Compressive Behavior of Pieces of Wood Reinforced with Fabrics Composed of Carbon Fiber and Basalt Fiber

Abstract

1. Introduction

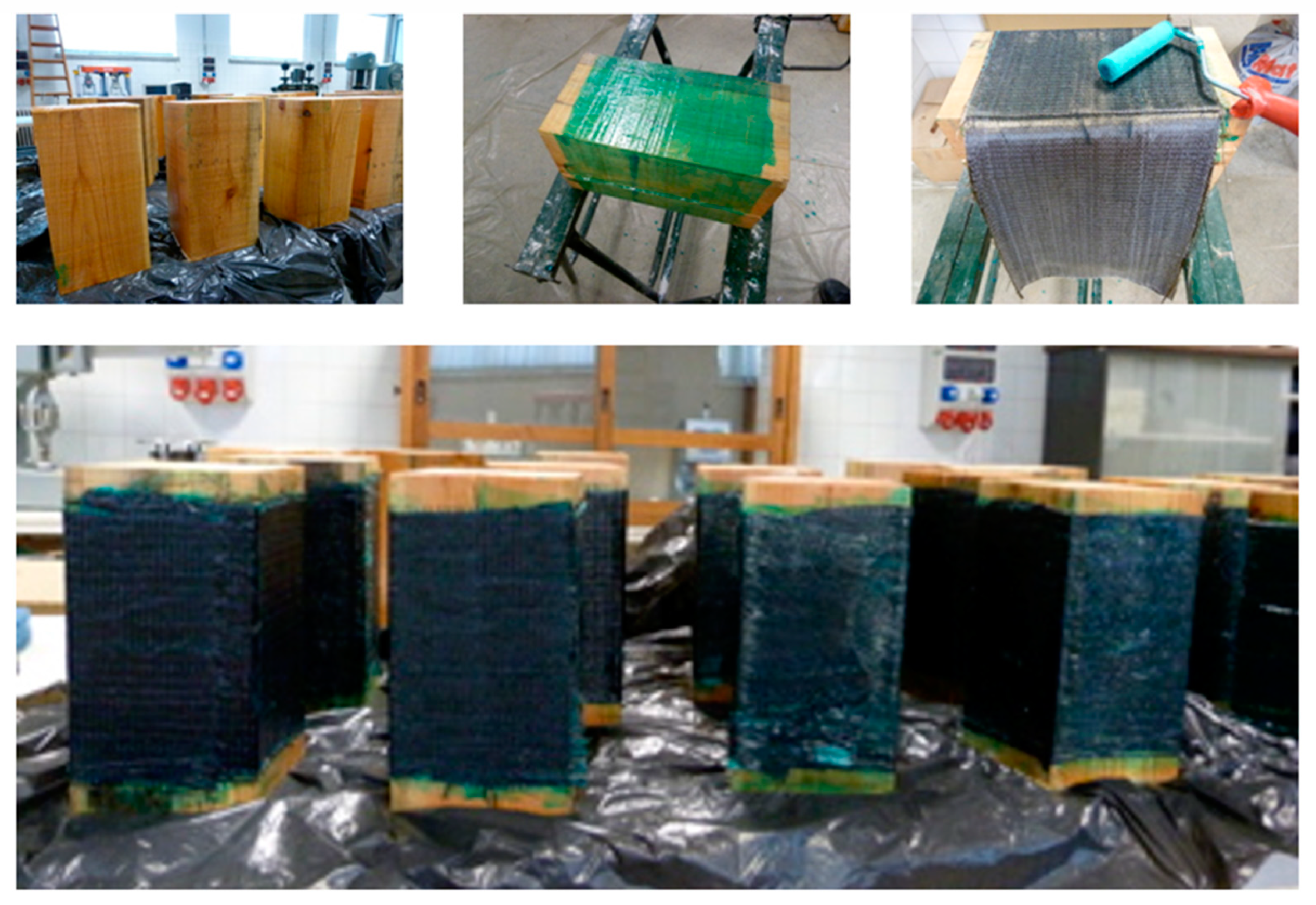

2. Experimental Procedure

3. Results and Discussion

3.1. Visual Classification and Density

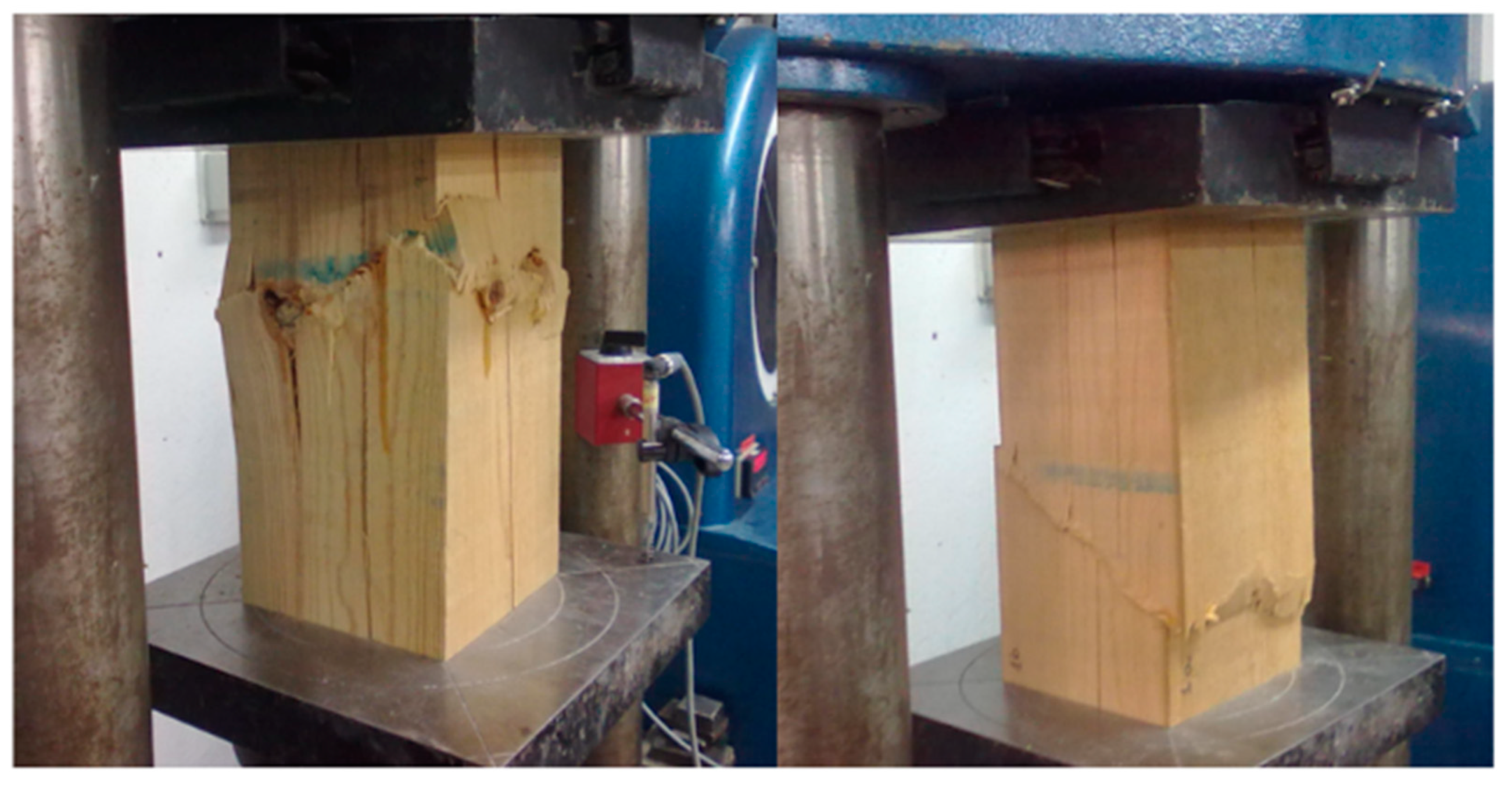

3.2. Compression Tests

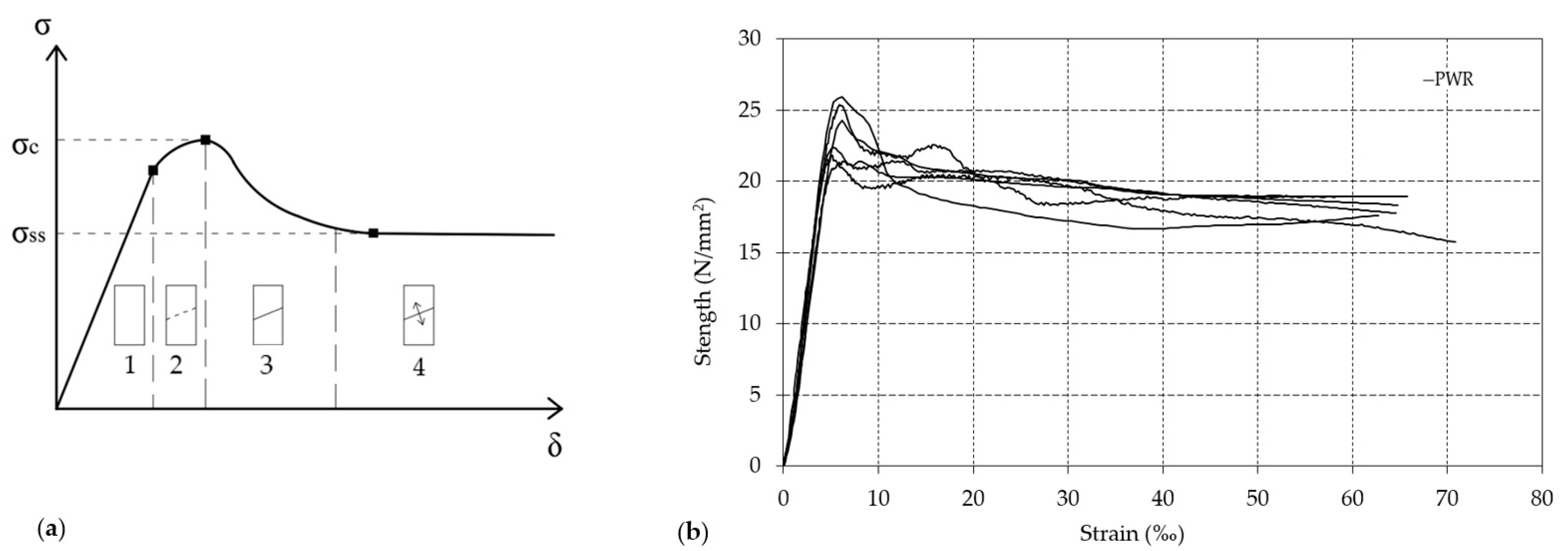

3.2.1. Unreinforced Pieces

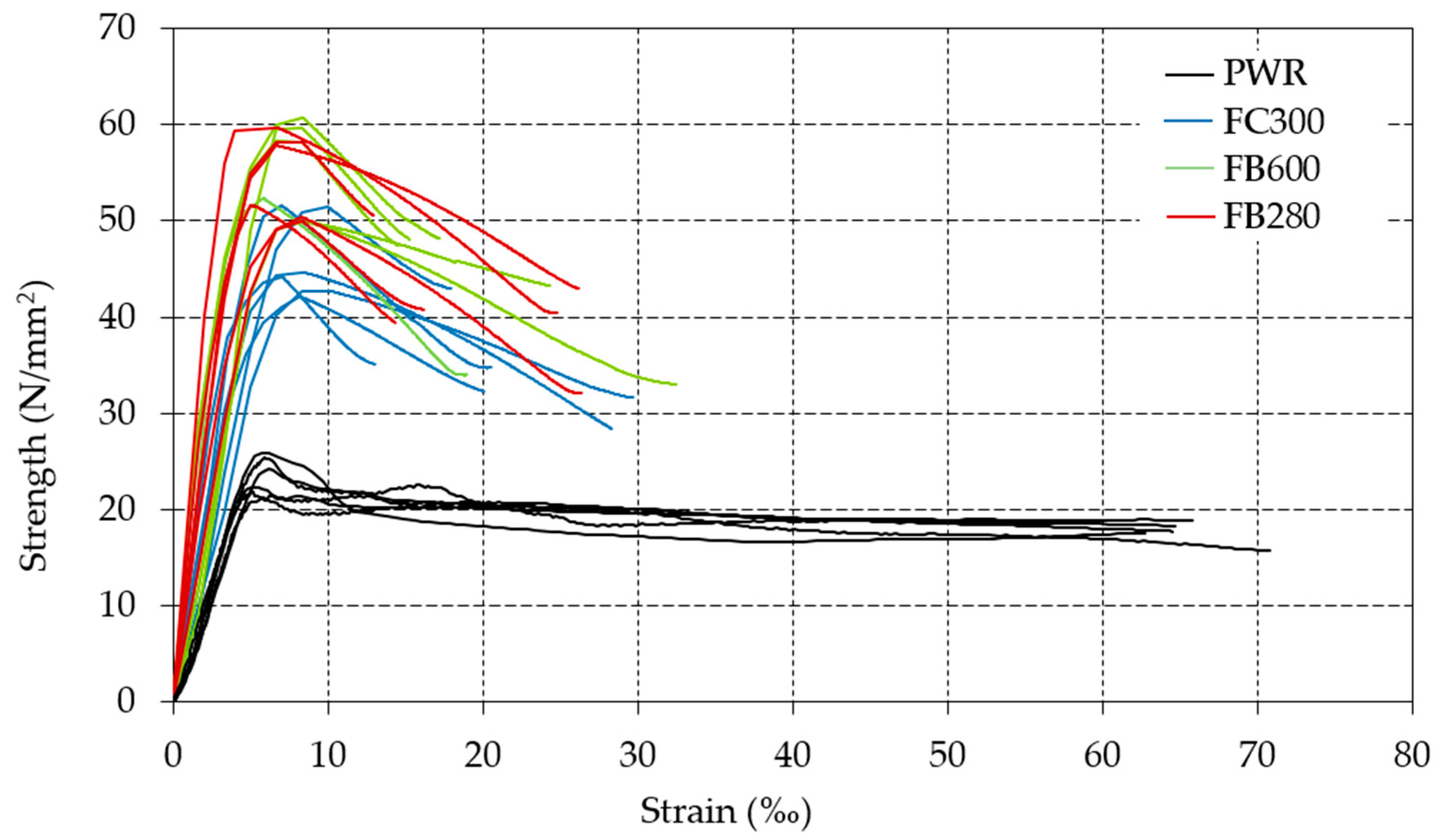

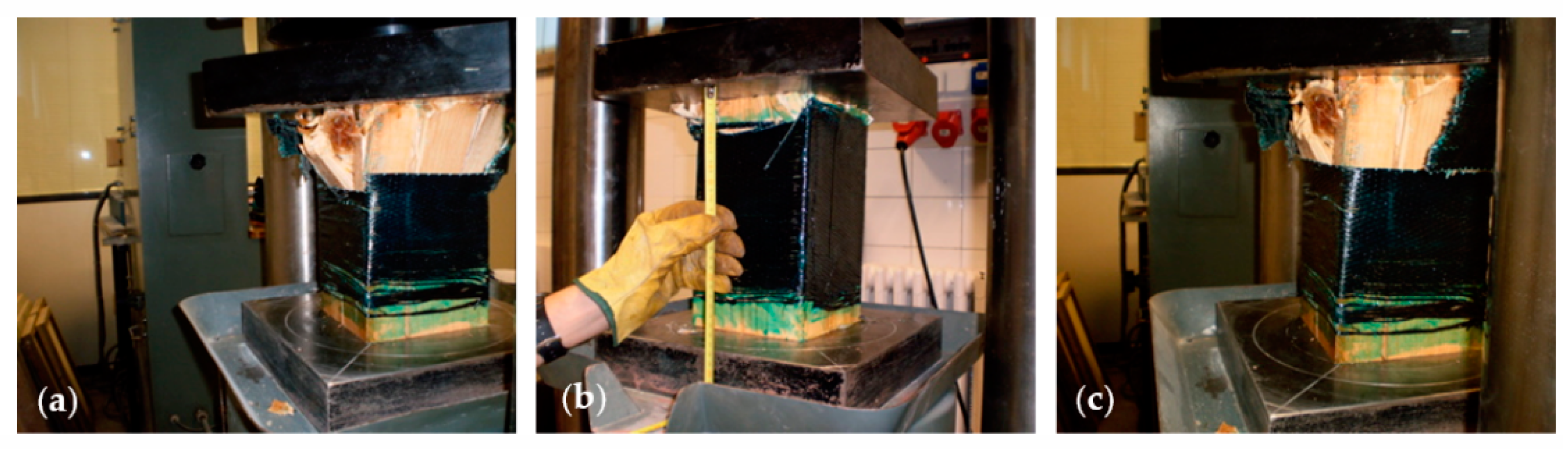

3.2.2. Reinforced Pieces

3.2.3. Comparison between Reinforced and Unreinforced Pieces

4. Conclusions

- The appearance of the strength–strain graph for all of the reinforced pieces is very similar, despite the huge difference between the three types of reinforcement;

- There are highly significant differences between the reinforced and unreinforced pieces, both in terms of the shape of the graphs and the values attained;

- All of the reinforced pieces exhibit a significant decrease in breaking strain, compared to the unreinforced pieces. Although the modulus of elasticity and the maximum strengths increases, the density of deformation energy of the reinforced pieces decreases;

- There is no relationship between the mechanical capacity of the reinforcement and the ultimate strength of the test piece tested;

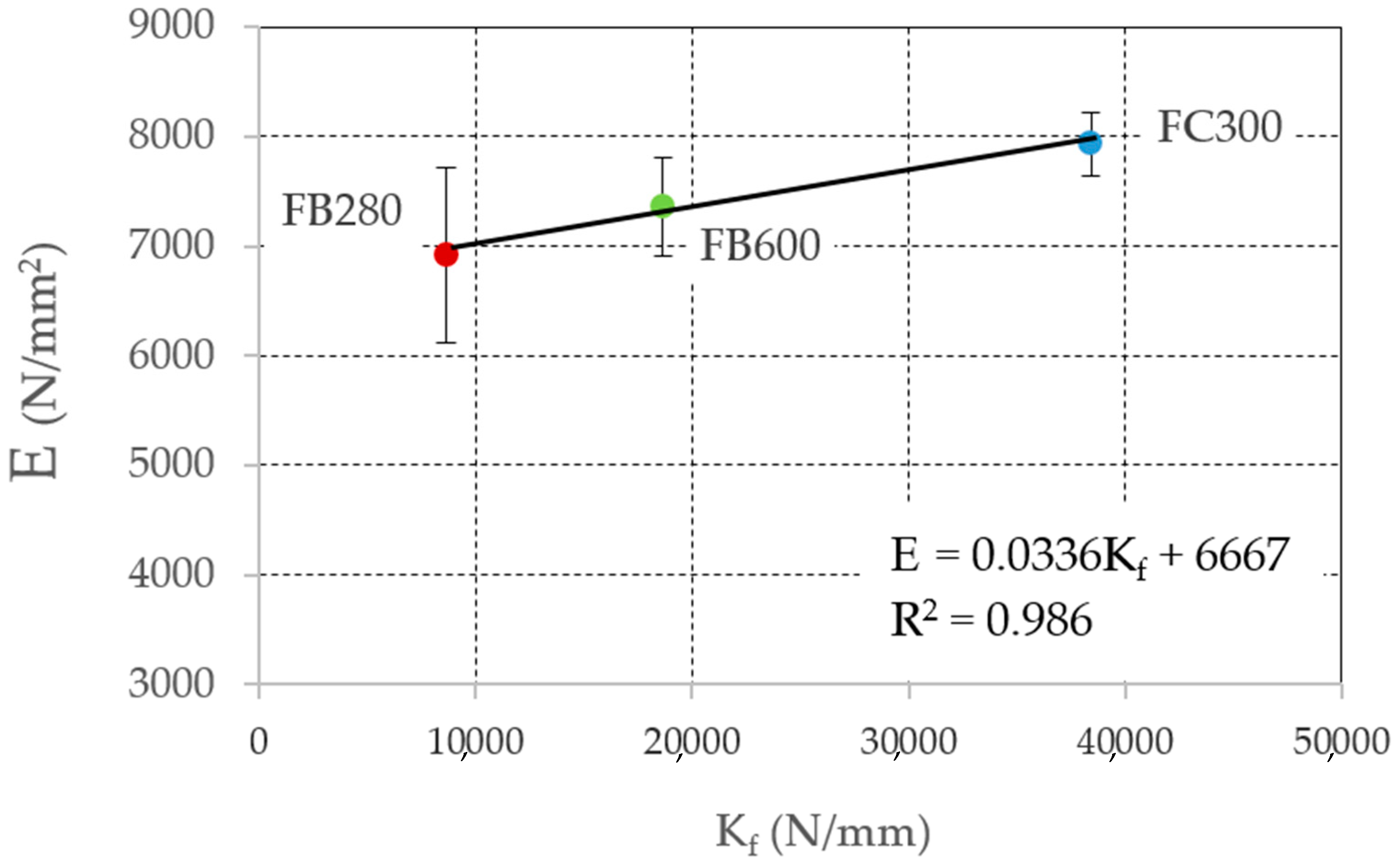

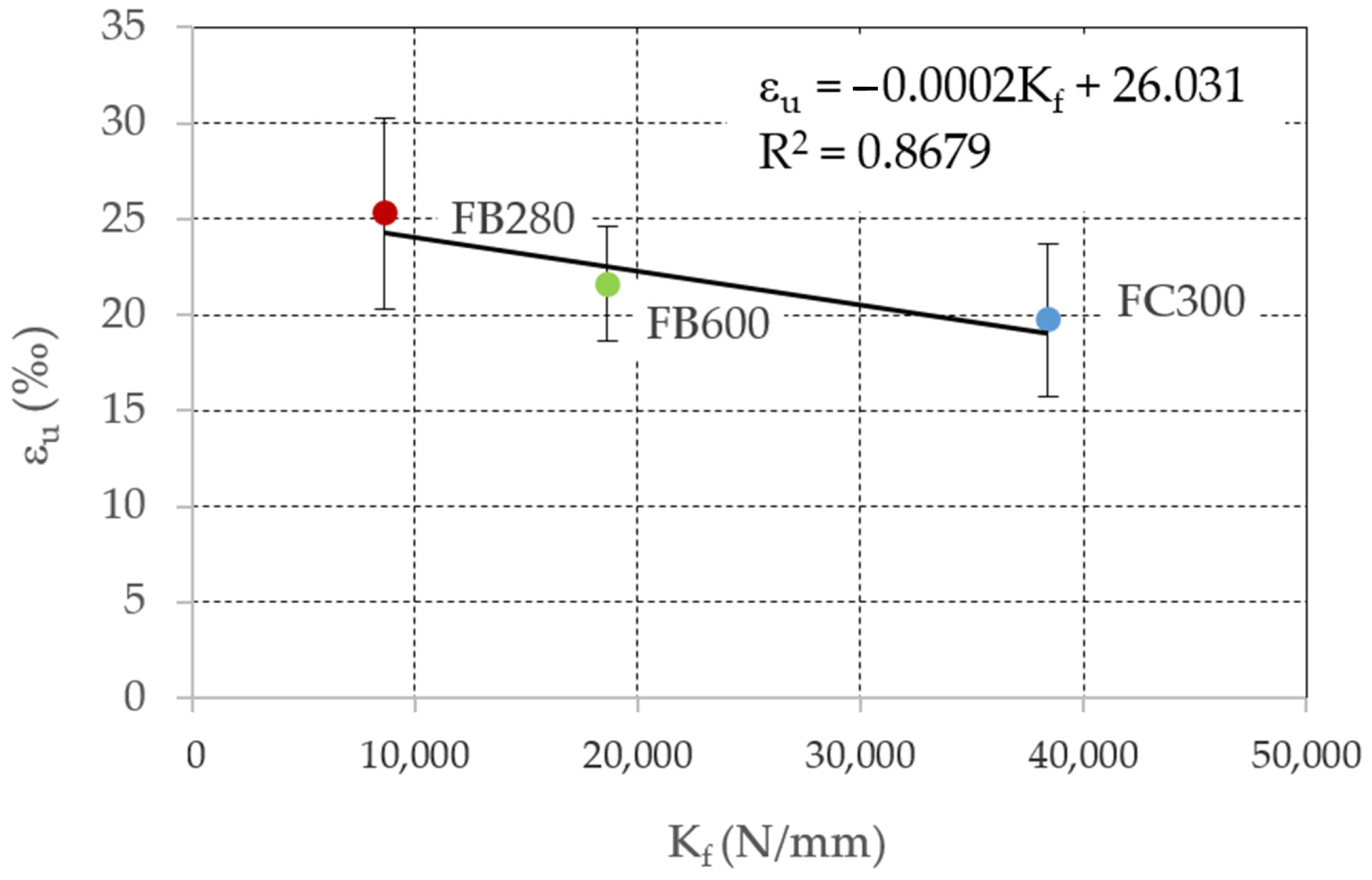

- There is a strong relationship between the rigidity of the reinforcement and modulus of elasticity and the ultimate strain of the reinforced test piece. The greater the rigidity of the reinforcement, the greater the modulus of elasticity and the lower the ultimate strain;

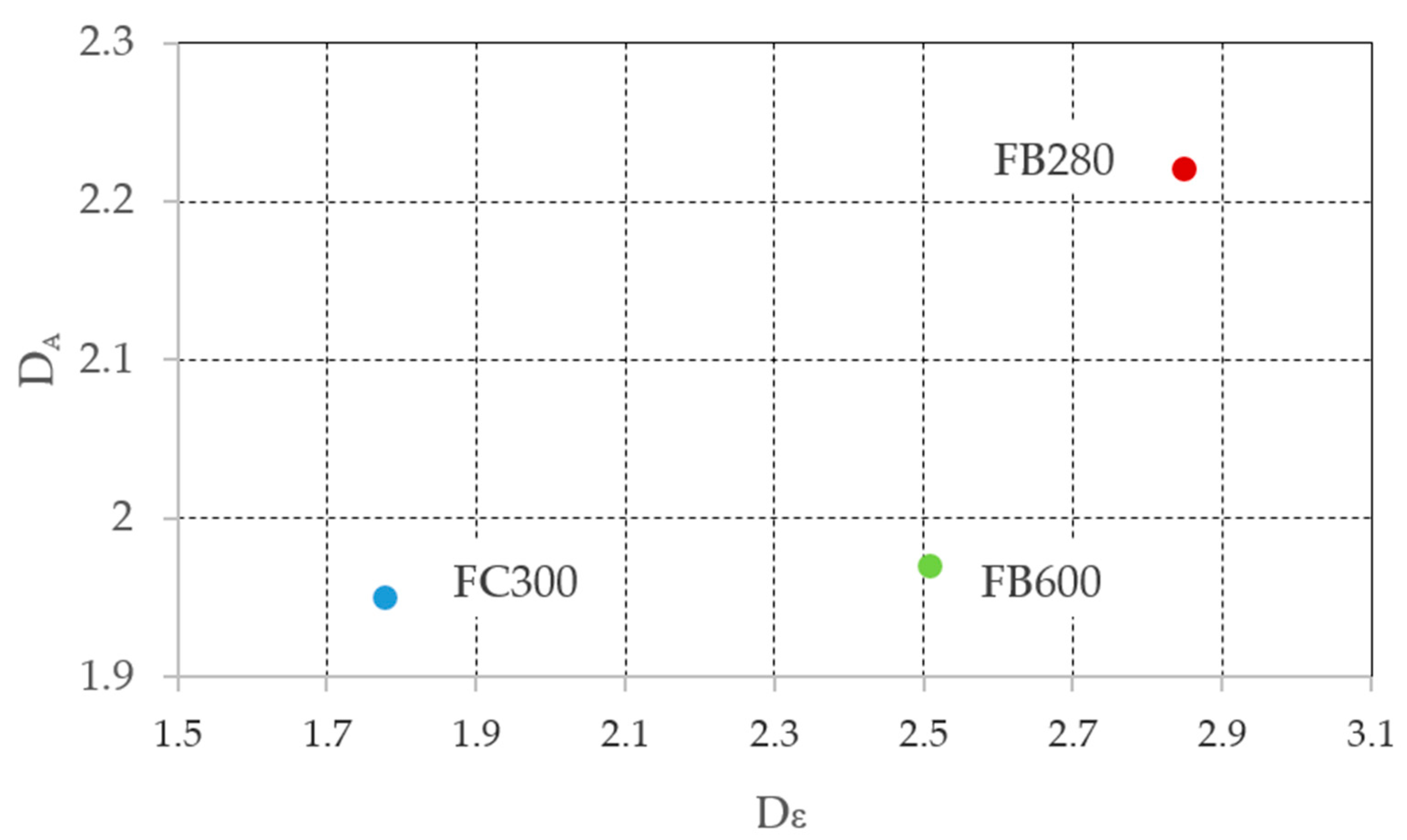

- There is not a strong relationship between the ductilities measured using terms of deformation and strain energy density;

- As a final conclusion, it can be indicated that the three types of reinforcement have very similar strength–strain diagrams in the pieces tested, with important increases in maximum strength and a very significant decrease in ultimate strain. This means that in projects of wooden structures reinforced by these procedures, it is necessary to take into account the decrease in ductility that occurs in the reinforced elements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Walberg, D. Solid and timber construction in residential buildings/Massiv-und Holzbau bei Wohngebäuden. Mauerwerk 2016, 20, 16–31. [Google Scholar] [CrossRef]

- Conners, T.E. Segmented models for stress-strain diagrams. Wood Sci. Technol. 1989, 23, 65–73. [Google Scholar] [CrossRef]

- Handbook, W. Edition Wood Handbook-Wood as an Engineering Material; General Technical Report FPL-GTR-190; US Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010. [Google Scholar]

- Cabrero, J.M.; Heiduschke, A.; Haller, P. Analytical assessment of the load-carrying capacity of axially loaded wooden reinforced tubes. Compos. Struct. 2010, 92, 2955–2965. [Google Scholar] [CrossRef]

- Buchanan, A.H. Bending Strength of Lumber. J. Struct. Eng. 1990, 116, 1213–1229. [Google Scholar] [CrossRef]

- Benabou, L. Predictions of compressive strength and kink band orientation for wood species. Mech. Mater. 2010, 42, 335–343. [Google Scholar] [CrossRef]

- Zhang, W.; Song, X.; Gu, X.; Tang, H. Compressive Behavior of Longitudinally Cracked Timber Columns Retrofitted Using FRP Sheets. J. Struct. Eng. 2012, 138, 90–98. [Google Scholar] [CrossRef]

- Custódio, J.; Broughton, J.; Cruz, H. A review of factors influencing the durability of structural bonded timber joints. Int. J. Adhes. Adhes. 2009, 29, 173–185. [Google Scholar] [CrossRef]

- Beckmann, P.; Bowles, R. Structural Aspects of Building Conservation; Routledge: London, UK, 2012. [Google Scholar] [CrossRef]

- Li, Y.-F.; Xie, Y.-M.; Tsai, M.-J. Enhancement of the flexural performance of retrofitted wood beams using CFRP composite sheets. Constr. Build. Mater. 2009, 23, 411–422. [Google Scholar] [CrossRef]

- Dehn, F.; Gebhardt, M.; Pollnow, E. Rehabilitation and strengthening of foundation components. Bautechnik 2008, 85, 120–132. [Google Scholar] [CrossRef]

- Johns, K.C.; Lacroix, S. Composite reinforcement of timber in bending. Can. J. Civ. Eng. 2000, 27, 899–906. [Google Scholar] [CrossRef]

- Plevris, N.; Triantafillou, T.C. FRP-Reinforced Wood as Structural Material. J. Mater. Civ. Eng. 1992, 4, 300–317. [Google Scholar] [CrossRef]

- Triantafillou, T.C.; Deskovic, N. Prestressed FRP Sheets as External Reinforcement of Wood Members. J. Struct. Eng. 1992, 118, 1270–1284. [Google Scholar] [CrossRef]

- Bank, L.C. Composites for Construction: Structural Design with FRP Materials; Wiley: Hoboken, NJ, USA, 2006; ISBN 978-0-471-68126-7. [Google Scholar]

- Machida, A. State-of-the-art report on continuous fiber reinforcing materials. In Second Research Committee on CFRM, Japan Society of Civil Engineers: Concrete Engineering Series; Japan Society of Civil Engineers: Tokyo, Japan, 1993. [Google Scholar]

- Pendhari, S.S.; Kant, T.; Desai, Y.M. Application of polymer composites in civil construction: A general review. Compos. Struct. 2008, 84, 114–124. [Google Scholar] [CrossRef]

- Neale, K.W. Advanced Composite Materials in Bridges and Structures: 1st International Conference, Sheerbrooke, Québec, Canada, 1992; Canadian Society for Civil Engineering: Montreal, QC, Canada, 1992. [Google Scholar]

- Nanni, A.; Di Tommaso, A.; Cheng, J.; Arduini, M. International Research on Advanced Composites in Construction (IRACC-96); Final Report to US National Science Foundation; National Science Foundation: Alexandria, VA, USA, 1996.

- Lopresto, V.; Leone, C.; De Iorio, I. Mechanical characterisation of basalt fibre reinforced plastic. Compos. Part B Eng. 2011, 42, 717–723. [Google Scholar] [CrossRef]

- Wang, X.; Wu, Z.; Wu, G.; Zhu, H.; Zen, F. Enhancement of basalt FRP by hybridization for long-span cable-stayed bridge. Compos. Part B Eng. 2013, 44, 184–192. [Google Scholar] [CrossRef]

- Larrinaga, P.; Chastre, C.; Biscaia, H.C.; San-José, J.T. Experimental and numerical modeling of basalt textile reinforced mortar behavior under uniaxial tensile stress. Mater. Des. 2014, 55, 66–74. [Google Scholar] [CrossRef]

- Alam, P.; Ansell, M.P.; Smedley, D. Mechanical repair of timber beams fractured in flexure using bonded-in reinforcements. Compos. Part B Eng. 2009, 40, 95–106. [Google Scholar] [CrossRef]

- Ogawa, H. Architectural application of carbon fibers. Carbon 2000, 38, 211–226. [Google Scholar] [CrossRef]

- Ahmad, S.; Shah, A.; Nawaz, A.; Salimullah, K. Refuerzo a cortante de ménsulas con polímeros reforzados con fibra de car-bono (CFRP). Mater. Constr. 2010, 299, 79–97. [Google Scholar] [CrossRef]

- Parra, C.; Martínez-Conesa, E.; Valcuende, M.; Garrido, A. Análisis de métodos para evaluar el refuerzo a esfuerzo cortante con CFRP en vigas de hormigón armado. Inf. Constr. 2012, 64, 197–206. [Google Scholar] [CrossRef]

- Subagia, I.A.; Kim, Y.; Tijing, L.D.; Kim, C.S.; Shon, H.K. Effect of stacking sequence on the flexural properties of hybrid composites reinforced with carbon and basalt fibers. Compos. Part B Eng. 2014, 58, 251–258. [Google Scholar] [CrossRef]

- Karbhari, V.M.; Chin, J.W.; Hunston, D.; Benmokrane, B.; Juska, T.; Morgan, R.; Lesko, J.J.; Sorathia, U.; Reynaud, D. Durability Gap Analysis for Fiber-Reinforced Polymer Composites in Civil Infrastructure. J. Compos. Constr. 2003, 7, 238–247. [Google Scholar] [CrossRef]

- Zhou, J.; Lucas, J.P. Hygrothermal effects of epoxy resin. Part II: Variations of glass transition temperature. Polymers 1999, 40, 5513–5522. [Google Scholar] [CrossRef]

- DT202, C. Guidelines for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Structures; National Research Council, Advisory Committee on Technical Regulations for Constructions: Rome, Italy, 2005. [Google Scholar]

- FIB. FRP reinforcement in RC structures. In Desing and Use of Fibre Reinforced Polymer Reinforcement (FRP) in Reinforced Con-Crete Structures; FIB bulletin Nº. 40 September 2007; International Federation for Structural Concrete: Lausanne, Switzerland, 2007; ISBN 978-2-88394-080-2. [Google Scholar]

- Li, Y.-F.; Tsai, M.-J.; Wei, T.-F.; Wang, W.-C. A study on wood beams strengthened by FRP composite materials. Constr. Build. Mater. 2014, 62, 118–125. [Google Scholar] [CrossRef]

- Rescalvo, F.J.; Valverde-Palacios, I.; Suarez, E.; Gallego, A. Experimental and analytical analysis for bending load capacity of old timber beams with defects when reinforced with carbon fiber strips. Compos. Struct. 2018, 186, 29–38. [Google Scholar] [CrossRef]

- Gómez, E.; Cobo, A.; González, M. Reinforcement and repair of small sawn Pinus Sylvestris beams with carbon fiber. Compos. Part B Eng. 2016, 101, 147–154. [Google Scholar] [CrossRef]

- de la Rosa, P.; Cobo, A.; González, M. Analysis of the flexural stiffness of timber beams reinforced with carbon and basalt composite materials. Compos. Part B Eng. 2016, 86, 152–159. [Google Scholar] [CrossRef]

- de la Rosa, P.; Cobo, A.; González, M. Bending reinforcement of timber beams with composite carbon fiber and basalt fiber materials. Compos. Part B Eng. 2013, 55, 528–536. [Google Scholar] [CrossRef]

- Gómez, E.; González, M.; Hosokawa, K.; Cobo, A. Experimental study of the flexural behavior of timber beams reinforced with different kinds of FRP and metallic fibers. Compos. Struct. 2019, 213, 308–316. [Google Scholar] [CrossRef]

- Turgay, T.; Polat, Z.; Koksal, H.; Doran, B.; Karakoç, C. Compressive behavior of large-scale square reinforced concrete columns confined with carbon fiber reinforced polymer jackets. Mater. Des. 2010, 31, 357–364. [Google Scholar] [CrossRef]

- Feng, P.; Cheng, S.; Bai, Y.; Ye, L. Mechanical behavior of concrete-filled square steel tube with FRP-confined concrete core subjected to axial compression. Compos. Struct. 2015, 123, 312–324. [Google Scholar] [CrossRef]

- Toutanji, H. Stress-Strain Characteristics of Concrete Columns Externally Confined with Advanced Fiber Composite Sheets. ACI Mater. J. 1999, 96, 397–404. [Google Scholar] [CrossRef]

- Nanni, A.; Norris, M.; Bradford, N. Lateral confinement of concrete using FRP reinforcement. Spec. Publ. 1993, 138, 193–210. [Google Scholar]

- Hooton, R.; Larralde, J. Compressive Strength of Small Concrete Specimens Confined with Fiberglass Laminates. Cem. Concr. Aggreg. 1997, 19, 17. [Google Scholar] [CrossRef]

- Saafi, M.; Toutanji, H.; Li, Z. Behavior of Concrete Columns Confined with Fiber Reinforced Polymer Tubes. ACI Mater. J. 1999, 96, 500–509. [Google Scholar] [CrossRef]

- Csuka, B.; Kollár, L.P. Analysis of FRP confined columns under eccentric loading. Compos. Struct. 2012, 94, 1106–1116. [Google Scholar] [CrossRef]

- Aire, C.; Gettu, R.; Casas, J.R.; Marques, S.; Marqués, D. Estudio experimental y modelo teórico del hormigón confinado lateralmente con polímeros reforzados con fibras (FRP). Mater. Constr. 2010, 60, 19–31. [Google Scholar] [CrossRef]

- De Diego, A.; Arteaga, A.; Fernández, J.; Perera, R.; Cisneros, D. Behaviour of FRP confined concrete in square columns. Mater. Constr. 2015, 65, 069. [Google Scholar] [CrossRef]

- El Maaddawy, T. Strengthening of Eccentrically Loaded Reinforced Concrete Columns with Fiber-Reinforced Polymer Wrapping System: Experimental Investigation and Analytical Modeling. J. Compos. Constr. 2009, 13, 13–24. [Google Scholar] [CrossRef]

- Daugevičius, M.; Valivonis, J.; Beinaravičius, A.; Skuturna, T.; Budvytis, M. Experimental Investigation of the Load Carrying Capacity of Eccentrically Loaded Reinforced Concrete Elements Strengthened with CFRP. Procedia Eng. 2013, 57, 232–237. [Google Scholar] [CrossRef]

- Harmon, T.G.; Ramakrishnan, S.; Wang, E.H. Confined Concrete Subjected to Uniaxial Monotonic Loading. J. Eng. Mech. 1998, 124, 1303–1309. [Google Scholar] [CrossRef]

- Li, Q.; Ansari, F. High-Strength Concrete in Triaxial Compression by Different Sizes of Specimens. ACI Mater. J. 2000, 97, 684–689. [Google Scholar] [CrossRef]

- Xie, J.; Elwi, A.; MacGregor, J. Mechanical Properties of Three High-Strength Concretes Containing Silica Fume. ACI Mater. J. 1995, 92, 135–145. [Google Scholar] [CrossRef]

- Almusallam, T.H. Behavior of normal and high-strength concrete cylinders confined with E-glass/epoxy composite laminates. Compos. Part B Eng. 2007, 38, 629–639. [Google Scholar] [CrossRef]

- Micelli, F.; Modarelli, R. Experimental and analytical study on properties affecting the behaviour of FRP-confined concrete. Compos. Part B Eng. 2013, 45, 1420–1431. [Google Scholar] [CrossRef]

- Vincent, T.; Ozbakkaloglu, T. Influence of concrete strength and confinement method on axial compressive behavior of FRP confined high- and ultra high-strength concrete. Compos. Part B Eng. 2013, 50, 413–428. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J. Stress–strain model for FRP-confined concrete under cyclic axial compression. Eng. Struct. 2009, 31, 308–321. [Google Scholar] [CrossRef]

- Abbasnia, R.; Ziaadiny, H. Behavior of concrete prisms confined with FRP composites under axial cyclic compression. Eng. Struct. 2010, 32, 648–655. [Google Scholar] [CrossRef]

- Abbasnia, R.; Hosseinpour, F.; Rostamian, M.; Ziaadiny, H. Cyclic and monotonic behavior of FRP confined concrete rectangular prisms with different aspect ratios. Constr. Build. Mater. 2013, 40, 118–125. [Google Scholar] [CrossRef]

- Faustino, P.; Frade, P.; Chastre, C. Lateral Cyclic Behaviour of RC Columns Confined With Carbon Fibres. Structures 2016, 5, 196–206. [Google Scholar] [CrossRef]

- Bouchelaghem, H.; Bezazi, A.; Scarpa, F. Compressive behaviour of concrete cylindrical FRP-confined columns subjected to a new sequential loading technique. Compos. Part B Eng. 2011, 42, 1987–1993. [Google Scholar] [CrossRef]

- Li, P.; Wu, Y.-F. Stress–strain model of FRP confined concrete under cyclic loading. Compos. Struct. 2015, 134, 60–71. [Google Scholar] [CrossRef]

- Fernández-Cánovas, M.; González-García, M.N.; Piñero, J.Á.; Cobo, A. Compressive strength behaviour of low- and medium-strength concrete specimens confined with carbon fibres in defective implementation conditions: An experimental study. Mater. Constr. 2016, 66, 103. [Google Scholar] [CrossRef][Green Version]

- André, A.; Kliger, R.; Olsson, R. Compression failure mechanism in small-scale wood specimens reinforced with CFRP: An experimental study. Constr. Build. Mater. 2013, 41, 790–800. [Google Scholar] [CrossRef]

- Gezer, H.; Aydemir, B. The effect of the wrapped carbon fiber reinforced polymer material on fir and pine woods. Mater. Des. 2010, 31, 3564–3567. [Google Scholar] [CrossRef]

- Najm, H.; Secaras, J.; Balaguru, P. Compression Tests of Circular Timber Column Confined with Carbon Fibers Using Inorganic Matrix. J. Mater. Civ. Eng. 2007, 19, 198–204. [Google Scholar] [CrossRef]

- Kim, K.-H.E.; Andrawes, B. Compression behavior of FRP strengthened bridge timber piles subjected to accelerated aging. Constr. Build. Mater. 2016, 124, 177–185. [Google Scholar] [CrossRef]

- Wang, L.; Liu, W.; Hui, D. Compression strength of hollow sandwich columns with GFRP skins and a paulownia wood core. Compos. Part B Eng. 2014, 60, 495–506. [Google Scholar] [CrossRef]

- Asociación Española de Normalización. Visual Grading for Structural Sawn Timber. Coniferous Timber (UNE 56544). 2011. Available online: https://www.aenor.com/normas-y-libros/buscador-de-normas/une/?c=N0048310 (accessed on 14 December 2020).

- Asociación Española de Normalización. Structural Timber—Strength Classes—Assignment of Visual Grades and Species (UNE-EN 1912). 2012. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0049485 (accessed on 10 December 2020).

- Asociación Española de Normalización. Structural Timber—Strength Classes (UNE-EN 338). 2016. Available online: https://www.aenor.com/normas-y-libros/buscador-de-normas/une/c=N0057443 (accessed on 7 January 2021).

- Argon, A. Fracture of Composites. Treatise Mater. Sci. Technol. 1972, 1, 79–114. [Google Scholar] [CrossRef]

- Budiansky, B. Micromechanics. Comput. Struct. 1983, 16, 3–12. [Google Scholar] [CrossRef]

- André, A.; Kliger, R.; Asp, L. Compression failure mechanism in small scale timber specimens. Constr. Build. Mater. 2014, 50, 130–139. [Google Scholar] [CrossRef]

- Esteban, M.; Arriaga, F.; Íñiguez, G.; Bobadilla, I.; Mateo, R.; Iñiguez-Gonzalez, G.; Maldonado, I.B. Influencia de las fendas en la resistencia de la madera estructural. Mater. Constr. 2010, 60, 115–132. [Google Scholar] [CrossRef]

- Stehn, L.; Björnfot, A. Comparison of different ductility measures for a nailed steel-to-timber connection. In Proceedings of the World Conference on Timber Engineering, Shah Alam, Malaysia, 12–15 August 2002; Volume 2, pp. 155–162. [Google Scholar]

- Jorissen, A.; Fragiacomo, M. General notes on ductility in timber structures. Eng. Struct. 2011, 33, 2987–2997. [Google Scholar] [CrossRef]

- Malo, K.; Siem, J.; Ellingsbø, P. Quantifying ductility in timber structures. Eng. Struct. 2011, 33, 2998–3006. [Google Scholar] [CrossRef]

| G (g/m2) | t (mm) | σf (N/mm2) | Ef (GPa) | Ff (N/mm) | Kf (N/mm) | |

|---|---|---|---|---|---|---|

| FC300 | 300 | 0.167 | 4900 | 230 | 818 | 38,410 |

| FB280 | 280 | 0.103 | 4000 | 84 | 412 | 8652 |

| FB600 | 600 | 0.222 | 4000 | 84 | 888 | 18,648 |

| σmax * (N/mm2) | E (N/mm2) | εmax * (‰) | εu * (‰) | ||

|---|---|---|---|---|---|

| WR | 23.70/1.52 | 5532 | 5.84/0.34 | 67.25/2.78 | |

| FC300 | 46.14/3.89 | 7934 | 11.11/0.72 | 19.74/3.95 | |

| FB280 | 54.64/4.00 | 6912 | 8.88/0.78 | 25.30/4.95 | |

| FB600 | 55.16/4.49 | 7362 | 8.61/0.15 | 21.62/3.37 | |

| Ae (N/mm2) | Au (N/mm2) | Dε | DA | ρ (kg/m3) | |

| WR | 92.04 | 1115.60 | 11.51 | 12.12 | 554.31 |

| FC300 | 307.32 | 599.83 | 1.78 | 1.95 | 527.68 |

| FB280 | 276.35 | 612.59 | 2.85 | 2.22 | 513.19 |

| FB600 | 310.57 | 611.90 | 2.51 | 1.97 | 534.27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

de la Rosa, P.; González, M.d.l.N.; Prieto, M.I.; Gómez, E. Compressive Behavior of Pieces of Wood Reinforced with Fabrics Composed of Carbon Fiber and Basalt Fiber. Appl. Sci. 2021, 11, 2460. https://doi.org/10.3390/app11062460

de la Rosa P, González MdlN, Prieto MI, Gómez E. Compressive Behavior of Pieces of Wood Reinforced with Fabrics Composed of Carbon Fiber and Basalt Fiber. Applied Sciences. 2021; 11(6):2460. https://doi.org/10.3390/app11062460

Chicago/Turabian Stylede la Rosa, Pilar, María de las Nieves González, María Isabel Prieto, and Enrique Gómez. 2021. "Compressive Behavior of Pieces of Wood Reinforced with Fabrics Composed of Carbon Fiber and Basalt Fiber" Applied Sciences 11, no. 6: 2460. https://doi.org/10.3390/app11062460

APA Stylede la Rosa, P., González, M. d. l. N., Prieto, M. I., & Gómez, E. (2021). Compressive Behavior of Pieces of Wood Reinforced with Fabrics Composed of Carbon Fiber and Basalt Fiber. Applied Sciences, 11(6), 2460. https://doi.org/10.3390/app11062460