A Genetic Crow Search Algorithm for Optimization of Operation Sequencing in Process Planning

Abstract

1. Introduction

2. Related Work

3. Operation Sequencing: Problem Formulation

- (1)

- Setup plan includes a group operations that can be performed with the same TADs.

- (2)

- These operations have to be machined using the same machine.

- (3)

- Reduction of machine, tool and TAD changes is an objective.

- (4)

- Only one operation can be performed on a single machine.

- (5)

- Only one operation can be performed using a single cutting tool.

- (6)

- Only one TAD can be used in a given time.

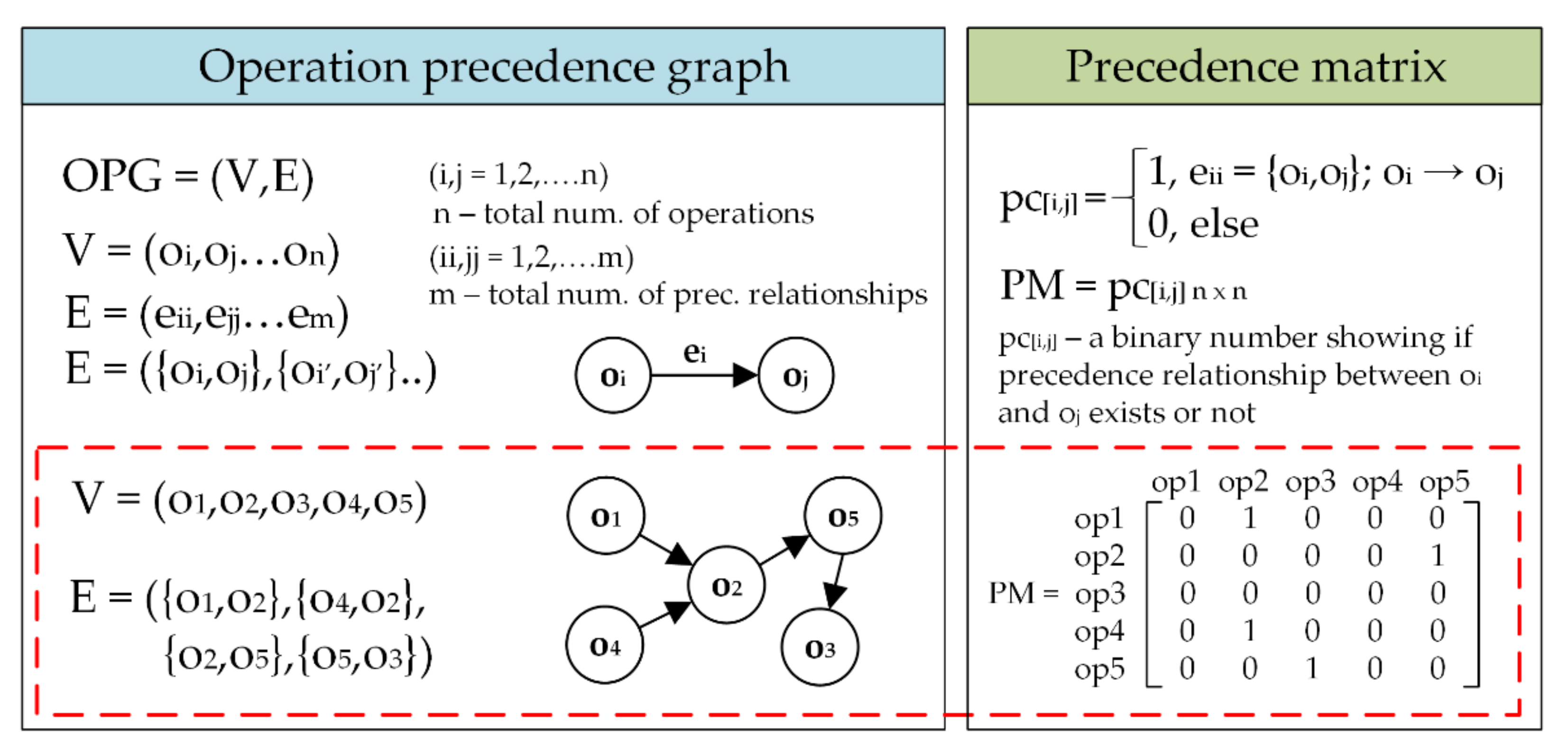

Precedence Constraints

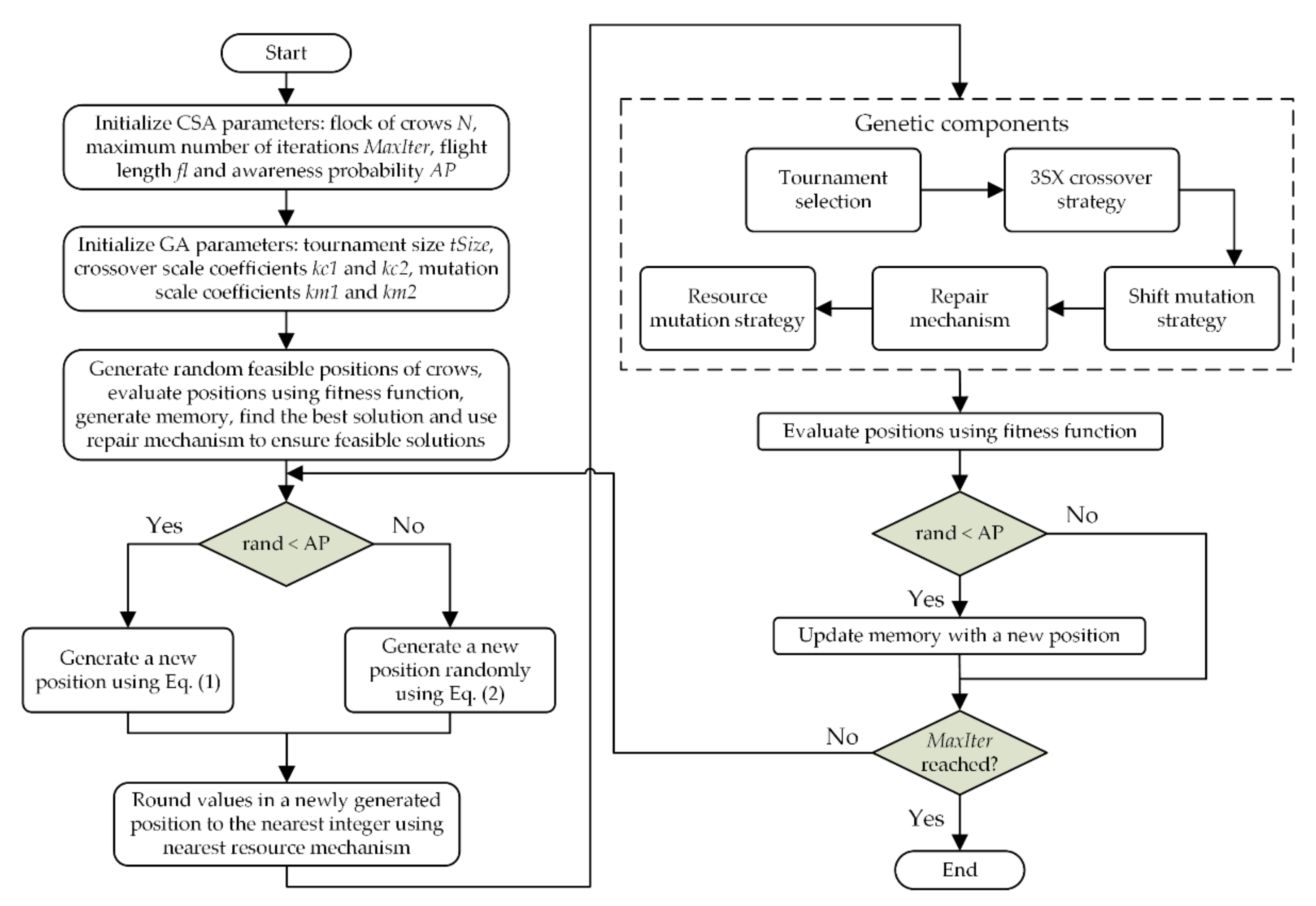

4. A Genetic Crow Search Algorithm (GCSA) for Optimization of Operation Sequencing

4.1. Crow Search Algorithm

4.2. GCSA Methodology

4.3. Evaluation Criterion of the Operation Sequencing Problem

- (1)

- Total machine cost (TMC) — the total sum of costs of used machines where machine cost indices denote the constant cost values for each machine.

- (2)

- Total tool cost (TTC) — the total sum of costs of used cutting tools, where tool cost indices denote the constant cost values for each tool.

- (3)

- Total machine change cost (TMCC)—the product of the number of machine changes and machine change cost indices, which denote the cost values of machine replacement.

- (4)

- Total tool change cost (TTCC)—the product of the number of tool changes and tool change cost indices, which denote the constant cost values of tool replacement.

- (5)

- Total setup cost (TSC)—the product of the number of setup changes and setup change cost indices which denote the constant cost values of a single machine setup.

4.4. Nearest Resource Mechanism

| Algorithm 1. The nearest machine mechanism |

| Machines{} – set of all machine candidates for each operation currentMachine – current machine candidate currentOperation – current operation in a process plan diff = |Machines{currentOperation} – currentMachine| for i = 1: number of operations if currentMachine > Machines{ currentOperation } for j = 1: diff check if the set Machines{currentOperation} contains |currentMachine – diff (j)| Use |currentMachine – diff (j)| as a machine candidate; else continue loop; end if end for elseif currentMachine < Machines{ currentOperation } for j = 1: diff check if the set Machines{currentOperation} contains |currentMachine + diff (j)| Use |currentMachine + diff (j)| as a machine candidate; else continue loop; end if end for else for j = 1: diff check if the set Machines{currentOperation} contains |currentMachine - diff (j)| Use |currentMachine - diff (j)| as a machine candidate; elseif the set Machines{currentOperation} contains |currentMachine + diff (j)| Use |currentMachine + diff (j)| as a machine candidate; end if end for end if end for |

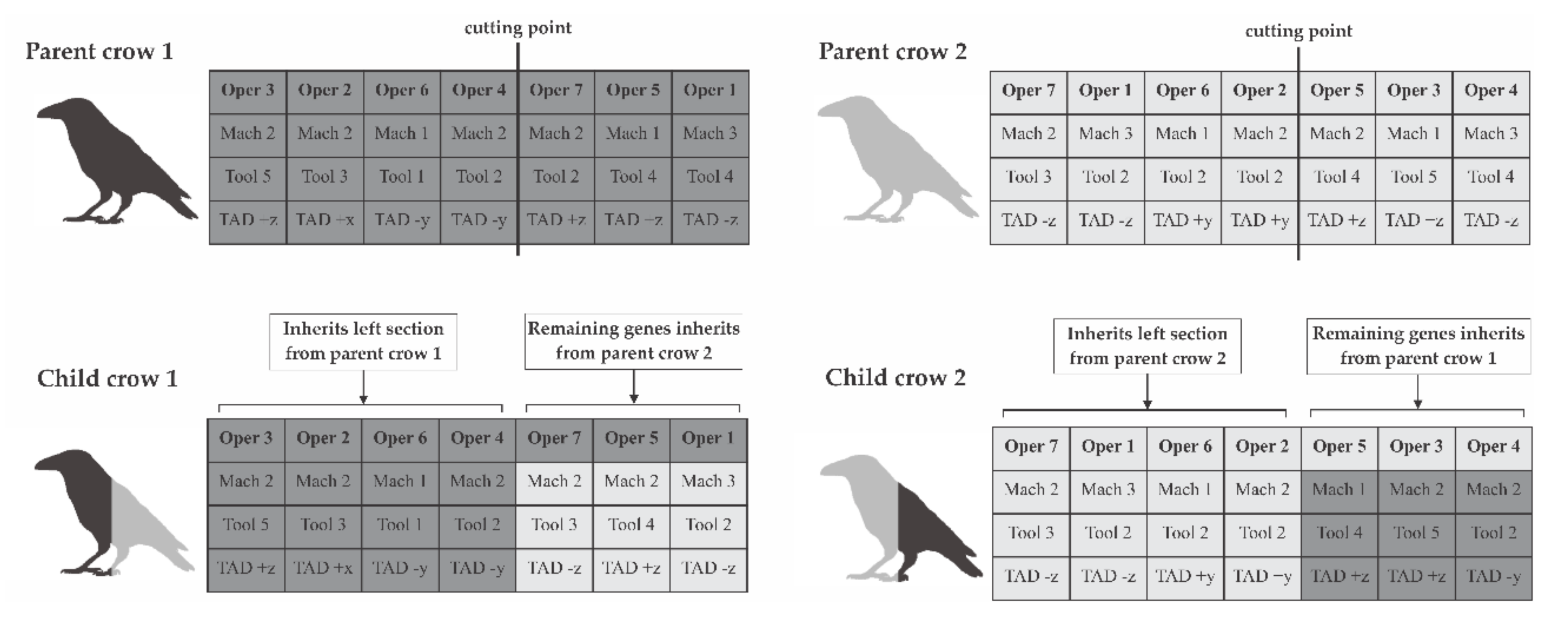

4.5. Genetic Components of the GCSA Approach

- (1)

- Two crows from a new flock are randomly selected as parent crows;

- (2)

- From random cutting point, two parent crows are divided into sections to produce two child crows;

- (3)

- Resources (machines, tools and TADs) from the right section of child crow 1 are replaced by resources of the same operations from parent crow 2;

- (4)

- Following the same pattern, resources in the right section of child crow 2 are replaced by resources of the same operations from parent crow 1.

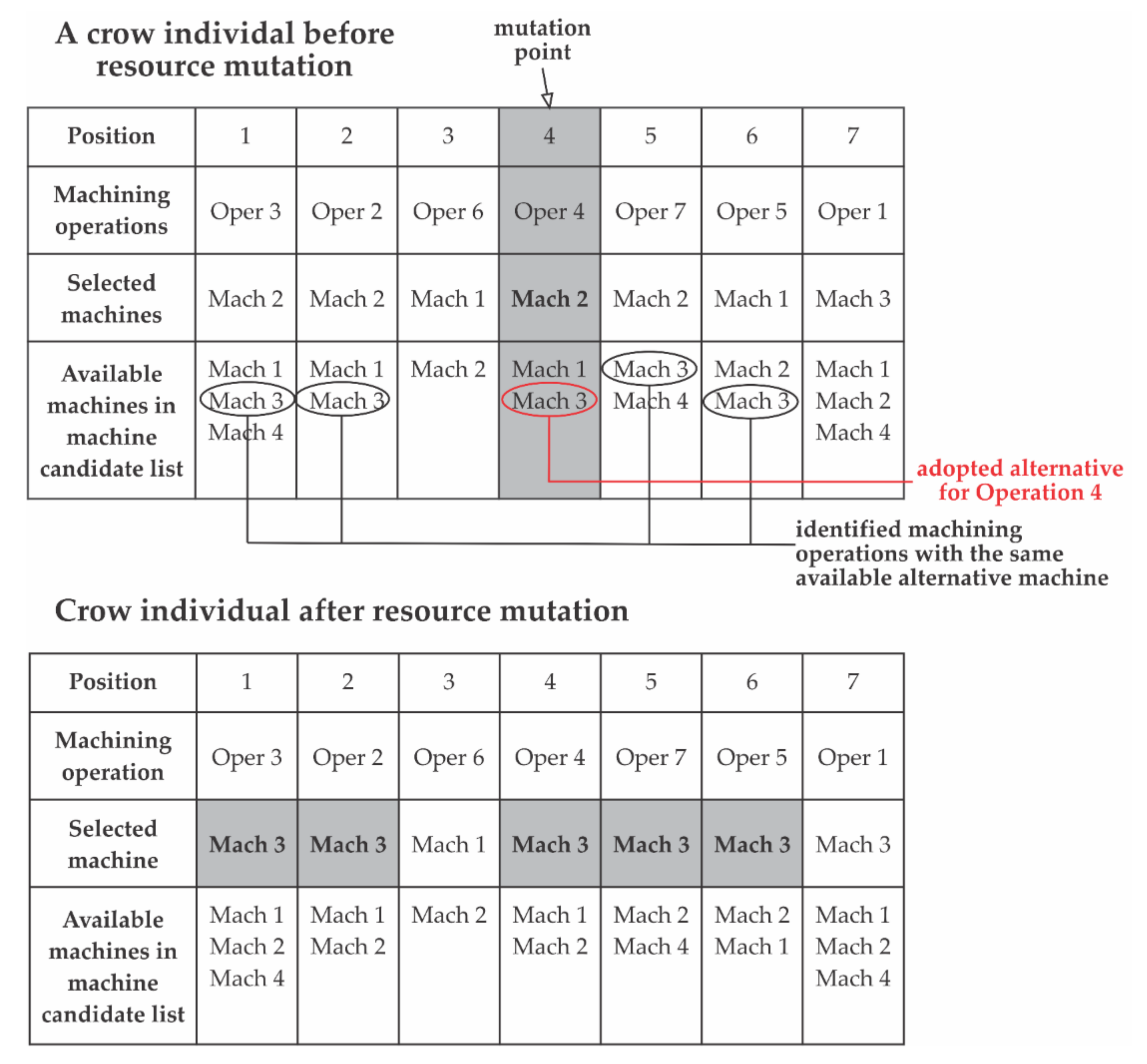

- (1)

- Randomly select a crow individual;

- (2)

- Randomly select the mutation point, i.e., operation with its index;

- (3)

- Check available machines in the Machines{} for selected operation;

- (4)

- Randomly select a machine from the Machines{} as the current machine;

- (5)

- Identify other operations that have the same machine alternative in the Machines{}.

- (6)

- Assign the same machine alternative as the current machine for other operations.

- (7)

- Repeat the same steps for tool and TAD vectors using the Tool{} and the TADs{} sets.

5. Case Studies

5.1. Parameter Settings

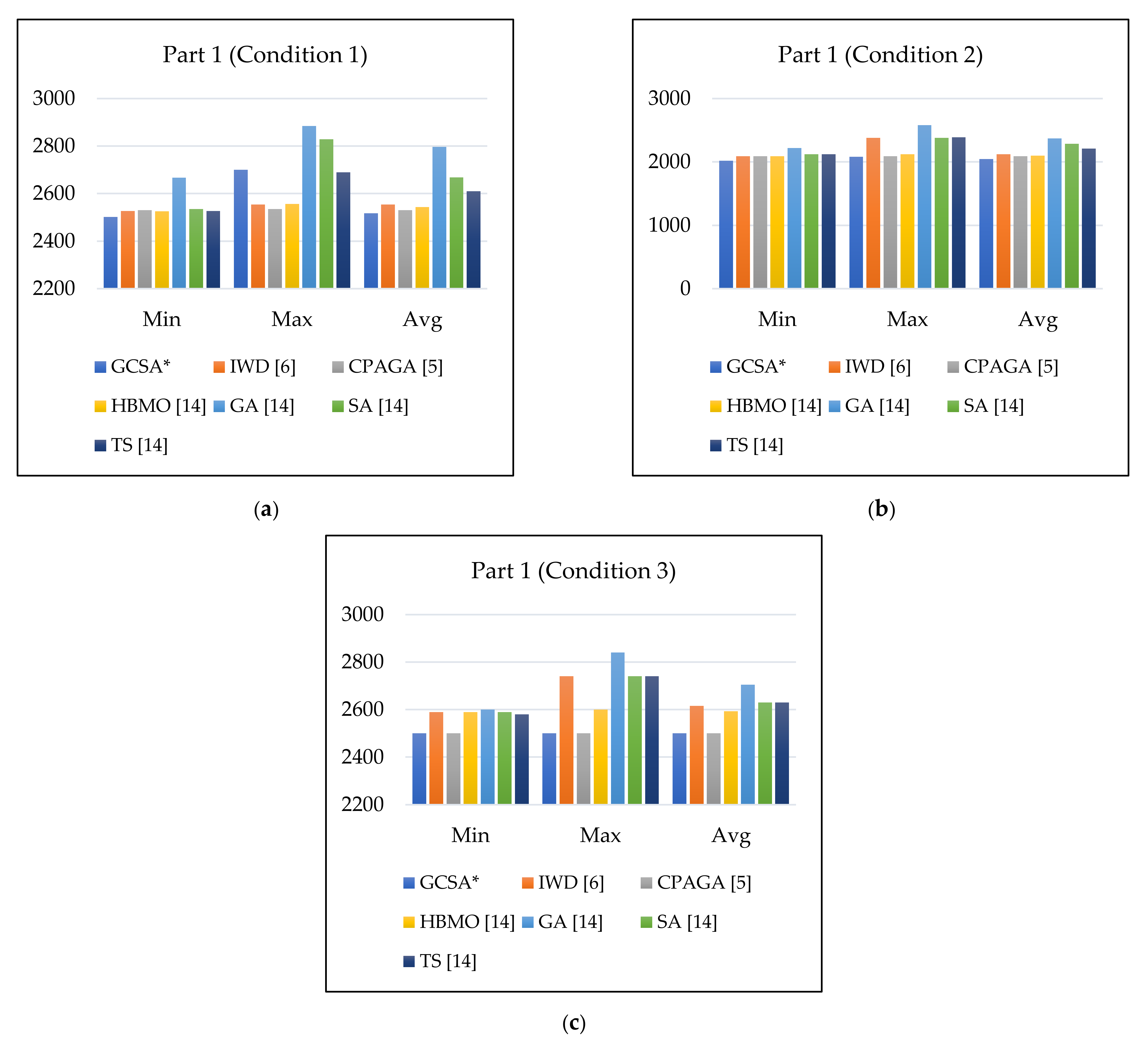

5.2. Computational Results and Analysis

- (1)

- All manufacturing resources are available.

- (2)

- Tool costs and tool cost changes are excluded.

- (3)

- Same as the second with machine 2 and tool 8 not available.

- (1)

- All manufacturing resources are available.

- (2)

- Machines 3 and 7 and tool 8 are down.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, X.; Wang, L.; Newman, S.T. Computer-aided process planning—A critical review of recent developments and future trends. Int. J. Comput. Integr. Manuf. 2011, 24, 1–31. [Google Scholar] [CrossRef]

- Lukić, D.; Milošević, M.; Erić, M.; Đurđev, M.; Vukman, J.; Antić, A. Improving Manufacturing Process Planning Through the Optimization of Operation Sequencing. Mach. Des. 2017, 9, 123–132. [Google Scholar] [CrossRef]

- Denkena, B.; Shpitalni, M.; Kowalski, P.; Molcho, G.; Zipori, Y. Knowledge Management in Process Planning. CIRP Ann. 2007, 56, 175–180. [Google Scholar] [CrossRef]

- Dou, J.; Li, J.; Su, C. A discrete particle swarm optimisation for operation sequencing in CAPP. Int. J. Prod. Res. 2018, 56, 3795–3814. [Google Scholar] [CrossRef]

- Falih, A.; Shammari, A.Z.M. Hybrid constrained permutation algorithm and genetic algorithm for process planning problem. J. Intell. Manuf. 2020, 31, 1079–1099. [Google Scholar] [CrossRef]

- Gao, B.; Hu, X.; Peng, Z.; Song, Y. Application of intelligent water drop algorithm in process planning optimization. Int. J. Adv. Manuf. Technol. 2020, 106, 5199–5211. [Google Scholar] [CrossRef]

- Petrović, M.; Mitić, M.; Vuković, N.; Miljković, Z. Chaotic particle swarm optimization algorithm for flexible process planning. Int. J. Adv. Manuf. Technol. 2016, 85, 2535–2555. [Google Scholar] [CrossRef]

- Huang, W.; Lin, W.; Xu, S. Application of graph theory and hybrid GA-SA for operation sequencing in a dynamic workshop environment. Comput. Aided Des. Appl. 2017, 14, 148–159. [Google Scholar] [CrossRef]

- Milošević, M.; Đurđev, M.; Lukić, D.; Antić, A.; Ungureanu, N. Intelligent Process Planning for Smart Factory and Smart Manufacturing. In Proceedings of the 5th International Conference on the Industry 4.0 Model for Advanced Manufacturing; Springer: Cham, Switzerland, 2020; pp. 205–214. [Google Scholar] [CrossRef]

- Wang, Y.F.; Zhang, Y.F.; Fuh, J.Y.H. A hybrid particle swarm based method for process planning optimisation. Int. J. Prod. Res. 2012, 50, 277–292. [Google Scholar] [CrossRef]

- Huang, W.; Hu, Y.; Cai, L. An effective hybrid graph and genetic algorithm approach to process planning optimization for prismatic parts. Int. J. Adv. Manuf. Technol. 2012, 62, 1219–1232. [Google Scholar] [CrossRef]

- Lian, K.; Zhang, C.; Shao, X.; Gao, L. Optimization of process planning with various flexibilities using an imperialist competitive algorithm. Int. J. Adv. Manuf. Technol. 2012, 59, 815–828. [Google Scholar] [CrossRef]

- Liu, X.-j.; Yi, H.; Ni, Z.-h. Application of ant colony optimization algorithm in process planning optimization. J. Intell. Manuf. 2013, 24, 1–13. [Google Scholar] [CrossRef]

- Wen, X.-y.; Li, X.-y.; Gao, L.; Sang, H.-y. Honey bees mating optimization algorithm for process planning problem. J. Intell. Manuf. 2014, 25, 459–472. [Google Scholar] [CrossRef]

- Wang, J.; Wu, X.; Fan, X. A two-stage ant colony optimization approach based on a directed graph for process planning. Int. J. Adv. Manuf. Technol. 2015, 80, 839–850. [Google Scholar] [CrossRef]

- Hu, Q.; Qiao, L.; Peng, G. An ant colony approach to operation sequencing optimization in process planning. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 470–489. [Google Scholar] [CrossRef]

- Su, Y.; Chu, X.; Chen, D.; Sun, X. A genetic algorithm for operation sequencing in CAPP using edge selection based encoding strategy. J. Intell. Manuf. 2018, 29, 313–332. [Google Scholar] [CrossRef]

- Liu, Q.; Li, X.; Gao, L. Mathematical modeling and a hybrid evolutionary algorithm for process planning. J. Intell. Manuf. 2020. [Google Scholar] [CrossRef]

- Jiang, S.; Cao, J.; Wu, H.; Yang, Y. Fairness-based Packing of Industrial IoT Data in Permissioned Blockchains. IEEE Trans. Ind. Inform. 2020, 1. [Google Scholar] [CrossRef]

- Li, W.; Ong, S.; Nee, A.Y.C. Integrated and Collaborative Product Development Environment: Technologies and Implementations; World Scientific: Singapore, 2006; Volume 2. [Google Scholar] [CrossRef]

- Askarzadeh, A. A novel metaheuristic method for solving constrained engineering optimization problems: Crow search algorithm. Comput. Struct. 2016, 169, 1–12. [Google Scholar] [CrossRef]

- Huang, K.-W.; Girsang, A.S.; Wu, Z.-X.; Chuang, Y.-W. A Hybrid Crow Search Algorithm for Solving Permutation Flow Shop Scheduling Problems. Appl. Sci. 2019, 9, 1353. [Google Scholar] [CrossRef]

- Laabadi, S.; Naimi, M.; Amri, H.E.; Achchab, B. A Binary Crow Search Algorithm for Solving Two-dimensional Bin Packing Problem with Fixed Orientation. Procedia Comput. Sci. 2020, 167, 809–818. [Google Scholar] [CrossRef]

- Shirke, S.; Udayakumar, R. Evaluation of Crow Search Algorithm (CSA) for Optimization in Discrete Applications. In Proceedings of the 2019 3rd International Conference on Trends in Electronics and Informatics (ICOEI), Tirunelveli, India, 23–25 April 2019; pp. 584–589. [Google Scholar] [CrossRef]

- Guo, Y.W.; Mileham, A.R.; Owen, G.W.; Li, W.D. Operation sequencing optimization using a particle swarm optimization approach. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 1945–1958. [Google Scholar] [CrossRef]

| Data Types | Variables | Description |

|---|---|---|

| double | Operation[n] | The ID of the operation as a part of an operation sequence |

| double | Machines[n] | The ID of the machine as a part of a machine vector of n machines for performing n operations |

| double | Tools[n] | The ID of the tool as a part of a tool vector of n tools for performing n operations |

| double | TADs[n] | The ID of the cutting tool as a part of a TAD vector of n TADs for performing n operations |

| cell | Machines{n} | Array of machine candidates list for n cells with each cell containing alternative machines for the n-th operation |

| cell | TADs{n} | Array of tool candidates list for n cells where each cell contains alternative tools for the n-th operation |

| cell | Tools{n} | Array of TAD candidates list for n cells where each cell contains alternative TADs for the n-th operation |

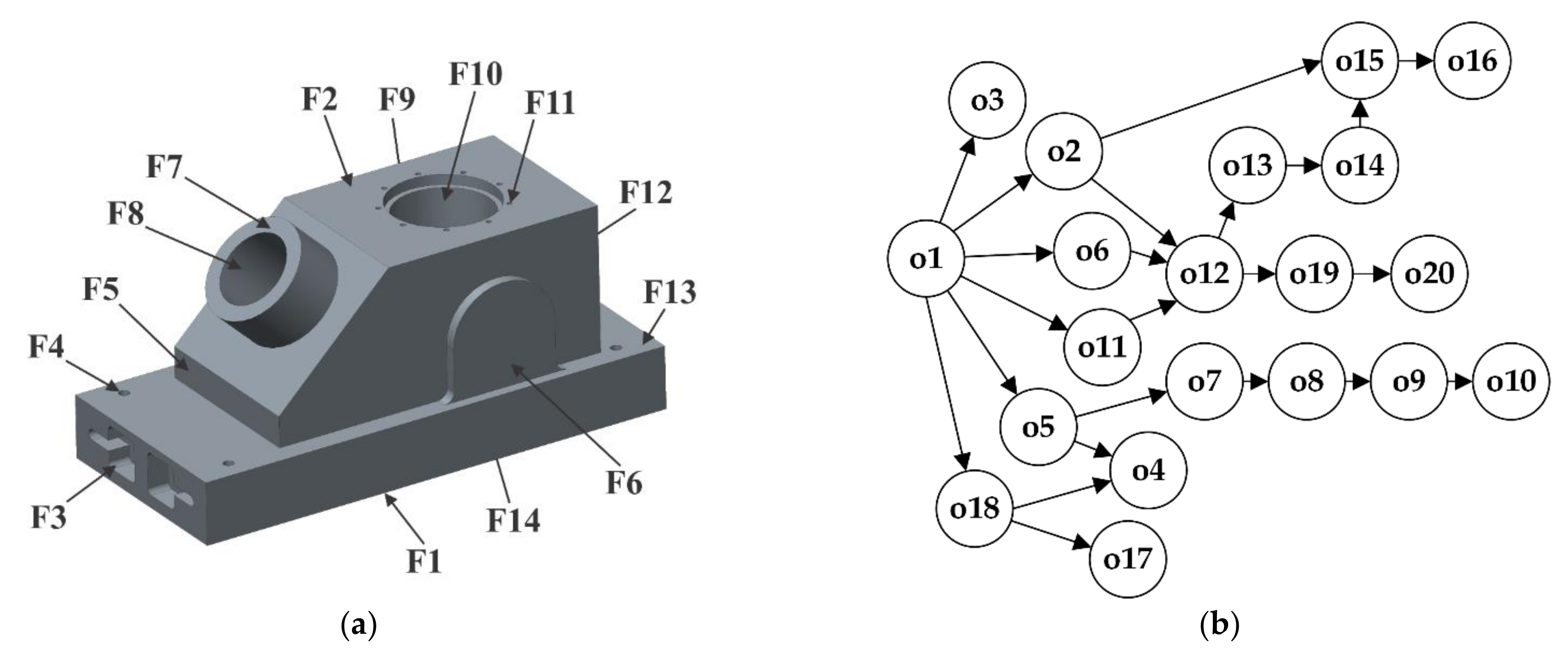

| Feature Definition | Operations | Machines{} | Tools{} | TADs{} | Predecessors |

|---|---|---|---|---|---|

| F1—A planar surface | Milling (o1) | m2,m3 | t6,t7,t8 | +z | |

| F2—A planar surface | Milling (o2) | m2,m3 | t6,t7,t8 | -z | o1 |

| F3—Two pockets arranged as a replicated feature | Milling (o3) | m2,m3 | t6,t7,t8 | +x | o1 |

| F4—Four holes arranged as a replicated feature | Drilling (o4) | m1,m2,m3 | t2 | +z,-z | o1,o5,o18 |

| F5—A step | Milling (o5) | m2,m3 | t6,t7 | +x,-z | o1 |

| F6—A rib | Milling (o6) | m2,m3 | t7,t8 | +y,-z | o1 |

| F7—A boss | Milling (o7) | m2,m3 | t7,t8 | -a | o1, o5 |

| F8—A compound hole | Drilling (o8) | m1,m2,m3 | t2,t3,t4 | -a | o1, o7 |

| Reaming (o9) | m1,m2,m3 | t9 | o1, o7, o8 | ||

| Boring (o10) | m2,m3 | t10 | o1, o7, o8, o9 | ||

| F9—A rib | Milling (o11) | m2,m3 | t7,t8 | -y,-z | o1 |

| F10—A compound hole | Drilling (o12) | m1,m2,m3 | t2,t3,t4 | -z | o1, o2, o6, o11 |

| Reaming (o13) | m1,m2,m3 | t9 | o1, o2, o6, o11, o12 | ||

| Boring (o14) | m3,m4 | t10 | o1, o2, o6, o11, o12, o13 | ||

| F11—Nine holes arranged as a replicated feature | Drilling (o15)Tapping (o16) | m1,m2,m3 | t1 | -z | o1, o2, o12, o13, o14 |

| m1,m2,m3 | t5 | o1, o2, o12, o13, o14, o15 | |||

| F12—A pocket | Milling (o17) | m2,m3 | t7,t8 | -x | o1, o18 |

| F13—A step | Milling (o18) | m2,m3 | t6, t7 | -x,-z | o1 |

| F14—A compound hole | Reaming (o19) | m1,m2,m3 | t9 | +z | o1, o12 |

| Boring (o20) | m3,m4 | t10 | o1, o12, o19 |

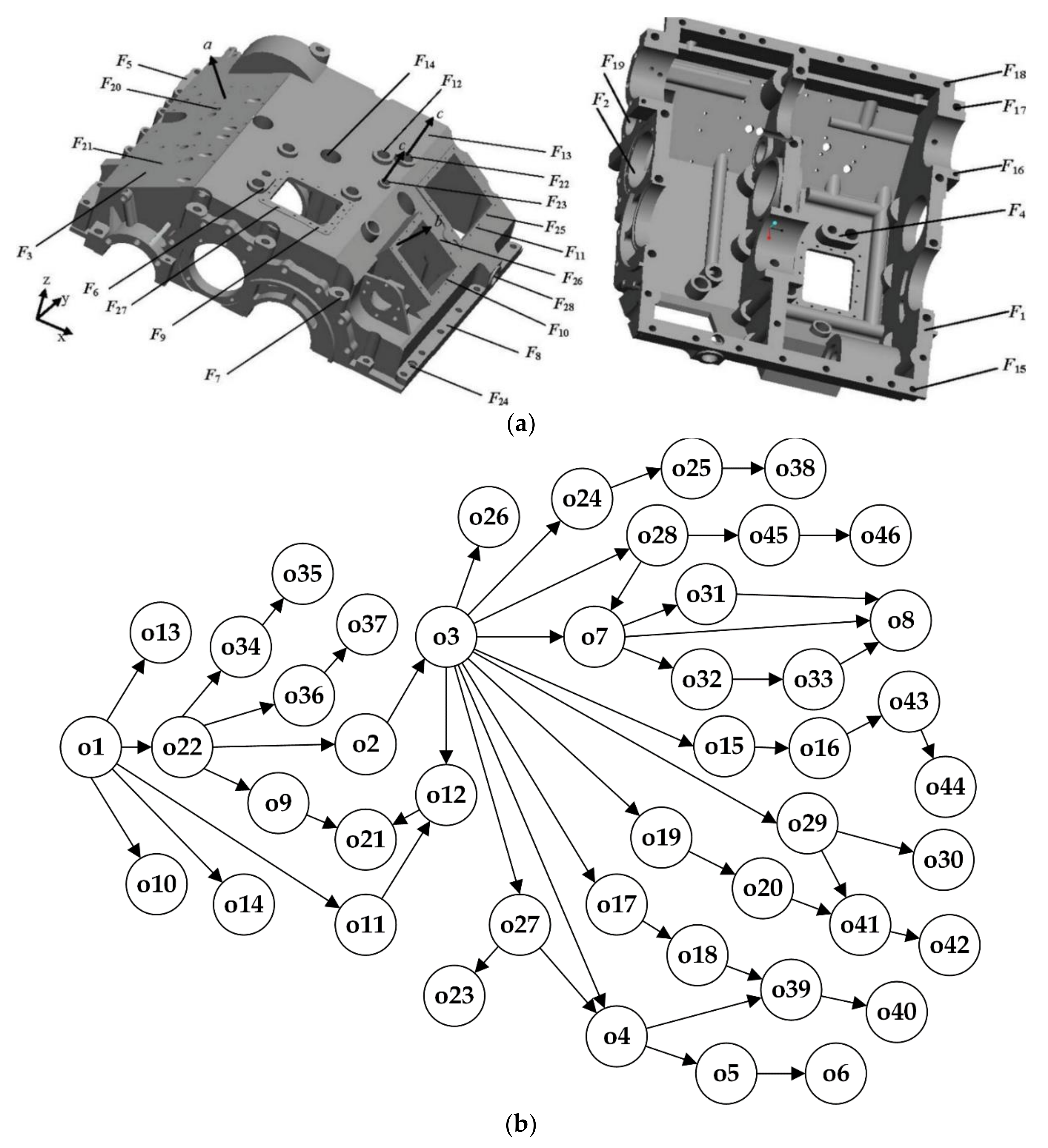

| Feature Definition | Operations | Machines{} | Tools{} | TADs{} | Predecessors |

|---|---|---|---|---|---|

| F1—Flat surface | Rough turning (o1) | m1,m2 | t1,t2,t3 | +z | |

| Half-finished turning (o2) | m2 | t1,t2,t3 | +z | o1,o22 | |

| Finished turning (o3) | m2 | t1,t2,t3 | +z | o1,o22,o2 | |

| F2—Bearing hole | Rough boring (o4) | m7, m8 | t4 | -y,+y | o1,o22,o2,o3,o27 |

| Half-finished boring (o5) | m6,m7,m8 | t5 | -y,+y | o1,o22,o2,o3,o27, o4 | |

| Finished boring (o6) | m6,m7,m8 | t5 | -y,+y | o1,o22,o2,o3,o27, o4,o5 | |

| F3—Angular surface | Rough milling (o7) | m5,m7,m8 | t7,t8,t9 | -a | o1,o22,o2,o3,o27, o4 |

| Finished milling (o8) | m3,m4,m6 | t7,t8,t9 | -a | o1,o22,o2,o3,o28, o31,o32,o33 | |

| F4—Four bosses | Rough milling (o9) | m3,m4,m5 | t8,t9 | +z | o1,o22 |

| F5—Plane 1 | Rough milling (o10) | m3,m4,m5 | t8,t9 | -z | o1 |

| F6—Top boss | Rough milling (o11) | m3,m4,m5 | t8,t9 | -z | o1 |

| Finished milling (o12) | m4,m5 | t8,t9 | -z | o1,o22,o2,o3,o11 | |

| F7—Six bosses | Rough milling (o13) | m3,m4,m5 | t8,t9 | -z | o1 |

| F8—Plane 2 | Rough milling (o14) | m3,m4,m5 | t8,t9 | -z | o1 |

| F9—Top window surface | Rough milling (o15) | m3,m4,m5 | t7,t8 | -z | o1,o22,o2,o3 |

| Finished milling (o16) | m3,m4,m5 | t7,t8 | -z | o1,o22,o2,o3,o15 | |

| F10—Inclined plane 1 | Rough milling (o17) | m3,m4,m6,m7 | t7,t8 | -b | o1,o22,o2,o3 |

| Finished milling (o18) | m3,m4,m6,m7 | t7,t8 | -b | o1,o22,o2,o3,o17 | |

| F11—Inclined plane 2 | Rough milling (o19) | m3,m4,m6,m7 | t7,t8 | -b | o1,o22,o2,o3 |

| Finished milling (o20) | m3,m4,m6,m7 | t7,t8 | -b | o1,o22,o2,o3,o19 | |

| F12—The top holes | Drilling (o21) | m9,m10 | t10 | -z,+z | o1,o22,o2,o3,o12, o9 |

| F13—Top plane | Rough milling (o22) | m4,m5 | t7,t8,t9 | -z | o1 |

| F14—Counterbore hole | Spot facing (o23) | m9,m10 | t20 | -z | o1,o22,o2,o3,o27 |

| F15—∅18H7 hole | Drilling (o24) | m9,m10 | t11 | +z | o1,o22,o2,o3 |

| Reaming (o25) | m9,m10 | t22 | +z | o1,o22,o2,o3,o34 | |

| F16—2-∅12.5 hole | Drilling (o26) | m9,m10 | t12 | +z | o1,o22,o2,o3 |

| F17—12-∅21 hole | Drilling (o27) | m9,m10 | t13 | +z | o1,o22,o2,o3 |

| F18—18-∅17 hole | Drilling (o28) | m9,m10 | t14 | +z | o1,o22,o2,o3 |

| F19—Side hole | Rough boring (o29) | m7,m8 | t6 | -y | o1,o22,o2,o3 |

| Finish boring (o30) | m6,m7,m8 | t6 | -y | o1,o22,o2,o3,o29 | |

| F20—5-∅20 hole | Drilling (o31) | m7,m8, m9,m10 | t15 | -a | o1,o22,o2,o3,o7, o28 |

| F21—24-∅8 hole | Drilling (o32) | m7,m8,m9,m10 | t16 | -a | o1,o22,o2,o3,o7,o28 |

| Tapping (o33) | m7,m8,m9,m10 | t23 | -a | o1,o22,o2,o3,o7, o28,o32 | |

| F22—Oil passage hole 1 | Reaming (o34) | m6,m7,m8 | t28 | -c | o1,o22 |

| Tapping (o35) | m6,m7,m8 | t24 | -c | o1,o22,o34 | |

| F23—Oil passage hole 2 | Drilling (o36) | m6,m7,m8 | t17 | -c | o1,o22 |

| Tapping (o37) | m6,m7,m8 | t25 | -c | o1,o22,o36 | |

| F24—∅23 Counterbore hole | Spot facing (o38) | m3,m4,m9,m10 | t21 | -z | o1,o22,o2,o3,o24,o25 |

| F25—Holes in inclined plane 1 | Drilling (o39) | m9,m10 | t18 | -b | o1,o22,o2,o3,o17, o18,o27,o4 |

| Tapping (o40) | m9,m10 | t26 | -b | o1,o22,o2,o3,o17, o18,o27,o4,o39 | |

| F26—Holes in inclined plane 2 | Drilling (o41) | m9,m10 | t18 | -b | o1,o22,o2,o3,o29, o19,o20 |

| Tapping (o42) | m9,m10 | t26 | -b | o1,o22,o2,o3,o29, o19,o20,o41 | |

| F27—Top holes | Drilling (o43) | m3,m4,m9,m10 | t18 | -z | o1,o22,o2,o3,o15, o16 |

| Tapping (o44) | m3,m4,m9,m10 | t26 | -z | o1,o22,o2,o3,o15,o16,o43 | |

| F28—Oil passage hole 3 | Drilling (o45) | m6,m7,m8 | t19 | -x | o1,o22,o2,o3,o28 |

| Tapping (o46) | m6,m7,m8 | t27 | -x | o1,o22,o2,o3,o28, o45 |

| Part 1 | Part 2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cost per use | |||||||||

| M | MC | T | TC | M | MC | T | TC | T | TC |

| m1 | 10 | t1 | 7 | m1 | 25 | t1 | 5 | t15 | 4 |

| m2 | 40 | t2 | 5 | m2 | 45 | t2 | 6 | t16 | 3 |

| m3 | 100 | t3 | 3 | m3 | 50 | t3 | 7 | t17 | 4 |

| m4 | 60 | t4 | 8 | m4 | 55 | t4 | 12 | t18 | 2 |

| t5 | 7 | m5 | 20 | t5 | 13 | t19 | 2 | ||

| t6 | 10 | m6 | 80 | t6 | 9 | t20 | 4 | ||

| t7 | 15 | m7 | 45 | t7 | 8 | t21 | 3 | ||

| t8 | 30 | m8 | 48 | t8 | 9 | t22 | 5 | ||

| t9 | 15 | m9 | 16 | t9 | 10 | t23 | 3 | ||

| t10 | 20 | m10 | 18 | t10 | 4 | t24 | 4 | ||

| t11 | 4 | t25 | 4 | ||||||

| t12 | 3 | t26 | 3 | ||||||

| t13 | 4 | t27 | 4 | ||||||

| t14 | 3 | t28 | 3 | ||||||

| Cost per change | |||||||||

| MCCI = 160 SCCI = 100 TCCI = 20 | MCCI = 120 SCCI = 90 TCCI = 15 | ||||||||

| Case Study | MaxIter | FlockSize | AP | fl | TourSize | kc1 | kc2 | km1 | km2 |

|---|---|---|---|---|---|---|---|---|---|

| Part 1 | 1000 | 100 | 0.8 | 0.7 | 5 | 0.8 | 0.6 | 0.3 | 0.3 |

| Part 2 | 2000 | 80 | 0.8 | 0.5 | 5 | 0.86 | 0.2 | 0.3 | 0.3 |

| Condition 1 | ||||||||||||||||||||

| Operation | 1 | 5 | 3 | 18 | 2 | 11 | 6 | 17 | 4 | 12 | 13 | 19 | 7 | 8 | 9 | 10 | 20 | 14 | 15 | 16 |

| Machine | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 4 | 4 | 4 | 1 | 1 |

| Tool | 6 | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 2 | 2 | 9 | 9 | 7 | 4 | 9 | 10 | 10 | 10 | 1 | 5 |

| TAD | +z | +x | +x | -z | -z | -z | -z | -z | -z | -z | -z | +z | -a | -a | -a | -a | +z | -z | -z | -z |

| TMC = 800, TMCC = 320, NMC = 2, TTC = 247, TTCC = 180, NTC = 9, TSC = 900, NSC = 9, TWPC = 2447 | ||||||||||||||||||||

| TMCC—Total machine change cost; NMC—Number of machine changes; TTCC—Total tool change cost; NTC—Number of tool changes; NSC—Number of setup changes | ||||||||||||||||||||

| Condition 2 | ||||||||||||||||||||

| Operation | 1 | 6 | 18 | 17 | 5 | 2 | 11 | 12 | 4 | 13 | 7 | 8 | 9 | 3 | 19 | 20 | 10 | 14 | 15 | 16 |

| Machine | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 4 | 4 | 4 | 1 | 1 |

| Tool | 7 | 7 | 7 | 7 | 6 | 8 | 8 | 4 | 2 | 9 | 8 | 4 | 9 | 6 | 9 | 10 | 10 | 10 | 1 | 5 |

| TAD | +z | -z | -z | -z | -z | -z | -z | -z | -z | -z | -a | -a | -a | +x | +z | +z | -a | -z | -z | -z |

| TMC = 800, TMCC = 320, NMC = 2, TSC = 900, NSC = 9, TWPC = 2020 | ||||||||||||||||||||

| Condition 3 | ||||||||||||||||||||

| Operation | 1 | 3 | 5 | 7 | 8 | 9 | 10 | 2 | 6 | 11 | 18 | 12 | 17 | 13 | 14 | 15 | 16 | 4 | 19 | 20 |

| Machine | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Tool | 6 | 6 | 6 | 7 | 4 | 9 | 10 | 6 | 7 | 7 | 6 | 4 | 7 | 9 | 10 | 1 | 5 | 2 | 9 | 10 |

| TAD | +z | +x | +x | -a | -a | -a | -a | -z | -z | -z | -z | -z | -z | -z | -z | -z | -z | -z | +z | +z |

| TMC = 2000, TMCC = 0, NMC = 0, TCTC = 250, TCTCC = 3200, NCTC = 16, TSC = 500, NSC = 5, TWPC = 2500 | ||||||||||||||||||||

| Part 1 | Condition 1 | Condition 2 | Condition 3 | ||||||

| Min | Max | Avg | Min | Max | Avg | Min | Max | Avg | |

| GCSA* | 2502 | 2700 | 2516,9 | 2020 | 2080 | 2047 | 2500 | 2500 | 2500 |

| IWD, Gao et al. [6] | 2527 | 2554 | 2553,5 | 2090 | 2380 | 2123 | 2590 | 2740 | 2615,3 |

| CPAGA, Falih and Shammari [5] | 2530 | 2535 | 2530,5 | 2090 | 2090 | 2090 | 2500 | 2500 | 2500 |

| HBMO, Wen et al. [14] | 2525 | 2557 | 2543,5 | 2090 | 2120 | 2098 | 2590 | 2600 | 2592,4 |

| GA, Wen et al. [14] | 2667 | 2885 | 2796 | 2220 | 2580 | 2370 | 2600 | 2840 | 2705 |

| SA, Wen et al. [14] | 2535 | 2829 | 2668,5 | 2120 | 2380 | 2287 | 2590 | 2740 | 2630 |

| TS, Wen et al. [14] | 2527 | 2690 | 2609,6 | 2120 | 2390 | 2208 | 2580 | 2740 | 2630 |

| Part 2 | Condition 1 | Condition 2 | |||||||

| Min | Max | Avg | Min | Max | Avg | ||||

| GCSA* | 4135 | 4496 | 4306,5 | 4338 | 4924 | 4544,7 | |||

| CPAGA, Falih and Shammari [5] | 4299 | 4315 | 4302 | 4503 | 4503 | 4503 | |||

| GA-SA, Huang et al. [8] | 4368 | - | - | 4450 | - | - | |||

| Indices | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Operation | 1 | 22 | 2 | 3 | 10 | 11 | 15 | 16 | 12 | 14 | 13 | 17 | 18 | 19 | 20 | 9 |

| Machine | 1 | 5 | 2 | 2 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Tool | 1 | 7 | 1 | 1 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| TAD | +z | -z | +z | +z | -z | -z | -z | -z | -z | -z | -z | -b | -b | -b | -b | +z |

| Indices | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 |

| Operation | 27 | 24 | 28 | 26 | 25 | 45 | 46 | 36 | 37 | 34 | 35 | 7 | 32 | 33 | 31 | 4 |

| Machine | 9 | 9 | 9 | 9 | 9 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 |

| Tool | 13 | 11 | 14 | 12 | 22 | 19 | 27 | 17 | 25 | 28 | 24 | 8 | 16 | 23 | 15 | 4 |

| TAD | +z | +z | +z | +z | +z | -x | -x | -c | -c | -c | -c | -a | -a | -a | -a | -y |

| Indices | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 46 | ||

| Operation | 5 | 6 | 29 | 30 | 8 | 41 | 39 | 40 | 42 | 23 | 38 | 43 | 44 | 21 | ||

| Machine | 7 | 7 | 7 | 7 | 3 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | ||

| Tool | 5 | 5 | 6 | 6 | 8 | 18 | 18 | 26 | 26 | 20 | 21 | 18 | 26 | 10 | ||

| TAD | -y | -y | -y | -y | -a | -b | -b | -b | -b | -z | -z | -z | -z | -z | ||

| TMC = 1319, TMCC = 840, NMC = 7, TTC = 281, TTCC = 435, NTC = 29, TSC = 1260, NSC = 14, TWPC = 4135 | ||||||||||||||||

| Indices | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Operation | 1 | 22 | 2 | 3 | 15 | 16 | 11 | 14 | 13 | 10 | 12 | 9 | 24 | 28 | 27 | 25 |

| Machine | 1 | 5 | 2 | 2 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 9 | 9 | 9 | 9 |

| Tool | 1 | 7 | 1 | 1 | 7 | 7 | 9 | 9 | 9 | 9 | 9 | 9 | 11 | 14 | 13 | 22 |

| TAD | +z | -z | +z | +z | -z | -z | -z | -z | -z | -z | -z | +z | +z | +z | +z | +z |

| Indices | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 |

| Operation | 26 | 7 | 31 | 32 | 33 | 4 | 5 | 6 | 29 | 30 | 45 | 46 | 34 | 35 | 36 | 37 |

| Machine | 9 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Tool | 12 | 7 | 15 | 16 | 23 | 4 | 5 | 5 | 6 | 6 | 19 | 27 | 28 | 24 | 17 | 25 |

| TAD | +z | -a | -a | -a | -a | -y | -y | -y | -y | -y | -x | -x | -c | -c | -c | -c |

| Indices | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 46 | ||

| Operation | 17 | 18 | 19 | 20 | 8 | 41 | 39 | 42 | 40 | 43 | 23 | 21 | 44 | 38 | ||

| Machine | 4 | 4 | 4 | 4 | 4 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | ||

| Tool | 7 | 7 | 7 | 7 | 7 | 18 | 18 | 26 | 26 | 18 | 20 | 10 | 26 | 21 | ||

| TAD | -b | -b | -b | -b | -a | -b | -b | -b | -b | -z | -z | -z | -z | -z | ||

| TMC = 1509, TMCC = 840, NMC = 7, TTC = 279, TTCC = 450, NTC = 30, TSC = 1260, NSC = 14, TWPC = 4338 | ||||||||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Djurdjev, M.; Cep, R.; Lukic, D.; Antic, A.; Popovic, B.; Milosevic, M. A Genetic Crow Search Algorithm for Optimization of Operation Sequencing in Process Planning. Appl. Sci. 2021, 11, 1981. https://doi.org/10.3390/app11051981

Djurdjev M, Cep R, Lukic D, Antic A, Popovic B, Milosevic M. A Genetic Crow Search Algorithm for Optimization of Operation Sequencing in Process Planning. Applied Sciences. 2021; 11(5):1981. https://doi.org/10.3390/app11051981

Chicago/Turabian StyleDjurdjev, Mica, Robert Cep, Dejan Lukic, Aco Antic, Branislav Popovic, and Mijodrag Milosevic. 2021. "A Genetic Crow Search Algorithm for Optimization of Operation Sequencing in Process Planning" Applied Sciences 11, no. 5: 1981. https://doi.org/10.3390/app11051981

APA StyleDjurdjev, M., Cep, R., Lukic, D., Antic, A., Popovic, B., & Milosevic, M. (2021). A Genetic Crow Search Algorithm for Optimization of Operation Sequencing in Process Planning. Applied Sciences, 11(5), 1981. https://doi.org/10.3390/app11051981