Measurement of Amount for Steel Abrasive Material Transported by Special Scraper Conveyor

Abstract

1. Introduction

2. Materials and Methods

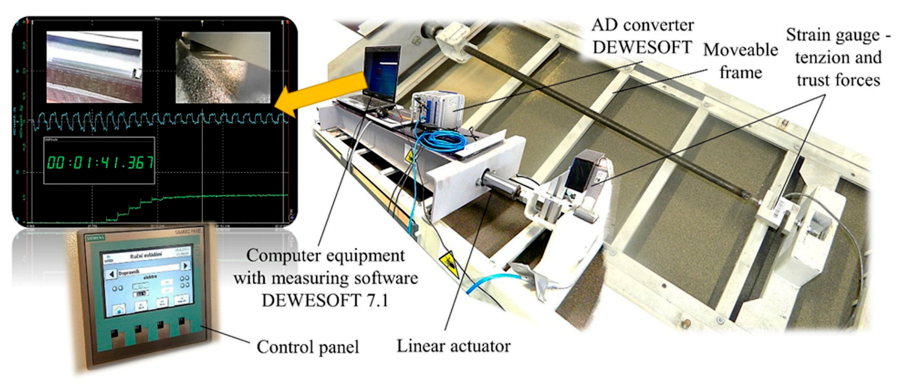

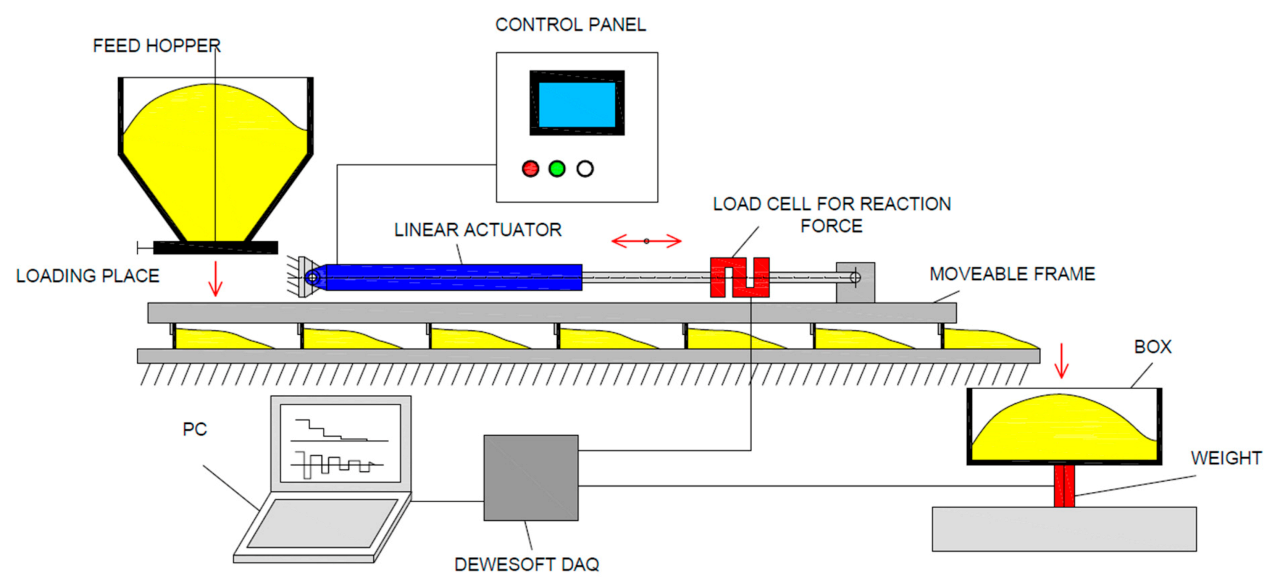

2.1. Experimental Testing Equipment and Measured Parameters

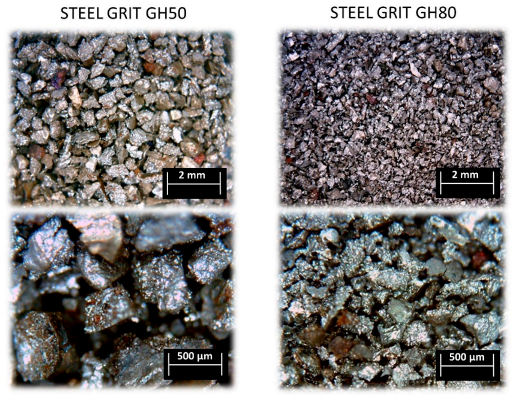

2.2. Specification of the Transported Material

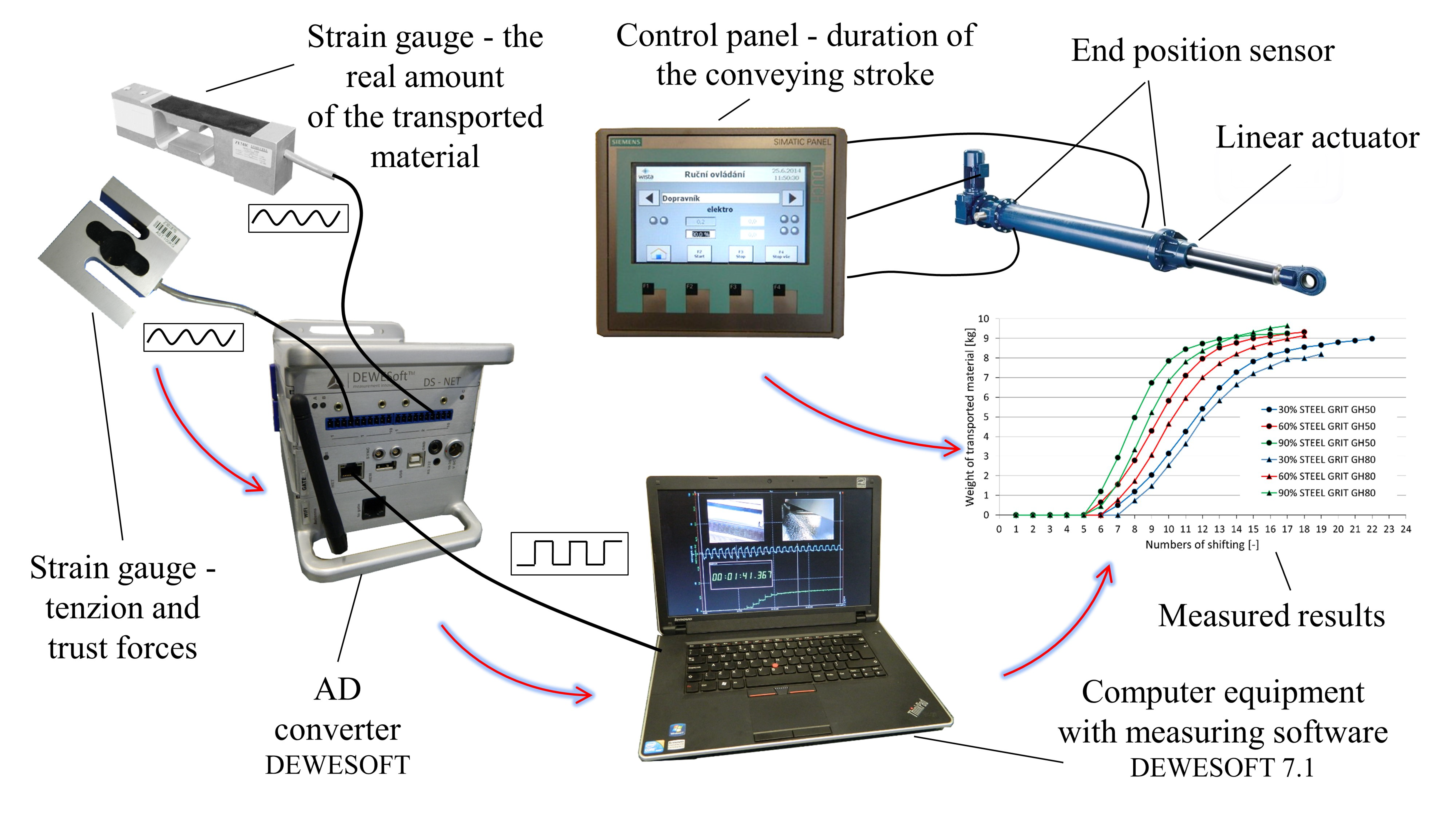

2.3. Measuring System

2.4. Measuring Procedure

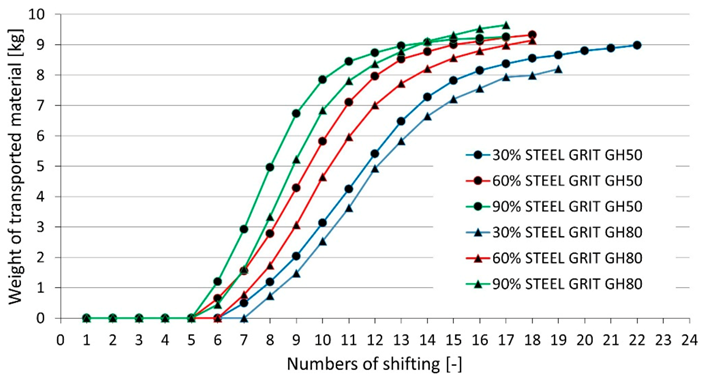

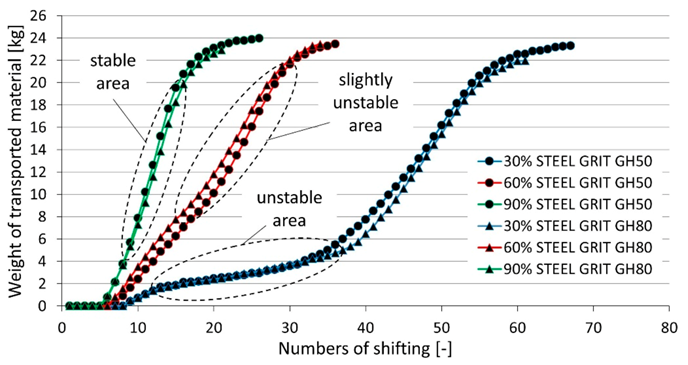

3. Results

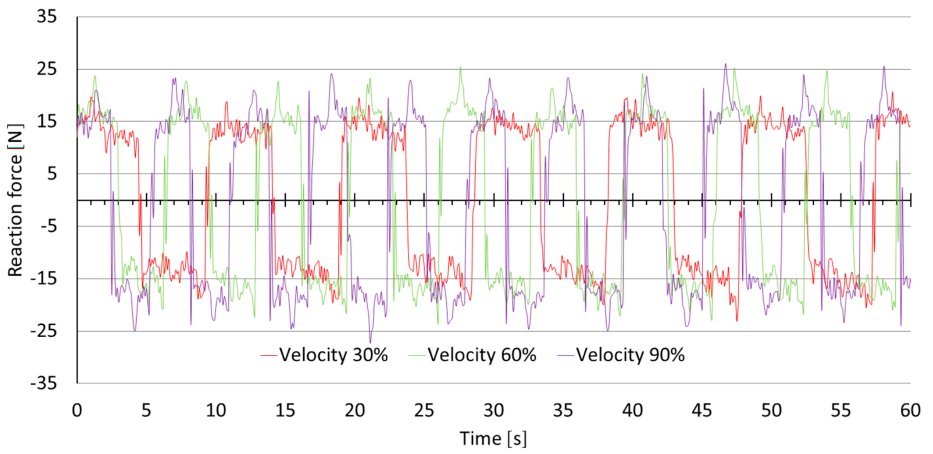

3.1. Measuring of Reaction Forces during Conveyor Operation Without Material

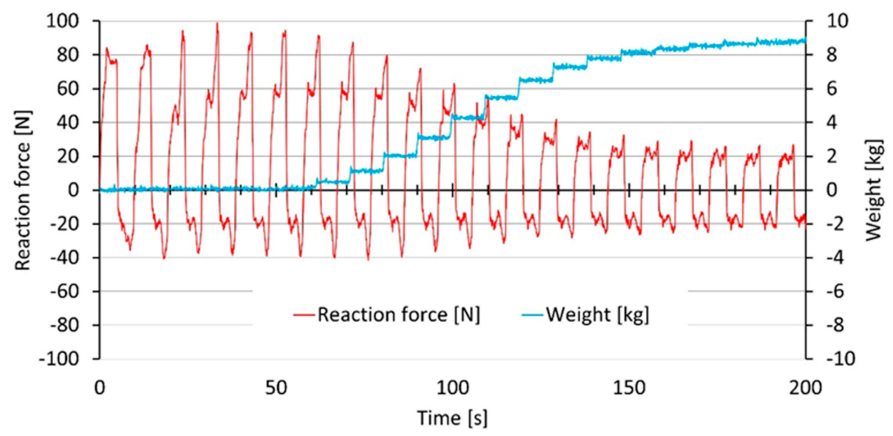

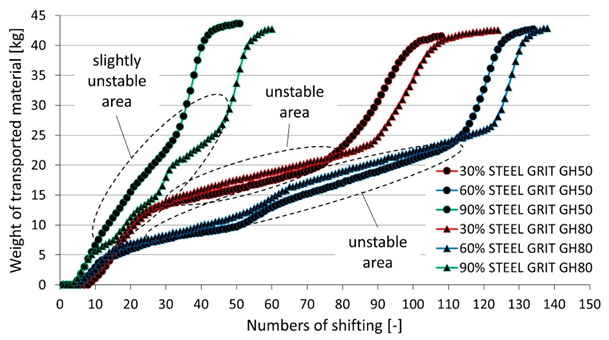

3.2. Measuring of Reaction Forces Acting on the Driving Mechanism during Conveyor Operation with Material

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Woodcock, C.R.; Mason, J.S. Bulk Solids Handling; Springer: Dordrecht, The Netherlands, 1988; ISBN 978-94-010-7689-0. [Google Scholar]

- Wu, Z.-H.; Zhu, H.; Wang, Y.-H.; Li, G. Mining Scraper Conveyor’s Wear Failure and Countermeasure. Coal Mine Mach. 2005, 7, 28. [Google Scholar]

- Landry, H.; Laguë, C.; Roberge, M. Discrete element modeling of machine–manure interactions. Comput. Electron. Agric. 2006, 52, 90–106. [Google Scholar] [CrossRef]

- Wang, G. New development of longwall mining equipment based on automation and intelligent technology for thin seam coal. J. Coal Sci. Eng. 2013, 19, 97–103. [Google Scholar] [CrossRef]

- Chunzhi, Z.; Guoying, M. Dynamic modeling of scraper conveyor sprocket transmission system and simulation analysis. In Proceedings of the 2011 IEEE International Conference on Mechatronics and Automation, ICMA 2011, Beijing, China, 7–10 August 2011; pp. 1390–1394. [Google Scholar]

- Xia, R.; Wang, X.; Li, B.; Wei, X.; Yang, Z. Discrete Element Method-(DEM-) Based Study on the Wear Mechanism and Wear Regularity in Scraper Conveyor Chutes. Math. Probl. Eng. 2019, 2019. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, P.; Li, S. Article Study on the fault diagnosis method of scraper conveyor gear under time-varying load condition. Appl. Sci. 2020, 10, 5053. [Google Scholar] [CrossRef]

- Pei, Z.; Wang, R. Failure Analysis and Improvement of Chute of Scraper Conveyor. Coal Mine Mach. 2007, 3, 58. [Google Scholar]

- Min, X.; Yang, G.; Wu, H.; Xu, K. Finite element analysis for round link chains of scraper conveyor based on ANSYS. Mach. Des. Manuf. 2011, 6, 42. [Google Scholar]

- Mao, J.; Zhang, D.; Shi, J. Simulation Research of Tension Automatic Control System of Scraper Conveyor. J. Syst. Simul. 2008, 16, 62. [Google Scholar]

- Liu, T.; Tan, C.; Wang, Z.; Xu, J.; Man, Y.; Wang, T. Horizontal bending angle optimization method for scraper conveyor based on improved bat algorithm. Algorithms 2019, 12, 84. [Google Scholar] [CrossRef]

- Xiao-yan, G. Dynamic analysis of round-link chain for scraper conveyer under chain blocked. Hoisting Conveying Mach. 2006, 8, 20. [Google Scholar]

- Zhang, D.S.; Liu, X.H.; Shi, J.G.; Mao, J.; Li, Z. Scraper Conveyor Dynamic Modeling and Simulation. Adv. Mater. Res. 2011, 217–218, 426–430. [Google Scholar] [CrossRef]

- Lu, E.; Li, W.; Yang, X.; Xu, S. Simulation study on speed control of permanent magnet direct-driven system for mining scraper conveyor. Int. J. Eng. Syst. Model. Simul. 2018, 10, 1–11. [Google Scholar] [CrossRef]

- Wang, X.; Li, B.; Yang, Z. Analysis of the bulk coal transport state of a scraper conveyor using the discrete element method. J. Mech. Eng. 2018, 64, 37–46. [Google Scholar] [CrossRef]

- Mikusova, N.; Stopka, O.; Stopkova, M.; Opettova, E. Use of simulation by modelling of conveyor belt contact forces. Open Eng. 2019, 9, 709–715. [Google Scholar] [CrossRef]

- Mikusova, N.; Millo, S. Modelling conveyor belt passage with a driving drum using finite element methods. Adv. Sci. Technol. J. 2017, 11, 239–246. [Google Scholar] [CrossRef]

- Wang, S.P.; Yang, Z.J. Improve Design and Analysis on Transitional Chute of Scraper Conveyor. Adv. Mater. Res. 2010, 145, 541–545. [Google Scholar] [CrossRef]

- Ren, Z.Q.; Zhang, J.L.; Liang, X. FEA on Ramp Plate of Scraper Conveyor Based on ABAQUS. Adv. Mater. Res. 2014, 1014, 71–75. [Google Scholar] [CrossRef]

- Chen, L.-G.; Zhao, J.-H.; Mei, X.-F. Automation and intelligent control technologies of scraper conveyor of fully-mechanized Face. Gongkuang Zidonghua-Ind. Mine Autom. 2011, 37, 24–26. [Google Scholar]

- Hastie, D.B.; Grima, A.P.; Wypych, P.W. Validation of particle flow through a conveyor transfer spoon via particle velocity analysis. In Bulk Europe 2008; University Leoben: Leoben, Austria, 2008; pp. 1–5. [Google Scholar]

- Hastie, D.B.; Wypych, P.W. Experimental validation of particle flow through conveyor transfer hoods via continuum and discrete element methods. Mech. Mater. 2010, 42, 383–394. [Google Scholar] [CrossRef]

- Hastie, D.B.; Wypych, P.W.; Grima, A.P.; LaRoche, R.; Curry, D. Predication of the Behaviour of Bulk Materials in the Design and Operation of Bulk Handling and Processing Plants. Aust. Bulk Handl. Rev. 2012, 17, 76–80. [Google Scholar]

- Grima, A.P.; Mills, B.P.; Wypych, P.W. Investigation of Measuring Wall Friction on a Large Scale Wall Friction Tester and the Jenike Direct Shear Tester Investigation of Measuring Wall Friction on a Large Scale Wall Friction. In 3rd International Conference Exhibition BulkSolids Europe 2010; Gerd Kielburger: Wuerzburg, Germany, 2010; pp. 1–14. [Google Scholar]

| Adjusted Shifting Speed Level [%] | Shifting Speed [mm.s−1] | Duration of Stroke [s] | Length of Stroke [mm] |

|---|---|---|---|

| 30 | 55.67 | 4.85 | 270 |

| 60 | 81.82 | 3.3 | 270 |

| 90 | 94.41 | 2.86 | 270 |

| Adjusted Shifting Speed Level [%] | Kind of the Transported Abrasive Material STEEL GRIT | Feeding with Abrasive Material [kg] | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 30 | GH50 | GH80 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 |

| 60 | GH50 | GH80 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 |

| 90 | GH50 | GH80 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 |

| Shifting Speed Level [%] | 30 | 60 | 90 | |||

|---|---|---|---|---|---|---|

| Kind of Material STEEL GRIT | GH50 | G80 | GH50 | G80 | GH50 | G80 |

| Weight of Material [kg] | Transported Amount [t·hour−1] | |||||

| 5 | 0.216 | 0.273 | 0.543 | 0.558 | 1.247 | 1.152 |

| 10 | 0.369 | 0.403 | 0.776 | 0.775 | 1.488 | 1.177 |

| 15 | 0.356 | 0.356 | 0.800 | 0.860 | 1.600 | 1.634 |

| Average value [t·hour−1] | 0.314 | 0.344 | 0.706 | 0.731 | 1.445 | 1.321 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fedorko, G.; Nečas, J.; Zegzulka, J.; Gelnar, D.; Molnár, V.; Tomašková, M. Measurement of Amount for Steel Abrasive Material Transported by Special Scraper Conveyor. Appl. Sci. 2021, 11, 1852. https://doi.org/10.3390/app11041852

Fedorko G, Nečas J, Zegzulka J, Gelnar D, Molnár V, Tomašková M. Measurement of Amount for Steel Abrasive Material Transported by Special Scraper Conveyor. Applied Sciences. 2021; 11(4):1852. https://doi.org/10.3390/app11041852

Chicago/Turabian StyleFedorko, Gabriel, Jan Nečas, Jiří Zegzulka, Daniel Gelnar, Vieroslav Molnár, and Marianna Tomašková. 2021. "Measurement of Amount for Steel Abrasive Material Transported by Special Scraper Conveyor" Applied Sciences 11, no. 4: 1852. https://doi.org/10.3390/app11041852

APA StyleFedorko, G., Nečas, J., Zegzulka, J., Gelnar, D., Molnár, V., & Tomašková, M. (2021). Measurement of Amount for Steel Abrasive Material Transported by Special Scraper Conveyor. Applied Sciences, 11(4), 1852. https://doi.org/10.3390/app11041852