Spatially Explicit Model for Anaerobic Co-Digestion Facilities Location and Pre-Dimensioning Considering Spatial Distribution of Resource Supply and Biogas Yield in Northwest Portugal

Abstract

1. Introduction

2. Materials and Methods

2.1. Scope, Objectives and Research Framework

2.2. Spatio-Temporal Patterns of Sewage Sludge and Dairy Cattle Manure Production and Availability

2.3. Spatial Multicriteria Model Development to Support Biogas Facilities Location

2.4. Multicriteria Model Validation, Resources Allocation and Biogas Plants Pre-Dimensioning

2.5. Multicriteria Spatially Explicit Model Development

3. Results

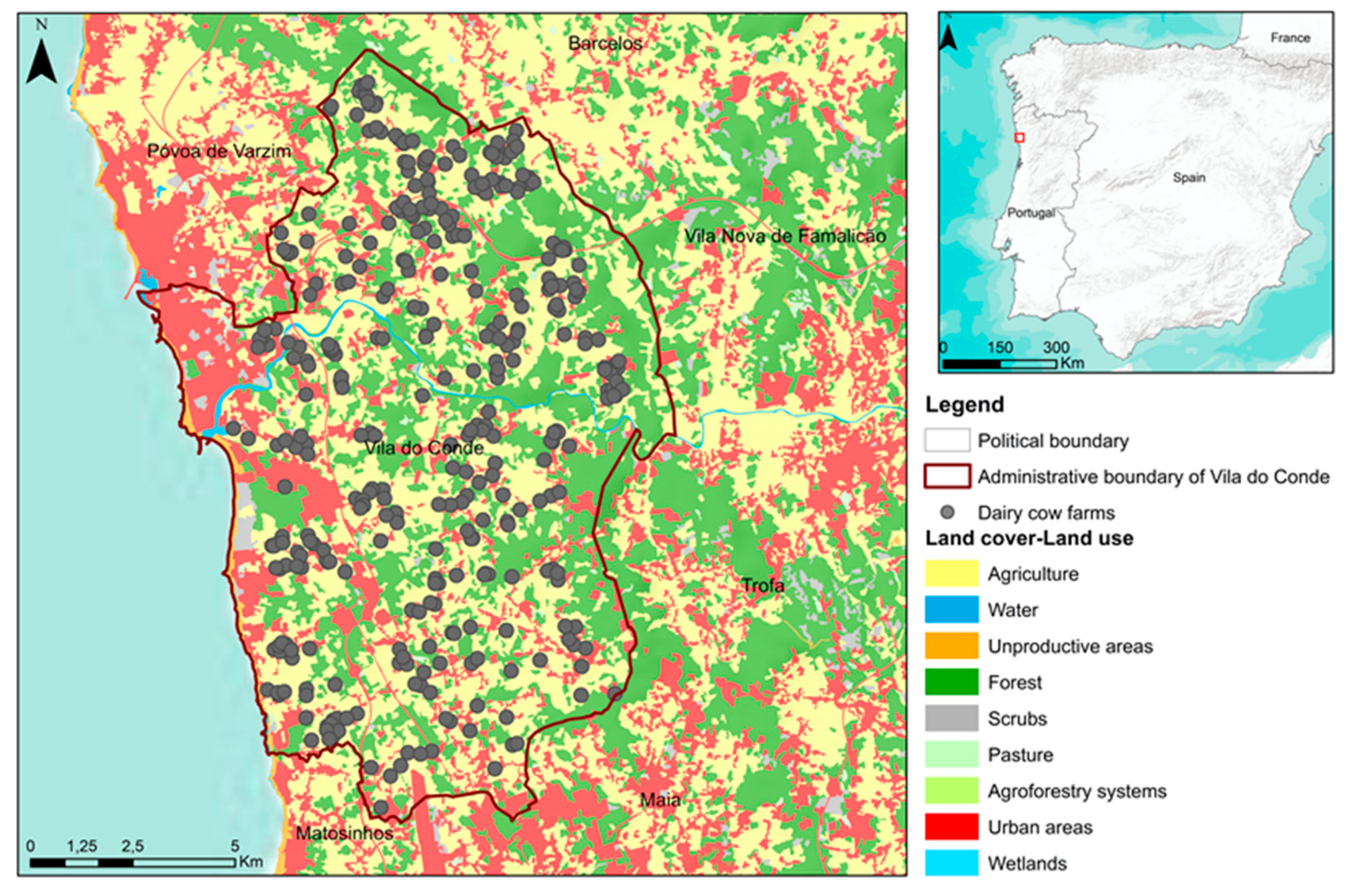

3.1. Unit Area, Research Scope and Challenges

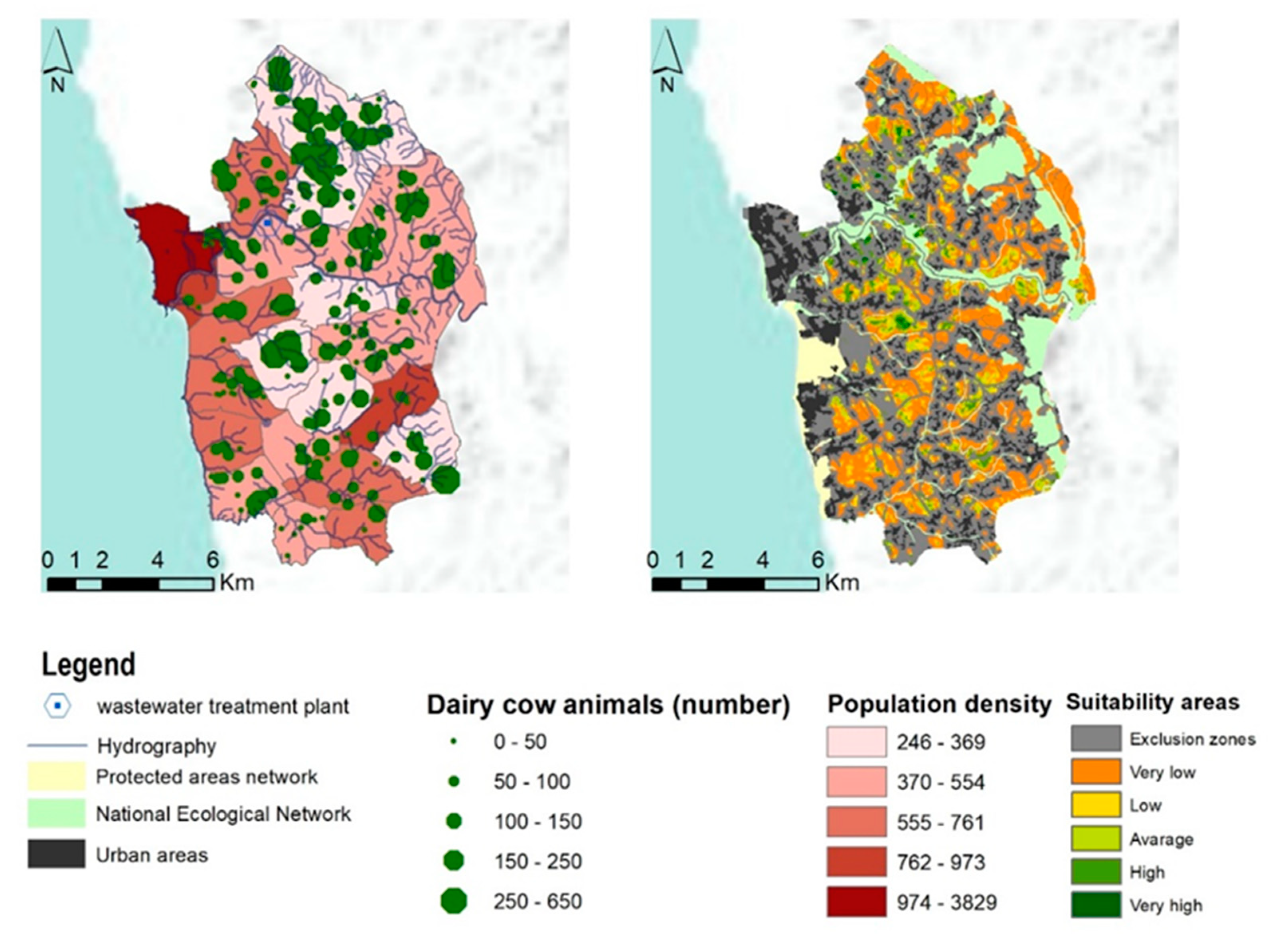

3.2. Sewage Sludge and Cattle Manure Spatio-Temporal Patterns

3.3. Environmental, Social and Economic Criteria in Biogas Plant Location

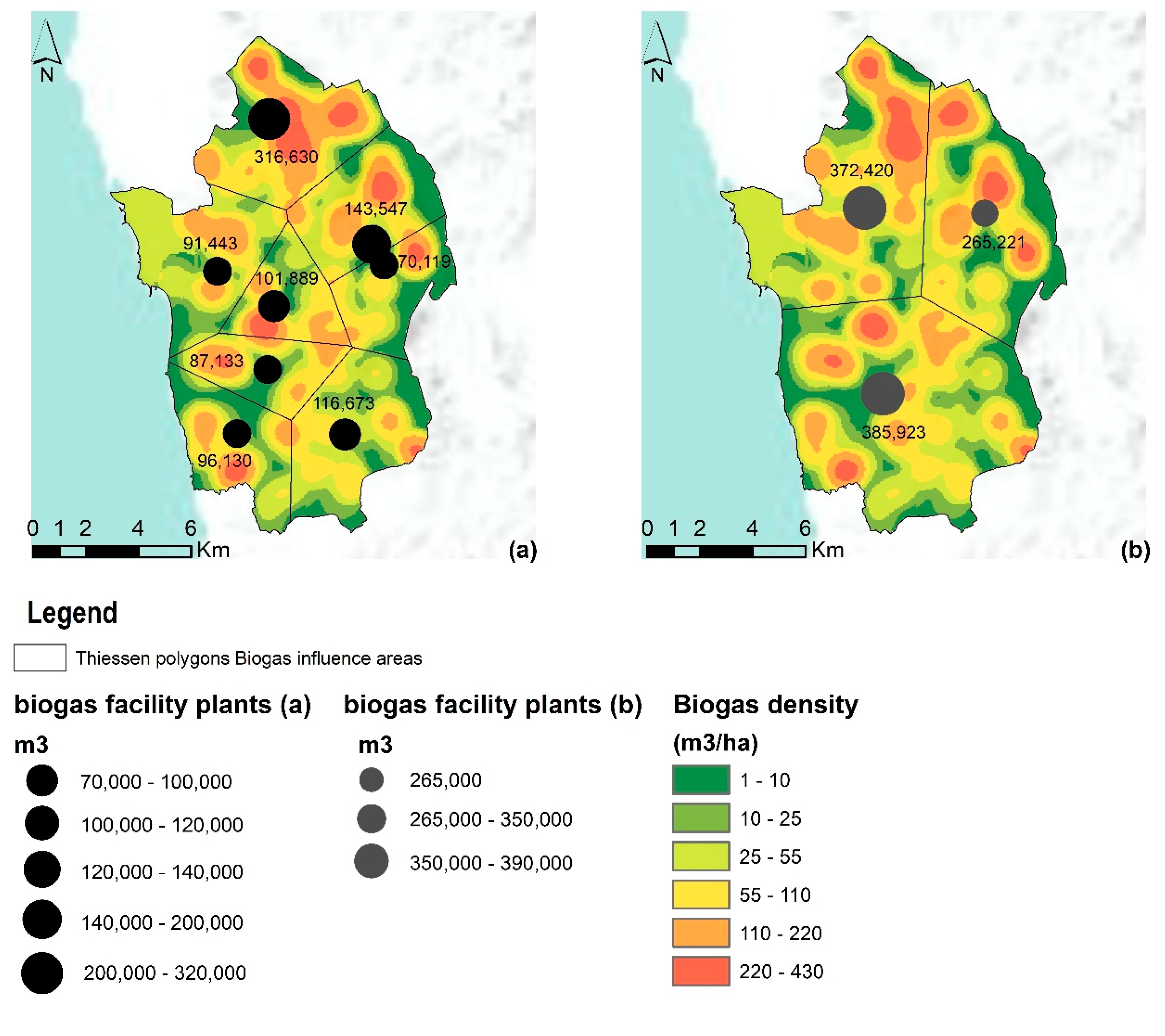

3.4. Biogas Facilities’ Location, Resources Allocation and Pre-Dimensioning

| Indicators | Value | Reference |

|---|---|---|

| Volatile solids/Total solids (%) | 65 | [29] |

| Methane yield (mL gVS−1) | 48.5 | [29] |

| Biogas yield (mL gVS−1) | 93.3 | [29] |

| Average methane content (%) | 52 | [29] |

| Biogas calorific value (MJ m−3) | 21.5 | [47] |

| Waste sludge production (kg TS capita−1 year−1) | 16.4 | [43] |

4. Discussion

5. Conclusions

- A high potential of local bioenergy resources available for biogas production (dairy cattle manure and sewage sludge) and the interest in complementing, at a local scale, the use of existing biogas producing facilities (including those integrated in wastewater treatment plants) with new collective facilities;

- The suitable locations for the installation of biogas production facilities in low altitude, forested areas, near to cattle farms, the road network and electric injection points, but far from the hydrographic network and avoiding the ecological reserves and protected areas;

- The need to collect and analyze additional and detailed thematic and temporal (e.g., seasonal) data on sewage sludge and animal manure production;

- The importance of developing multicriteria optimization algorithms to test a set of maximization and optimization functions (location and allocation issues), considering economic and econometric functions and objectives;

- The reinforcement of multi-objective assessment to compare sites and alternative management models, considering investment and cost analysis.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Winarso, H.; Hudalah, D.; Firman, T. Peri-urban transformation in the Jakarta metropolitan area. Habitat Int. 2015, 49, 221–229. [Google Scholar] [CrossRef]

- Lefebvre, M.; Espinosa, G.; Gomez, Y.P.S. JRC Scientifics and Policy Reports—The Influence of the Common Agricultural Policy on Agricultural Landscape EUR 25459 EN:75; Publications Office of the European Union: Brusels, Belgium, 2012. [Google Scholar] [CrossRef]

- Lima, M.L.; Romanelli, A.; Massone, H.E. Assessing groundwater pollution hazard changes under different socio-economic and environmental scenarios in an agricultural watershed. Sci. Total Environ. 2015, 530, 333–346. [Google Scholar] [CrossRef]

- Rammel, C.; Stagl, S.; Wilfing, H. Managing complex adaptive systems — A co-evolutionary perspective on natural resource management. Ecol. Econ. 2007, 63, 9–21. [Google Scholar] [CrossRef]

- Paolini, V.; Petracchini, F.; Segreto, M.; Tomassetti, L.; Naja, N.; Cecinato, A. Environmental impact of biogas: A short review of current knowledge. J. Environ. Sci. Health Part A 2018, 53, 899–906. [Google Scholar] [CrossRef] [PubMed]

- Kelly, C.; Ferrara, A.; Wilson, G.A.; Ripullone, F.; Nolè, A.; Harmer, N.; Salvati, L. Community resilience and land degradation in forest and shrubland socio-ecological systems: Evidence from Gorgoglione, Basilicata, Italy. Land Use Policy 2015, 46, 11–20. [Google Scholar] [CrossRef]

- Biggs, E.M.; Bruce, E.; Boruff, B.; Duncan, J.M.; Horsley, J.; Pauli, N.; McNeill, K.; Neef, A.; van Ogtrop, F.; Curnow, J.; et al. Sustainable development and the water–energy–food nexus: A perspective on livelihoods. Environ. Sci. Policy 2015, 54, 389–397. [Google Scholar] [CrossRef]

- Young, O.R.; Berkhout, F.; Gallopin, G.C.; Janssen, M.A.; Ostrom, E.; van der Leeuw, S. The globalization of socio-ecological systems: An agenda for scientific research. Glob. Environ. Chang. 2006, 16, 304–316. [Google Scholar] [CrossRef]

- Torres-Lima, P.; Pinel, S.L.; Conway-Gómez, K. Adaptive Governance for Resilience of Peri-Urban Socioecological Systems. In Resilient Cities; Springer International Publishing: Cham, Switzerland, 2019; pp. 43–58. [Google Scholar]

- Racoviceanu, A.I.; Karney, B.W.; Kennedy, C.A.; Colombo, A.F. Life-Cycle Energy Use and Greenhouse Gas Emissions Inventory for Water Treatment Systems. J. Infrastruct. Syst. 2007, 13, 261–270. [Google Scholar] [CrossRef]

- Steinhäußer, R.; Siebert, R.; Steinführer, A.; Hellmich, M. National and regional land-use conflicts in Germany from the perspective of stakeholders. Land Use Policy 2015, 49, 183–194. [Google Scholar] [CrossRef]

- Scarlat, N.; Fahl, F.; Dallemand, J.-F. Status and Opportunities for Energy Recovery from Municipal Solid Waste in Europe. Waste Biomass Valorization 2019, 10, 2425–2444. [Google Scholar] [CrossRef]

- Escalante, H.; Castro, L.; Gauthier-Maradei, P.; de la Vega, R.R. Spatial decision support system to evaluate crop residue energy potential by anaerobic digestion. Bioresour. Technol. 2016, 219, 80–90. [Google Scholar] [CrossRef]

- Zareei, S. Evaluation of biogas potential from livestock manures and rural wastes using GIS in Iran. Renew. Energy 2018, 118, 351–356. [Google Scholar] [CrossRef]

- Castellet-Viciano, L.; Torregrossa, D.; Hernández-Sancho, F. The relevance of the design characteristics to the optimal operation of wastewater treatment plants: Energy cost assessment. J. Environ. Manag. 2018, 222, 275–283. [Google Scholar] [CrossRef] [PubMed]

- Cook, S.M.; Skerlos, S.J.; Raskin, L.; Love, N.G. A stability assessment tool for anaerobic codigestion. Water Res. 2017, 112, 19–28. [Google Scholar] [CrossRef]

- Bardi, L.; Malusà, E.; Zoppellari, F.; Bosco, F.; Bergesio, B.; Bertin, L. Production of renewable energies and biomolecules from livestock and agro-industrial waste: The BIOMOLENER Project. J. Biotechnol. 2010, 150, 172. [Google Scholar] [CrossRef]

- Sheets, J.P.; Yang, L.; Ge, X.; Wang, Z.; Li, Y. Beyond land application: Emerging technologies for the treatment and reuse of anaerobically digested agricultural and food waste. Waste Manag. 2015, 44, 94–115. [Google Scholar] [CrossRef] [PubMed]

- Fodor, Z.; Klemeš, J.J. Waste as alternative fuel—Minimising emissions and effluents by advanced design. Process. Saf. Environ. Prot. 2012, 90, 263–284. [Google Scholar] [CrossRef]

- Kousksou, T.; Allouhi, A.; Belattar, M.; Jamil, A.; el Rhafiki, T.; Arid, A.; Zeraouli, Y. Renewable energy potential and national policy directions for sustainable development in Morocco. Renew. Sustain. Energy Rev. 2015, 47, 46–57. [Google Scholar] [CrossRef]

- Mastrangelo, M.E.; Weyland, F.; Herrera, L.P.; Villarino, S.H.; Barral, M.P.; Auer, A.D. Ecosystem services research in contrasting socio-ecological contexts of Argentina: Critical assessment and future directions. Ecosyst. Serv. 2015, 16, 63–73. [Google Scholar] [CrossRef]

- Ma, J.; Scott, N.R.; Degloria, S.D.; Lembo, A.J. Siting analysis of farm-based centralized anaerobic digester systems for distributed generation using GIS. Biomass Bioenergy 2005, 28, 591–600. [Google Scholar] [CrossRef]

- Farahani, R.Z.; Steadieseifi, M.; Asgari, N. Multiple criteria facility location problems: A survey. Appl. Math. Model. 2010, 34, 1689–1709. [Google Scholar] [CrossRef]

- Höhn, J.; Lehtonen, E.; Rasi, S.; Rintala, J. A Geographical Information System (GIS) based methodology for determination of potential biomasses and sites for biogas plants in southern Finland. Appl. Energy 2014, 113, 1–10. [Google Scholar] [CrossRef]

- Alonso, J.; Castro, P.; Martins, I.; Honrado, J.; Calafate, M.; Gonçalves, J.; Pratola, C. Framework for user-oriented quality evaluation routines (D5.3). In Ecopotential: Improving Future Ecosystem Benefits Through Earth Observations; European Union: Brusels, Belgium, 2017; pp. 1–156. Available online: https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5b723633b&appId=PPGMS (accessed on 1 September 2019).

- Goodchild, M.F.; Li, L. Assuring the quality of volunteered geographic information. Spat. Stat. 2012, 1, 110–120. [Google Scholar] [CrossRef]

- Theuerl, S.; Herrmann, C.; Heiermann, M.; Grundmann, P.; Landwehr, N.; Kreidenweis, U.; Prochnow, A. The Future Agricultural Biogas Plant in Germany: A Vision. Energies 2019, 12, 396. [Google Scholar] [CrossRef]

- Fagbohun, B.; Aladejana, O. Integrating knowledge-based multi-criteria evaluation techniques with GIS for landfill site selection: A case study using AHP. Mater. Geoenviron. 2016, 63, 169–182. [Google Scholar] [CrossRef]

- Coura, R.D. Biomethanization of Nitrogen Rich Agricultural and Urban Wastewaters: Biological Kinetics and Management Optimization Using Sequencing Batch Reactors. Ph.D. Thesis, ISA—University of Lisbon, Lisbon, Portugal, 2019. [Google Scholar]

- Spigolon, L.M.; Giannotti, M.; la Rocca, A.P.; Russo, M.A.; Souza, N.D.C. Landfill siting based on optimisation, multiple decision analysis, and geographic information system analyses. Waste Manag. Res. 2018, 36, 606–615. [Google Scholar] [CrossRef]

- Boroushaki, S.; Malczewski, J. Measuring consensus for collaborative decision-making: A GIS-based approach. Comput. Environ. Urban Syst. 2010, 34, 322–332. [Google Scholar] [CrossRef]

- Malczewski, J. A Geographic Information Sciences Approach. In Spatial Multicriteria Decision Making and Analysis; Thill, J.E., Ed.; Routledge: Abingdon, UK, 2019; p. 393. [Google Scholar] [CrossRef]

- Malczewski, J. GIS and Multi-Criteria Decision Analysis; Wiley: New York, NY, USA, 1999; p. 408. [Google Scholar]

- Church, R.L. Geographical information systems and location science. Comput. Oper. Res. 2002, 29, 541–562. [Google Scholar] [CrossRef]

- Malczewski, J. GIS-based multicriteria decision analysis: A survey of the literature. Int. J. Geogr. Inf. Sci. 2006, 20, 703–726. [Google Scholar] [CrossRef]

- Alonso, J.; Curado, M.; Silva, A.; Eça, P. Plano de ordenamento da Bacia Leiteira Primária do Entre Douro e Minho. Direção Reg. Agric. Entre Douro Minhon 2012, 1, 1–153. [Google Scholar]

- Silva, S. Sistema de Apoio à Decisão Espacial Multicritério na Localização de Centrais de Biogás. Ph.D. Thesis, Universidade de Coimbra, Coimbra, Portugal, 2014. (In Portuguese). [Google Scholar]

- Zubaryeva, A.; Zaccarelli, N.; del Giudice, C.; Zurlini, G. Spatially explicit assessment of local biomass availability for distributed biogas production via anaerobic co-digestion—Mediterranean case study. Renew. Energy 2012, 39, 261–270. [Google Scholar] [CrossRef]

- Perpiña, C.; Martínez-Llario, J.C.; Pérez-Navarro, Á. Multicriteria assessment in GIS environments for siting biomass plants. Land Use Policy 2013, 31, 326–335. [Google Scholar] [CrossRef]

- Thompson, E.; Wang, Q.; Li, M. Anaerobic digester systems (ADS) for multiple dairy farms: A GIS analysis for optimal site selection. Energy Policy 2013, 61, 114–124. [Google Scholar] [CrossRef]

- Bojesen, M.; Birkin, M.; Clarke, G. Spatial competition for biogas production using insights from retail location models. Energy 2014, 68, 617–628. [Google Scholar] [CrossRef]

- INE. Censos 2011; Instituto Naciona de Estatistica: Lisbon, Portugal, 2011. [Google Scholar]

- Germany ATV-DYWK GFA. Rules and Standards; Dimensioning of Single Stage Actived Studge Plants; GFA Publishing company: Hennef, Germany, 2000. [Google Scholar]

- CBPA. Código de Boas Praticas Agrícolas: Para a Proteção da Agua Contra a Poluição com Nitratos de Origem Agrícola; Ministério da Agricultura do Desenvolvimento Rural e das Pescas: Lisbon, Portugal, 1997. [Google Scholar]

- Brito, L.; Alonso, J.; Rey-Grana, J. Gestão de efluentes nas explorações leiteiras do Entre Douro e Minho. Rev. Ciências Agrar. 2011, 36, 80–93. [Google Scholar]

- Batzias, F.; Sidiras, D.; Spyrou, E. Evaluating livestock manures for biogas production: A GIS based method. Renew. Energy 2005, 30, 1161–1176. [Google Scholar] [CrossRef]

- Braun, R. Anaerobic digestion: A multi-faceted process for energy, environmental management and rural development. In Improvement of Crop Plants for Industrial End Uses; Springer International Publishing: Cham, Switzerland, 2007; pp. 335–416. [Google Scholar]

- AQPER. Association Quebecoise de la Production D’Energie Renouvelable. Available online: https://www.aqper.com/en/biogas (accessed on 27 July 2019).

- Rohstoffe, V. Biogas Basisdaten Deutschland–Stand: Oktober 2008. 7p. Very Short But Comprehensive Overview of the Biogas Situation in Germany; Biogas Zorg: Munich, Germany, 2019; Available online: http://www.fnr.de/fileadmin/allgemein/pdf/broschueren/Broschuere_Basisdaten_Bioenergie_2018_web.pdf (accessed on 12 August 2019).

- Santos, S. Viabilidad de las explotaciones lecheras es un escenario de desconexión del apoyo y condicionalidade: Un estudio de caso en el noroeste de Portugal. Ph.D. Thesis, Universidade Politecnica de Madrid, Madrid Spain, 2011. [Google Scholar]

- Massé, D.; Lu, D.; Masse, L.; Droste, R. Effect of antibiotics on psychrophilic anaerobic digestion of swine manure slurry in sequencing batch reactors. Bioresour. Technol. 2000, 75, 205–211. [Google Scholar] [CrossRef]

- Kitazono, Y.; Ihara, I.; Toyoda, K.; Umetsu, K. Degradation of veterinary antibiotics during anaerobic digestion of dairy manure. Water Pract. Technol. 2015, 10, 532–537. [Google Scholar] [CrossRef]

- Van Epps, A.; Blaney, L. Antibiotic Residues in Animal Waste: Occurrence and Degradation in Conventional Agricultural Waste Management Practices. Curr. Pollut. Rep. 2016, 2, 135–155. [Google Scholar] [CrossRef]

- Font-Palma, C. Methods for the Treatment of Cattle Manure—A Review. J. Carbon Res. 2019, 5, 27. [Google Scholar] [CrossRef]

- Panichelli, L.; Gnansounou, E. GIS-based approach for defining bioenergy facilities location: A case study in Northern Spain based on marginal delivery costs and resources competition between facilities. Biomass Bioenergy 2008, 32, 289–300. [Google Scholar] [CrossRef]

- Tuzkaya, G.; Önüt, S.; Tuzkaya, U.R.; Gülsün, B. An analytic network process approach for locating undesirable facilities: An example from Istanbul, Turkey. J. Environ. Manag. 2008, 88, 970–983. [Google Scholar] [CrossRef]

- Tavares, G.; Zsigraiová, Z.; Semiao, V. Multi-criteria GIS-based siting of an incineration plant for municipal solid waste. Waste Manag. 2011, 31, 1960–1972. [Google Scholar] [CrossRef]

- Ferretti, V.; Pomarico, S. Integrated sustainability assessments: A spatial multicriteria evaluation for siting a waste incinerator plant in the Province of Torino (Italy). Environ. Dev. Sustain. 2012, 14, 843–867. [Google Scholar] [CrossRef]

- Sultana, A.; Kumar, A. Optimal siting and size of bioenergy facilities using geographic information system. Appl. Energy 2012, 94, 192–201. [Google Scholar] [CrossRef]

- Sanchezlozano, J.M.; Teruel-Solano, J.; Soto-Elvira, P.L.; García-Cascales, M.S. Geographical Information Systems (GIS) and Multi-Criteria Decision Making (MCDM) methods for the evaluation of solar farms locations: Case study in south-eastern Spain. Renew. Sustain. Energy Rev. 2013, 24, 544–556. [Google Scholar] [CrossRef]

- Chau, K.W.; Chan, I.Y.S.; Lu, W.; Webster, C. (Eds.) Proceedings of the 21st International Symposium on Advancement of Construction Management and Real Estate; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

- Franco, C.; Bojesen, M.; Hougaard, J.L.; Nielsen, K. A fuzzy approach to a multiple criteria and Geographical Information System for decision support on suitable locations for biogas plants. Appl. Energy 2015, 140, 304–315. [Google Scholar] [CrossRef]

- Villamar, C.A.; Rivera, D.; Aguayo, M. Anaerobic co-digestion plants for the revaluation of agricultural waste: Sustainable location sites from a GIS analysis. Waste Manag. Res. 2016, 34, 316–326. [Google Scholar] [CrossRef]

- Lindkvist, E.; Johansson, M.T.; Rosenqvist, J. Methodology for Analysing Energy Demand in Biogas Production Plants—A Comparative Study of Two Biogas Plants. Energies 2017, 10, 1822. [Google Scholar] [CrossRef]

- Timonen, K.; Sinkko, T.; Luostarinen, S.; Tampio, E.; Joensuu, K. LCA of anaerobic digestion: Emission allocation for energy and digestate. J. Clean. Prod. 2019, 235, 1567–1579. [Google Scholar] [CrossRef]

- Espinosa, M.P.; Pizarro-Irizar, C. Is renewable energy a cost-effective mitigation resource? An application to the Spanish electricity market. Renew. Sustain. Energy Rev. 2018, 94, 902–914. [Google Scholar] [CrossRef]

- Saaty, T. Método de Análise Hierárquica; McGraw-Hill Makron Books: São Paulo, Brasil, 1991; p. 367. [Google Scholar]

- ESRI. The Language of Spatial Analysis; ESRI: Redlands, CA, USA, 2011; pp. 189–197. [Google Scholar]

- Church, R.; Medrano, A. University of California at Santa Barbara Location-allocation Modeling. Geogr. Inf. Sci. Technol. Body Knowl. 2018, 2018. [Google Scholar] [CrossRef]

- ESRI. Location-Allocation Analysis layer: What Is a Location Allocation? 2019. Available online: https://desktop.arcgis.com/en/arcmap/latest/extensions/network-analyst/location-allocation.htm (accessed on 24 August 2019).

- Lomba, A.; Vicente, J.; Moreira, F.; Honrado, J. Effects of multiple factors on plant diversity of forest fragments in intensive farmland of Northern Portugal. For. Ecol. Manag. 2011, 262, 2219–2228. [Google Scholar] [CrossRef]

- Cerqueira, J. Avaliação de bem-estar animal em bovinos de leite na região Norte de Portugal. Ph.D. Thesis, Instituto de Ciências Biomédicas Abel Salazar da Universidade do Porto, Porto, Portugal, 2012. [Google Scholar]

- Thiriet, P.; Bioteau, T.; Tremier, A. Optimization method to construct micro-anaerobic digesters networks for decentralized biowaste treatment in urban and peri-urban areas. J. Clean. Prod. 2020, 243, 118478. [Google Scholar] [CrossRef]

- Wang, J. Decentralized Biogas Technology of Anaerobic Digestion and Farm Ecosystem: Opportunities and Challenges. Front. Energy Res. 2014, 2. [Google Scholar] [CrossRef]

- Comber, A.; Dickie, J.; Jarvis, C.; Phillips, M.; Tansey, K. Locating bioenergy facilities using a modified GIS-based location–allocation-algorithm: Considering the spatial distribution of resource supply. Appl. Energy 2015, 154, 309–316. [Google Scholar] [CrossRef]

- Rajabifard, A. Spatial Enablement from an International Context—A Vision for the North and West Melbourne Corridor. In Spatial Data Access and Integration to Support Liveability: A Case Study in North and West Melbourne, 1st ed.; Rajabifard, A., Eagleson, S., Eds.; Centre for Spatial Data Infrastructures and Land Administration, University of Melbourne: Victoria, Australia, 2013; pp. 1–10. ISBN 978-0-9922918-0-8. [Google Scholar]

| Criteria | Spatial Analysis | Reclassify | Data Source | Analytic Hierarchy Process (AHP) (value %) | |

|---|---|---|---|---|---|

| SOCIAL | Land Cover/Land Use | Distance (m), Reclassify; Overlay (land use planning) | (Forest 5; semi-natural 4; Agriculture 1; Urban e Water 0) | Portuguese land cover/land use database (COS 2015) | 19.60 |

| Urban areas | Distance (m), Reclassify; (land use planning; social sensibility) | (0–250 m- 0; 250–500 m- 1; 500–750 m- 2; 750–1000 m- 3; 1000–1250 m- 4; >1250 m- 5) | Portuguese land cover/land use database (COS 2015), Municipal Land Use Masterplan (PDM) | 19.30 | |

| Industrial areas distance | Distance (m), Reclassify; (land use planning; social sensibility) | (0–250 m- 5; 250–500 m- 4; 500–750 m- 3; 750–1000 m- 2; >1000 m- 0) | Portuguese land cover/land use database (COS 2015) | 25.90 | |

| Forest areas | Distance (m), Reclassify; (land use planning; social and visual impact) | (0–250 m- 5; 250–500 m- 4; 500–750 m- 3; 750–1000 m- 2; 1000–1250 m- 1; >1250 m- 0) | Portuguese land cover/land use database (COS 2015) | 30.70 | |

| Heritage Classifies | Distance (m), Reclassify; Overlay (land use planning; social and environmental impact) | (0–250 m- 0; 250–500 m- 1; 500–750 m- 2; 750–1000 m- 3; 1000–1250 m- 4; >1250 m- 5) | Portuguese classified heritage (IGESPAR) and Municipal Land Use Masterplan (PDM) | 4.40 | |

| ECONOMIC | Roads and Train Network | Distance (m), Reclassify; Overlay; network analysis (land use planning; economic costs) | (0–50 m- 0; 50–500 m- 5; 500–750 m- 4; 750–1000 m- 3; 1000–1250 m- 2; >1250 m- 1) | National Cartography Series (SCN 25 k; SCN 10 k) | 5.80 |

| Energetic (electric and gas network) | Distance (m), Reclassify; Overlay; network analysis (land use planning; economic costs) | (0–250 m- 5; 250–500 m- 4; 500–750 m- 3; 750–1000 m- 2; 1000–1250 m- 1; >1250 m- 1) | National electric Network (REN, EDP) | 9.00 | |

| Farm Distance | Distance (m), Reclassify; Overlay; network analysis (land use planning; economic and social costs) | (0–250 m- 5; 250–500 m- 4; 500–750 m- 3; 750–1000 m- 2; 1000–1250 m- 1; >1250 m- 1) | [36] | 24.30 | |

| Wastewater Treatment units (ETARS) distance | Distance (m), Reclassify; Overlay; network analysis (land use planning; economic costs) | (0–250 m- 5; 250–500 m- 4; 500–750 m- 3; 750–1000 m- 2; 1000–1250 m- 1; >1250 m- 1) | Águas de Portugal | 26.70 | |

| Bioenergy resource availability density (urban and rural) Total Solid (TS) | Density; network analysis (economic costs) | (0–100 g m−2- 1; 100–200 g m −2- 2; 200–400 g m −2- 3; 400–600 g m− 2- 4; >600 g m−2- 5) | National Cartography Series (SCN 25 k; SCN 10 k) | 34.20 | |

| ENVIRONMENTAL | Digital Terrain Model (Altimetry) | 3D surface analysis (flood, soil water content level) | (0–10 m- 0; 10–40- 5; 40–60- 4; 60–80- 3; 80–100 m- 2; >100 m- 1) | National Cartography Series (SCN 25 k, 10 k) and Shuttle Radar Topography Mission (SRTM) | 8.70 |

| Lithology and Soils | Distance (m), Reclassify; Overlay (Permeability, stability and productivity) | (Fluvissoils- 1; Cambissoils- 4; Regossoils-3; Lepstosoils 5; Antrossoils- 0, Water- 0; Urban- 0) | Soil capacity and Soil suitability database (Carta de Solos e Aptidão da Terra do Entre Douro e Minho) | 14.70 | |

| Hydrography and water areas (superficial and sub terrain) | Distance (m), Reclassify; Overlay (Public hydric domain) | (0–20 m- 0; 20–50 m- 1; 50–100 m- 2; 100–150 m- 3; 150–200 m- 4; >200 m- 5) | National Cartography Series (SCN 10 k); Water Framework Directive (WFD) and River basin Plans (APA, PGRH) | 16.0 | |

| Environmental Protected and Classified Areas | Distance (m), Reclassify; Overlay (land use planning) | (0–20 m- 0; 20–50 m- 1; 50–100 m- 2; 100–150 m- 3; 150–200 m- 4; >200 m- 5) | Portuguese environment national Agency (APA) | 31.50 | |

| National Ecological Reserve | Distance (m), Reclassify; Overlay (land use planning) | (0–20 m- 0; 20–50 m- 1; 50–100 m- 2; 100–150 m- 3; 150–200 m- 4; >200 m- 5) | Municipal Land Use Masterplan (PDM) | 15.70 | |

| National Agricultural Reserve | Distance (m), Reclassify; Overlay (land use planning) | (Interior 0–20 m- 1; 20–50 m- 2; 50–100 m- 3; 100–150 m- 4; 150–200 m- 5; >200 m- 6) | Regional Agriculture Administration (DRAPN), Municipal Land Use Masterplan (PDM) | 10.10 | |

| Geological risks areas | 3d Surface, Reclassify, Distance; Overlay Risk Modelling | Without risk- 5; Low risk- 3; Moderate Risk- 1; High risk- 0 | 3.40 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coura, R.D.; Alonso, J.M.; Rodrigues, A.C.; Ferraz, A.I.; Mouta, N.; Silva, R.; Brito, A.G. Spatially Explicit Model for Anaerobic Co-Digestion Facilities Location and Pre-Dimensioning Considering Spatial Distribution of Resource Supply and Biogas Yield in Northwest Portugal. Appl. Sci. 2021, 11, 1841. https://doi.org/10.3390/app11041841

Coura RD, Alonso JM, Rodrigues AC, Ferraz AI, Mouta N, Silva R, Brito AG. Spatially Explicit Model for Anaerobic Co-Digestion Facilities Location and Pre-Dimensioning Considering Spatial Distribution of Resource Supply and Biogas Yield in Northwest Portugal. Applied Sciences. 2021; 11(4):1841. https://doi.org/10.3390/app11041841

Chicago/Turabian StyleCoura, Renata D’arc, Joaquim Mamede Alonso, Ana Cristina Rodrigues, Ana Isabel Ferraz, Nuno Mouta, Renato Silva, and A. G. Brito. 2021. "Spatially Explicit Model for Anaerobic Co-Digestion Facilities Location and Pre-Dimensioning Considering Spatial Distribution of Resource Supply and Biogas Yield in Northwest Portugal" Applied Sciences 11, no. 4: 1841. https://doi.org/10.3390/app11041841

APA StyleCoura, R. D., Alonso, J. M., Rodrigues, A. C., Ferraz, A. I., Mouta, N., Silva, R., & Brito, A. G. (2021). Spatially Explicit Model for Anaerobic Co-Digestion Facilities Location and Pre-Dimensioning Considering Spatial Distribution of Resource Supply and Biogas Yield in Northwest Portugal. Applied Sciences, 11(4), 1841. https://doi.org/10.3390/app11041841