Fire Safety Risk Analysis of Conventional Submarines

Abstract

1. Introduction

2. Methodology

Limitations

3. Overview of Systems and Risks

3.1. General Objectives of Submarine Mission and Hazards

- Fire damage to the propulsion system or supporting subsystems which compromises propulsion of the submarine, leading to depth excursion, resulting in loss of the submarine.

- Fire and smoke damage causing multiple system failure and compromised ability to monitor and control the submarine, resulting in loss of the submarine.

- Heat from fire reducing the strength of the pressure hull, leading to loss of structural integrity, resulting in loss of the submarine.

- Fire damage and/or firefighting and damage control actions leading to compromise of fluid containment systems, causing internal flooding of the submarine, resulting in loss of the submarine.

- Fires resulting from malfunction of weapon systems, torpedoes and missiles.

3.2. Fire Dynamics on Submarines and Possible Consequences

- Fire Growth and Intensity—Submerged submarines are pressurised and without ventilation, creating ideal conditions for accelerated fire growth and overall higher intensity.

- Spread of Smoke and Heat—the layout of a submarine places many ignition and fuel sources at the bottom of the submarine whilst access points in many compartments are provided to the decks above which provides ideal conditions and pathways for the spread of rising smoke and heat.

- Occupant Behaviour—in fire scenarios, occupant characteristics can be wide and varied with some contributing significantly to the outcome of a fire incident. Fortunately, in a submarine all occupants are fit, well trained, intimately familiar with the layout of the submarine and there is always at least a subset of the crew that is highly alert and actively monitoring the health of the submarine.

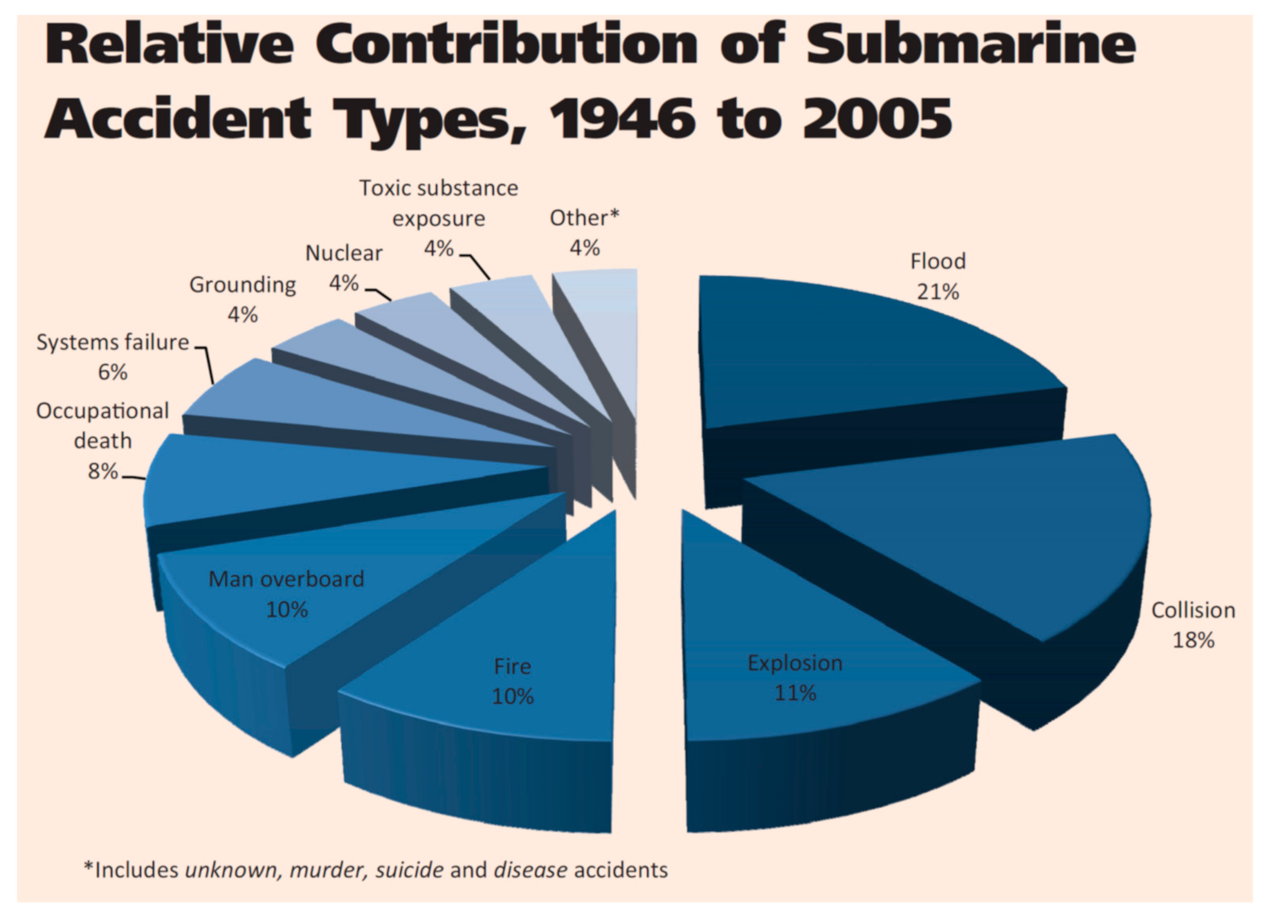

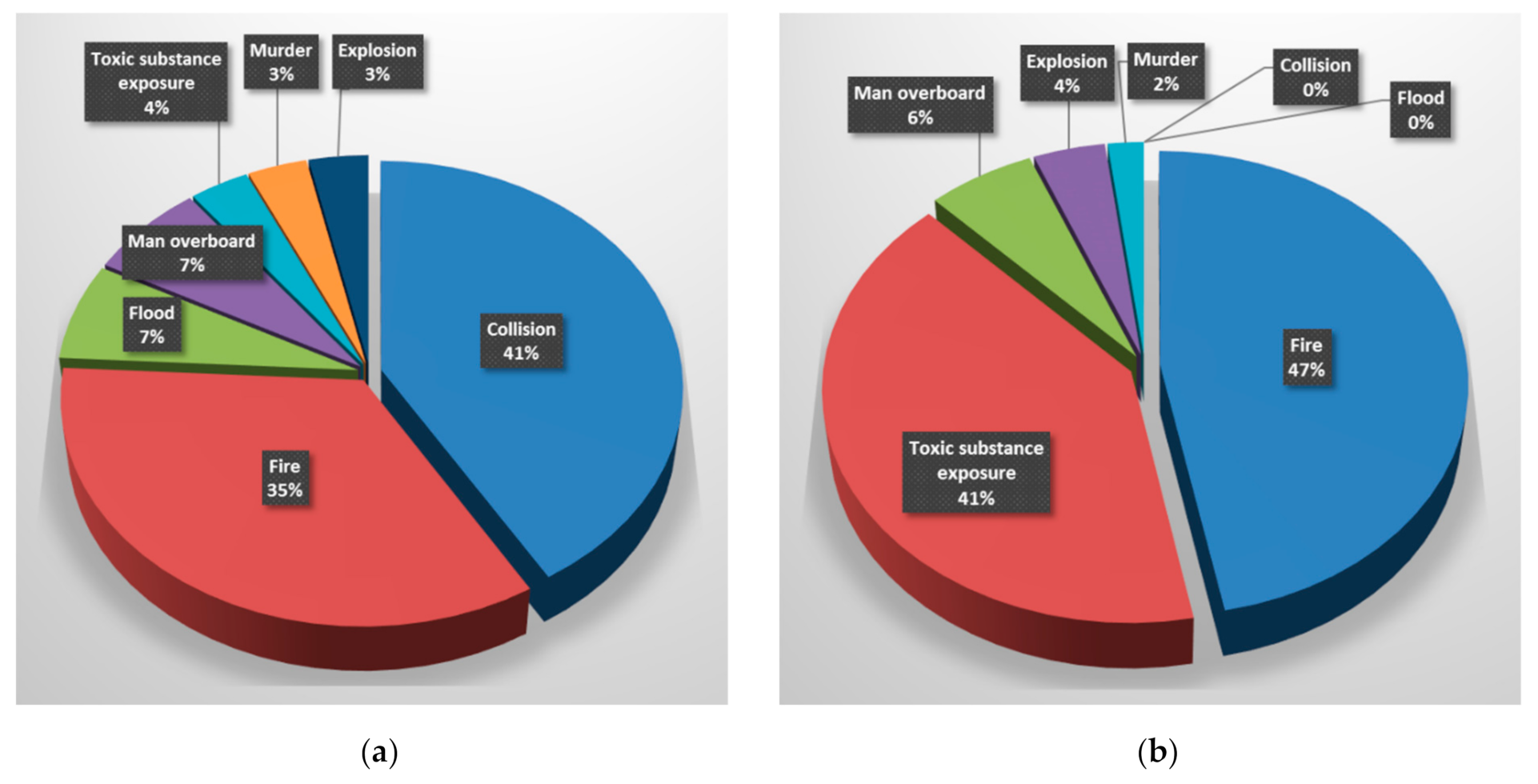

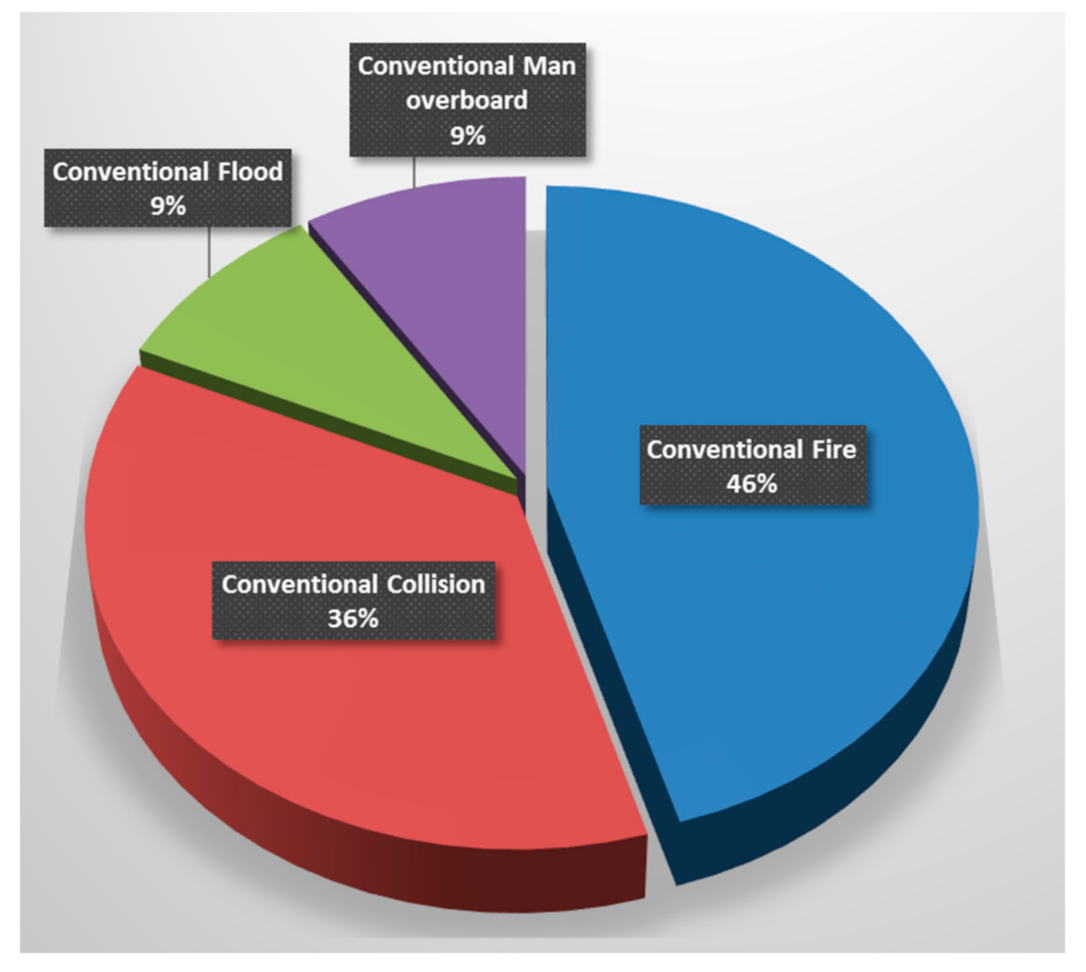

3.3. Safety Incident On-Board Submarines

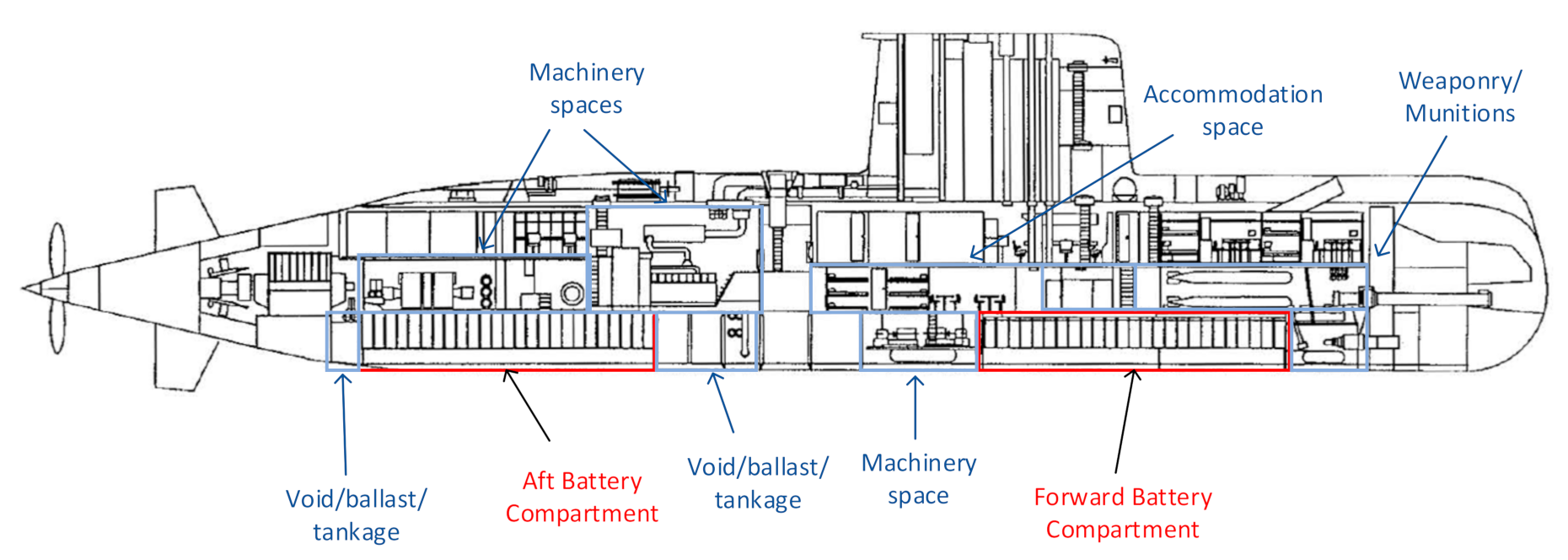

3.4. Fire Safety Risks for Conventional Submarines

3.4.1. Current State—Australia’s Collins Class

3.4.2. Future Submarine

- Prevention: Hypoxic atmosphere fire prevention system, monitoring and control systems;

- Suppression: Water mist, foam, gaseous agents; and

- Structure and materials: Fire resistant casing for batteries.

3.4.3. Fire Risk Considerations

- Diesel engines:

- Air Independent Propulsion:

- Lithium-ion batteries:

4. Fire Safety Risk Considerations—Technology Review

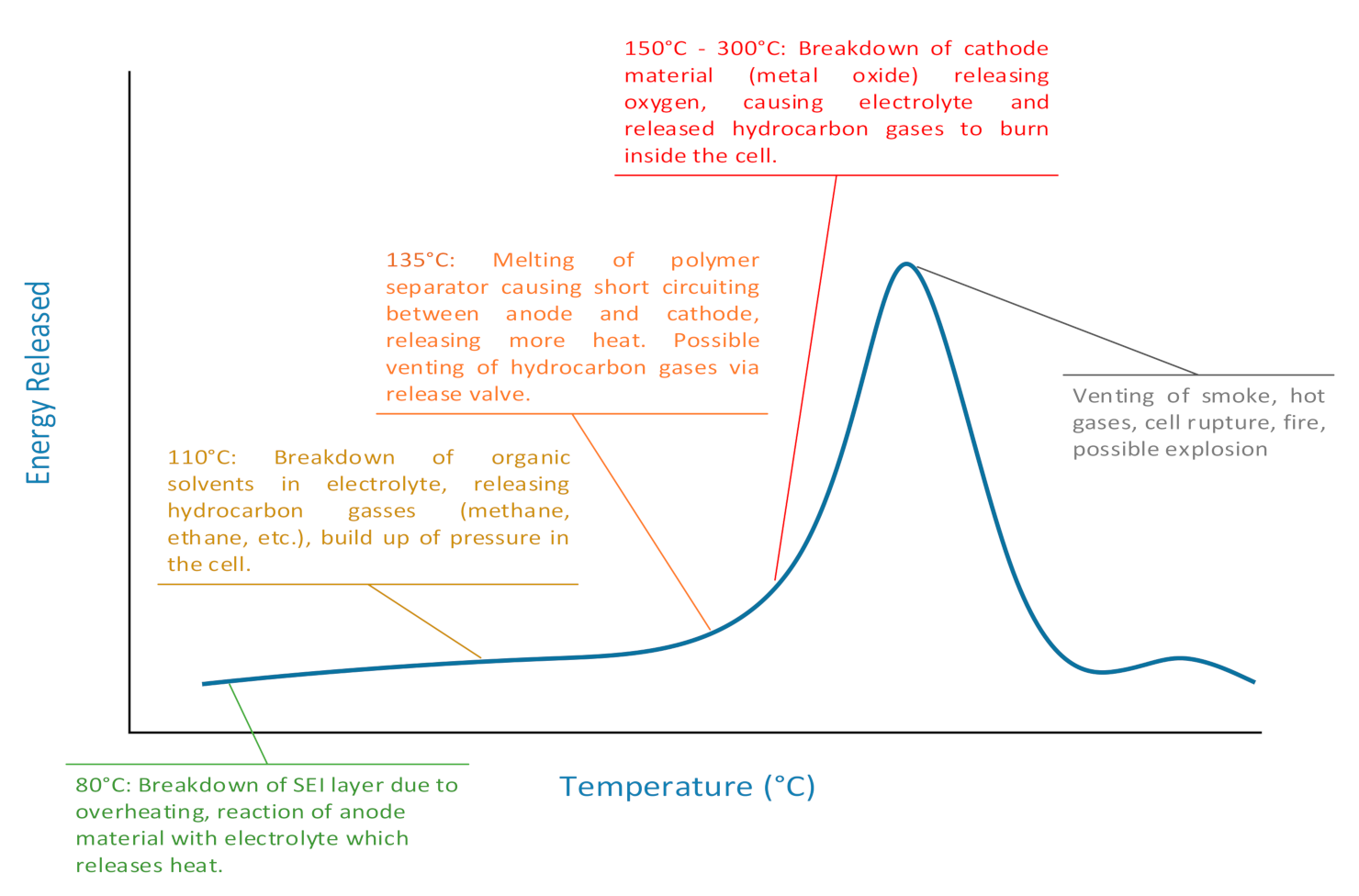

4.1. Lithium-Ion Batteries

4.1.1. Future Submarine Context

4.1.2. Functional Description

4.2. Fire Risk—Lithium-Ion Batteries

4.2.1. Fuel Sources

4.2.2. Ignition Sources

4.2.3. Technology Maturity

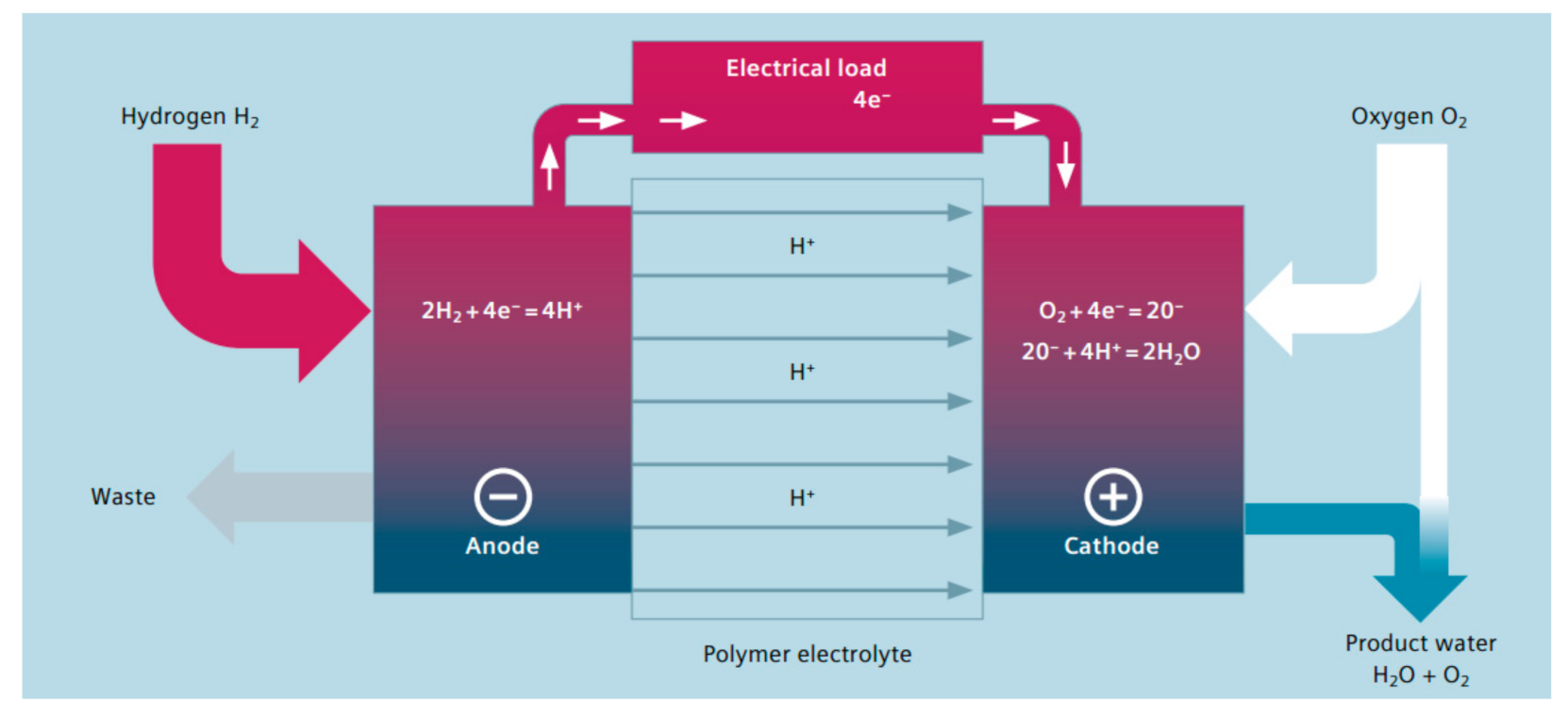

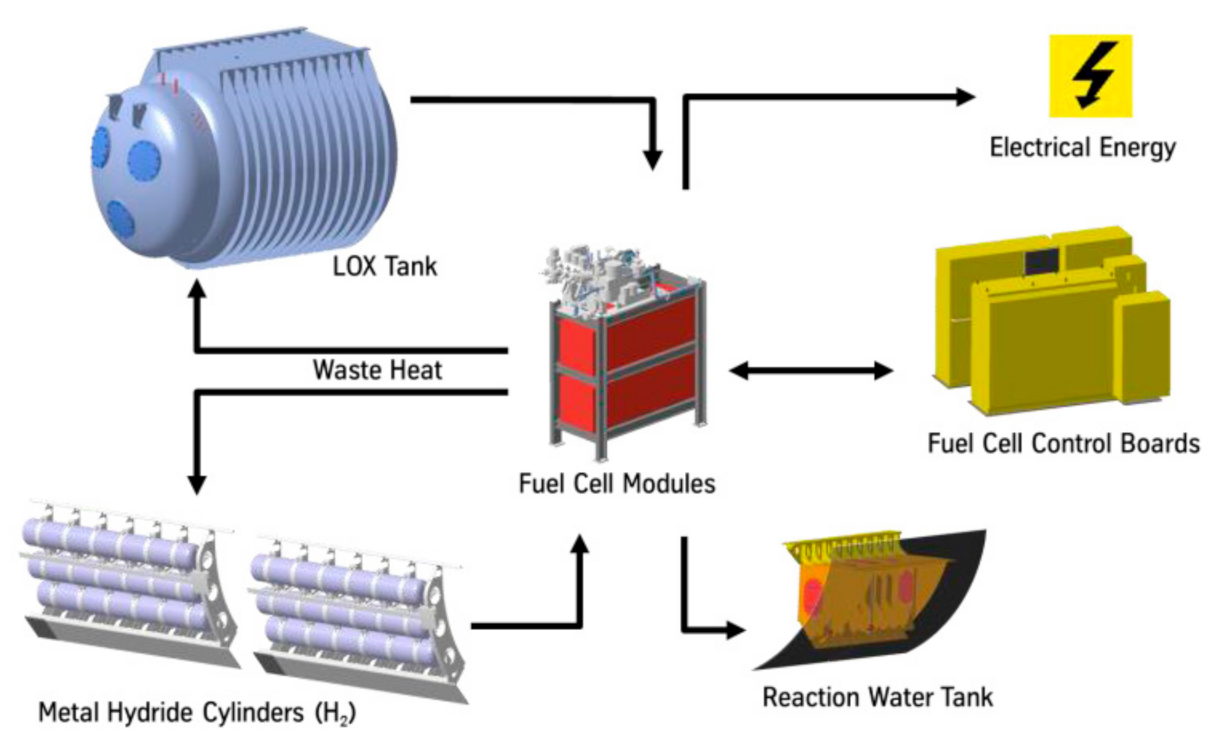

4.3. Hydrogen Fuel Cell

4.3.1. Future Submarine Context

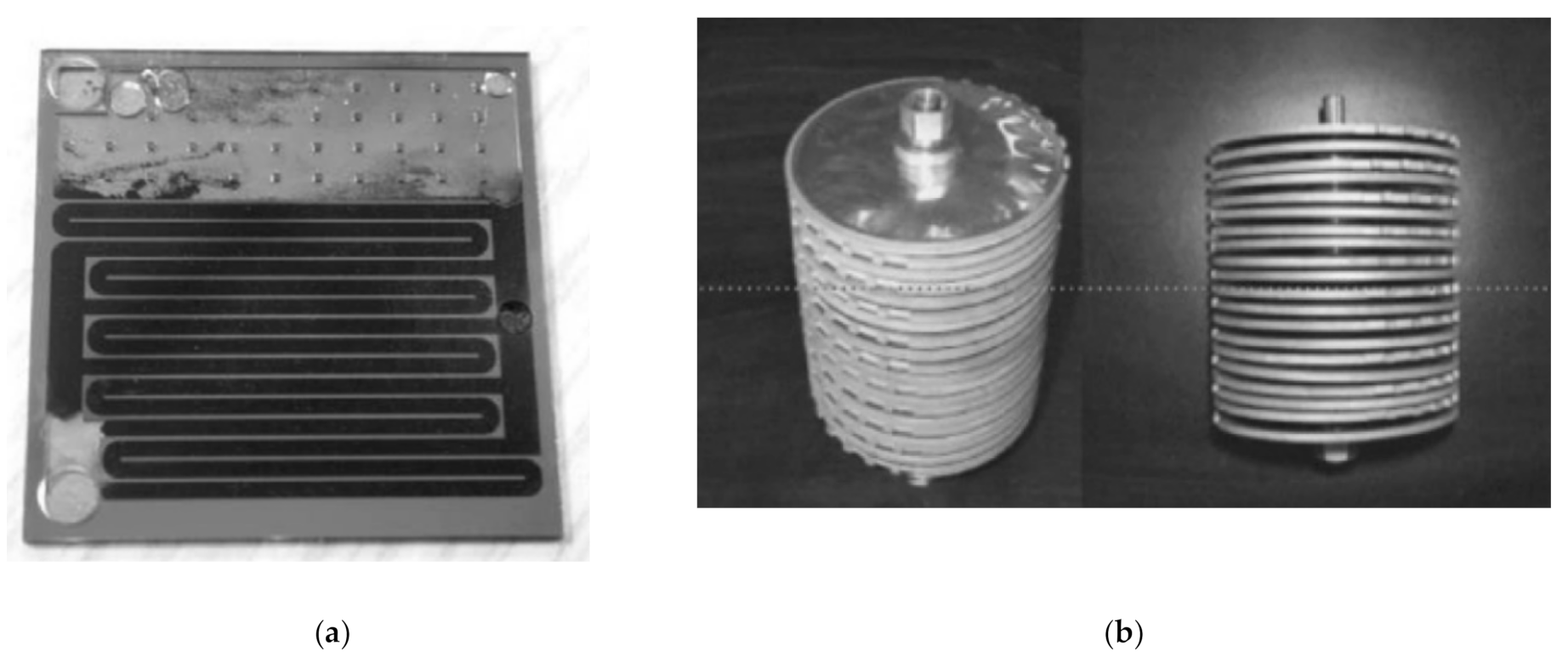

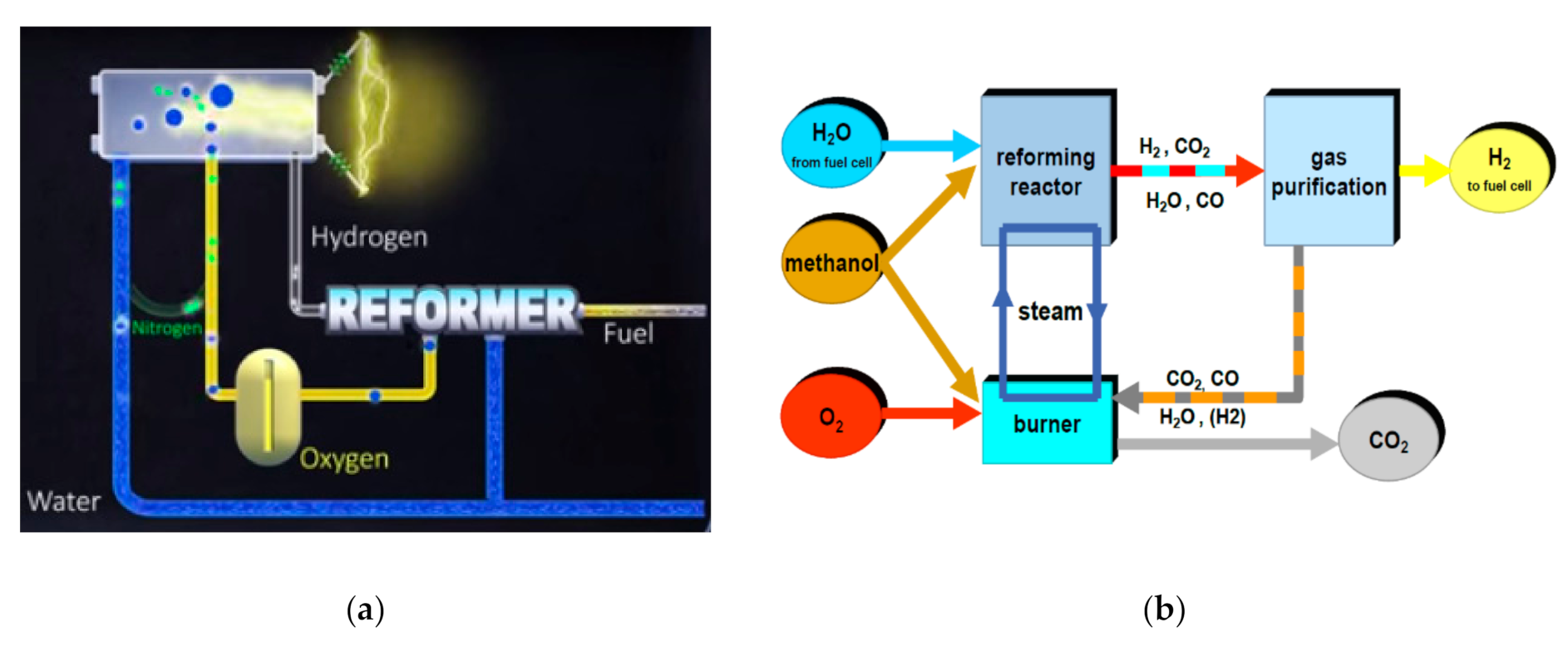

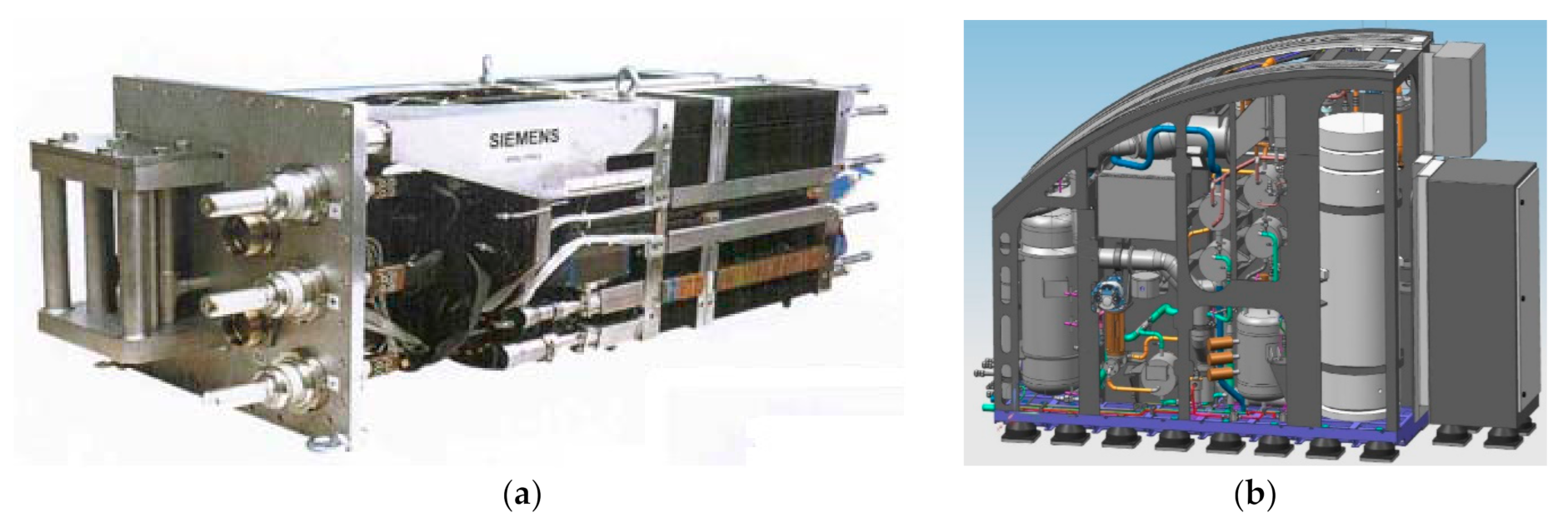

4.3.2. Functional Description

4.4. Fire Risk—Hydrogen Fuel Cell

4.4.1. Failure Modes

4.4.2. Fuel Sources

4.4.3. Ignition Sources

4.4.4. Technology Maturity

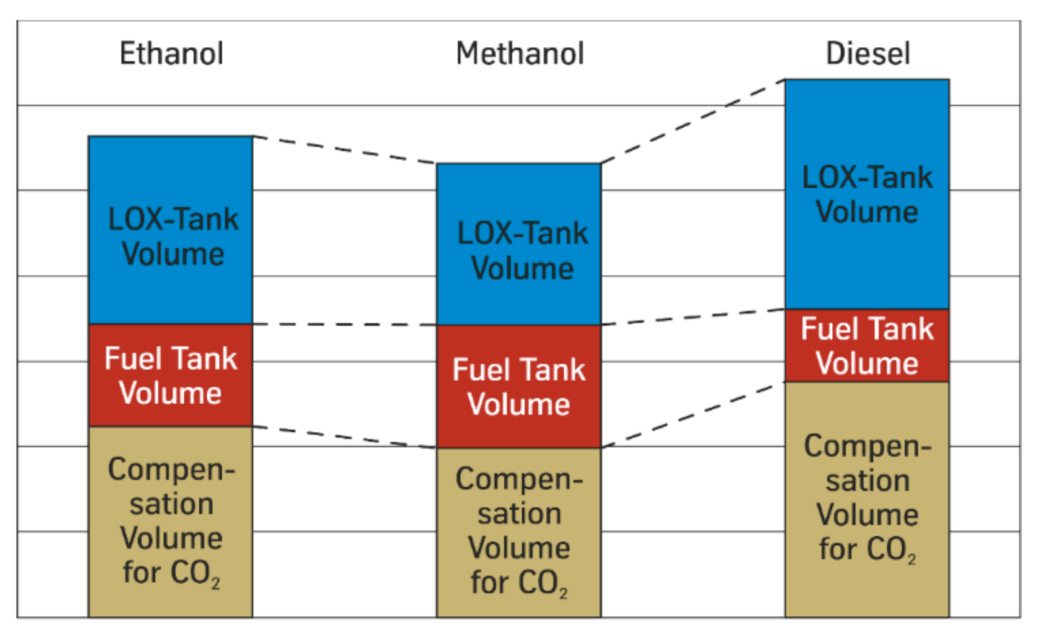

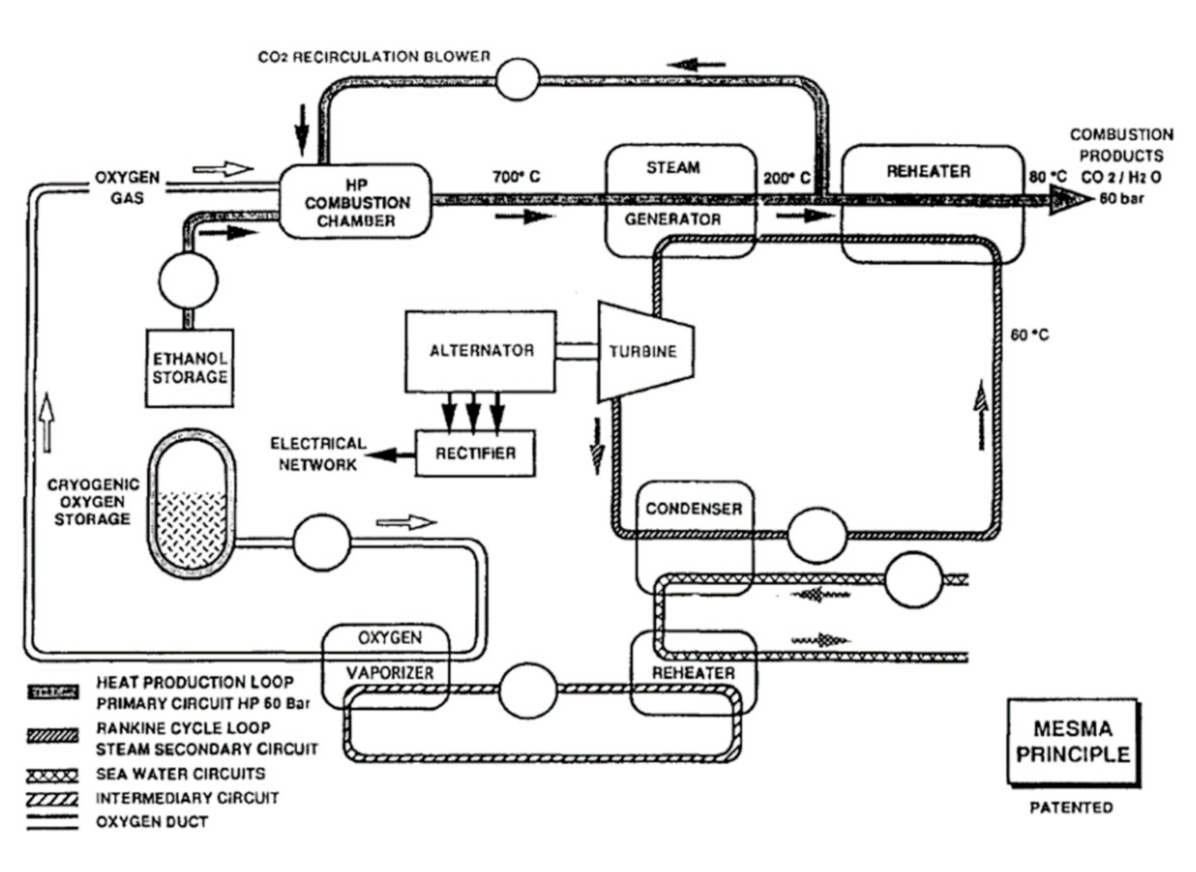

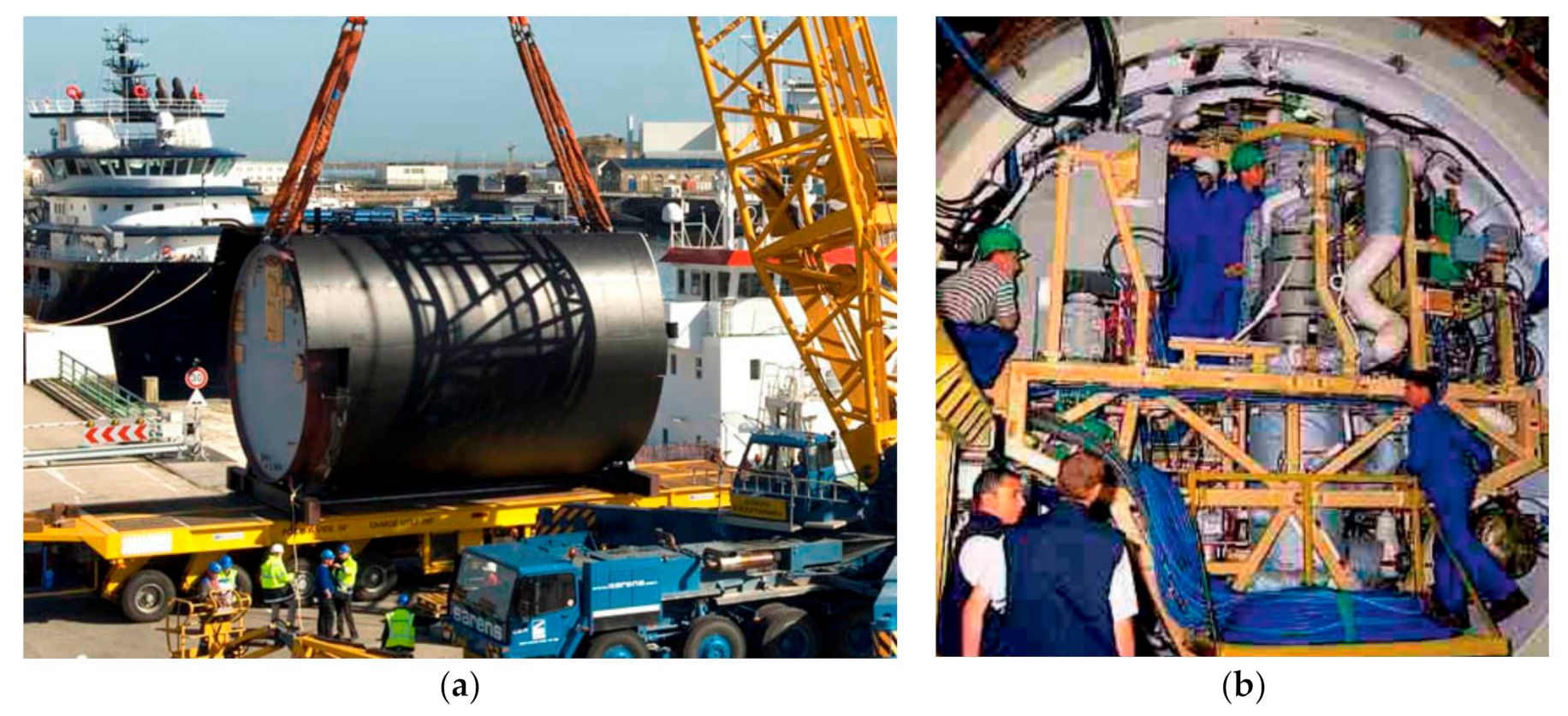

4.5. MESMA Steam Turbine

Future Submarine Context and Functional Description

4.6. Fire Risk-MESMA Steam Turbine

4.6.1. Failure Modes

4.6.2. Fuel and Ignition Sources

4.6.3. Technology Maturity

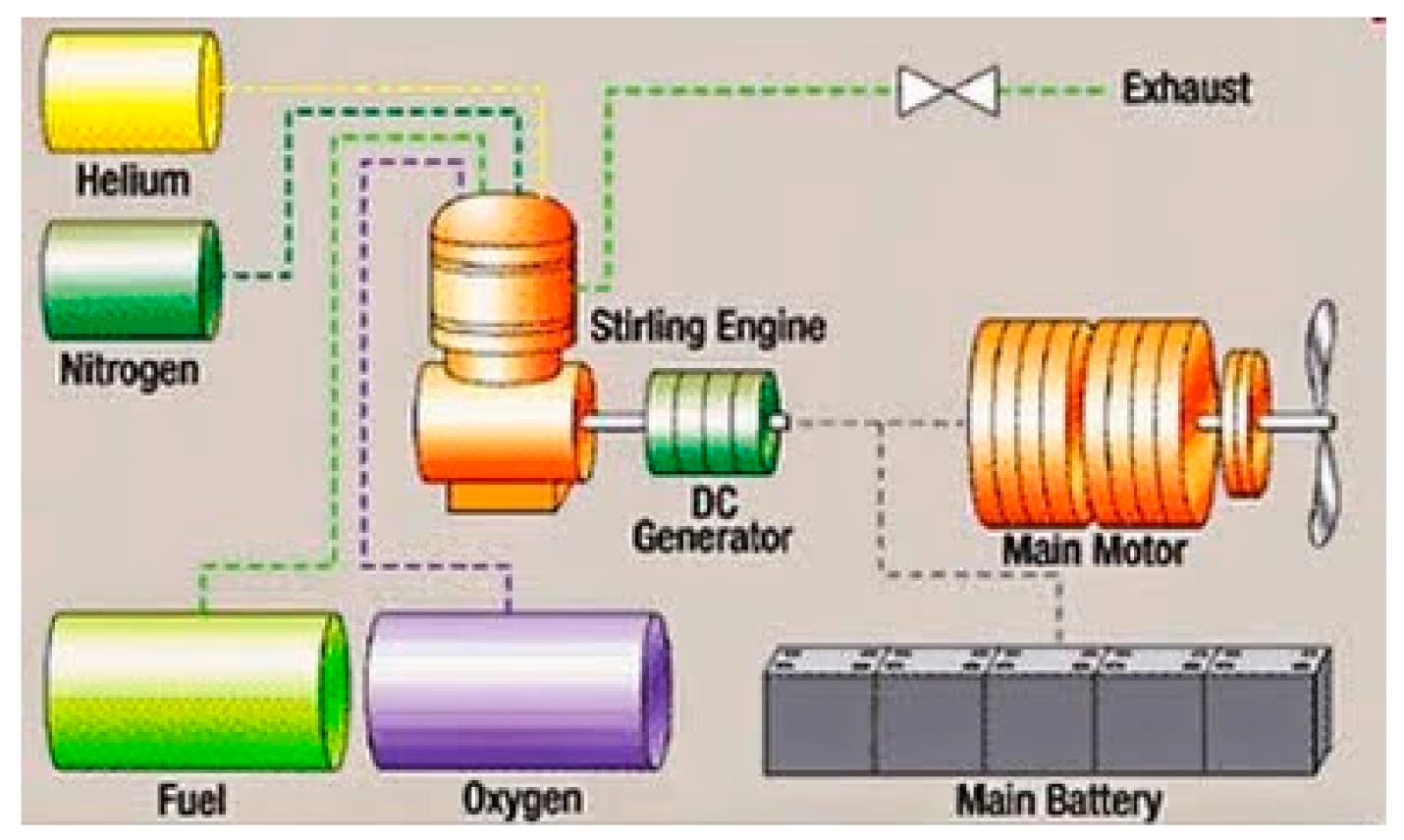

4.7. Stirling Engine

- Helium gas enclosed within the Stirling engine is passed through tubes in the combustion chamber where it is heated.

- Pistons push the helium to through a regenerator which absorbs heat, and a cooler which further cools the gas before entering the lower, cool part of the cylinder.

- Compression of the cooled gas assists the double acting piston to push the cool gas back through the tubes, past the cooler and past the regenerator which transfers the heat absorbed earlier back to the gas.

- Gas moves back through the heater tubes in the combustion chamber and into the hot part of the cylinder where it expands, pushes the piston down and restarts the cycle.

4.8. Fire Risk-Stirling Engine

4.8.1. Failure Modes

4.8.2. Fuel Sources

4.8.3. Ignition Sources

4.8.4. Technology Maturity

5. Fire Risk Assessment

5.1. Overview

5.2. Risk Assessment Framework

The Effect of Technology Maturity on Risk

- System reliability: The level of reliability of system components and the integrated system itself is dependent on the maturity and rigour of associated design and manufacturing standards. This is largely dependent on the maturity of the technology inherent in the system and the scale of its use and production. The higher the reliability, the lower the probability of failure and the lower the overall risk.

- Safety integrity: Whilst related to reliability, safety integrity is closely connected to the service history of a technology and the collective knowledge of how the system operates and fails. The longer a system has served in a particular application, the better the operational risk and safety factors are able to be understood which leads to more robust system design and better overall safety. In the context of fire risk, this can lead to fewer failures that cause fires and or less severe fires should they occur.

- Effectiveness of available mitigation measures: Referring specifically to fire risk, the nature of a technology’s operation, the chemicals used and the environment in which it operates all affect the availability and effectiveness of preventative and reactionary mitigation measures. The level of understanding about which fire prevention, detection and suppression systems work best with a certain system is dependent on the maturity of the technology, the degree of testing and development and the length of its service in a submarine environment.

5.3. Assessment

5.3.1. Scenario

5.3.2. Quantification

5.3.3. Sensitivity Analysis

5.4. Potential Mitigation Measures for Lithium-Ion Batteries

6. Conclusions and Further Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Telegraph Media Group Limited. Nuclear Submarines Hit by More Than 200 Fires in the Past 25 Years. Available online: http://www.telegraph.co.uk/news/uknews/9384766/Nuclear-submarines-hit-by-more-than-200-fires-in-the-past-25-years.html (accessed on 8 July 2012).

- Telegraph Media Group Limited. Sailors Killed in Indian Submarine Explosion. Available online: http://www.telegraph.co.uk/news/worldnews/asia/india/10241917/Sailors-killed-in-Indian-submarine-explosion.html (accessed on 14 August 2013).

- Unnithan, S.; Aroor, S. INS Chakra Formally Joins Indian Navy Today. Available online: http://indiatoday.intoday.in/story/ins-chakra-formally-joins-indian-navy-nuclear-submarine/1/182889.html (accessed on 4 April 2012).

- Wikimedia Foundation, Inc. List of Submarine Incidents Since 2000. Available online: http://en.wikipedia.org/wiki/List_of_submarine_incidents_since_2000 (accessed on 9 March 2015).

- Depetro, A. The Design & Safety Challenges of a Lithium-ion Main Storage Battery for Conventional Submarines. In Proceedings of the 4th SIA Submarine Science, Technology and Engineering Conference 2017 (SubSTEC4), Adelaide, Austrilia, 13–16 November 2017. [Google Scholar]

- Naval Sea Systems Command. Naval Ships’ Technical Manual Chapter 555 Volume 2 Submarine Firefighting, 5th ed.; Naval Sea Systems Command, United States Navy: Washington, DC, USA, 1998.

- Tingle, C. Submarine Accidents: A 60-year statistical assessment. Prof. Safety 2009, 54, 31–39. [Google Scholar]

- British Broadcasting Corporation. Two Killed in Russian Sub Blaze. British Broadcasting Corporation, 7 September 2006. Available online: http://news.bbc.co.uk/2/hi/europe/5322474.stm (accessed on 14 April 2015).

- Wilcock, D. Nuclear Submarine Incident ‘Close to Catastrophe’. The Independent. 21 June 2011. Available online: http://www.independent.co.uk/news/uk/home-news/nuclear-submarine-incident-close-to-catastrophe-2300569.html (accessed on 14 April 2015).

- Cable News Network. U.S. Sub Collides with Japan Ship. Cable News Network. 8 January 2007. Available online: http://edition.cnn.com/2007/WORLD/asiapcf/01/08/japan.us.ship/index.html (accessed on 14 April 2015).

- British Broadcasting Corporation. Oxygen Device Sparked Sub Blast. British Broadcasting Corporation, 22 March 2007. Available online: http://news.bbc.co.uk/2/hi/uk_news/england/6478127.stm (accessed on 14 April 2015).

- British Broadcasting Corporation. UK Submarine Hits Red Sea rocks. British Broadcasting Corporation, 27 May 2008. Available online: http://news.bbc.co.uk/2/hi/uk_news/7422774.stm (accessed on 14 April 2015).

- Loiko, S.L. False Alarm Blamed in Sub Fatalities. Los Angeles Times. 10 November 2008. Available online: http://articles.latimes.com/2008/nov/10/world/fg-russiasub10 (accessed on 14 April 2015).

- IP Marine. MV Leeds Castle. IP Marine Solutions Pvt., Ltd., 7 January 2008. Available online: http://www.ipmarine.com/Collision/New%20Folder/A-Summary%20MV%20Leeds%20castle.pdf (accessed on 15 April 2015).

- British Broadcasting Corporation. Nuclear Subs Collide in Atlantic. British Broadcasting Corporation, 16 February 2009. Available online: http://news.bbc.co.uk/2/hi/uk_news/7892294.stm (accessed on 14 April 2015).

- Commander US Naval Forces Central Command. Two U.S. Navy Vessels Collide in the Strait of Hormuz. US Navy, 20 March 2009. Available online: http://www.cusnc.navy.mil/articles/2009/046.html (accessed on 14 April 2015).

- Unnithan, S. Explosion on Indian Navy Submarine INS Sindhurakshak Possibly Due to Gas Buildup. Living Media India Limited, 14 August 2013. Available online: http://indiatoday.intoday.in/story/indian-navy-submarine-ins-sindhurakshak-fire-explosion-gas-buildup/1/299408.html (accessed on 14 April 2015).

- The Indian Express Ltd. In Bid to Save Crew, Commander of Submarine Is Killed. The Indian Express Ltd., 31 August 2010. Available online: http://archive.indianexpress.com/news/in-bid-to-save-crew-commander-of-submarine-is-killed/674693/ (accessed on 15 April 2015).

- British Broadcasting Corporation. Nuclear Submarine HMS Astute Runs Aground Off Skye. British Broadcasting Corporation, 22 October 2010. Available online: http://www.bbc.com/news/uk-scotland-highlands-islands-11605365 (accessed on 14 April 2015).

- Gordon, R. Navy Submarine Damage Severe, Internal Report Says. Canadian Broadcasting Corporation, 16 July 2013. Available online: http://www.cbc.ca/news/canada/nova-scotia/navy-submarine-damage-severe-internal-report-says-1.1353463 (accessed on 14 April 2015).

- Australian Broadcasting Corporation. Fire on Russian Nuclear Sub ‘Totally Extinguished’. Australian Broadcasting Corporation, 30 December 2011. Available online: http://www.abc.net.au/news/2011-12-30/russia-submarine-fire-put-out/3753360 (accessed on 14 April 2015).

- Lawrence, T. Flooding Worries for Royal Navy’s New Multi-Billion Pound Submarine HMS Astute. The Independent, UK, 16 November 2012. Available online: http://www.independent.co.uk/news/uk/home-news/flooding-worries-for-royal-navys-new-multibillion-pound-submarine-hms-astute-8323154.html (accessed on 14 April 2015).

- Wright, S.; Drury, I.; Greenwood, C. Smiling Face of Sailor Pictured Just 48 Hours Before He Gunned Down Two of His Officers, Killing One on Nuclear Sub HMS Astute. Associated Newspapers Ltd., 10 April 2011. Available online: http://www.dailymail.co.uk/news/article-1374850/HMS-Astute-shooting-Ryan-Donovan-pictured-smiling-48-hours-incident.html (accessed on 14 April 2015).

- McDermott, J. Fire-Stricken Submarine USS Miami Is Decommissioned. Stars and Stripes. 29 March 2014. Available online: http://www.stripes.com/news/us/fire-stricken-submarine-uss-miami-is-decommissioned-1.275179 (accessed on 14 April 2015).

- Martinez, L. Navy Submarine and Cruiser Collide Off Florida. American Broadcasting Company News Internet Ventures, 13 October 2012. Available online: http://abcnews.go.com/blogs/politics/2012/10/navy-submarine-and-cruiser-collide-off-florida/ (accessed on 14 April 2015).

- News Limited. Engine Fire Aboard Collins-Class Submarine. News Limited, 25 September 2012. Available online: http://www.news.com.au/national/engine-fire-aboard-collins-class-submarine/story-fndo4eg9-1226480933310 (accessed on 14 April 2015).

- Ellery, D. A “Minor Flood” in One of Our Submarines Says Defence. Fairfax Media, 25 July 2012. Available online: http://www.canberratimes.com.au/it-pro/a-minor-flood-in-one-of-our-submarines-says-defence-20120725-22qgp.html (accessed on 14 April 2015).

- Thapar, V. Navy Retires Disaster-Hit Submarine, Leaves Gaping Hole in Its Fleet. Information TV Group, 14 March 2015. Available online: http://www.sunday-guardian.com/news/navy-retires-disaster-hit-submarine-leaves-gaping-hole-in-its-fleet (accessed on 14 April 2015).

- Gutterman, S. Fire on Russian Sub Injured 15: Investigators. Thomson Reuters, 17 September 2013. Available online: http://www.reuters.com/article/2013/09/17/us-russia-submarine-fire-idUSBRE98G0GP20130917 (accessed on 14 April 2015).

- Martinez, L. Navy Sub Goes Bump in the Night and Loses Its Periscope. American Broadcasting Company News Internet Ventures, 10 January 2013. Available online: http://abcnews.go.com/blogs/politics/2013/01/navy-sub-goes-bump-in-the-night-and-loses-its-periscope/ (accessed on 14 April 2015).

- The Hindu. Fire in Cables Led to INS Sindhuratna Mishap: Navy. The Hindu, 3 March 2014. Available online: http://www.thehindu.com/news/national/fire-in-cables-led-to-ins-sindhuratna-mishap-navy/article5746312.ece (accessed on 14 April 2015).

- Australian Department of Defence. Fire onboard Royal Australian Navy submarine. Australian Department of Defence, 27 February 2014. Available online: http://news.defence.gov.au/2014/02/27/fire-onboard-royal-australian-navy-submarine/ (accessed on 15 April 2015).

- Bennett, Coleman & Co., Ltd. Submarine Hits Ground Due to Low Tide, No Casualty. Bennett, Coleman & Co. Ltd., 19 January 2014. Available online: http://www.mumbaimirror.com/mumbai/others/Submarine-hits-ground-due-to-low-tide-no-casualty/articleshow/29021702.cms (accessed on 14 April 2015).

- Nicol, M. Bang Goes the No Claims! Royal Navy Nuclear Submarine Suffers £500,000 Damage After ‘Hitting Floating Ice’ While Tracking Russian Vessels. Associated Newspapers Ltd., 5 April 2015. Available online: http://www.dailymail.co.uk/news/article-3025839/Royal-Navy-nuclear-submarine-suffers-500-000-damage-hitting-floating-ice-tracking-Russian-vessels.html (accessed on 14 April 2015).

- Maritimenews. Collided Chilean Submarine with Frigate. Maritimenews. 31 July 2014. Available online: http://www.maritimenews.pl/2014/07/collided-chilean-submarine-with-frigate.html (accessed on 15 April 2015).

- Grove, T. Russian Nuclear Submarine Orel Catches Fire in Shipyard in Northern City of Severodvinsk. Fairfax Media. 8 April 2015. Available online: http://www.smh.com.au/world/russian-nuclear-submarine-orel-catches-fire-in-shipyard-in-northern-city-of-severodvinsk-20150407-1mgara.html (accessed on 14 April 2015).

- Australian Department of Defence. Collins Class Submarine Ship’s Information Book; Australian Department of Defence: Canberra, Australia, 1993.

- News Corp. Submarine Dossier. Advertiser, 2015; 12–15. [Google Scholar]

- BMT Design & Technology. BMT Submarine Design & Engineering Course; BMT Design & Technology: Melbourne, Australia, 2015. [Google Scholar]

- Australian Department of Defence. An Introduction to Collins, Canberra; Australian Department of Defence: Canberra, Australia, 1991.

- Burch, I.; Ghiji, M.; Gamble, G.; Suenermann, B.; Joseph, P.; Moinuddin, K.; Novozhilov, V. Lithium-ion battery fire suppression in submarine battery compartments. In Proceedings of the Royal Institution of Naval Architects Pacific 2019 International Maritime Conference, IMC 2019, Sydney, Australia, 8–10 October 2019. [Google Scholar]

- Woodbank Communications Ltd. Electropaedia. Woodbank Communications Ltd., 15 June 2005. Available online: http://www.mpoweruk.com/chemistries.htm (accessed on 20 August 2015).

- Ponchaut, N.; Marr, K.; Colella, F.; Somandepalli, V.; Horn, Q. Thermal Runaway and Safety of Large Lithium-Ion Battery Systems; Exponent Inc.: Natick, MA, USA, 2015. [Google Scholar]

- Golubkov, A.W.; Scheikl, S.; Planteu, R.; Voitic, G.; Helmar, W.; Stangl, C.; Fauler, G.; Thaler, A.; Hacker, V. Thermal runaway of commercial 18650 Li-ion batteries with LFP and NCA cathodes impact of state of charge and overcharge. RSC Adv. 2015, 5, 57171–57186. [Google Scholar] [CrossRef]

- International Air Transport Association. Lithium Batteries Risk Mitigation Guidance for Operators, 1st ed.; International Air Transport Association: Montreal, QC, Canada, 2014. [Google Scholar]

- Naval Sea Systems Command. Lithium Battery Systems Navy Platform Integration Safety Manual; Naval Sea Systems Command: Bethesda, MD, USA, 2011.

- Battista, J. High-Speed Imaging Tests on Batteries to Help Design Safe Enclosures on Navy Ships; NAVSSES Public Affairs, Naval Sea Systems Command: Bethesda, MD, USA, 2015.

- Banner, J.; Winchester, C. Lithium Battery Safety in Support of Operation Fielding of Unmanned Underwater Vehicles; Naval Surface Warfare Center, Carderock Division: Bethesda, MD, USA, 2011.

- Saft, Saft Lithium Battery Systems Cutting-Edge Technology for Underwater Vehicles; Saft Specialty Battery Group: Bethesda, MD, USA, 2010.

- Kallender-Umezu, P. Japan To Make Major Switch on Sub Propulsion. Gannett Government Media Corporation, 29 September 2014. Available online: http://archive.defensenews.com/article/20140929/DEFREG03/309290032/Japan-Make-Major-Switch-Sub-Propulsion (accessed on 27 August 2015).

- Sightline Media Group. Japan Commissions Its First Submarine Running on Lithium-ion Batteries. Sightline Media Group, 6 March 2020. Available online: https://www.defensenews.com/global/asia-pacific/2020/03/06/japan-commissions-its-first-submarine-running-on-lithium-ion-batteries/ (accessed on 2 November 2020).

- Want China Times. PLA Developing Submarines Powered by Lithium-ion Batteries. WantChinaTimes.com, 31 May 2015. Available online: http://www.wantchinatimes.com/news-subclass-cnt.aspx?id=20150531000123&cid=1101 (accessed on 27 August 2015).

- Janke, A.; Nagorny, B. Lithium-Ion Batteries for Submarine; ThyssenKrupp Marine Systems: Kiel, Germany, 2015. [Google Scholar]

- Siemens, A.G. SINAVY PEM Fuel Cell for Submarines; Siemens AG: Hamburg, Germany, 2013. [Google Scholar]

- Mechsner, A.; Hauschlidt, P. Improvements in Air Independent Propulsion on Submarines; ThyssenKrupp Marine Systems GmbH: Kiel, Germany, 2015. [Google Scholar]

- Palo, D.R.; Dagle, R.A.; Holladay, J.D. Methanol Steam Reforming for Hydrogen Production. Chem. Rev. 2007, 107, 3992–4021. [Google Scholar] [CrossRef] [PubMed]

- Kundu, A.; Ahn, J.E.; Park, S.-S.; Shul, Y.G.; Han, H.S. Process intensification by micro-channel reactor for steam reforming of methanol. Chem. Eng. J. 2008, 135, 113–119. [Google Scholar] [CrossRef]

- Hansen, J.B. Methanol reformer design considerations. In Handbook of Fuel Cells; John Wiley & Sons: New York, NY, USA, 2010. [Google Scholar]

- Direction des Constructions et Armes Navales (DCNS). Major DCNS Innovations Improve Submarine Capabilities. DCNS. 29 October 2014. Available online: http://en.dcnsgroup.com/news/major-dcns-innovations-improve-submarine-capabilities/ (accessed on 28 August 2015).

- Pacific Northwest National Laboratory. Hydrogen Tools Lessons Learned. Pacific Northwest National Laboratory, U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy, 1 February 2001. Available online: https://h2tools.org/lessons (accessed on 1 September 2015).

- Naval Surface Warfare Center. Carderock DivisionNaval, Handbook of Prediction Procedures for Mechanical Equipment; Naval Surface Warfare Center: Bethesda, MD, USA, 2011.

- Asia Industrial Gases Association. AIGA 005/10 Fire Hazards of Oxygen and Oxygen Enriched Atmospheres; Asia Industrial Gases Association: Singapore, 2010. [Google Scholar]

- National Aeronautics and Space Administration (NASA). NSS 1740.15 Safety Standard for Oxygen and Oxygen Systems; National Aeronautics and Space Administration (NASA): Washington, DC, USA, 1996.

- EG&G Technical Services, Inc. Fuel Cell Handbook, 7th ed.; National Technical Information Service, U.S. Department of Commerce: Morgantown, WV, USA, 2004.

- Wing, J. Fuel Cells and Submarines; Johnson Matthey PLC.: London, UK, 2013. [Google Scholar]

- Hammerschmidt, A.E. Fuel Cell Propulsion of Submarines. In Advanced Naval Propulsion Symposium; American Society of Naval Engineers: Arlington, TX, USA, 2006. [Google Scholar]

- Kerros, P.; Inizan, C.; Grousset, D. MESMA: AIP system for submarines. In OCEANS ‘94; IEEE: Brest, France, 1994; Volume 3. [Google Scholar]

- Konstantinos, P.; Whitcomb, C.A.; Hootman, J.C. Design of Conventional Submarines with Advanced Air Independent Propulsion Systems and Determination of Corresponding Theatre-Level Impacts. Nav. Eng. J. 2010, 1, 111–123. [Google Scholar]

- Kuala Lumpur Strategic Watch. Second DCNS’s Mesma® AIP Ready for Shipment to Pakistan. WordPress.com, 22 June 2011. Available online: https://klswatch.wordpress.com/2011/06/22/second-dcnss-mesma%C2%AE-aip-ready-for-shipment-to-pakistan/ (accessed on 11 September 2015).

- DCNS Group. MESMA AIP Module for Conventional Submarines; DCNS Group: Paris, France, 2012. [Google Scholar]

- Defense Industry Daily, LLC. Brazil & France in Deal for SSKs, SSN. Defense Industry Daily, LLC, 12 December 2014. Available online: http://www.defenseindustrydaily.com/brazil-france-in-deal-for-ssks-ssn-05217/ (accessed on 11 September 2015).

- Nilsson, H. Air Independent Power Systems for Autonomous Submarines. In OCEANS ‘85 Ocean Engineering and the Environment; IEEE: Malmo, Sweden, 1985. [Google Scholar]

- Walker, G. Stirling Engines; Oxford University Press: New York, NY, USA, 1980. [Google Scholar]

- Cocking, J. The Application of Stirling Engines to Air Independent Operations Lessons for the Collins Class to be Drawn from the Swedish Experience. Def. Force J. 1994, 105, 33–40. [Google Scholar]

- Coates, P. Submarine Matters. 5 August 2014. Available online: http://gentleseas.blogspot.com.au/2014/08/air-independent-propulsion-aip.html (accessed on 12 September 2015).

- Sala, F.; Invernizzi, C.; Garcia, D.; Gonzales, M.-A.; Prieto, J.-I. Preliminary design criteria of Stirling engines taking into account real gas effects. Appl. Therm. Eng. 2015, 89, 978–989. [Google Scholar] [CrossRef]

- US Department of Defense. MIL-STD-882D Standard Practice for System Safety; US Department of Defense: Pentagon in Arlington, VA, USA, 2000.

| Submarine | Sub Type | Year | Incident Type | Cause | Fate | Fatalities | Injured | Ref |

|---|---|---|---|---|---|---|---|---|

| Daniil Moskovsky | Nuclear | 2006 | Fire | Electrical wiring fault | Significant Damage | 2 | 0 | [8] |

| USS Minneapolis Saint Paul | Nuclear | 2006 | Man overboard | Bad weather | Significant Damage | 2 | 2 | [9] |

| USS Newport News | Nuclear | 2007 | Collision | Navigation error | Damage | 0 | 0 | [10] |

| HMS Tireless | Nuclear | 2007 | Explosion | Emergency oxygen system fault | Significant Damage | 2 | 1 | [11] |

| HMS Superb | Nuclear | 2008 | Collision | Navigation error | Damage | 0 | 0 | [12] |

| Nerpa | Nuclear | 2008 | Toxic substance exposure | Accidental triggering of fire extinguishing system | Significant Damage | 20 | 21 | [13] |

| INS Sindhughosh | Conventional | 2008 | Collision | Navigation error | Damage | 0 | 0 | [14] |

| HMS Vanguard/Le Triomphant | Nuclear | 2009 | Collision | Navigation error | Damage | 0 | 0 | [15] |

| USS Hartford | Nuclear | 2009 | Collision | Navigation error | Damage | 0 | 0 | [16] |

| INS Sindhurakshak | Conventional | 2010 | Fire | Faulty battery valve, subsequent gas leak | Significant Damage | 1 | 2 | [17] |

| INS Shankush | Conventional | 2010 | Man overboard | Washed overboard during repair operation | Significant Damage | 1 | 0 | [18] |

| HMS Astute | Nuclear | 2010 | Collision | Navigation error | Damage | 0 | 0 | [19] |

| HMCS Corner Brook | Conventional | 2011 | Collision | Navigation error | Damage | 0 | 2 | [20] |

| Yekaterinburg | Nuclear | 2011 | Fire | Fire whilst alongside, caused during welding | Damage | 0 | 9 | [21] |

| HMS Astute | Nuclear | 2011 | Flood | Cooling pipe leakage | Damage | 0 | 0 | [22] |

| HMS Astute | Nuclear | 2011 | Murder | Crew member deliberately fired weapon | Significant Damage | 1 | 1 | [23] |

| USS Miami | Nuclear | 2012 | Fire | Deliberately lit | Decommissioned | 0 | 0 | [24] |

| USS Montpelier | Nuclear | 2012 | Collision | Navigation error | Damage | 0 | 0 | [25] |

| Collins Class (unknown) | Conventional | 2012 | Fire | Fuel leak | Damage | 0 | 0 | [26] |

| HMAS Farncomb | Conventional | 2012 | Flood | Weight compensation system, hose rupture | Damage | 0 | 0 | [27] |

| INS Sindhurakshak | Conventional | 2013 | Fire | Fire whilst alongside, cause unknown | Sunk | 18 | 0 | [28] |

| Tomsk | Nuclear | 2013 | Fire | Fire whilst alongside, caused during welding | Damage | 0 | 15 | [29] |

| USS Jacksonville | Nuclear | 2013 | Collision | Navigation error | Damage | 0 | 0 | [30] |

| INS Sindhuratna | Conventional | 2014 | Fire | Electrical wiring fault | Significant Damage | 2 | 7 | [31] |

| HMAS Waller | Conventional | 2014 | Fire | Unknown | Damage | 0 | 0 | [32] |

| INS Sindhughosh | Conventional | 2014 | Collision | Navigation error | Damage | 0 | 0 | [33] |

| HMS Talent | Nuclear | 2014 | Collision | Navigation error | Damage | 0 | 0 | [34] |

| SS Carrera | Conventional | 2014 | Collision | Navigation error | Damage | 0 | 0 | [35] |

| Orel | Nuclear | 2015 | Fire | Fire whilst alongside, caused during welding | Damage | 0 | 0 | [36] |

| Options | Soryu Class (Japan) | Barracuda Class—Conventional Variant (France) | Type 216 (Germany) |

|---|---|---|---|

| Diesel engines | √ | √ | √ |

| AIP | √ (4 Stirling engines) | √ (MESMA steam turbine) MESMA-Module Energie Sous-Marin Autonome | √ (Hydrogen fuel cell) |

| Lithium ion batteries | √ | √ * | √ |

| Failure | Effect | Consequence |

|---|---|---|

| Over-voltage | Lithium plating, increased Joule heating of the cell | Permanent capacity loss, short circuit, overheating |

| Under-voltage/Over-discharge | Electrode breakdown | Permanent capacity loss, short circuit, overheating |

| Low Temperature Operation | Lithium plating, reduced chemical reaction rate | Performance reduction, short circuit, overheating |

| High Temperature Operation | Increased chemical reaction rate, breakdown of SEI layer | Overheating |

| Mechanical Fatigue | Electrode cracking, increased internal impedance, breakdown of SEI layer | Overheating |

| Mechanical Impact | Dislocation of internal components | Functional failure, short circuit, overheating |

| Design/Manufacturing Defect | Component failure | Functional failure, short circuit, overheating |

| Component | Failure | Effect | Consequence |

|---|---|---|---|

| Hydrogen distribution | Failed valve, gasket, seal or flange | Reduced or loss of hydrogen supply to fuel cell, release of hydrogen gas | Loss of fuel cell power, build-up of hydrogen gas and ignition leading to explosion/fire, or jet flame stemming from leak leading to fire |

| LOX distribution | Failed valve, gasket, seal or flange | Reduced or loss of oxygen supply to fuel cell/reformer, release of liquid and gaseous oxygen, localised rapid cooling from cryogenic liquid | Loss of fuel cell power, embrittlement and possible failure of components exposed to cryogenic liquid, oxygen enriched atmosphere leading to ignition of surrounding materials and explosion/fire |

| Feedstock distribution | Failed valve, gasket, seal or flange | Reduced or loss of feedstock supply to reformer, release of hydrocarbon fuel in the form of a drip or spray | Loss of fuel cell power, spray of flammable liquid onto hot surface or accumulation of flammable liquid leading to ignition and fire |

| Reformer reactor | Failed pipe/channel | Reduced or loss of hydrogen supply to fuel cell, high or low pressure release of heated feedstock, steam and hydrogen | Loss of fuel cell power, spray or leakage of heated, flammable liquid-gas mixture leading to ignition and fire |

| Component | Failure | Effect | Consequence |

|---|---|---|---|

| LOX distribution | Failed valve, gasket, seal or flange | Reduced or loss of oxygen supply to combustion chamber, release of liquid and gaseous oxygen, localised rapid cooling from cryogenic liquid | Loss of MESMA power, embrittlement and possible failure of components exposed to cryogenic liquid, oxygen enriched atmosphere leading to ignition of surrounding materials and explosion/fire |

| Fuel (ethanol) distribution | Failed valve, gasket, seal or flange | Reduced or loss of fuel supply to combustion chamber, release of fuel in the form of a drip or spray | Loss of MESMA power, spray of flammable liquid onto hot surface or accumulation of flammable liquid leading to ignition and fire |

| Combustion chamber | Failed seal, overpressure | Reduced or loss of steam pressure to turbine, high or low pressure release of fuel, exhaust gases and or oxygen | Loss of MESMA power, spray or leakage of heated, flammable liquid-gas mixture leading to ignition and fire |

| Component | Failure | Effect | Consequence |

|---|---|---|---|

| LOX distribution | Failed valve, gasket, seal or flange | Reduced or loss of oxygen supply to combustion chamber, release of liquid and gaseous oxygen, localised rapid cooling from cryogenic liquid | Loss of Stirling engine power, embrittlement and possible failure of components exposed to cryogenic liquid, oxygen enriched atmosphere leading to ignition of surrounding materials and explosion/fire |

| Fuel (diesel) distribution | Failed valve, gasket, seal or flange | Reduced or loss of fuel supply to combustion chamber, release of fuel in the form of a drip or spray | Loss of Stirling engine power, spray of flammable liquid onto hot surface or accumulation of flammable liquid leading to ignition and fire |

| Combustion chamber | Failed seal, overpressure | Reduced or loss of heat transfer to working fluid, high or low pressure release of fuel, exhaust gases and or oxygen | Loss of Stirling engine power, spray or leakage of heated, flammable liquid-gas mixture leading to ignition and fire |

| Consequence | ||||

|---|---|---|---|---|

| Likelihood | Catastrophic | Critical | Major | Minor |

| Frequent | 1, 1, 1 | 3, 5, 7 | 7, 13, 19 | 13, 25, 37 |

| Probable | 2, 3, 4 | 5, 9, 13 | 9, 17, 25 | 16, 31, 46 |

| Occasional | 4, 7, 10 | 6, 11, 16 | 11, 21, 31 | 18, 35, 52 |

| Remote | 8, 15, 22 | 10, 19, 28 | 14, 27, 40 | 19, 37, 55 |

| Improbable | 12, 23, 34 | 15, 29, 43 | 17, 33, 49 | 20, 39, 58 |

| Likelihood Category | Definition | Consequence Category | Definition |

|---|---|---|---|

| Frequent | Likely to occur often in the life of an item | Catastrophic | Failure which could result in death, permanent total disability and or total mission failure |

| Probable | Will occur several times in the life of an item | Critical | Failure which could result in permanent partial disability and or failure to achieve significant mission requirements |

| Occasional | Likely to occur sometime in the life of an item | Major | Failure which could result in temporary partial disability and or conduct of mission in a degraded state |

| Remote | Unlikely but possible to occur in the life of an item | Minor | Failure which could minor injury and or minor capability degradation |

| Improbable | So unlikely, it can be assumed occurrence may not be experienced |

| Weighting Factor | Definition | ||

|---|---|---|---|

| Base | Sensitivity 1 | Sensitivity 2 | |

| 1.0 | 1.0 | 1.0 | Proven service history in large conventional submarines. |

| 0.8 | 0.85 | 0.9 | Proven service history in medium sized conventional submarines. Extensive development and testing for large conventional submarines, but no service history. |

| 0.6 | 0.7 | 0.8 | Proven service history in other industries and applications other than submarines. Extensive development and testing for submarines, but no service history. |

| 0.4 | 0.55 | 0.7 | Service history in other industries and applications other than submarines. Some testing and development for submarine applications. |

| 0.2 | 0.4 | 0.6 | No proven history or extensive development, considered to be an experimental technology. |

| Technology | Risk Description | Consequence | Consequence Description | Likelihood | Likelihood Description | MRA | Technology Maturity Weighting | Technology Maturity Description | Maturity AdjustedMRA |

|---|---|---|---|---|---|---|---|---|---|

| Lithium-ion Battery | There is a risk of cell failure resulting in thermal runaway of an individual cell, leading to cascading thermal runaway of a battery bank and severe fire. This is likely to occur at depth whilst discharging or charging batteries (via AIP) or when charging batteries whilst snorting at periscope depth. | Catastrophic | A severe fire in the main battery compartment could lead to multiple system failure including loss of propulsion, multiple fatalities, incapacitation of crew and possibly loss of the submarine. Given the likely spread of heat and smoke through the submarine, response to the fire would likely require surfacing which, depending on the location of the submarine at the time, could lead to detection and total mission failure. | Probable | Although dependent on design, there is likely to be several thousand Lithium-ion cells in each submarine. Given 6–12 submarines over the course of 30 years, the number of cells and the typical occurrence rate of manufacturing faults, it is likely more than one of these cells will experience thermal runaway at some time. | 2 | 0.4 | Lithium-ion batteries have no service history in conventional submarines, large or small. They have service history in other industries, however continue to encounter fire safety issues in the aero and auto industries. There is publicly reported development and testing of this technology for submarines, although this does not appear to be extensive. | 0.8 |

| PEMFC with Reformer | There is a risk of containment loss of the feedstock, hydrogen or oxygen leading to ignition of fluid and severe fire. This is likely to occur at depth whilst AIP is being used to recharge batteries or directly power submarine propulsion and hotel load. | Catastrophic | A severe fire in the AIP compartment could lead to multiple fatalities, incapacitation of crew, possible explosion if LOX and fuel storage is breached and loss of the submarine. If unable to be isolated, response to the fire would likely require surfacing, leading to detection and mission failure. | Occasional | The components most likely to cause loss of fluid containment are flanges, gaskets and flexible hoses. A high level of standardisation and maintenance is associated with these components, and leakages are generally detectable before escalation into a fire. Occurrence for an individual submarine is unlikely, however over the course of 30 years, it is likely at least one submarine will experience such an incident. | 4 | 0.7 | A compound weighting has been given as follows: PEMFC-0.8- PEMFCs have over 10 years of proven service history on a number of small to medium sized conventional submarines, but no service history on large conventional submarines. Reformer-0.6-Steam reformers have a proven service history in other industries whilst a number of submarine designers have undertaken full scale land-based testing in conjunction with PEMFCs. Reformers currently have no service history on submarines, however. | 2.8 |

| MESMA | There is a risk of containment loss of ethanol or LOX leading to ignition of fluid and severe fire. This is likely to occur at depth whilst AIP is being used to recharge batteries or directly power submarine propulsion and hotel load. | Catastrophic | Occasional | 4 | 0.8 | MESMA has nearly 10 years of proven service history in medium sized conventional submarines, but currently has no proven service history in large conventional submarines. | 3.2 | ||

| Stirling Engine | There is a risk of containment loss of diesel fuel or LOX leading to ignition of fluid and severe fire. This is likely to occur at depth whilst AIP is being used to recharge batteries or directly power submarine propulsion and hotel load. | Catastrophic | Occasional | 4 | 1.0 | The Stirling engine has over 25 years of proven service history on medium sized conventional submarines and over 5 years of proven service on large conventional submarines. | 4 |

| Scoring | Adjusted MRA Values = MRA × TMW | ||||

|---|---|---|---|---|---|

| MRA | Technology Maturity Weightage (TMW) | Lithium-Ion Battery | PEMFC with Reformer | MESMA | Stirling Engine |

| Risk Rating Base | TMW Base | 2 × 0.4 = 0.8 | 4 × 0.7 = 2.8 | 4 × 0.8 = 3.2 | 4 × 1 = 4 |

| TMW Sensitivity 1 | 2 × 0.55 = 1.1 | 4 × 0.78 = 3.1 | 4 × 0.85 = 3.4 | 4 × 1 = 4 | |

| TMW Sensitivity 2 | 2 × 0.7 = 1.4 | 4 × 0.85 = 3.4 | 4 × 0.9 = 3.6 | 4 × 1 = 4 | |

| Risk Rating Sensitivity 1 | TMW Base | 3 × 0.4 = 1.2 | 7 × 0.7 = 4.9 | 7 × 0.8 = 5.6 | 7 × 1 = 7 |

| TMW Sensitivity 1 | 3 × 0.55 = 1.65 | 7 × 0.78 = 5.43 | 7 × 0.85 = 5.95 | 7 × 1 = 7 | |

| TMW Sensitivity 2 | 3 × 0.7 = 2.1 | 7 × 0.85 = 5.95 | 7 × 0.9 = 6.3 | 7 × 1 = 7 | |

| Risk Rating Sensitivity 2 | TMW Base | 4 × 0.4 = 1.6 | 10 × 0.7 = 7.0 | 10 × 0.8 = 8.0 | 10 × 1 = 10 |

| TMW Sensitivity 1 | 4 × 0.55 = 2.2 | 10 × 0.78 = 7.8 | 10 × 0.85 = 8.5 | 10 × 1 = 10 | |

| TMW Sensitivity 2 | 4 × 0.7 = 2.8 | 10 × 0.85 = 8.5 | 10 × 0.9 = 9.0 | 10 × 1 = 10 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Depetro, A.; Gamble, G.; Moinuddin, K. Fire Safety Risk Analysis of Conventional Submarines. Appl. Sci. 2021, 11, 2631. https://doi.org/10.3390/app11062631

Depetro A, Gamble G, Moinuddin K. Fire Safety Risk Analysis of Conventional Submarines. Applied Sciences. 2021; 11(6):2631. https://doi.org/10.3390/app11062631

Chicago/Turabian StyleDepetro, Aidan, Grant Gamble, and Khalid Moinuddin. 2021. "Fire Safety Risk Analysis of Conventional Submarines" Applied Sciences 11, no. 6: 2631. https://doi.org/10.3390/app11062631

APA StyleDepetro, A., Gamble, G., & Moinuddin, K. (2021). Fire Safety Risk Analysis of Conventional Submarines. Applied Sciences, 11(6), 2631. https://doi.org/10.3390/app11062631