CFD Analysis of a Tubular Heat Exchanger for the Conditioning of Olive Paste

Abstract

1. Introduction

2. Materials and Methods

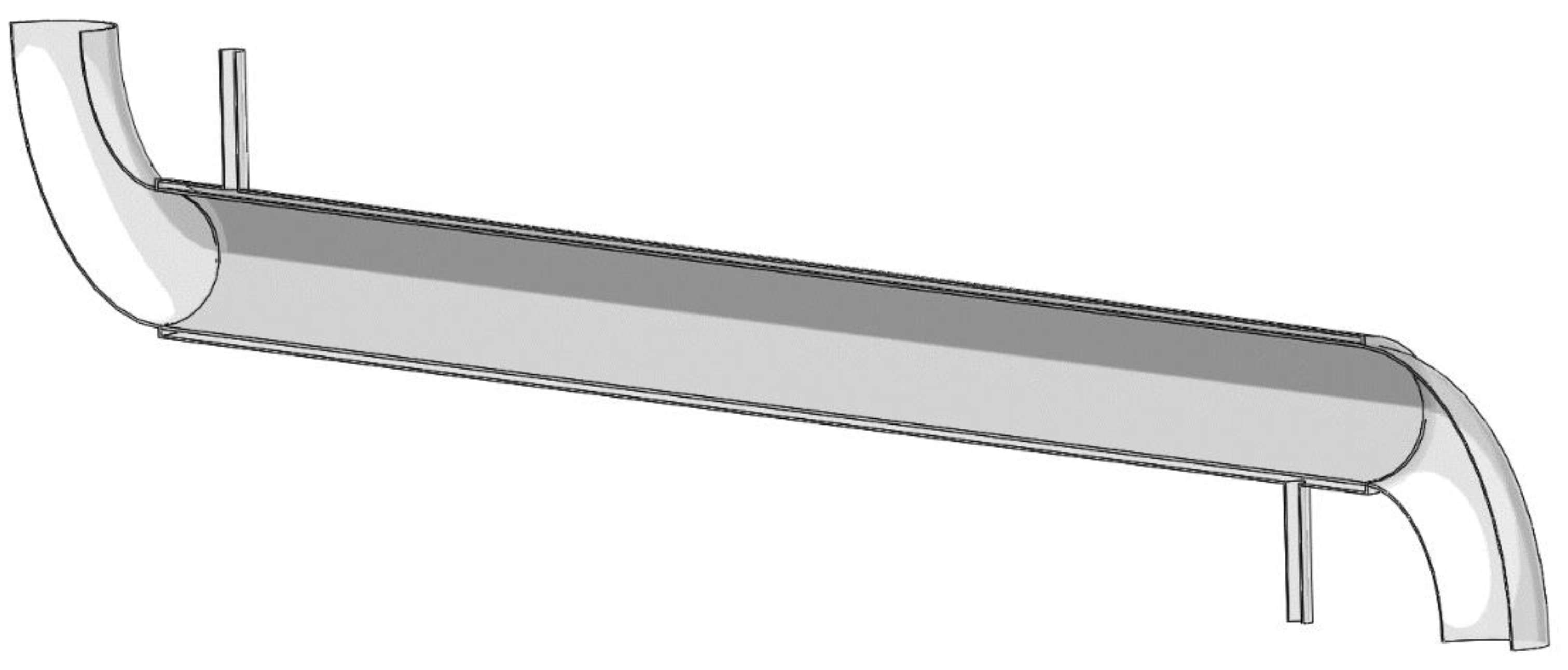

2.1. Physical Model of the Studied Heat Exchanger

2.2. Governing Equation and Boundary

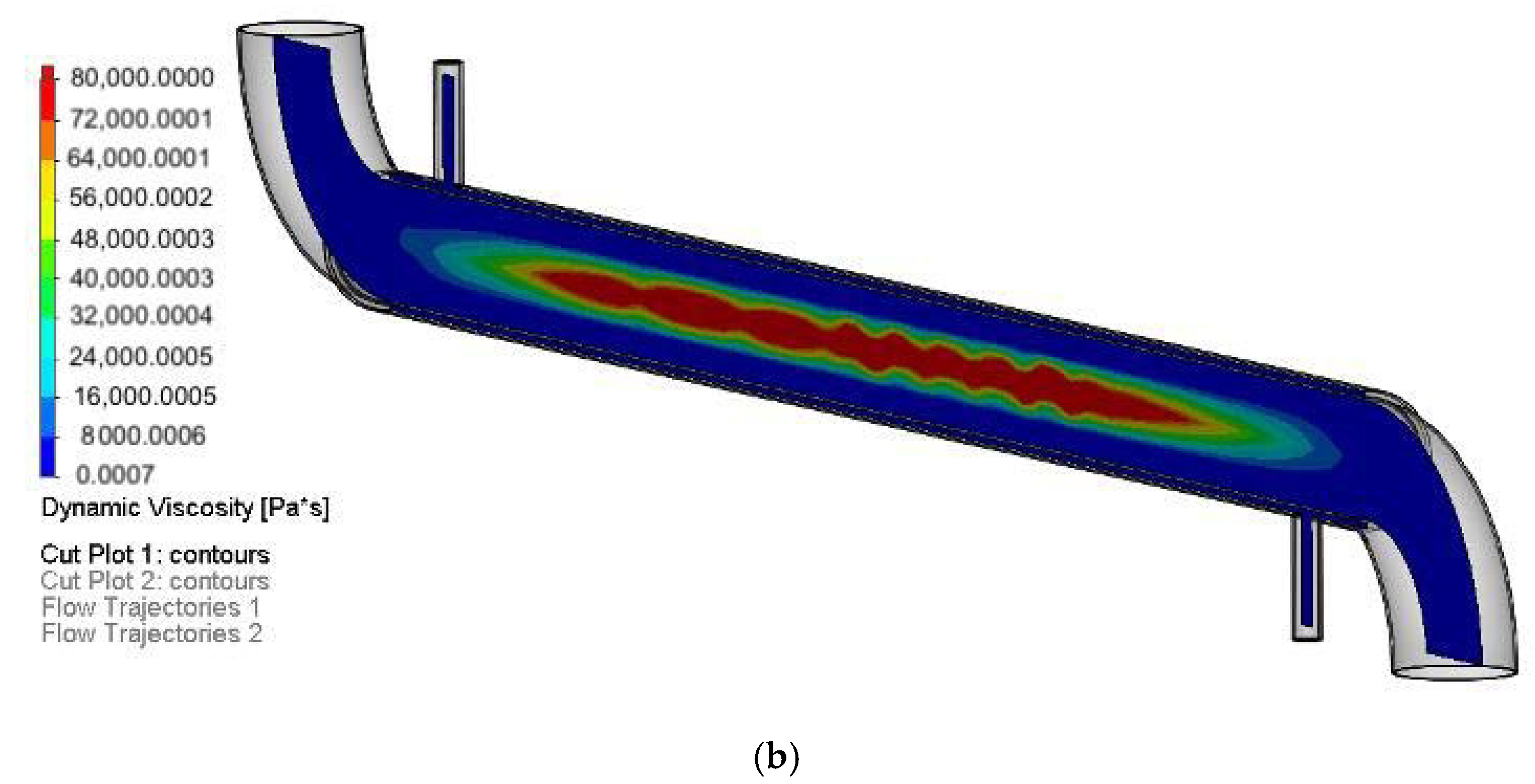

2.3. Olive Paste Flow Behavior

2.4. Turbulence Model

- A “thin” boundary layer treatment that is used when the number of cells across the boundary layer is not enough for direct, or even simplified, determination of the flow and thermal profiles;

- A “thick” boundary layer approach when the number of cells across the boundary layer exceeds that required to accurately resolve the boundary layer.

2.5. Conjugate Heat Transfer

2.6. Boundary Conditions and Simplifications

- The olive mass flow rate and olive paste temperature was set at the inlet of the inner tube;

- The inner tube outlet is set at environmental pressure to calculate the pressure drop;

- The pressure at which the water is supplied in the jacket is set at its inlet side equals to 2.4 bar;

- The temperature at which the water is supplied in the jacket is set at its inlet side equals to 40 °C;

- The solid walls of both inner tube and external jacket were set with momentum boundary condition of no slip;

- The walls of both inner tube and external jacket had the heat flux exchanged with the environment set to zero.

- Properties of both olive paste and water are assumed as constant;

- There is not leakage between the tube and the jacket;

- The natural convection induced by the fluid density variation is not considered.

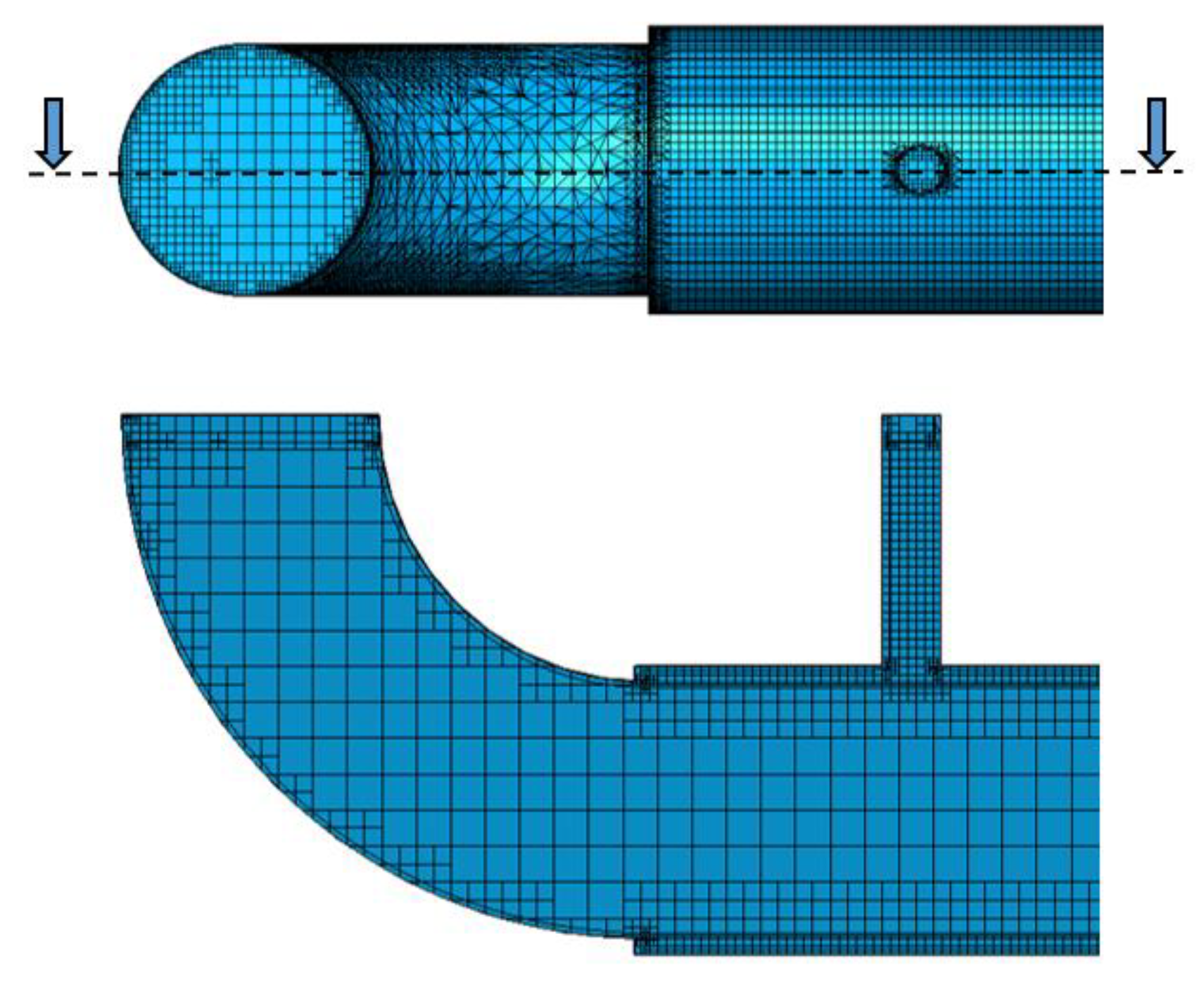

2.7. Mesh Generation, Mesh Independence Study and Validation

2.8. Parametric Study with “What If Analysis” Scenarios

- Delta—difference between maximum and minimum values of averaged values over the last iteration;

- Criterion—difference between maximum and minimum values of current values estimated from the previous travel to the current one.

- Pressure of the olive paste at the inlet of the inner tube;

- Temperature of the olive paste at the outlet of the inner tube;

- Pressure of the water at the outlet of the external jacket;

- Temperature of the water at the outlet of the external jacket;

- Velocity of the water at the inlet of the external jacket.

3. Results and Discussion

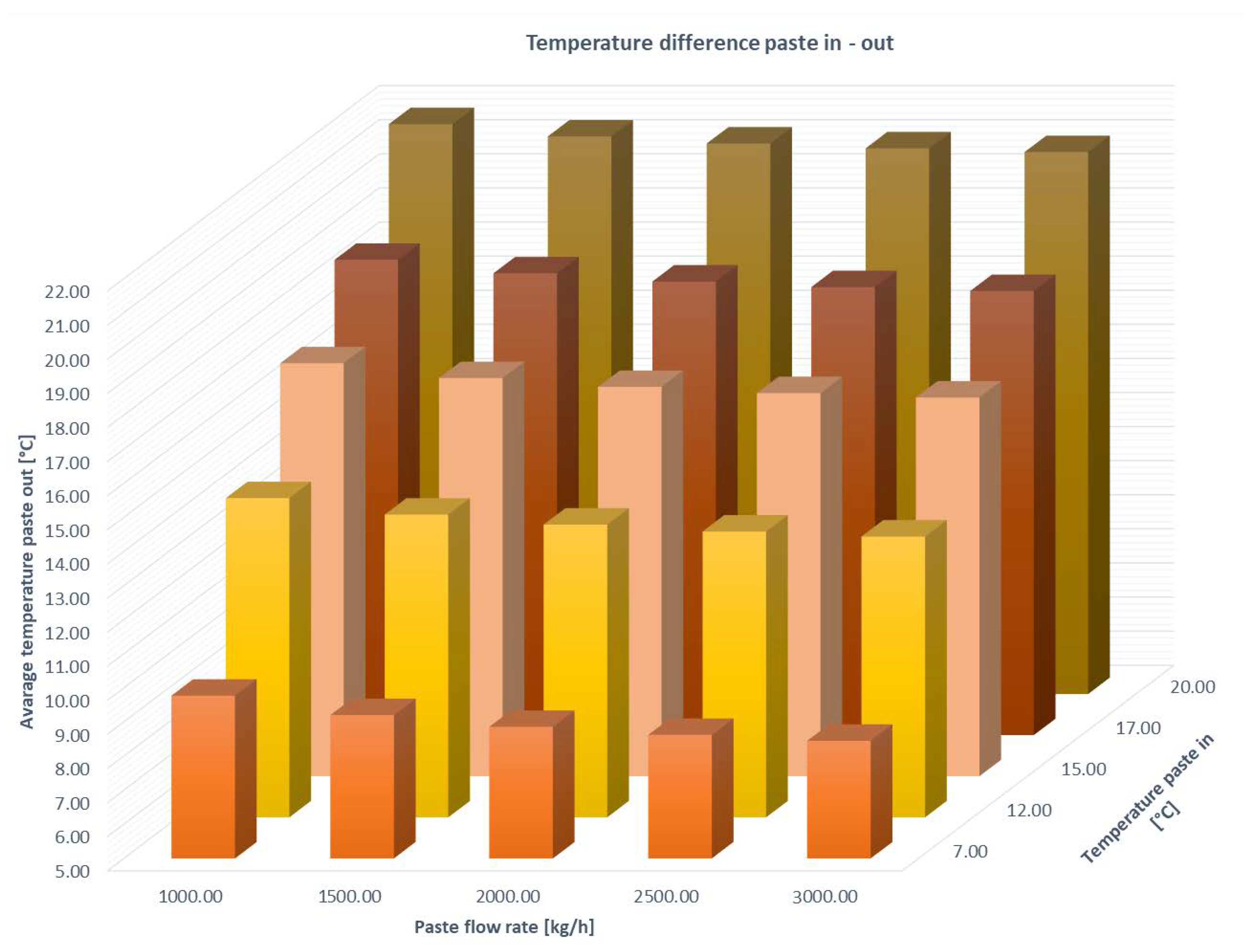

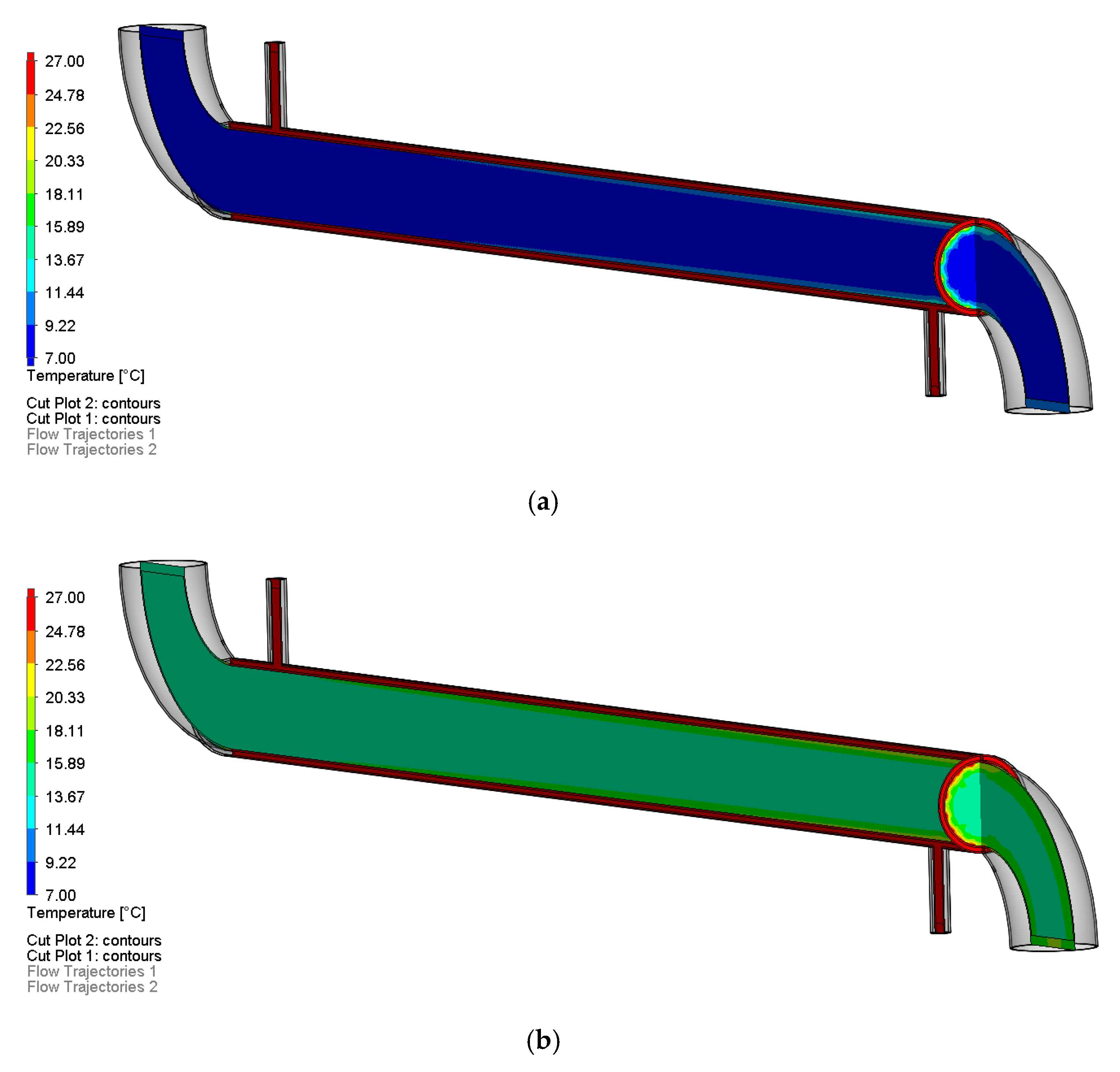

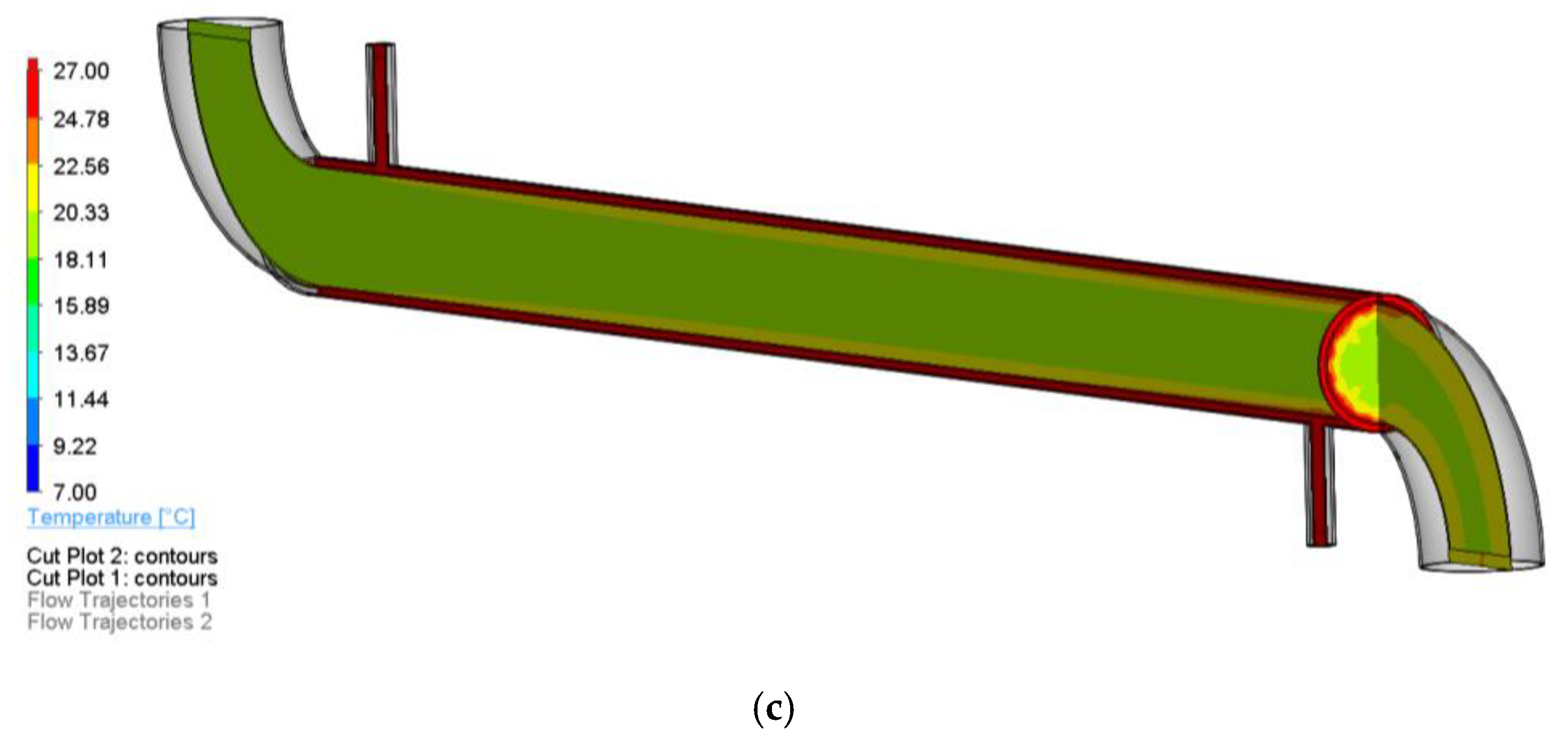

3.1. Temperature Variation in Different Scenarios

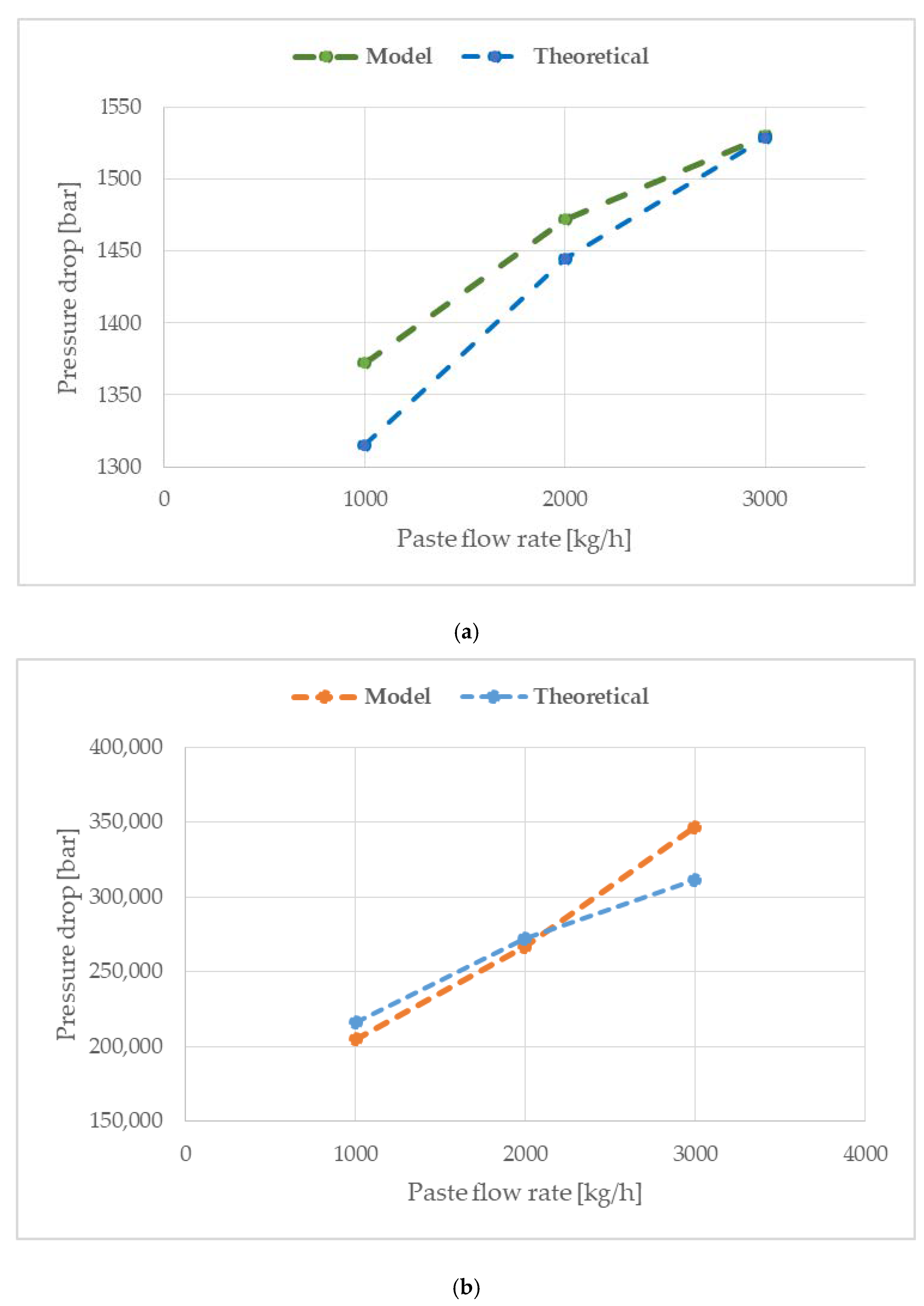

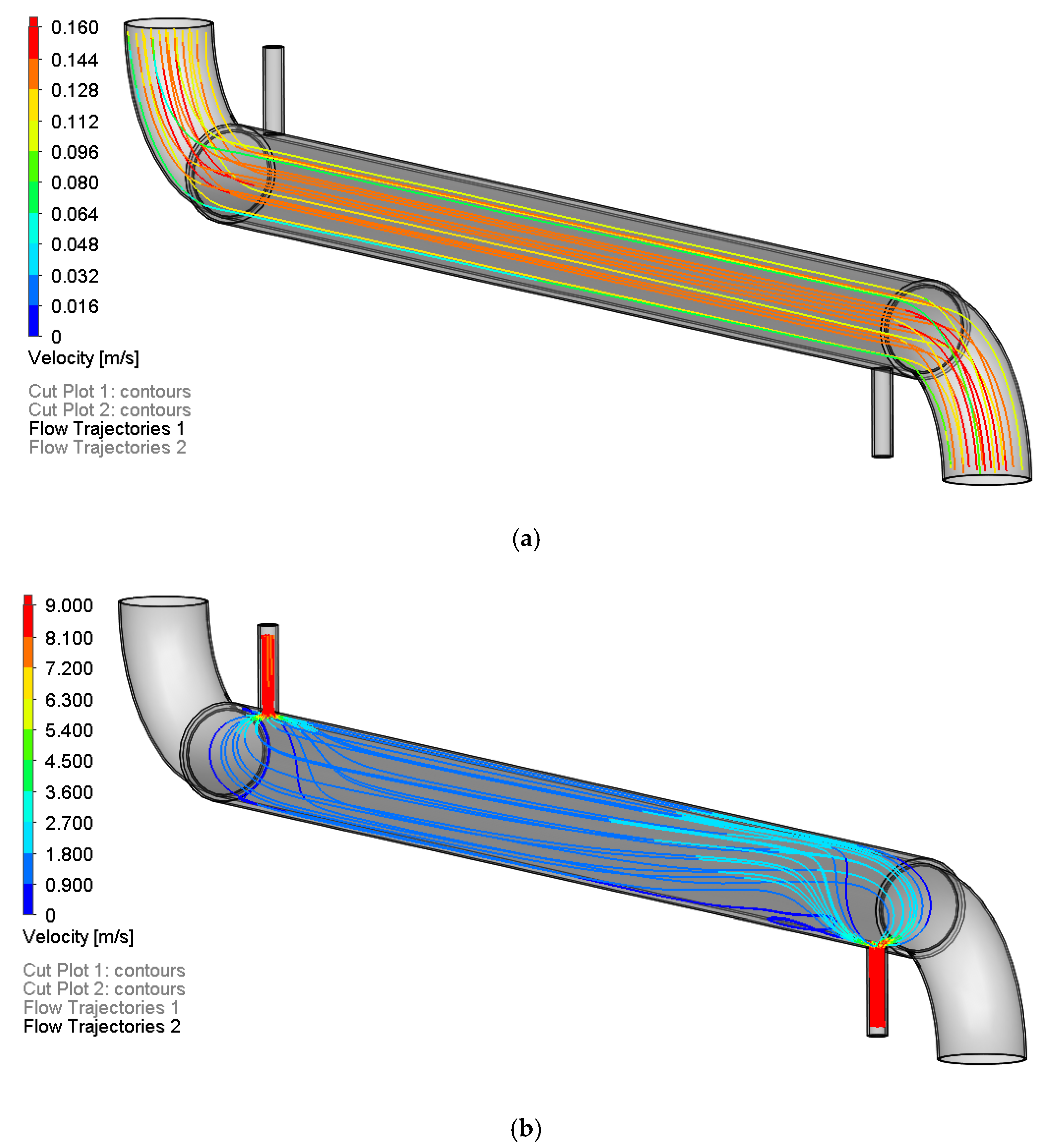

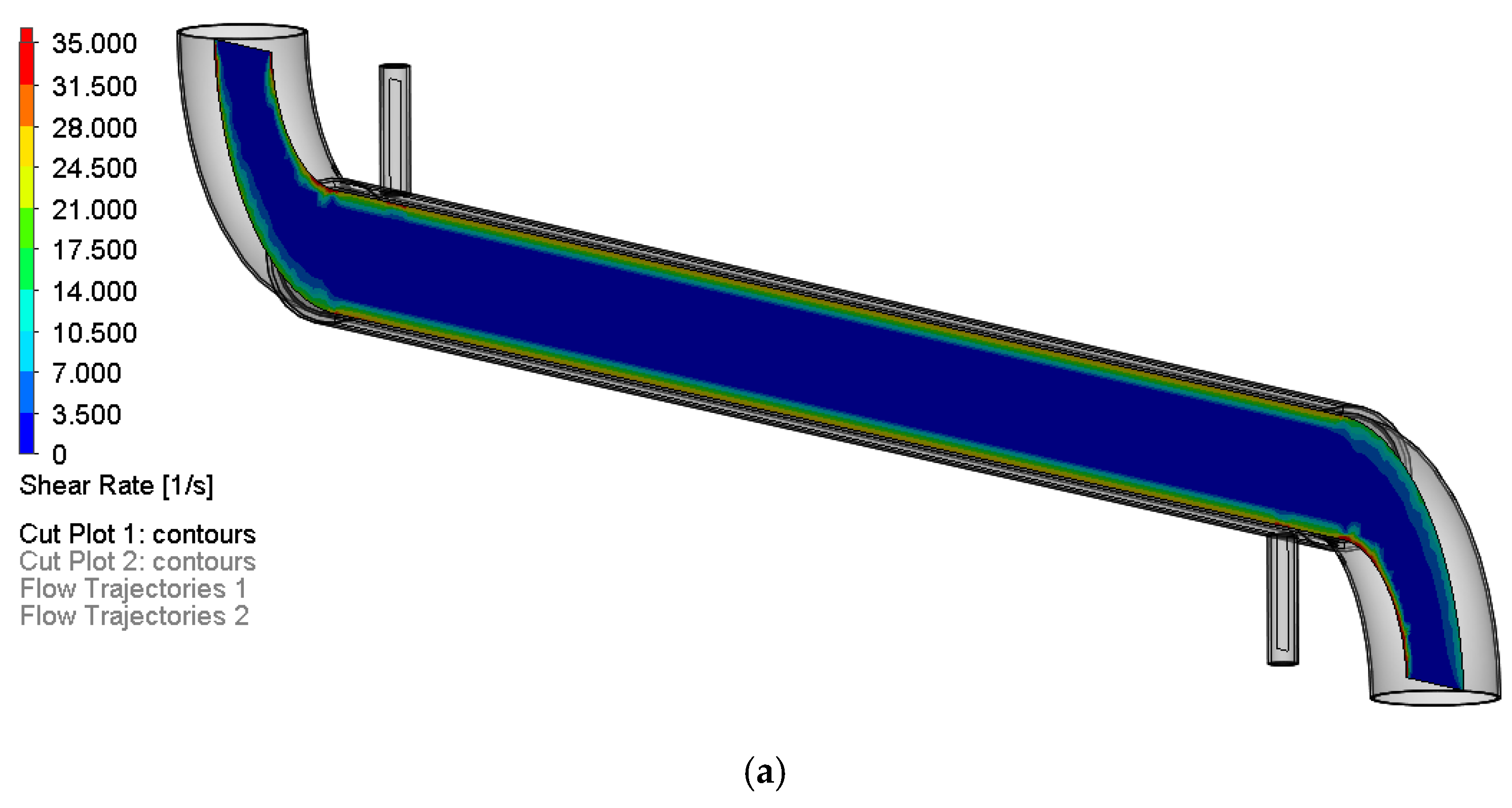

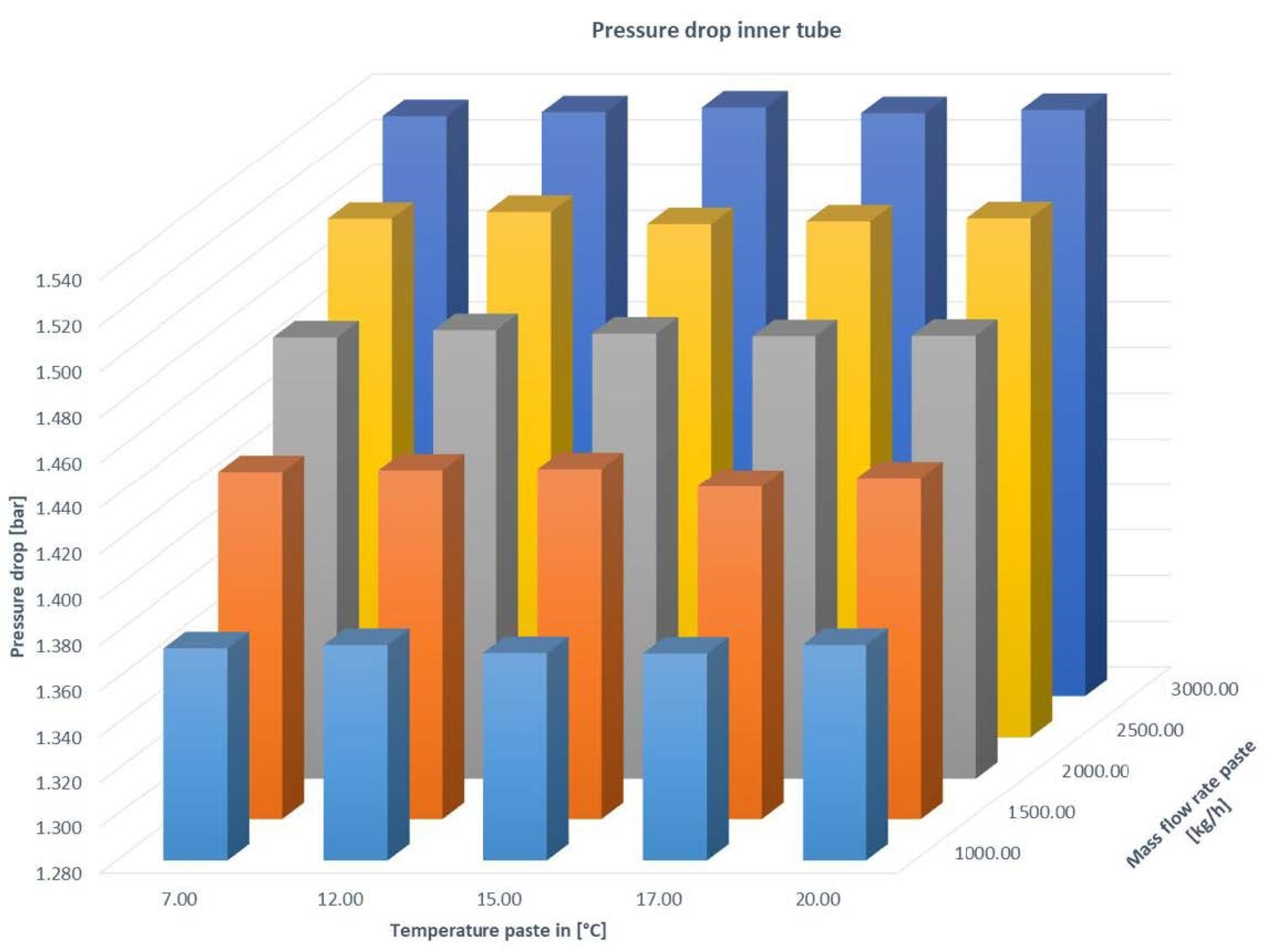

3.2. Pressure Variations in Different Scenarios

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References and Note

- Strpić, K.; Barbaresi, A.; Tinti, F.; Bovo, M.; Benni, S.; Torreggiani, D.; Macini, P.; Tassinari, P. Application of ground heat exchangers in cow barns to enhance milk cooling and water heating and storage. Energy Build. 2020, 224, 110213. [Google Scholar] [CrossRef]

- Jafari, S.M.; Saremnejad, F.; Dehnad, D. Nano-fluid thermal processing of watermelon juice in a shell and tube heat exchanger and evaluating its qualitative properties. Innov. Food Sci. Emerg. Technol. 2017, 42, 173–179. [Google Scholar] [CrossRef]

- Balaji, C.; Srinivasan, B.; Gedupudi, S. Heat Transfer Engineering: Fundamentals and Techniques; Academic Press: Cambridge, MA, USA, 2020; ISBN 0128185031. [Google Scholar]

- Ayr, U.; Tamborrino, A.; Catalano, P.; Bianchi, B.; Leone, A. 3D computational fluid dynamics simulation and experimental validation for prediction of heat transfer in a new malaxer machine. J. Food Eng. 2015, 154, 30–38. [Google Scholar] [CrossRef]

- Angerosa, F.; Mostallino, R.; Basti, C.; Vito, R. Influence of malaxation temperature and time on the quality of virgin olive oils. Food Chem. 2001, 72, 19–28. [Google Scholar] [CrossRef]

- Servili, M.; Selvaggini, R.; Taticchi, A.; Esposto, S.; Montedoro, G.F. Volatile Compounds and Phenolic Composition of Virgin Olive Oil: Optimization of Temperature and Time of Exposure of Olive Pastes to Air Contact during the Mechanical Extraction Process. J. Agric. Food Chem. 2003, 51, 7980–7988. [Google Scholar] [CrossRef] [PubMed]

- Tamborrino, A.; Clodoveo, M.L.; Leone, A.; Amirante, P.; Paice, A.G. The Malaxation Process: Influence on Olive Oil Quality and the Effect of the Control of Oxygen Concentration in Virgin Olive Oil. In Olives and Olive Oil in Health and Disease Prevention; Elsevier: Amsterdam, The Netherlands, 2010; pp. 77–83. ISBN 9780123744203. [Google Scholar]

- Bianchi, B.; Tamborrino, A.; Giametta, F.; Squeo, G.; Difonzo, G.; Catalano, P. Modified rotating reel for malaxer machines: Assessment of rheological characteristics, energy consumption, temperature profile, and virgin olive oil quality. Foods 2020, 9, 813. [Google Scholar] [CrossRef]

- Leone, A.; Tamborrino, A.; Romaniello, R.; Zagaria, R.; Sabella, E. Specification and implementation of a continuous microwave-assisted system for paste malaxation in an olive oil extraction plant. Biosyst. Eng. 2014, 125, 24–35. [Google Scholar] [CrossRef]

- Catalano, F.; Perone, C.; Iannacci, V.; Leone, A.; Tamborrino, A.; Bianchi, B. Energetic analysis and optimal design of a CHP plant in a frozen food processing factory through a dynamical simulation model. Energy Convers. Manag. 2020, 225, 113444. [Google Scholar] [CrossRef]

- Perone, C.; Catalano, F.; Giametta, F.; Tamborrino, A.; Bianchi, B.; Ayr, U. Study and analysis of a cogeneration system with microturbines in a food farming of dry pasta. Chem. Eng. Trans. 2017, 58, 499–504. [Google Scholar] [CrossRef]

- Servili, M.; Veneziani, G.; Taticchi, A.; Romaniello, R.; Tamborrino, A.; Leone, A. Low-frequency, high-power ultrasound treatment at different pressures for olive paste: Effects on olive oil yield and quality. Ultrason. Sonochem. 2019, 59, 104747. [Google Scholar] [CrossRef] [PubMed]

- Leone, A.; Romaniello, R.; Tamborrino, A.; Xu, X.Q.; Juliano, P. Microwave and megasonics combined technology for a continuous olive oil process with enhanced extractability. Innov. Food Sci. Emerg. Technol. 2017, 42, 56–63. [Google Scholar] [CrossRef]

- Romaniello, R.; Tamborrino, A.; Leone, A. Use of ultrasound and pulsed electric fields technologies applied to the olive oil extraction process. Chem. Eng. Trans. 2019, 75, 13–18. [Google Scholar] [CrossRef]

- Tamborrino, A.; Urbani, S.; Servili, M.; Romaniello, R.; Perone, C.; Leone, A. Pulsed electric fields for the treatment of olive pastes in the oil extraction process. Appl. Sci. 2020, 10, 114. [Google Scholar] [CrossRef]

- Amirante, P.; Clodoveo, M.L.; Dugo, G.; Leone, A.; Tamborrino, A. Advance technology in virgin olive oil production from traditional and de-stoned pastes: Influence of the introduction of a heat exchanger on oil quality. Food Chem. 2006, 98, 797–805. [Google Scholar] [CrossRef]

- Esposto, S.; Veneziani, G.; Taticchi, A.; Selvaggini, R.; Urbani, S.; Di Maio, I.; Sordini, B.; Minnocci, A.; Sebastiani, L.; Servili, M. Flash thermal conditioning of olive pastes during the olive oil mechanical extraction process: Impact on the structural modifications of pastes and oil quality. J. Agric. Food Chem. 2013, 61, 4953–4960. [Google Scholar] [CrossRef] [PubMed]

- Veneziani, G.; Esposto, S.; Taticchi, A.; Selvaggini, R.; Urbani, S.; Di Maio, I.; Sordini, B.; Servili, M. Flash Thermal Conditioning of Olive Pastes during the Oil Mechanical Extraction Process: Cultivar Impact on the Phenolic and Volatile Composition of Virgin Olive Oil. J. Agric. Food Chem. 2015, 63, 6066–6074. [Google Scholar] [CrossRef] [PubMed]

- Leone, A.; Esposto, S.; Tamborrino, A.; Romaniello, R.; Taticchi, A.; Urbani, S.; Servili, M. Using a tubular heat exchanger to improve the conditioning process of the olive paste: Evaluation of yield and olive oil quality. Eur. J. Lipid Sci. Technol. 2016, 118, 308–317. [Google Scholar] [CrossRef]

- Veneziani, G.; Esposto, S.; Taticchi, A.; Urbani, S.; Selvaggini, R.; Di Maio, I.; Sordini, B.; Servili, M. Cooling treatment of olive paste during the oil processing: Impact on the yield and extra virgin olive oil quality. Food Chem. 2017, 221, 107–113. [Google Scholar] [CrossRef] [PubMed]

- Leone, A.; Romaniello, R.; Juliano, P.; Tamborrino, A. Use of a mixing-coil heat exchanger combined with microwave and ultrasound technology in an olive oil extraction process. Innov. Food Sci. Emerg. Technol. 2018, 50, 66–72. [Google Scholar] [CrossRef]

- Tamborrino, A.; Romaniello, R.; Caponio, F.; Squeo, G.; Leone, A. Combined industrial olive oil extraction plant using ultrasounds, microwave, and heat exchange: Impact on olive oil quality and yield. J. Food Eng. 2019, 245, 124–130. [Google Scholar] [CrossRef]

- D’Addio, L.; Carotenuto, C.; Di Natale, F.; Nigro, R. A new arrangement of blades in scraped surface heat exchangers for food pastes. J. Food Eng. 2012, 108, 143–149. [Google Scholar] [CrossRef]

- Hernández-Parra, O.D.; Plana-Fattori, A.; Alvarez, G.; Ndoye, F.-T.; Benkhelifa, H.; Flick, D. Modeling flow and heat transfer in a scraped surface heat exchanger during the production of sorbet. J. Food Eng. 2018, 221, 54–69. [Google Scholar] [CrossRef]

- Stachnik, M.; Jakubowski, M. Multiphase model of flow and separation phases in a whirlpool: Advanced simulation and phenomena visualization approach. J. Food Eng. 2020, 274, 109846. [Google Scholar] [CrossRef]

- Ambekar, A.S.; Sivakumar, R.; Anantharaman, N.; Vivekenandan, M. CFD simulation study of shell and tube heat exchangers with different baffle segment configurations. Appl. Therm. Eng. 2016, 108, 999–1007. [Google Scholar] [CrossRef]

- Abbasian Arani, A.A.; Moradi, R. Shell and tube heat exchanger optimization using new baffle and tube configuration. Appl. Therm. Eng. 2019, 157, 113736. [Google Scholar] [CrossRef]

- Mokkapati, V.; Lin, C. Sen Numerical study of an exhaust heat recovery system using corrugated tube heat exchanger with twisted tape inserts. Int. Commun. Heat Mass Transf. 2014, 57, 53–64. [Google Scholar] [CrossRef]

- Korres, D.; Bellos, E.; Tzivanidis, C. Investigation of a nanofluid-based compound parabolic trough solar collector under laminar flow conditions. Appl. Therm. Eng. 2019, 149, 366–376. [Google Scholar] [CrossRef]

- Bellos, E.; Mathioulakis, E.; Tzivanidis, C.; Belessiotis, V.; Antonopoulos, K.A. Experimental and numerical investigation of a linear Fresnel solar collector with flat plate receiver. Energy Convers. Manag. 2016, 130, 44–59. [Google Scholar] [CrossRef]

- Boncinelli, P.; Catalano, P.; Cini, E. Olive paste rheological analysis. Trans. ASABE 2013, 56, 237–243. [Google Scholar] [CrossRef]

- Tamborrino, A.; Squeo, G.; Leone, A.; Paradiso, V.M.; Romaniello, R.; Summo, C.; Pasqualone, A.; Catalano, P.; Bianchi, B.; Caponio, F. Industrial trials on coadjuvants in olive oil extraction process: Effect on rheological properties, energy consumption, oil yield and olive oil characteristics. J. Food Eng. 2017, 205, 34–46. [Google Scholar] [CrossRef]

- Lam, C.K.G.; Bremhorst, K. A modified form of the k-ε model for predicting wall turbulence. J. Fluids Eng. Trans. ASME 1981, 103, 456–460. [Google Scholar] [CrossRef]

- Invernizzi, M.; Juel, C.; Swank, L.; Meier, J. Technical reference 2016

- Van Driest, E.R. On Turbulent Flow Near a Wall. J. Aeronaut. Sci. 1956, 23, 1007–1011. [Google Scholar] [CrossRef]

- Córcoles, J.I.; Marín-Alarcón, E.; Almendros-Ibáñez, J.A. Heat transfer performance of fruit juice in a heat exchanger tube using numerical simulations. Appl. Sci. 2020, 10, 648. [Google Scholar] [CrossRef]

- Steffe, J.F.; Mohamed, I.O.; Ford, E.W. Pressure Drop Across Valves and Fittings for Pseudoplastic Fluids in Laminar Flow. Trans. Am. Soc. Agric. Eng. 1984, 27, 616–619. [Google Scholar] [CrossRef]

- Guerrini, L.; Masella, P.; Angeloni, G.; Zanoni, B.; Breschi, C.; Calamai, L.; Parenti, A. The effect of an increase in paste temperature between malaxation and centrifugation on olive oil quality and yield: Preliminary results. Ital. J. Food Sci. 2019, 31, 451–458. [Google Scholar] [CrossRef]

- Taticchi, A.; Esposto, S.; Veneziani, G.; Urbani, S.; Selvaggini, R.; Servili, M. The influence of the malaxation temperature on the activity of polyphenoloxidase and peroxidase and on the phenolic composition of virgin olive oil. Food Chem. 2013, 136, 975–983. [Google Scholar] [CrossRef] [PubMed]

- Lukić, I.; Žanetić, M.; Jukić Špika, M.; Lukić, M.; Koprivnjak, O.; Brkić Bubola, K. Complex interactive effects of ripening degree, malaxation duration and temperature on Oblica cv. virgin olive oil phenols, volatiles and sensory quality. Food Chem. 2017, 232, 610–620. [Google Scholar] [CrossRef] [PubMed]

- Marx, Í.M.G.; Rodrigues, N.; Veloso, A.C.A.; Casal, S.; Pereira, J.A.; Peres, A.M. Effect of malaxation temperature on the physicochemical and sensory quality of cv. Cobrançosa olive oil and its evaluation using an electronic tongue. LWT 2021, 137, 110426. [Google Scholar] [CrossRef]

- Garrido-Delgado, R.; Dobao-Prieto, M.D.M.; Arce, L.; Valcárcel, M. Determination of volatile compounds by GC-IMS to assign the quality of virgin olive oil. Food Chem. 2015, 187, 572–579. [Google Scholar] [CrossRef]

- Selvaggini, R.; Esposto, S.; Taticchi, A.; Urbani, S.; Veneziani, G.; Di Maio, I.; Sordini, B.; Servili, M. Optimization of the temperature and oxygen concentration conditions in the malaxation during the oil mechanical extraction process of four italian olive cultivars. J. Agric. Food Chem. 2014, 62, 3813–3822. [Google Scholar] [CrossRef] [PubMed]

- Rozzi, S.; Massini, R.; Paciello, G.; Pagliarini, G.; Rainieri, S.; Trifirò, A. Heat treatment of fluid foods in a shell and tube heat exchanger: Comparison between smooth and helically corrugated wall tubes. J. Food Eng. 2007, 79, 249–254. [Google Scholar] [CrossRef]

- Rainieri, S.; Bozzoli, F.; Mordacci, M.; Pagliarini, G. Numerical 2-D Modeling of a Coaxial Scraped Surface Heat Exchanger Versus Experimental Results Under the Laminar Flow Regime. Heat Transf. Eng. 2012, 33, 1120–1129. [Google Scholar] [CrossRef]

- Rainieri, S.; Bozzoli, F.; Cattani, L.; Vocale, P. Parameter estimation applied to the heat transfer characterisation of Scraped Surface Heat Exchangers for food applications. J. Food Eng. 2014, 125, 147–156. [Google Scholar] [CrossRef]

| Description | Unit | Value |

|---|---|---|

| Inner tube diameter | mm | 88.9 |

| Inner tube thickness | mm | 2.0 |

| Inner tube length | m | 1.6 |

| External jacket inner diameter | mm | 101.6 |

| External jacket thickness | mm | 1.5 |

| External jacket inlet/outlet diameter | mm | 16.4 |

| External jacket inlet/outlet length | mm | 90.7 |

| Number of elbows | - | 2.0 |

| Elbows r/D | - | 1.75 |

| Elbows inner diameter | mm | 88.9 |

| Elbows thickness | mm | 2.0 |

| Fluid | [kg/m3] | [Pa sn] | [W/mK] | [Pa s] | ||

|---|---|---|---|---|---|---|

| Olive paste | 1100 | 1200 | 0.1 | 3.31 | 0.46 | - |

| Water | 992.17 | - | - | 4.18 | 0.63 | 6.53 × 10−4 |

| Mesh 1 | Mesh 2 | Mesh 3 | Mesh 4 | |

|---|---|---|---|---|

| N° elements | 324,301 | 569,322 | 964,659 | 2,163,502 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perone, C.; Romaniello, R.; Leone, A.; Catalano, P.; Tamborrino, A. CFD Analysis of a Tubular Heat Exchanger for the Conditioning of Olive Paste. Appl. Sci. 2021, 11, 1858. https://doi.org/10.3390/app11041858

Perone C, Romaniello R, Leone A, Catalano P, Tamborrino A. CFD Analysis of a Tubular Heat Exchanger for the Conditioning of Olive Paste. Applied Sciences. 2021; 11(4):1858. https://doi.org/10.3390/app11041858

Chicago/Turabian StylePerone, Claudio, Roberto Romaniello, Alessandro Leone, Pasquale Catalano, and Antonia Tamborrino. 2021. "CFD Analysis of a Tubular Heat Exchanger for the Conditioning of Olive Paste" Applied Sciences 11, no. 4: 1858. https://doi.org/10.3390/app11041858

APA StylePerone, C., Romaniello, R., Leone, A., Catalano, P., & Tamborrino, A. (2021). CFD Analysis of a Tubular Heat Exchanger for the Conditioning of Olive Paste. Applied Sciences, 11(4), 1858. https://doi.org/10.3390/app11041858