Advances in Multi-Process Hybrid Production Cells for Rapid Individualised Laser-Based Production

Abstract

1. Introduction

- (i)

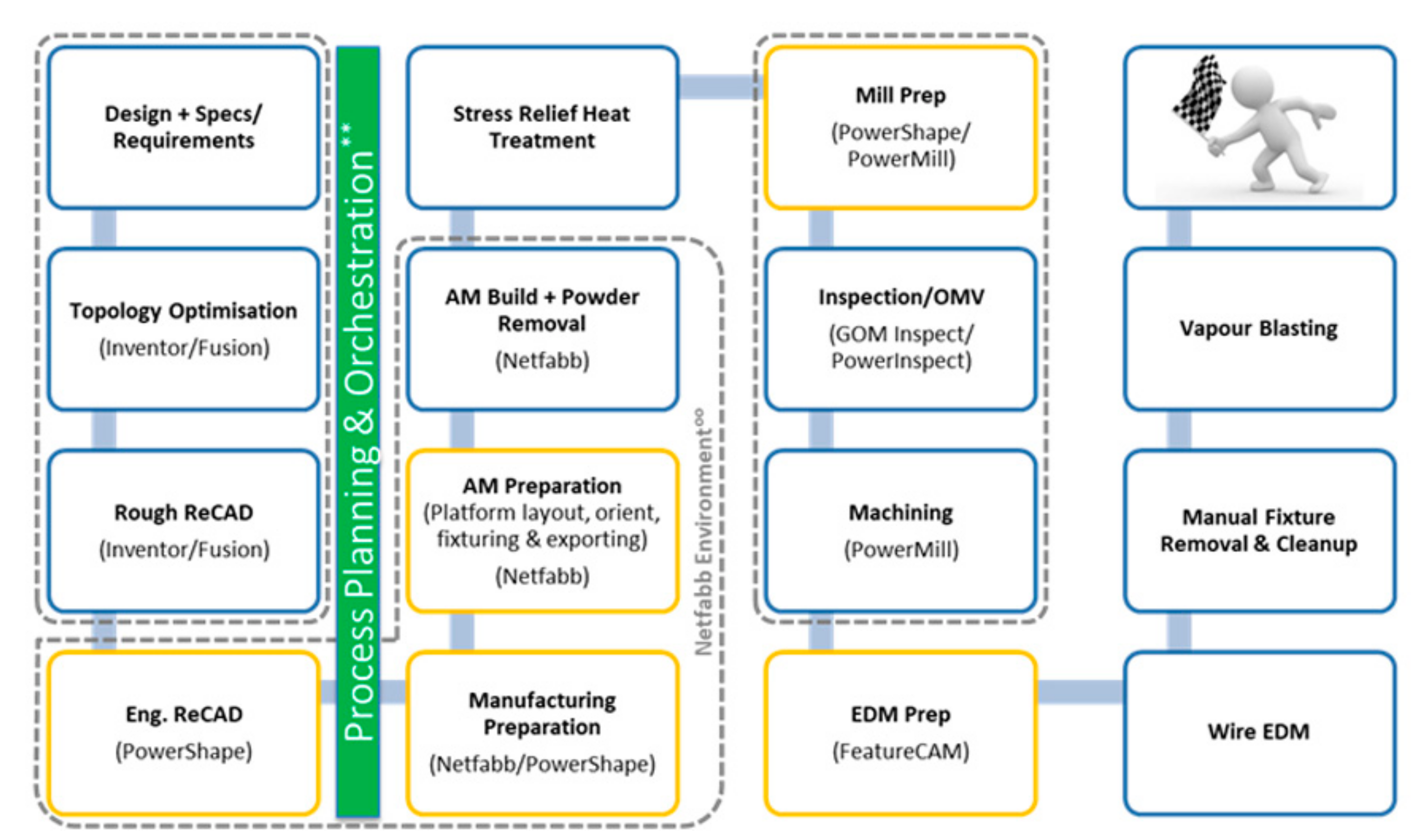

- Development of software and toolboxes to generate modelling and manufacturing data for hybrid AM workflow

- (ii)

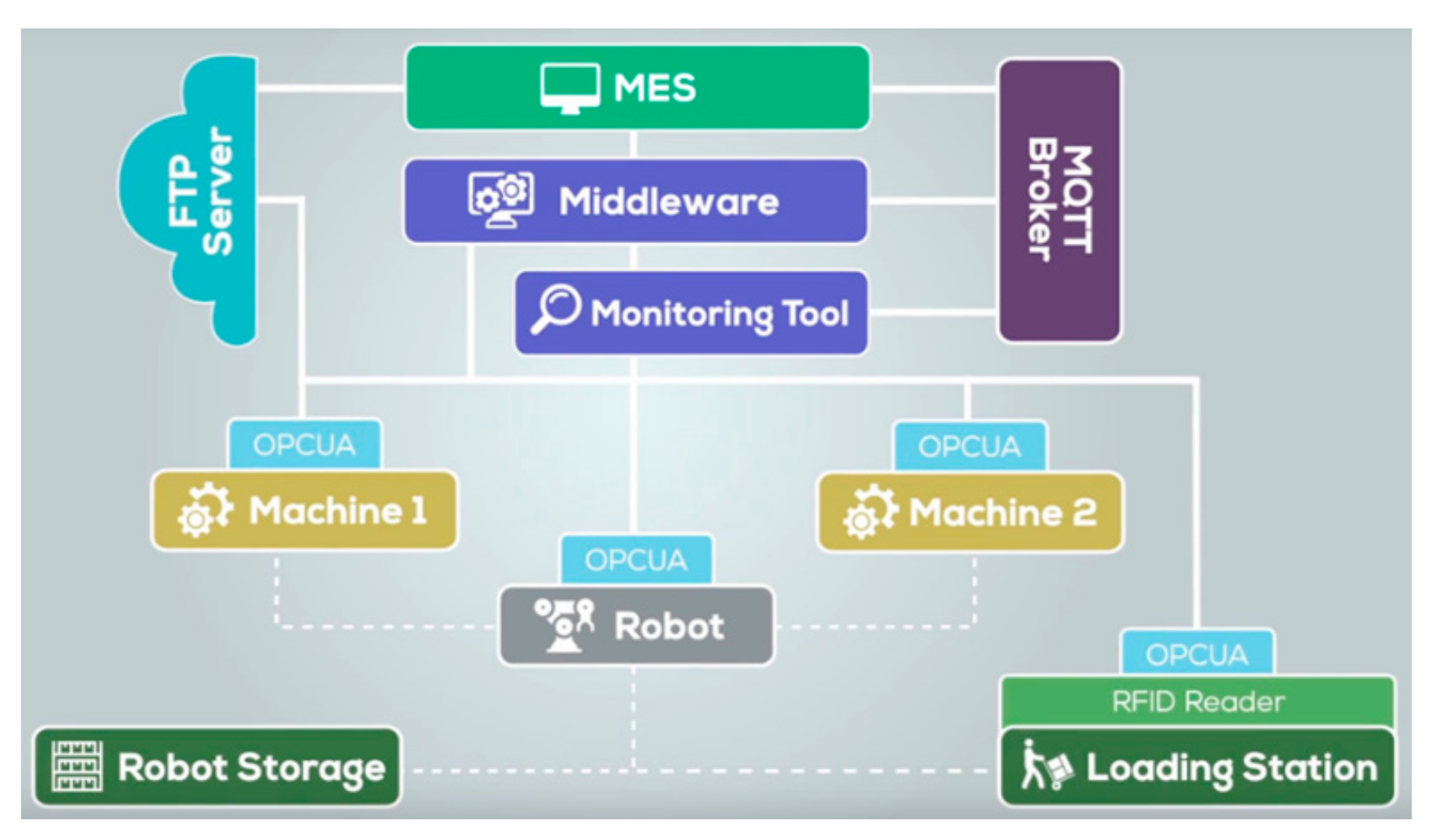

- Development of a modular architecture with unified adapters (OPC-UA) for the machines

- (iii)

- Development of middleware components for modularity and interrelation between machines and robots

- (iv)

- Provision of suitable robotic arms and design of robust pallets and fixturing systems capable of storing and handling large and heavy parts in an inert chamber

- (v)

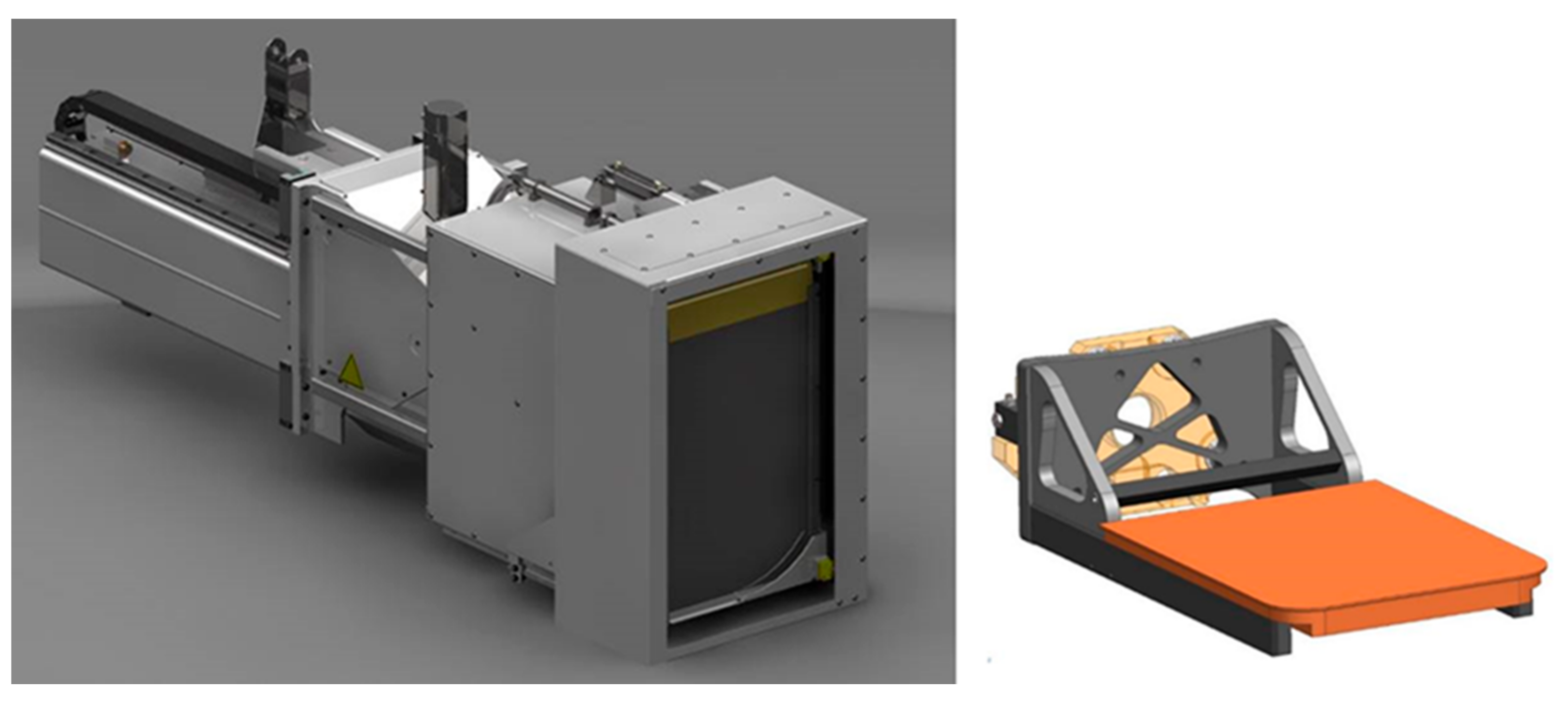

- Addition of external controls to the ADIRA AC AddCreator (https://adira.pt/en/product/additive-manufacturing-2/ (accessed on 16 January 2021)) machine to make it operational as a connected module of an integrated production process, notably the addition of the automatic robot access door, new sealing elements and an automatic vacuum powder removal system for the powder remaining in the chamber after manufacturing the part

- (vi)

- Integration of the remaining powder extraction process (inside the part), incorporating an automatic SOLUKON machine (https://www.solukon.de/en/metall/sfm-at800/ (accessed on 16 January 2021)) for powder extraction in the cell

- (vii)

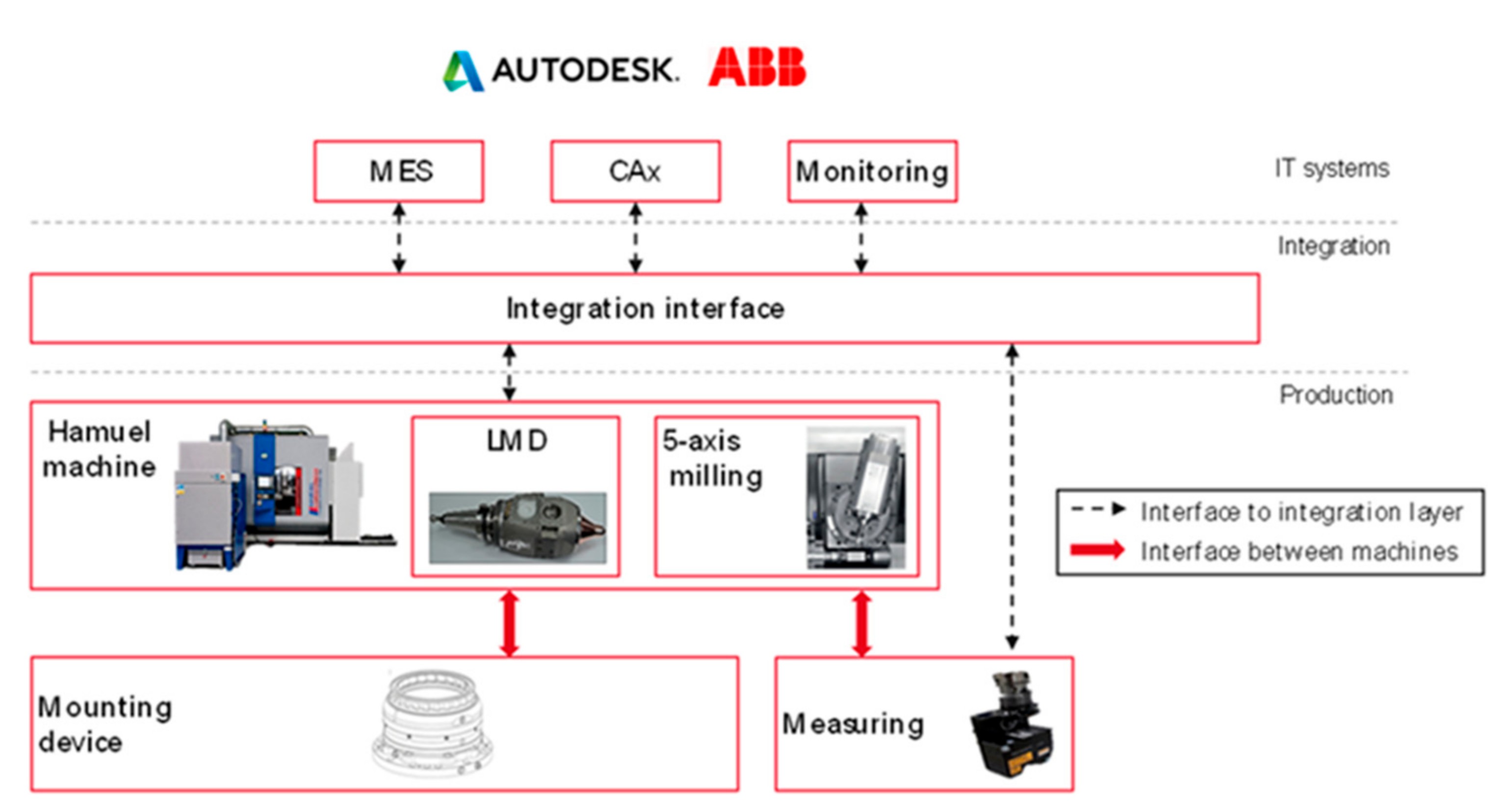

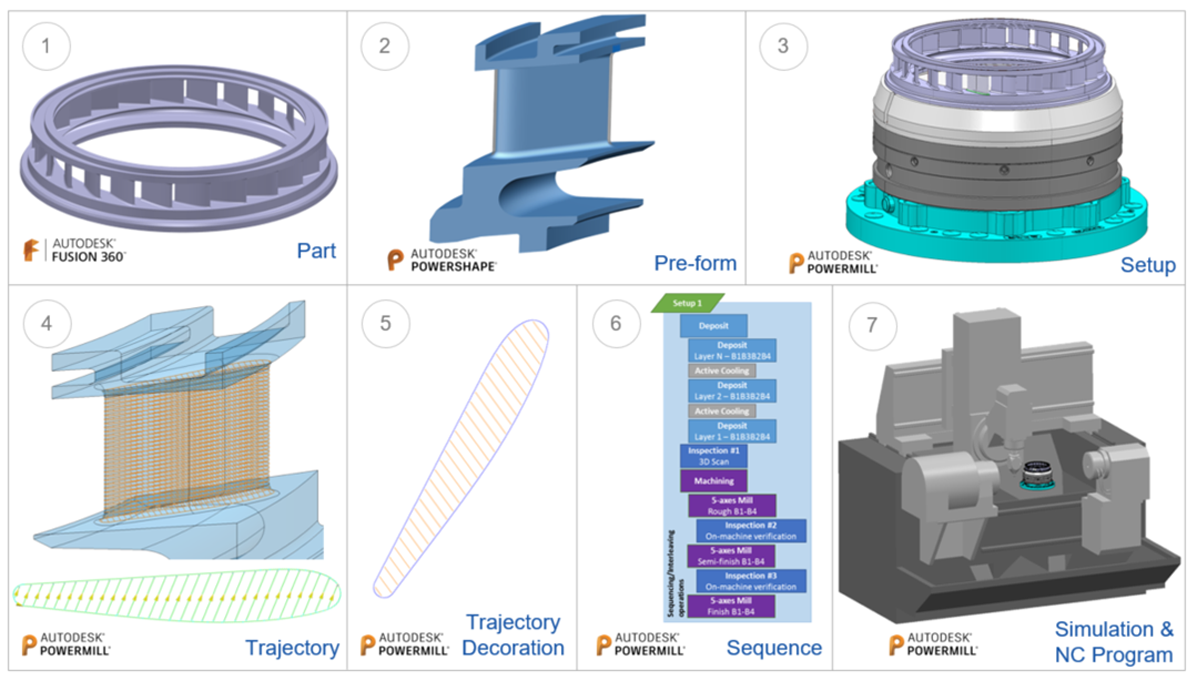

- Adaptation of the HAMUEL LMD hybrid (https://hamuel.de/en/products/5-axis-machining-center-hstm (accessed on 16 January 2021))machine for use under the HyProCell approach, achieving superior on-line measurement and control capabilities for the manufacturing of nozzle rings (with blades) and turbine Blisks for the turbomachinery sector

- (viii)

- Development of an integrated manufacturing execution system (MES) that acts as an information dispatcher between the integration layer and other system components

- (ix)

- And finally, the development of a method called splitting, clustering, graph-making (SCG) for data analysis and mining using time series processing of data acquired from SLM machines

2. HyProCell Implementation

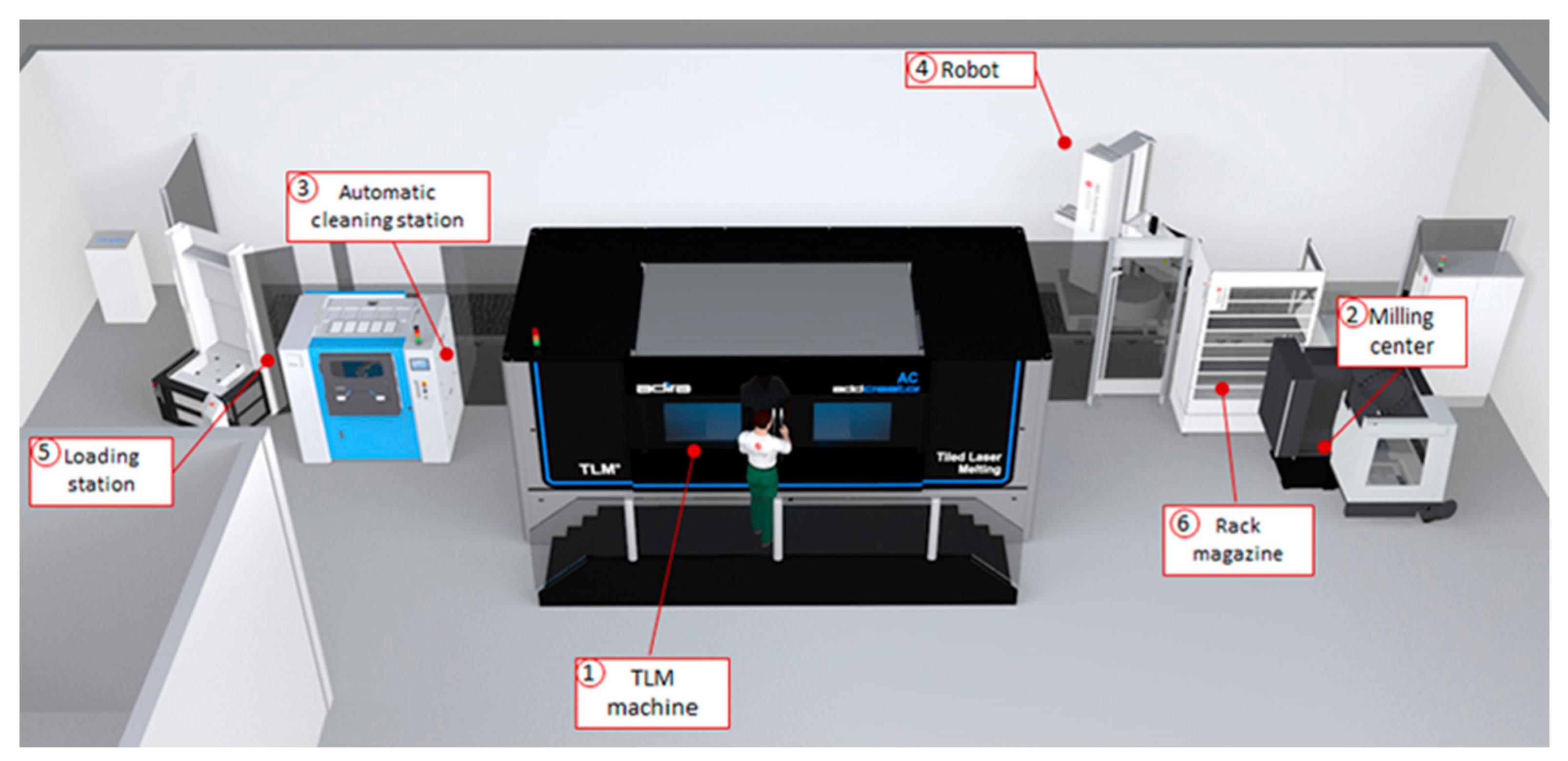

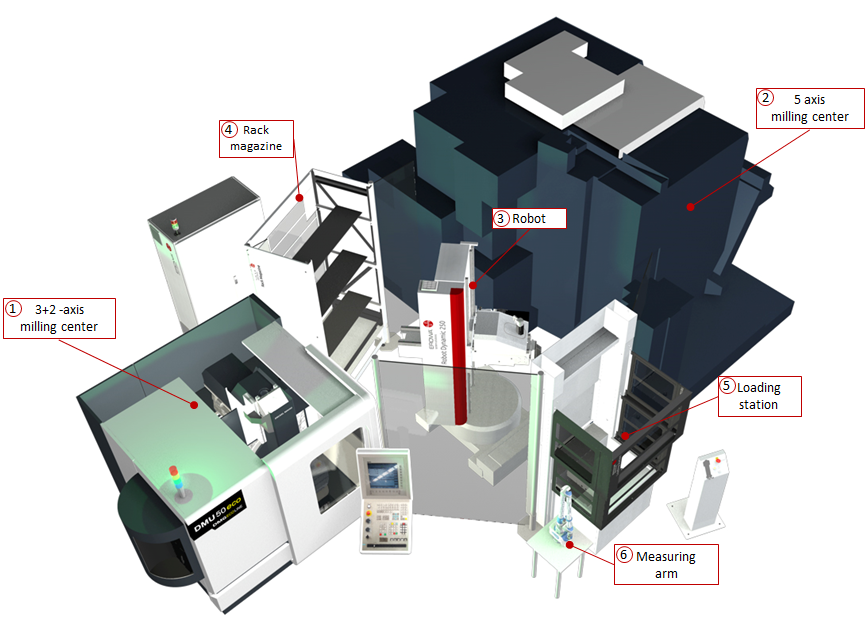

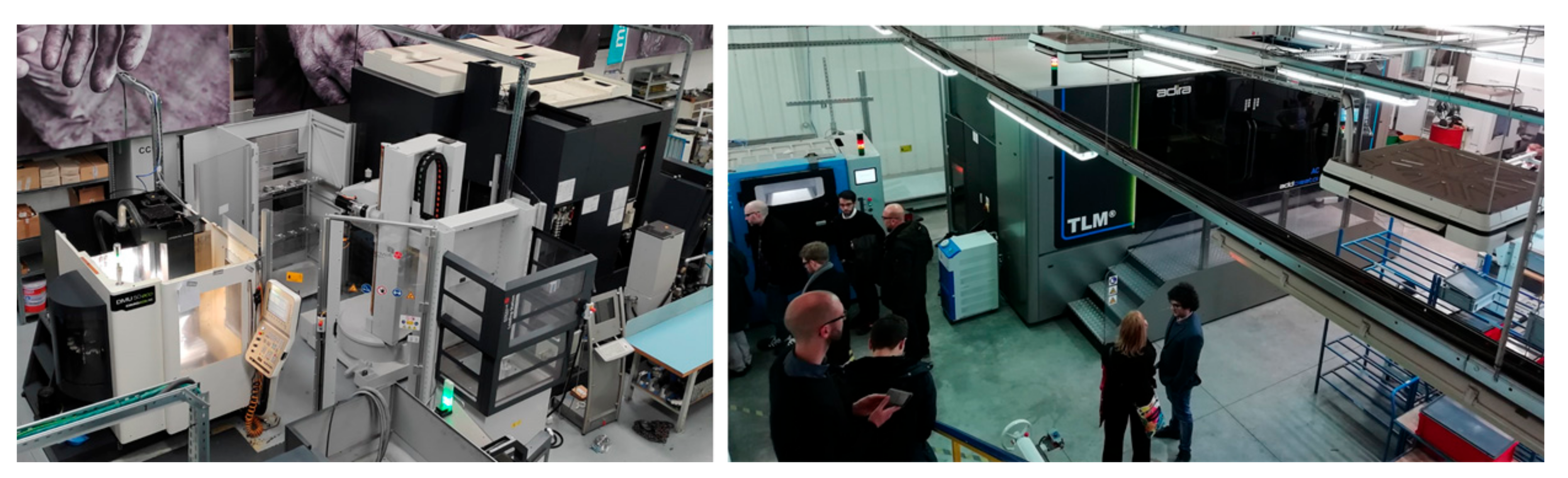

2.1. Pilot Facilities Setup

- ➢

- The use of the ADIRA TLM machine itself, which contains a primary powder removal device utilizing an automated vacuum cleaner attached to the processing head.

- ➢

- The use of an automated powder removal machine (SOLUKON) to perform thorough powder removal from the part, with a CNC programme specifically designed for each part.

- ➢

- The use of a dust box designed by EROWA for its robot, which interfaces with the ADIRA and SOLUKON machines to ensure no powder is spilled during transportation to promote safety and security of personnel and goods.

- ➢

- The use of the MES to ensure that every necessary step is followed.

- ➢

- The 400 × 500 mm2 maximum size was set by the capacity of the smallest chamber: the CNC milling machine. The need to machine distorted build plates after AM led the team to design a system with substrate plates screwed on top of the pallet, which, in turn, provides the interface with a positioning system and the robot gripper.

- ➢

- The dimensions of the ADIRA machine, combined with the weight of a 400 × 500 mm2 quench and tempered steel plate with a part built on it, compelled EROWA to design a special telescopic axis to handle a 300 kg payload and a dedicated clamping system with extremely high precision (2 μm) when deployed and clamped.

- ➢

- An adaptable sealing element was designed to adapt such a plate to the ADIRA machine, initially planned for a 1000 × 1000 mm2 plate. The main goal behind this development was to limit the amount of powder that could contaminate the system: less powder to spread, less powder emitted during processing, less powder to clean.

- ➢

- The pallet was designed to adapt to different type of plates so that the cell could be used to process different plates coming from various machines.

- ➢

- Workflow on the MES combined with design templates for CAM tools permits the production of several parts on a single pallet.

- ➢

- The number of plates and the size of the magazine were scaled to allow different operations to happen simultaneously: building a part in the SLM machine, removing powder from a second newly built part, machining a plate from an external SLM machine, etc.

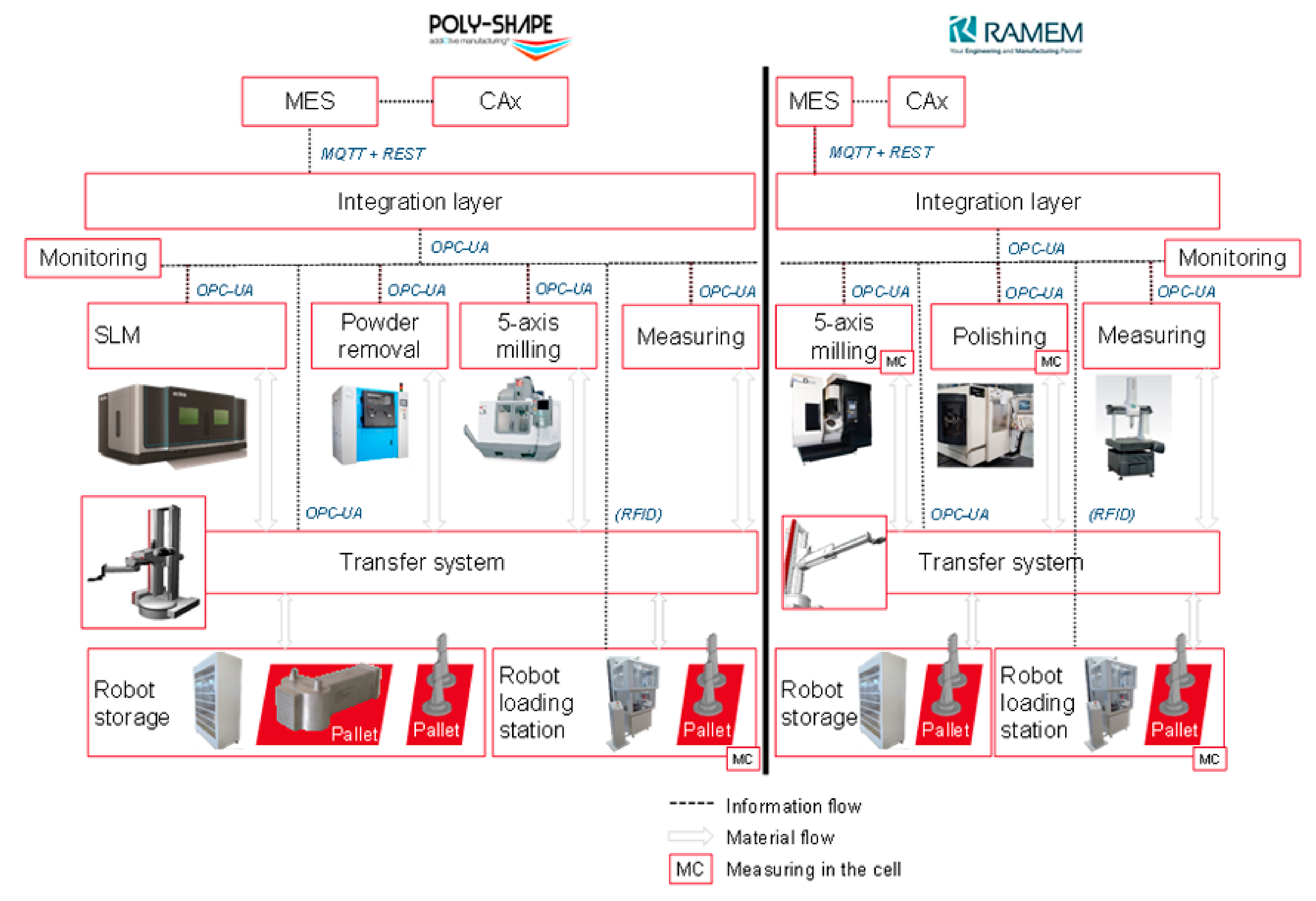

2.2. Modular Architecture, Automation, and Pallet Handling System

- (i)

- High interoperability between various manufacturing modules/processes/technologies

- (ii)

- Quick and easy reconfiguration of the production cell

- (iii)

- Scalable production infrastructure that is adaptable to other situations and demands. This modular architecture using OPC-UA adapters is required to connect the machines and the integration layer with CAx, MES and monitoring system.

- (i)

- A long travel arm to access the inside of the ADIRA machine combined with a high potential transfer weight of over 300 kg, which required a new high-accuracy (2 μm) robot arm design;

- (ii)

- A new fork gripper and special pallet design to deal with the impact of the powder on the robot gripper system;

- (iii)

- Sealing the pallet to the machine table inside the ADIRA machine, which was solved with a special chuck base plate and fitted sealing;

- (iv)

- The transfer of the pallet from the ADIRA machine to the SOLUKON powder removal system without leaving an unacceptable amount of powder in the environment. To prevent this, a special box on the robot with the sealing concept was chosen and designed to keep falling powder inside a controlled area;

- (v)

- Finally, the modular communication interface was extended with an appropriate concept to maintain modularity and keep the system safe.

3. Key Results

3.1. ICT Framework and Toolbox

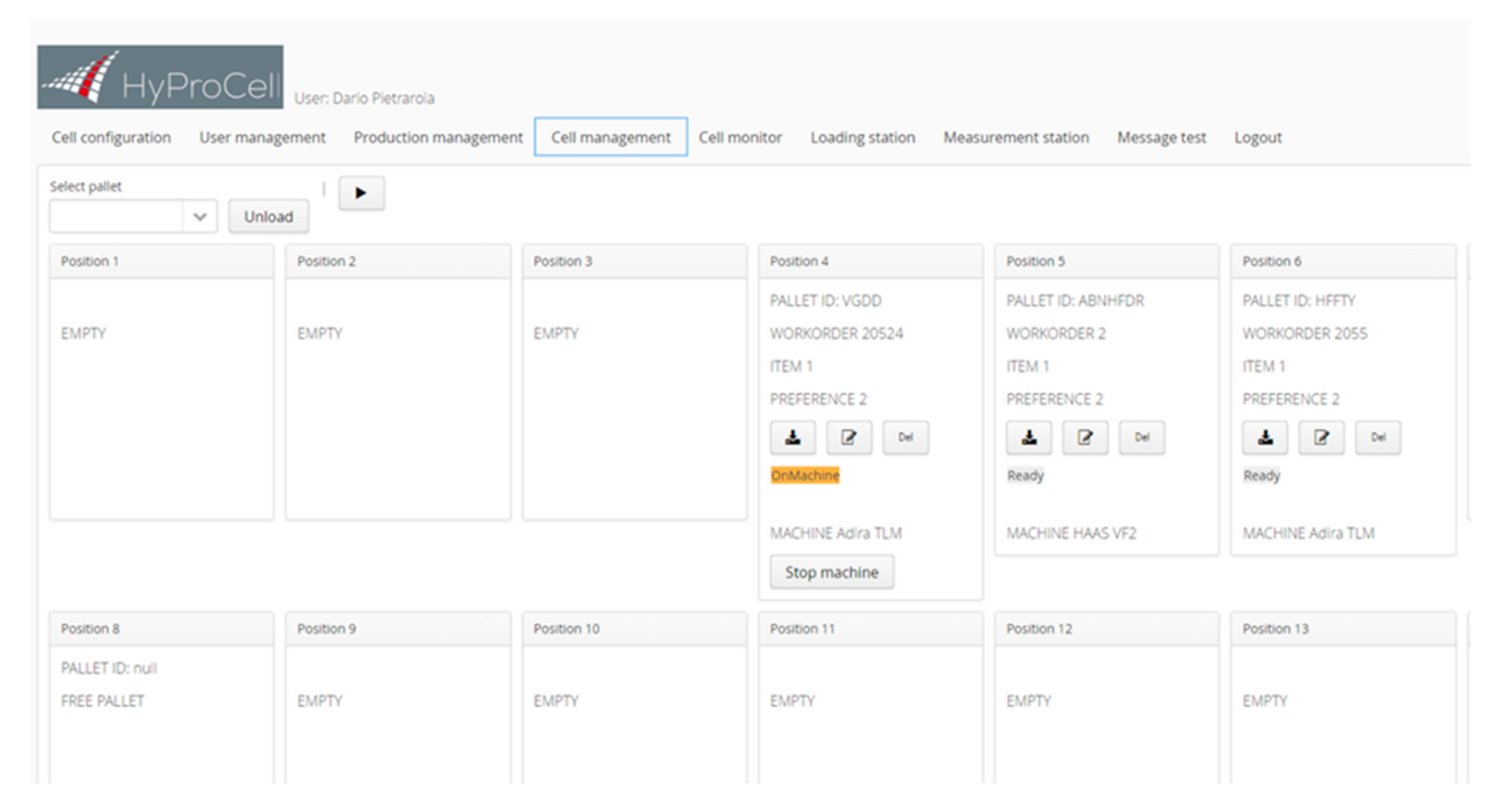

3.2. MES and Data Management

- (i)

- Controls machines from different vendors adapted to the HyProCell architecture using unified standard commands. Different machines can be added to the cell if a suitable OPC-UA adapter can be developed.

- (ii)

- Provides a browser-based human-machine interface (HMI) for the operator of the production cells. The operator can load and unload pallets into the cell, associate work orders to pallets, and start and stop machines manually when the MES is not in automatic mode. The operator can also download drawings in PDF format for tooling reference.

- (iii)

- Unifies the HMI with manual stations outside the cells to track production all along the production cycle. Operators of external workstations can connect to the MES using a web browser and update the status of manual operations.

- (iv)

- Allows the upload of measurement results and associates them to the corresponding job for later retrieval.

- (v)

- Collects information about the state of machines as well as the start and end time of each job on each machine.

- (vi)

- Tracks pallet loading and unloading using the RFID reader integrated in the loading station. This also allows pallet tracking outside the cell using a USB RFID reader.

- (vii)

- Provides a remote interface for production engineers to define a work sequence for products, associating the required part programs to the work order.

- (viii)

- Provides a remote interface for the production manager to create work orders and send them to the production schedule. Once a production manager sends an order to production, it will appear in the HMI of the cell for the operator, who will be able to load it into the cell.

- (ix)

- Automatically downloads the part programs from a central repository and uploads them on the machines when in automatic mode.

- (x)

- Automatically unloads the machines when a job is finished and loads the next pallet according to a schedule algorithm.

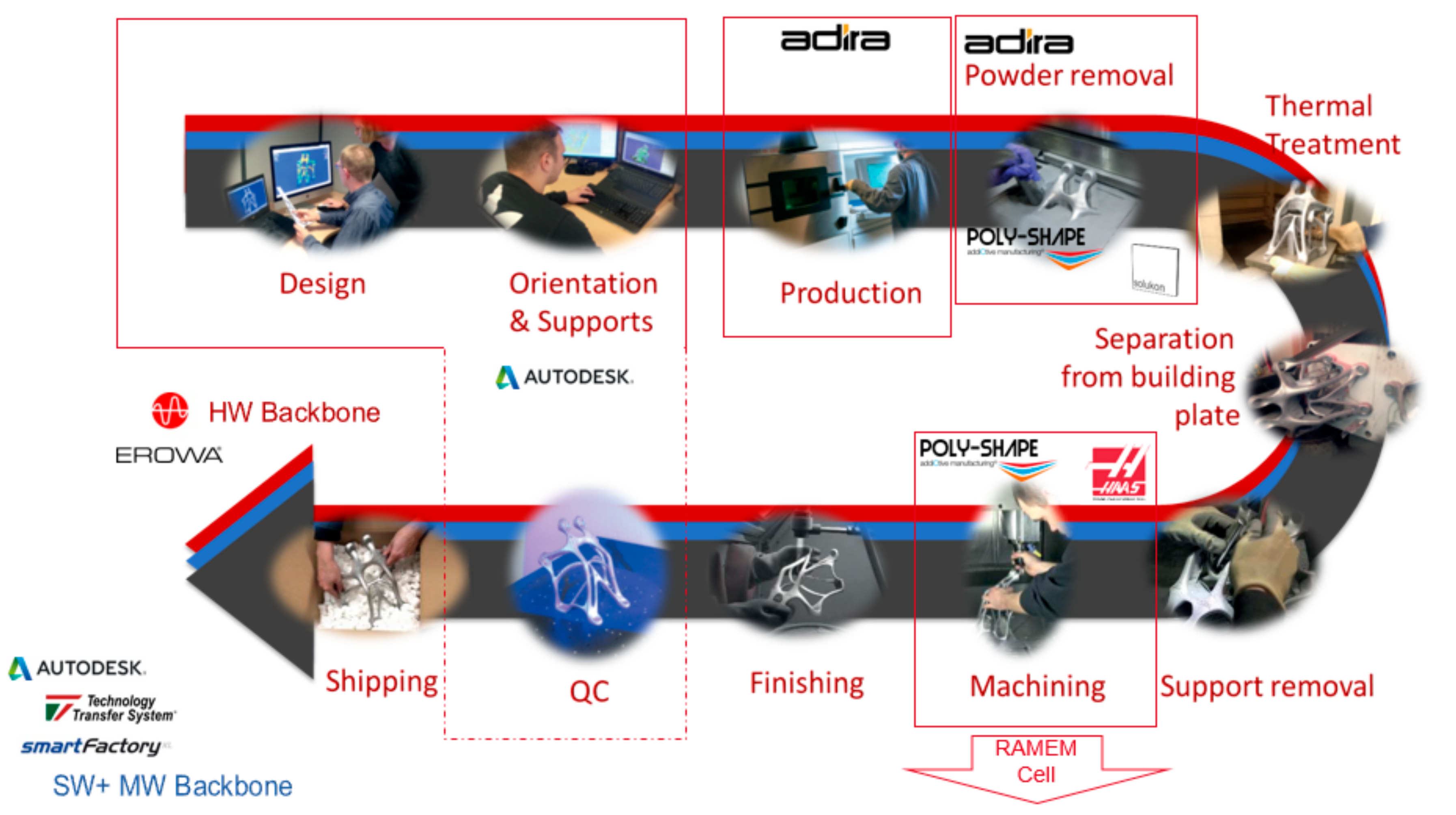

3.3. Hybrid AM Workflow and Pilot Facilities Implementation

- Heat treatment

- Separation from building plate

- Support removal

- Additional surface finishing (with an automated dry electropolishing system if required)

4. Discussion

5. Conclusions

- (i)

- Modularity and reconfigurable hybrid AM production cell is a reality; however, such solutions are useful for certain business cases, not as a general solution for all cases.

- (ii)

- The main limitation for hybrid AM industrial production of large and heavy parts is the additive manufacturing process and the intervention of operators. With the ADIRA machine and its modifications to operate in HyProCell, the build size restrictions and operability are significantly tackled. The solutions developed for transfer and handling of these parts were shown to be robust, efficient, and accurate. In addition, the MES developed in HyProCell opens new possibilities for automating the zeroing of AM machines and getting a stock of available build plates. The missing bricks to be included in future versions of the MES are: ability to manage substrates instead of pallets; automated probing cycles to establish thickness and flatness of substrate; in-line data analysis of build plate geometry; and adequate positioning of parts on substrates in accordance with production planning and risks of distortion.

- (iii)

- The major challenge of integrating AM and subtractive machining in the current hybrid workflow is the need for a “hybrid process-planning” protocol for post-processing of AM parts that accounts for the varying processing nature of AM (material shrinkage, layer thickness, orientation, anisotropy, etc.), machining (tool design, machining allowance, etc.), and part-specific attributes (critical features and tolerance requirements).

- (i)

- Integration of real machines in a hybrid AM cell is an effort which should receive further development attention, especially when such cells use legacy machines. The standardisation of OPC-UA and the use of the standard is still uncommon in both additive and subtractive machine tools. Since the implementation of all or some elements of the OPC-UA standard is left to the discretion of the manufacturers of PLCs, best practices, tutorials, and open “code snippets” are needed to boost their use. A platform for different PLCs from different manufacturers, where this “integration-knowledge” is stored, will facilitate the development of OPC-UA interfaces so that PLC programmers might gain more control, freedom, and speed in development. To make it easier for them, the tools to create this OPC-UA models must also be easy to operate and understand.

- (ii)

- A fast feedback loop between different system designers (monitoring tool, machine manufacturer, control device programmers, information model, MES, etc.) is crucial for a good product. Starting with an appropriate project platform can help a lot for the future.

- (iii)

- It is advantageous to use a constant/fixed part coordinate system, such as the pallet system, to seamlessly switch between additive, subtractive, and other operations. It is necessary to guarantee part accuracy and repeatability. Methods to define/create a part coordinate system in the hybrid AM workflow need to be considered from the beginning of the cell conception. Distortions during the AM process can cause differences of positioning compared to theoretical expectations, and this needs to be corrected by testing measurements in the machining machine.

- (iv)

- Reaching the best level of automation and integration in the SLM pilot cell would result in a significant reduction in downtime. This was demonstrated for each defined batch production scenario.

- (i)

- The function of a combined machine for additive and subtractive machining is a highly focused one with a clear need. It must be clear that the required process relies on the functions available within such a machine type. Such functional combination is required for repair. Repair has a strong focus on adaptive machining as well, which makes measurement capabilities in the machine essential. The currently available measurement solutions in machine tools such as touch probes and laser line scanning sensors are accurate but slow; therefore, compromises between timeliness and accuracy must be made.

- (ii)

- The machine operator on the shop floor must be properly supported. Machine operators are usually focused on a single process. The combination of additive, adaptive, and subtractive machining with all their relations is very difficult for an operator to handle. The process needs—and this is essential—complete adaptation of the additive and subtractive tool paths for each individual part. Automated communication and exchange of data between the machine and connected CAM system ensures a fast and reliable process.

- (iii)

- In hybrid LMD workflows, the downtime associated with constant tool changes caused by switching between deposition and machining is a non-value adding step. It is preferable to carry out as much material deposition as possible before moving on to the machining phases. Software tools are needed in the future to optimise this sequencing.

- (iv)

- Creating net shape of LMD structures is currently not possible with today’s technology. Near net shape of LMD structures is possible, as demonstrated with the nozzle ring and turbine blades demonstrators. Hybrid manufacturing allows shapes to be simultaneously produced and finished, which would otherwise be difficult to access with a milling tool, as was the case with turbine blades.

- (v)

- Multi-layer LMD process (not just cladding for coating, but build-up of a 3D structure) is possible and has been demonstrated. Production of slight overhangs with LMD is possible, and if deposition speeds and powder capture efficiency can be increased and made repeatable, more positive business cases can be reached.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schmidt, M.; Merklein, M.; Bourell, D.; Dimitrov, D.; Hausotte, T.; Wegener, K.; Overmeyer, L.; Vollertsen, F.; Levy, G.N. Laser based additive manufacturing in industry and academia. CIRP Ann. 2017, 66, 561–583. [Google Scholar] [CrossRef]

- Gisario, A.; Kazarian, M.; Martina, F.; Mehrpouya, M. Metal additive manufacturing in the commercial aviation industry: A review. J. Manuf. Syst. 2019, 53, 124–149. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Foteinopoulos, P.; Papacharalampopoulos, A.; Bikas, H. Addressing the challenges for the industrial application of additive manufacturing: Towards a hybrid solution. Int. J. Light. Mater. Manuf. 2018, 1, 157–168. [Google Scholar] [CrossRef]

- Campbell, I.; Diegel, O.; Kowen, J.; Wohlers, T. Wohlers Report 2018: 3D Printing and Additive Manufacturing State of the Industry: Annual Worldwide Progress Report; Wohlers Associates: Fort Collins, CO, USA, 2018. [Google Scholar]

- Chong, L.; Ramakrishna, S.; Singh, S. A review of digital manufacturing-based hybrid additive manufacturing processes. Int. J. Adv. Manuf. Technol. 2018, 95, 2281–2300. [Google Scholar] [CrossRef]

- Dröder, K.; Heyn, J.K.; Gerbers, R.; Wonnenberg, B.; Dietrich, F. Partial Additive Manufacturing: Experiments and Prospects with Regard to Large Series Production. Procedia CIRP 2016, 55, 122–127. [Google Scholar] [CrossRef][Green Version]

- Reichler, A.-K.; Gabriel, F.; Timmann, F.; Steil, J.; Dröder, K. An architecture for AutomationML-based constraint modelling and orchestration of Incremental Manufacturing. Procedia CIRP 2019, 86, 173–178. [Google Scholar] [CrossRef]

- Torres-Carrillo, S.; Siller, H.R.; Vila, C.; López, C.; Rodríguez, C.A. Environmental analysis of selective laser melting in the manufacturing of aeronautical turbine blades. J. Clean. Prod. 2020, 246, 119068. [Google Scholar] [CrossRef]

- Ramakrishnan, A.; Dinda, G.P. Direct laser metal deposition of Inconel 738. Mater. Sci. Eng. A 2019, 740–741, 1–13. [Google Scholar] [CrossRef]

- Zakoldaev, D.A.; Shukalov, A.V.; Zharinov, I.O.; Novikov, A.S. Modular architecture of cyber-physical production for Industry 4.0. J. Phys. Conf. Ser. 2019, 1399, 44010. [Google Scholar] [CrossRef]

- Pahlevannejad, P.; Herget, A.; Moreno, R.; Hennecke, A.; Ruskowski, M. Implementation and Testing of a Modular System Architecture for Generic Hybrid Production Cells in an Industrial Environment. In Proceedings of the IECON 2019 45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; Volume 1, pp. 4229–4234. [Google Scholar]

- SmartFactory-KL HyProCell Software System Architecture. Available online: https://youtu.be/a1RXyIEj_IE (accessed on 23 June 2020).

- Autodesk Netfabb 3D Printing Software. Available online: https://www.autodesk.com/products/netfabb/features (accessed on 24 June 2020).

- Autodesk PowerShape CAD Software. Available online: https://www.autodesk.es/products/powershape/ (accessed on 24 June 2020).

- Autodesk PowerMill Additive Plugin. Available online: https://knowledge.autodesk.com/support/powermill/getting-started/caas/CloudHelp/cloudhelp/2019/ENU/PWRM-Additive/files/GUID-5B32F5CB-8DDC-475C-9450-07285615BF9E-htm.html (accessed on 24 June 2020).

- Jacob, A.; Steimer, S.; Stricker, N.; Häfner, B.; Lanza, G. Integrating product function design, production technology optimization and process equipment planning on the example of hybrid additive manufacturing. Procedia CIRP 2019, 86, 222–227. [Google Scholar] [CrossRef]

- Landolfi, G.; Barni, A.; Menato, S.; Cavadini, F.A.; Rovere, D.; Dal Maso, G. Design of a multi-sided platform supporting CPS deployment in the automation market. In Proceedings of the 2018 IEEE Industrial Cyber-Physical Systems (ICPS), St. Petersburg, Russia, 15–18 May 2018; pp. 684–689. [Google Scholar]

- Hennecke, A.; Ruskowski, M. Design of a flexible robot cell demonstrator based on CPPS concepts and technologies. In Proceedings of the 2018 IEEE Industrial Cyber-Physical Systems (ICPS), St. Petersburg, Russia, 15–18 May 2018; pp. 534–539. [Google Scholar]

- Aghabozorgi, S.; Seyed Shirkhorshidi, A.; Ying Wah, T. Time-series clustering—A decade review. Inf. Syst. 2015, 53, 16–38. [Google Scholar] [CrossRef]

- Gokalp, M.O.; Kayabay, K.; Akyol, M.A.; Eren, P.E.; Koҫyiğit, A. Big Data for Industry 4.0: A Conceptual Framework. In Proceedings of the 2016 International Conference on Computational Science and Computational Intelligence (CSCI), Las Vegas, NV, USA, 15–17 December 2016; pp. 431–434. [Google Scholar]

- Murtagh, F.; Legendre, P. Ward’s Hierarchical Agglomerative Clustering Method: Which Algorithms Implement Ward’s Criterion? J. Classif. 2014, 31, 274–295. [Google Scholar] [CrossRef]

- Moreno, R.; Pereira, J.C.; López, A.; Mohammed, A.; Pahlevannejad, P. Time Series Display for Knowledge Discovery on Selective Laser Melting Machines. In Intelligent Data Engineering and Automated Learning—IDEAL 2019; Yin, H., Camacho, D., Tino, P., Tallón-Ballesteros, A.J., Menezes, R., Allmendinger, R., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 280–290. [Google Scholar]

- Mehrpouya, M.; Dehghanghadikolaei, A.; Fotovvati, B.; Vosooghnia, A.; Emamian, S.S.; Gisario, A. The potential of additive manufacturing in the smart factory industrial 4.0: A review. Appl. Sci. 2019, 9, 3865. [Google Scholar] [CrossRef]

- Häfele, T.; Schneberger, J.-H.; Kaspar, J.; Vielhaber, M.; Griebsch, J. Hybrid Additive Manufacturing—Process Chain Correlations and Impacts. Procedia CIRP 2019, 84, 328–334. [Google Scholar] [CrossRef]

- Behandish, M.; Nelaturi, S.; de Kleer, J. Automated process planning for hybrid manufacturing. Comput. Des. 2018, 102, 115–127. [Google Scholar] [CrossRef]

- Fotovvati, B.; Dehghanghadikolaei, A.; Namdari, N. Laser-Assisted coating techniques and surface modifications: A short review. Part. Sci. Technol. 2020, 1–10. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Dhekne, P.P.; Dadbakhsh, S.; Kruth, J.-P.; Van Humbeeck, J.; Vanmeensel, K. Surface Modified Copper Alloy Powder for Reliable Laser-based Additive Manufacturing. Addit. Manuf. 2020, 35, 101418. [Google Scholar] [CrossRef]

- European Technology Platform Photonics21. Annual Review: Photonics21 Strategy Implementation 2016. 2017. Available online: https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5b1efae61&appId=PPGMS (accessed on 5 January 2021).

| HyProCell Objectives | KPI | Measured (Value or Feature) | Comments |

|---|---|---|---|

| 1. More flexible and reconfigurable LBAM focused production cells | Capacity of the cells to be reconfigurable | Yes, modular architecture developed, validated, and demonstrated | Guaranteed flexibility for quick cell reconfiguration |

| 2. Reduce the time required to develop manufacturing procedures for new products | Time to develop new products | With CAx toolboxes deployed and with LBAM machines modified and tested for both LMD and SLM use cases, a reduction of time-to-develop new product from weeks to days was observed | Different toolboxes developed to drive the manufacturing processes (hybrid AM workflow) in the entire value chain with the HyProCell approach |

| 3. Decrease downtime by 50% when SLM is the process involved in part production | Downtime for production of Hybrid SLM parts | Downtime in HyProCell Hybrid SLM cell: ↓ 110 min (35%) | Best results achieved in one of the use cases. Comparisons against conventional AM route |

| 4. Increase the incomes coming from functional parts provided to industry from the current 10% to >50% | Production productivity | Full use of AM machines and robots would lead to a productivity increase in Hybrid SLM. However, more rigorous analysis covering the entire value chain with HyProCell workflow is required to evaluate incomes from functional parts | 8-10 SLM machines are required to take full advantage of the HyProCell approach in the near future |

| 5. Extend the type of components manufactured by LBAM based on the new automated hybrid production workflow | Capacity to manufacture different part geometries and sizes for different sectors | Yes, the capacity to produce six (6) different parts from three (3) sectors was demonstrated: four (4) in Hybrid SLM and two (2) in Hybrid LMD pilot cell | New automated Hybrid AM production workflow developed in HyProCell can be extrapolated to a wide range of components manufactured by LBAM |

| 6. Improve data management, allowing a better monitoring of process data and cell performance | Improved production cell performance after optimisation through data mining | Solutions based on algorithms for data analytics were developed, but more data mining during TLM machine life/operation is needed to foresee improvements in production time and part quality | Basis for knowledge discovery module were established and tested [22] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira, J.C.; Moreno, R.; Tenbrock, C.; Herget, A.; Wittich, T.; Hamilton, K. Advances in Multi-Process Hybrid Production Cells for Rapid Individualised Laser-Based Production. Appl. Sci. 2021, 11, 1812. https://doi.org/10.3390/app11041812

Pereira JC, Moreno R, Tenbrock C, Herget A, Wittich T, Hamilton K. Advances in Multi-Process Hybrid Production Cells for Rapid Individualised Laser-Based Production. Applied Sciences. 2021; 11(4):1812. https://doi.org/10.3390/app11041812

Chicago/Turabian StylePereira, Juan Carlos, Ramón Moreno, Christian Tenbrock, Arnold Herget, Thomas Wittich, and Kelvin Hamilton. 2021. "Advances in Multi-Process Hybrid Production Cells for Rapid Individualised Laser-Based Production" Applied Sciences 11, no. 4: 1812. https://doi.org/10.3390/app11041812

APA StylePereira, J. C., Moreno, R., Tenbrock, C., Herget, A., Wittich, T., & Hamilton, K. (2021). Advances in Multi-Process Hybrid Production Cells for Rapid Individualised Laser-Based Production. Applied Sciences, 11(4), 1812. https://doi.org/10.3390/app11041812