Thermal Strain-Based Simplified Prediction of Thermal Deformation Caused by Flame Bending

Abstract

:1. Introduction

2. Prediction of Thermal Deformation

2.1. Residual Strain

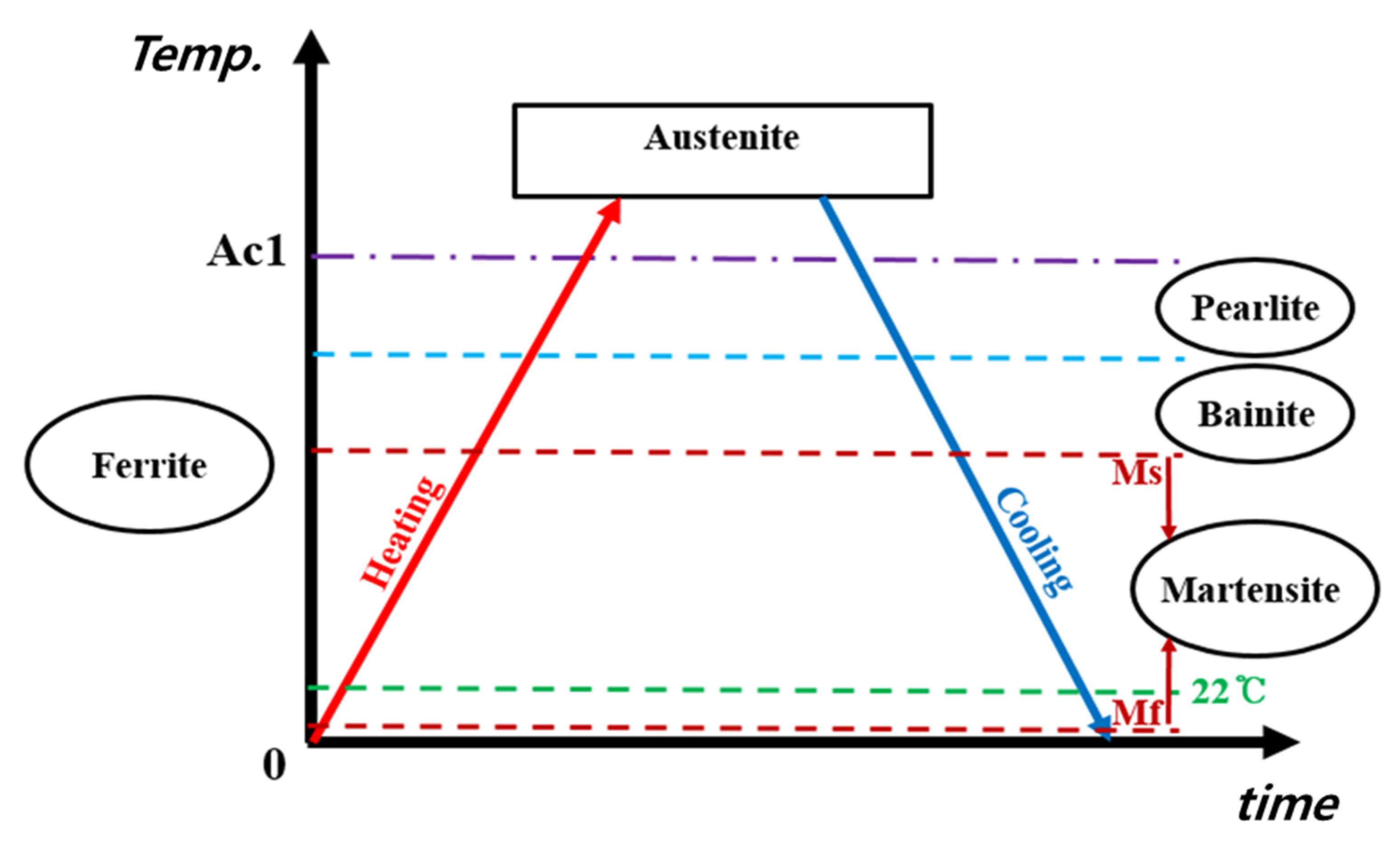

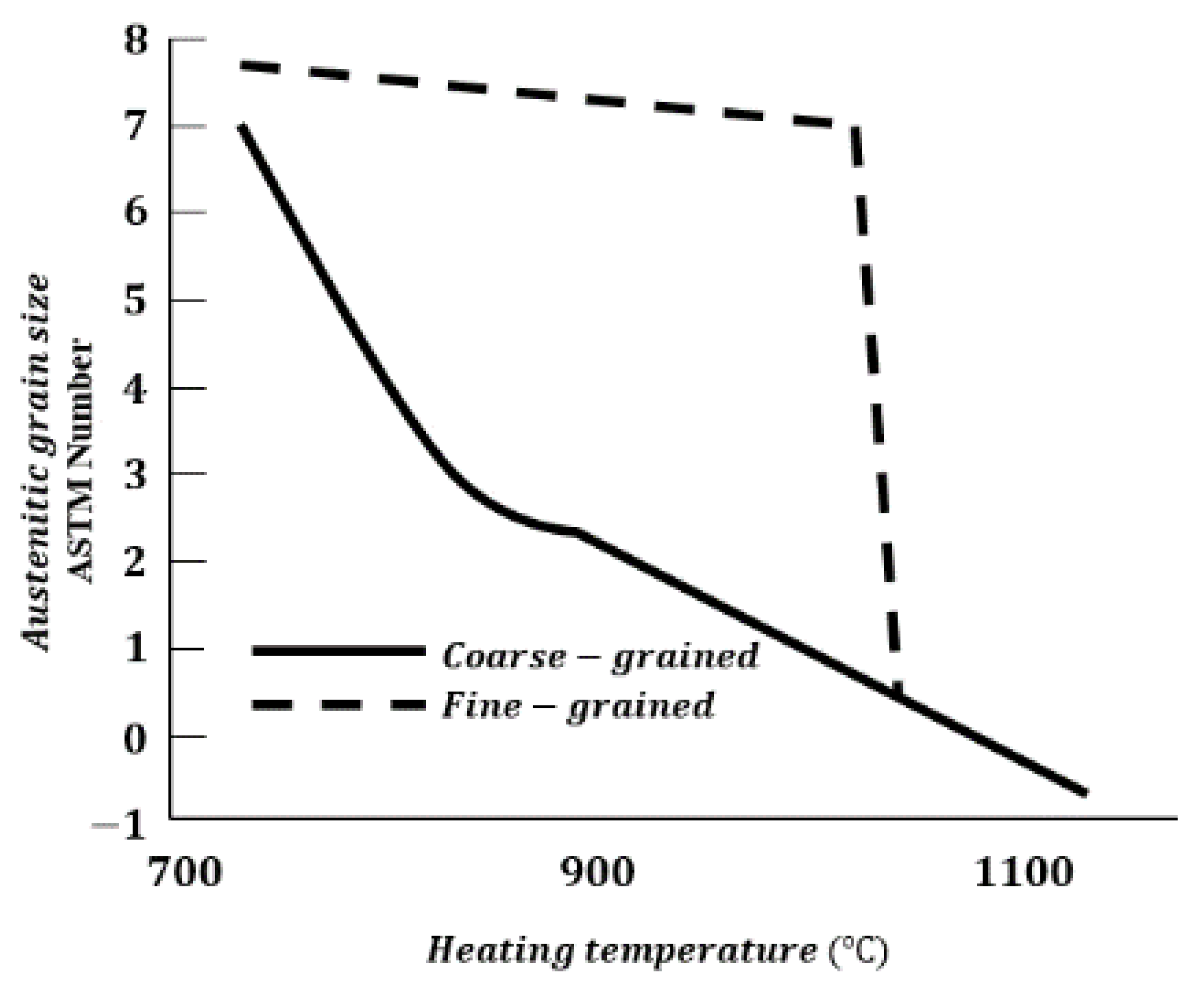

2.2. Phase Transformation during Heating and Cooling Cycle

2.3. Material Properties during Cooling Phase

2.4. Modified Thermal Strain

3. Strain as Direct Boundary (SDB)

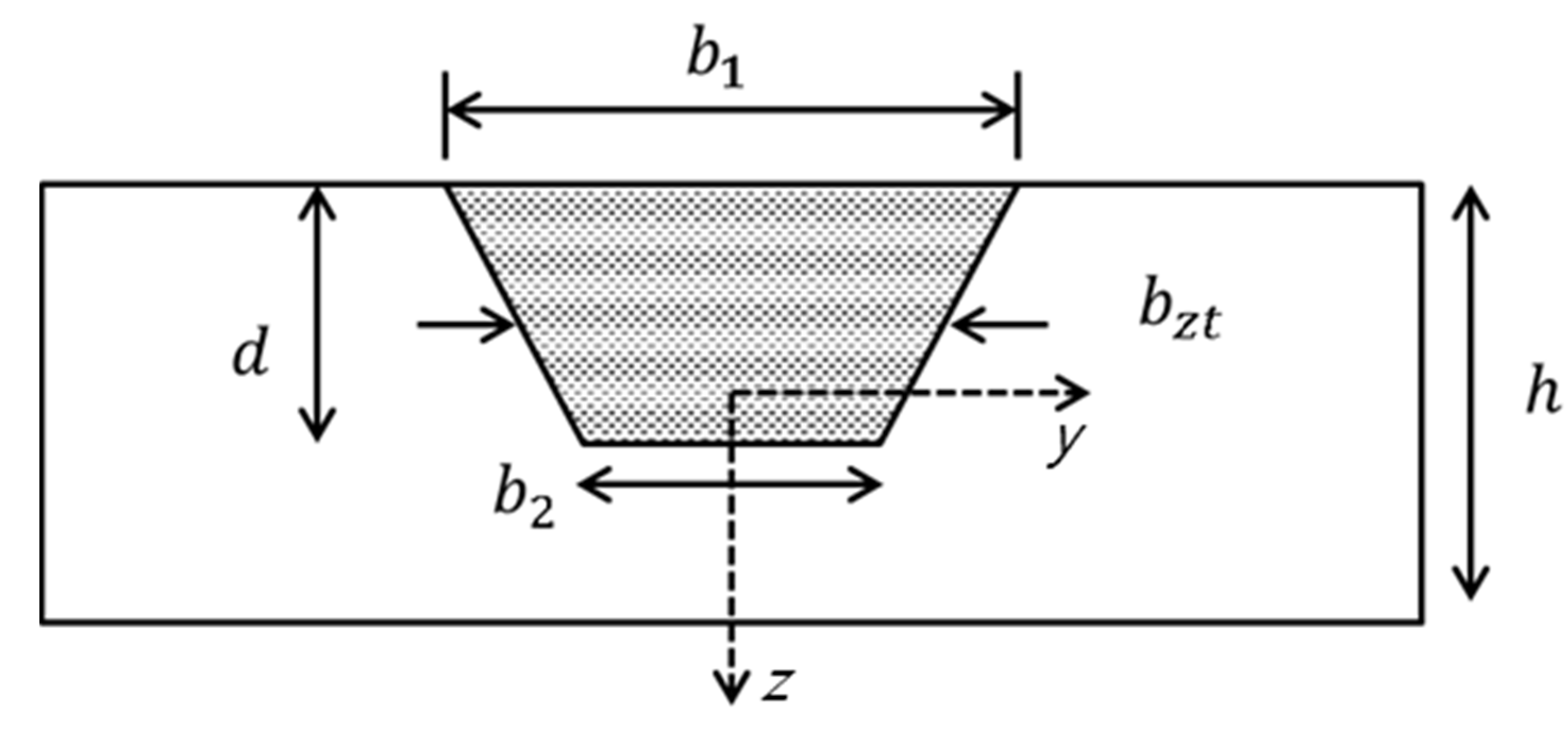

3.1. Determination of Heat Affected Zone (HAZ)

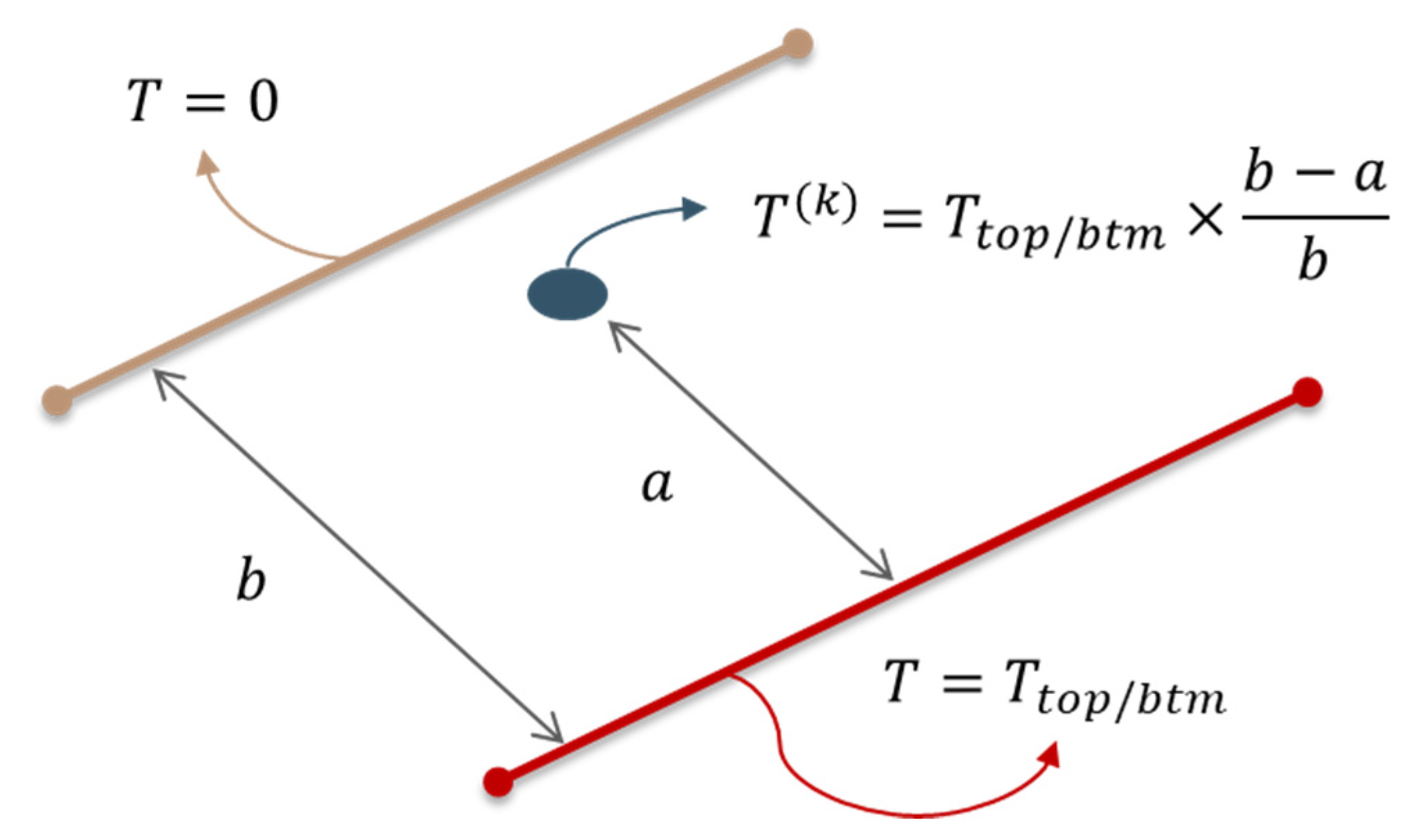

3.2. Determination of Virtual Temperature

4. Application of Method

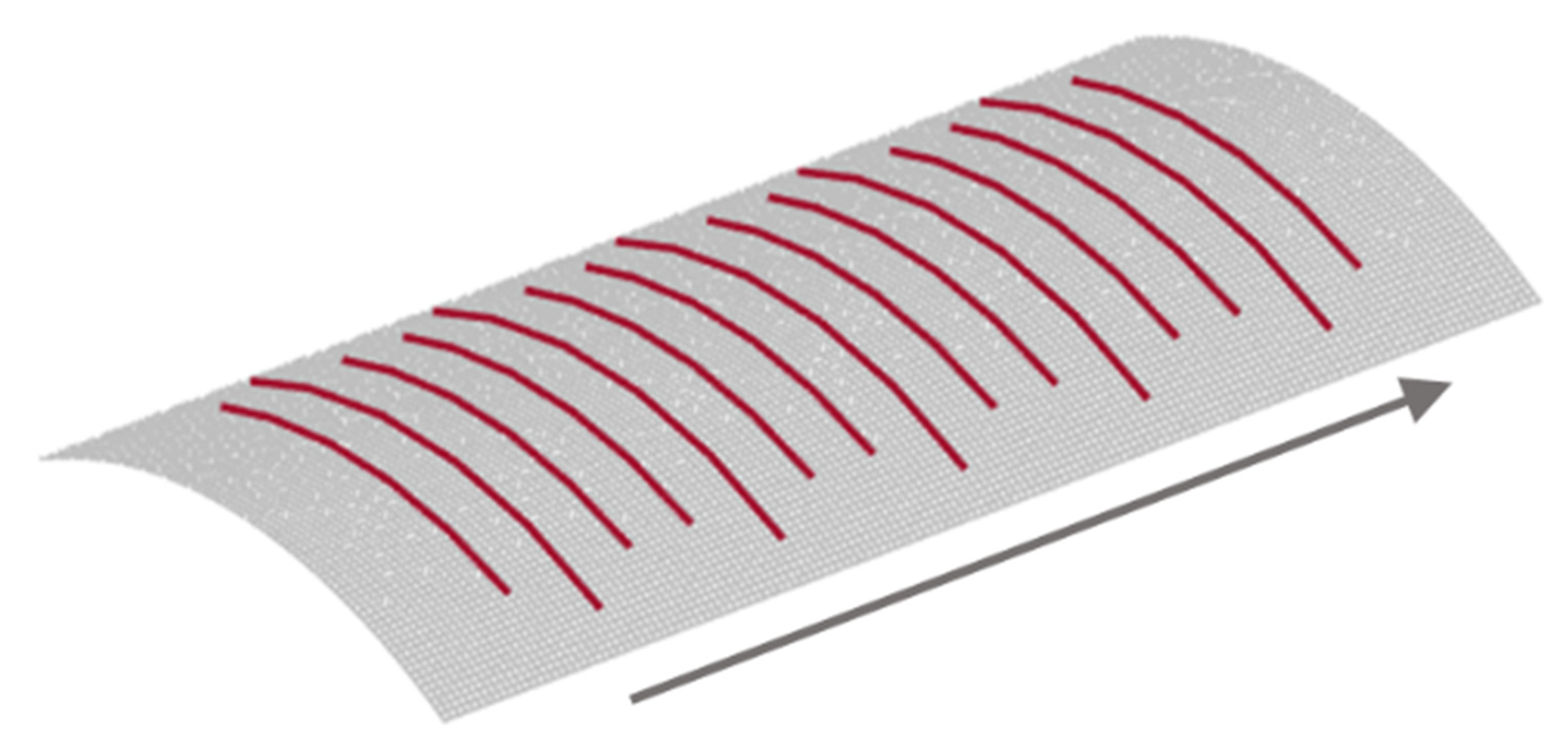

4.1. Problem Description

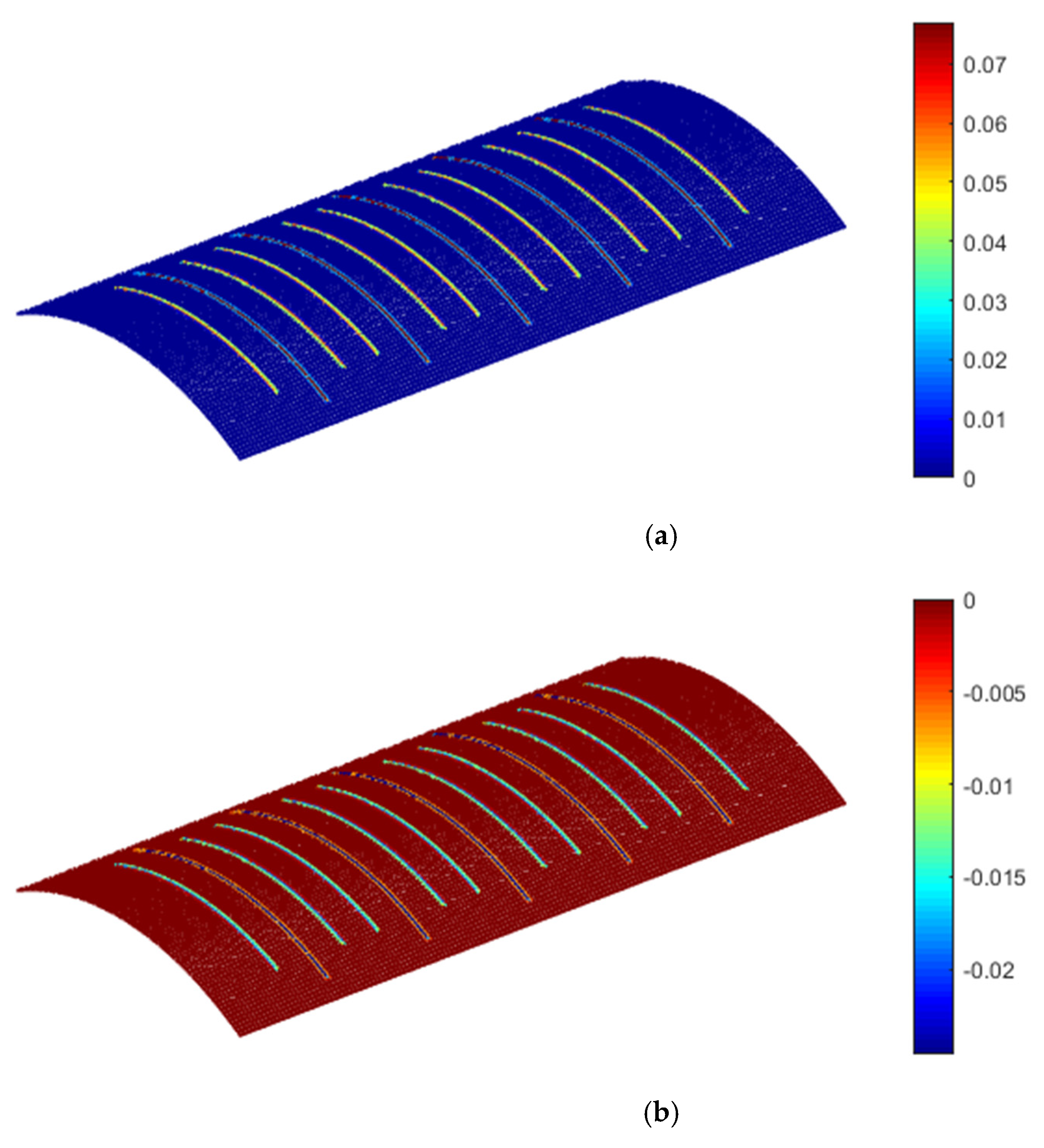

4.2. Virtual Temperature Fields

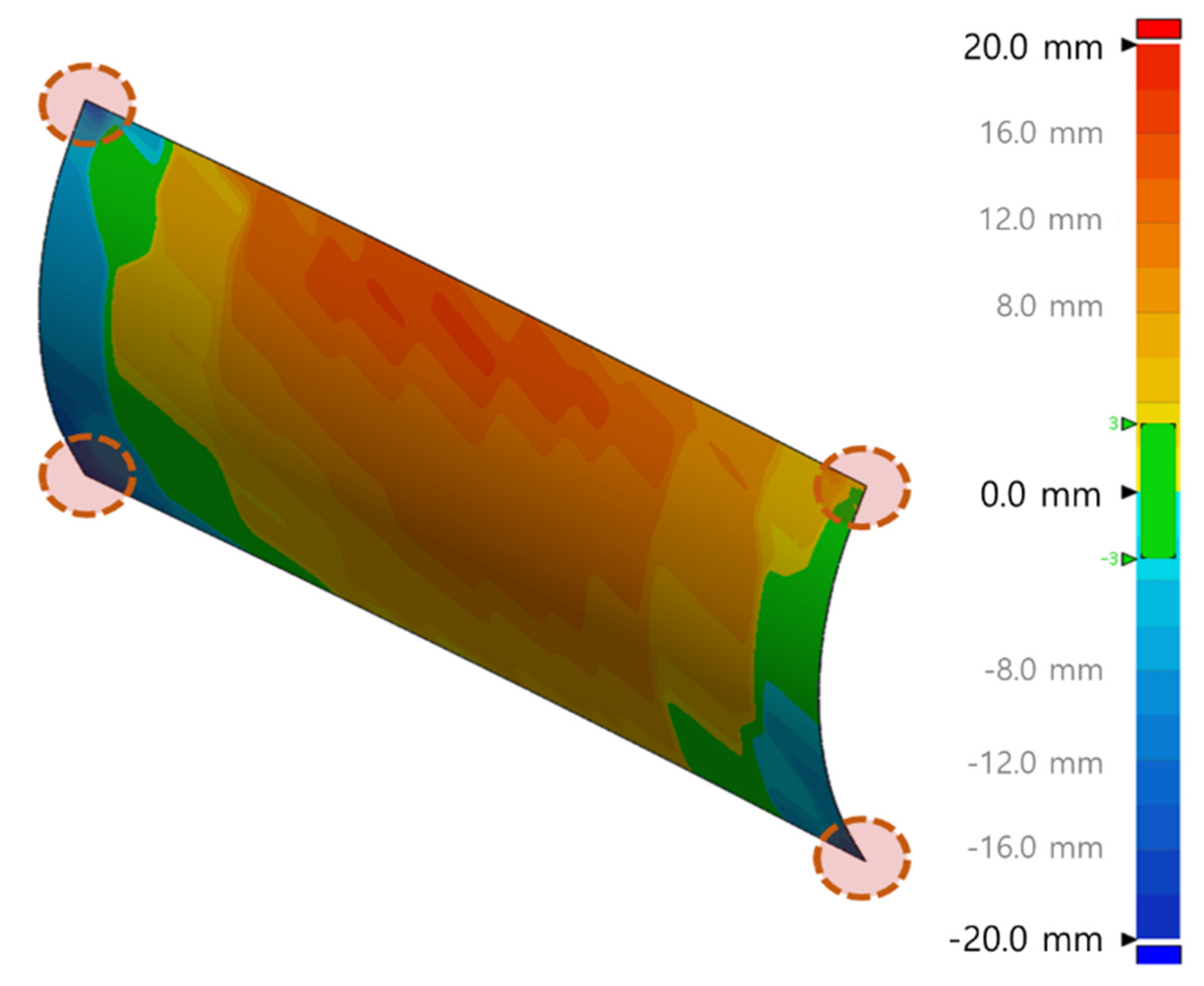

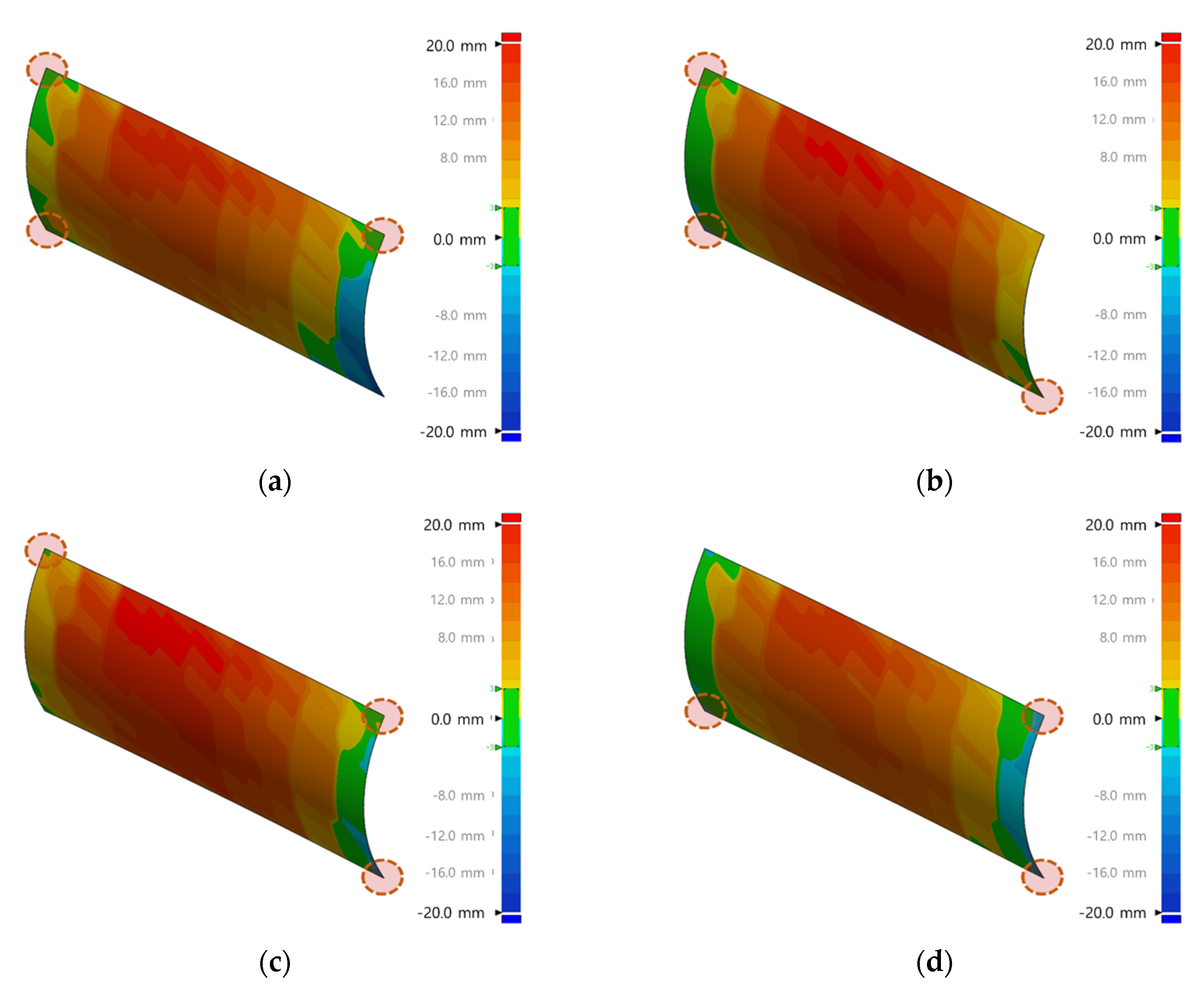

4.3. Results Comparison

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shin, J.G.; Lee, J.H. Nondimensionalized relationship between heating conditions and residual deformations in the line heating process. J. Ship Res. 2002, 46, 229–238. [Google Scholar] [CrossRef]

- Shin, J.G.; Ryu, C.H.; Lee, J.H.; Kim, W.D. User-friendly, advanced line heating automation for accurate plate forming. J. Ship Prod. 2003, 19, 8–15. [Google Scholar] [CrossRef]

- Nomoto, T.; Ohmori, T.; Sutoh, T.; Enosawa, M.; Aoyama, K.; Saitoh, M. Development of simulator for plate bending by line-heating. J. Soc. Nav. Archit. Jpn. 1990, 168, 527–535. [Google Scholar] [CrossRef]

- Jang, C.D.; Kim, H.K.; Ha, Y.S. Prediction of plate bending by high-frequency induction heating. J. Ship Prod. 2002, 18, 226–236. [Google Scholar] [CrossRef]

- Yu, G. Modeling of Shell Forming by Line Heating. Ph.D. Thesis, Massachusetts Institute of Technology, Massachusetts Ave., Cambridge, MA, USA, 2000. [Google Scholar]

- Jang, C.D. A study on the prediction of deformations of plates due to line heating using a simplified thermal elasto-plastic analysis. J. Ship Prod. 1997, 13, 22–27. [Google Scholar] [CrossRef]

- Jang, C.D.; Ha, Y.S.; Ko, D.E. An Improved Inherent Strain Analysis for the Prediction of Plate Deformations Induced by Line Heating Considering Phase Transformation of Steel. In Proceedings of the Thirteenth International Offshore and Polar Engineering Conference, Honolulu, HI, USA, 25–30 May 2003. [Google Scholar]

- Ha, Y.S. Development of thermal distortion analysis method on large shell structure using inherent strain as boundary condition. J. Soc. Nav. Archit. Korea 2008, 45, 93–100. [Google Scholar] [CrossRef]

- Ha, Y.S.; Jang, C.D. Developed Inherent Strain Method Considering Phase Transformation of Mild Steel in Line Heating. J. Soc. Nav. Archit. Korea 2004, 41, 65–74. [Google Scholar]

- Ha, Y.S. A study on weldment boundary condition for elasto-plastic thermal distortion analysis of large welded structures. J. Weld. Join. 2011, 29, 48–53. [Google Scholar] [CrossRef]

- Satoh, K.; Matsui, S.; Terai, K.; Iwamura, Y. Water-cooling effect on angular distortion caused by the process of line heating in steel plates. J. Soc. Nav. Archit. Jpn. 1969, 126, 445–458. [Google Scholar] [CrossRef]

- Chiang, J.; Boyd, J.D.; Pilkey, A.K. Effect of microstructure on retained austenite stability and tensile behaviour in an aluminum-alloyed TRIP steel. Mater. Sci. Eng. A. 2005, 638, 132–142. [Google Scholar] [CrossRef]

- Payson, P.; Savage, C.H. Martensitic reactions in alloy steels. Trans. ASM 1994, 33, 261–275. [Google Scholar]

- Koistinen, D.P.; Marburger, R.E. A general equation prescribing the extent of the austenite-martensite transformation in pure iron-carbon alloys and plain carbon steels. Acta Metall. 1959, 7, 59–60. [Google Scholar] [CrossRef]

- Steven, W. The Temperature of Martensite and Bainite in Low-alloy Steels. J. Iron Steel Inst. 1956, 183, 349–359. [Google Scholar]

- Guo, Z.; Saunders, N.; Miodownik, P.; Schillé, J.P. Modelling phase transformations and material properties critical to the prediction of distortion during the heat treatment of steels. Int. J. Microstruct. Mater. Prop. 2009, 4, 187–195. [Google Scholar] [CrossRef]

- Melloy, G.F. Austenite Grain Size—Its Control and Effects; Metals Engineering Institute, American Society for Metals: Metals Park, OH, USA, 1968. [Google Scholar]

- Swarr, T.; Krauss, G. The effect of structure on the deformation of as-quenched and tempered martensite in an Fe-0.2 pct C alloy. Metall. Trans. A 1976, 7, 41–48. [Google Scholar] [CrossRef]

- Krauss, G.; Marder, A.R. The morphology of martensite in iron alloys. Metall. Trans. 1971, 2, 2343–2357. [Google Scholar] [CrossRef]

- Ha, Y.S.; Jang, C.D. An improved inherent strain analysis for plate bending by line heating considering phase transformation of steel. Int. J. Offshore Polar Eng. 2007, 17, ISOPE-07-17-2-139. [Google Scholar]

- Bain, E.C.; Paxton, H.W. Alloying Elements in Steel; American Society for Metals: Cleveland, OH, USA, 1966. [Google Scholar]

- Krauss, G. Chapter 29, Phases and Structures. In Steels: Processing, Structure, and Performance, 2nd ed.; Materials, P., Ed.; American Society for Metals: Cleveland, OH, USA, 2015; pp. 17–38. [Google Scholar]

- Besl, P.J.; McKay, N.D. A method for registration of 3-D shapes. IEEE Tpami 1992, 14, 239–256. [Google Scholar] [CrossRef]

- Horn, B.K. Closed-form solution of absolute orientation using unit quaternions. J. Opt. Soc. Am. A 1987, 4, 629–642. [Google Scholar] [CrossRef]

| Grade A | C | Si | Mn | P | S |

|---|---|---|---|---|---|

| Wt% | 0.18 | 0.45 | 0.02 | 0.02 | 0.02 |

| Case Number | Max. [mm] | Min. [mm] | Average [mm] | RMS [mm] | Standard Deviation [mm] | Within Tolerance Range [%] |

|---|---|---|---|---|---|---|

| 1 | −17.8434 | 16.3479 | 4.7602 | 8.8977 | 7.5173 | 5.4656 |

| 2 | −15.1433 | 19.5864 | 8.1553 | 11.2521 | 7.7526 | 3.4413 |

| 3 | −6.6646 | 20.7406 | 11.6054 | 13.4235 | 6.7459 | 3.6437 |

| 4 | −6.0407 | 21.7511 | 11.6627 | 13.7764 | 7.3329 | 2.0243 |

| 5 | −6.7746 | 17.9434 | 8.1489 | 10.7141 | 6.9561 | 7.0850 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, S.-Y.; Park, K.-G.; Heo, J.; Lee, J.-H. Thermal Strain-Based Simplified Prediction of Thermal Deformation Caused by Flame Bending. Appl. Sci. 2021, 11, 2011. https://doi.org/10.3390/app11052011

Hwang S-Y, Park K-G, Heo J, Lee J-H. Thermal Strain-Based Simplified Prediction of Thermal Deformation Caused by Flame Bending. Applied Sciences. 2021; 11(5):2011. https://doi.org/10.3390/app11052011

Chicago/Turabian StyleHwang, Se-Yun, Kyoung-Geun Park, Jeeyeon Heo, and Jang-Hyun Lee. 2021. "Thermal Strain-Based Simplified Prediction of Thermal Deformation Caused by Flame Bending" Applied Sciences 11, no. 5: 2011. https://doi.org/10.3390/app11052011

APA StyleHwang, S.-Y., Park, K.-G., Heo, J., & Lee, J.-H. (2021). Thermal Strain-Based Simplified Prediction of Thermal Deformation Caused by Flame Bending. Applied Sciences, 11(5), 2011. https://doi.org/10.3390/app11052011