A series of test cases is presented here to attempt to validate the physics included in the PFEM based model for welding and additive manufacturing simulations. The main modeling capabilities needed for such simulations are a thermo-fluid solver that can model the buoyancy and Marangoni effects that drive the convective flow in the melt pool and the phase change effects on momentum and heat equation.

3.1. Buoyancy-Driven Convection in a Square Cavity

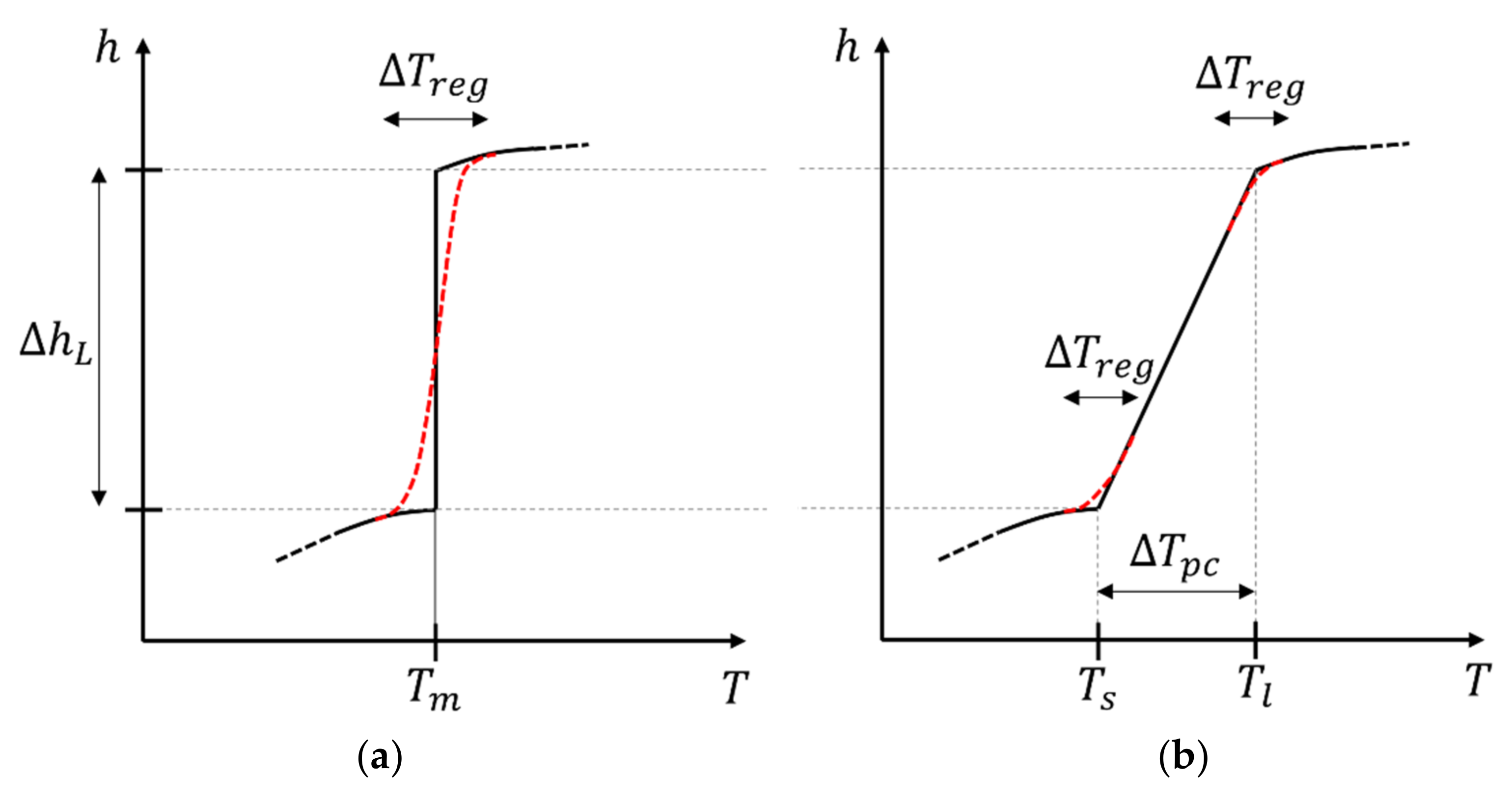

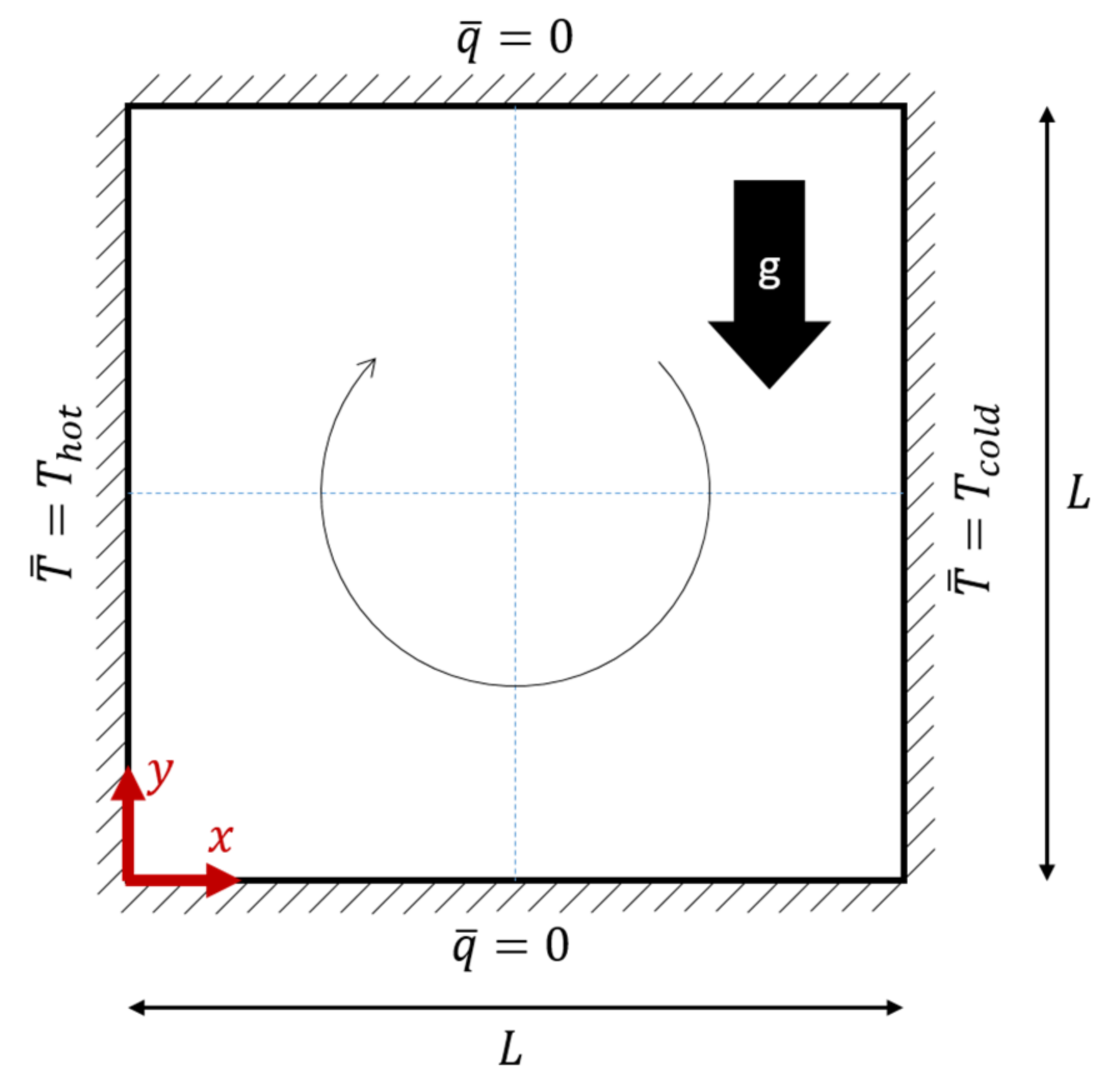

This simple 2D test case contains a square cavity in which a fluid encounters a hot wall on one side and a cold wall on the opposite side, leading to natural convection, as illustrated in

Figure 2. For any choice of material parameters and experimental setup, the resulting flow and the balance between heat conduction and heat convection can be compared using dimensionless numbers, which use the thermal diffusivity, α:

It has the dimension

and characterizes the rate of conductive heat transfer through a medium. The first relevant dimensionless number in this case is the Prandtl number

, which reads

where

is the kinematic viscosity.

describes the ratio between momentum diffusion and thermal diffusion. The second relevant dimensionless number is the Rayleigh number,

, which reads:

where

is the characteristic temperature difference and

is the characteristic length scale of the problem;

describes the ratio between convective heat transfer and conductive heat transfer. Following Aubry et al. [

32], we use an edge length

and a temperature difference

, where the left side is arbitrarily chosen by the authors to be “hot” at

and the right side to be cold at

. The authors have taken these settings from Strada et al. [

37], whom they use as their reference. The dimensionless numbers are given as

and

. To achieve these, we chose

, although the other authors do not state their exact choice and their mesh specifics are also not mentioned. We use a uniform triangular mesh with an average edge length of

, and the time step is set to

.

When using the same

Pr and

Ra, the steady state solutions are expected to match. Aubry et al. [

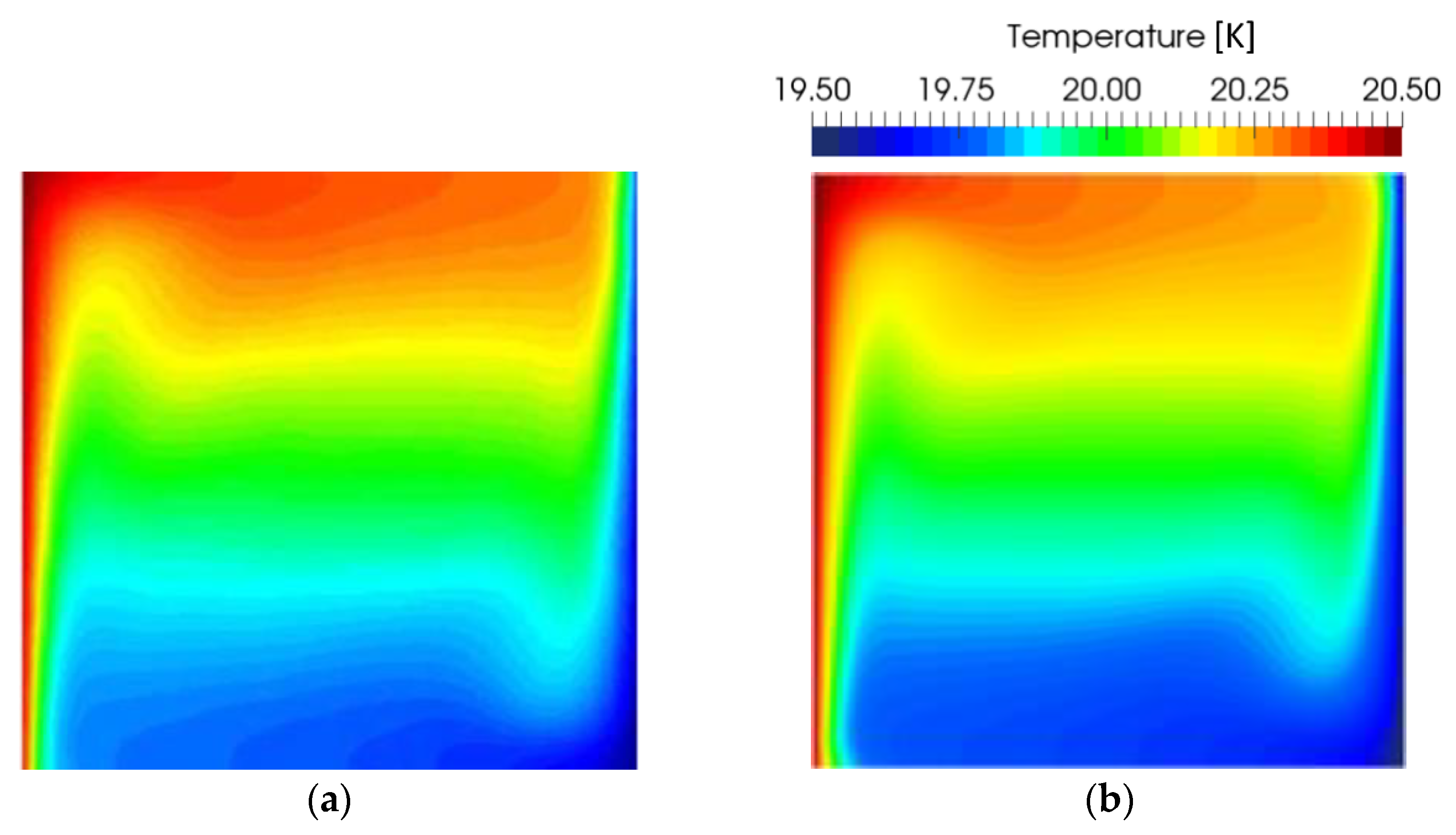

32] reach the steady state solution after a long simulation time of 396 s. In

Figure 3a, good agreement of the temperature distribution can be observed. The color maps may not match exactly, as the color distribution over the range of temperatures is not provided by Aubry et al., but the temperature fields are obviously very similar.

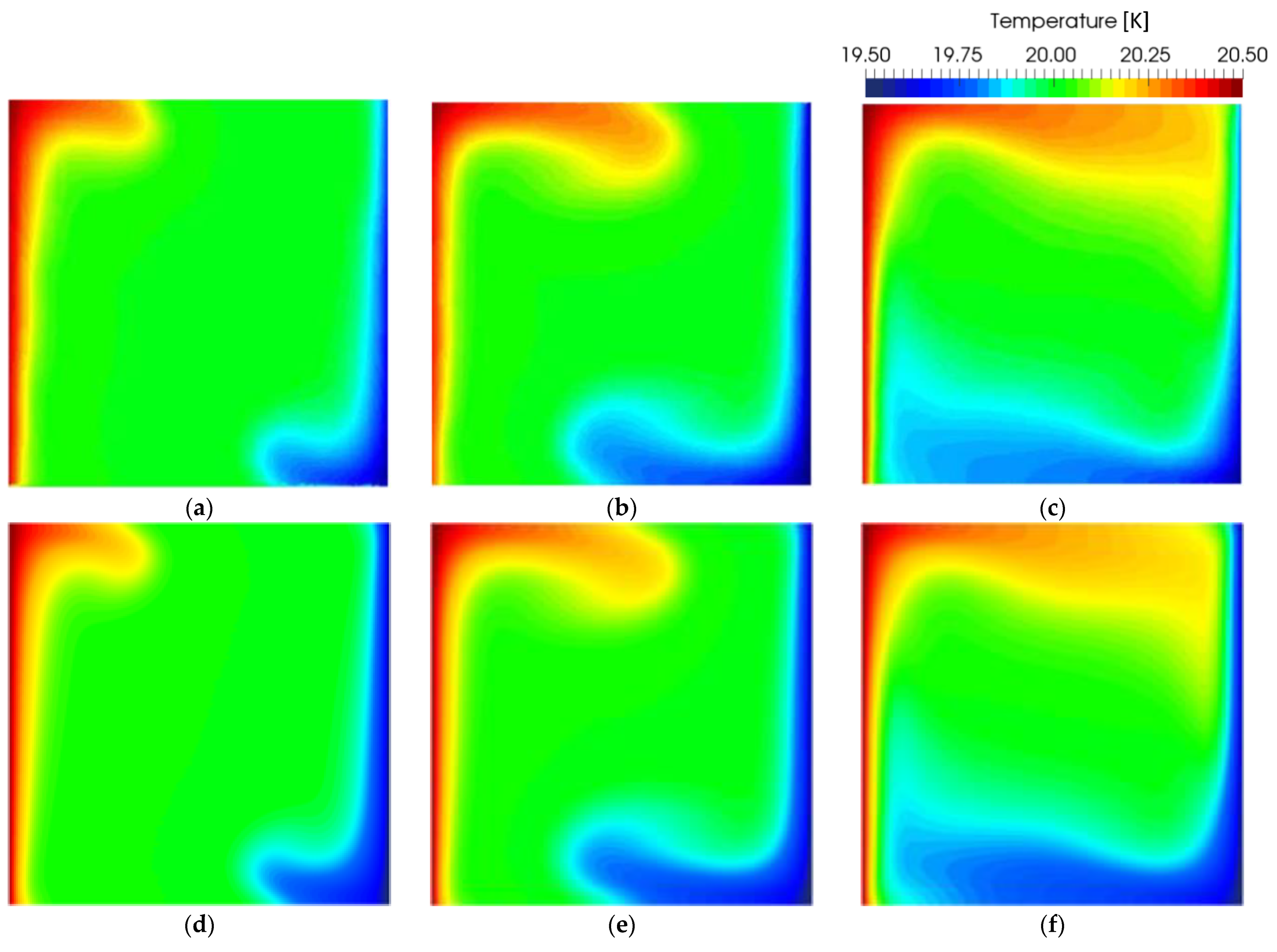

Next, the transient evolution of the temperature field before reaching the steady state is compared in

Figure 4; good agreement during the whole simulation time can be observed. The gradual mixing of cold and hot fluid, along with the developing convective flow are clearly visible and no major differences can be found. It is interesting to note that a different combination of input parameters can produce the same

Pr and

Ra, and therefore the same steady state solution, whereas the evolution over time may be at a different rate. This can be explained by the fact that the input parameters are non-dimensional, while the time is dimensional. The use of a non-dimensionalized time, such as the one discussed in the following section, would be more appropriate. Strada and Heinrich [

37], the reference used by Aubry et al., only features the steady state results; thus, no dimensionless time is required. Also note that Strada and Heinrich define

Ra using

K (instead of the usual α) as the symbol for the thermal diffusivity, which led Aubry et al. to accidentally define

Ra with a

, denoting thermal conductivity, in the place of thermal diffusivity,

K.

An almost identical test case is presented by Marti and Ryzhakov [

12], simulated with their own PFEM code. The quadratic domain still has an edge length of

L = 1 m and a temperature difference of ∆

T = 1 K. The main differences are that the steady state results are compared with the existing literature and that the input variables are changed. Marti and Ryzhakov first show the temperature contour plots, as above, then compare the maximum velocities encountered on the horizontal and vertical centerlines with the works of de Vahl Davis [

38], Corzo et al. [

39] and Sklar et al. [

40]. Distance, time and velocity are non-dimensionalized as follows: non-dimensional position

and

, a non-dimensional time

and non-dimensional velocity

, as explained by Corzo et al. and de Vahl Davis. The other parameters used by Marti and Ryzhakov are

= 1 kg/m

3,

v = 10

−3 m

2/s, α = 10

−3 m

2/s,

g = −10 m/s

2. Furthermore, Marti and Ryzhakov mention using

Pr = 0.71, while the parameters inserted into Equation (38) give

Pr = 1.0, which we use in this work. The comparisons are done using

Ra = 10

4,

Ra = 10

5 and

Ra = 10

6. The uniform triangular mesh has an edge length of

h = 0.015 m, the same as Marti and Ryzhakov, with a time step of ∆

t = 0.5 s, ∆

t = 0.05 s and ∆

t = 0.005 s, respectively, for the different Rayleigh numbers in respect of the condition

CFL =

vmax ∆

t/

h < 1, and results averaged over 25 time steps after reaching the steady state.

Table 1,

Table 2 and

Table 3 show good agreement between our results and those reported in the literature. The differences lie somewhat in the range of the fluctuations between the various results in the literature. The best agreement was expected with Marti and Ryzhakov, as they used the same method and the same mesh. De Vahl Davis and Corzo et al. used different simulation methods, the Finite Difference Method (FDM) and the Finite Volume Method (FVM) respectively, both of which use Eulerian formalism.

The temperature contours obtained were also compared with those shown by Marti and Ryzhakov, with good agreement observed (not shown here).

3.2. Buoyancy and Marangoni-Driven Convection in a Square Cavity

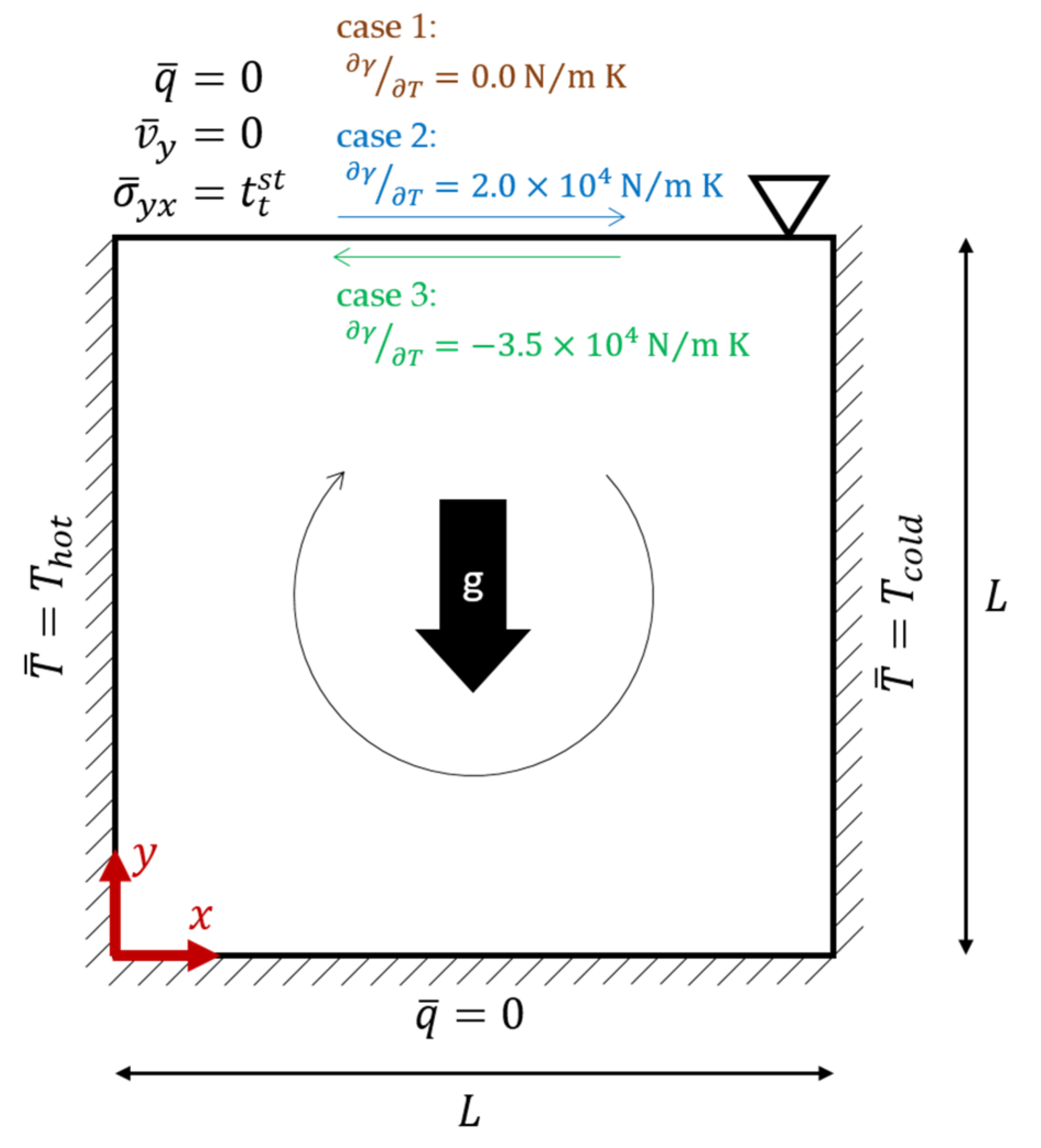

This 2D test case also uses a square cavity with a buoyancy driven flow, as above, but with additional surface tension acting on the top surface, see

Figure 5. Comparisons are done with literature results from Saldi’s PhD thesis from 2012 [

33], who himself uses older results from Bergman and Keller from 1988 as a reference [

34]. Since all the authors use a Eulerian Finite Volume Method, the top surface is assumed to remain flat, limiting the effect of surface tension to the tangential component, which is referred to as the Marangoni effect. Three test cases are investigated; the first one does not include the Marangoni effect, recovering a test case similar to those in the previous section. The second test case includes a negative Marangoni coefficient

, causing the Marangoni effect to push fluid at the surface in the same direction as the circulation caused by the underlying buoyancy-driven convective flow, reinforcing the circulation. The third case uses a positive

, leading to an opposite effect where the surface tension pushes against the underlying buoyancy-driven flow, counteracting the circulation at the surface.

The material data are given in detail by Bergman and Keller, resembling molten aluminum at 660 °C:

= 2385 kg/m

3,

μ = 1.3 × 10

−3 Pa s,

cp = 1080 J/kg K,

= 94.03 W/m K,

βV = 1.17 × 10

−4 K

−1. This gives us

Pr = 0.0149 and

Ra = 4.6 × 10

4. These settings fully describe case 1, where only the buoyancy effect is driving the flow. For the other cases we superimpose the Marangoni effect; thus, the Marangoni number

Ma (sometimes denoted as

Mg to avoid confusion with the Mach number) that describes the relative importance of the Marangoni effect compared to the viscosity is defined as

The Marangoni coefficient is and for case 3. This results in , and for cases 1, 2 and 3, respectively. The cavity has an edge length of and a Temperature difference between cold and hot walls. All results are compared after reaching steady state equilibrium. We use an element size of and a time step of , and for the three cases, respectively, to accommodate the higher local velocities produced by the Marangoni effect. Further refinement of the time step mesh size does not improve the results. Saldi uses a Eulerian FVM approach, and does not state mesh size or time step length. Bergman and Keller use a steady state Eulerian FVM approach with a similar mesh size, but with a refinement near the boundaries.

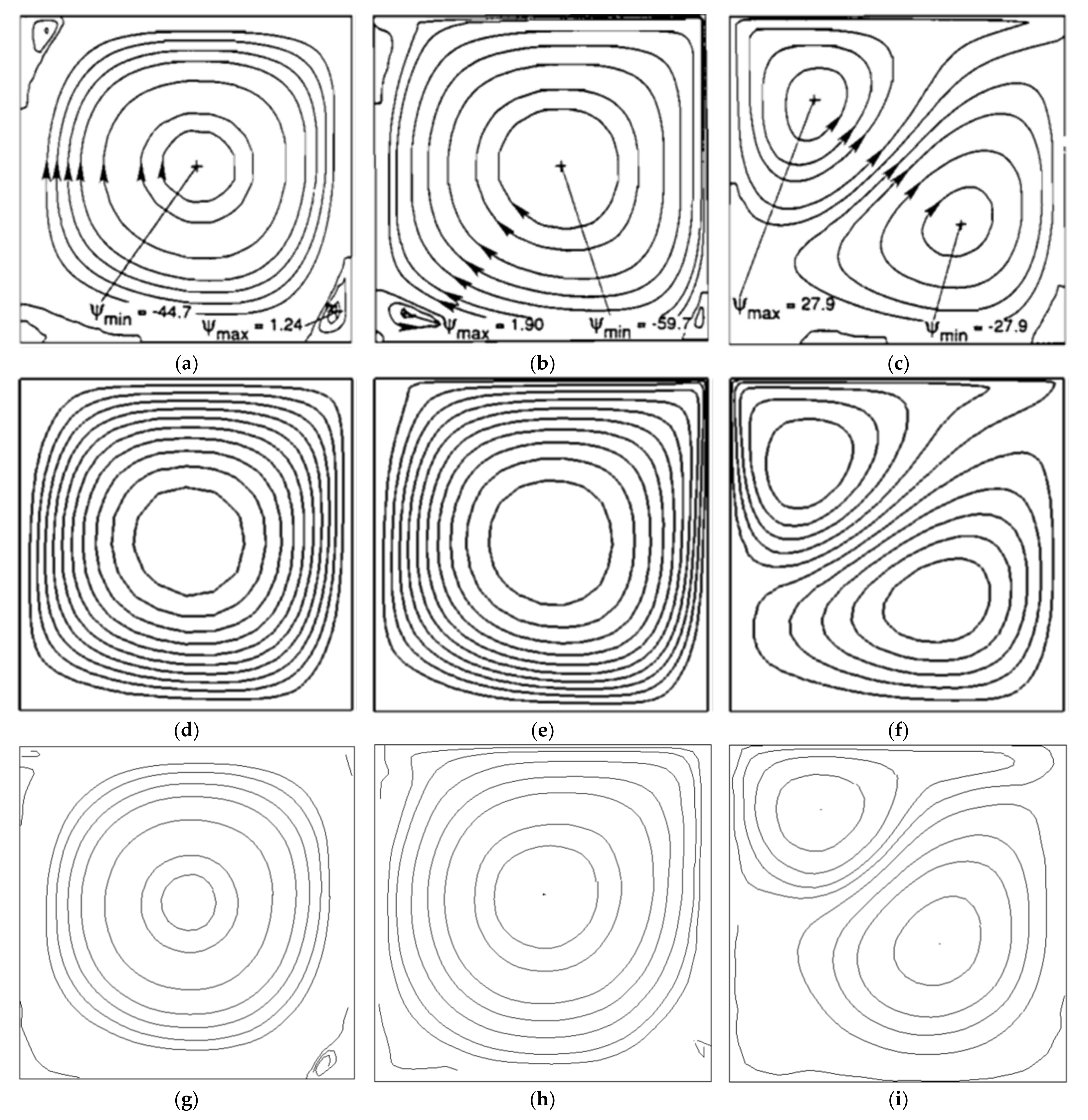

Both Saldi [

33] and Bergman and Keller [

34] compare streamlines that highlight the flow pattern for each case. As we do not have the stream function (see e.g., [

41], p. 14) available in our results, we constructed the streamlines by integrating from a given seed point in space over the velocity vector field. For this approach, the seed points must be chosen by the user, and the resulting streamlines do not necessarily represent the same value of the stream function as given by Bergman and Keller. We chose each seed point at a location that is intersected by the streamlines from Bergman and Keller in an attempt to produce the most qualitatively similar representation of the main flow field. For the recirculation bubbles that can appear in the corners, we freely chose a convenient location for the seed points with the aim of best capturing the flow pattern in the corners. Crucially, these different procedures for obtaining the streamlines introduce some uncertainty when comparing streamlines. The comparison between Bergman and Keller (top), Saldi (middle) and our work (right) can be found in

Figure 6.

The results show good overall agreement, although a few discrepancies can be found as well. For case 1 in

Figure 6a,d,g, the main flow fields are nearly indistinguishable. Small differences can be found with the recirculation bubbles in the corners, and no bubble is found in the bottom left corner at all. Such recirculation bubbles are, however, naturally rather unstable and sensitive to the main flow field. Good agreement regarding the size and position of cells of slow-moving fluid and reversed flow can be seen.

For case 2 in

Figure 6b,e,h, the effect of the surface tension enhancing the underlying buoyancy-driven circulation can be seen. The streamlines reach much further into the top right corner before changing direction, and the streamlines there also come closer together. Otherwise, the flow pattern is largely the same as in case 1. The agreement is better between Bergman and Keller (b) and Saldi (e) than with our results (h). Again, we find slightly different recirculation bubbles in the corners, and the vortex center of the main circulation is more centered in (h) than in (b) and (e).

For case 3, in

Figure 6c,f, the surface tension can clearly be seen counteracting the buoyancy, as the flow pattern is neatly divided into two distinct vortices. A line of zero vorticity, where the two vortices meet, would occur close to the diagonal between bottom left and top right corner. This flow pattern is found to be sensitive to

Ra and

Ma, such that a small change in input parameters would quickly favor one of the two effects over the other, quickly leading to one of the main vortices to dominate over the other. It is possible that this delicate balance was deliberately chosen by Bergman and Keller to emphasize the importance of the Marangoni effect, as they argue that the Marangoni effect has been largely neglected in applications where convective flows in liquid metals are of importance. The agreement of all three results is less good than before, and the size and position of the two distinct vortices is slightly different in each case. Given the delicate balance that causes this flow pattern, our result agrees well with the literature, as the differences are very minor.

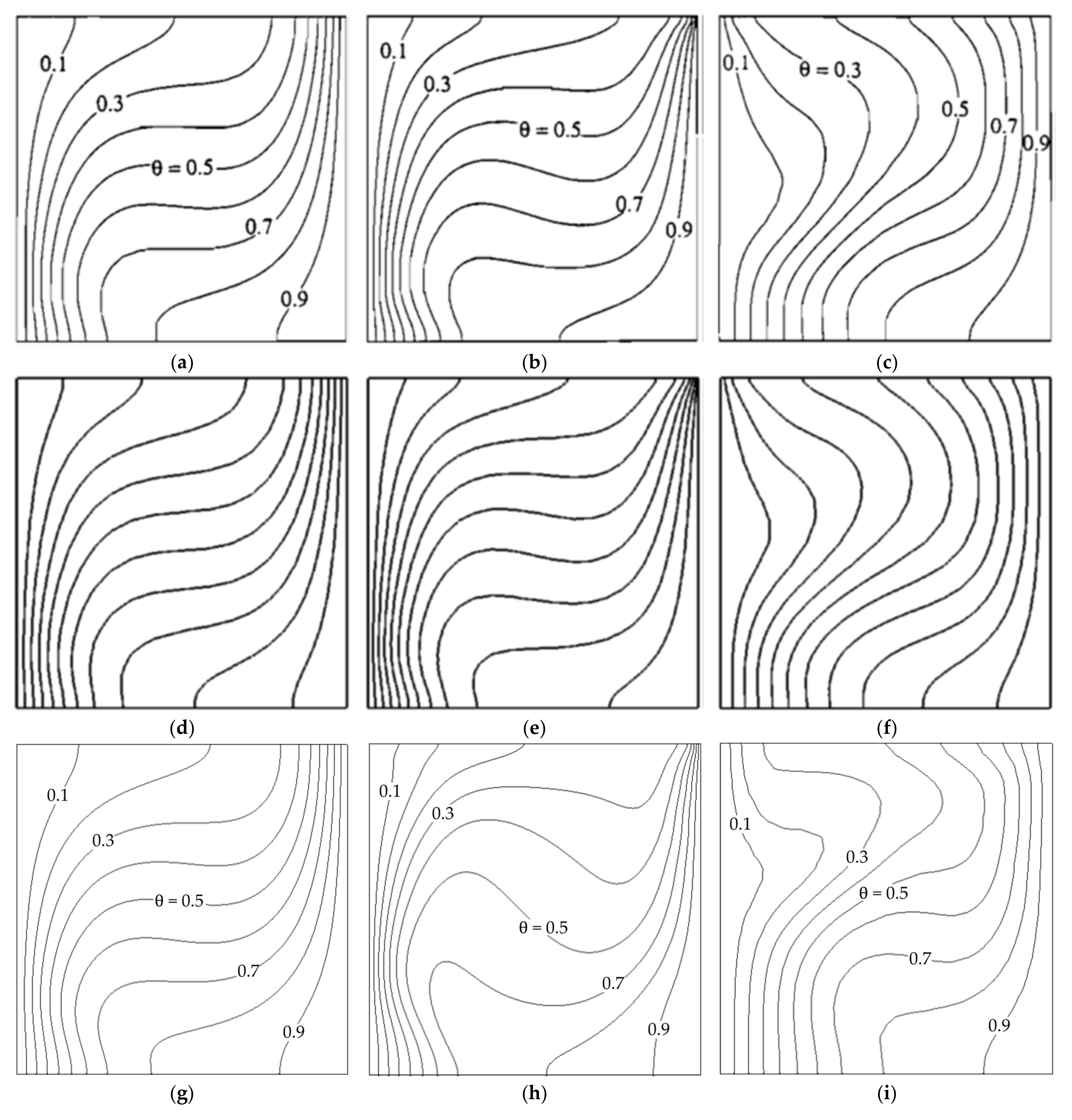

Both Saldi [

33] and Bergman and Keller [

34] also present plots of isotherms using a non-dimensionalized temperature

θ = (

T −

Tmin)/∆

T with a spacing of 0.1. The agreement between all three publications is good. Comparing Bergman and Keller’s result in the top row of

Figure 7 with Saldi’s in the middle and ours on the bottom row, a similar tendency as in the previous comparison can be observed: qualitatively a good agreement when looking at the overall appearance of the plots; the spacing of the isotherms in most cases is especially well captured, indicating that the important temperature gradients are well-captured. On the other hand, several discrepancies can be found for cases 2 and 3 between literature results in

Figure 7b,e and

Figure 7c,f and our results

Figure 7h,i respectively. In both cases 2 and 3, the isotherms appear more twisted in a clockwise direction in the areas where the convective flow is strongest. Unfortunately, no experimental results that can validate the simulation results from the literature could be found, which leaves some uncertainty regarding any of the results presented.

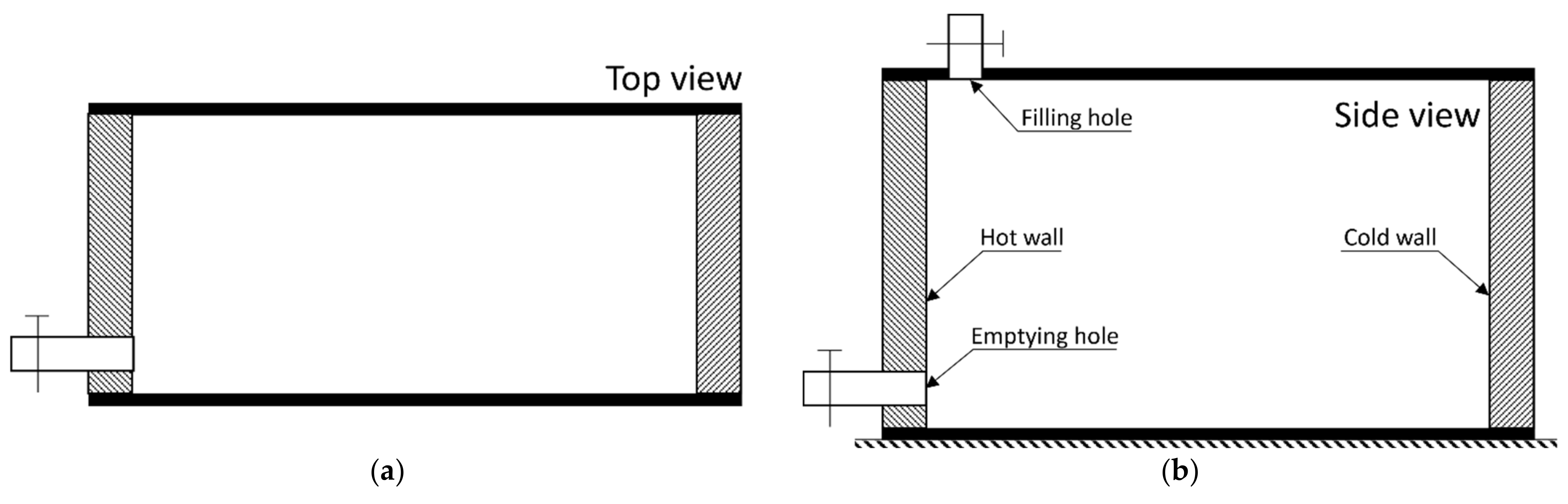

3.3. Melting of a Block of Gallium

A rectangular block of solid gallium slightly below the melting point is in a closed box. The block is exposed to a hot wall on the left, which is of constant temperature significantly above the melting point. The gallium then progressively melts from left to right. This test case combines a buoyancy-driven convective flow and the modelling of phase change, which affects momentum equation and heat. All of these effects are strongly coupled, leading to an interesting test case. A schematic is provided in

Figure 8.

This test case is based on experiments originally conducted by Gau and Viskanta in 1986 [

35]. The advantage of choosing gallium is that the melting point,

Tm = 302.78 K, is near room temperature, greatly simplifying the experimental setup. Likewise, a pure metal exhibits a sharp melting front, which is easier to measure. The remaining material parameters are

= 6093 kg/m

3,

μ = 1.81 × 10

−3 Pa s,

cp = 381.5 J/kg K,

= 32.0 W/m K,

βV = 1.2 × 10

−4 K

−1 and ∆

hL = 8,016,021 J/kg. The hot wall on the left has

Thot = 311.0 K, and the cold wall on the right has

Tcold = 301.3 K, which is also used as initial temperature

T0 from the entire domain. Note that the initial temperature is very close to the melting point. The experimental setup is shown in

Figure 9. The cavity can be adjusted to have different dimensions, resulting in different aspect ratios

A =

H/

W, where

H = 0.0635 m and

W = 0.0889 m are typically used for the height and width of the cavity, respectively, to arrive at an aspect ratio of

A = 0.714. This aspect ratio is used in the simulations described below, and other aspect ratios mentioned by Gau and Viskanta are ignored in this work.

The process of obtaining the position of the melting front in the experiment is not simple, as gallium is not visually transparent. First, melted gallium is poured into the cavity through the opening at the top, which is sealed afterwards. Then, the entire cavity is cooled down to the initial condition, which is a fixed temperature slightly below the melting point. At this stage, the gallium has completely solidified in the cavity. The experiment begins by pushing fluid of a constant given temperature through the side walls, the left one hot and the right one cold; this way, the side walls maintain a constant temperature throughout the entire experiment. As time passes, the gallium melts near the hot wall and convective flow sets in. After a given time, the experiment is interrupted and the liquid quickly evacuated from the cavity, leaving only the remaining solid part of the gallium block behind. From this block, the melting front is traced and photographed. For each time duration, the experiment is repeated from the beginning to finally reconstruct the progression of the melting front over time. This way, the melting front position is obtained for nine different time marks (2, 3, 6, 8, 10, 12.5, 15, 17 and 19 min). It is not disclosed if the experiment was repeated several times and the results averaged for each time mark. It is also not discussed in detail how the experiment could be flawed. Potential issues can arise from:

3D effects that are not represented in the 2D curves of the melting front;

Shrinkage after filling the cavity with liquid gallium and letting it solidify, leading to potential loss of contact between the gallium and the walls;

Heat losses or parasitic heat conduction in the walls;

Possible transient temperature evolution in the “constant temperature walls” upon switching on the constant temperature liquid feeding system;

Possible continuation of the melting while the liquid is evacuated too slowly, leading to sloshing potentially affecting the roughness of the resulting surface;

Possible errors from tracing and photography, not explained in detail.

Another large uncertainty is introduced through the strong anisotropy of the thermal conduction of solid gallium. This issue is discussed in the work Gau and Viskanta in the context of the inverse experiment, where the gallium is initially liquid and then solidified on a constant temperature cold wall, as opposed to the melting of solid gallium on a hot wall, which is the topic of this work. In the solidification experiment, the physical behavior has been found to be highly dependent on the crystallography of the freshly solidified gallium, introducing significant variability into the position of the solidification front. In the melting experiment, the authors explain that the anisotropy of the solid gallium plays a lesser role, as the physical behavior is dominated by the heat transfer in the liquid, which is plausible. However, a quantitative evaluation of the variability of the experiment should have been included. It is also not clear if the presented results were obtained through several repetitions and subsequent averaging.

In 1988, Brent et al. [

36] attempted to match the experimental results with a Eulerian Finite Volume Method approach that used an extremely coarse mesh by today’s standards. The latent heat absorption was accounted for using an iterative nodal enthalpy formulation that also works on coarse, fixed grids. The authors point out that this scheme creates a diffuse phase change region rather than a sharp front. The momentum equations are modified for the solid using the same Carman–Kozeny equation for porous media as in

Section 2.5. This combination of nodal enthalpy with an iterative scheme for the phase change and the porosity model for the solid is called the enthalpy–porosity approach in their work. The authors model the experiment as closely as possible, using the same material properties and a fixed rectangular domain with an aspect ratio

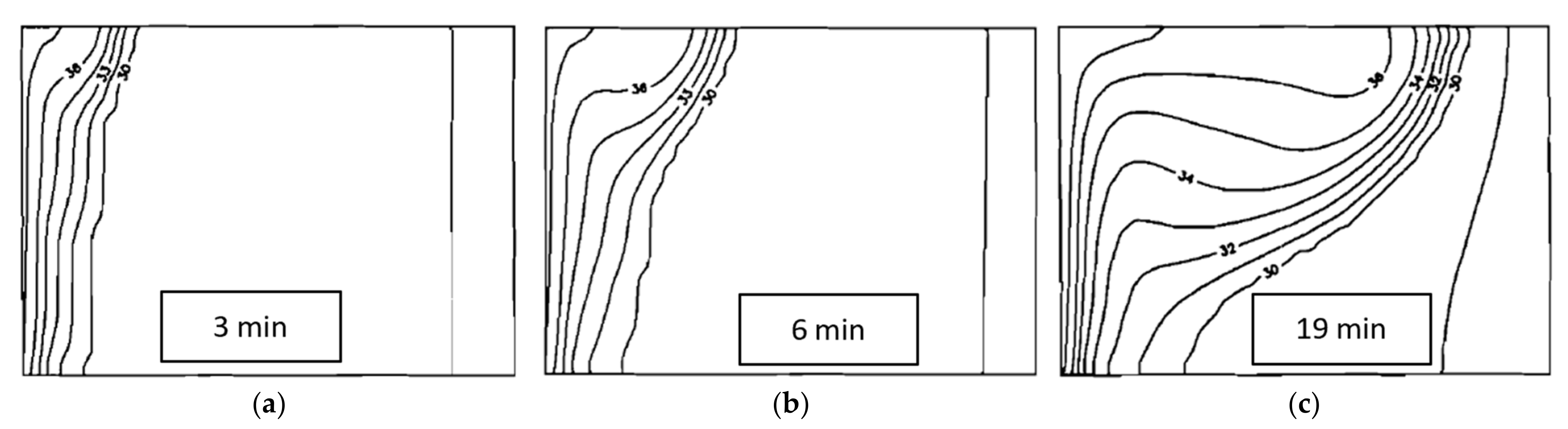

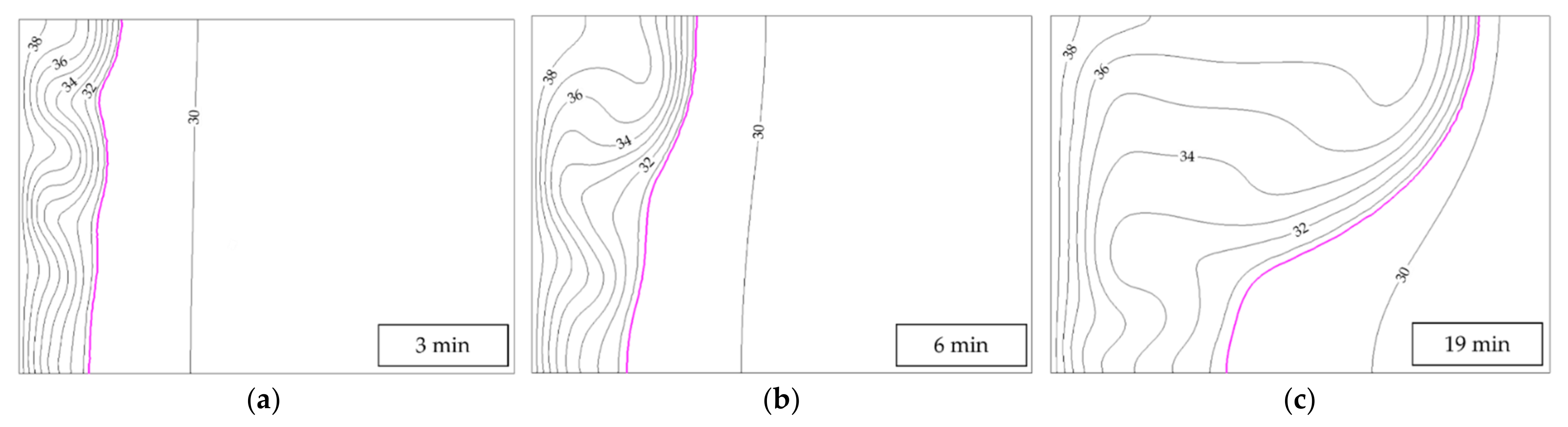

A = 0.714. The boundary conditions at all walls are no-slip conditions. The authors provide results on streamlining and temperature contour plots for four time marks (3, 6, 10, 19 min) as well as the melting front position for all nine time marks, as was done for this experiment.

More recently, Saldi [

33] also used a Eulerian Finite Volume Method approach with the same Carman–Kozeny equation to freeze the fluid’s motion as in

Section 2.5. For the latent heat, Saldi uses a separate source term calculated using an iterative scheme similar to the one used by Brent et al. [

36]. Saldi’s work unfortunately does not state what numerical parameters (such as time step size, mesh size or residual target) were used. It is also not clear which type of boundary conditions were used on the walls.

The latest research publications that feature this test case tend to use it as a validation step. Unfortunately, this means that these publications provide neither an exhaustive description of the setup, nor an in-depth discussion of the results. We have picked two recent publications that highlight the variability of numerical results. First, Tiari et al. 2021 [

42], who use the commercial FVM fluid dynamics code Ansys, with a mesh resolution between 12,500 and 50,000 elements. Secondly, Sharma et al. 2021 [

43], who use the commercial (Eulerian) FEM code COMSOL. The equations to be solved are clearly described, but no further details about the simulation setup are given in either reference.

Our simulation setup is shown in

Figure 8. Several mesh densities were tested to determine the required mesh resolution, as further discussed below. It was found that an initial mesh with 61 × 85 = 5185 nodes and 10′080 triangular elements is sufficiently fine to adequately capture the main features of the solution. Further refinement does not improve the results. A constant time step of ∆

t = 0.02 s was used, which requires 57,000 time steps to complete 19 min of real time. The normalized residuals for momentum and heat equation must reach a threshold of

. The width of the regularization was chosen to be ∆

Tpc = 0.4 K, which is a close approximation of the step function, although not the smallest value that we could achieve before encountering convergence issues. The results shown below were obtained with an adaptive mesh refinement, where the regions of the mesh that are solid and far from the melting front were allowed to be coarsened by a factor of ten.

The top boundary was originally modelled with a no-slip boundary condition, the same as all other walls. This was specifically described by Brent et al., whereas other authors do not explicitly mention it. Alternatively, we repeated the simulation with a free slip boundary condition at the top. This choice is discussed below.

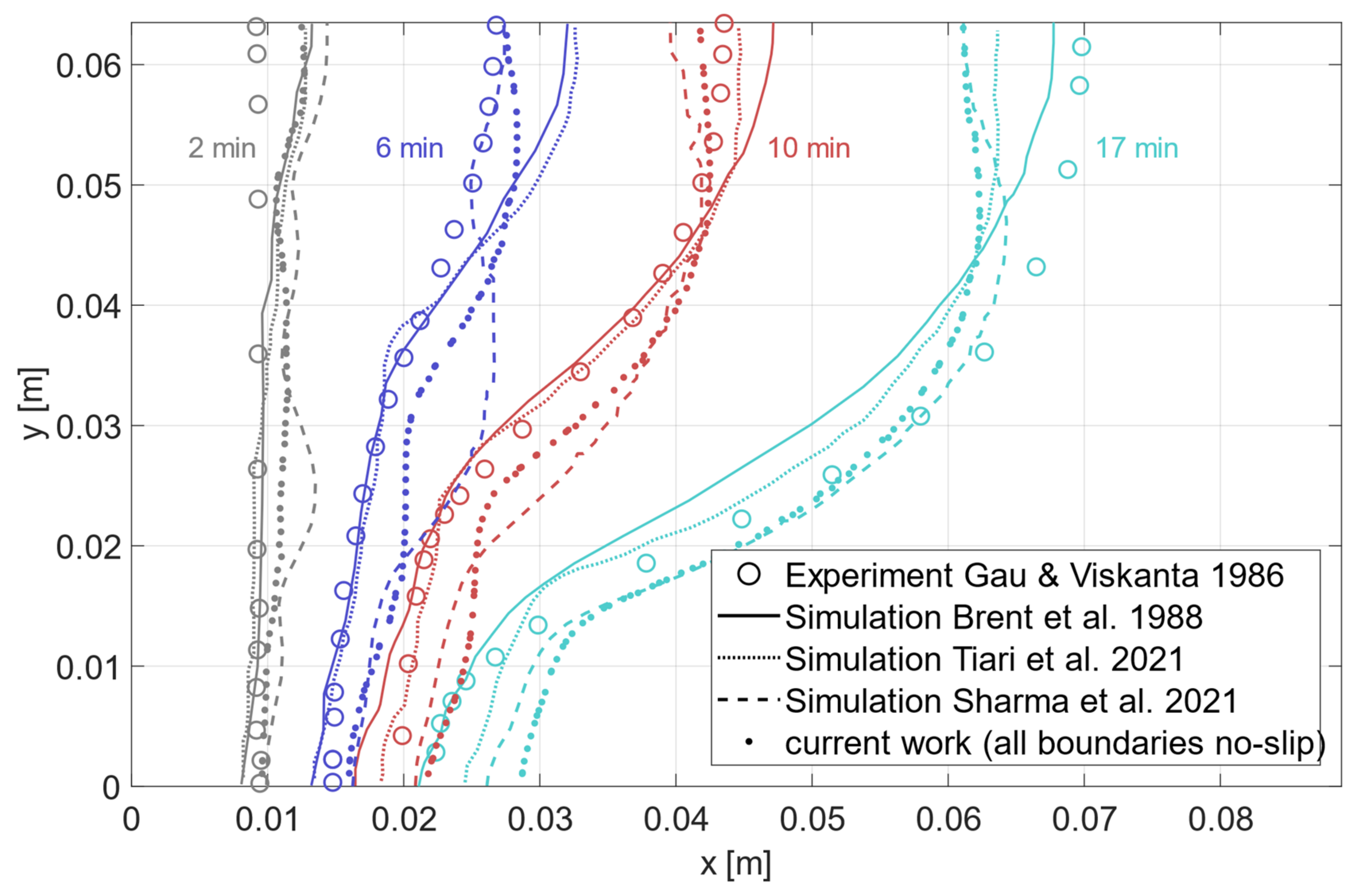

A comparison of the position of the melting front at four time instances with the original no-slip boundaries is found in

Figure 10. None of the methods agree perfectly with the experiments by Gau and Viskanta, but all show at least the same overall behavior: The melting front is faster near the top, as the heat transfer is convection-dominated there. This effect becomes more pronounced over time. Conversely, the bottom advances considerably more slowly due to the reduced influence of the heat convection compared to heat conduction, which dominates there. These effects combine to produce the curved shape of the melting front.

Evidently, this creates a shape of the curve that does not agree well with the experiments. One finds a backwards curved front near the top boundary that is not observed in the experiments. When instead switching to a free slip boundary at the top, the results seem to agree better with the experiments, as shown in

Figure 11. With the original no-slip condition, the advancement of the front is slowed near the top surface. A hypothetical explanation regarding the experimental results relies on the strong assumption that the top surface of the liquid gallium may not be in contact with the casing during the experiment due to shrinkage. We cannot know if this was the case during the experiments; however, the possibility persists, and our results improve noticeably with this boundary condition. An alternative justification could be a thin boundary layer that is best modelled by a free slip condition; however, assuming a laminar flow, the mesh that we use seems to be sufficiently fine. More work is needed to confirm or reject this assumption. We also see this shape in the results by Saldi [

33] and Brent et al. [

36], although there is no reason to assume that a free slip condition was used at the top boundary.

In general, we observe the same overall behavior in all cases: At the 2-min mark, all simulation results seem to have the same tendency of a rather straight vertical melting front that exhibits a slight shift to the right at the very top. This effect is not observed in the experiments. After 6 min, when the problem transitions from conduction-dominated to convection-dominated, the greatest dispersion of results is observed. While the experiments start to show the effect of the convective heat transfer in the top half of the domain, where the front position is slightly shifted to the right, the simulations all tend to overestimate the advancement of the melting front. At later time instances (10, 15, 17, 19 min) all simulation results agree much better with the experimental result, as the curves have the more or less correct shape and advancement in the x-direction. This can be explained by the stable vortex structure that has formed at these times, as discussed in following paragraphs.

Some explanations for the above observations can be drawn from a more detailed look at the velocity and temperature field. No such information is provided in the experimental work of Gau and Viskanta [

35], and details provided about the simulation results of Saldi [

33] and Brent et al. [

36] are scarce. Tiari et al. [

42] and Sharma et al. [

43] do not provide any deeper insight into the velocity and temperature fields. The flow field at the beginning is characterized by a narrow vertical column of fluid between the hot left wall and the comparably cold melting front, which is advancing evenly towards the right. This column of fluid, with its large temperature gradient, immediately begins to develop a circulation driven by buoyancy. The circulation forms into several separate circulation cells or vortices. When the width increases over time as more material is continuously melted, the size of the vortices increases, which means that the number of vortices that can fit in the height of the fluid column must decrease over time; this process thus begins with many small vortices and develops into few large vortices.

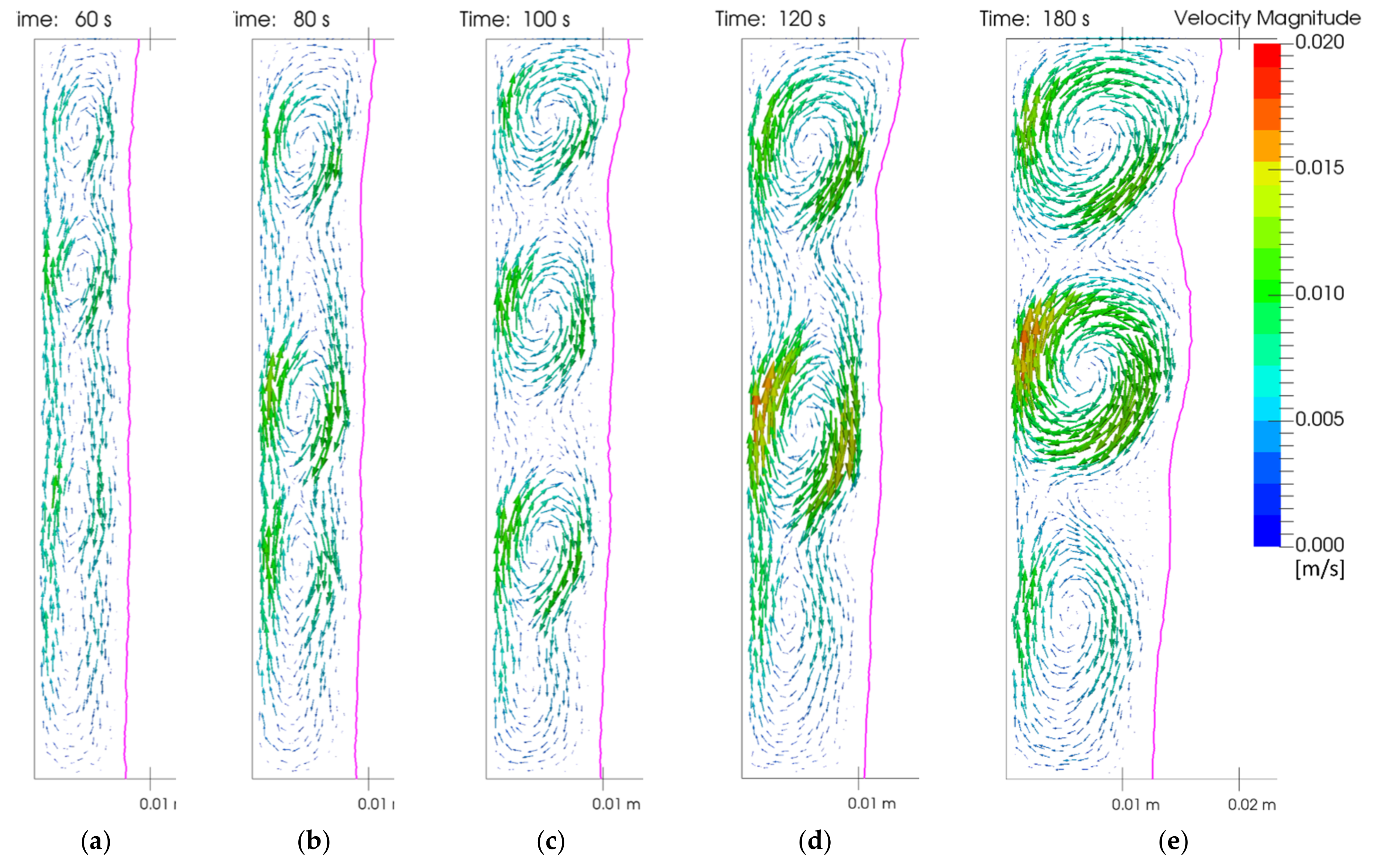

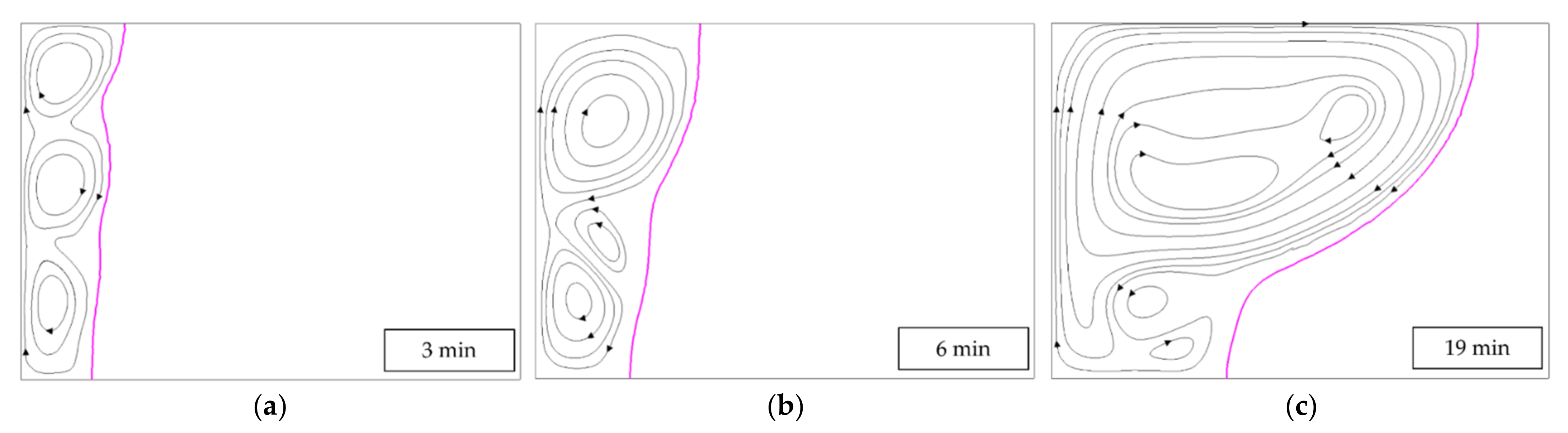

The development of the vortex structure over time can be analyzed using

Figure 12. It is at around 60 s (a) that the vortices establish themselves for the first time, in this case three distinct vortices and three transition regions where the fluid motion is less pronounced. Shortly after, at 80 s (b), the dominant vortices are found to be more compact and more round, creating more space at the bottom, where a fourth vortex is in the process of establishing itself. Before it can fully develop, the entire flow field collapses and two dominant vortices emerge after 100 s (c). Again, the vortices grow more compact, faster and more circular, allowing a weak vortex at the bottom to grow into a fully developed one, as apparent after 120 s (d). This flow structure gains further momentum and stabilizes itself at 180 s (e), before it begins collapsing after 240 s (f), where a completely different flow field has emerged. In the transition between 180 s and 240 s, the two strong vortices at the top have merged temporarily into one vortex that shortly afterward gives rise to another weak vortex, which can be seen in (f). From there on, the final more stable flow field develops, as the strong vortex in the middle becomes more and more dominant, as evident in (g) and (h). Note that all vortices literally carve concave cavities into the remaining solid over time. As a result, the phase front is never perfectly straight and constantly evolves in a curving fashion according to the flow pattern. Conversely, the only reason the front remains mostly straight for so long in the beginning is because the vortices shift around, collapse and reappear so vigorously and frequently that no vortex ever stays in one position for long, therefore not getting the time to carve deeper into the solid.

This process of vortex formation and collapse between 1 min and 5 min is found to be strongly mesh-dependent, as each slight modification can produce a very different evolution of the flow field. There is no tendency that a mesh refinement necessarily converges to some sort of final result. However, for the flow field after 5 min when the main vortex has established itself, mesh dependence is no longer observed. As for the effect on the position of the melting front shown in

Figure 10, there is a delay of 1–2 min after a given vortex pattern has established itself. This explains the discrepancies at the 6 min mark, as the curve in

Figure 10 depends on the vortex configuration at 4–6 min.

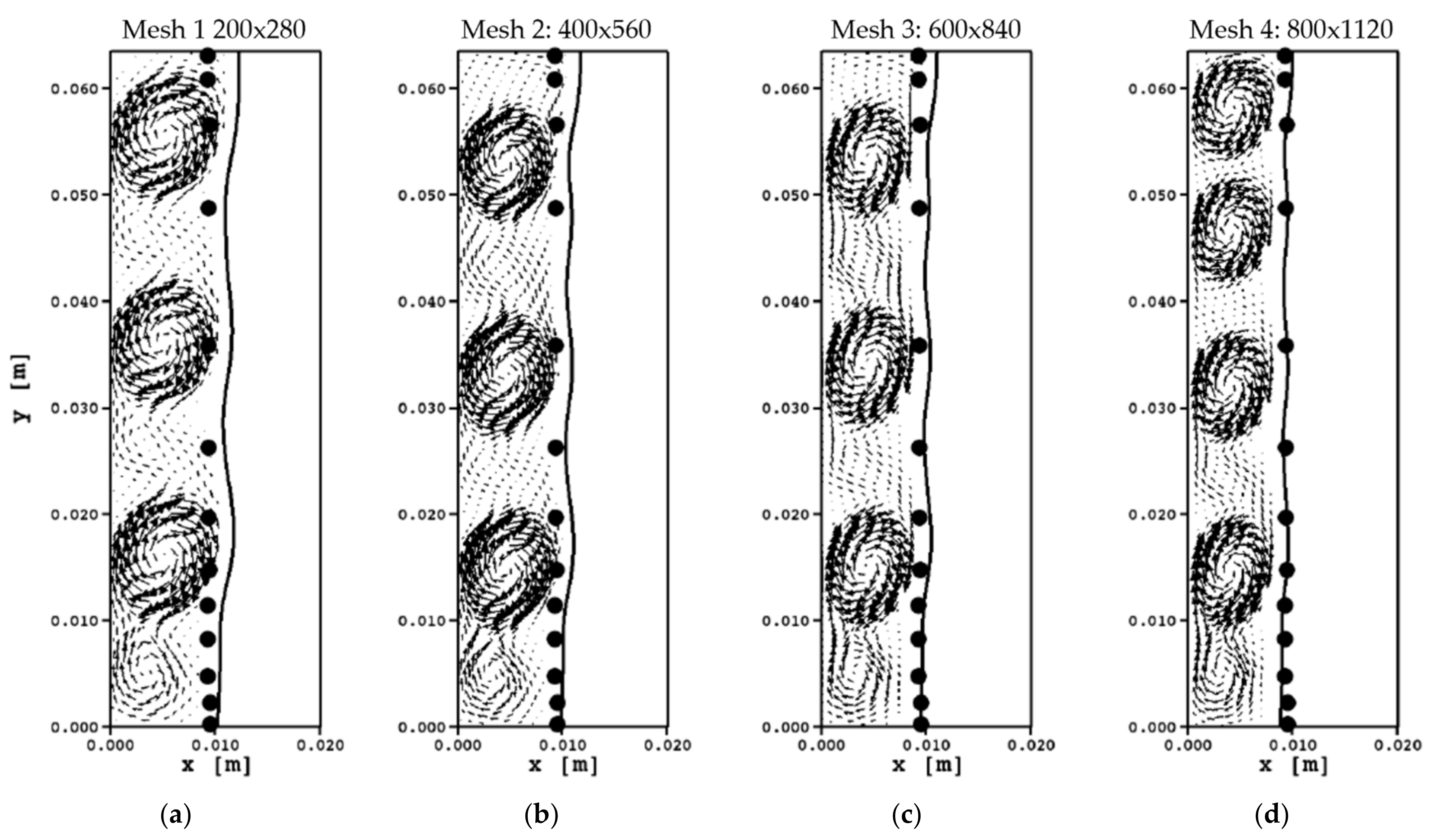

When directly comparing the flow field at the 2 min mark in

Figure 12d to Saldi’s vector plots in

Figure 13, one can see that the best match is obtained with the coarse mesh in

Figure 13a. This may not be surprising at first, as the presented results are obtained on a mesh that is coarser than any of the ones used by Saldi. However, from the evolution over time in

Figure 12 it becomes apparent that choosing a snapshot at one single time instance does not describe the flow very well due to how rapidly the flow field changes. Whether Saldi’s solution features the same rapid and chaotic development of the vortex structure over time cannot be deduced from the single snapshot that is provided.

Saldi’s plots are instead intended to show the mesh dependence of the early solution. Upon further refinement, the flow field changes completely. Instead of 3 well developed vortices, the fine mesh in

Figure 13d produces 4 vortices. The effect of this is an even straighter phase front as with the coarser mesh, which, as pointed out by Saldi, agrees better with the experiments (black circles). However, for the results in

Figure 10 Saldi seems to use one of the coarser meshes (

Figure 13a–c or even coarser), since the melting front at the 2-min mark in

Figure 10 is curvy and shifted slightly to the right. Brent et al. [

36] use an even coarser mesh of 42 × 32 cells, which is not sufficient to resolve the vortex structure found in the other simulations. In fact, there seems to be only one vortex that covers the entire liquid region at all times in

Figure 14. Unfortunately, a direct comparison with Saldi is not possible, as Saldi only provides details about the flow field at 2 min, while Brent et al. provide details for 3 min and later (

Figure 14a). Nevertheless, it can be clearly concluded that the extremely coarse mesh does not resolve the physics of the flow well. It is also remarkable that Brent et al. seem to generally produce rather small velocity gradients, which we do not observe (see

Figure 15). Our streamlines also show steeper gradients and relatively large vortex centers.

Likewise, in the results of Brent et al. the isotherms in

Figure 16 reflect the smoothness of the flow field, as they are not strongly twisted or curved. Our results clearly show the influence of the flow on the temperature field, as isotherms are twisted by the vortices and re-circulation bubbles (

Figure 17).

In summary, neither the streamlines nor the isotherms agree well. The explanation is that the simulations by Brent et al. use such a coarse mesh that all the details of the complex flow field are smeared out or not captured at all. Note that the streamlines of our results are obtained by integrating over the velocity field from freely chosen seed points. This leaves some uncertainty when comparing velocity gradients. Nonetheless, the overall flow pattern and vortex structure can be reliably compared.

While some minor differences in the results remain, the overall behavior of the melting of Gallium is well-captured. The PFEM-based method can run a simulation featuring complex physics without stability issues, even over a long simulation time. The agreement with other simulation methods has been shown to be good. Future work should explore the effects of further mesh refinement, which may require better optimization of the simulation code to counteract the quickly-increasing computational cost.