Prediction of Subsidence during TBM Operation in Mixed-Face Ground Conditions from Realtime Monitoring Data

Abstract

:1. Introduction

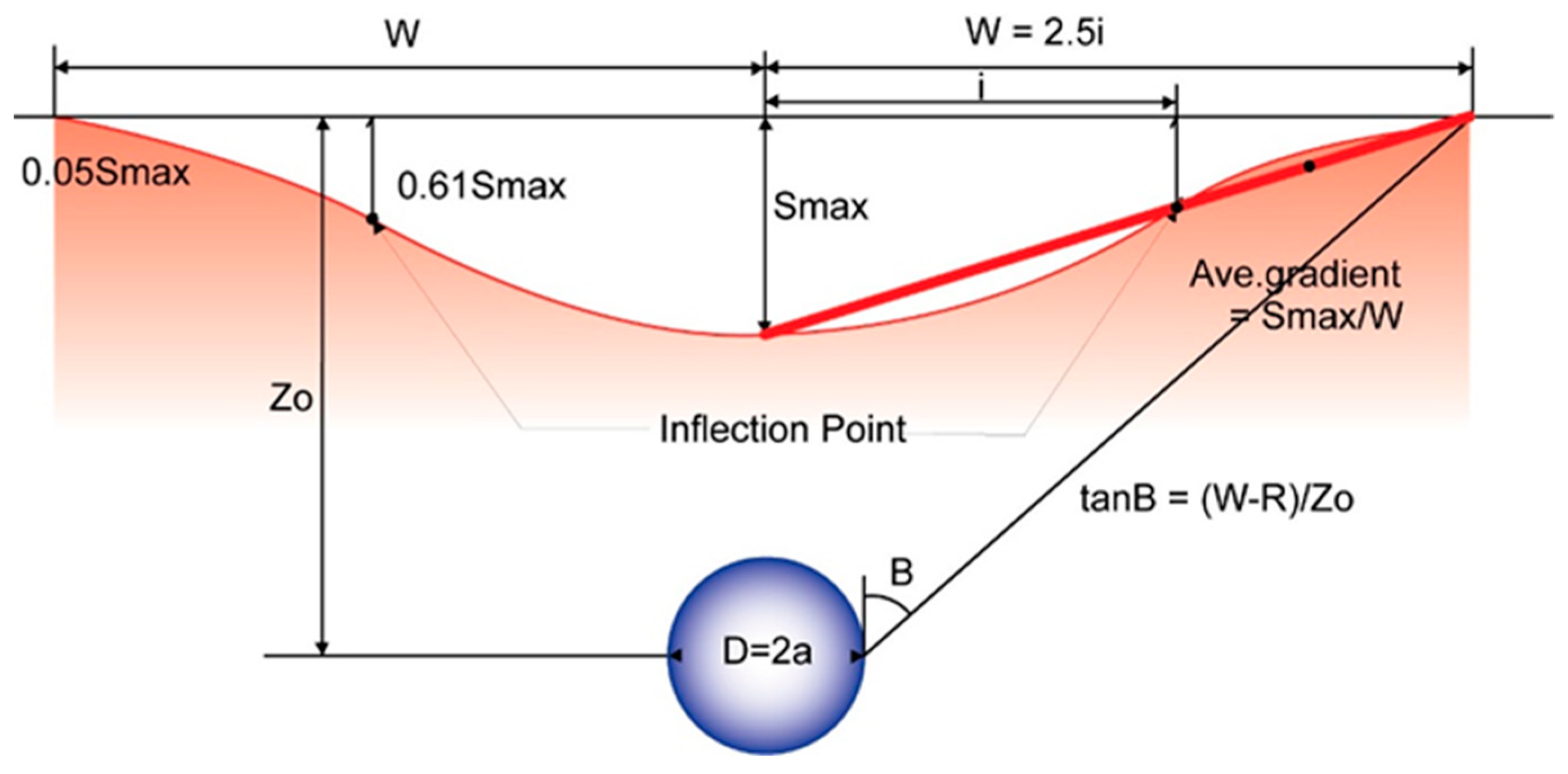

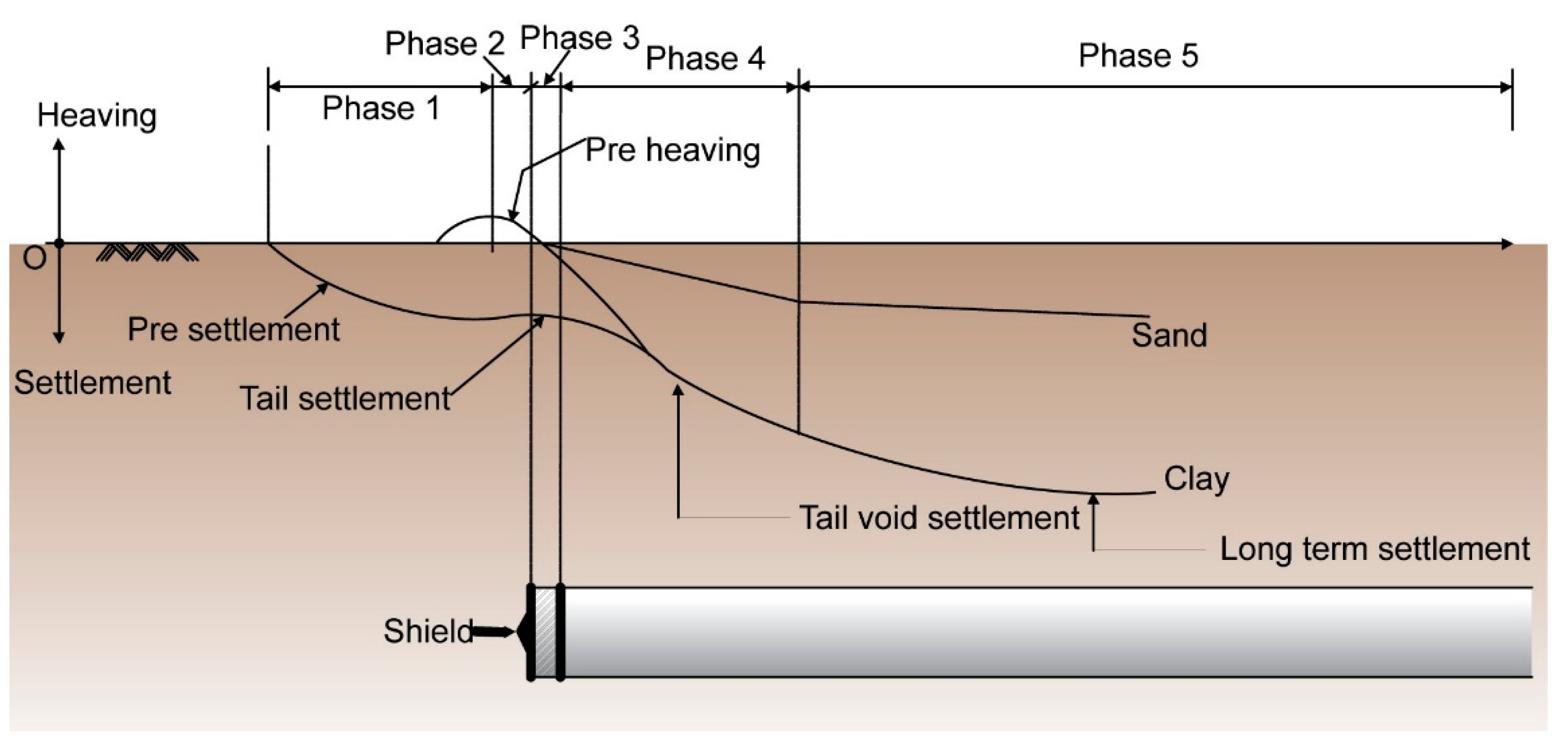

2. Literature Review

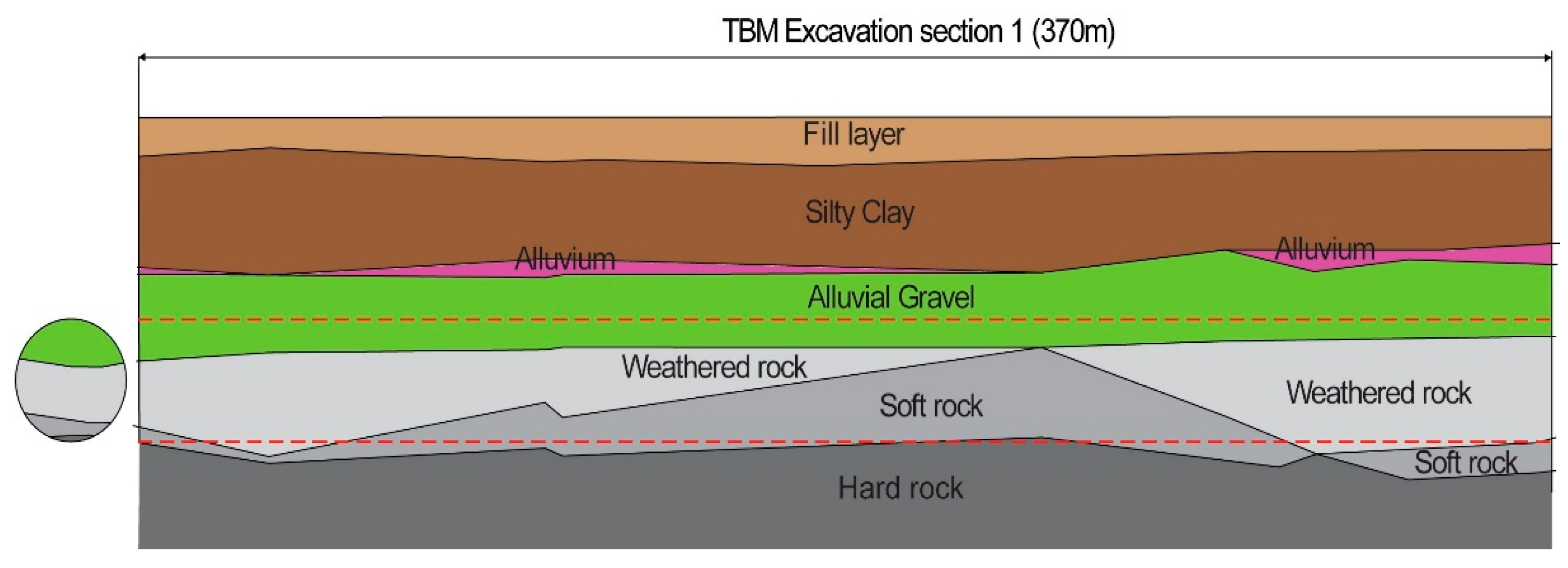

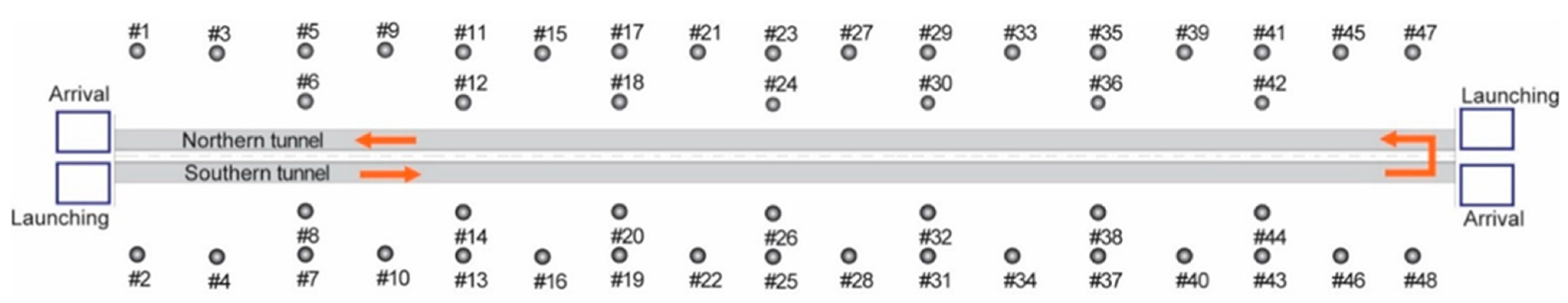

3. Description of Project and EPB (Earth Pressure Balance) TBM Driving

3.1. TBM Driving

3.2. Geological Site Conditions

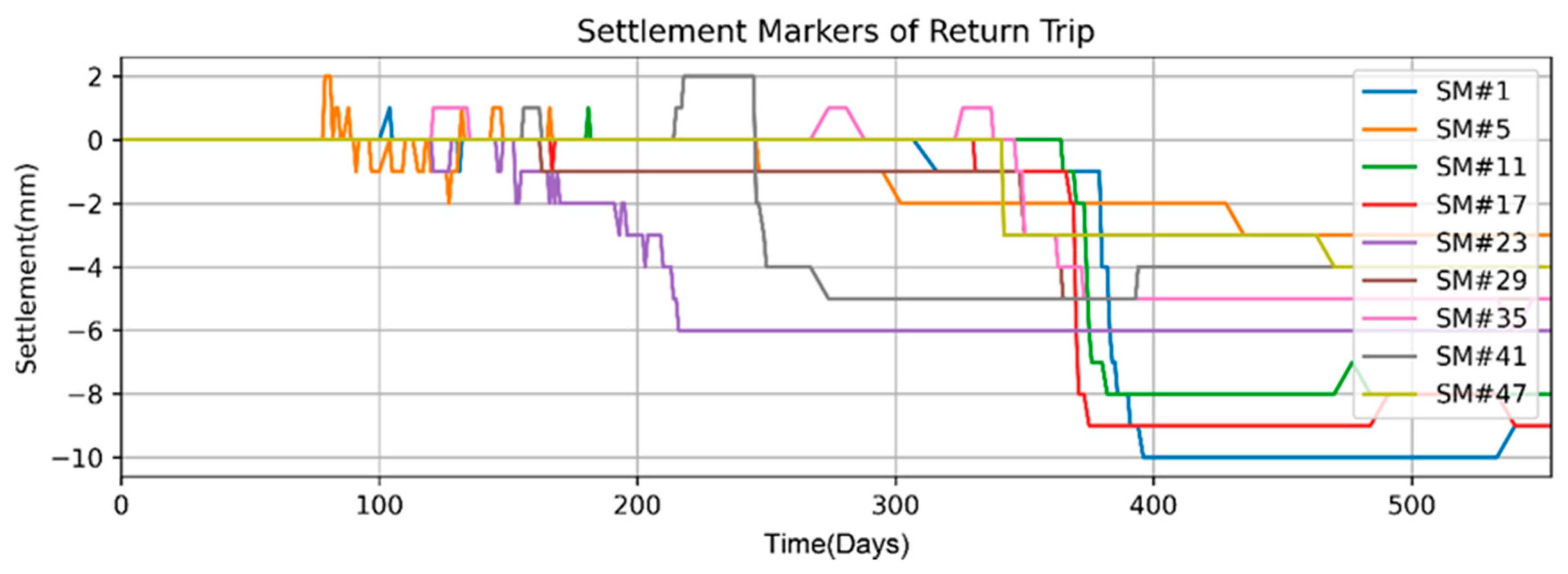

3.3. Occurrence of Subsidence

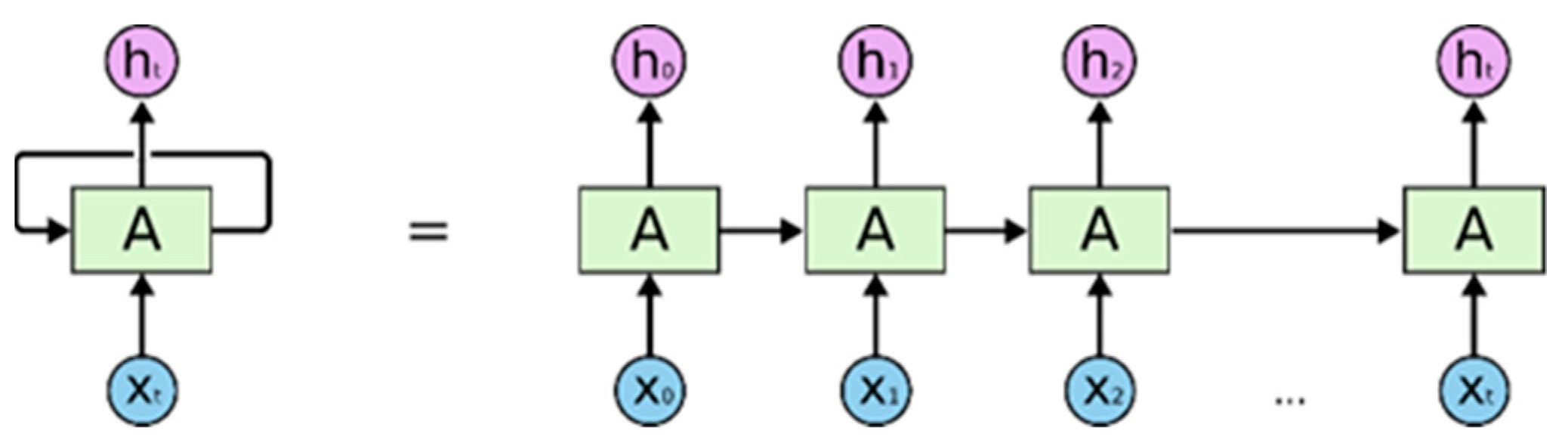

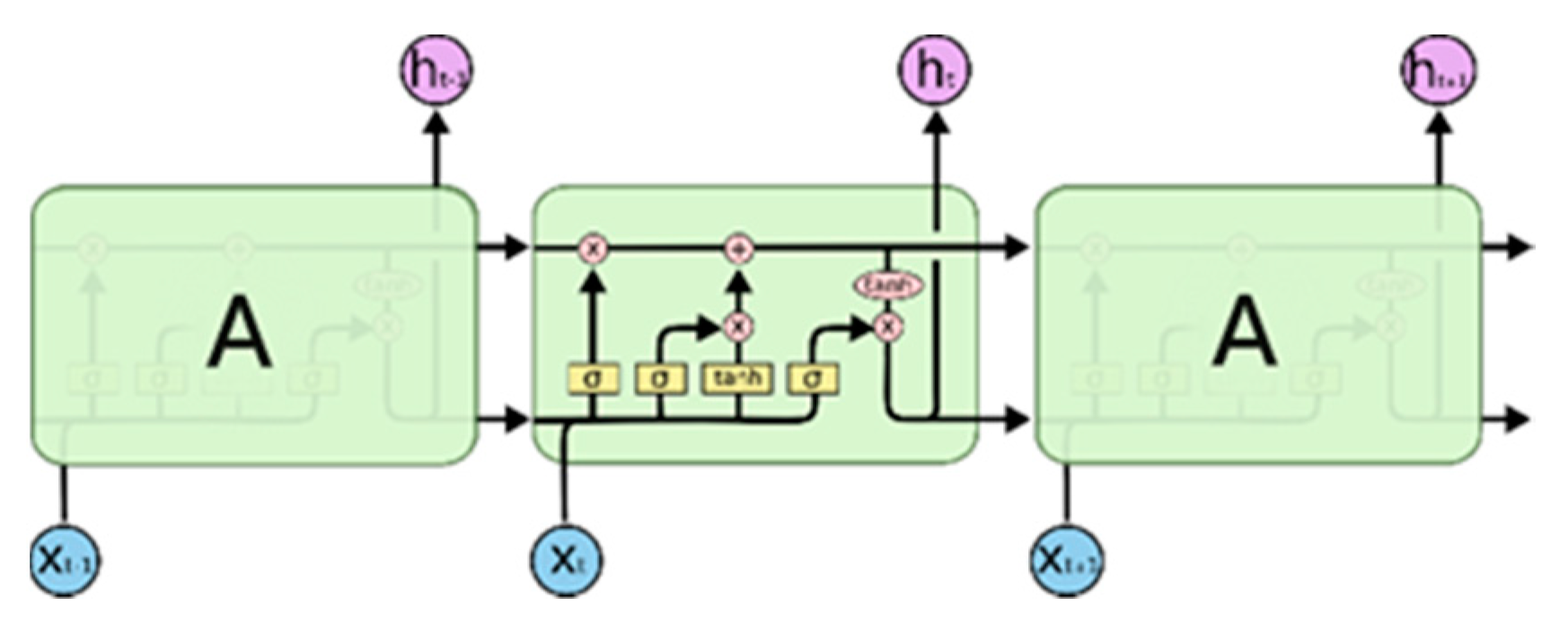

4. LSTM Networks

5. Training Model and Prediction for Subsidence

5.1. Challenges

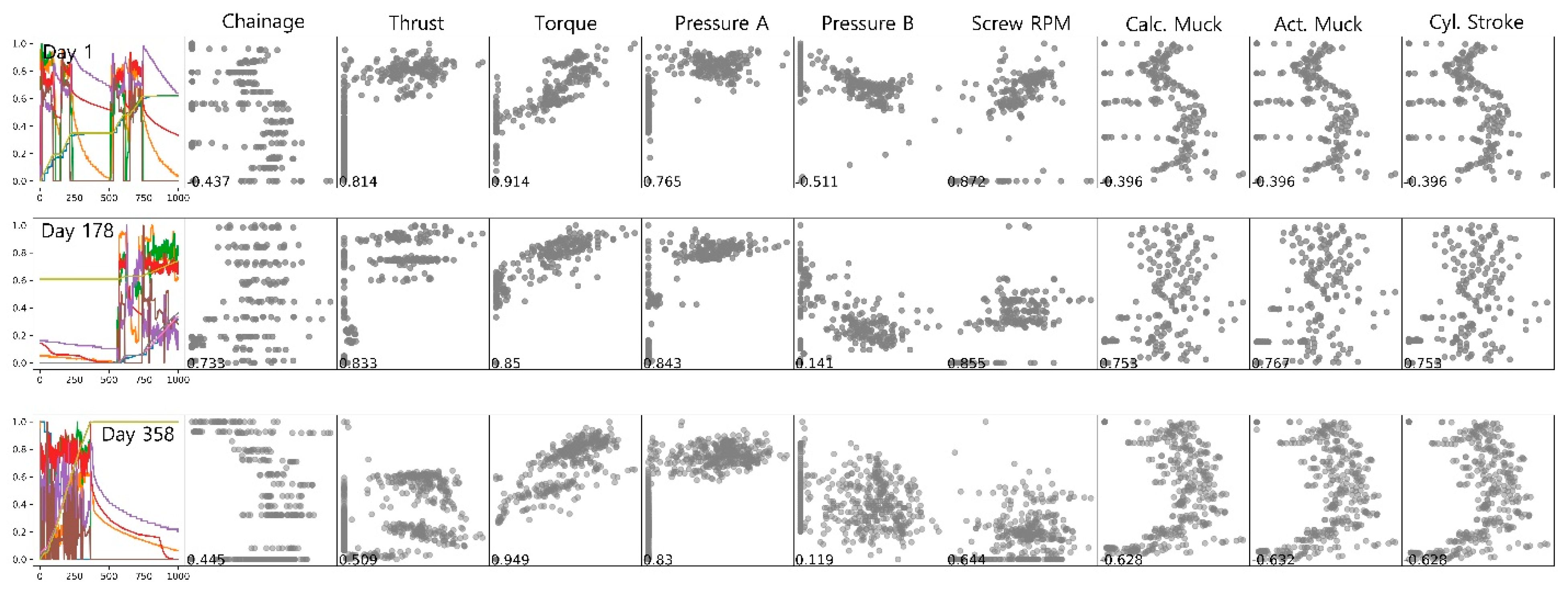

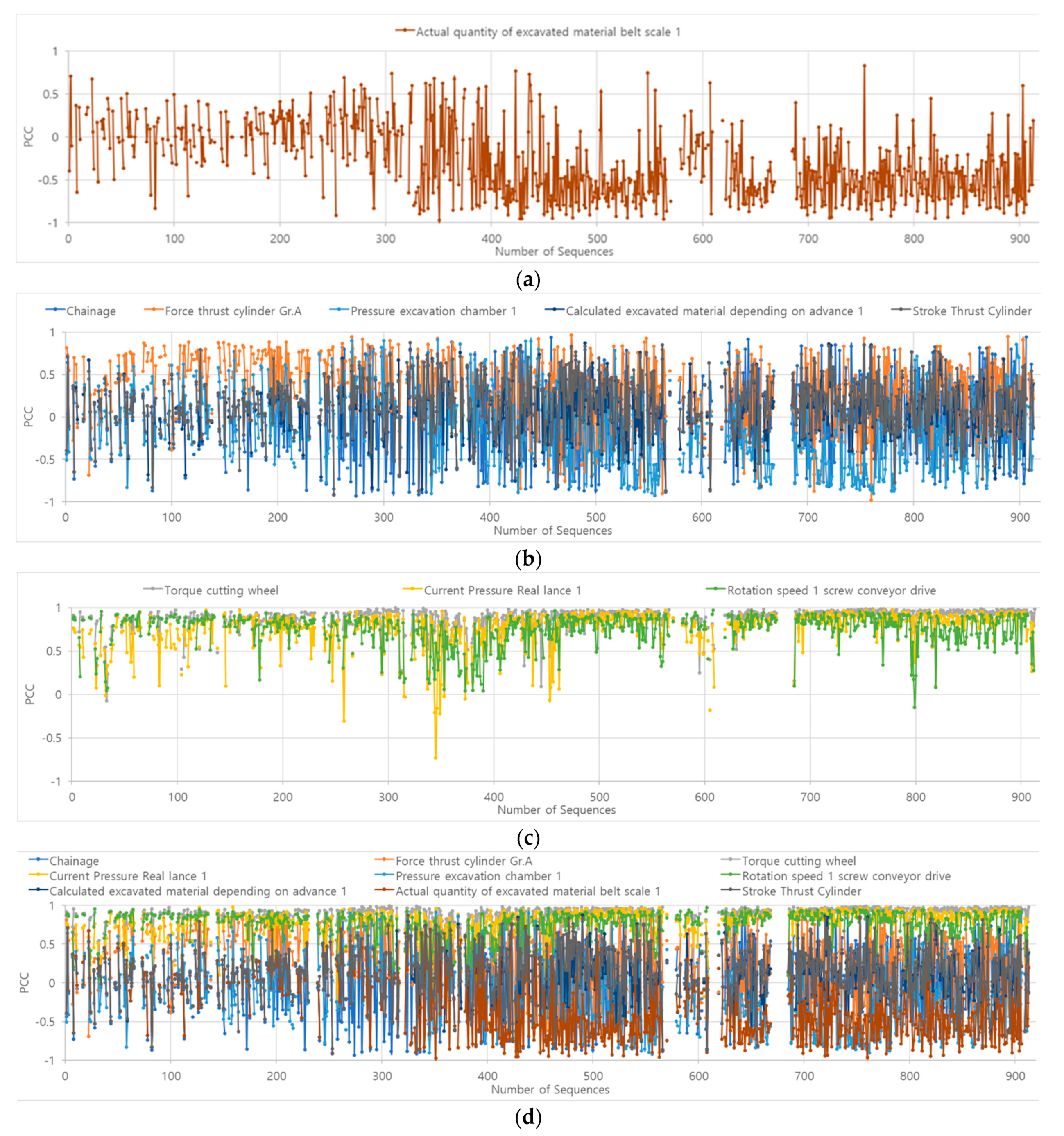

5.2. Training Phase One: Feature Extraction from Machine Data

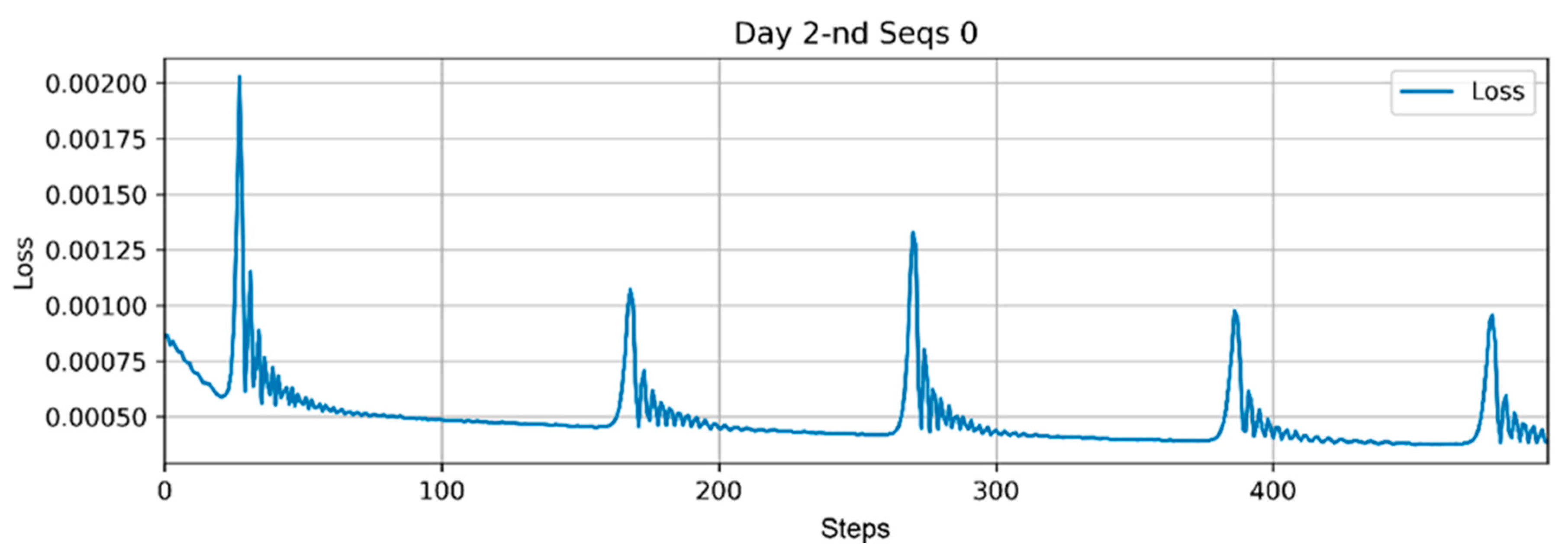

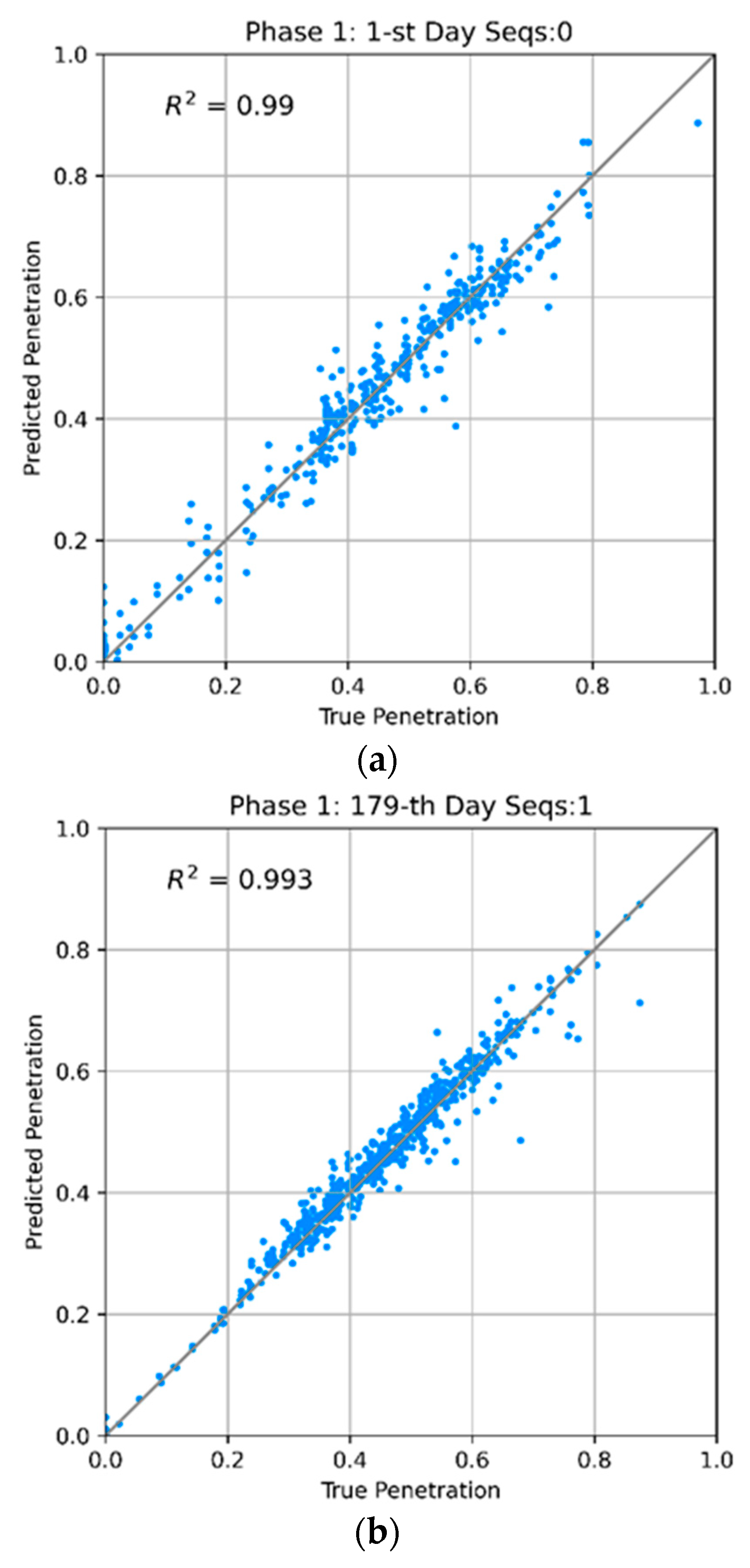

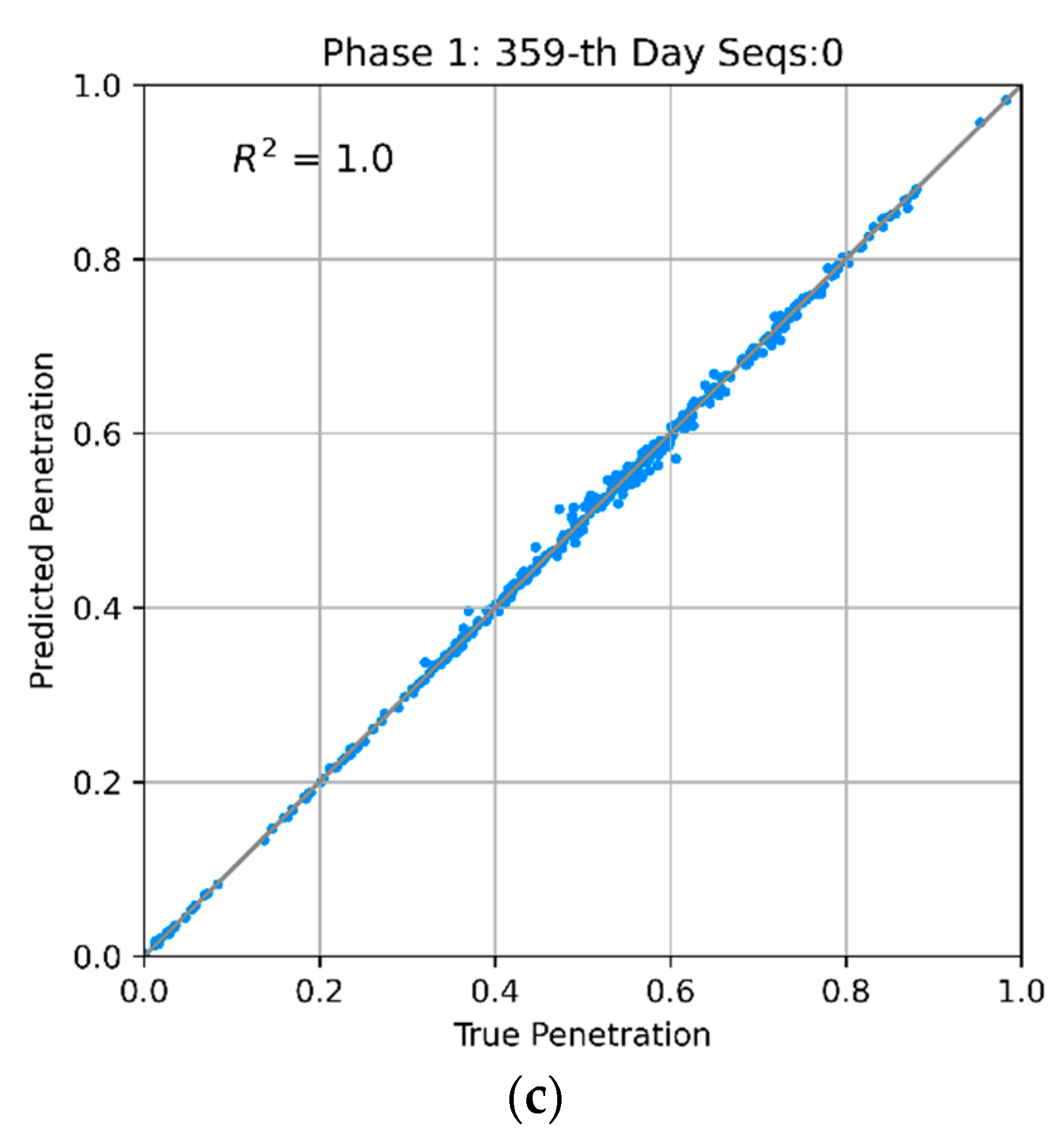

5.3. Results of Phase 1 Training

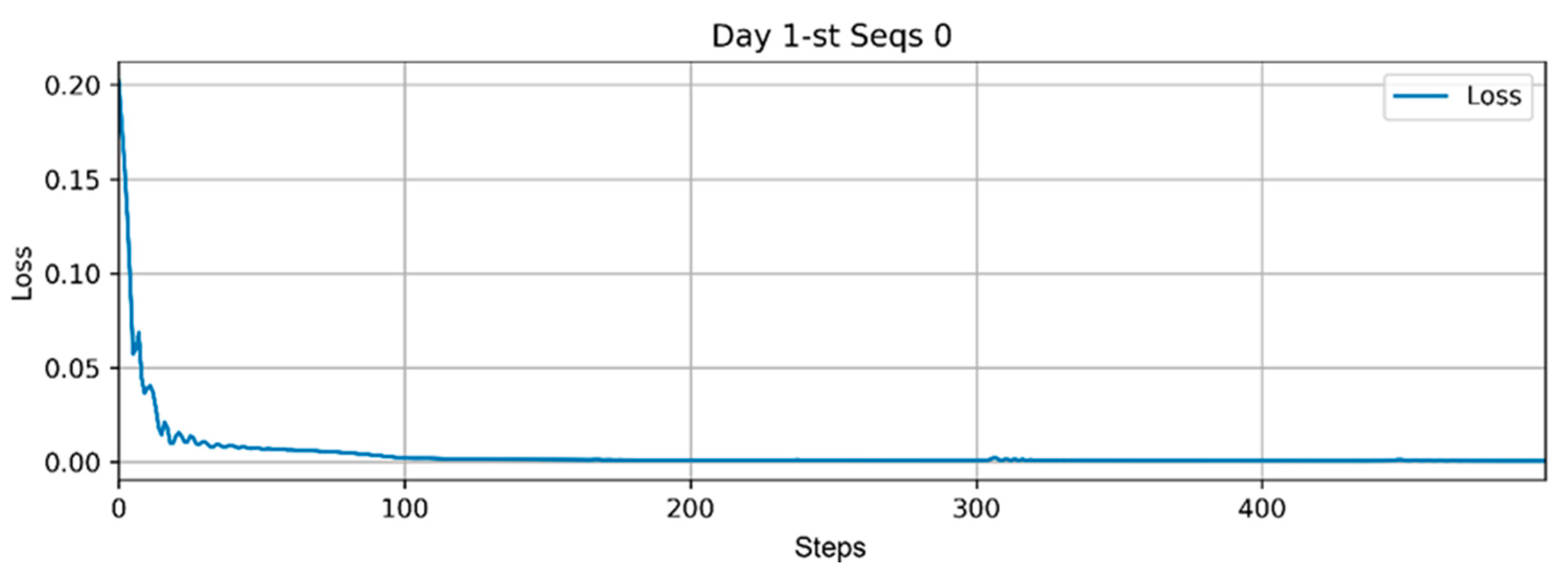

5.4. Training Phase Two: Subsidence Estimation of Features from Machine Data

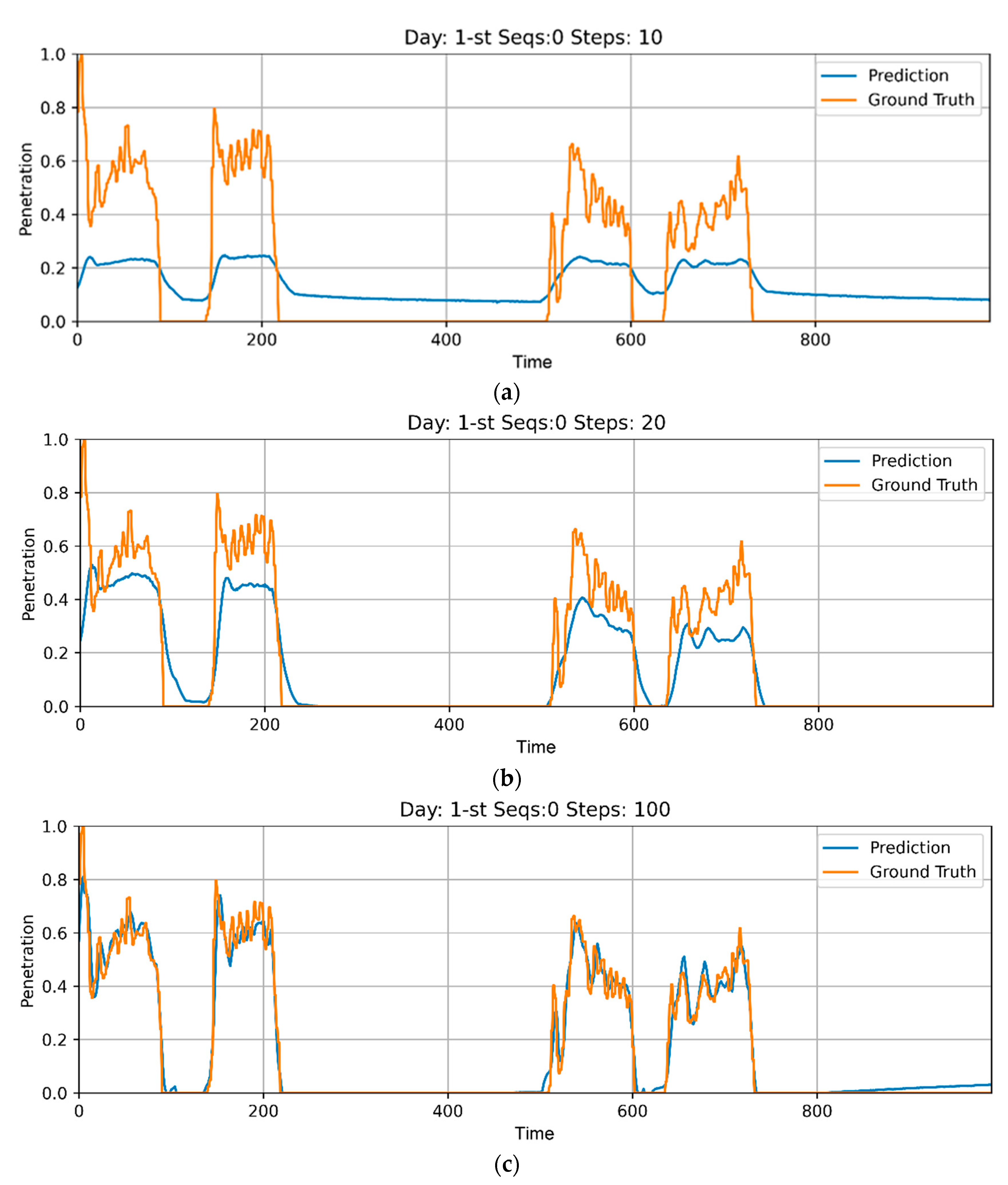

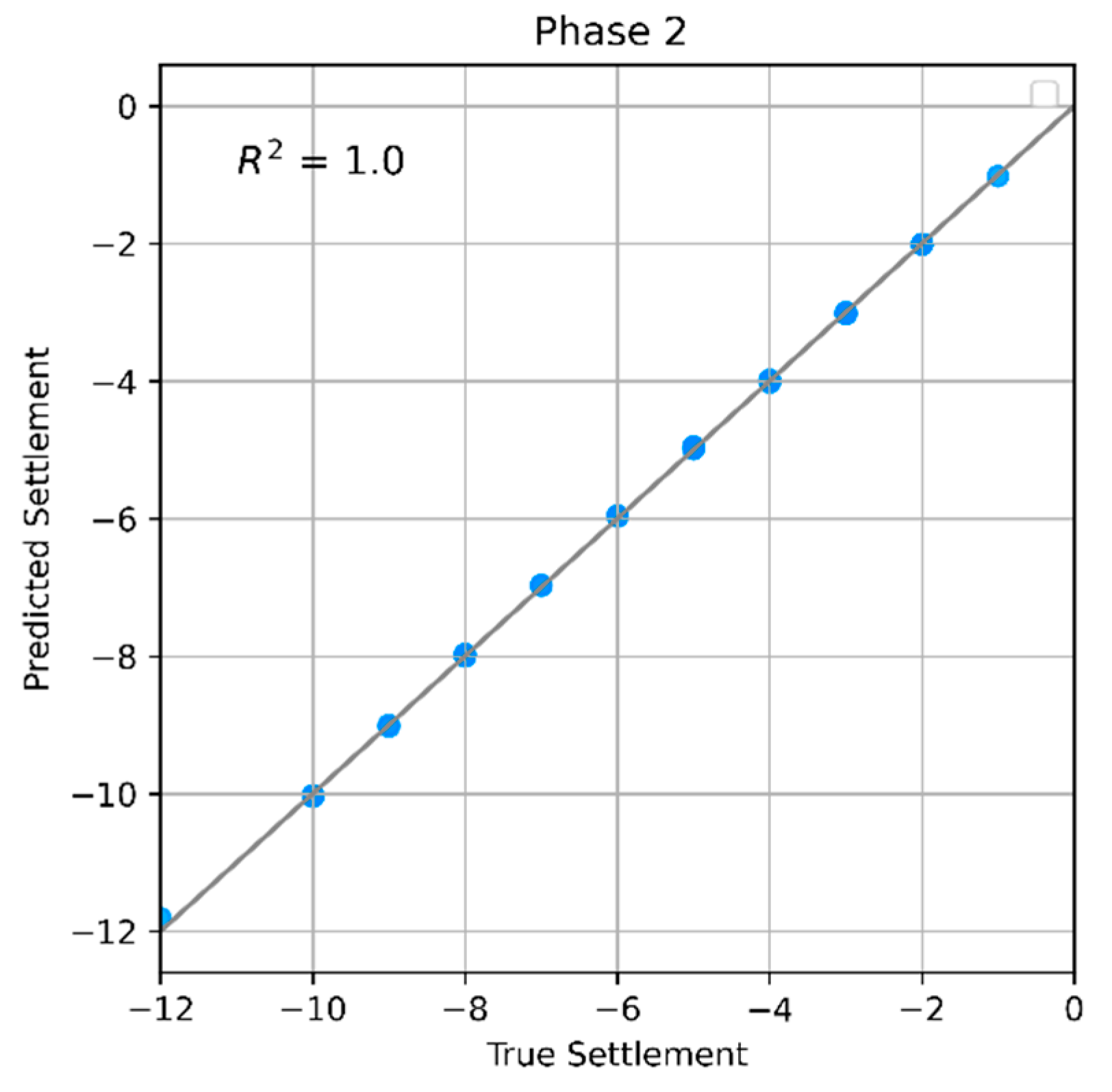

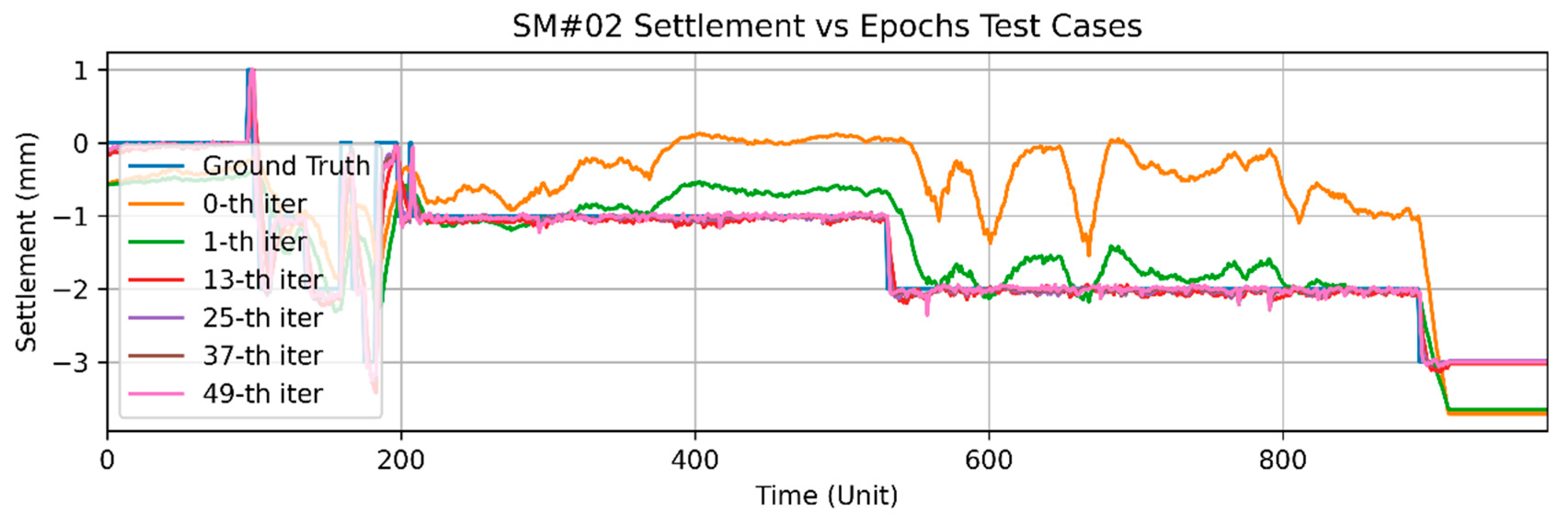

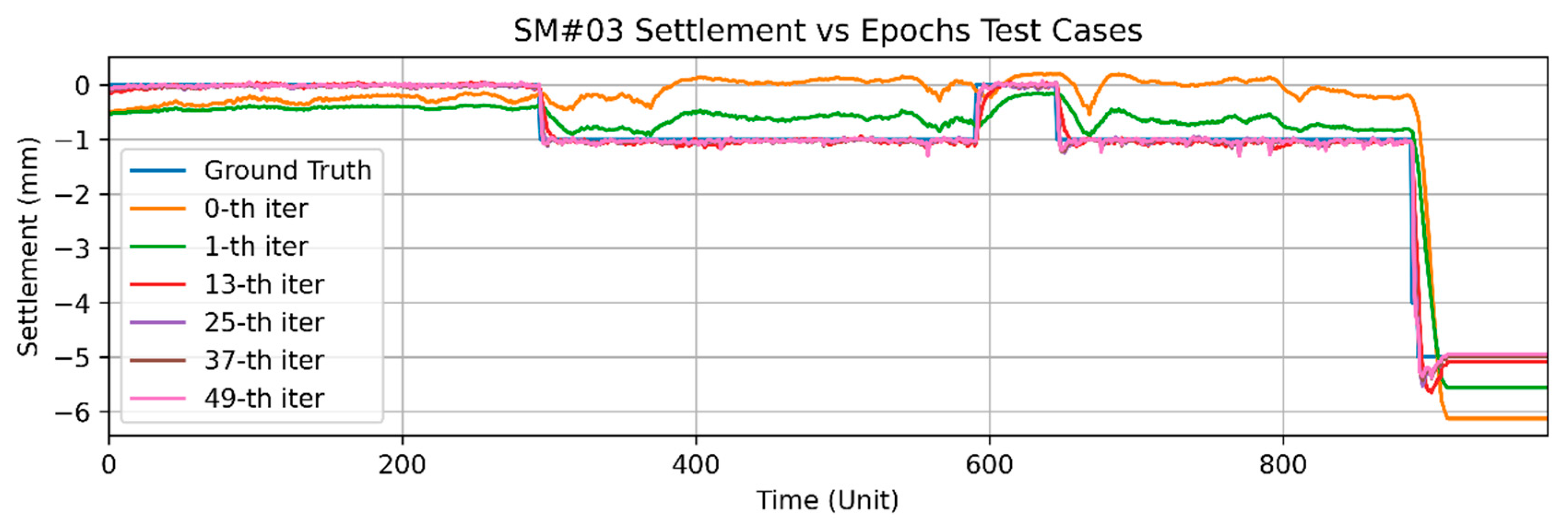

5.5. Results of Phase Two Training

5.6. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ko, T.Y.; Lee, S.W. Effect of Rock Abrasiveness on Wear of Shield Tunneling in Bukit Timah Granite. Appl. Sci. 2020, 10, 3231. [Google Scholar] [CrossRef]

- Peck, R. Deep excavations and tunneling in soft ground. In Proceedings of the 7th International Conference on Soil Mechanics and Foundation Engineering, Mexico City, Mexico, 29 August 1969; pp. 225–292. [Google Scholar]

- You, K.H.; Jung, S.T. A study on the behavior of surface settlement due to the excavation of twin TBM tunnels in the clay grounds. J. Korean Geo-Environ. Soc. 2019, 20, 29–40. [Google Scholar] [CrossRef]

- Kasper, T.; Meschke, G. On the influence of face pressure, grouting pressure and TBM design in soft ground tunneling. Tun-Nelling Undergr. Space Technol. 2006, 21, 160–171. [Google Scholar] [CrossRef]

- Zhang, K.; Lyu, H.M.; Shen, S.L.; Zhou, A.; Yin, Z.Y. Evolutionary hybrid neural network approach to predict shield tunneling induced ground settlements. Tunn. Undergr. Space Technol. 2020, 106, 103594. [Google Scholar] [CrossRef]

- Mair, R.; Taylor, R.; Burland, J. Prediction of ground movements and assessment of risk of building damage due to bored tunneling. In Geotechnical Aspects of Underground Construction in Soft Ground; Balkema, Brookfield: Rotterdam, The Netherlands, 1996; pp. 713–718. [Google Scholar]

- Vorster, T.E.B.; Klar, A.; Soga, K.; Mair, R.J. Estimating the effects of tunneling on existing pipelines. J. Geotech. Geo-Environ. Eng. 2005, 131, 1399–1410. [Google Scholar] [CrossRef]

- Franza, A.; Marshall, A.M. Empirical and semi-analytical methods for evaluating tunneling-induced ground movements in sands. Tunn. Undergr. Space Technol. 2019, 88, 47–62. [Google Scholar] [CrossRef]

- Meschke, G. From advance exploration to real time steering of TBMs: A review on pertinent research in the collaborative research center, “interaction modeling in mechanized tunneling”. Undergr. Space 2018, 3, 1–20. [Google Scholar] [CrossRef]

- Lee, H.; Choi, H.; Choi, S.; Chang, S.; Kang, T.; Lee, C. Numerical Simulation of EPB Shield Tunneling with TBM Operational Condition Control Using Coupled DEM–FDM. Appl. Sci. 2021, 11, 2551. [Google Scholar] [CrossRef]

- Chou, J.S.; Lin, C. Predicting disputes in public-private partnership projects: Classification and ensemble models. J. Comput. Civ. Eng. 2013, 27, 51–60. [Google Scholar] [CrossRef]

- Bouayad, D.; Emeriault, F. Modeling the relationship between ground surface settlements induced by shield tunneling and the operational and geological parameters based on the hybrid PCA/ANFIS method. Tunn. Undergr. Space Technol. 2017, 68, 142–152. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, P.; Wu, H.; Wang, Z.; Zhong, Z. Prediction of shield tunneling-induced ground settlement using machine learning techniques. Front. Struct. Civ. Eng. 2019, 13, 1363–1378. [Google Scholar] [CrossRef]

- Kim, C.; Bae, G.; Hong, C.; Park, S.; Moon, H.; Shin, H. Neural network-based prediction of ground surface settlements due to tunneling. Comput. Geotech. 2001, 28, 517–547. [Google Scholar] [CrossRef]

- Suwansawat, S.; Einstein, H. Artificial neural networks for predicting the maximum surface settlement caused by EPB shield tunneling. Tunn. Undergr. Space Technol. 2006, 21, 133–150. [Google Scholar] [CrossRef]

- Hasanipanah, M.; Noorian-Bidgoli, M.; Jahed Armaghani, D.; Khamesi, H. Feasibility of PSO-ANN model for predicting surface settlement caused by tunneling. Eng. Comput. 2016, 32, 705–715. [Google Scholar] [CrossRef]

- Samui, P.; Sitharam, T. Least-square support vector machine applied to settlement of shallow foundations on cohesionless soils. Int. J. Numer. Anal. Meth. Geomech. 2008, 32, 2033–2043. [Google Scholar] [CrossRef]

- Choi, Y.-H.; Lee, S.S. Predictive Modelling for Blasting-Induced Vibrations from Open-Pit Excavations. Appl. Sci. 2021, 11, 7487. [Google Scholar] [CrossRef]

- Dindarloo, S.; Siami-Irdemoosa, E. Maximum surface settlement-based classification of shallow tunnels in soft ground. Tunn. Undergr. Space Technol. 2015, 49, 320–327. [Google Scholar] [CrossRef]

- Santos, O.J.J.; Celestino, T.B. Artificial neural networks analysis of Sao Paulo subway tunnel settlement data. Tunn. Undergr. Space Technol. 2008, 23, 481–491. [Google Scholar] [CrossRef]

- Shi, J.; Ortigao, J.A.R.; Bai, J. Modular neural networks for predicting settlements during tunneling. J. Geotech. Geo-Environ. Eng. 1998, 389–395. [Google Scholar] [CrossRef]

- Gao, M.; Zhang, N.; Shen, S.; Zhou, A. Real-time dynamic earth pressure regulation model for shield tunneling by integrating GRU deep learning method with GA optimization. IEEE Access 2020, 8, 64310–64323. [Google Scholar] [CrossRef]

- Kim, Y.K.; Lee, S.W. Study on Risk Assessment of Mine Subsidence by Machine Learning. Appl. Sci. 2020, 9, 1302. [Google Scholar] [CrossRef] [Green Version]

| AI Model | Researcher | Theme | Year |

|---|---|---|---|

| PCA/ANFIS | Bouayad, D; Emeriault, F. [12] | Ground surface settlements induced by shield tunneling | 2017 |

| Evolutionary Hybrid Neural Network | Zhang, K.; Lyu, H. M.; Shen, S. L.; Zhou, A.; Yin, Z. Y. [5] | Predicting shield tunneling induced ground settlement | 2020 |

| Machine Learning | Chen, R.; Zhang, P.; Wu, H.; Wang, Z.; Zang, Z. [13] | Predicting shield tunneling induced ground settlement | 2019 |

| ANN (Artificial Neural Network) | Kim, C.; Bae, G.; Hong, C.; Park, S.; Shin, H. [14] | Prediction of ground surface settlement due to tunneling | 2001 |

| Suwansawat, S.;Einstein, H. [15] | Prediction the max. surface settlement caused by EPB Shield | 2006 | |

| PSO-ANN | Hasanipanah, M.; Nooria-Bidgoli, M.; Jahed Armaghani, D.; Khamesi, H. [16] | Predicting surface settlement caused by tunneling | 2016 |

| SVM (Support Vector Machine) | Samui, P. Sitharam, T. [17] | Settlement of shallow foundation on cohesionless soil | 2008 |

| Item | Description |

|---|---|

| Type | Earth pressure balance |

| Supplier | Herrenknecht (Germany) |

| OD/ID | 7.71 m/7.69 m |

| Thrust force | 1154 kN/m2/53,878 kN |

| Cutter head | Dome type, 17-inch cutter, scraper |

| Torque | 10,364–6500 kN-m (α = 22~25) |

| RPM | 3.4 RPM, electric motor type |

| Segment | RC-segment, L1, 500 mm + t300 mm, 7 pieces |

| Muck handling | Muck car + vertical conveyor belt, belt scale |

| Grouting | Upper Section 4 EA, probe drilling (22 holes) |

| Item | Characteristics of Rock Type |

|---|---|

| Residual soil | Sandy gravel, N: 3~50, max size: φ500 mm |

| Weathered rock | Silty core, Cohesion: 31 kPa, φ = 32° |

| Soft rock | Gneiss, RMR: 30~50 |

| Water Level | Approx. GL-7 m |

| Unit weight | 20–21 kN/m2 |

| UCS | 20–110 MPa |

| Permeability | 2.5 × 10−3~2.5 × 10−5 cm/s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.-K.; Song, M.-K.; Lee, S.S. Prediction of Subsidence during TBM Operation in Mixed-Face Ground Conditions from Realtime Monitoring Data. Appl. Sci. 2021, 11, 12130. https://doi.org/10.3390/app112412130

Lee H-K, Song M-K, Lee SS. Prediction of Subsidence during TBM Operation in Mixed-Face Ground Conditions from Realtime Monitoring Data. Applied Sciences. 2021; 11(24):12130. https://doi.org/10.3390/app112412130

Chicago/Turabian StyleLee, Hyun-Koo, Myung-Kyu Song, and Sean Seungwon Lee. 2021. "Prediction of Subsidence during TBM Operation in Mixed-Face Ground Conditions from Realtime Monitoring Data" Applied Sciences 11, no. 24: 12130. https://doi.org/10.3390/app112412130

APA StyleLee, H.-K., Song, M.-K., & Lee, S. S. (2021). Prediction of Subsidence during TBM Operation in Mixed-Face Ground Conditions from Realtime Monitoring Data. Applied Sciences, 11(24), 12130. https://doi.org/10.3390/app112412130