Effects of Heat Treatment of Selective Laser Melting Printed Ti-6Al-4V Specimens on Surface Texture Parameters and Cell Attachment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Samples Preparation

2.2. Microstructure and Surface Feature Analysis

2.3. Wavelet Transforms of the Surface Profiles

2.4. Surface Wettability Analysis

2.5. Cell Proliferation Assay

2.6. Immunofluorescence

2.7. Statistical Analysis

3. Results and Discussion

3.1. Ti64 Powdersize Distribution

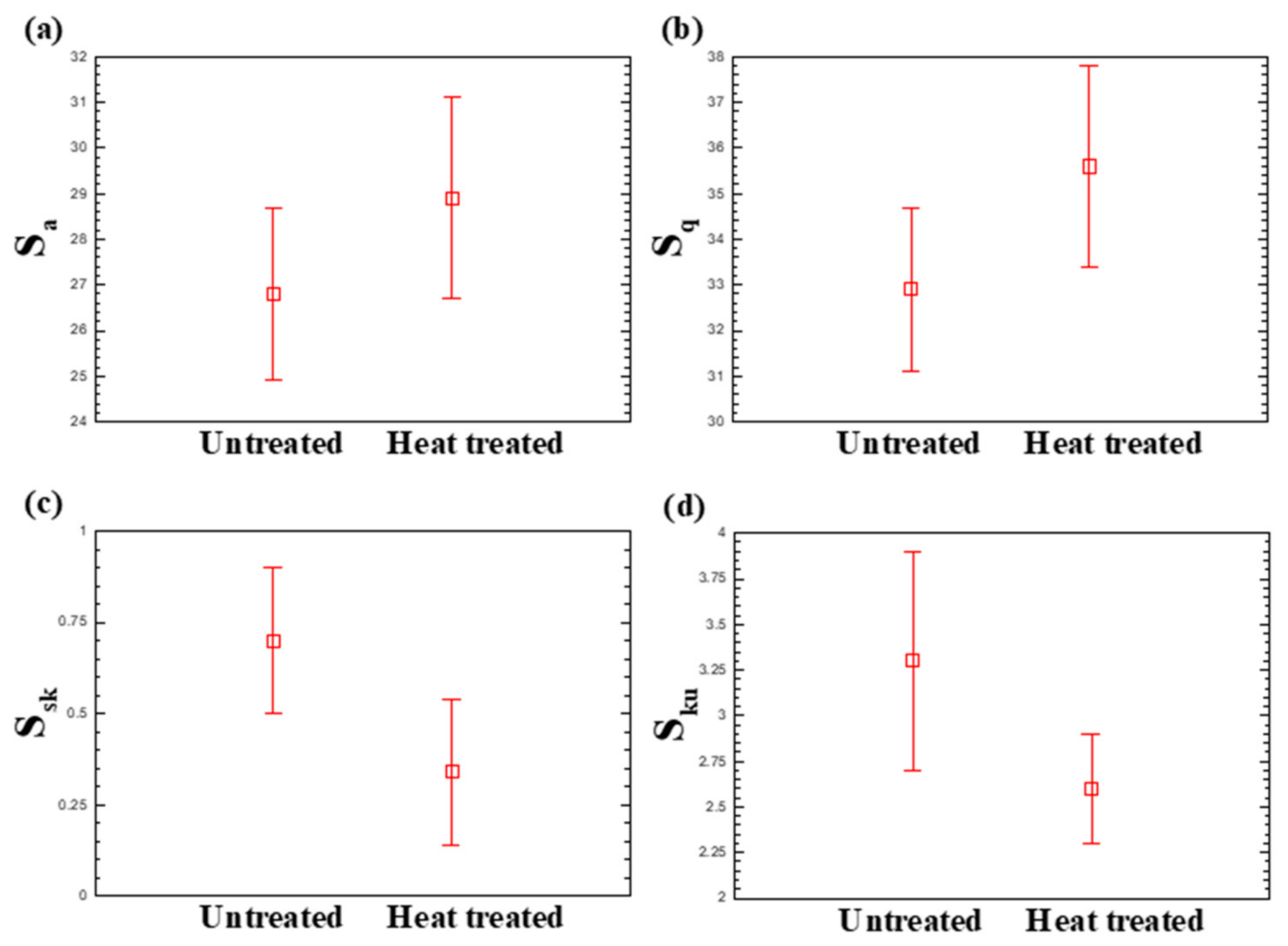

3.2. Surface Morphology and Roughness Analysis

3.3. Surface Morphology and Roughness Analysis

3.4. Surface Wettablity Analysis

3.5. Cell Viability Analysis

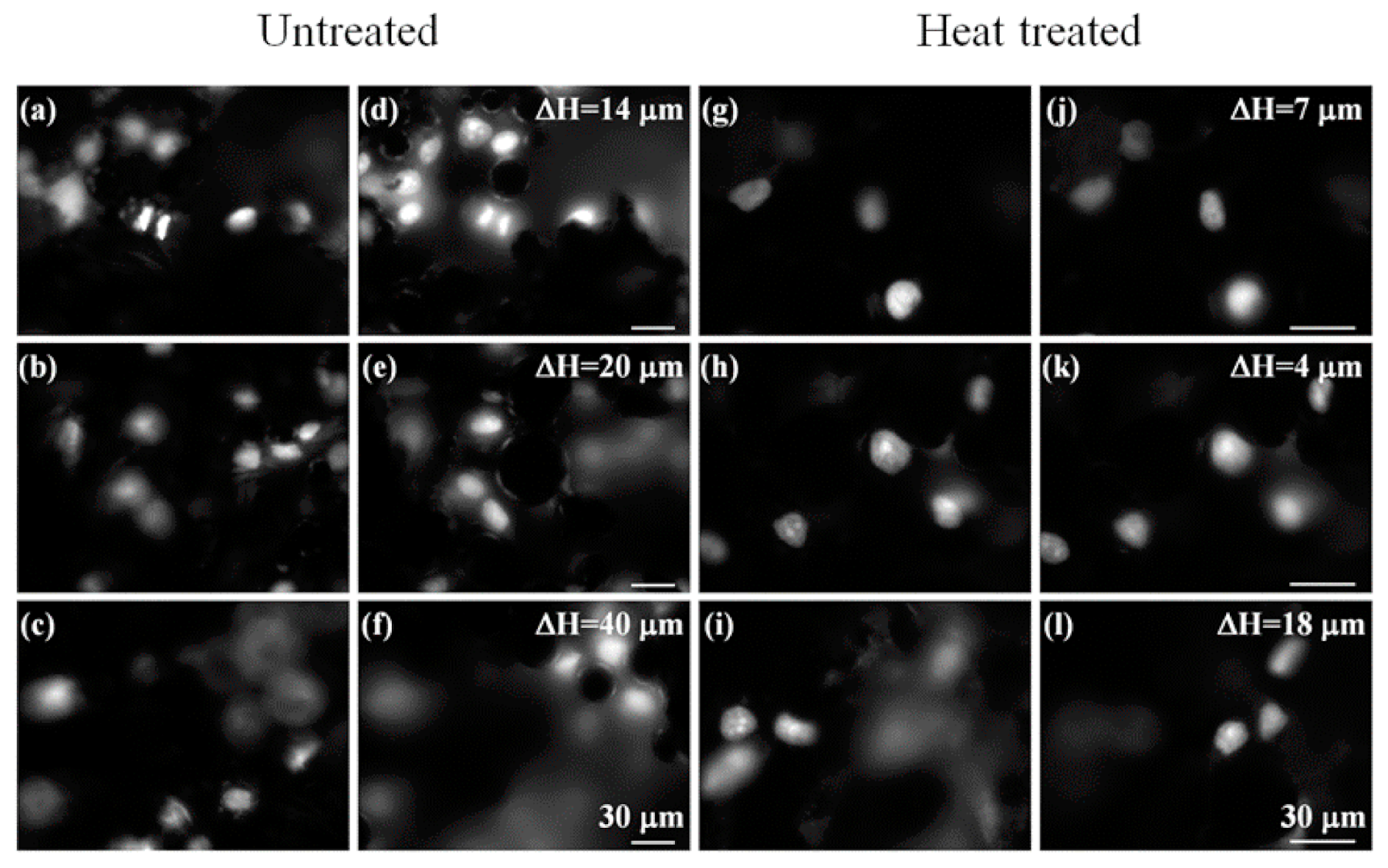

3.6. Cell Adhesion Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vandenbroucke, B.; Kruth, J.P. Selective laser melting of biocompatible metals for rapid manufacturing of medical parts. Rapid Prototyp. J. 2007, 13, 196–203. [Google Scholar] [CrossRef]

- Sidambe, A.T. Biocompatibility of advanced manufactured titanium implants-A review. Materials 2014, 7, 8168–8188. [Google Scholar] [CrossRef] [PubMed]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: Berlin/Heidelberg, Germany, 2010; Volume 238. [Google Scholar]

- Thijs, L.; Verhaege, F.; Craeghs, T.; van Humbeeck, J.; Kruth, J.P. A study of the microstructural evolution during selective laser melting of Ti-6Al-4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Kok, Y.; Tan, X.P.; Wang, P.; Nai, M.L.S.; Loh, N.H.; Liu, E.; Tor, S.B. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Kajima, Y.; Takaichi, A.; Kittikundecha, N. Effect of heat-treatment temperature on microstructures and mechanical properties of Co–Cr–Mo alloys fabricated by selective laser melting. Mater. Sci. Eng. A 2018, 726, 21–31. [Google Scholar] [CrossRef]

- Lee, W.F.; Wang, J.C.; Hsu, C.Y.; Peng, P.W. Microstructure, mechanical properties, and retentive forces of cobalt-chromium removable partial denture frameworks fabricated by selective laser melting followed by heat treatment. J. Prosthet. Dent. in press.

- Peng, P.W.; Hsu, C.Y.; Huang, H.Y.; Chao, J.C.; Lee, W.F. Trueness of removable partial denture frameworks additively manufactured with selective laser melting. J. Prosthet Dent. in press.

- Zavala-Arredondo, M.; Ali, H.; Groom, K.M. Investigating the melt pool properties and thermal effects of multi-laser diode area melting. Int. J. Adv. Manuf. Technol. 2018, 97, 1383–1396. [Google Scholar] [CrossRef]

- Wang, A.M.; Wu, Y.; Lu, S.; Chen, T.; Zhao, Y. Fabrication and characterization of selective laser melting printed Ti–6Al–4V alloys subjected to heat treatment for customized implants design. Prog. Nat. Sci. Mater. Int. 2016, 26, 671–677. [Google Scholar] [CrossRef]

- Beese, A.M.; Carroll, B.E. Review of Mechanical Properties of Ti-6Al-4V Made by Laser-Based Additive Manufacturing Using Powder Feedstock. JOM 2016, 68, 724–734. [Google Scholar] [CrossRef]

- Colpitts, C.; Ektesabi, A.M.; Wyatt, R.A.; Crawford, B.D.; Kiani, A. Mammalian fibroblast cells avoid residual stress zone caused by nanosecond laser pulses. J. Mech. Behav. Biomed. Mater. 2017, 74, 214–220. [Google Scholar] [CrossRef]

- Martin, F.; Konecna, R.; Nicoletto, G. Microstructure and fatigue performance of SLM-fabricated Ti6Al4V alloy after different stress-relief heat treatments. Transport Res. Procedia 2019, 40, 24–29. [Google Scholar]

- Potomati, F.; Giordani, E.J.; Duarte, L.T. Fatigue behavior and physical characterization of surface-modified Ti-6Al-4V ELI alloy by micro-arc oxidation. Mater. Res. Ibero Am. J. Mater. 2012, 15, 305–311. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I. Selective laser melting of Ti6Al4V alloy for biomedical applications: Temperature monitoring and microstructural evolution. J. Alloy. Compd. 2014, 583, 404–409. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, P.; Liu, S.; Attarilar, S.; Ma, R.L.W.; Zhong, Y. Multi-scale surface treatments of titanium implants for rapid osseointegration: A Review. Nanomaterials 2020, 10, 1244. [Google Scholar] [CrossRef]

- Ataee, A.; Li, Y.; Wen, C. A comparative study on the nanoindentation behavior, wear resistance and in vitro biocompatibility of SLM manufactured CP–Ti and EBM manufactured Ti64 gyroid scaffolds. Acta Biomater. 2019, 97, 587–596. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Y.; Wang, W.; Gao, R.; Zhang, H.; Dong, L.; Qin, J.; Wang, B.; Jia, W.; Li, X. Fatigue behavior and osseointegration of porous Ti-6Al-4V scaffolds with dense core for dental application. Mater. Des. 2020, 195, 108994. [Google Scholar] [CrossRef]

- Elias, C.N.; Oshida, Y.; Lima, J.H.; Muller, C.A. Relationship between surface properties (roughness, wettability and morphology) of titanium and dental implant removal torque. J. Mech. Behav. Biomed. Mater. 2008, 1, 234–242. [Google Scholar] [CrossRef]

- Lin, N.; Li, D.; Zou, J.; Xie, R.; Wang, Z.; Tang, B. Surface texture-based surface treatments on Ti6Al4V titanium alloys for tribological and biological applications: A mini review. Materials 2018, 11, 487. [Google Scholar] [CrossRef]

- Ponader, S.; Vairaktaris, E.; Heinl, P.; Wilmowsky, C.V.; Rottmair, A.; Körner, C.; Singer, R.F.; Holst, S.; Schlegel, K.A.; Neukam, F.W.; et al. Effects of topographical surface modifications of electron beam melted Ti-6Al-4V titanium on human fetal osteoblasts. J. Biomed. Mater. Res. A 2008, 84, 1111–1119. [Google Scholar] [CrossRef]

- ISO_4287 BE; BS EN ISO_4287. Geometrical Product Specification (GPS): Surface Texture: Profile Method: Terms, Definitions and Surface Texture Parameters; British Standards Institute: London, UK, 2000. [Google Scholar]

- ISO_25178-2 BE; BS EN ISO_25178-2. Geometrical Product Specifications (GPS): Surface Texture: Areal 2: Terms, Definitions and Surface Texture Parameters; British Standards Institute: London, UK, 2012. [Google Scholar]

- Hansson, K.N.; Hansson, S. Skewness and kurtosis: Important parameters in the characterization of dental implant surface roughness—A computer simulation. ISRN Mater. Sci. 2011, 2011, 1–6. [Google Scholar] [CrossRef]

- Olivares-Navarrete, R.; Hyzy, S.L.; Berg, M.E. Osteoblast Lineage Cells Can Discriminate Microscale Topographic Features on Titanium–Aluminum–Vanadium Surfaces. Ann. Biomed. Eng. 2014, 42, 2551–2561. [Google Scholar] [CrossRef]

- Eseholi, T.; Coudoux, F.-X.; Corlay, P.; Sadli, R.; Bigerelle, M. A Multiscale Topographical Analysis Based on Morphological Information: The HEVC Multiscale Decomposition. Materials 2020, 13, 5582. [Google Scholar] [CrossRef] [PubMed]

- Newton, L.; Senin, N.; Chatzivagiannis, E.; Smith, B.; Leach, R. Feature-based characterisation of Ti6Al4V electron beam powder bed fusion surfaces fabricated at different surface orientations. Addit. Manuf. 2020, 35, 101273. [Google Scholar]

- Brown, C.A.; Hansen, H.N.; Jiang, X.; Blateyron, F.; Berglund, J.; Senin, N.; Bartkowiak, T.; Dixon, B.; Goïc, G.L.; Quinsat, Y.; et al. Multiscale Analyses and Characterizations of Surface Topographies. CIRP Ann. 2018, 67, 839–862. [Google Scholar] [CrossRef]

- Workman, M.J.; Serov, A.; Halevi, B.; Atanassov, P.; Artyushkova, K. Application of the discrete wavelet transform to SEM and AFM micrographs for quantitative analysis of complex surfaces. Langmuir 2015, 31, 4924–4933. [Google Scholar] [CrossRef] [PubMed]

- Maksumov, A.; Vidu, R.; Palazoglu, A.; Stroeve, P. Enhanced feature analysis using wavelets for scanning probe microscopy images of surfaces. J. Colloid Interface Sci. 2004, 27, 365–377. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.; Mukherjee, R.; Stroeve, P.; Palazoglu, A.; Romagnoli, J.A. A multi-resolution approach for line-edge roughness detection. Microelectron. Eng. 2009, 86, 340–351. [Google Scholar] [CrossRef]

- Farge, M. Wavelet transforms and their applications to turbulence. Ann. Rev. Fluid Mech. 1992, 24, 395–456. [Google Scholar] [CrossRef]

- Yang, T.S.; Shy, S.S. Two-way interaction between solid particles and homogeneous air turbulence: Particle settling rate and turbulence modification measurements. J. Fluid Mech. 2005, 526, 171. [Google Scholar] [CrossRef]

- Clark, N.; Jones, N.; Porch, A. Measurement of average particle size in metal powders by microwave cavity perturbation in the magnetic field. Sens. Actuators A 2017, 259, 137–143. [Google Scholar] [CrossRef]

- Albrektsson, T.; Wennerberg, A. On osseointegration in relation to implant surfaces. Clin. Implant. Dent. Relat. Res. 2019, 21 (Suppl. 1), 4–7. [Google Scholar] [CrossRef] [PubMed]

- Sarker, A.; Tran, N.; Rifai, A.; Brandt, M.; Tran, P.; Leary, M.; Fox, K.; Williams, R. Rational design of additively manufactured Ti6Al4V implants to control Staphylococcus aureus biofilm formation. Materialia 2019, 5, 100250. [Google Scholar] [CrossRef]

- Huang, C.F.; Colley, M.M.S.; Lu, L.S.; Chang, C.Y.; Peng, P.W.; Yang, T.S. Performance characterization of continuous-wave laser-induced forward transfer of liquid bioink. Appl. Phys. Express 2019, 12, 116504. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, P.-W.; Yang, J.-C.; Lee, W.-F.; Fang, C.-Y.; Chang, C.-M.; Chen, I.-J.; Hsu, C.; Yang, T.-S. Effects of Heat Treatment of Selective Laser Melting Printed Ti-6Al-4V Specimens on Surface Texture Parameters and Cell Attachment. Appl. Sci. 2021, 11, 2234. https://doi.org/10.3390/app11052234

Peng P-W, Yang J-C, Lee W-F, Fang C-Y, Chang C-M, Chen I-J, Hsu C, Yang T-S. Effects of Heat Treatment of Selective Laser Melting Printed Ti-6Al-4V Specimens on Surface Texture Parameters and Cell Attachment. Applied Sciences. 2021; 11(5):2234. https://doi.org/10.3390/app11052234

Chicago/Turabian StylePeng, Pei-Wen, Jen-Chang Yang, Wei-Fang Lee, Chih-Yuan Fang, Chun-Ming Chang, I-Jan Chen, Chengpo Hsu, and Tzu-Sen Yang. 2021. "Effects of Heat Treatment of Selective Laser Melting Printed Ti-6Al-4V Specimens on Surface Texture Parameters and Cell Attachment" Applied Sciences 11, no. 5: 2234. https://doi.org/10.3390/app11052234

APA StylePeng, P.-W., Yang, J.-C., Lee, W.-F., Fang, C.-Y., Chang, C.-M., Chen, I.-J., Hsu, C., & Yang, T.-S. (2021). Effects of Heat Treatment of Selective Laser Melting Printed Ti-6Al-4V Specimens on Surface Texture Parameters and Cell Attachment. Applied Sciences, 11(5), 2234. https://doi.org/10.3390/app11052234