Abstract

The bearing is a machine element that plays an important role in rotating the shaft of a machine while supporting its weight and load. Numerous bearings have been developed to improve durability and life, depending on the functions and operating conditions in which they are desired. White metal is one of method to improve durability that is soft and bonded to the inner surface of the bearing to protect the bearing shaft. Currently, the centrifugal casting process is used as a white metal lamination method, but it involves problems such as long processing times, high defect rates and harmful health effects. In this paper, a laser cladding treatment is applied to bond powdered white metal to SCM440 alloy steel, which is used as bearing material in terms of replacing the risks of a centrifugal process. In order to understand whether laser cladding is a suitable process, this paper compares the mechanical properties of white metal produced on SCM440 alloy steel by centrifugal casting and the laser cladding process. The laser power, powder feed rate and laser head speed factors are varied to understand the mechanical properties and measure the hardness using micro Vickers and conduct field emission scanning electron microscopy, energy-dispersive X-ray spectroscopy, X-ray diffraction and friction testing to understand the mechanical properties and surface characteristics. Based on the results, the hardness values of the cladding (white metal) layer ranged between 24 and 26 HV in both the centrifugal casting and laser cladding methods. However, the hardness of the white metal produced by laser cladding at about a depth of 0.1 mm rose rapidly in the cladding process, forming a heat-affected zone (HAZ) with an average hardness value of 200 HV at a laser power of 1.1 kW, 325 HV at 1.3 kW and 430 HV at 1.5 kW. The surface friction testing results revealed no significant differences in the friction coefficient between the centrifugal casting and laser cladding methods, which allows the assumption that the processing method does not significantly influence the friction coefficient.

1. Introduction

The bearing is a machine element that plays an important role in rotating the shaft of a machine while supporting its deadweight load. It is an elementary machine component used in all industries, including leading and future industries. There is a wide range of bearing types for a diverse range of applications and functions in various industries. Durability is an important requirement for a bearing, whose service life is greatly affected by the vibration and wear between the shaft and bearing surfaces and fatigue damage [1]. Given the close association between the service life of a bearing and its durability, the durability is an important engineering parameter of a bearing which is directly related to its reliability in terms of the maintenance and repair of the entire machine. Intensive studies are therefore being conducted to establish methods to enhance the durability, such as techniques for the homogenization and surface treatment of the bearing material [2].

In order to increase the durability of bearings, there are several techniques for improving the surface to enhance bearing life. One of technique is a spray coating process which uses a high-temperature plasma jet, spraying it on the metal surface to form a thin layer. In this process, in order to form a thin layer on the surface, the plasma of the spray coating process is used to melt metallic or non-metallic powders. However, peeling will often occur during this process if the process conditions for the size, speed, temperature, degree of solidification, substrate material and temperature are not optimized [3,4].

Another technique used to improve metal surfaces is arc plasma cladding. Arc plasma cladding is a process which uses gas metal arc welding (GMAW) equipment to melt a deposit on a surface by using the heat generated by the electric arc. This technique has the advantages of being inexpensive, having a high deposition rate and being suitable to apply with various metal fillers. However, there is a disadvantage: it has a lot of influence on the base metal thanks to the high heat and residual stress generated by the electric arc [5,6].

A white metal is commonly used to improve the bearing component, which is mainly composed of tin, lead and zinc. It has a low melting point, softness and low friction, so it is a material used for minimizing shaft wear and improving durability in the rotating mechanical elements. In general, it is widely used in sliding bearings for large generators used in high-load and high-speed conditions, and as a soft material, it can protect against shaft damage [7,8]. Currently, centrifugal casting and gravity casting are used as common white metal lamination processes in the manufacturing industry. The centrifugal casting process is the most widely used method in the bonding process because it provides high adhesion, high production speed and excellent mechanical properties. However, since the centrifugal casting process chemically treats the base material and performs preheating, it can cause problems in the work environment and the safety of the worker. Productivity can also be affected [9].

In order to overcome these drawbacks and improve the white metal lamination state on the bearing surface, laser cladding or laser metal deposition can be used as an appropriate process instead of the centrifugal casting process. Lasers are widely used in the manufacturing industry, as they can control the high-density energy output and precision bonding and welding [10,11]. The laser cladding deposition process improves wear resistance, fatigue strength and corrosion resistance at high temperatures, and it improves the basic properties of the base metal. It is a lamination process that has various advantages in the field of surface treatment, as it is used to maintain and protect the base material from the external environment, abrasion and corrosion, among other factors [12,13,14].

For this reason, research of treatments using the laser cladding technique has been conducted by several researchers. Rasool Saeedi et al. conducted research on laser claddings on AISI 420 stainless steel, which is used as a major material for midterm turbine blades [15]. Jianli Liu et al. also have studied laser cladding as a means to improve the abrasion resistance of engine blocks and steering wheel planes in the automotive field [16]. Yanxin Qiao et. al. performed the laser cladding effect on the microstructure, microhardness and corrosion behavior of the Ni45 coating according to the scanning speed [17]. Based on these previous studies, it can be said that laser cladding has a simple, eco-friendly and economical advantage, and it has a high cooling rate so that a microstructure with excellent adhesion and excellent corrosion resistance and abrasion resistance can be obtained.

In this study, cladding was performed on SCM440 alloy steel, which was used as the shaft and bearing material and varied the process parameters such as the laser power, powder feed rate and laser head speed. This study aims to determine the mechanical properties of the mounted test specimens under different conditions by analyzing the hardness, scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), X-ray diffraction (XRD) and friction test results and identifying the optimal laser cladding conditions for white metal cladding.

2. Materials and Methods

2.1. White Metal Powder

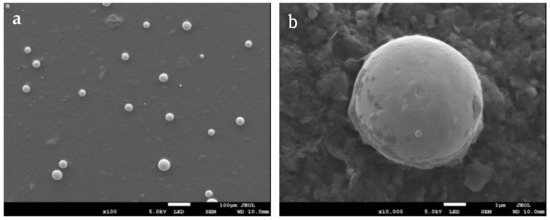

All specimens were subjected to dehydrogenation heat treatment prior to cladding. The powder used for the white metal cladding was to reduce the wear of the shaft surface coming into contact with the bearing, and its components are presented in Table 1. The powder particle size ranged from 2 μm to 30 μm, as shown in the SEM images in Figure 1. The particles were relatively homogeneous in terms of size and distribution, as shown in Figure 1a. All specimens were fabricated within the mounted size range of 20 mm × 30 mm and polished up to a 2000 grit finish.

Table 1.

Chemical composition (%) of white metal powder.

Figure 1.

Scanning electron microscopy (SEM) image of white metal at magnifications of (a) ×100 and (b) ×10,000.

2.2. Test Methods

The laser cladding machine was composed of a coaxial-type laser head and nozzle (maximum power = 2.0 kW, powder feed rate = 5–200 g/min and beam size = 8 mm × 3 mm). All tests were performed in an argon atmosphere to prevent oxidation. Table 2 outlines the major white metal cladding process parameters. White metal begins to melt above 240 °C and completely melts above 354 °C. Therefore, the melting point for the SCM440 alloy steel bearing base material (1416 °C) had a temperature difference of about 1100 °C [18]. For hardness testing, an automatic hardness testing system (AMT-X7FS, Matsuzawa) was used. To analyze the hardness change, dependent on the depth of the cladding layer and substrate, the cladding layer was measured 5 times, and the substrate was measured 15 times, moving in units of 1 mm × 0.1 mm. For material composition analysis, field emission SEM (SU8220, Hitachi) was used to observe the structure and cladding layer morphology, and EDS analysis was performed to determine the components of the cladding layer, base metal and heat-affected zone (HAZ). Friction testing was performed using a ball-on-disc-type tribometer (maximum load = 30 N and maximum speed = 600 rpm). Three measurements were performed per condition to ensure the reliability of the test results. Steel with a diameter of Φ8 mm was used as the bearing material. Wear testing specimens (20 mm × 6 mm × 8 mm) were prepared, and each cladding layer surface was subjected to sandpaper grinding and automatic polishing in the same manner as the SEM specimens. The specimens, thus fabricated, were tested under the loading condition of 20 N and a rotational speed of 200 rpm for 3600 s. Additionally, this study performed XRD analysis using the X’Pert Pro-MPD by PANalytical to analyze the components of the powders generated during the white metal treatment and change to the crystalline structure.

Table 2.

Parameters of the laser cladding process.

3. Results and Discussion

3.1. Micro Vickers Hardness Testing

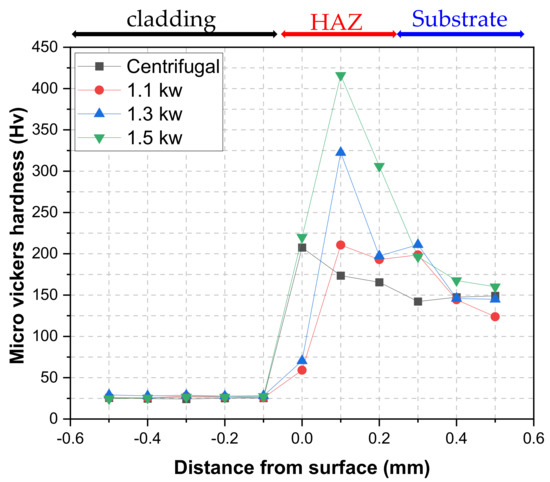

Figure 2 plots the hardness testing results at each SCM440 alloy steel depth as the laser power increases from 1.1 kW to 1.3 kW and 1.5 kW, with the powder feed rate, head speed and head height fixed at 2.5 rpm, 10 mm/s and 22 mm, respectively. In the case of the centrifugal casting method (black line), the Vickers hardness of the white metal layer ranged between 24 HV and 26 HV and was measured at about 205 HV at the boundary layer point. The hardness values, depending on the depth toward the core at 0.1 mm, did not vary significantly, and the average hardness value was 155.6 HV. When comparing the hardness values in the cladding layer, the laser cladding process hardness value was close to the centrifugal casting process hardness value, so it seemed that it could be replaced. However, a rapidly increasing hardness value behavior was exhibited at a depth of 0.1 mm. In particular, the hardness values of the HAZ rose to a greater extent with the laser power. At a depth of 0.1 mm, the laser power of 1.3 kW yielded a hardness of 325 HV. This hardness increased to 380–450 HV at 1.5 kW, and a hardened layer of over 270–330 HV appeared down to a depth of 0.2 mm. The higher the laser power of the cladding, the wider the heat-affected zone (HAZ), and the increase in the hardness value was inferred by the difference in the amount of powder absorbed by the base material being affected by the high-power energy beam.

Figure 2.

Comparison of micro Vickers average hardness according to the variable laser power of 3.1.

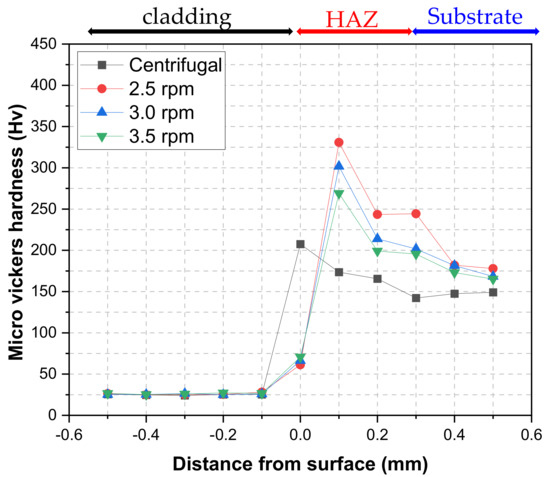

Figure 3 plots the hardness testing results depending on the powder feed rate (2.5, 3.0 or 3.5 rpm), with the laser power, head speed and head height fixed at 1.3 kW, 10 mm/s and 22 mm, respectively. The highest hardness values were presented at the 0.1 mm depth, with the most hardened layer forming at the lowest powder feed rate. This was ascribable to the influence of the material composition change due to the increased heat input from the laser directly irradiating the substrate, as the powder feed rate decreased under the same laser power and head speed conditions.

Figure 3.

Comparison of micro Vickers average hardness according to the variable supply rate.

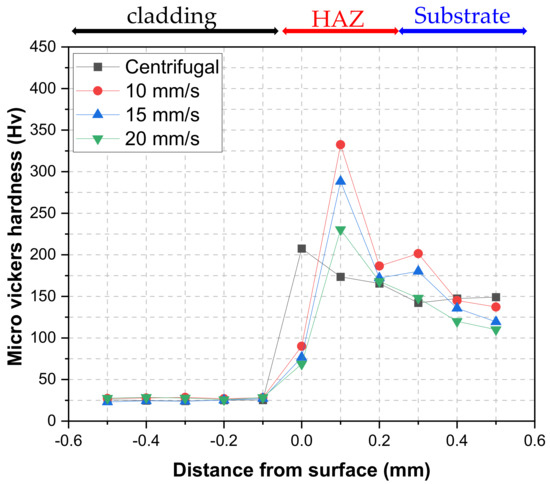

Figure 4 plots the hardness testing results depending on the head speed (10, 15 or 20 mm/s), with the laser power, powder feed rate and head height fixed at 1.3 kW, 2.5 rpm and 22 mm, respectively. It is shown therein that the hardness value decreased with the head speed, with the measured hardness values ranging between 220 and 350 HV.

Figure 4.

Comparison of the micro Vickers average hardness values according to the variable head speed.

As a result of the micro Vickers hardness analysis, it was shown that the higher the laser power, the lower the powder feed rate, or the lower the head transfer speed, the higher the hardened layer was formed. This means that the ratio of the absorbed laser beam energy increased, and it could be estimated that the characteristics of the white metal gradually deteriorated [19]. Therefore, if the hardness of the laser cladding is higher than that of the centrifugal casting process, then the laser cladding conditions are not satisfied, which adversely affects the product quality.

3.2. SEM Microstructure Analysis and EDS Analysis

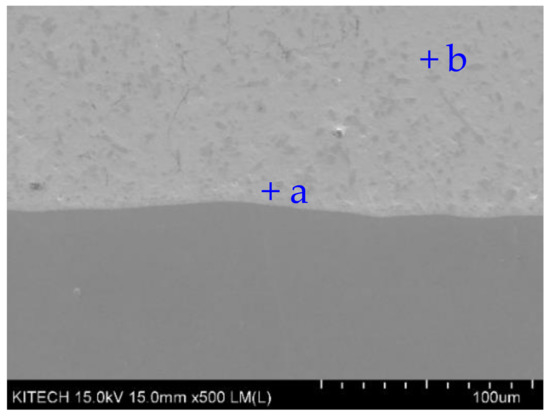

In the case of the white metal produced by the centrifugal casting method, no HAZ was observed at the interface with the substrate, as shown in Figure 5, which was consistent with the hardness data presented above. Table 3 outlines the EDS-analyzed chemical composition of the boundary layer and white metal cladding layer. As shown therein, Sn occupied the highest proportion.

Figure 5.

SEM image of the centrifugal casting-type white metal.

Table 3.

Chemical composition of the centrifugal casting specimen at the (a) boundary layer and (b) additive manufacturing layer. (spot a. b.).

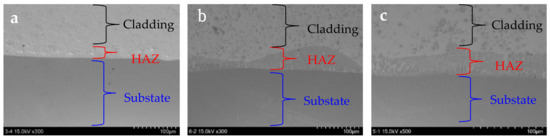

Figure 6 presents SEM images of the laser cladding layers with the laser power. As shown in Figure 6a, an uneven HAZ was formed at the interface between the SCM440 alloy steel substrate and the white metal at a laser power of 1.1 kW. Moreover, power particles could not be mounted properly during the cladding because of insufficient melting. In the case of 1.5 kW, a relatively uniform HAZ of about 81.0 μm formed, presumably owing to the strong adhesion between the substrate and the white metal. However, Figure 6c indicates that more substrate components were mixed into the white metal layer as a result of excessive energy output from the 1.5 kW laser during white metal mounting.

Figure 6.

SEM images of the laser cladding at laser powers of (a) 1.1 kW, (b) 1.3 kW and (c) 1.5 kW.

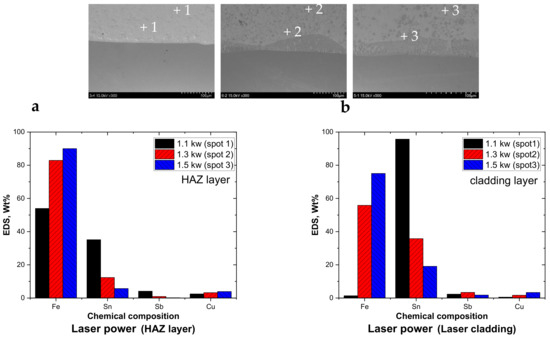

As demonstrated in the EDS analysis graphs in Figure 7, representing the components of such a mixed layer, the proportion of Fe in the white metal layer increased from 1.39% at 1.1 kW to 75.06% at 1.5 kW, while Sn, a major component of white metal, substantially decreased from 95.74% to 19.01%. In the HAZ (Figure 7b), Fe increased from 53.98% to 90.02%, and Sn decreased from 35.14% to 5.71%. These results are consistent with the measurement results plotted in Figure 2, indicating that the hardness of the cladding layer in the 0.1 mm section increased with the laser power because of the dispersion of Fe in the substrate into the cladding layer.

Figure 7.

Comparison of energy-dispersive X-ray spectroscopy (EDS) results with the laser power of the laser cladding at (a) the cladding layer and (b) the heat-affected zone (HAZ) layer.

As a result of SEM and EDS analysis, according to the laser power, the higher and wider HAZ layer was formed as the laser power increased, and the composition analysis of the cladding layer showed that the Fe (base material) ratio increased and the Sn (white metal) ratio decreased. During the white metal lamination, the amount of heat input was increased, and the inner part of the base material was affected so that a layer in which the base material components were mixed up and the cladding layer was formed. Therefore, it can be seen that it is consistent with the result of increasing the micro Vickers hardness value shown in Figure 2. It is expected that the formation of the mixed layer will increase the wear of the shaft surface in contact with the bearing.

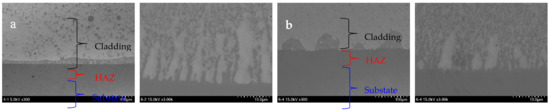

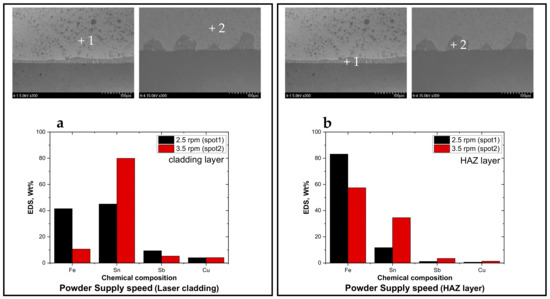

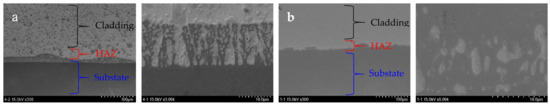

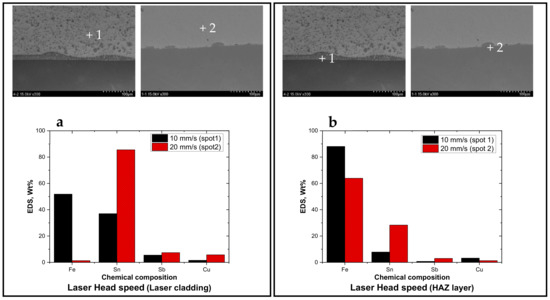

Then, at a laser power of 1.3 kW, the microstructure changes with the powder feed rate and laser head speed were analyzed. According to the analysis results, a uniform HAZ with an average thickness of 32.8 μm formed at a powder feed rate of 2.5 rpm (Figure 8a), whereas the HAZ exhibited an uneven morphology at a powder feed rate of 3.5 rpm (Figure 9b). The comparison of the HAZ morphology, depending on the laser head speed (10 mm/s vs. 20 mm/s), revealed that a uniform HAZ formed at a head speed of 10 mm/s, as shown in Figure 10. The EDS analysis of each condition revealed that the Fe decreased and Sn (major component) increased as the powder feed rate increased or the head speed decreased, as shown by the graphs in Figure 9 and Figure 11, respectively.

Figure 8.

SEM images of the laser cladding at powder supply rates of (a) 2.5 rpm and (b) 3.5 rpm.

Figure 9.

Comparison of EDS results with powder supply rates at (a) the cladding layer and (b) the HAZ layer.

Figure 10.

SEM images of the laser cladding at head speeds of (a) 10 mm/s and (b) 20 mm/s.

Figure 11.

Comparison of EDS results with head speeds at (a) the cladding layer and (b) the HAZ layer.

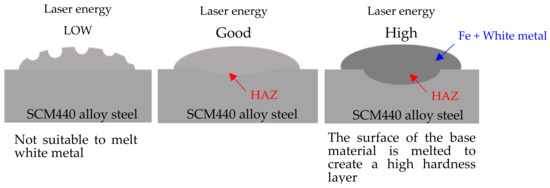

As shown in Figure 12, the melting state of white metal varied, depending on the amount of laser energy in the laser cladding process. If the amount of laser energy was low, the white metal bonded in a state where it did not completely melt, and if the amount of rare energy was high, the base material was affected, and a high-hardness layer was formed. If the laser power was high, the Fe component in the base meter was mixed into the white metal, which induced high hardness in the study.

Figure 12.

White metal melting form according to the laser energy level.

When white metal is laminated on the surface using the laser cladding process, it is important to produce high-quality clad by preventing the generation of mixed layers and HAZs, which cause the hardness to increase. This study focused on practical research by cladding white metal with SCM440 alloy steel, which is used as a material for tilting pad bearings, using laser cladding equipment that is actually used for industrial purposes. In this paper, micro Vickers hardness measurement, SEM and EDS analysis were verified. We discovered the effect of the heat input generated according to the process parameters of laser cladding on the hardness and composition of the cladding and proved that laser cladding is an effective alternative process.

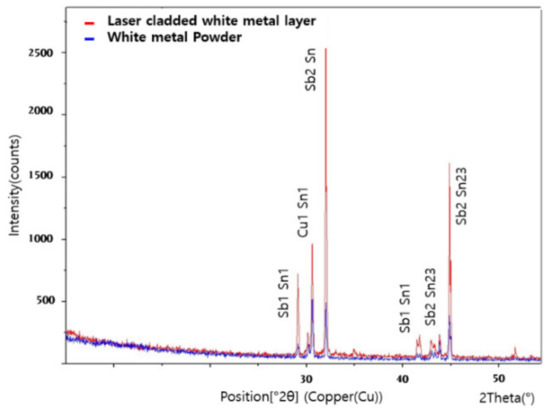

3.3. XRD Analysis of Laser Cladding

Figure 13 presents the results of the XRD analysis carried out to compare the components of the crystalline structure of the white metals mounted with white metal powder and laser cladding. The powder spectrum displayed a tin-based typical white metal component pattern. The Sb1, Sn1, Sb2 and Sn23 crystal phases exhibited high peaks with broad bandwidths. The spectrum of the white metal layer produced by the laser cladding method showed similar values, but the peak values were much higher than those of the pure powder. This is presumably ascribable to the improved orientation compared with the powder state, due to crystallization occurring concurrently with the intense coagulation of powders at temperatures beyond the crystallization temperature during melting.

Figure 13.

X-ray diffraction (XRD) results of the powder and laser-cladded white metal.

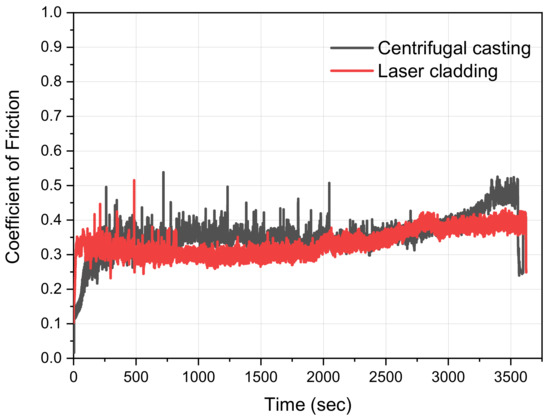

3.4. Friction Testing Analysis

As shown in Figure 14, when comparing the friction coefficients in the centrifugal casting and laser cladding methods, no significant differences in the friction coefficient were observed between these two methods. From this, it can be inferred that the processing method does not influence the friction coefficient, which in turn allows the conclusion to be made that laser cladding can replace centrifugal casting in the actual process.

Figure 14.

Comparison of friction coefficients between centrifugal casting and laser cladding.

4. Conclusions

This paper presents a method of laser cladding treatment using a white metal on SCM440 alloy steel to increase the durability and wear resistance for application in the bearing industry. Unlike the conventional centrifugal casting process, laser cladding treatment has the advantage of solving the environmental and worker safety problems.

Based on the experimental studies, the following results were obtained:

- The hardness values of the cladding (white metal) layer ranged between 24 HV and 26 HV in both the centrifugal casting and laser cladding methods. However, the hardness of white metal produced by laser cladding at about a depth of 0.1 mm rose rapidly in the cladding process, forming an HAZ with an average hardness value of 200 HV at a laser power of 1.1 kW, 325 HV at 1.3 kW and 430 HV at 1.5 kW. In addition, the hardness value increased as the powder feed rate and laser head speed decreased;

- No HAZ was observed in centrifugal casting, and adequate powder cladding and uniform HAZ formation were achieved at an adequate laser power during laser cladding. A laser power of 1.3 kW, powder feed rate of 2.5 rpm and head speed of 10 mm/s were found to be the optimal conditions for white metal cladding;

- The analysis of the surface friction testing results revealed no significant differences in the friction coefficient between the centrifugal casting and laser cladding methods, which allows the assumption that the processing method does not significantly influence the friction coefficient;

- The XRD analyses of the white metal powder and laser-cladded white metal revealed peaks of Sb1, Sn1, Sb2 and Sn23 crystal phases, with a much higher intensity in the case of the laser-cladded white metal. This indicates an increased density during crystallization, along with the particle coagulation during cladding.

Author Contributions

Conceptualization: J.-I.J., J.-H.K., Y.T.C. and C.-K.K. Data curation: J.-I.J., J.-H.K. and S.-G.C. Formal analysis: J.-I.J. and J.-H.K. Investigation: J.-I.J., S.-G.C., Y.T.C. and C.-K.K. Writing—original draft preparation: J.-I.J. Writing—review and editing: J.-I.J. and H.L. Validation: J.-H.K. and H.L. Project administration: S.-G.C. and H.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This study has been conducted with the support of the Korea Institute of Industrial Technology as “Development of intelligent root technology with add-on modules (KITECH EO-21-0009).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kim, S.; Choi, J.-H.; An, D. Feature Extraction for Bearing Prognostics based on Frequency Energy. J. Korea Inst. Intell. Transp. Syst. 2017, 16, 128–139. [Google Scholar] [CrossRef]

- Zhang, J.; Fang, B.; Hong, J.; Zhu, Y. Effect of preload on ball-raceway contact state and fatigue life of angular contact ball bearing. Tribol. Int. 2017, 114, 365–372. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Santos, T.G.; Miranda, R.M. Revisiting fundamental welding concepts to improve additive manufacturing: From theory to practice. Prog. Mater. Sci. 2020, 107, 100590. [Google Scholar] [CrossRef]

- Mostaghimi, J.; Chandra, S.; Ghafouri-Azar, R.; Dolatabadi, A. Modeling thermal spray coating processes: A powerful tool in design and optimization. Surf. Coat. Technol. 2003, 163, 1–11. [Google Scholar] [CrossRef]

- Shihab, S.K.; Mohamed, R.H.; Mubarek, E.M. Optimization of Process Parameters in Cladding of Stainless Steel over Mild Steel. Mater. Today Proc. 2019, 16, 816–823. [Google Scholar] [CrossRef]

- Jian, Z.; Qingwei, G.; Houqin, W.; Fengyuan, S.; Hongyun, Z.; Wenxiong, H.; Zhishui, Y. Microstructure and mechanical properties of Co-based alloy coatings fabricated by laser cladding and plasma arc spray welding. J. Alloys Compd. 2019, 785, 846–854. [Google Scholar]

- Dang, P.V.; Chatterton, S.; Pennacchi, P.; Vania, A. Effect of the load direction on non-nominal five-pad tilting-pad journal bearings. Tribol. Int. 2016, 98, 197–211. [Google Scholar] [CrossRef]

- Golchin, A.; Simmons, G.F.; Glavatskih, S.B. Break-away friction of PTFE materials in lubricated conditions. Tribol. Int. 2012, 48, 54–62. [Google Scholar] [CrossRef]

- Koutsky, J.; Vesela, J. Evaluation of white metal adhesion (conventional casting and thermalwire arc spraying) by ultrasonic non-destructive method. J. Mater. Process. Technol. 2004, 157–158, 724–772. [Google Scholar] [CrossRef]

- Negi, S.; Kapil, S.; Sharma, A.; Choudhary, P.; Bhargava, P.; Karunakaran, K.P. Retrofitment of laser cladding system with CNC machine for hybrid layer manufacturing. In Advances in Additive Manufacturing and Joining; Springer: Singapore, 2020; pp. 47–59. [Google Scholar]

- Telasang, G.; Majumdar, J.D.; Padmanabham, G.; Manna, I. Structure–property correlation in laser surface treated AISI HI3 tool steel for improved mechanical properties. Mater. Sci. Eng. A 2014, 599, 255–261. [Google Scholar] [CrossRef]

- Siddiqui, A.A.; Dubey, A.K. Recent trends in laser cladding and surface alloying. Opt. Laser Technol. 2021, 134, 106619. [Google Scholar] [CrossRef]

- Kim, J.D.; Lee, E.J.; Kim, C.G. The Study on Laser Cladding of Heat Resisting Steel Using EuTroLoy 16006 Powder(I)—Characteristics of 1 Pass Clad Layer with Process Parameters. Trans. Korean Soc. Mech. Eng. A 2017, 41, 299–305. [Google Scholar]

- Wang, Y.; Zhao, S.; Gao, W.; Zhou, C.; Liu, F.; Lin, X. Microstructure and properties of laser cladding FeCrBSi composite powder coatings with higher Cr content. J. Mater. Proc. Technol. 2014, 214, 899–905. [Google Scholar] [CrossRef]

- Saeedi, R.; Razavi, R.S.; Bakhshi, S.R.; Erfanmanesh, M.; Bani, A.A. Optimization and characterization of laser cladding of NiCr and NiCr–TiC composite coatings on AISI 420 stainless steel. Ceram. Int. 2021, 47, 4097–4110. [Google Scholar] [CrossRef]

- Liu, J.; Yu, H.; Chen, C.; Weng, F.; Dai, J. Research and development status of laser cladding on magnesium alloys: A review. Opt. Lasers Eng. 2017, 93, 195–210. [Google Scholar] [CrossRef]

- Qiao, Y.; Huang, J.; Huang, D.; Chen, J.; Liu, W.; Wang, Z.; Zhibin, Z. Effects of Laser Scanning Speed on Microstructure, Microhardness, and Corrosion Behavior of Laser Cladding Ni45 Coating. Hindawi J. Chem. 2020, 2020, 1438473. [Google Scholar] [CrossRef]

- Kim, C.K.; Choi, S.G.; Kim, J.H.; Jo, H.J.; Jo, Y.C.; Choi, S.P.; Cho, Y.T. Characterization of surface modification by laser cladding using low melting point metal. J. Ind. Eng. Chem. 2020, 87, 54–59. [Google Scholar] [CrossRef]

- Lee, K.H.; Lee, Y.R.; Woo, S.H.; Lee, C.S.; Park, L.J. Experimental characterization of dynamic deformation behaviour for SCM440 alloy steel steel at high strain rates. EPJ Web Conf. 2018, 183, 02019. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).