Combined Effects of Optimized Heat Treatment and Nickel Coating for the Improvement of Interfacial Bonding in Aluminum–Iron Alloys Hybrid Structures

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Effects of the Nickel Coating on the Interfacial Microstructures

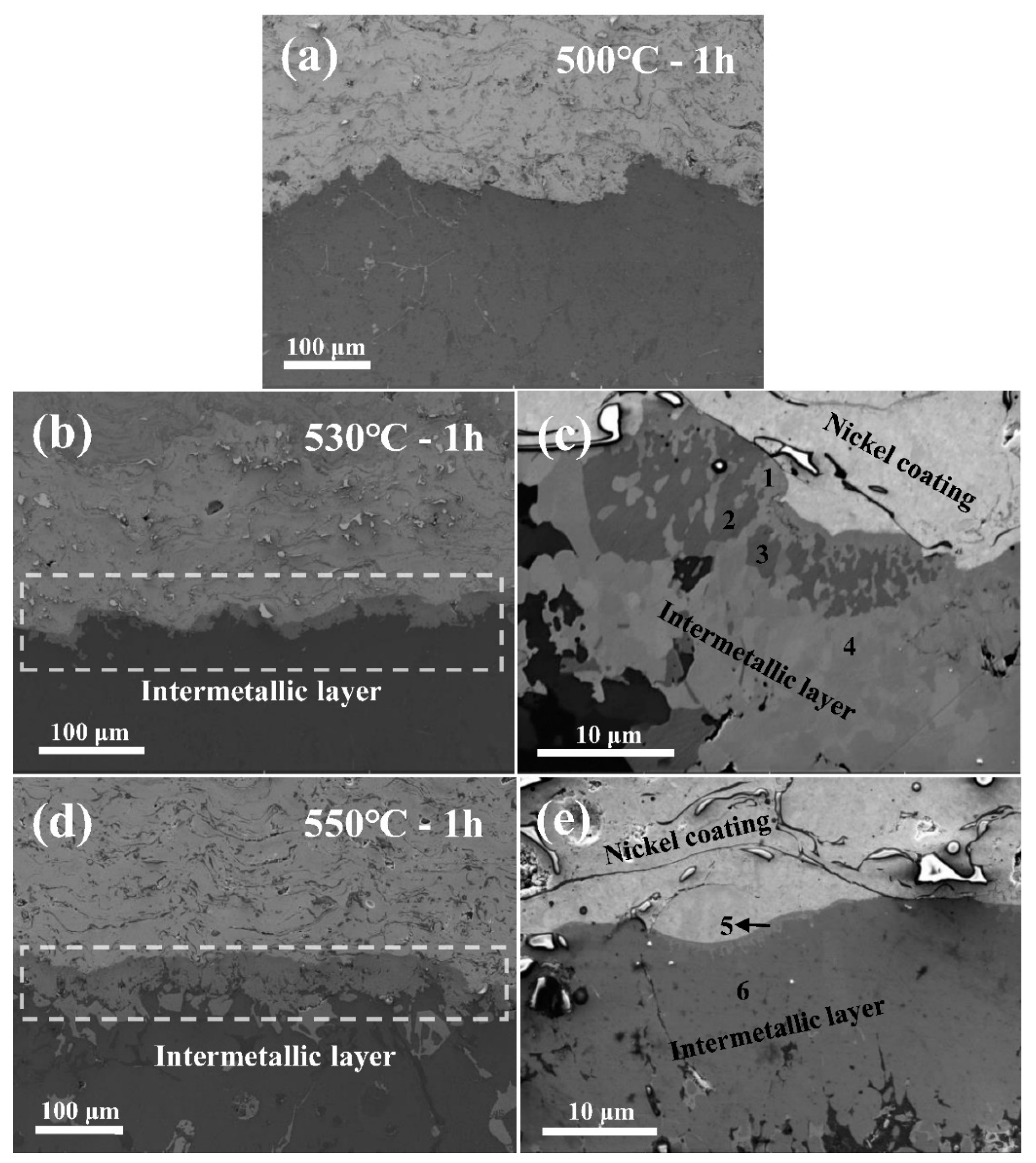

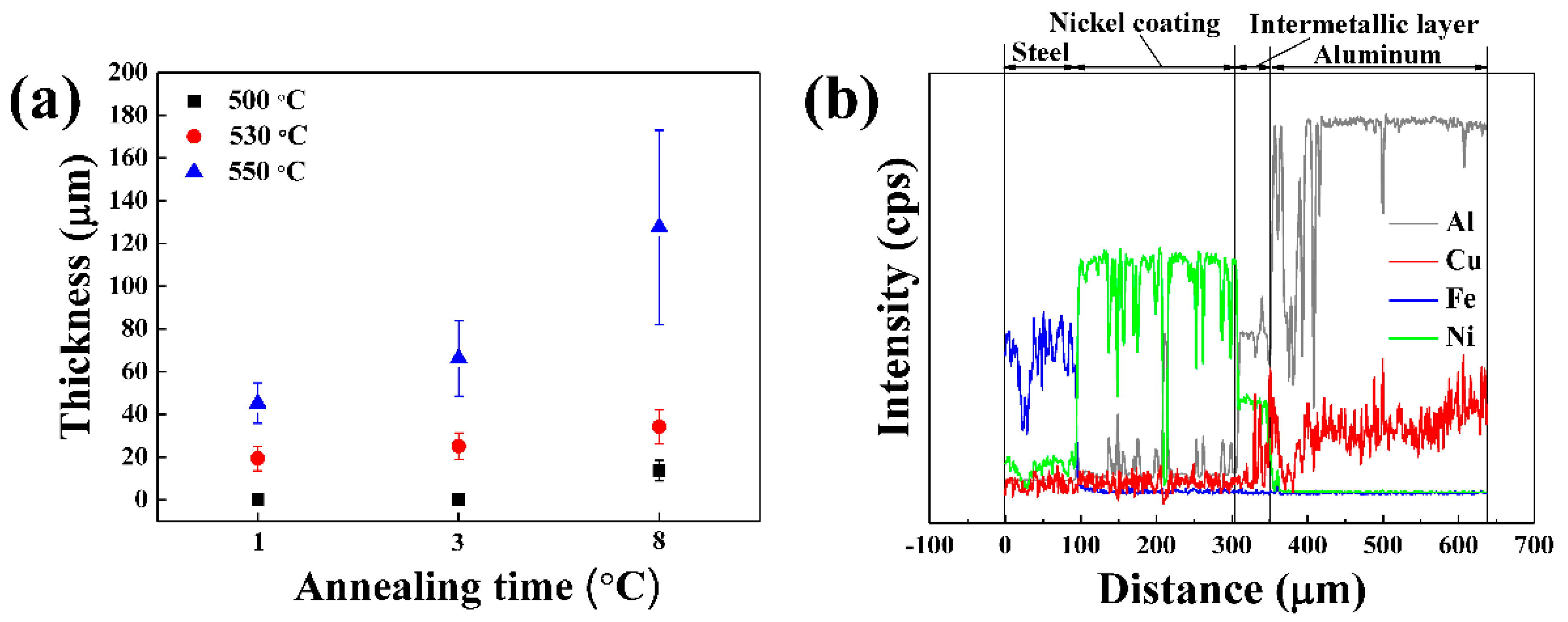

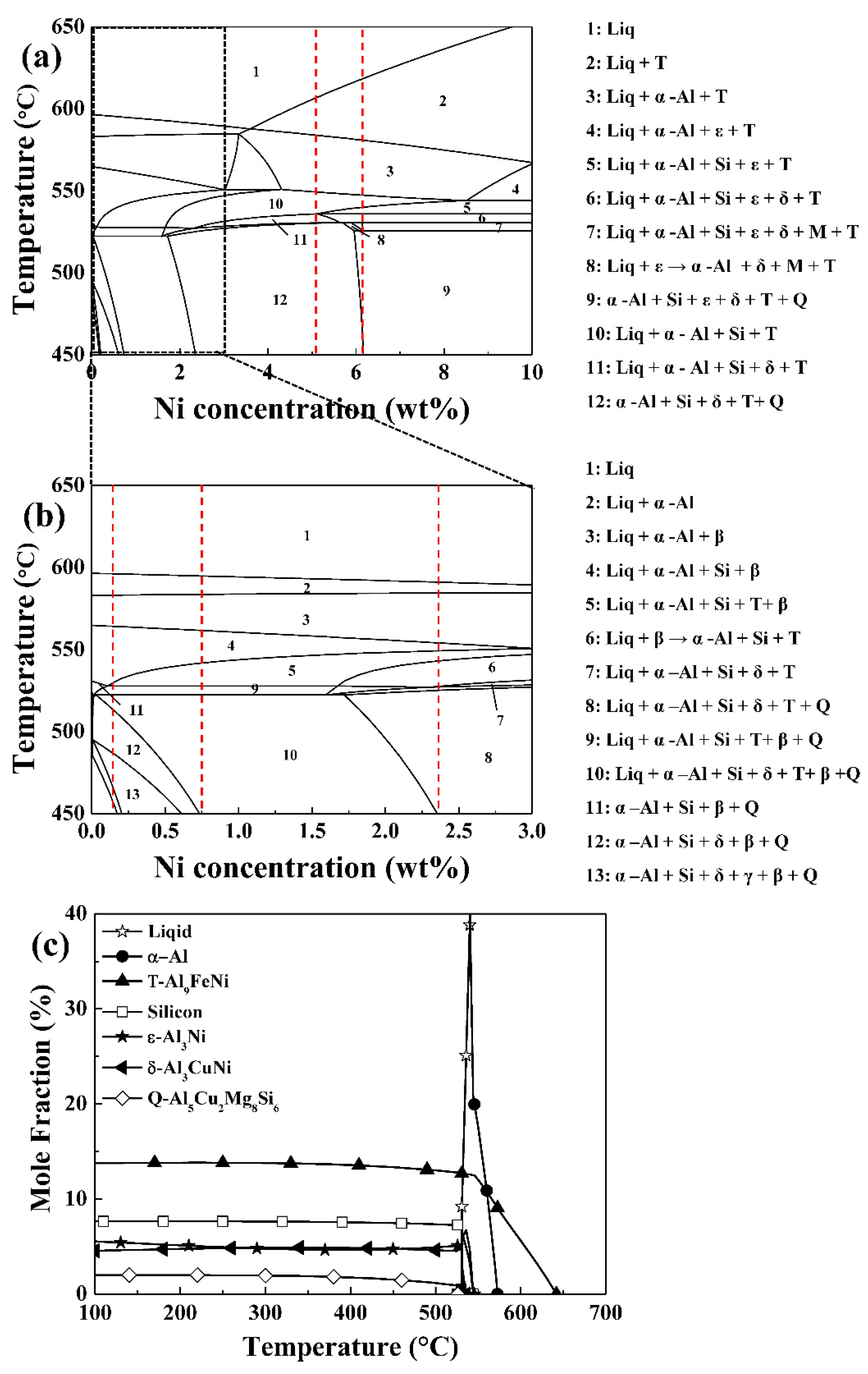

3.2. Effects of Heat Treatment on the Interfacial Microstructures

3.3. Micro-Hardness Distribution in the Al/Fe Alloys Hybrid Structure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Grosselle, F.; Timelli, G.; Bonollo, F. Doe applied to microstructural and mechanical properties of Al-Si-Cu-Mg casting alloys for automotive applications. Mater. Sci. Eng. A 2010, 527, 3536–3545. [Google Scholar] [CrossRef]

- Liu, Y.; Bian, X.; Zhang, K.; Yang, C.; Feng, L.; Kim, H.S.; Guo, J. Interfacial microstructures and properties of aluminum alloys/galvanized low-carbon steel under high-pressure torsion. Mater. Des. 2014, 64, 287–293. [Google Scholar] [CrossRef]

- Lee, E.; Mishra, B. Effect of solidification cooling rate on mechanical properties and microstructure of Al-Si-Mn-Mg alloy. Mater. Trans. 2017, 58, 1624–1627. [Google Scholar] [CrossRef]

- Ahn, C.; Jo, I.; Ji, C.; Cho, S.; Mishra, B.; Lee, E. Creep behavior of high-pressure die-cast AlSi10MnMg aluminum alloy. Mater. Charact. 2020, 167, 110495. [Google Scholar] [CrossRef]

- Khoonsari, E.; Jalilian, F.; Paray, F.; Emadi, D.; Drew, R.A.L. Interaction of 308 stainless steel insert with A319 aluminium casting alloy. Mater. Sci. Technol. 2010, 26, 833–841. [Google Scholar] [CrossRef]

- Jiang, W.; Fan, Z.; Li, G.; Li, C. Effects of zinc coating on interfacial microstructures and mechanical properties of aluminum/steel bimetallic composites. J. Alloy Compd. 2016, 678, 249–257. [Google Scholar] [CrossRef]

- Jiang, W.; Fan, Z.; Li, G.; Liu, X.; Liu, F. Effects of hot-dip galvanizing and aluminizing on interfacial microstructures and mechanical properties of aluminum/iron bimetallic composites. J. Alloy Compd. 2016, 688, 742–751. [Google Scholar] [CrossRef]

- Wróbel, T.; Wiedermann, J.; Skupień, P. Bimetallic castings in a chromium–nickel stainless steel working surface layer configuration with a grey cast iron base. Trans. Indian Inst. Met. 2015, 68, 571–580. [Google Scholar] [CrossRef]

- Mola, R.; Bucki, T. Characterization of the bonding zone in AZ91/AlSi12 bimetals fabricated by liquid-solid compound casting using unmodified and thermally modified AlSi12 alloy. Stroj. Vestn. J. Mech. Eng. 2020, 66, 439–448. [Google Scholar] [CrossRef]

- Ramadan, M.; Alghamdi, A.S.; Hafez, K.M.; Subhani, T.; Abdel Halim, K.S. Development and optimization of tin/flux mixture for direct tinning and interfacial bonding in aluminum/steel bimetallic compound casting. Materials 2020, 13, 5642. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Bian, X.; Yang, J.; Zhang, K.; Feng, L.; Yang, C. An investigation of metallurgical bonding in Al-7Si/gray iron bimetal composites. J. Mater. Res. 2013, 28, 3190. [Google Scholar] [CrossRef]

- Springer, H.; Kostka, A.; Payton, E.J.; Raabe, D.; Kaysser-Pyzalla, A.; Eggeler, G. On the formation and growth of intermetallic phases during interdiffusion between low-carbon steel and aluminum alloys. Acta Mater. 2011, 59, 1586–1600. [Google Scholar] [CrossRef]

- Bakke, A.O.; Arnberg, L.; Løland, J.-O.; Jørgensen, S.; Kvinge, J.; Li, Y. Formation and evolution of the interfacial structure in al/steel compound castings during solidification and heat treatment. J. Alloy Compd. 2020, 849, 156685. [Google Scholar] [CrossRef]

- Jiang, W.; Fan, Z.; Li, C. Improved steel/aluminum bonding in bimetallic castings by a compound casting process. J. Mater. Process. Technol. 2015, 226, 25–31. [Google Scholar] [CrossRef]

- Szymczak, T. The structure of connection of the AlSi5–HS6-5-2 compound casting obtained by alphinising. Arch. Foundry Eng. 2011, 11, 175–184. [Google Scholar]

- Kundu, S.; Chatterjee, S. Characterization of diffusion bonded joint between titanium and 304 stainless steel using a Ni interlayer. Mater. Charact. 2008, 59, 631–637. [Google Scholar] [CrossRef]

- Zhang, J.; Luo, G.-Q.; Shen, Q.; Zhang, L.-M.; Huang, Z.-J. Characterization of diffusion-bonded joint between Al and Mg using a Ni interlayer. Rare Met. 2016, 35, 537–542. [Google Scholar] [CrossRef]

- Meng, F.; Wu, Y.; Hu, K.; Li, Y.; Sun, Q.; Liu, X. Evolution and strengthening effects of the heat-resistant phases in Al–Si Piston alloys with different Fe/Ni ratios. Materials 2019, 12, 2506. [Google Scholar] [CrossRef]

- Awe, S.A.; Seifeddine, S.; Jarfors, A.E.W.; Lee, Y.C.; Dahle, A.K. Development of new Al-Cu-Si alloys for high temperature performance. Adv. Mater. Lett. 2017, 8, 695–701. [Google Scholar] [CrossRef]

- Medrano-Prieto, H.; Garaz-Reyes, C.G.; Gomez-Esparza, C.D.; Estrada-Guel, I.; Aguilar-Santillan, J.; Maldonado-Orozco, M.C.; Martinez-Sanchez, R. Effect of Nickel addition and solution treatment time on microstructure and hardness of Al-Si-Cu aged alloys. Mater. Charact. 2016, 120, 168–174. [Google Scholar] [CrossRef]

- Te, A.; Harrison, R.A.; Olson, S.D. Dissimilar Metal Casting; Worcester Polytechnic Institute: Worcester, MA, USA, 2016. [Google Scholar]

- Pakzaman, H.; Divandari, M.; Khavandi, A. Effect of nickel coating on steel wire reinforcement on mechanical properties of aluminum matrix composites produced via lost foam casting. In Proceedings of the Iran International Aluminum Conference (IIAC2012), Arak, Iran, 15–16 May 2012. [Google Scholar]

- Zolotorevsky, V.S.; Belov, N.A.; Glazoff, M.V. Casting Aluminum Alloys; Elsevier: Amsterdam, The Netherlands, 2007; Volume 12. [Google Scholar]

- Seeger, A. The mechanisms of diffusion in metals and alloys. J. Less Common Met. 1972, 28, 387–418. [Google Scholar] [CrossRef]

- Kobayashi, S.; Yakou, T. Control of intermetallic compound layers at interface between steel and aluminum by diffusion-treatment. Mater. Sci. Eng. A 2002, 338, 44–53. [Google Scholar] [CrossRef]

- Jiang, W.; Li, G.; Wu, Y.; Liu, X.; Fan, Z. Effect of heat treatment on bonding strength of aluminum/steel bimetal produced by a compound casting. J. Mater. Process. Technol. 2018, 258, 239–250. [Google Scholar] [CrossRef]

- Farkoosh, A.; Javidani, M.; Hoseini, M.; Larouche, D.; Pekguleryuz, M. Phase formation in as-solidified and heat-treated Al-Si-Cu-Mg-Ni alloys: Thermodynamic assessment and experimental investigation for alloy design. J. Alloy Compd. 2013, 551, 596–606. [Google Scholar] [CrossRef]

- Adabi, M.; Amadeh, A.A. Formation mechanisms of Ni-Al intermetallics during heat treatment of Ni coating on 6061 Al substrate. Trans. Nonferrous Met. Soc. China 2015, 25, 3959–3966. [Google Scholar] [CrossRef]

- Mondolfo, L.F. Aluminum Alloys: Structure and Properties; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Evans, H.; Lobb, R. Conditions for the initiation of oxide-scale cracking and spallation. Corros. Sci. 1984, 24, 209–222. [Google Scholar] [CrossRef]

- Paul, A.; Laurila, T.; Vuorinen, V.; Divinski, S.V. Interdiffusion and the Kirkendall effect in binary systems. In Thermodynamics, Diffusion and the Kirkendall Effect in Solids; Springer: Cham, Switzerland, 2014; pp. 239–298. [Google Scholar]

- Tavoosi, M. The Kirkendall void formation in Al/Ti interface during solid-state reactive diffusion between Al and Ti. Surf. Interfaces 2017, 9, 196–200. [Google Scholar] [CrossRef]

- Ma, Z.; Samuel, A.M.; Samuel, F.H.; Doty, H.W.; Valtierra, S. A study of tensile properties in Al-Si-Cu and Al-Si-Mg alloys: Effect of β-iron intermetallics and porosity. Mater. Sci. Eng. A 2008, 490, 36–51. [Google Scholar] [CrossRef]

- Puncreobutr, C.; Lee, P.D.; Kareh, K.M.; Connolley, T.; Fife, J.L.; Phillion, A.B. Influence of Fe-rich intermetallics on solidification defects in Al–Si–Cu alloys. Acta Mater. 2014, 68, 42–51. [Google Scholar] [CrossRef]

- Mbuya, T.; Odera, B.; Ng’ang’a, S. Influence of iron on castability and properties of aluminium silicon alloys: Literature review. Int. J. Cast Met. Res. 2003, 16, 451–465. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Wu, Y.; Wang, L.; Liu, X. Quantitative comparison of three Ni-containing phases to the elevated-temperature properties of Al-Si piston alloys. Mater. Sci. Eng. A 2010, 527, 7132–7137. [Google Scholar] [CrossRef]

- Furukawa, M.; Horita, Z.; Nemoto, M.; Valiev, R.Z.; Langdon, T.G. Microhardness measurements and the Hall-Petch relationship in an Al-3% Mg alloy with submicrometer grain size. Acta Mater. 1996, 44, 4619–4629. [Google Scholar] [CrossRef]

- Krupiński, M.; Król, M.; Maniara, R. Heat treatment of Al-Si-Cu alloys. In Solid State Phenomena; Trans Tech Publications: Zurich, Switzerland, 2018. [Google Scholar]

| A319 | Si | Cu | Mg | Fe | Al | ||

| Content | 7.98 | 2.8 | 0.64 | 0.74 | Bal. | ||

| SS316 | Cr | Ni | Mo | Mn | C | Si | Fe |

| Content | 19.11 | 11.23 | 1.98 | 1.64 | 0.219 | 0.181 | Bal. |

| Ni-5wt% Al | Al | Mn | Ti | Si | Fe | Cu | Ni |

| Content | 4.5~5.5 | <0.3 | <0.4 | <0.5 | <0.3 | <0.08 | Bal. |

| Coating Material | Voltage (V) | Current (A) | Wire Diameter (mm) | Air Pressure (psi) | Spray Distance (mm) | Spray Gum Moving Speed (mm·s−1) | Thickness (μm) |

|---|---|---|---|---|---|---|---|

| Ni-5wt% Al | 28~32 | 200~220 | φ 1.6 | 100 | 150 | 300 | 200 |

| Temperature (°C) | Number | Compositions (at.%) | Inference Component | ||||

|---|---|---|---|---|---|---|---|

| Al | Fe | Ni | Cu | Si | |||

| 530 | 1 | 53.3 | - | 25.72 | 20.32 | - | Al3CuNi |

| 2 | 72.28 | - | 27.72 | - | - | Al3Ni | |

| 3 | 74.36 | - | 25.64 | - | - | Al3Ni | |

| 4 | 58.72 | - | 21.33 | 18.98 | - | Al3CuNi | |

| 550 | 5 | 47.77 | - | 48.47 | - | 3.76 | NiAl |

| 6 | 73.84 | - | 26.16 | - | - | Al3Ni | |

| Number | Compositions (at.%) | Inference Component | ||||

|---|---|---|---|---|---|---|

| Al | Fe | Ni | Cu | Si | ||

| 1 | 65.73 | - | - | 34.27 | - | Al2Cu |

| 2 | 66.36 | 16.3 | - | - | 17.34 | Al4.5FeSi |

| 3 | 70.45 | 13.14 | - | 1.32 | 15.08 | Al4.5FeSi |

| 4 | 66.64 | - | - | 33.36 | - | Al2Cu |

| 5 | 70.98 | 14.81 | - | - | 14.21 | Al4.5FeSi |

| 6 | 70.71 | 4.94 | 18.88 | - | 5.47 | Al9FeNi |

| 7 | 58.28 | - | 20.55 | 21.18 | - | Al3CuNi |

| 8 | 70.04 | 5.29 | 18.93 | - | 5.75 | Al9FeNi |

| 9 | - | - | - | - | 100 | Si particle |

| 10 | 57.63 | - | 22.28 | 20.08 | - | Al3CuNi |

| 11 | 68.46 | - | - | 30.35 | 1.19 | Al2Cu |

| 12 | - | - | - | - | 100 | Si particle |

| 13 | 67.42 | 17.06 | - | - | 15.53 | Al4.5FeSi |

| 14 | 70.2 | 13.32 | - | - | 16.48 | Al4.5FeSi |

| Nickel Concentration (=X) | Nickel-Bearing Phase Transformation of the Al–Si–Cu–Mg–Fe System under Equilibrium Conditions | |||||

|---|---|---|---|---|---|---|

| X > 6.16% | L → T | L → α + T | L → α + Si + T | L → α + Si + ε + T | L → α + Si + ε + δ + T | - |

| 5.14% < X < 6.16% | L → T | L → α + T | L → α + Si + T | L → α + Si + ε + δ + T | L + ε → α + Si + δ + T | - |

| 2.32% < X < 5.14% | L → α | L → α + β | L → α + Si + β | L + β → α + Si + T + β | L + β → α + Si + T | L→α + Si + δ + T |

| 0.73% < X < 2.32% | L → α | L → α + β | L → α + Si + β | L + β → α + Si + T + β | L → α + Si + δ + β + T | - |

| 0.15% < X < 0.73% | L → α | L → α + β | L → α + Si + β + T | L → α + Si + δ + β | - | - |

| 0.15% > X | L → α | L → α + β | L → α + Si + β | L → α + Si + δ + β | L → α + Si + δ + γ + β | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moon, G.; Lee, E. Combined Effects of Optimized Heat Treatment and Nickel Coating for the Improvement of Interfacial Bonding in Aluminum–Iron Alloys Hybrid Structures. Appl. Sci. 2021, 11, 1501. https://doi.org/10.3390/app11041501

Moon G, Lee E. Combined Effects of Optimized Heat Treatment and Nickel Coating for the Improvement of Interfacial Bonding in Aluminum–Iron Alloys Hybrid Structures. Applied Sciences. 2021; 11(4):1501. https://doi.org/10.3390/app11041501

Chicago/Turabian StyleMoon, Gihoon, and Eunkyung Lee. 2021. "Combined Effects of Optimized Heat Treatment and Nickel Coating for the Improvement of Interfacial Bonding in Aluminum–Iron Alloys Hybrid Structures" Applied Sciences 11, no. 4: 1501. https://doi.org/10.3390/app11041501

APA StyleMoon, G., & Lee, E. (2021). Combined Effects of Optimized Heat Treatment and Nickel Coating for the Improvement of Interfacial Bonding in Aluminum–Iron Alloys Hybrid Structures. Applied Sciences, 11(4), 1501. https://doi.org/10.3390/app11041501