Shift-Scheduling Calibration

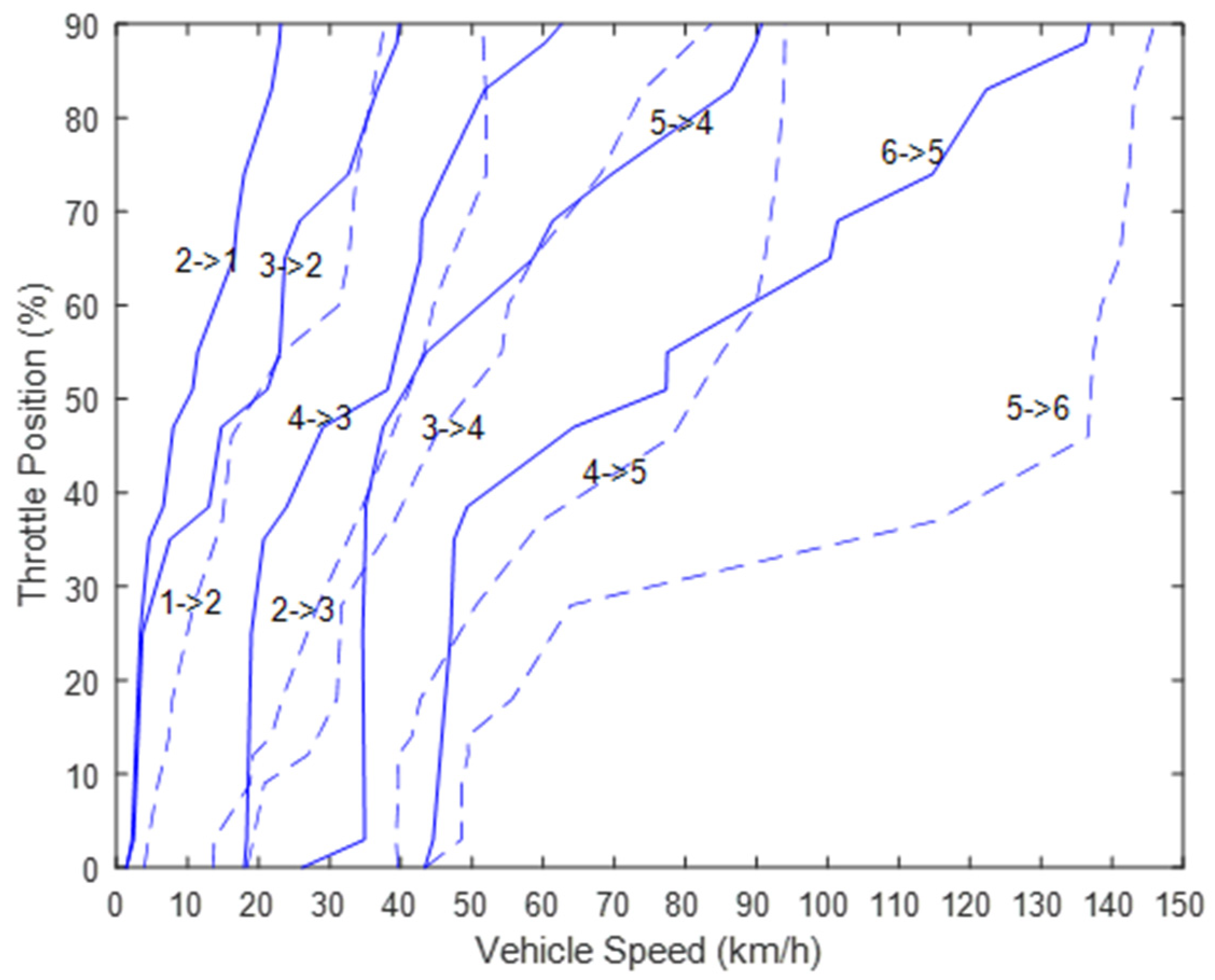

3.1. Descriptions of Shifting Schedules and Preferences

3.2. Shifting Performance Evaluation

3.3. Preference Integration and Automated Calibration of Shift Scheduling

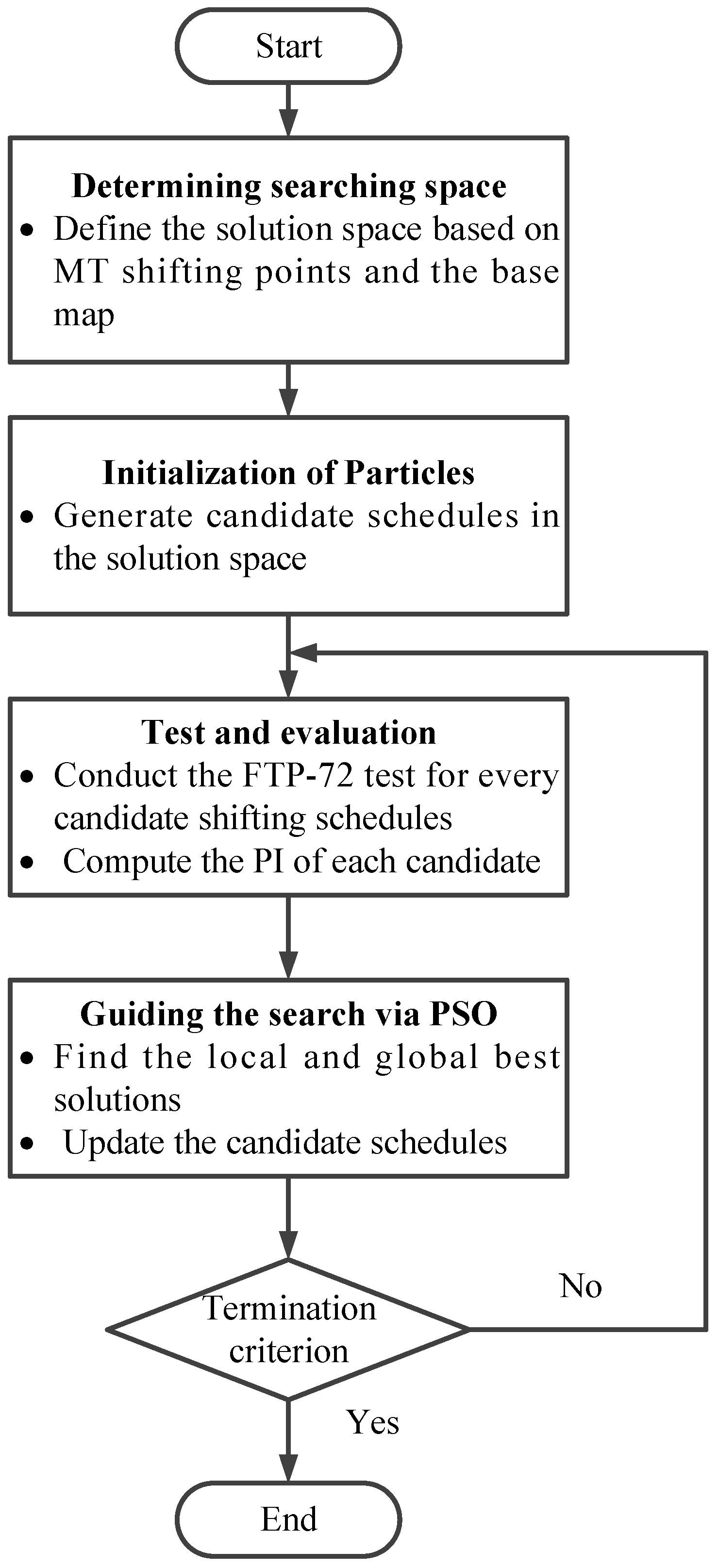

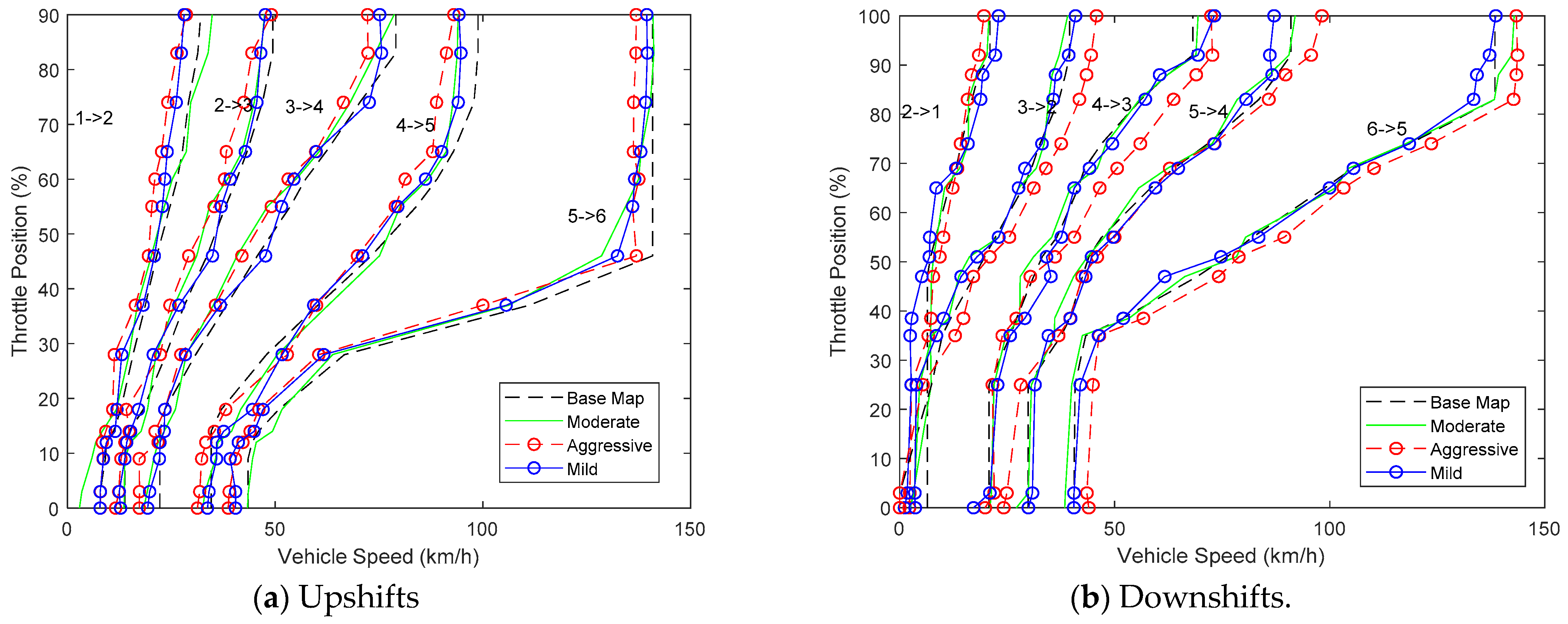

- Determining the searching space of the shifting-schedulesIn consideration of the drivers’ shifting preferences, the shifting points of MT drivers are collected for each kind of shifting event. Then, the searching space is obtained by the overlapped zone of MT shifting points and the space around the base map.

- Initializing the candidate shifting schedulesEach particle is a 150-dimension vector, which stands for 150 shifting points of the shift map. The candidate shifting schedules are generated in the aforementioned searching space.

- Decide the operations of the driver model

- 4.

- Adjust the intervals of candidate schedules

- 5.

- Regulate the gear positions

- 6.

- Generate the vehicle speed

4. Numerical Experiments and Results

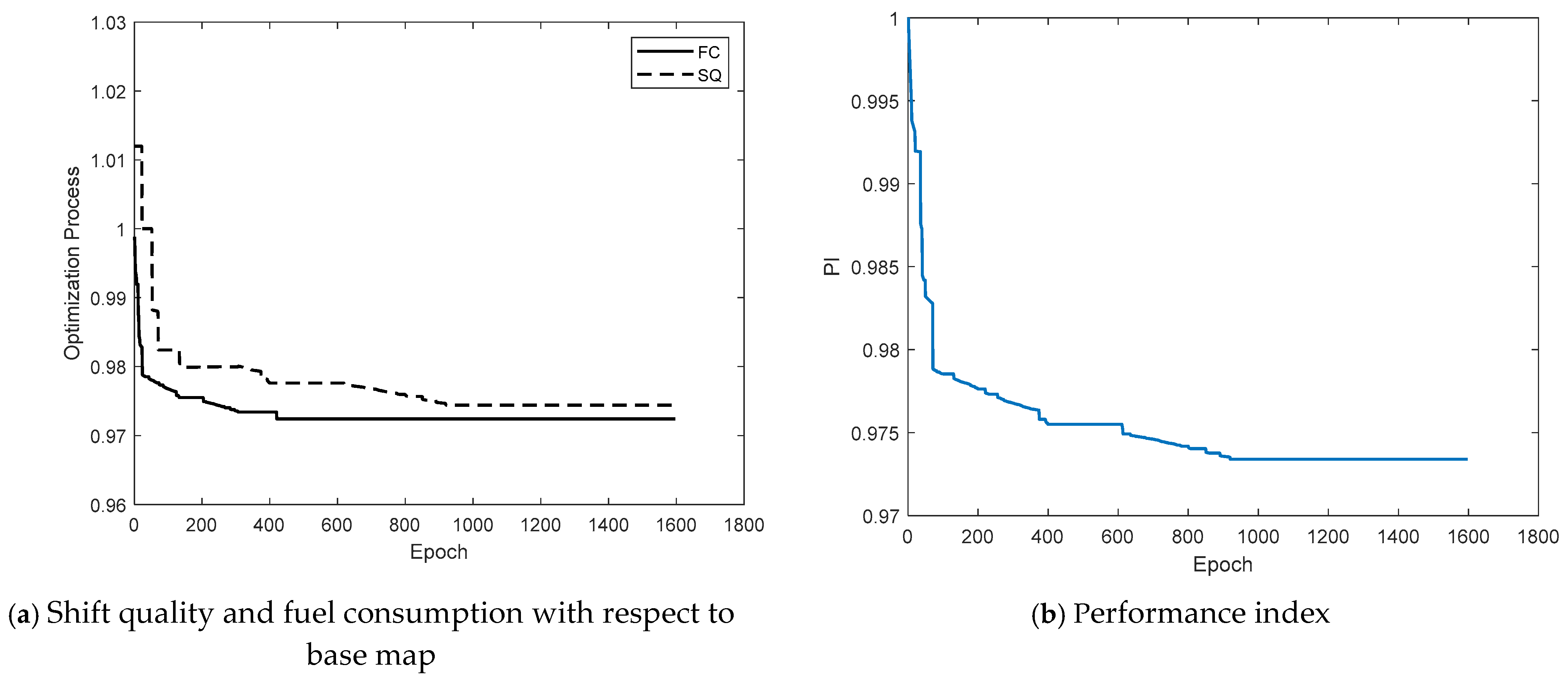

4.1. Automated Calibration Based on MTDM and ATVM

- 1.

- Calibration based on real MT shifting points

- 2.

- Calibration process for the performance index

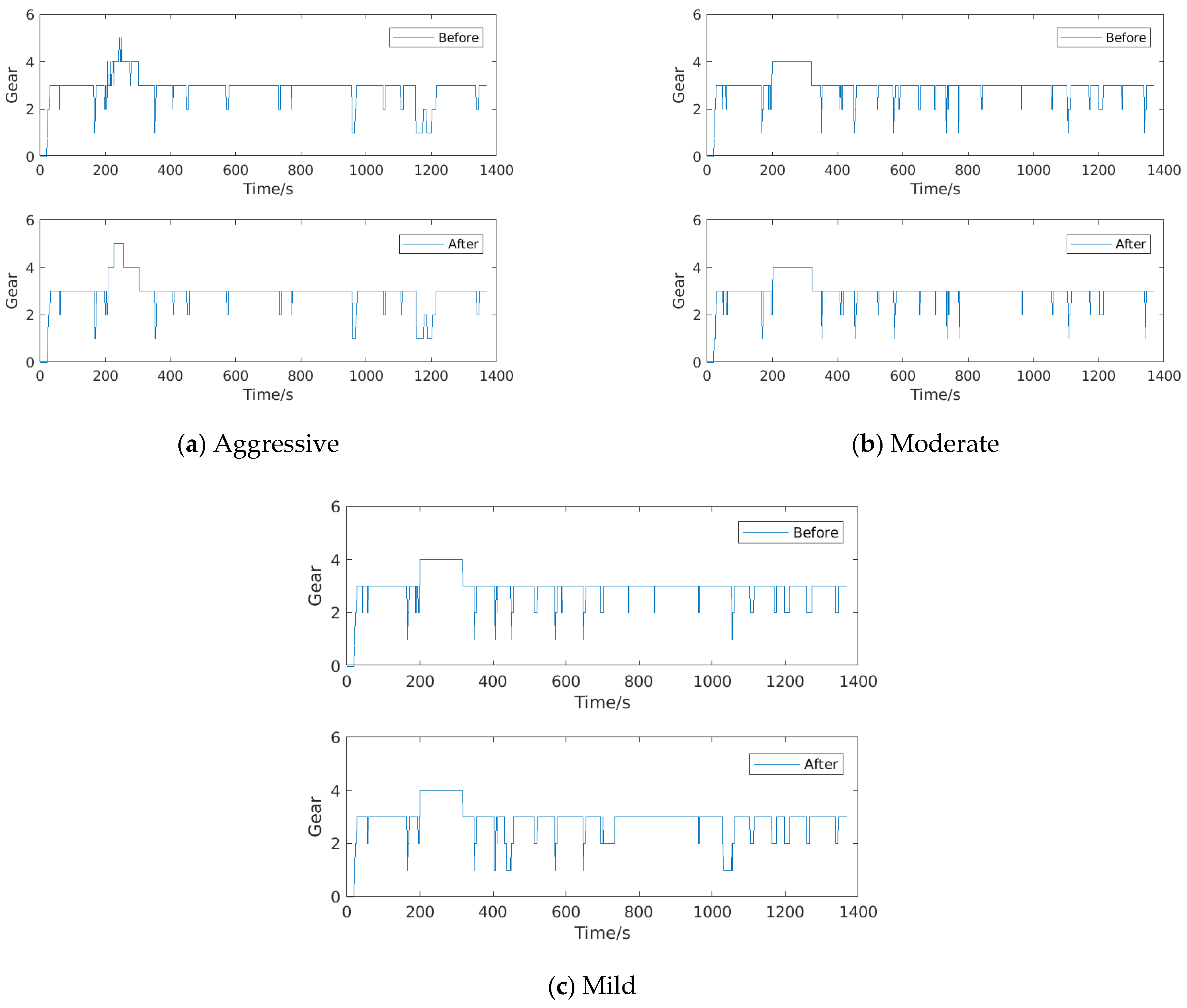

4.2. Consistency Analysis: Before vs. after Calibration

4.3. Effects of Driving Preference

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, N.; Vijayagopal, R.; Rousseau, A.; Lee, B.; Kim, S. Gearshift Calibration for Automatic Transmission Using a Model-Based Optimization Algorithm, Proceedings of the 2017 IEEE Vehicle Power and Propulsion Conference VPPC, Belfort, France, 11–14 December 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Sangeetha, R.T.; Shankar, V.; Bose, A.; Jayaraman, B. A Unique Approach to Optimize the Gear-Shift Map of a Compact SUV to Improve FE and Performance; SAE Technol. Pap.; SAE International: Warrendale, PA, USA, 2020; Volume 2020, pp. 1–9. [Google Scholar] [CrossRef]

- Nikzadfar, K.; Bakhshinezhad, N.; Mirmohammadsadeghi, S.A.; Taheri Ledari, H.; Fathi, A. An Optimal Gear Shifting Strategy for Minimizing Fuel Consumption Based on Engine Optimum Operation Line; SAE Technol. Pap.; SAE International: Warrendale, PA, USA, 2019; Volume 2019, pp. 1–9. [Google Scholar] [CrossRef]

- Guen, D.; Weck, T.; Balihe, A.; Verbeke, B. Definition of gearshift pattern: Innovative optimization procedures using system simulation. SAE Int. J. Engines 2011, 4, 412–431. [Google Scholar] [CrossRef]

- Eckert, J.; Santiciolli, F.; Costa, E.; de Alkmin e Silva, L.; Dionísio, H.J.; Corrêa, F.C.; Dedini, F.G. Fuel Consumption Reduction Based on the Optimization of the Vehicle Gear Shifting Strategy Considering New Gear Ratios. In 24th SAE Brasil International Congress and Display, Sao Paulo, Brasil, 22–24 September 2015; SAE Technol. Pap.; SAE International: Warrendale, PA, USA, 2015; No. 2015-36-0136. [Google Scholar] [CrossRef]

- Kirtane, C.; Ghodke, S.; Kurode, S.; Prakash, A.K.; Malkhede, D.N. Gear Shift Schedule Optimization and Drive Line Modeling for Automatic Transmission. In Proceedings of the 1st International and 16th National Conference on Machines and Mechanics, Roorke, India, 18–20 December 2013; pp. 254–261. [Google Scholar]

- He, C.R.; Qin, W.B.; Ozay, N.; Orosz, G. Optimal gear shift schedule design for automated vehicles: Hybrid system based analytical approach. IEEE Trans. Control Syst. Technol. 2018, 26, 2078–2090. [Google Scholar] [CrossRef]

- Li, G.; Hu, J. Modeling and Analysis of Shift Schedule for Automatic Transmission Vehicle Based on Fuzzy Neural Network. In Proceedings of the World Congres Intell, Control Autom, London, UK, 30 June–2 July 2010; pp. 4839–4844. [Google Scholar] [CrossRef]

- Saini, V.; Singh, S.; NV, S.; Jain, H. Genetic algorithm based gear shift optimization for electric vehicles. SAE Int. J. Altern. Powertrains 2016, 5. [Google Scholar] [CrossRef]

- Liu, Y.; Qin, D.; Lei, Z.; Ding, R. Intelligent correction of shift schedule for dual clutch transmissions based on different driving conditions. Appl. Mech. Mater. 2012, 121–126, 3982–3987. [Google Scholar] [CrossRef]

- Ngo, V.D.; Colin Navarrete, J.A.; Hofman, T.; Steinbuch, M.; Serrarens, A. Optimal gear shift strategies for fuel economy and driveability. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2013, 227, 1398–1413. [Google Scholar] [CrossRef]

- Nüesch, T.; Elbert, P.; Flankl, M.; Onder, C.; Guzzella, L. Convex optimization for the energy management of hybrid electric vehicles considering engine start and gearshift costs. Energies 2014, 7, 834–856. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, J.; Shi, B.; Meng, W. Automating shift-scheduling calibration by using bionic optimization and personalized driver models. IEEE Trans. Intell. Transp. Syst. 2019, 20, 4367–4376. [Google Scholar] [CrossRef]

- He, R.; Hu, N. A Gear Shifting Indication Strategy of Eco-Driving Vehicle; SAE Tech. Pap.; SAE International: Warrendale, PA, USA, 2020; Volume 2020, pp. 1–9. [Google Scholar] [CrossRef]

- Yang, C.; Jiao, X.; Li, L.; Zhang, Y.; Zhang, L.; Song, J. Robust coordinated control for hybrid electric bus with single-shaft parallel hybrid powertrain. IET Control Theor. Appl. 2015, 9, 270–282. [Google Scholar] [CrossRef]

- Roozegar, M.; Angeles, J. The optimal gear-shifting for a multi-speed transmission system for electric vehicles. Mech. Mach. Theory 2017, 116, 1–13. [Google Scholar] [CrossRef]

- Shen, W.; Yu, H.; Hu, Y.; Xi, J. Optimization of shift schedule for hybrid electric vehicle with automated manual transmission. Energies 2016, 9, 220. [Google Scholar] [CrossRef]

- Lin, C.; Zhao, M.; Pan, H.; Yi, J. Blending gear shift strategy design and comparison study for a battery electric city bus with AMT. Energy 2019, 185, 1–14. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. Adapt. Learn. Optim. 2014, 15, 45–82. [Google Scholar] [CrossRef]

- Poli, R.; Kennedy, J.; Blackwell, T. Particle swarm optimization: An overview. Swarm Intell. 2007, 1, 33–57. [Google Scholar] [CrossRef]

- Irpino, A.; Verde, R. Dynamic clustering of interval data using a Wasserstein-based distance. Pattern Recognit. Lett. 2008, 29, 1648–1658. [Google Scholar] [CrossRef]

- Mescheder, L.; Nowozin, S.; Geiger, A. The numerics of GANs. arXiv 2017, arXiv:1705.10461. [Google Scholar]

- Rüschendorf, L. The Wasserstein distance and approximation theorems. Zeitschr. Wahrscheinlichkeitstheor. Verwandte Gebiete 1985, 70, 117–129. [Google Scholar] [CrossRef]

- Massey, F.J. The Kolmogorov-Smirnov test for goodness of fit. J. Am. Stat. Assoc. 1951, 46, 68–78. [Google Scholar] [CrossRef]

- Xu, L.; Hu, J.; Jiang, H.; Meng, W. Establishing style-oriented driver models by imitating human driving behaviors. IEEE Trans. Intell. Transp. Syst. 2015, 16, 2522–2530. [Google Scholar] [CrossRef]

- Shi, B.; Xu, L.; Hu, J.; Tang, Y.; Jiang, H.; Meng, W.; Liu, H. Evaluating driving styles by normalizing driving behavior based on personalized driver modeling. IEEE Trans. Syst. Man, Cybern. Syst. 2015, 45, 1502–1508. [Google Scholar] [CrossRef]

| (a) Upshift Points | (b) Downshift Points | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| TP | VS(km/h) | TP | VS(kph) | ||||||||

| 1→2 | 2→3 | 3→4 | 4→5 | 5→6 | 2→1 | 3→2 | 4→3 | 5→4 | 6→5 | ||

| 0 | 7.91 | 13.84 | 22.24 | 34.6 | 43.5 | 0 | 6.43 | 0 | 20.76 | 29.9 | 40.53 |

| 0.03 | 7.91 | 13.84 | 22.24 | 34.6 | 43.5 | 0.03 | 6.43 | 0 | 20.76 | 29.9 | 40.53 |

| 0.09 | 9.14 | 13.84 | 22.24 | 34.6 | 43.5 | 0.25 | 6.43 | 7.41 | 20.76 | 29.9 | 40.78 |

| 0.12 | 9.39 | 13.84 | 22.24 | 34.6 | 44.48 | 0.35 | 6.43 | 9.89 | 25.7 | 37.56 | 43.25 |

| 0.14 | 11.12 | 14.83 | 22.24 | 34.6 | 45.97 | 0.385 | 6.43 | 11.86 | 27.18 | 39.54 | 51.9 |

| 0.18 | 12.85 | 18.29 | 23.48 | 37.07 | 50.91 | 0.47 | 6.43 | 17.3 | 31.14 | 42.51 | 69.2 |

| 0.28 | 15.82 | 23.73 | 30.89 | 47.94 | 66.73 | 0.51 | 7.17 | 19.77 | 33.12 | 43.99 | 76.12 |

| 0.37 | 18.78 | 28.17 | 38.31 | 60.3 | 111.21 | 0.55 | 8.4 | 22.24 | 36.58 | 46.96 | 82.05 |

| 0.46 | 21.5 | 33.61 | 45.72 | 73.15 | 140.87 | 0.65 | 11.44 | 28.67 | 41.52 | 58.32 | 98.85 |

| 0.55 | 24.71 | 38.06 | 53.63 | 84.03 | 140.87 | 0.69 | 13.1 | 30.64 | 43 | 63.76 | 105.28 |

| 0.6 | 26.44 | 40.78 | 57.34 | 88.97 | 140.87 | 0.74 | 14.33 | 32.62 | 46.96 | 71.67 | 118.63 |

| 0.65 | 27.68 | 43.25 | 62.28 | 92.92 | 140.87 | 0.83 | 16.81 | 37.07 | 56.1 | 83.53 | 138.4 |

| 0.74 | 29.16 | 46.96 | 70.43 | 97.87 | 140.87 | 0.88 | 18.29 | 38.55 | 62.28 | 87.73 | 138.4 |

| 0.83 | 31.39 | 49.43 | 79.08 | 98.85 | 140.87 | 0.92 | 21.01 | 39.54 | 68.21 | 90.95 | 138.4 |

| 0.9 | 32.13 | 49.43 | 79.08 | 98.85 | 140.87 | 1 | 21.01 | 39.54 | 68.21 | 90.95 | 138.4 |

| Parameter | Value | Performance Index | Processing Time (min) |

|---|---|---|---|

| 10 | 0.9883 | 18 | |

| 20 | 0.9852 | 23 | |

| Particle numbers | 50 | 0.9734 | 28 |

| 100 | 0.9727 | 54 | |

| 150 | 0.9725 | 89 |

| Driver ID | KS Test | |||

|---|---|---|---|---|

| Before | After | Before | After | |

| Aggr1 | 0.089 | 0.043 | 0 | 1 |

| Aggr2 | 0.092 | 0.037 | 1 | 1 |

| Aggr3 | 0.097 | 0.048 | 0 | 1 |

| Mode1 | 0.074 | 0.031 | 1 | 1 |

| Mode2 | 0.081 | 0.038 | 0 | 1 |

| Mode3 | 0.079 | 0.042 | 1 | 1 |

| Mild1 | 0.083 | 0.036 | 1 | 1 |

| Mild2 | 0.075 | 0.041 | 1 | 1 |

| Mild3 | 0.086 | 0.047 | 0 | 1 |

| Index | Aggressive No.1 | Moderate No.1 | Mild No.1 | |||

|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | |

| Gear counts | 92 | 74 | 81 | 65 | 73 | 58 |

| Speed error | 0.5621 | 0.5478 | 0.5328 | 0.5183 | 0.5227 | 0.5061 |

| Driver ID | Mean Acceleration for Upshifts (m/s2) | Mean Deceleration for Downshifts (m/s2) | ||||

|---|---|---|---|---|---|---|

| Raw | Before | After | Raw | Before | After | |

| Aggr1 | 1.228 | 1.065 | 1.332 | 0.534 | 0.419 | 0.522 |

| Aggr2 | 1.302 | 1.182 | 1.236 | 0.612 | 0.487 | 0.607 |

| Aggr3 | 1.352 | 1.195 | 1.378 | 0.589 | 0.367 | 0.617 |

| Mode1 | 0.746 | 0.589 | 0.814 | 0.350 | 0.281 | 0.373 |

| Mode2 | 0.795 | 0.572 | 0.842 | 0.432 | 0.335 | 0.448 |

| Mode3 | 0.839 | 0.645 | 0.881 | 0.419 | 0.316 | 0.435 |

| Mild1 | 0.537 | 0.488 | 0.563 | 0.227 | 0.167 | 0.243 |

| Mild2 | 0.521 | 0.451 | 0.542 | 0.284 | 0.245 | 0.275 |

| Mild3 | 0.492 | 0.379 | 0.502 | 0.316 | 0.260 | 0.349 |

| Index | Aggressive No.1 | Moderate No.1 | Mild No.1 | |||

|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | |

| FC | 3162.3 | 3032.5 | 3012.8 | 2978.6 | 2912.2 | 2885.7 |

| SQ | 365.9 | 342.7 | 346.1 | 321.7 | 308.7 | 296.4 |

| PI | 1 | 0.9477 | 1 | 0.9591 | 1 | 0.9755 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, X.; Lin, M.; Xu, L. Integrating Gear Shifting Preference into Personalized Shift-Scheduling Calibration. Appl. Sci. 2021, 11, 2986. https://doi.org/10.3390/app11072986

He X, Lin M, Xu L. Integrating Gear Shifting Preference into Personalized Shift-Scheduling Calibration. Applied Sciences. 2021; 11(7):2986. https://doi.org/10.3390/app11072986

Chicago/Turabian StyleHe, Xin, Mingming Lin, and Li Xu. 2021. "Integrating Gear Shifting Preference into Personalized Shift-Scheduling Calibration" Applied Sciences 11, no. 7: 2986. https://doi.org/10.3390/app11072986

APA StyleHe, X., Lin, M., & Xu, L. (2021). Integrating Gear Shifting Preference into Personalized Shift-Scheduling Calibration. Applied Sciences, 11(7), 2986. https://doi.org/10.3390/app11072986