Computational Modeling of Passive and Active Cooling Methods to Improve PV Panels Efficiency

Abstract

1. Introduction

2. Modeling and Computational Details

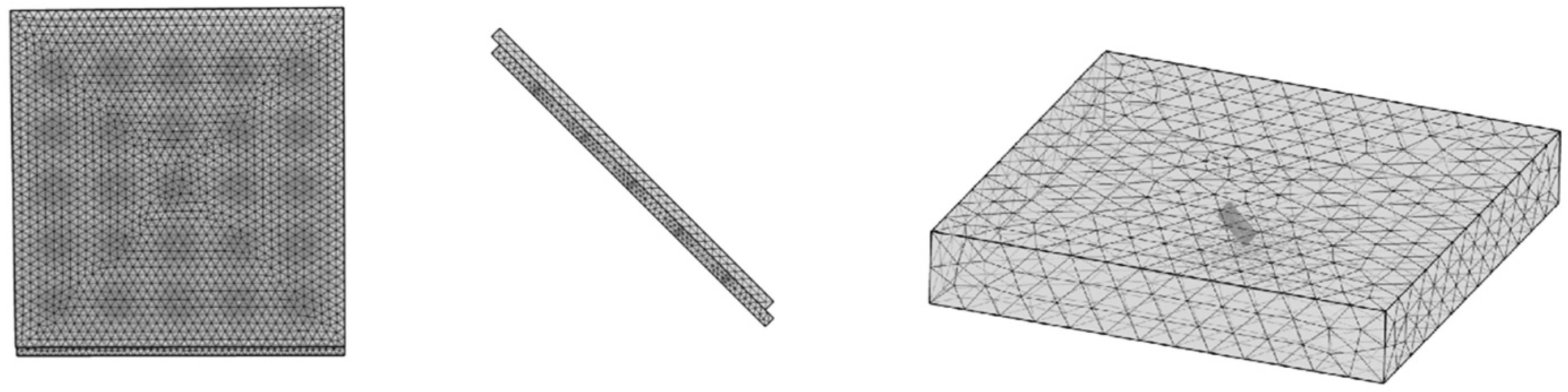

2.1. Modeling of the PV Panel

2.2. Description of the Physical Processes

2.2.1. Heat Transfer

2.2.2. Surface-to-Surface Radiation

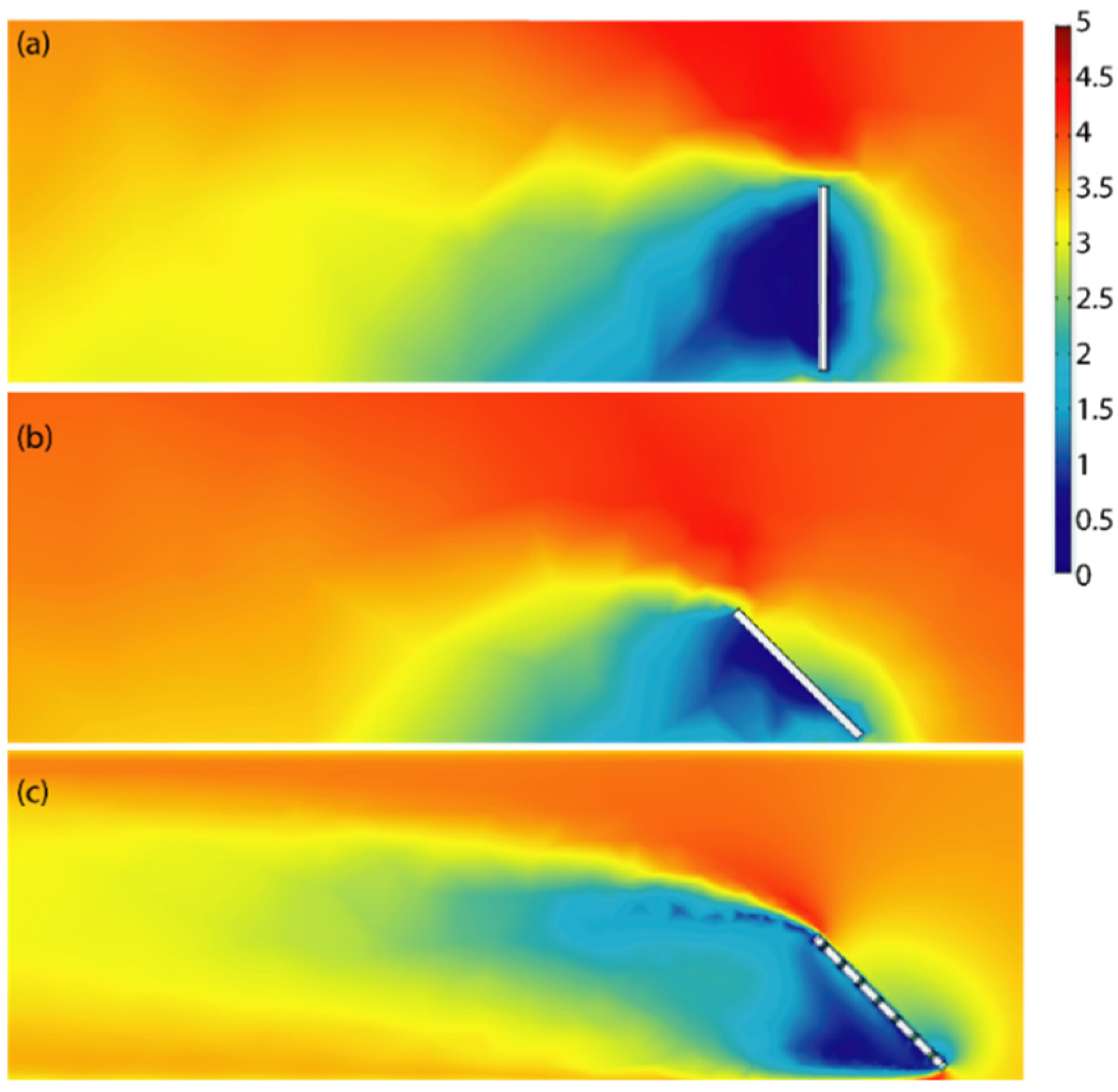

2.2.3. Turbulent Fluid Flow

2.2.4. RANS Turbulence Model

2.2.5. Photovoltaic Panel Equation

3. Results and Discussion

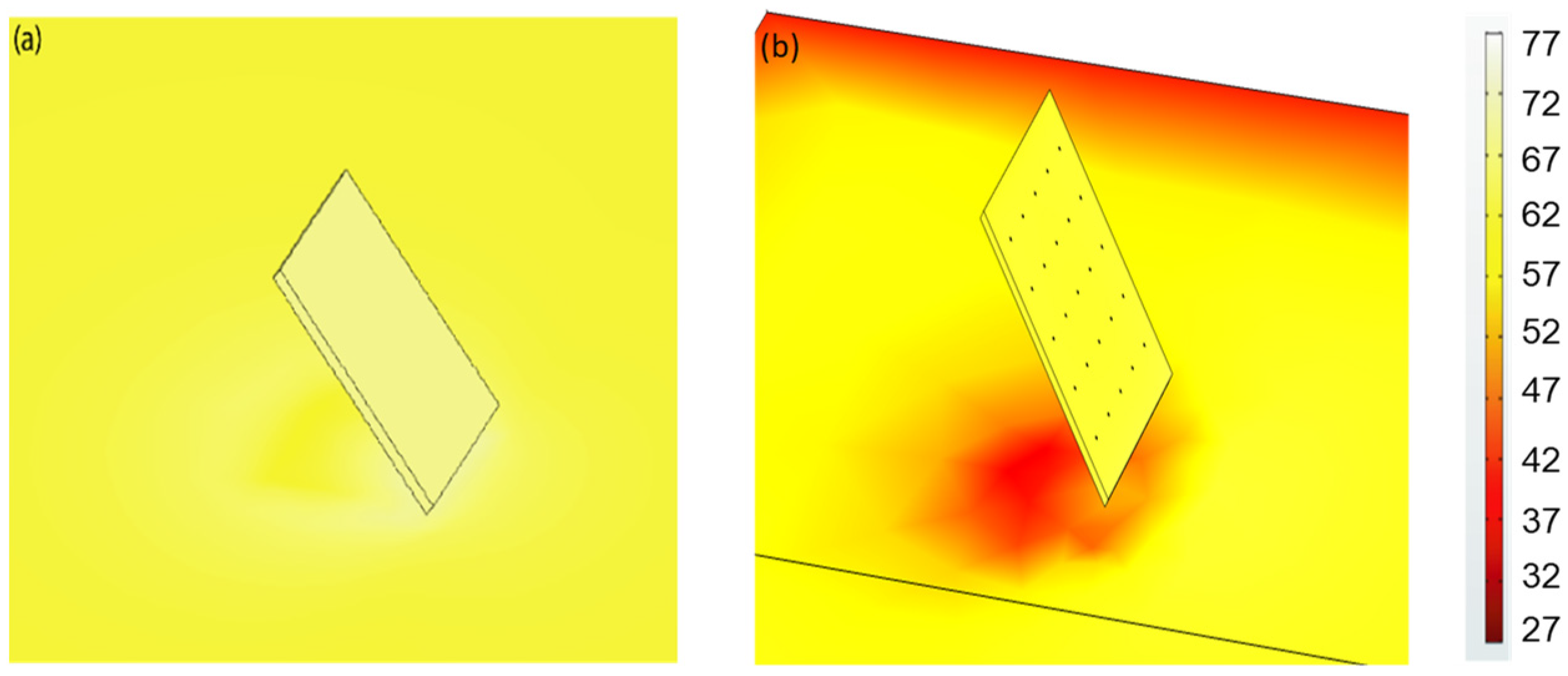

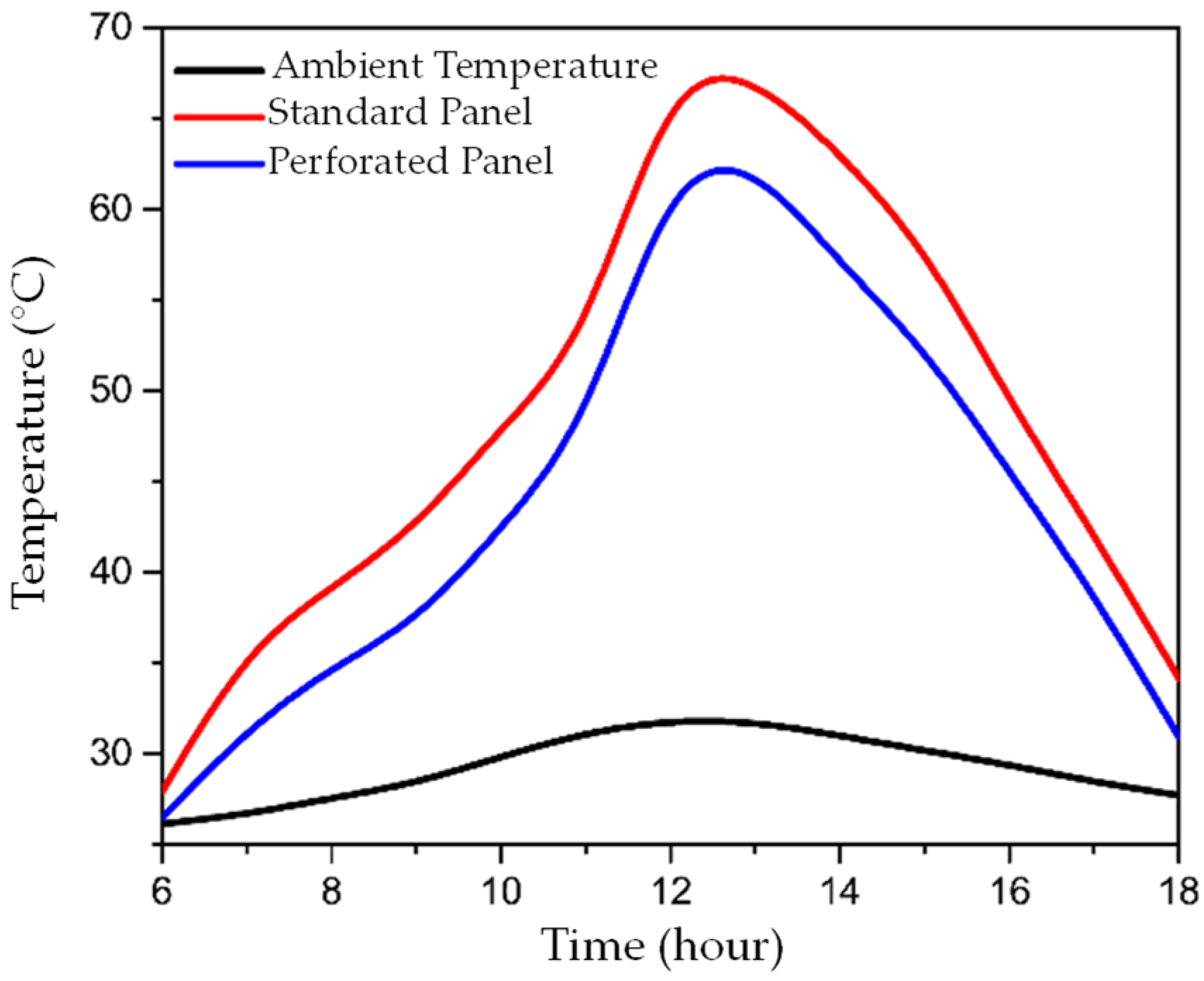

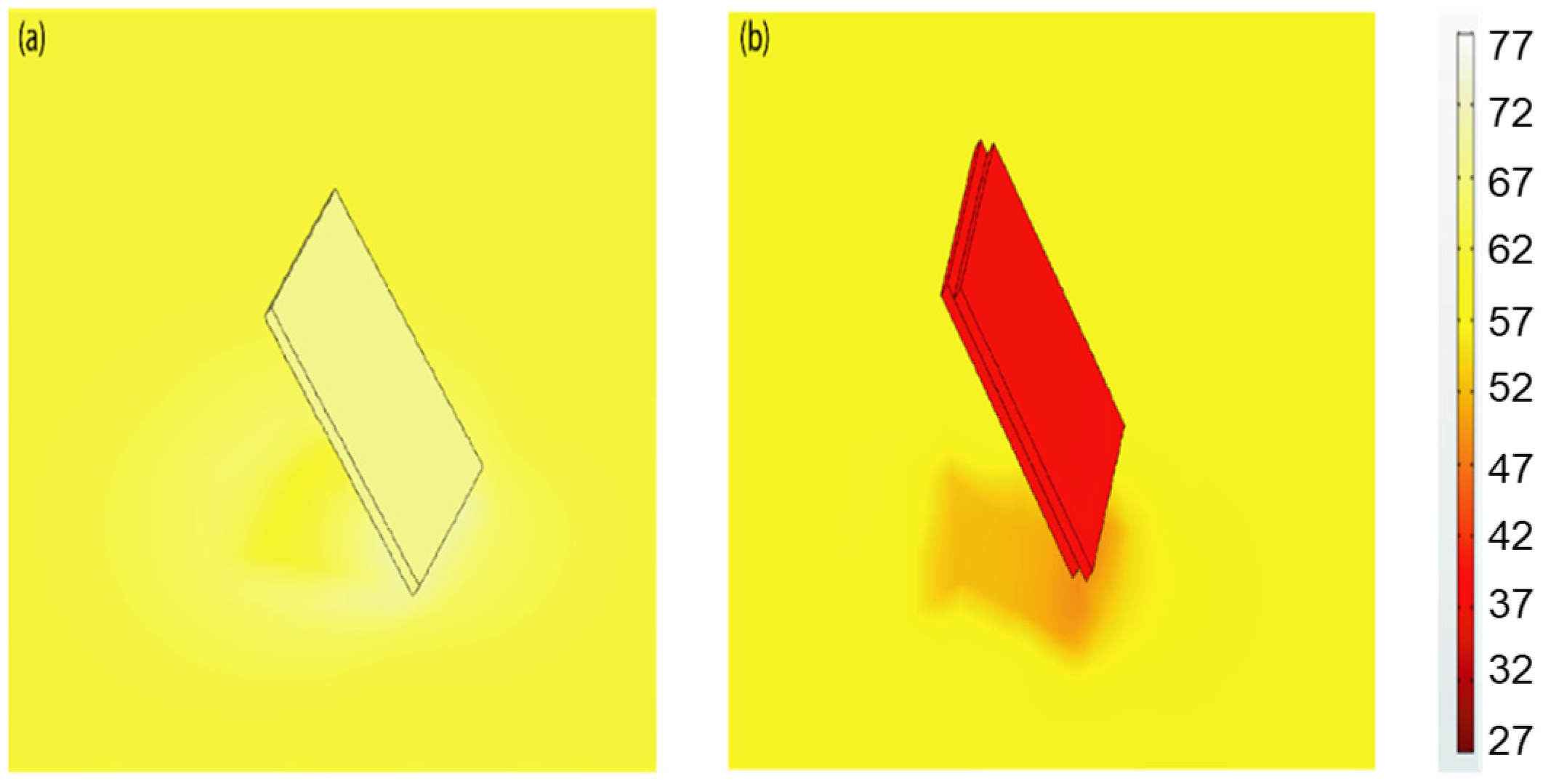

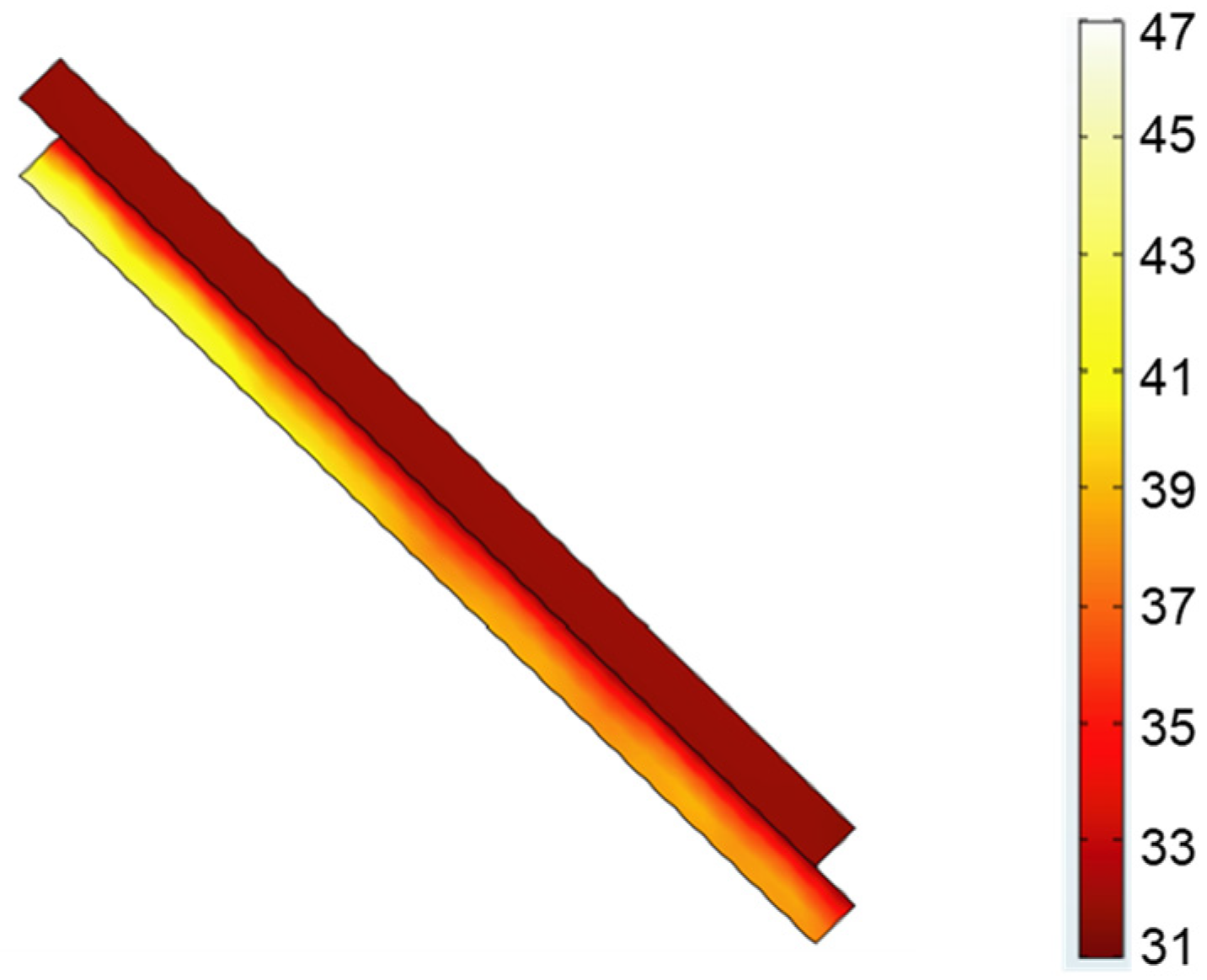

3.1. Passive Method

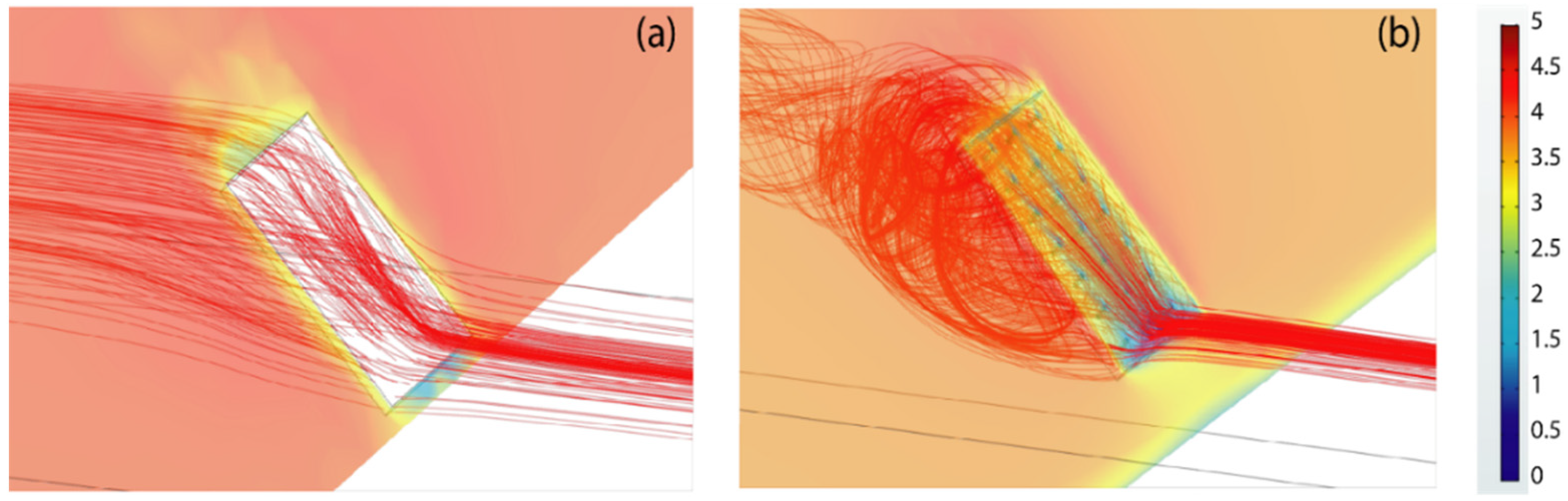

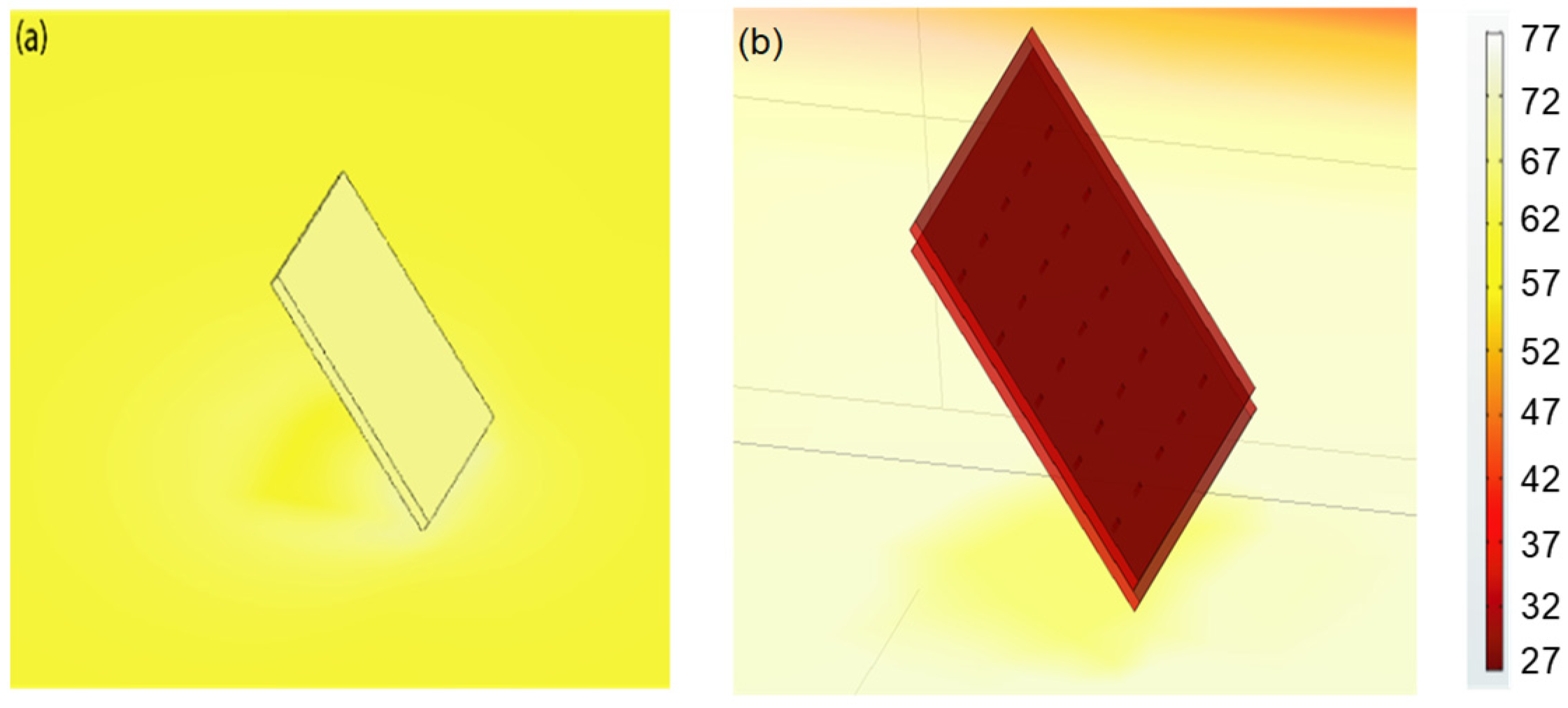

3.2. Active Method

3.3. Hybrid Method

3.4. Comparison of the Implemented Methods

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kannan, N.; Vakeesan, D. Solar energy for future world—A review. Renew. Sustain. Energy Rev. 2016, 62, 1092–1105. [Google Scholar] [CrossRef]

- Rauf, A.; Liu, X.; Amin, W.; Ozturk, I.; Rehman, O.U.; Sarwar, S. Energy and ecological sustainability: Challenges and panoramas in belt and road initiative countries. Sustainability 2018, 10, 2743. [Google Scholar] [CrossRef]

- Robles Algarin, C.; Rodríguez Álvarez, O. An overview of the renewable energy in the World, Latin America and Colombia. Espacios 2018, 39, 1–16. [Google Scholar]

- Franco, M.A.; Groesser, S.N. A Systematic Literature Review of the Solar Photovoltaic Value Chain for a Circular Economy. Sustainability 2021, 13, 9615. [Google Scholar] [CrossRef]

- Fouad, M.M.; Shihata, L.A.; Morgan, I. An integrated review of factors influencing the performance of photovoltaic panels. Renew. Sustain. Energy Rev. 2017, 80, 1499–1511. [Google Scholar] [CrossRef]

- Kasera, S.; Nayak, R.; Bhaduri, S.C. A Review of Performance of Solar Photovoltaic Refrigeration System. Lect. Notes Electr. Eng. 2022, 766, 641–651. [Google Scholar] [CrossRef]

- Hasanuzzaman, M.; Malek, A.B.M.A.; Islam, M.M.; Pandey, A.K.; Rahim, N.A. Global advancement of cooling technologies for PV systems: A review. Sol. Energy 2016, 137, 25–45. [Google Scholar] [CrossRef]

- Nizetic, S.; Papadopoulos, A.M.; Giama, E. Comprehensive analysis and general economic-environmental evaluation of cooling techniques for photovoltaic panels, Part I: Passive cooling techniques. Energy Convers. Manag. 2017, 149, 334–354. [Google Scholar] [CrossRef]

- Kim, J.; Nam, Y. Study on the Cooling Effect of Attached Fins on PV Using CFD Simulation. Energies 2019, 12, 758. [Google Scholar] [CrossRef]

- AlAmri, F.; AlZohbi, G.; AlZahrani, M.; Aboulebdah, M. Analytical Modeling and Optimization of a Heat Sink Design for Passive Cooling of Solar PV Panel. Sustainability 2021, 13, 3490. [Google Scholar] [CrossRef]

- Aamir Al-Mabsali, S.; Chaudhry, H.N.; Gul, M.S. Numerical Investigation on Heat Pipe Spanwise Spacing to Determine Optimum Configuration for Passive Cooling of Photovoltaic Panels. Energies 2019, 12, 4635. [Google Scholar] [CrossRef]

- Kandeal, A.W.; Thakur, A.K.; Elkadeem, M.R.; Elmorshedy, M.F.; Ullah, Z.; Sathyamurthy, R.; Sharshir, S.W. Photovoltaics performance improvement using different cooling methodologies: A state-of-art review. J. Clean. Prod. 2020, 273, 122772. [Google Scholar] [CrossRef]

- Maleki, A.; Haghighi, A.; El Haj Assad, M.; Mahariq, I.; Alhuyi Nazari, M. A review on the approaches employed for cooling PV cells. Sol. Energy 2020, 209, 170–185. [Google Scholar] [CrossRef]

- Osma-Pinto, G.; Ordóñez-Plata, G. Dynamic thermal modelling for the prediction of the operating temperature of a PV panel with an integrated cooling system. Renew. Energy 2020, 152, 1041–1054. [Google Scholar] [CrossRef]

- Sharma, S.; Sellami, N.; Tahir, A.A.; Mallick, T.K.; Bhakar, R. Performance Improvement of a CPV System: Experimental Investigation into Passive Cooling with Phase Change Materials. Energies 2021, 14, 3550. [Google Scholar] [CrossRef]

- Dwivedi, P.; Sudhakar, K.; Soni, A.; Solomin, E.; Kirpichnikova, I. Advanced cooling techniques of P.V. modules: A state of art. Case Stud. Therm. Eng. 2020, 21, 100674. [Google Scholar] [CrossRef]

- COMSOL Multiphysics. Available online: www.comsol.com (accessed on 9 September 2021).

- Lienhard, J.H., IV. A Heat Transfer Textbook, 5th ed.; Dover Publications, Inc.: New York, NY, USA, 2019; pp. 49–78. [Google Scholar]

- Surface to Surface Radiation Benchmarks. Available online: https://www.comsol.com/paper/surface-to-surface-radiation-benchmarks-35611 (accessed on 9 September 2021).

- Bernard, P.S. Turbulent Fluid Flow, 1st ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2019; pp. 1–65. [Google Scholar]

- Kajishima, T.; Taira, K. Computational Fluid Dynamics: Incompressible Turbulent Flows, 1st ed.; Springer: Cham, Switzerland, 2017; pp. 207–263. [Google Scholar]

- Viloria-Porto, J.; Robles-Algarín, C.; Restrepo-Leal, D. A Novel Approach for an MPPT Controller Based on the ADALINE Network Trained with the RTRL Algorithm. Energies 2018, 11, 3407. [Google Scholar] [CrossRef]

- Robles Algarín, C.; Sevilla Hernández, D.; Restrepo Leal, D. A Low-Cost Maximum Power Point Tracking System Based on Neural Network Inverse Model Controller. Electronics 2018, 7, 4. [Google Scholar] [CrossRef]

- Robles Algarín, C.; Taborda Giraldo, J.; Rodríguez Álvarez, O. Fuzzy Logic Based MPPT Controller for a PV System. Energies 2017, 10, 2036. [Google Scholar] [CrossRef]

- Vera, S.; Cortés, M.; Rao, J.; Fazio, P.; Bustamante, W. Testing turbulence models to predict interzonal mass airflows through a stairwell opening for both natural and mixed convection flows in buildings. Rev. Ing. Construcción 2015, 30, 2. [Google Scholar] [CrossRef][Green Version]

- Abd-Elhady, M.S.; Serag, Z.; Kandil, H.A. An innovative solution to the overheating problem of PV panels. Energy Convers. Manag. 2018, 157, 452–459. [Google Scholar] [CrossRef]

| Specifications | Value |

|---|---|

| Type | Monocrystalline |

| Maximum power | 100 W |

| Maximum power voltage | 18.75 V |

| Maximum power current | 5.34 A |

| Open-circuit voltage | 22.53 V |

| Short-circuit current | 5.70 A |

| Temperature power coefficient | −0.45%/°C |

| Dimensions | 820 × 808 × 35 mm |

| Properties | Silicon | Water | Air | Units |

|---|---|---|---|---|

| Density | 2329 | 1000 | 1.28 | kg/m3 |

| Thermal conductivity | 130 | 0.58 | 0.02 | W/(m × K) |

| Surface emissivity | 0.9 | 0.95 | 1.012 | - |

| Constant pressure heat capacity | 700 | 4180 | - | J/(kg × K) |

| Thermal expansion coefficient | 2.6 × 10−6 | - | - | 1/K |

| Relative permittivity | 11.7 | - | - | - |

| Dynamic viscosity | - | 0.001 | 0.0000174 | Pa × s |

| Parameter | Value |

|---|---|

| Maximum element size | 0.48 (m) |

| Minimum element size | 0.06 (m) |

| Maximum element growth rate | 1.45 |

| Curvature factor | 0.5 |

| Resolution of narrow regions | 0.6 |

| Computational Domain | Domains | Sides | Edges | Points |

|---|---|---|---|---|

| Standard panel | 3 | 17 | 32 | 20 |

| Passive panel | 3 | 117 | 332 | 220 |

| Active panel | 4 | 23 | 44 | 28 |

| Hybrid panel | 4 | 124 | 348 | 232 |

| Mesh Specifications | Domain Elements | Boundary Elements | Edge Elements | |

| Standard panel | 1415321 | 55018 | 1441 | |

| Passive panel | 3731403 | 107882 | 2931 | |

| Active panel | 920878 | 45450 | 1259 | |

| Hybrid panel | 3042372 | 135418 | 3329 |

| Time | Amb. T. (°C) | Std. Panel (°C) | Perf. Panel (°C) | Diff. Std.—Perf. Panel (°C) |

|---|---|---|---|---|

| 6:00 | 26.12 | 27.90 | 26.45 | 1.45 |

| 7:00 | 26.65 | 35.77 | 31.32 | 4.45 |

| 8:00 | 27.55 | 39.15 | 34.75 | 4.40 |

| 9:00 | 28.36 | 42.44 | 37.23 | 5.21 |

| 10:00 | 29.85 | 47.97 | 42.41 | 5.56 |

| 11:00 | 31.16 | 52.62 | 47.92 | 4.70 |

| 12:00 | 31.86 | 67.70 | 62.36 | 5.34 |

| 13:00 | 31.78 | 67.34 | 62.60 | 4.74 |

| 14:00 | 30.98 | 63.07 | 57.01 | 6.06 |

| 15:00 | 30.17 | 57.94 | 52.33 | 5.61 |

| 16:00 | 29.37 | 49.41 | 45.50 | 3.91 |

| 17:00 | 28.45 | 42.08 | 38.80 | 3.28 |

| 18:00 | 27.69 | 34.14 | 30.90 | 3.24 |

| Prom. | 29.23 | 48.27 | 43.81 | 4.46 |

| Time | Std. Panel (W) | Perf. Panel (W) | Diff. Std.—Perf. Panel (W) |

|---|---|---|---|

| 10:00 | 67.61 | 71.29 | 3.68 |

| 11:00 | 63.98 | 67.61 | 3.63 |

| 12:00 | 50.16 | 55.71 | 5.55 |

| 13:00 | 50.76 | 55.37 | 4.61 |

| 14:00 | 54.80 | 60.44 | 5.64 |

| 15:00 | 59.65 | 64.41 | 4.76 |

| Prom. | 57.83 | 62.47 | 4.65 |

| Time | Amb. T. (°C) | Std. Panel (°C) | Act. Panel Wat. Amb. T. (°C) | Act. Panel Wat. 10° (°C) | Act. Panel Wat. 5° (°C) | Diff. Std.—Act. Panel Wat. Amb. T. (°C) |

|---|---|---|---|---|---|---|

| 6:00 | 26.12 | 27.90 | 26.04 | 10.62 | 6.15 | 1.86 |

| 7:00 | 26.65 | 35.77 | 26.62 | 10.77 | 7.08 | 9.15 |

| 8:00 | 27.55 | 39.15 | 28.20 | 11.56 | 7.75 | 10.95 |

| 9:00 | 28.36 | 42.44 | 29.89 | 11.87 | 6.21 | 12.55 |

| 10:00 | 29.85 | 47.97 | 33.11 | 12.98 | 8.51 | 14.86 |

| 11:00 | 31.16 | 52.62 | 36.05 | 12.36 | 8.64 | 16.57 |

| 12:00 | 31.86 | 66.21 | 37.83 | 13.52 | 8.64 | 28.38 |

| 13:00 | 31.78 | 67.34 | 39.03 | 13.75 | 8.65 | 28.31 |

| 14:00 | 30.98 | 63.07 | 38.76 | 13.72 | 8.48 | 24.31 |

| 15:00 | 30.17 | 57.94 | 37.45 | 12.22 | 8.20 | 20.49 |

| 16:00 | 29.37 | 49.41 | 35.49 | 12.34 | 7.71 | 13.92 |

| 17:00 | 28.45 | 42.08 | 32.94 | 11.86 | 6.96 | 9.14 |

| 18:00 | 27.69 | 34.14 | 29.46 | 10.93 | 6.02 | 4.68 |

| Prom. | 29.23 | 48.16 | 33.14 | 12.19 | 7.62 | 15.01 |

| Time | Std. Panel (W) | Act. Panel Wat. Amb. T. (W) | Act. Panel Wat. 10° (W) | Act. Panel Wat. 5° (W) | Diff. Std.—Act. Panel Wat. Amb. T. (W) |

|---|---|---|---|---|---|

| 10:00 | 67.61 | 76.00 | 81.49 | 81.65 | 8.39 |

| 11:00 | 63.98 | 74.68 | 81.42 | 81.65 | 10.70 |

| 12:00 | 50.16 | 73.79 | 81.38 | 81.65 | 23.63 |

| 13:00 | 50.76 | 73.05 | 81.33 | 81.65 | 22.29 |

| 14:00 | 54.80 | 73.25 | 81.35 | 81.65 | 18.45 |

| 15:00 | 59.65 | 73.94 | 81.49 | 81.65 | 14.29 |

| Prom. | 57.83 | 74.12 | 81.41 | 81.65 | 16.29 |

| Time | Amb. T. (°C) | Std. Panel (°C) | Hyb. Panel Wat. Amb. T. (°C) | Diff. Std.—Hyb. Panel Wat. Amb. T. (°C) |

|---|---|---|---|---|

| 6:00 | 26.12 | 27.90 | 25.17 | 2.73 |

| 7:00 | 26.65 | 35.77 | 25.97 | 9.80 |

| 8:00 | 27.55 | 39.15 | 28.10 | 11.05 |

| 9:00 | 28.36 | 42.44 | 29.67 | 12.77 |

| 10:00 | 29.85 | 47.97 | 30.28 | 17.69 |

| 11:00 | 31.16 | 52.62 | 33.50 | 19.12 |

| 12:00 | 31.86 | 66.21 | 34.51 | 31.70 |

| 13:00 | 31.78 | 67.34 | 35.15 | 32.19 |

| 14:00 | 30.98 | 63.07 | 34.83 | 28.24 |

| 15:00 | 30.17 | 57.94 | 34.31 | 23.63 |

| 16:00 | 29.37 | 49.41 | 32.11 | 17.30 |

| 17:00 | 28.45 | 42.08 | 30.90 | 11.18 |

| 18:00 | 27.69 | 34.14 | 27.48 | 6.66 |

| Prom. | 29.23 | 48.16 | 30.92 | 17.24 |

| Time | Std. Panel (W) | Hyb. Panel Wat. Amb. T. (W) | Diff. Hyb.—Act. Panel Wat. Amb. T. (W) |

|---|---|---|---|

| 10:00 | 67.61 | 77.24 | 9.63 |

| 11:00 | 63.98 | 76.04 | 12.06 |

| 12:00 | 50.16 | 75.38 | 25.22 |

| 13:00 | 50.76 | 75.12 | 24.36 |

| 14:00 | 54.80 | 75.23 | 20.43 |

| 15:00 | 59.65 | 75.46 | 15.81 |

| Prom. | 57.83 | 75.75 | 17.92 |

| Time | Diff. Std.—Perf. Panel (°C) | Diff. Std.—Act. Panel Wat. Amb. T. (°C) | Diff. Std.—Hyb. Panel Wat. Amb. T. (°C) |

|---|---|---|---|

| 6:00 | 1.45 | 1.86 | 2.73 |

| 7:00 | 4.45 | 9.15 | 9.80 |

| 8:00 | 4.40 | 10.95 | 11.05 |

| 9:00 | 5.21 | 12.55 | 12.77 |

| 10:00 | 5.56 | 14.86 | 17.69 |

| 11:00 | 4.70 | 16.57 | 19.12 |

| 12:00 | 5.34 | 28.38 | 31.70 |

| 13:00 | 4.74 | 28.31 | 32.19 |

| 14:00 | 6.06 | 24.31 | 28.24 |

| 15:00 | 5.61 | 20.49 | 23.63 |

| 16:00 | 3.91 | 13.92 | 17.30 |

| 17:00 | 3.28 | 9.14 | 11.18 |

| 18:00 | 3.24 | 4.68 | 6.66 |

| Prom. | 4.46 | 15.01 | 17.24 |

| Time | Diff. Std.—Perf. Panel (W) | Diff. Std.—Act. Panel Wat. Amb. T. (W) | Diff. Hyb.—Act. Panel Wat. Amb. T. (W) |

|---|---|---|---|

| 10:00 | 3.68 | 8.39 | 9.63 |

| 11:00 | 3.63 | 10.7 | 12.06 |

| 12:00 | 5.55 | 23.63 | 25.22 |

| 13:00 | 4.61 | 22.29 | 24.36 |

| 14:00 | 5.64 | 18.45 | 20.43 |

| 15:00 | 4.76 | 14.29 | 15.81 |

| Prom. | 4.65 | 16.29 | 17.92 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pomares-Hernández, C.; Zuluaga-García, E.A.; Escorcia Salas, G.E.; Robles-Algarín, C.; Sierra Ortega, J. Computational Modeling of Passive and Active Cooling Methods to Improve PV Panels Efficiency. Appl. Sci. 2021, 11, 11370. https://doi.org/10.3390/app112311370

Pomares-Hernández C, Zuluaga-García EA, Escorcia Salas GE, Robles-Algarín C, Sierra Ortega J. Computational Modeling of Passive and Active Cooling Methods to Improve PV Panels Efficiency. Applied Sciences. 2021; 11(23):11370. https://doi.org/10.3390/app112311370

Chicago/Turabian StylePomares-Hernández, Cristhian, Edwin Alexander Zuluaga-García, Gene Elizabeth Escorcia Salas, Carlos Robles-Algarín, and Jose Sierra Ortega. 2021. "Computational Modeling of Passive and Active Cooling Methods to Improve PV Panels Efficiency" Applied Sciences 11, no. 23: 11370. https://doi.org/10.3390/app112311370

APA StylePomares-Hernández, C., Zuluaga-García, E. A., Escorcia Salas, G. E., Robles-Algarín, C., & Sierra Ortega, J. (2021). Computational Modeling of Passive and Active Cooling Methods to Improve PV Panels Efficiency. Applied Sciences, 11(23), 11370. https://doi.org/10.3390/app112311370