Improvement of Delivery Reliability by an Intelligent Control Loop between Supply Network and Manufacturing

Abstract

Featured Application

Abstract

1. Introduction

2. Related Work

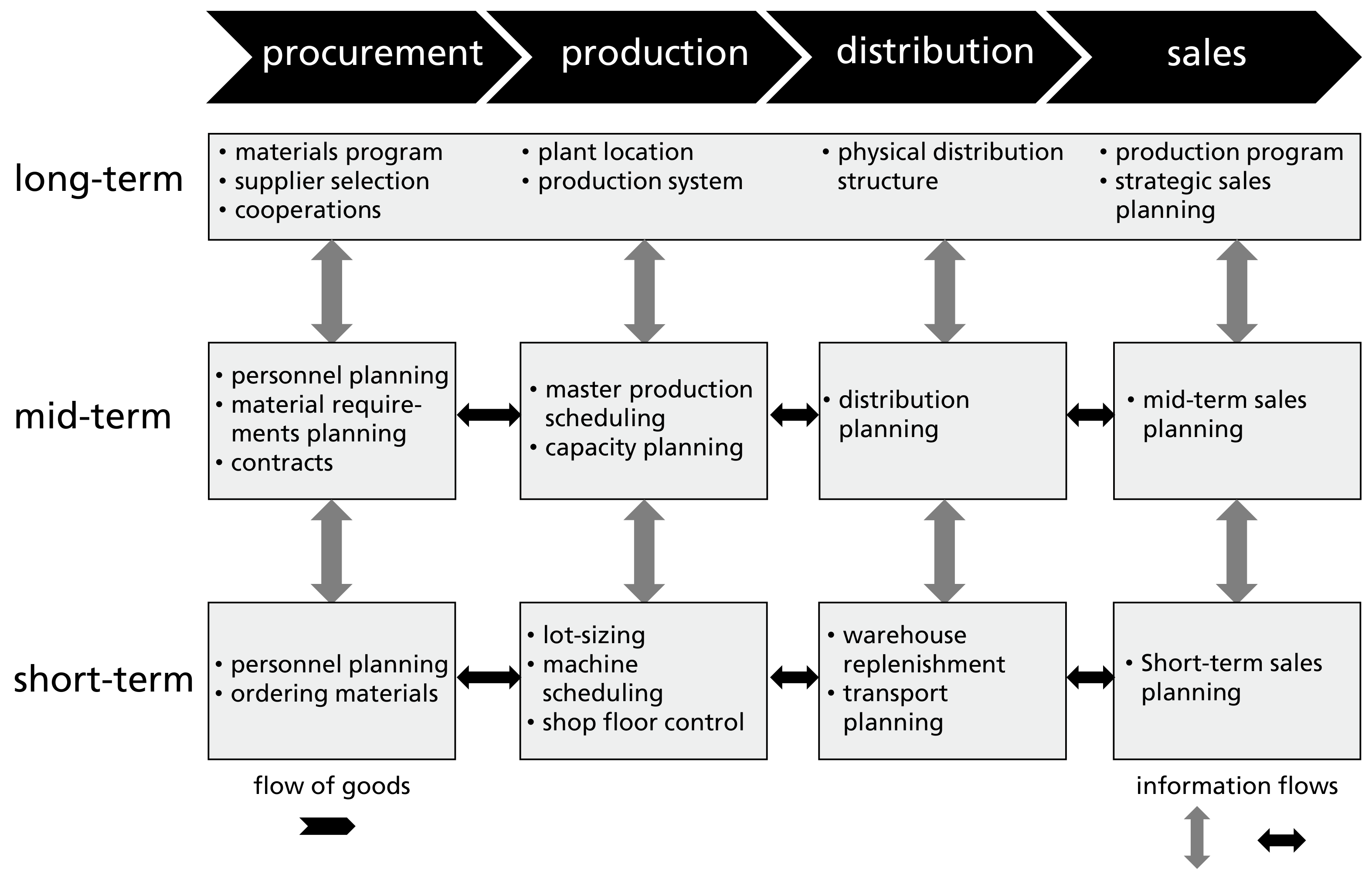

2.1. Interaction of Supply Network and Production Planning and Control

2.2. Approaches to Improve the Interaction of Supply Network and Production Planning and Control

2.2.1. Supply Chain Event Management

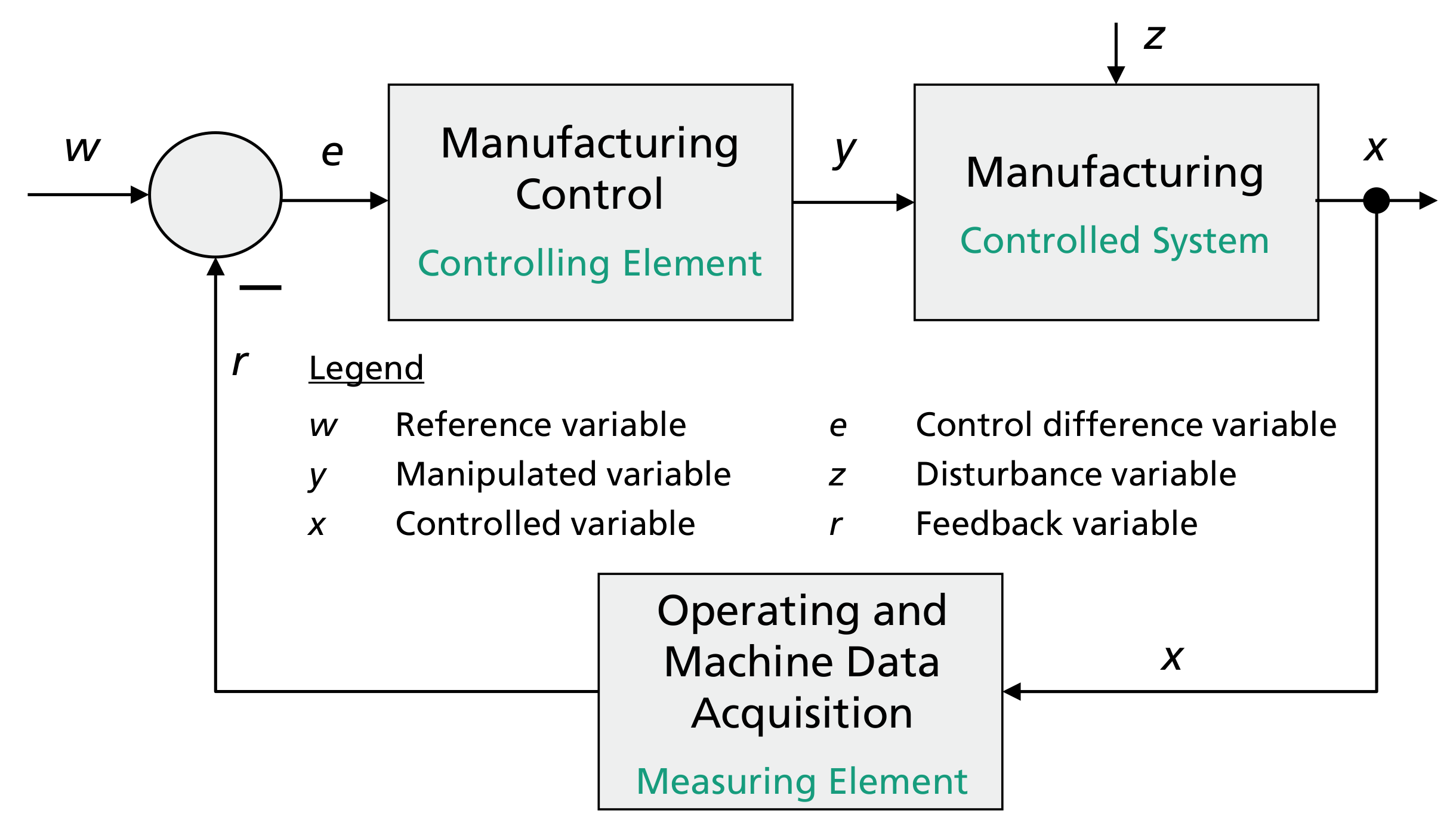

2.2.2. Closed-Loop Control

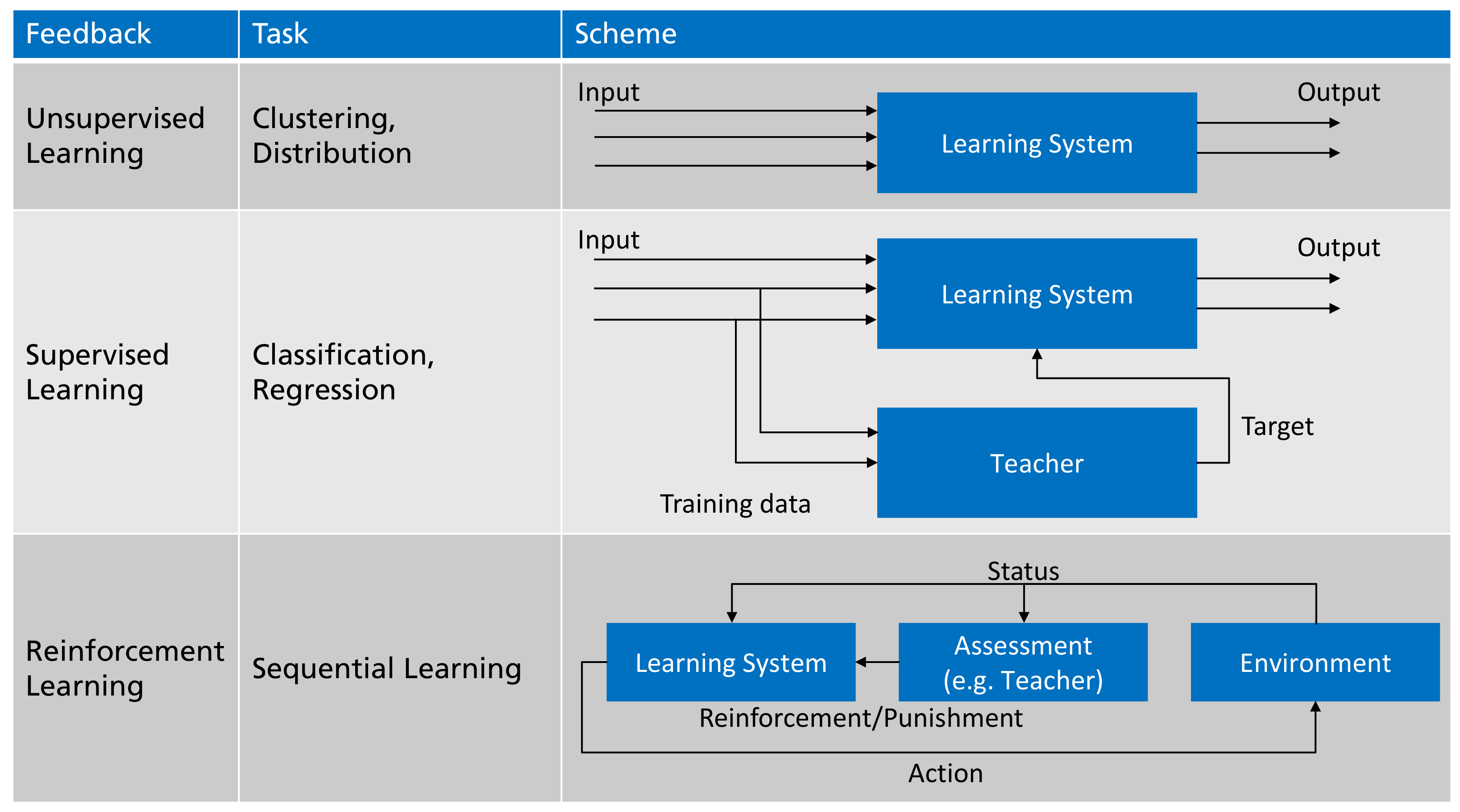

2.2.3. Machine Learning

3. Concept

3.1. Requirements

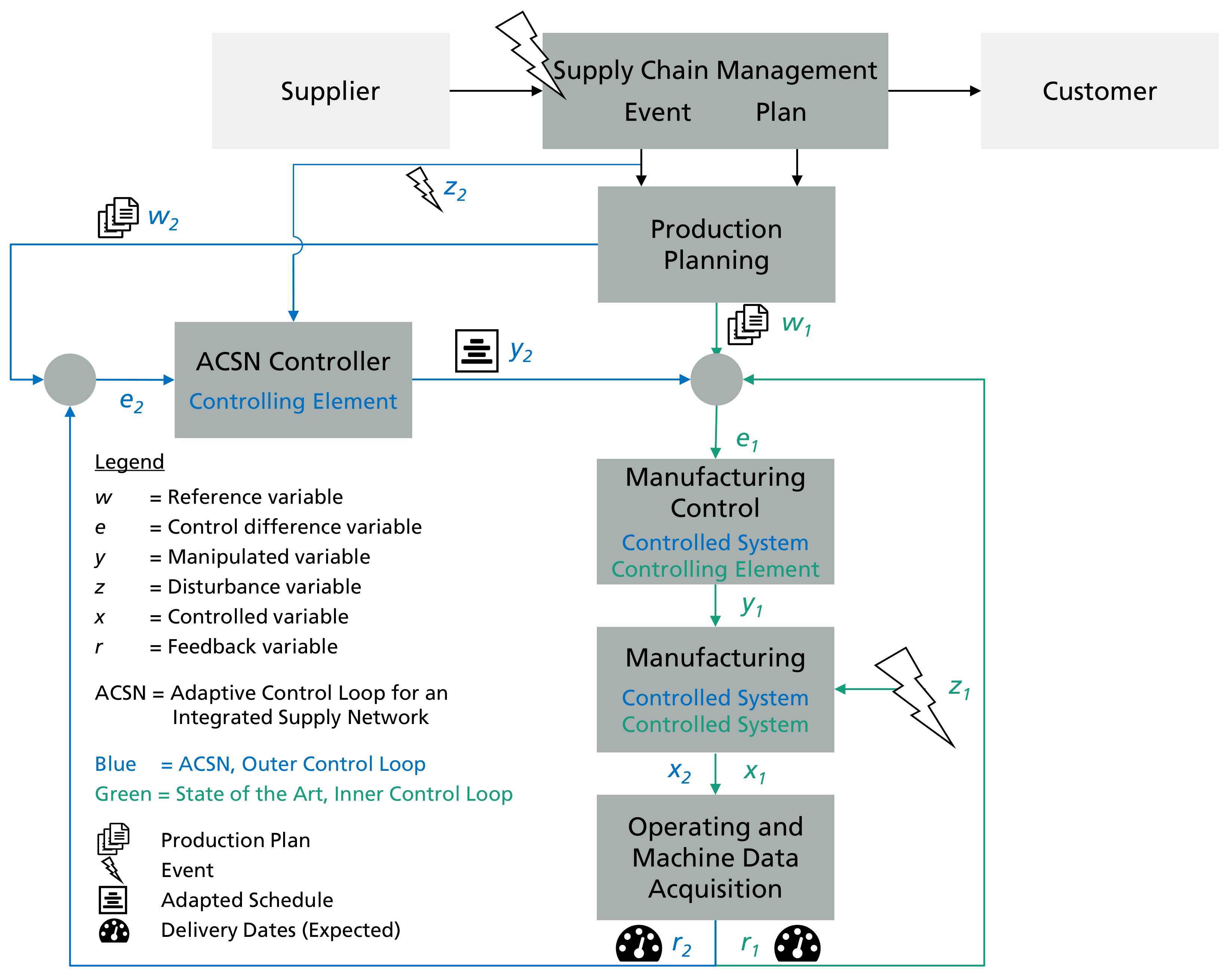

3.2. Control Loop Design

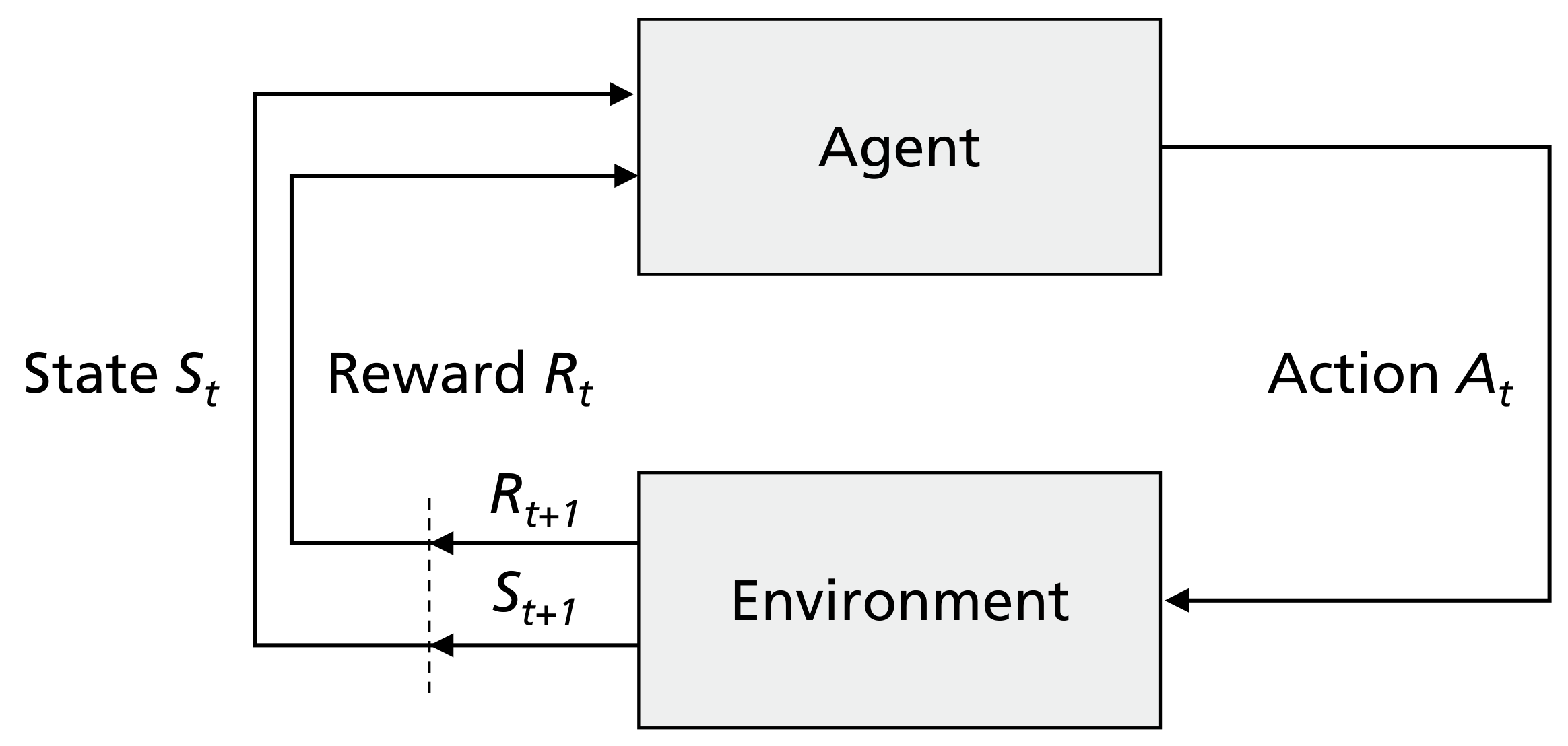

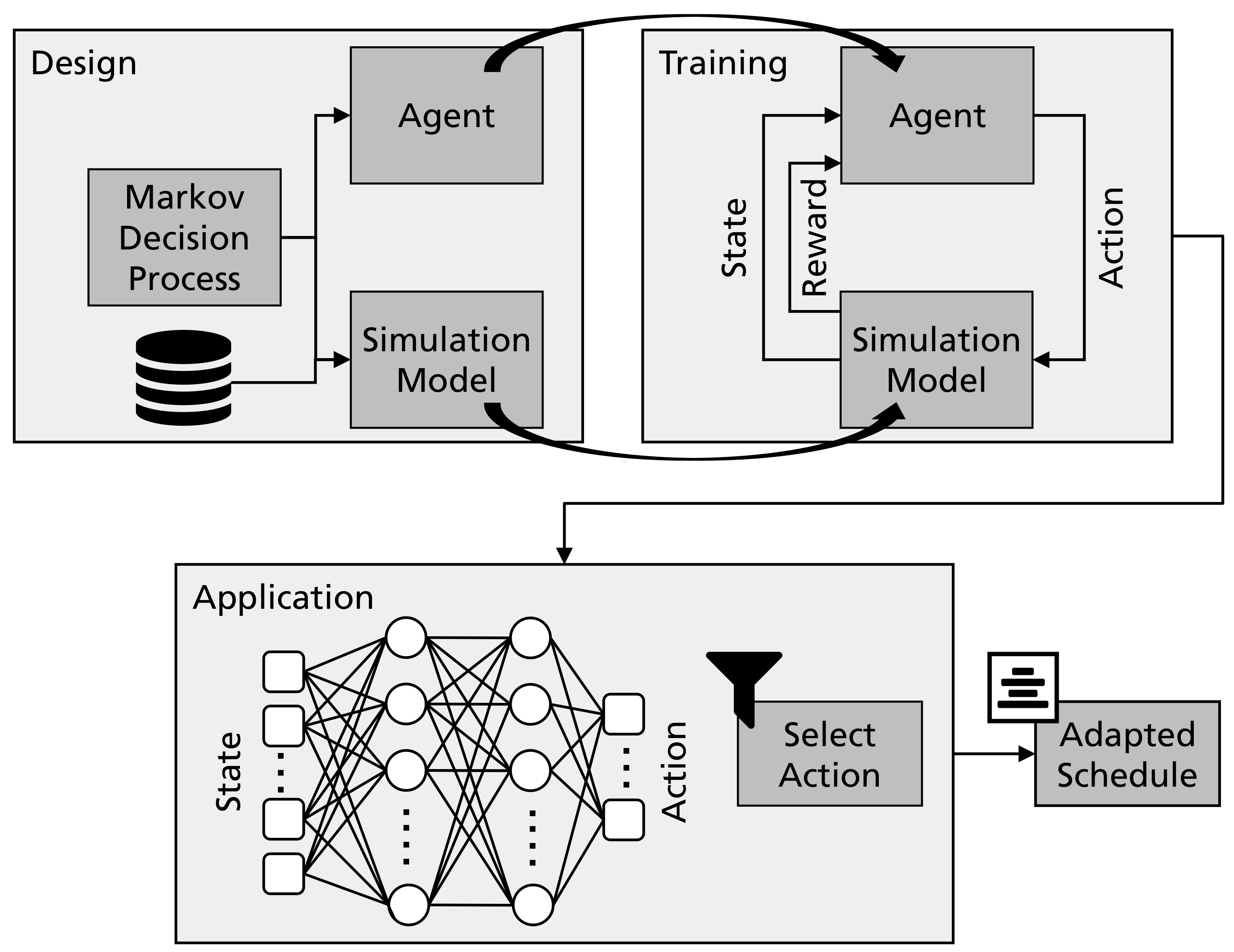

3.3. Reinforcement Learning-Based Controlling Element

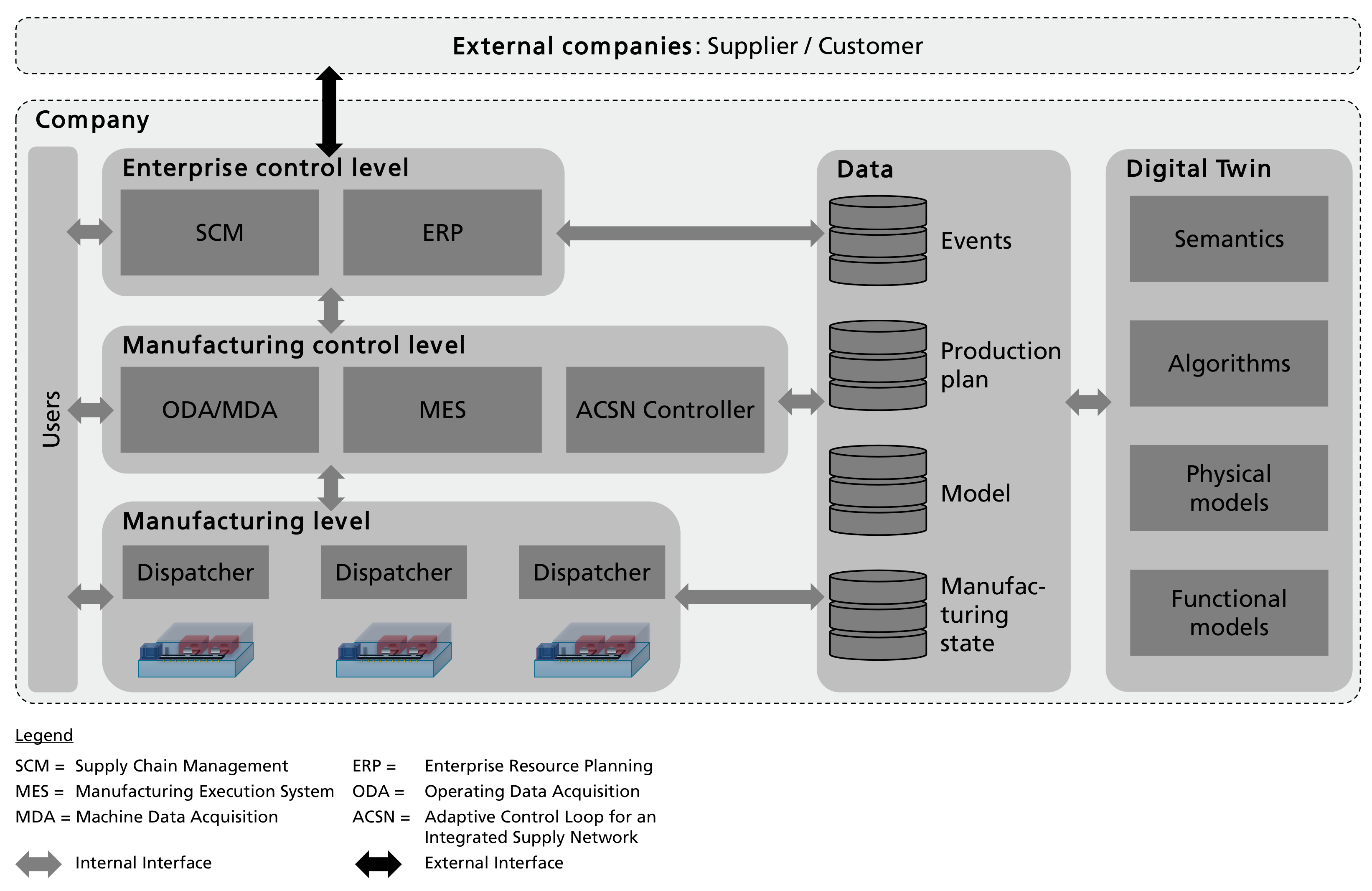

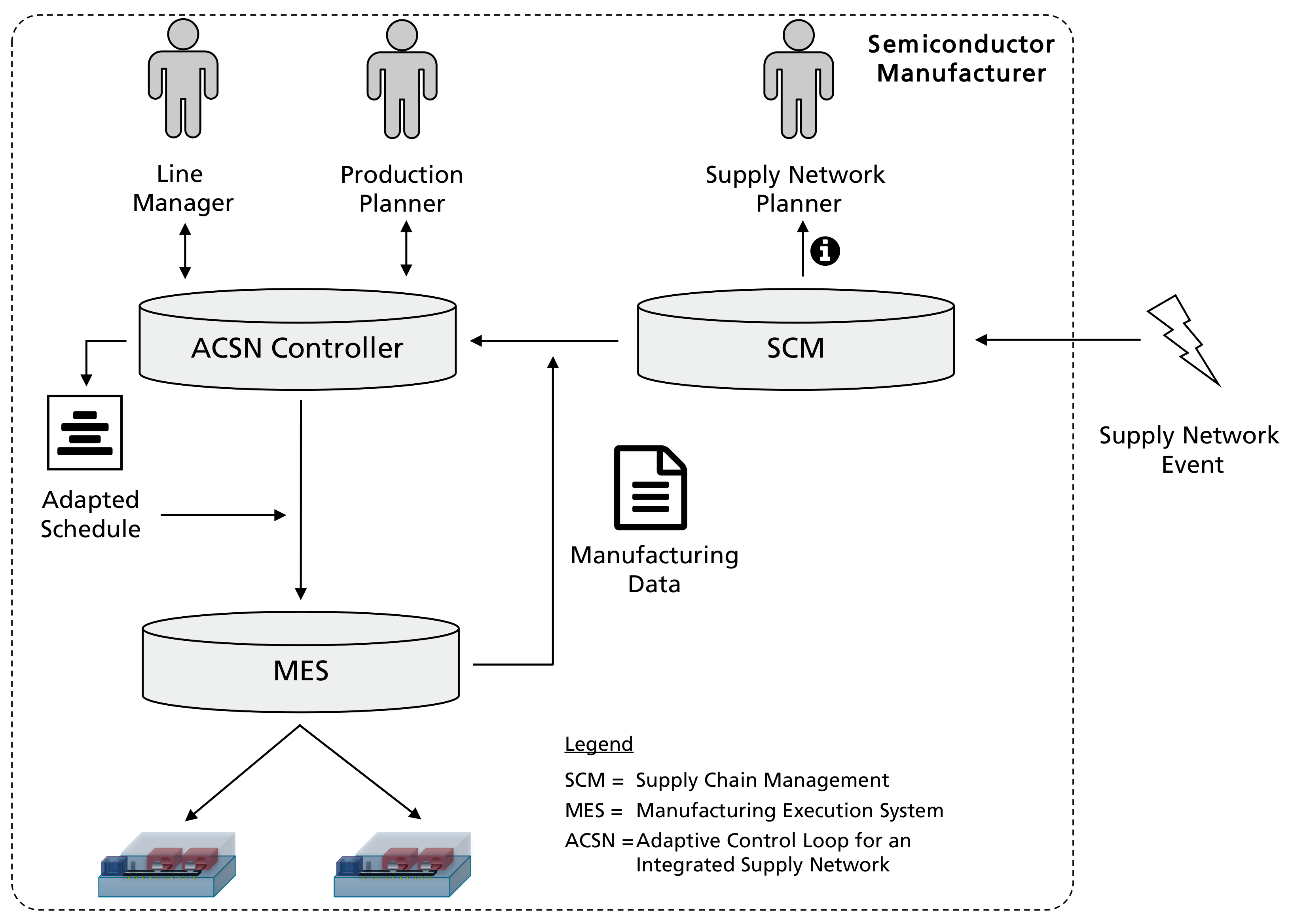

3.4. Embedding in Manufacturing IT Landscape

4. Application

4.1. Semiconductor Industry

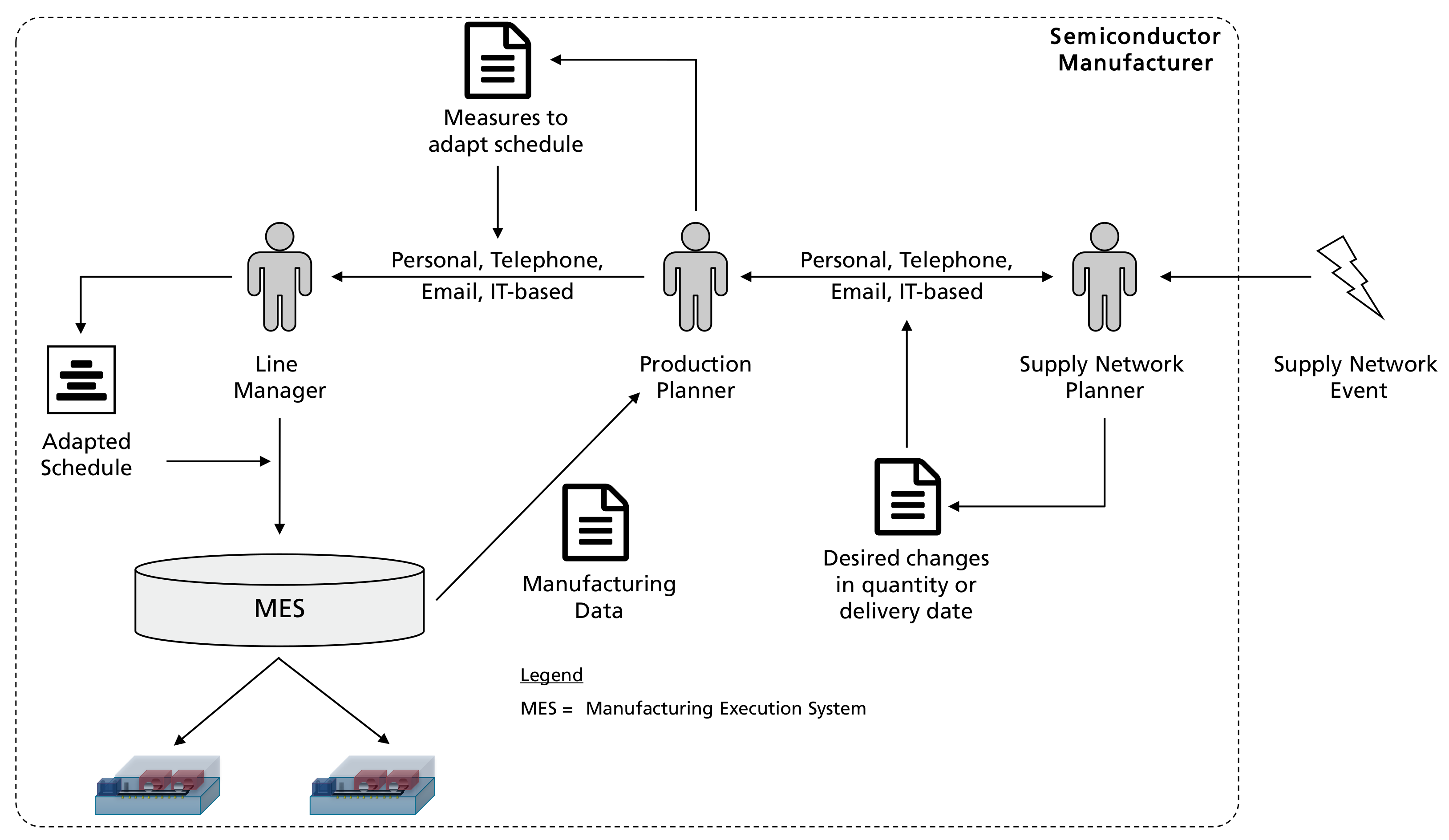

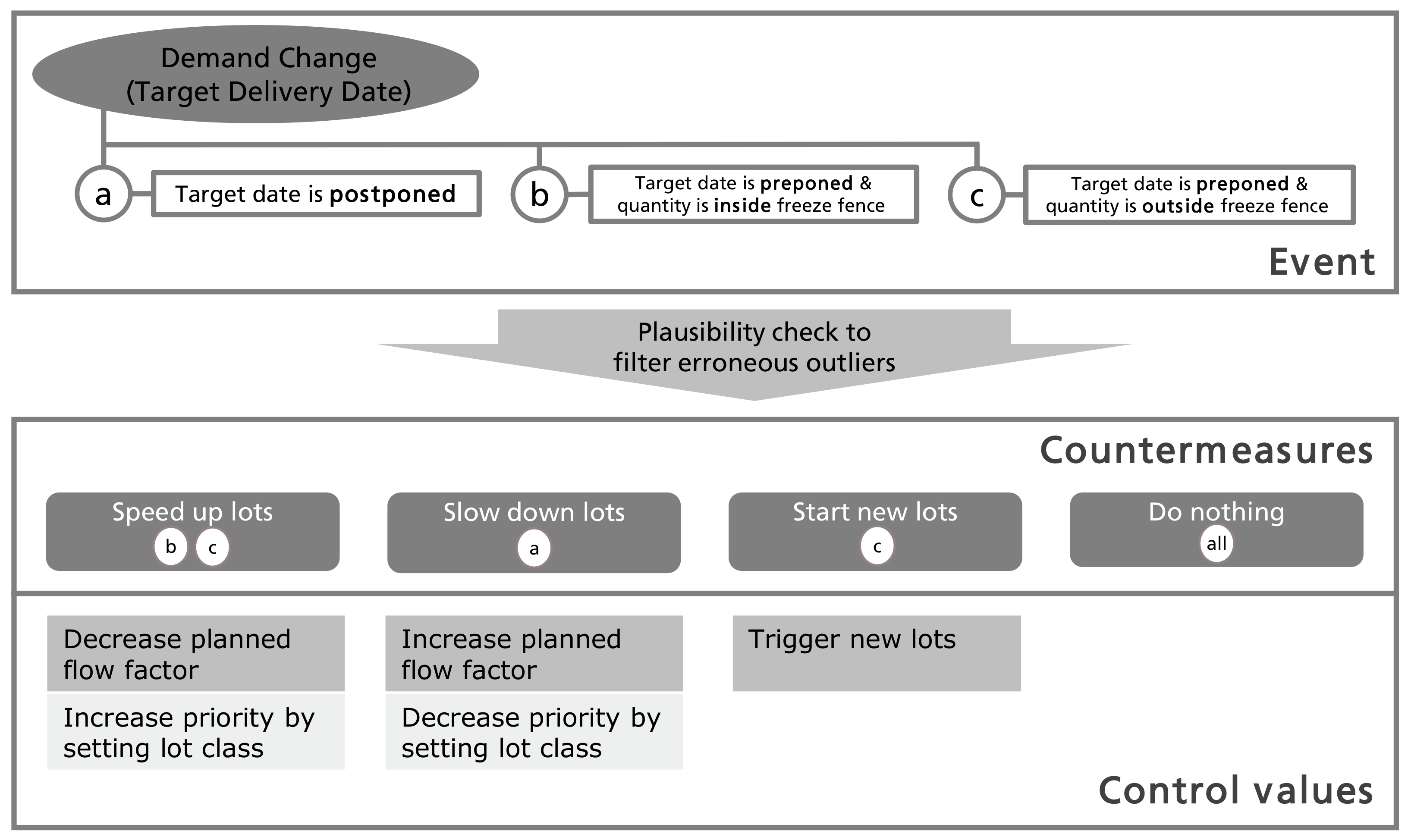

4.2. Existing Process for Responding to Supply Network Events

4.3. Application of the ACSN to Optimize this Process

5. Discussion

6. Conclusions and Contributions

7. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ACSN | Adaptive Control Loop for an Integrated Supply Network |

| CPS | Cyber-physical Systems |

| IoT | Internet of Things |

| MDP | Markov Decision Process |

| MES | Manufacturing Execution System |

| ML | Machine Learning |

| PPC | Production Planning and Control |

| RL | Reinforcement Learning |

| SCEM | Supply Chain Event Management |

References

- Bauernhansl, T.; Hörcher, G.; Bressner, M.; Röhm, M. MANUFUTURE-DE: Identification of Priority Research Topics for the Sustainable Development of European Research Programs for the Manufacturing Industry until 2030; Fraunhofer IPA: Stuttgart, Germany, 2018. [Google Scholar]

- Lödding, H. Handbook of Manufacturing Control: Fundamentals, Description, Configuration; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. Viability of intertwined supply networks: Extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. Int. J. Prod. Res. 2020, 58, 2904–2915. [Google Scholar] [CrossRef]

- Mack, O.; Khare, A. Perspectives on a VUCA world. In Managing in a VUCA World; Mack, O., Khare, A., Krämer, A., Burgartz, T., Eds.; Springer: Cham, Switzerland, 2016; pp. 3–19. [Google Scholar]

- Bauernhansl, T. Die Vierte Industrielle Revolution: Der Weg in ein Wertschaffendes Produktionsparadigma. In Handbuch Industrie 4.0; Vogel-Heuser, B., Bauernhansl, T., ten Hompel, M., Eds.; Springer Reference Technik; Springer Vieweg: Berlin, Germany, 2017; pp. 1–31. [Google Scholar]

- Chopra, S. Supply Chain Management: Strategy, Planning, and Operation, 7th ed.; Pearson: Boston, MA, USA, 2018. [Google Scholar]

- Stadtler, H. Supply chain management: An overview. In Supply Chain Management and Advanced Planning; Stadtler, H., Kilger, C., Meyr, H., Eds.; Springer Texts in Business and Economics; Springer: Berlin, Germany, 2015; pp. 3–28. [Google Scholar]

- Christopher, M. Logistics & Supply Chain Management, 4th. ed.; Financial Times Prentice Hall: Harlow, UK, 2011. [Google Scholar]

- Schuh, G.; Potente, T.; Thomas, C.; Hanagement; Iauptvogel, A. Cyber-Physical Production Mn Advances in Production Management Systems. Sustainable Production and Service Supply Chains; Prabhu, V., Ed.; IFIP Advances in Information and Communication Technology; Springer: Berlin, Germany, 2013; pp. 477–484. [Google Scholar]

- Bauer, D.; Bauernhansl, T.; Sauer, A. Enhanced Classification of Events for Manufacturing Companies in Supply Networks. Procedia CIRP 2019, 81, 87–92. [Google Scholar] [CrossRef]

- Vakharia, A.J.; Yenipazarli, A. Managing Supply Chain Disruptions. Found. Trends Technol. Inf. Oper. Manag. 2008, 2, 243–325. [Google Scholar] [CrossRef]

- Ponomarov, S.Y.; Holcomb, M.C. Understanding the concept of supply chain resilience. Int. J. Logist. Manag. 2009, 20, 124–143. [Google Scholar] [CrossRef]

- Miehe, R.; Bauernhansl, T.; Beckett, M.; Brecher, C.; Demmer, A.; Drossel, W.G.; Elfert, P.; Full, J.; Hellmich, A.; Hinxlage, J.; et al. The biological transformation of industrial manufacturing – Technologies, status and scenarios for a sustainable future of the German manufacturing industry. J. Manuf. Syst. 2020, 54, 50–61. [Google Scholar] [CrossRef]

- Hopp, W.J. Supply Chain Science; Waveland Press: Long Grove, IL, USA, 2008. [Google Scholar]

- Schenk, M.; Schürmeyer, M.; Bauhoff, F. Koordination interner produktionsnetzwerke. In Produktionsplanung und-Steuerung 1; Schuh, G., Stich, V., Eds.; VDI-Buch; Springer Vieweg: Berlin, Germany, 2012; pp. 426–470. [Google Scholar]

- Roth, A.V. Achieving strategic agility through Economies of Knowledge. Plan. Rev. 1996, 24, 30–36. [Google Scholar] [CrossRef]

- Fleischmann, B.; Meyr, H.; Wagner, M. Advanced planning. In Supply Chain Management and Advanced Planning; Stadtler, H., Kilger, C., Meyr, H., Eds.; Springer Texts in Business and Economics; Springer: Berlin/Heidelberg, Germany, 2015; pp. 71–95. [Google Scholar]

- Pinedo, M.L. Scheduling: Theory, Algorithms, and Systems, 5th ed.; Springer: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- ElMaraghy, W.; ElMaraghy, H.; Tomiyama, T.; Monostori, L. Complexity in engineering design and manufacturing. CIRP Ann.-Manuf. Technol. 2012, 61, 793–814. [Google Scholar] [CrossRef]

- Cadavid, J.P.U.; Lamouri, S.; Grabot, B.; Pellerin, R.; Fortin, A. Machine learning applied in production planning and control: A state-of-the-art in the era of industry 4.0. J. Intell. Manuf. 2020, 31, 1531–1558. [Google Scholar] [CrossRef]

- Luckham, D.C. The Power of Events: An Introduction to Complex Event Processing in Distributed Enterprise Systems, 6th ed.; Addison-Wesley: Boston, MA, USA, 2010. [Google Scholar]

- Etzion, O.; Niblett, P. Event Processing in Action; Manning: Greenwich, CT, USA, 2011. [Google Scholar]

- Theorin, A.; Bengtsson, K.; Provost, J.; Lieder, M.; Johnsson, C.; Lundholm, T.; Lennartson, B. An event-driven manufacturing information system architecture for Industry 4.0. Int. J. Prod. Res. 2017, 55, 1297–1311. [Google Scholar] [CrossRef]

- Buchmann, A.; Pfohl, H.C.; Appel, S.; Freudenreich, T.; Frischbier, S.; Petrov, I.; Zuber, C. Event-driven services: Integrating production, logistics and transportation. In Service-Oriented Computing; Maximilien, E.M., Ed.; Lecture Notes in Computer Science Services Science; Springer: Heidelberg, Germany, 2011; pp. 237–241. [Google Scholar] [CrossRef]

- Hinze, A.; Sachs, K.; Buchmann, A. Event-based applications and enabling technologies. In Proceedings of the Third ACM International Conference on Distributed Event-Based Systems-DEBS ’09, Nashville, TN, USA, 6–9 July 2009; Gokhale, A., Schmidt, D.C., Eds.; ACM Press: New York, NY, USA, 2009; pp. 1–15. [Google Scholar] [CrossRef]

- Zijm, W. Towards intelligent manufacturing planning and control systems. OR-Spektrum 2000, 22, 313–345. [Google Scholar] [CrossRef]

- Otto, A. Supply Chain Event Management: Three Perspectives. Int. J. Logist. Manag. 2003, 14, 1–13. [Google Scholar] [CrossRef]

- Konovalenko, I.; Ludwig, A. Event processing in supply chain management—The status quo and research outlook. Comput. Ind. 2019, 105, 229–249. [Google Scholar] [CrossRef]

- Steven, M.; Krüger, R. Supply Chain Event Management für globale Logistikprozesse: Charakteristika, konzeptionelle Bestandteile und deren Umsetzung in Informationssysteme. In Logistik-Management; Spengler, T.S., Voß, S., Kopfer, H., Eds.; Physica-Verl.: Heidelberg, Germany, 2004; pp. 179–195. [Google Scholar] [CrossRef]

- Baader, A.; Montanus, S. Transparency in Global Supply Chain Networks—Methods and Tools for Integrated Supply Chain Event Management. In Strategies and Tactics in Supply Chain Event Management; Ijioui, R., Emmerich, H., Ceyp, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 3–11. [Google Scholar]

- Hofstetter, J.S.; Stölzle, W. Supply Chain Event Management—Concept and Use in Business Practice. In Supply Chain Safety Management; Essig, M., Hülsmann, M., Kern, E.M., Klein-Schmeink, S., Eds.; Lecture Notes in Logistics; Springer: Berlin/Heidelberg, Germany, 2013; pp. 245–265. [Google Scholar] [CrossRef]

- Bearzotti, L.A.; Salomone, E.; Chiotti, O.J. An autonomous multi-agent approach to supply chain event management. Int. J. Prod. Econ. 2012, 135, 468–478. [Google Scholar] [CrossRef]

- Palma, F.; Saucedo, J.A.; Marmolejo-Saucedo, J.A.; Rodriguez-Aguilar, R. The supply chain event management application: A case study. IFAC-PapersOnLine 2019, 52, 2698–2703. [Google Scholar] [CrossRef]

- Küppers, S.; Kuhn, S.; Bauernfeind, D. Supply Chain Event Management in the Pharmaceutical Industry—Status and Outlook. In Strategies and Tactics in Supply Chain Event Management; Ijioui, R., Emmerich, H., Ceyp, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 13–35. [Google Scholar]

- Vlahakis, G.; Apostolou, D.; Kopanaki, E. Enabling situation awareness with supply chain event management. Expert Syst. Appl. 2018, 93, 86–103. [Google Scholar] [CrossRef]

- Tröger, R.; Alt, R. Service-oriented supply chain event management—A case study from the fashion industry. In Informatik 2010; Abramowicz, W., Alt, R., Eds.; GI-Edition Lecture Notes in Informatics P, Proceedings; Ges. für Informatik: Bonn, Germany, 2010; pp. 31–42. [Google Scholar]

- Bolene, D.; Bolinger, E.; Drees, M.; Fornarola, J. Supply Chain Event Management. U.S. Patent 10,592,848 B2, 17 March 2020. [Google Scholar]

- DIN EN 60027-6. Letter symbols to be used in electrical technology—Part 6: Control technology. Beuth Verlag: Berlin, Germany, 2008.

- DIN IEC 60050-351. International Electrotechnical Vocabulary—Part 351: Control Technology. Beuth Verlag: Berlin, Germany, 2013.

- Moyne, J. Run-to-Run Control in Semiconductor Manufacturing. In Encyclopedia of Systems and Control; Baillieul, J., Samad, T., Eds.; Springer: London, UK, 2015. [Google Scholar] [CrossRef]

- Pritschow, G.; Wiendahl, H.P. Application of Control Theory for Production Logistics—Results of a Joint Project. CIRP Ann.-Manuf. Technol. 1995, 44, 421–424. [Google Scholar] [CrossRef]

- Niehues, M.R.; Blum, M.; Teschemacher, U.; Reinhart, G. Adaptive job shop control based on permanent order sequencing. Prod. Eng. 2018, 12, 65–71. [Google Scholar] [CrossRef]

- Bauer, D.; Bauernhansl, T.; Sauer, A. Approach for an Adaptive Control Loop between Supply Network and Manufacturing. Procedia CIRP 2020, 93, 1552–1557. [Google Scholar] [CrossRef]

- Wiendahl, H.P. Fertigungsregelung: Logistische Beherrschung von Fertigungsabläufen auf Basis des Trichtermodells; Hanser: München, Germany, 1997. [Google Scholar]

- Begemann, C. Terminorientierte Kapazitätssteuerung in der Fertigung; Berichte aus dem IFA; PZH Produktionstechn. Zentrum: Hanover, Germany, 2005; Volume 02/2005. [Google Scholar]

- Scholz-Reiter, B.; Windt, K.; Liu, H. A multiple-logistic-objective-optimized manufacturing planning and control system. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 599–610. [Google Scholar] [CrossRef]

- Brackel, T. Adaptive Steuerung Flexibler Werkstattfertigungssysteme: Nutzung Moderner Informations- und Kommunikationstechnologien zur Effizienten Produktionssteuerung unter Echtzeitbedingungen; Schriften zur Quantitativen Betriebswirtschaftslehre; Gabler: Wiesbaden, Germany, 2009. [Google Scholar] [CrossRef]

- Philipp, T.; de Beer, C.; Windt, K.; Scholz-Reiter, B. Evaluation of Autonomous Logistic Processes: Analysis of the Influence of Structural Complexity. In Understanding Autonomous Cooperation and Control in Logistics; Windt, K., Hülsmann, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 302–324. [Google Scholar]

- Sachs, E.; Guo, R.S.; Ha, S.; Hu, A. On-line process optimization and control using the sequential design of experiments. In Proceedings of the Digest of Technical Papers.1990 Symposium on VLSI Technology, Honololu, HI, USA, 4–7 June 1990; pp. 99–100. [Google Scholar] [CrossRef]

- Russell, S.J.; Norvig, P. Artificial Intelligence: A Modern Approach, 3rd ed.; Prentice-Hall Series in Artificial Intelligence; Prentice-Hall: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Döbel, I.; Leis, M.; Vogelsang, M.M.; Neustroev, D.; Petzka, H.; Riemer, A.; Rüping, S.; Voss, A.; Wegele, M.; Welz, J. Maschinelles Lernen: Eine Analyse zu Kompetenzen, Forschung und Anwendung; Fraunhofer-Gesellschaft: Munich, Germany, 2018. [Google Scholar]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Kolodner, J.L. Case-Based Reasoning; Morgan Kaufmann Publishers: Burlington, MA, USA, 1993. [Google Scholar]

- Le Roux, N.; Bengio, Y.; Fitzgibbon, A. Improving First and Second-Order Methods by Modeling Uncertainty. In Optimization for Machine Learning; Sra, S., Nowozin, S., Wright, S.J., Eds.; Neural Information Processing Series; MIT Press: Cambridge, MA, USA, 2012; pp. 403–430. [Google Scholar]

- Robinson, S. Simulation: The Practice of Model Development and Use; John Wiley & Sons: Chichester, UK, 2004. [Google Scholar]

- Bauer, H.; Ranade, P.; Randon, S. Big Data and the Opportunities It Creates for Semiconductor Players. McKinsey on Semiconductors. 2012, pp. 46–55. Available online: https://www.mckinsey.de/~/media/mckinsey/dotcom/client_service/semiconductors/issue%202%20autumn%202012/pdfs/big_data_and_the_opportunities_it_creates_for_semiconductor_players.pdf (accessed on 2 March 2021).

- Susto, G.A.; Pampuri, S.; Schirru, A.; De Nicolao, G.; McLoone, S.; Beghi, A. Automatic Control and Machine Learning for Semiconductor Manufacturing: Review and Challenges. In Proceedings of the 10th European Workshop on Advanced Control and Diagnosis (ACD 2012), Lyngby, Denmark, 8–9 November 2012. [Google Scholar]

- Liu, K.; Chen, Y.; Zhang, T.; Tian, S.; Zhang, X. A survey of run-to-run control for batch processes. ISA Trans. 2018, 83, 107–125. [Google Scholar] [CrossRef]

- Walser, T.; Reisinger, M.; Hartmann, N.; Dierolf, C.; Sauer, A. Readiness of Short-term Load Forecasting Methods for their Deployment on Company Level. In Proceedings of the 4th Grid Service Markets Symposium (GSM 2020), Luzern, Switzerland, 19–20 October 2020; pp. 88–102. [Google Scholar]

- Stricker, N.; Kuhnle, A.; Sturm, R.; Friess, S. Reinforcement learning for adaptive order dispatching in the semiconductor industry. CIRP Ann.-Manuf. Technol. 2018, 67, 511–514. [Google Scholar] [CrossRef]

- Sutton, R.S.; Barto, A.G. Reinforcement Learning: An Introduction, 2nd ed.; Adaptive Computation and Machine Learning; MIT Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Arulkumaran, K.; Deisenroth, M.P.; Brundage, M.; Bharath, A.A. Deep Reinforcement Learning: A Brief Survey. IEEE Signal Process. Mag. 2017, 34, 26–38. [Google Scholar] [CrossRef]

- Kaelbling, L.P.; Littman, M.L.; Moore, A.W. Reinforcement learning: A survey. J. Artif. Intell. Res. 1996, 4, 237–285. [Google Scholar] [CrossRef]

- Kuhnle, A.; Kaiser, J.P.; Theiß, F.; Stricker, N.; Lanza, G. Designing an adaptive production control system using reinforcement learning. J. Intell. Manuf. 2020. [Google Scholar] [CrossRef]

- Fishman, G.S. Discrete-Event Simulation: Modeling, Programming, and Analysis; Springer Series in Operations Research; Springer: New York, NY, USA, 2001. [Google Scholar]

- DIN Spec 91329. Extension of the EPCIS event model by aggregated production events for use in corporate information systems. Beuth Verlag: Berlin, Germany, 2016.

- Schel, D.; Henkel, C.; Stock, D.; Meyer, O.; Rauhöft, G.; Einberger, P.; Stöhr, M.; Daxer, M.A.; Seidelmann, J. Manufacturing Service Bus: An Implementation. Procedia CIRP 2018, 67, 179–184. [Google Scholar] [CrossRef]

- Mönch, L.; Fowler, J.W.; Mason, S.J. Production Planning and Control for Semiconductor Wafer Fabrication Facilities: Modeling, Analysis, and Systems; Operations Research/Computer Science Interfaces Series; Springer: New York, NY, USA, 2013; Volume 52. [Google Scholar] [CrossRef]

- Aelker, J.; Bauernhansl, T.; Ehm, H. Managing Complexity in Supply Chains: A Discussion of Current Approaches on the Example of the Semiconductor Industry. Procedia CIRP 2013, 7, 79–84. [Google Scholar] [CrossRef]

- Mönch, L.; Fowler, J.W.; Dauzère-Pérès, S.; Mason, S.J.; Rose, O. A survey of problems, solution techniques, and future challenges in scheduling semiconductor manufacturing operations. J. Sched. 2011, 14, 583–599. [Google Scholar] [CrossRef]

- Kremers, L. 2010 State of Supply Chain Performance in Semiconductor Industry; iCognitive: Singapore, 2011. [Google Scholar]

- Chien, C.F.; Lin, Y.S.; Lin, S.K. Deep reinforcement learning for selecting demand forecast models to empower Industry 3.5 and an empirical study for a semiconductor component distributor. Int. J. Prod. Res. 2020, 58, 2784–2804. [Google Scholar] [CrossRef]

- Waschneck, B.; Bauernhansl, T.; Altenmüller, T.; Kyek, A. Production Scheduling in Complex Job Shops from an Industry 4.0 Perspective: A Review and Challenges in the Semiconductor Industry. i-KNOW 2016. [Google Scholar] [CrossRef]

- Pfund, M.E.; Scott, M.J.; Fowler, J.W. Semiconductor Manufacturing and Scheduling. In Handbook of Production Scheduling; Herrmann, J.W., Ed.; International Series in Operations Research & Management Science; Springer: Boston, MA, USA, 2006; pp. 213–241. [Google Scholar]

- Ehm, H.; Pötzsch, L.; Zeppin, M.; Effert, T.; Geisenberger, S.; Neuhaus, K.; Rimane, D.; Geiger, D.; Kastenholz, E.; Schober, C.; et al. Guideline: Supply Chain Management in Electronics Manufacturing; ZVEI: Frankfurt, Germany, 2014. [Google Scholar]

- Otto, B.; Jarke, M. Designing a multi-sided data platform: Findings from the International Data Spaces case. Electron. Mark. 2019, 29, 561–580. [Google Scholar] [CrossRef]

- De Waal, A.; Weaver, M.; Day, T.; van der Heijden, B. Silo-Busting: Overcoming the Greatest Threat to Organizational Performance. Sustainability 2019, 11, 6860. [Google Scholar] [CrossRef]

- Sarin, S.C.; Varadarajan, A.; Wang, L. A survey of dispatching rules for operational control in wafer fabrication. Prod. Plan. Control 2011, 22, 4–24. [Google Scholar] [CrossRef]

- Burkart, N.; Huber, M.F. A Survey on the Explainability of Supervised Machine Learning. J. Artif. Intell. Res. 2021, 70, 245–317. [Google Scholar] [CrossRef]

- Fowler, J.W.; Robinson, J. Measurement and Improvement of Manufacturing Capacity (MIMAC): Final Report; SEMATECH: Austin, TX, USA, 1995. [Google Scholar]

| Category According to [42] | Characteristic Representative |

|---|---|

| (1) Control of Inventory | Wiendahl [44] |

| (2) Control of Capacity | Begemann [45] |

| (3) Control of Load | Scholz-Reiter et al. [46] |

| (4) Control by Rescheduling | Brackel [47] |

| (5) Knowledge-based Control | Philipp et al. [48] |

| (6) Model-based Control | Sachs et al. [49] |

| No. | Requirement |

|---|---|

| (1) | Suitability for the Application |

| (2) | External Events |

| (3) | Adaptivity |

| (4) | Learning Capability |

| (5) | Degree of Automation |

| (6) | Multi-dimensional Parameters |

| (7) | Seamless Integration |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bauer, D.; Bauernhansl, T.; Sauer, A. Improvement of Delivery Reliability by an Intelligent Control Loop between Supply Network and Manufacturing. Appl. Sci. 2021, 11, 2205. https://doi.org/10.3390/app11052205

Bauer D, Bauernhansl T, Sauer A. Improvement of Delivery Reliability by an Intelligent Control Loop between Supply Network and Manufacturing. Applied Sciences. 2021; 11(5):2205. https://doi.org/10.3390/app11052205

Chicago/Turabian StyleBauer, Dennis, Thomas Bauernhansl, and Alexander Sauer. 2021. "Improvement of Delivery Reliability by an Intelligent Control Loop between Supply Network and Manufacturing" Applied Sciences 11, no. 5: 2205. https://doi.org/10.3390/app11052205

APA StyleBauer, D., Bauernhansl, T., & Sauer, A. (2021). Improvement of Delivery Reliability by an Intelligent Control Loop between Supply Network and Manufacturing. Applied Sciences, 11(5), 2205. https://doi.org/10.3390/app11052205