Notch Fracture in Polymeric Specimens under Compressive Stresses: The Role of the Equivalent Material Concept in Estimating the Critical Stress of Polymers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

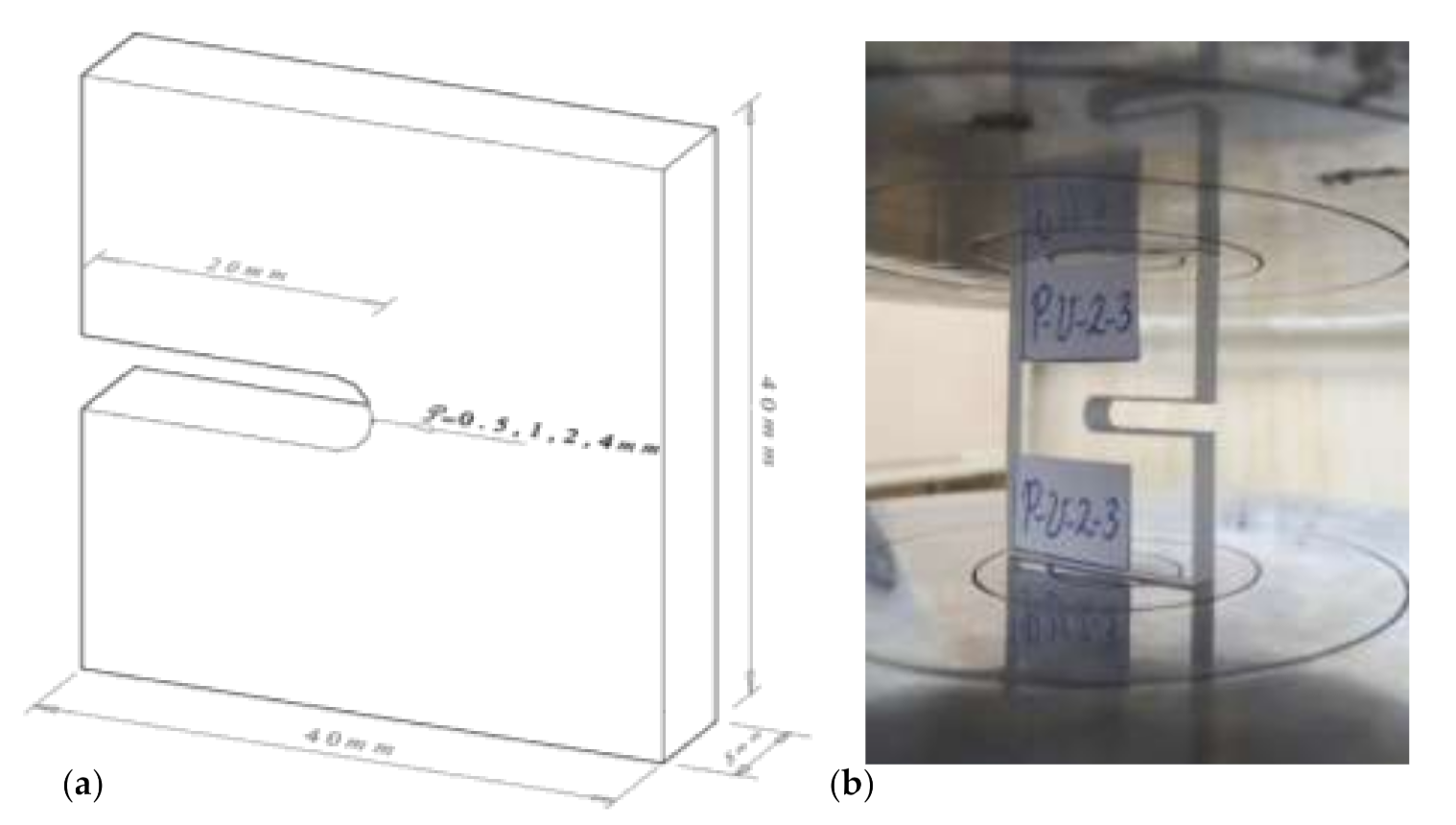

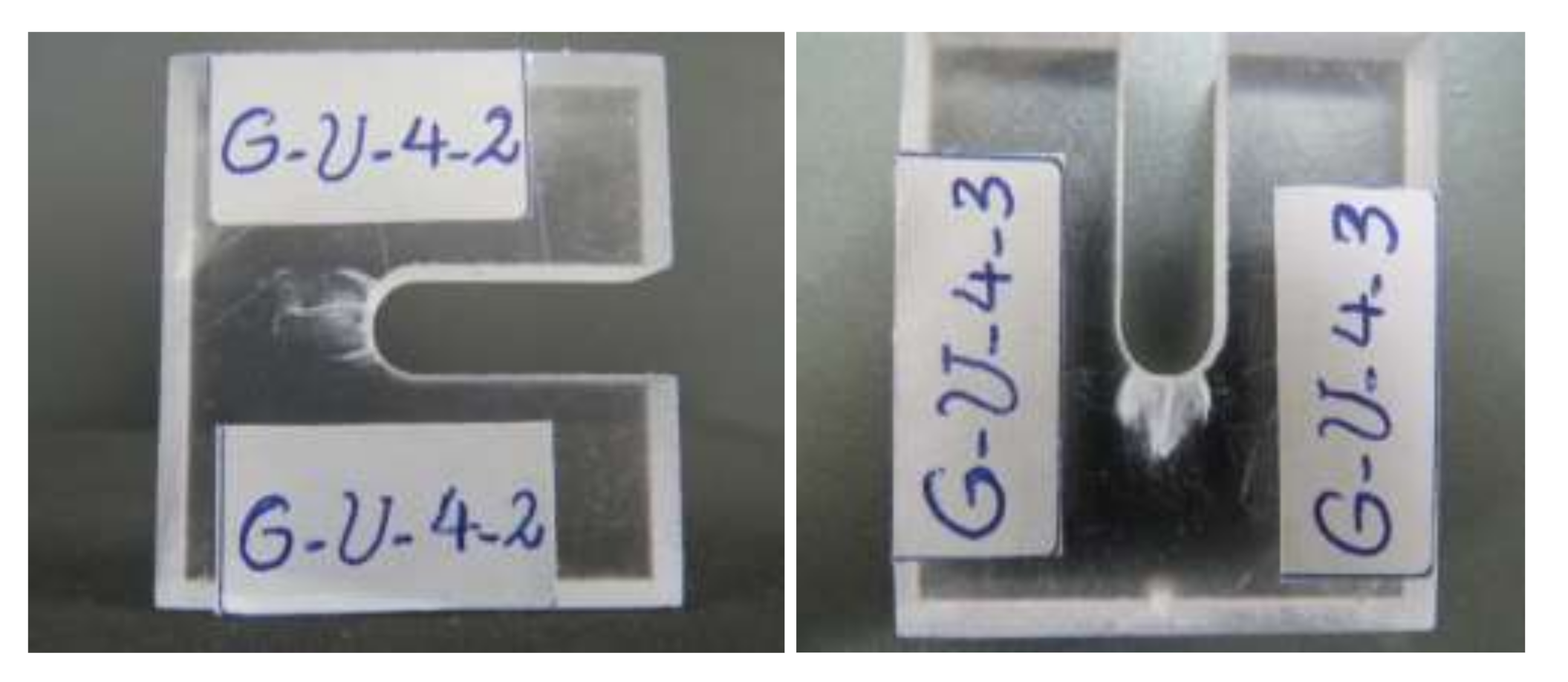

2.2. Fracture Tests on Notched Specimens

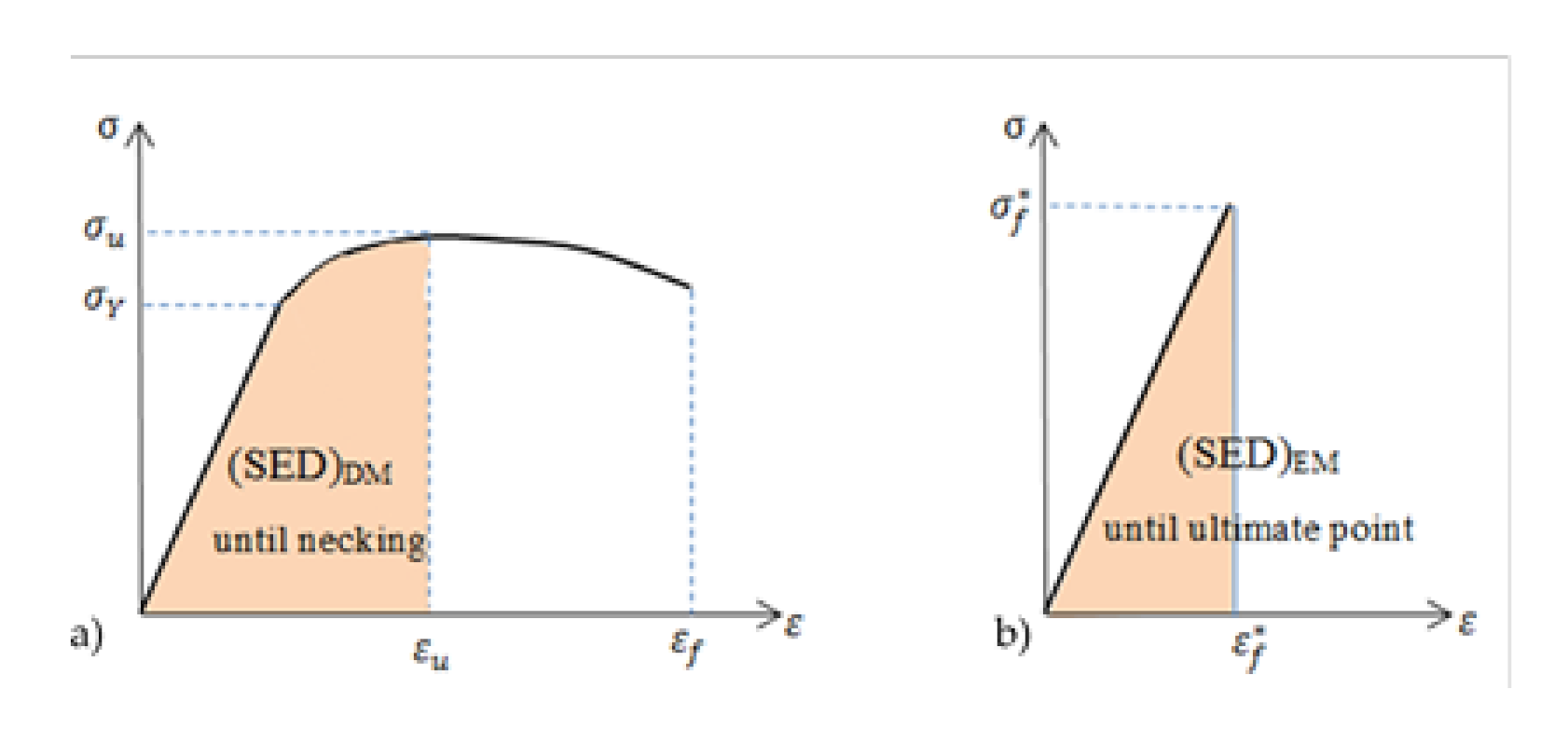

2.3. The Equivalent Material Concept under Compression Loading

2.4. Extension of the EMC to Compressive Loading

2.5. The maximum Tangential Stress and the Mean Stress Criteria under Positive Mode I Loading

2.6. MTS and MS Criteria under Negative Mode I Loading

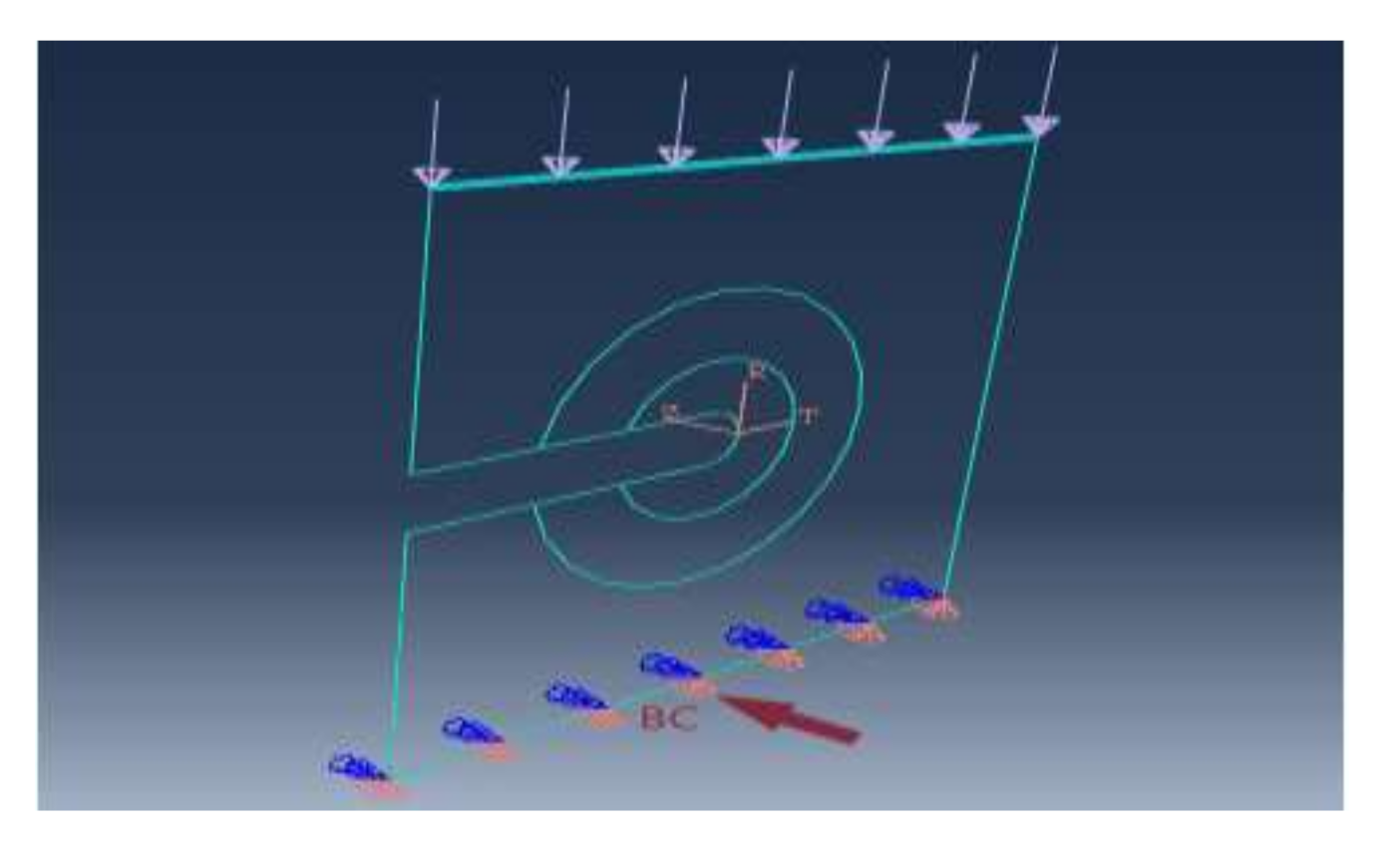

2.7. Finite Element Analysis

3. Results and Discussion

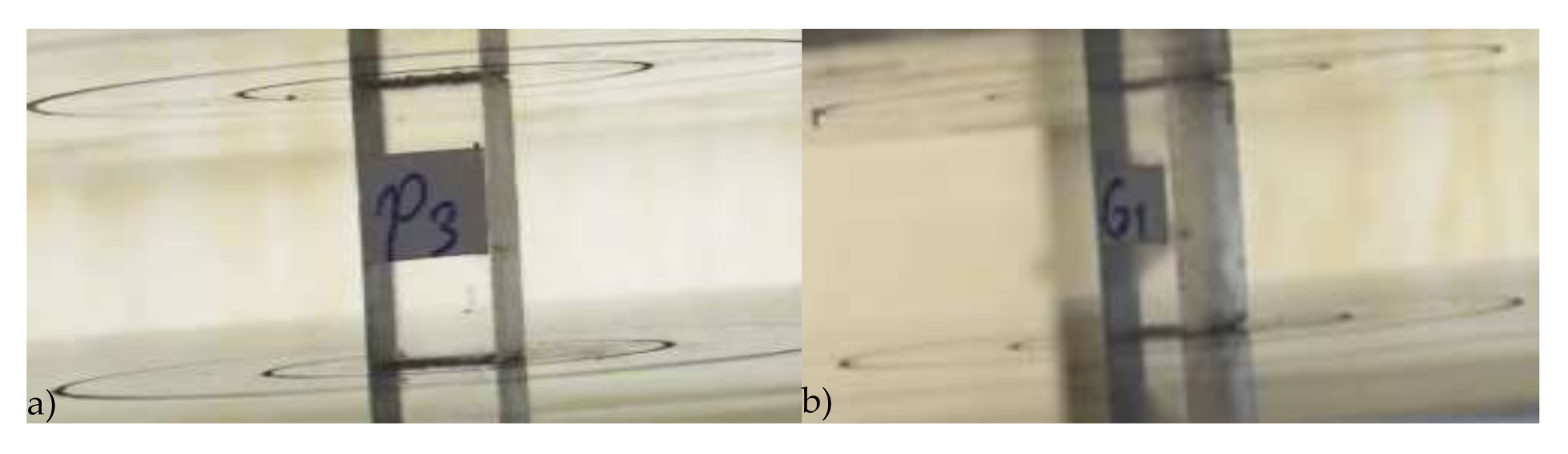

3.1. Material Characterization Tests

3.2. Fracture Tests on Notched Specimens

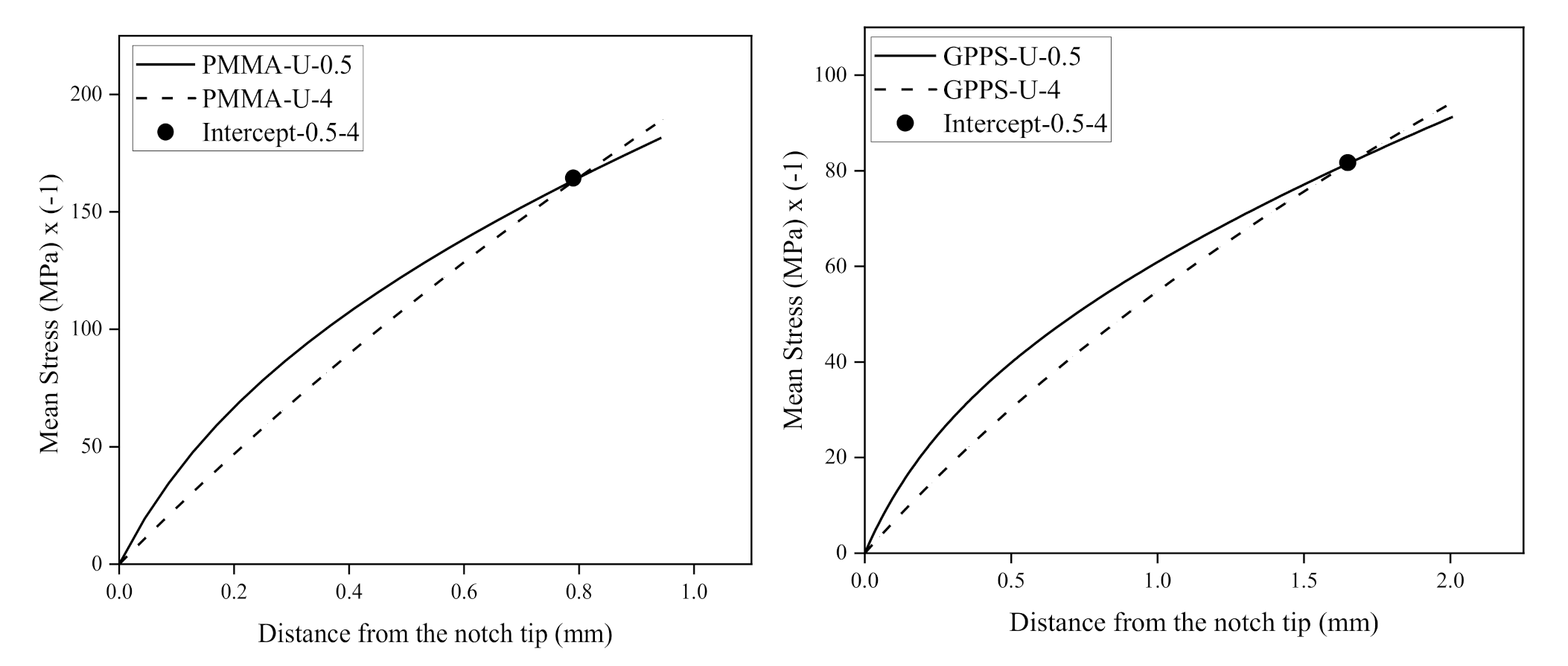

3.3. Calibration of Critical Stresses and Critical Distances

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lazzarin, P.; Zambardi, R. A finite-volume-energy based approach to predict the static and fatigue behavior of components with sharp V-shaped notches. Int. J. Fract. 2001, 112, 275–298. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Torabi, A.R. Determination of mode II fracture toughness for U-shaped notches using Brazilian disc specimen. Int. J. Solids Struct. 2010, 47, 454–465. [Google Scholar] [CrossRef]

- Zappalorto, M.; Carraro, P.A. An efficient energy-based approach for the numerical assessment of mode I NSIFs in isotropic and orthotropic notched plates. Theor. Appl. Fract. Mech. 2020, 108, 102612. [Google Scholar] [CrossRef]

- Gogotsi, G.A. Fracture toughness of ceramics and ceramic composites. Ceram. Int. 2003, 7, 777–784. [Google Scholar] [CrossRef]

- Bura, E.; Seweryn, A. Mode I fracture in PMMA specimens with notches—Experimental and numerical studies. Theor. Appl. Fract. Mech. 2018, 97, 140–155. [Google Scholar] [CrossRef]

- Gomez, F.J.; Elices, M.; Valiente, A. Cracking in PMMA containing U-shaped notches. Fatigue Fract. Eng. Mater. Struct. 2000, 23, 795–803. [Google Scholar] [CrossRef]

- Gomez, F.J.; Guinea, G.V.; Elices, M. Failure criteria for linear elastic materials with U-notches. Int. J. Fract. 2006, 141, 99–113. [Google Scholar] [CrossRef]

- Torabi, A.R.; Berto, F. Strain energy density to assess mode II fracture in U-notched disk-type graphite plates. Int. J. Damage Mech. 2014, 23, 917–930. [Google Scholar] [CrossRef]

- Kim, J.K.; Cho, S.B. Effect of second non-singular term of mode I near the tip of a V-notched crack. Fatigue Fract. Eng. Mater. Struct. 2009, 32, 346–356. [Google Scholar] [CrossRef]

- Sangsefidi, M.; Akbardoos, J.; Mesbah, M. Experimental and theoretical fracture assessment of rock-type U-notched specimens under mixed mode I/II loading. Eng. Fract. Mech. 2020, 230, 106990. [Google Scholar] [CrossRef]

- Berto, F.; Lazzarin, P.; Gomez, F.J.; Elices, M. Fracture assessment of U-notches under mixed mode loading: Two procedures based on the equivalent local mode I concept. Int. J. Fract. 2007, 148, 415–433. [Google Scholar] [CrossRef]

- Campagnolo, A.; Berto, F.; Leguillon, D. Fracture assessment of sharp V-notched components under Mode II loading: A comparison among some recent criteria. Theor. Appl. Fract. Mech. 2016, 85, 217–226. [Google Scholar] [CrossRef]

- Berto, F.; Lazzarin, P.; Marangon, C. Brittle fracture of U-notched graphite plates under mixed mode loading. Mater. Des. 2012, 41, 421–432. [Google Scholar] [CrossRef]

- Gomez, F.J.; Elices, M.; Berto, F.; Lazzarin, P. Local strain energy to assess the static failure of U-notches in plates under mixed mode loading. Int. J. Fract. 2007, 145, 29–45. [Google Scholar] [CrossRef]

- Berto, F.; Lazzarin, P. A review of the volume-based strain energy density approach applied to V-notches and welded structures. Theor. Appl. Fract. Mech. 2009, 52, 183–194. [Google Scholar] [CrossRef]

- Chen, D.H.; Ozaki, S. Investigation of failure criteria for a sharp notch. Int. J. Fract. 2008, 152, 63–74. [Google Scholar] [CrossRef]

- Jin, F.L.; Li, X.; Park, S.J. Synthesis and application of epoxy resins: A review. J. Indust. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Rodriguez, J.; Salazar, A.; Gómez, F.J.; Patel, Y.; Williams, J.G. Fracture of notched samples in epoxy resin: Experiments and cohesive model. Eng. Fract. Mech. 2015, 149, 402–411. [Google Scholar] [CrossRef]

- Kanchanomaia, C.; Rattananona, S.; Soni, M. Effects of loading rate on fracture behavior and mechanism of thermoset epoxy resin. Polym. Test 2005, 24, 886–892. [Google Scholar] [CrossRef]

- Razavi, S.M.J.; Ayatollahi, M.R.; Esmaeili, E.; da Silva, L.F.M. Mixed-mode fracture response of metallic fiber-reinforced epoxy adhesive. Eur. J. Mech. A Solids 2017, 65, 349–359. [Google Scholar] [CrossRef]

- Fiedler, B.; Hojo, M.; Ochiai, S.; Schulte, K.; Ando, M. Failure behavior of an epoxy matrix under different kinds of static loading. Comp. Sci. Tech. 2001, 61, 1615–1624. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Bahmani, A.; Akhondi, S. Mixed mode fracture toughness testing of PMMA with different three-point. bend type specimens. Eur. J. Mech. A Solids 2016, 58, 148–162. [Google Scholar] [CrossRef]

- Berto, F.; Campagnolo, A.; Elices, M.; Lazzarin, P. A synthesis of Polymethylmethacrylate data from U-notched specimens and V-notches with end holes by means of local energy. Mater. Des. 2013, 49, 826–833. [Google Scholar] [CrossRef]

- Cottrell, B. Brittle fracture in compression. Int. J. Fract. Mech. 1972, 8, 195–208. [Google Scholar] [CrossRef]

- Hoek, E.; Bieniawski, Z.T. Brittle fracture propagation in rock under compression. Int. J. Fract. Mech. 1965, 1, 137–155. [Google Scholar] [CrossRef]

- Kawakami, H. Notch sensitivity of graphite materials for VHTR. J. Atom. Energy Soc. Jpn. 1985, 27, 357–364. [Google Scholar] [CrossRef][Green Version]

- Wang, E.Z.; Shrive, N.G. Brittle fracture in compression: Mechanisms, models and criteria. Eng. Fract. Mech. 1995, 52, 1107–1126. [Google Scholar] [CrossRef]

- Lajtai, E.Z. Brittle fracture in compression. Int. J. Fract. 1974, 10, 525–536. [Google Scholar] [CrossRef]

- Lajtai, E.Z.; Carter, B.J.; Ayari, M.L. Criteria for brittle fracture in compression. Eng. Fract. Mech. 1990, 37, 59–74. [Google Scholar] [CrossRef]

- Bell, J.F. The experimental foundations of solid mechanics. In Encyclopedia of Physics; Springer: Berlin, Germany; New York, NY, USA, 1973; Volume 1, Section 3.3. [Google Scholar]

- Berto, F.; Lazzarin, P.; Ayatollahi, M.R. Brittle fracture of sharp and blunt V-notches in isostatic graphite under pure compression loading. Carbon 2013, 63, 101–116. [Google Scholar] [CrossRef]

- Torabi, A.R.; Ayatollahi, M.R. Compressive brittle fracture in V-notches with end holes. Eur. J. Mech. A/Solids 2014, 45, 32–40. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Torabi, A.R.; Firoozabadi, M. Theoretical and experimental investigation of brittle fracture in V-notched PMMA specimens under compressive loading. Eng. Fract. Mech. 2015, 135, 187–205. [Google Scholar] [CrossRef]

- Torabi, A.R.; Bahrami, B.; Ayatollahi, M.R. Mixed mode I/II brittle fracture in V-notched Brazilian Disk specimens under negative mode I conditions. Phys. MesoMech. 2016, 19, 332–348. [Google Scholar] [CrossRef]

- Torabi, A.R.; Majidi, H.R.; Ayatollahi, M.R. Brittle failure of key-hole notches under mixed mode I/II loading with negative mode I contributions. Eng. Fract. Mech. 2016, 168, 51–72. [Google Scholar] [CrossRef]

- Majidi, H.R.; Ayatollahi, M.R.; Torabi, A.R.; Zaheri, A. Energy-based assessment of brittle fracture in VO-notched polymer specimens under combined compression-shear loading conditions. Int. J. Damage Mech. 2019, 28, 664–689. [Google Scholar] [CrossRef]

- Bura, E.; Derpeński, Ł.; Seweryn, A. Fracture in PMMA notched specimens under compression—Experimental study. Polym. Test 2019, 77, 105923. [Google Scholar] [CrossRef]

- Torabi, A.R. Estimation of tensile load-bearing capacity of ductile metallic materials weakened by a V-notch: The equivalent material concept. Mater. Sci. Eng. A 2012, 536, 249–255. [Google Scholar] [CrossRef]

- Majidi, H.R.; Razavi, S.M.J.; Torabi, A.R. Application of EMC-J criterion to fracture prediction of U-notched polymeric specimens with nonlinear behaviour. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 352–362. [Google Scholar] [CrossRef]

- Torabi, A.R.; Berto, F.; Campagnolo, A. Elastic-plastic fracture analysis of notched Al 7075-T6 plates by means of the local energy combined with the Equivalent Material Concept. Phys. Mesomech. 2016, 19, 204–213. [Google Scholar] [CrossRef]

- Majidi, H.R.; Golmakani, M.E.; Torabi, A.R. On combination of the equivalent material concept and J-integral criterion for ductile failure prediction of U-notches subjected to tension. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 1476–1487. [Google Scholar] [CrossRef]

- Cicero, S.; Torabi, A.R.; Madrazo, V.; Azizi, P. Prediction of fracture loads in PMMA Unotched specimens using the equivalent material concept and the theory of critical distances combined criterion. Fatigue Fract. Eng. Mater. Struct. 2017, 41, 688–699. [Google Scholar] [CrossRef]

- Rahimi, A.S.; Ayatollahi, M.R.; Torabi, A.R. Fracture study in notched ductile polymeric plates subjected to mixed mode I/II loading: Application of equivalent material concept. Eur. J. Mech. A Solids 2018, 70, 37–43. [Google Scholar] [CrossRef]

- Rahimi, A.S.; Torabi, A.R.; Ayatollahi, M.R. Ductile failure analysis of blunt V-notched epoxy resin plates subjected to combined tension-shear loading. Polym. Test 2018, 70, 57–66. [Google Scholar] [CrossRef]

- ASTM D695-10. Standard Test Method for Compressive Properties of Rigid Plastics; American Society of Testing and Materials: Philadelphi, PA, USA, 2010. [Google Scholar]

- Erdogan, F.; Sih, G.C. On the crack extension in plates under plane loading and transverse shear. J. Basic Eng. Trans. ASME 1963, 85, 525–527. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Torabi, A.R.; Rahimi, A.S. Brittle fracture assessment of engineering components in the presence of notches: A review. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 267–291. [Google Scholar] [CrossRef]

- Wieghardt, K. Ueber das Spalten und Zerreissen elastischer Koerper. Z. Mathematik und Physik 1995, 55, 60–103. [Google Scholar]

- Seweryn, A. Brittle fracture criterion for structures with sharp notches. Eng. Fract. Mech. 1994, 47, 673–681. [Google Scholar] [CrossRef]

- Taylor, D. The theory of critical distances. Eng. Fract. Mech. 2008, 75, 1696–1705. [Google Scholar] [CrossRef]

| Material | Elastic Modulus, E (GPa) | Poisson’s Ratio υ | Ultimate Compressive Stress, σu (MPa) |

|---|---|---|---|

| PMMA | 1.70 | 0.34 | 86 |

| GPPS | 2.14 | 0.34 | 68 |

| Material | ρ (mm) | P1 (N) | P2 (N) | P3 (N) | Pavg (N) | SD (N) |

|---|---|---|---|---|---|---|

| PMMA | 0.5 | 6663 | 6474 | 6897 | 6678 | 173.0 |

| 1.0 | 7471 | 6879 | 7545 | 7298 | 298.0 | |

| 2.0 | 8575 | 8493 | 8681 | 8583 | 76.9 | |

| 4.0 | 9065 | 9464 | 9271 | 9266 | 162.9 | |

| GPPS | 0.5 | 4028 | 3839 | 4121 | 3996 | 117.3 |

| 1.0 | 4543 | 4323 | 4231 | 4365 | 130.8 | |

| 2.0 | 5396 | 5129 | 4996 | 5173 | 166.3 | |

| 4.0 | 5950 | 6004 | 6423 | 6125 | 211.3 |

| Material | rC (mm), MTS | σC (MPa), MTS | dC (mm), MS | σC (MPa), MS |

|---|---|---|---|---|

| PMMA | 0.25 | −171.9 | 0.79 | −164.4 |

| GPPS | 0.52 | −82.7 | 1.65 | −81.7 |

| Material | Fracture Criterion | Notch Radius, mm | Fracture Load (pred.), N | Fracture Load (exp.), N | Discrepancy, % | Average Discrepancy, % |

|---|---|---|---|---|---|---|

| PMMA | MTS | 0.5 | 6678 | 6678 | 0.0 | 4.7 |

| 1.0 | 6864 | 7298 | −5.9 | |||

| 2.0 | 8433 | 8681 | −3.5 | |||

| 4.0 | 9266 | 9266 | 0.0 | |||

| MS | 0.5 | 6678 | 6678 | 0 | −6.8 | |

| 1.0 | 7036 | 7298 | −3.5 | |||

| 2.0 | 7797 | 8681 | −10.1 | |||

| 4.0 | 9266 | 9266 | 0 | |||

| GPPS | MTS | 0.5 | 3996 | 3996 | 0.0 | −1.4 |

| 1.0 | 4309 | 4365 | −1.2 | |||

| 2.0 | 5048 | 5173 | −1.7 | |||

| 4.0 | 6125 | 6125 | 0.0 | |||

| MS | 0.5 | 3996 | 3996 | 0.0 | −1.5 | |

| 1.0 | 4320 | 4365 | −1.0 | |||

| 2.0 | 5061 | 5173 | −2.1 | |||

| 4.0 | 6125 | 6125 | 0.0 |

| Material | Fracture Criterion | Notch Radius, mm | Fracture Load (pred.), N | Fracture Load (exp.), N | Discrepancy, % | Average Discrepancy, % |

|---|---|---|---|---|---|---|

| PMMA | EMC–MTS | 0.5 | 6726 | 6678 | +0.7 | +1.0 |

| 1.0 | 7369 | 7298 | +0.9 | |||

| 2.0 | 8794 | 8681 | +1.3 | |||

| 4.0 | 9403 | 9266 | +1.4 | |||

| EMC–MS | 0.5 | 6888 | 6678 | +3.1 | +4.6 | |

| 1.0 | 7616 | 7298 | +4.3 | |||

| 2.0 | 9135 | 8681 | +5.2 | |||

| 4.0 | 9835 | 9266 | +6.1 | |||

| GPPS | EMC–MTS | 0.5 | 4123 | 3996 | +3.2 | +4.6 |

| 1.0 | 4530 | 4365 | +3.8 | |||

| 2.0 | 5404 | 5173 | +4.4 | |||

| 4.0 | 6558 | 6125 | +7.0 | |||

| EMC–MS | 0.5 | 4131 | 3996 | +3.4 | +5.4 | |

| 1.0 | 4572 | 4365 | +4.7 | |||

| 2.0 | 5483 | 5173 | +6.0 | |||

| 4.0 | 6591 | 6125 | +7.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torabi, A.R.; Hamidi, K.; Rahimi, A.S.; Cicero, S. Notch Fracture in Polymeric Specimens under Compressive Stresses: The Role of the Equivalent Material Concept in Estimating the Critical Stress of Polymers. Appl. Sci. 2021, 11, 2104. https://doi.org/10.3390/app11052104

Torabi AR, Hamidi K, Rahimi AS, Cicero S. Notch Fracture in Polymeric Specimens under Compressive Stresses: The Role of the Equivalent Material Concept in Estimating the Critical Stress of Polymers. Applied Sciences. 2021; 11(5):2104. https://doi.org/10.3390/app11052104

Chicago/Turabian StyleTorabi, Ali Reza, Kazem Hamidi, Abdol Saleh Rahimi, and Sergio Cicero. 2021. "Notch Fracture in Polymeric Specimens under Compressive Stresses: The Role of the Equivalent Material Concept in Estimating the Critical Stress of Polymers" Applied Sciences 11, no. 5: 2104. https://doi.org/10.3390/app11052104

APA StyleTorabi, A. R., Hamidi, K., Rahimi, A. S., & Cicero, S. (2021). Notch Fracture in Polymeric Specimens under Compressive Stresses: The Role of the Equivalent Material Concept in Estimating the Critical Stress of Polymers. Applied Sciences, 11(5), 2104. https://doi.org/10.3390/app11052104