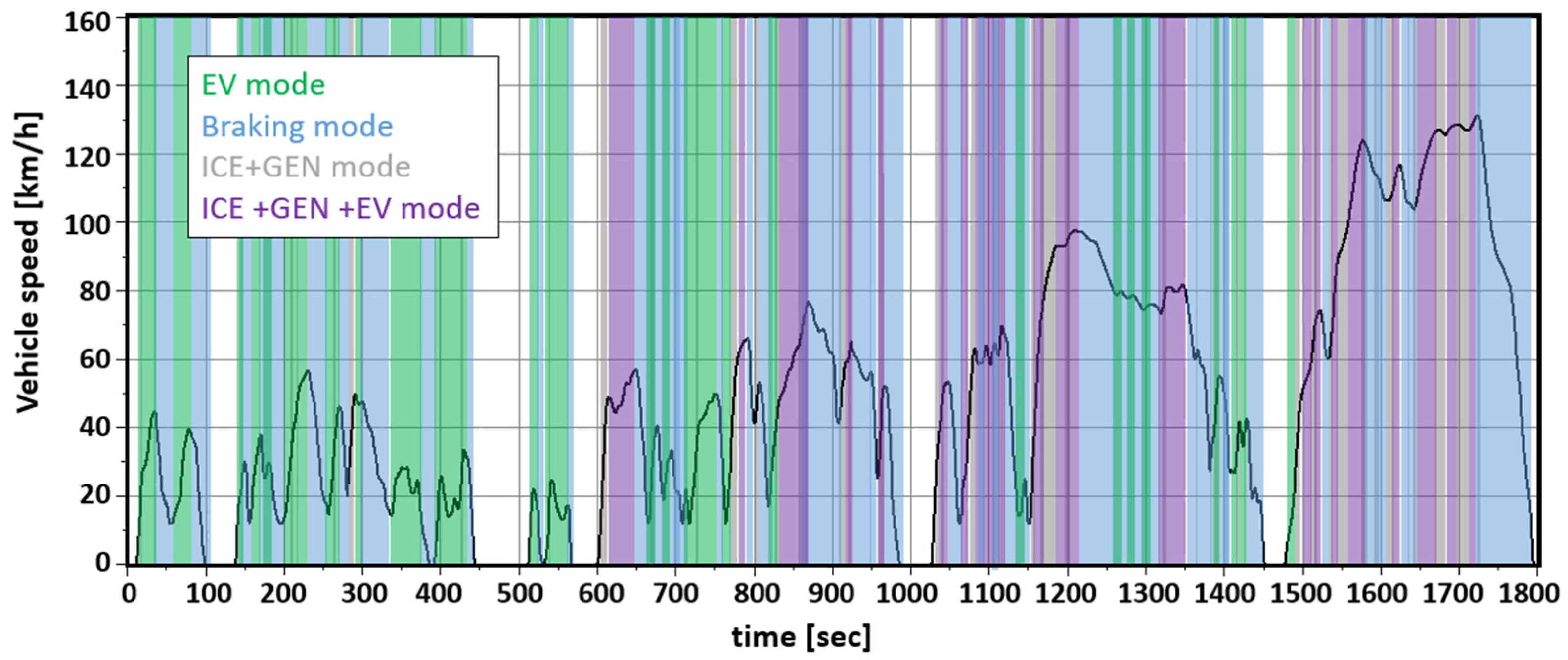

2.2.1. HEV Operating Modes

The control system/supervisor will determine various requests to decide the operating mode of the hybrid vehicle, and these parameters are the key in the control system:

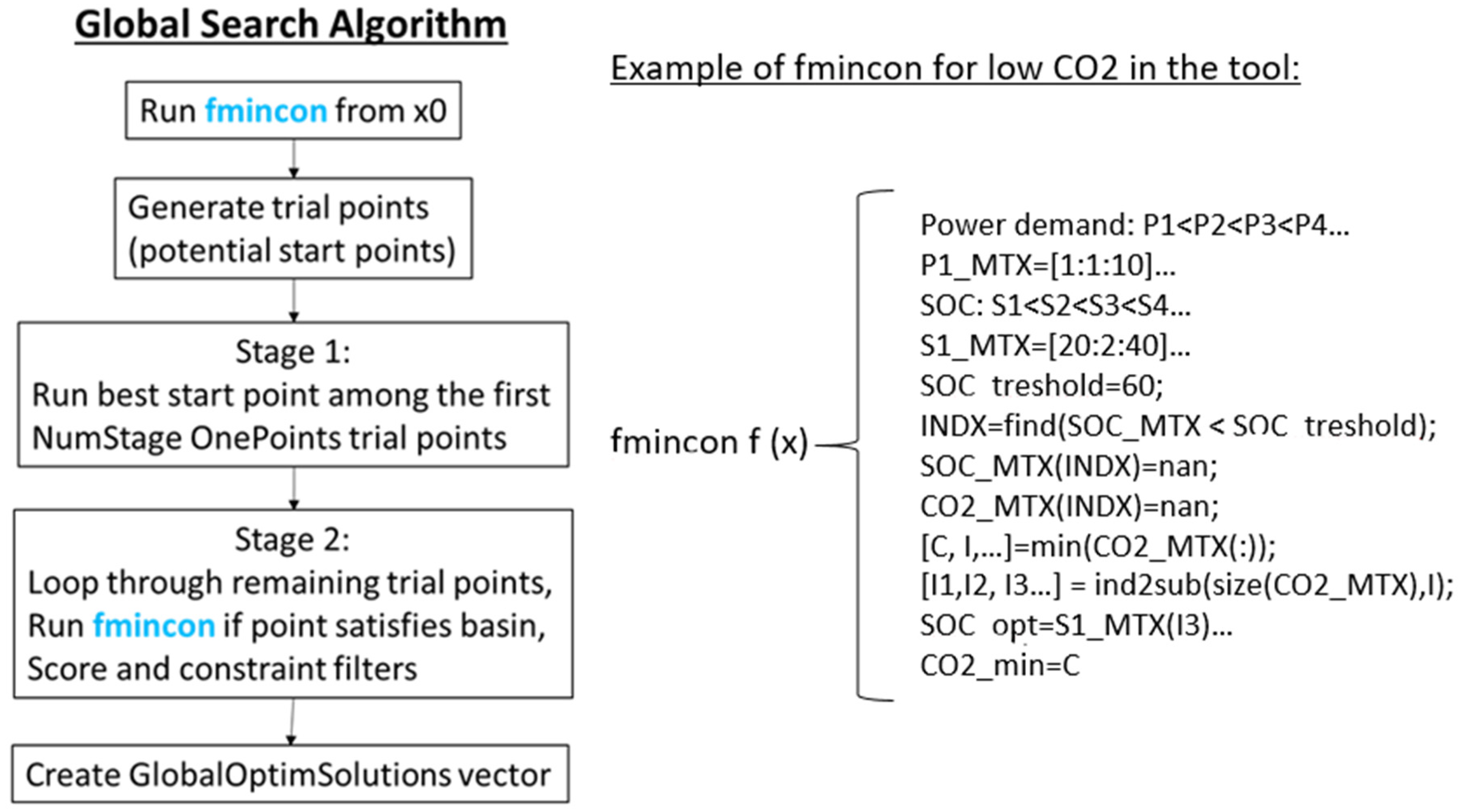

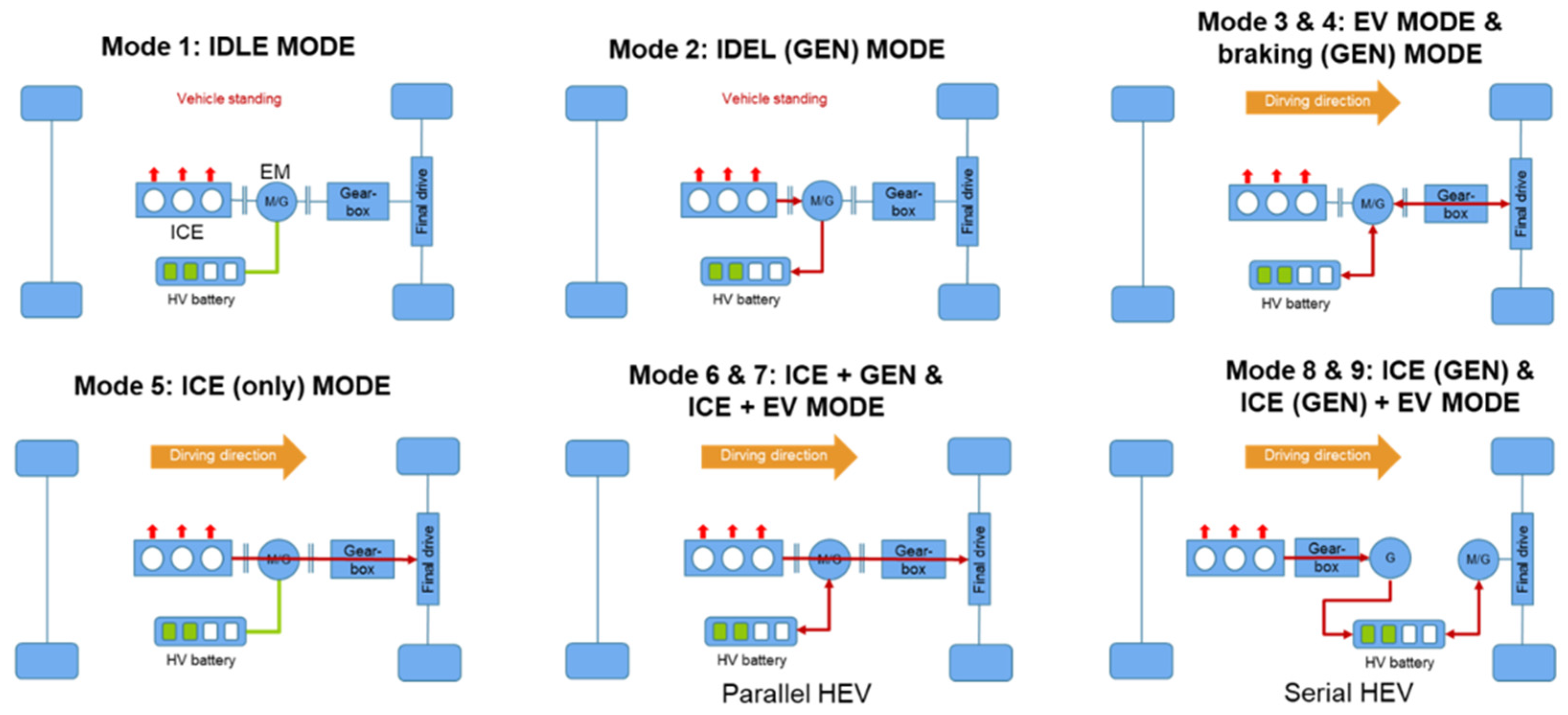

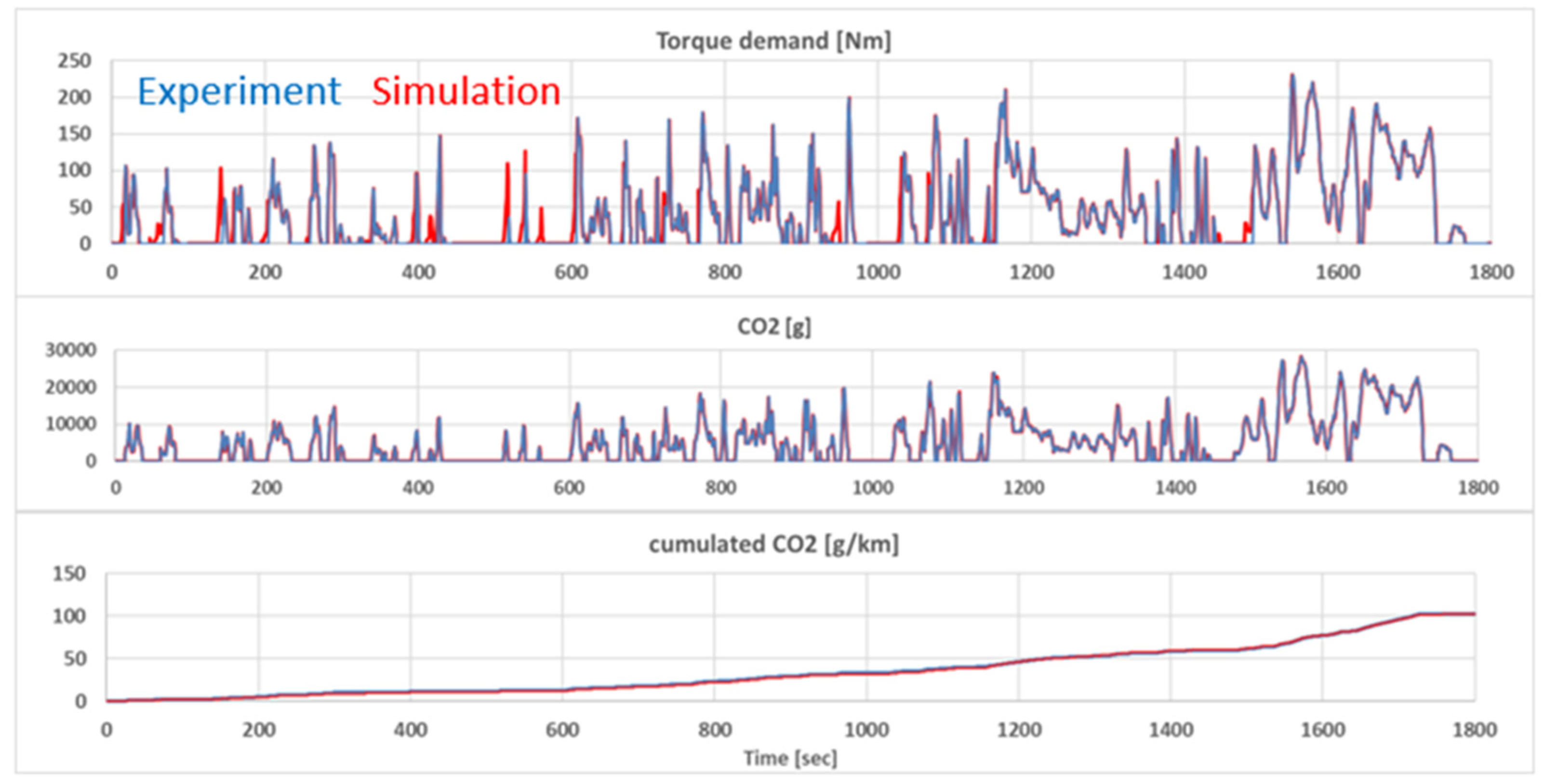

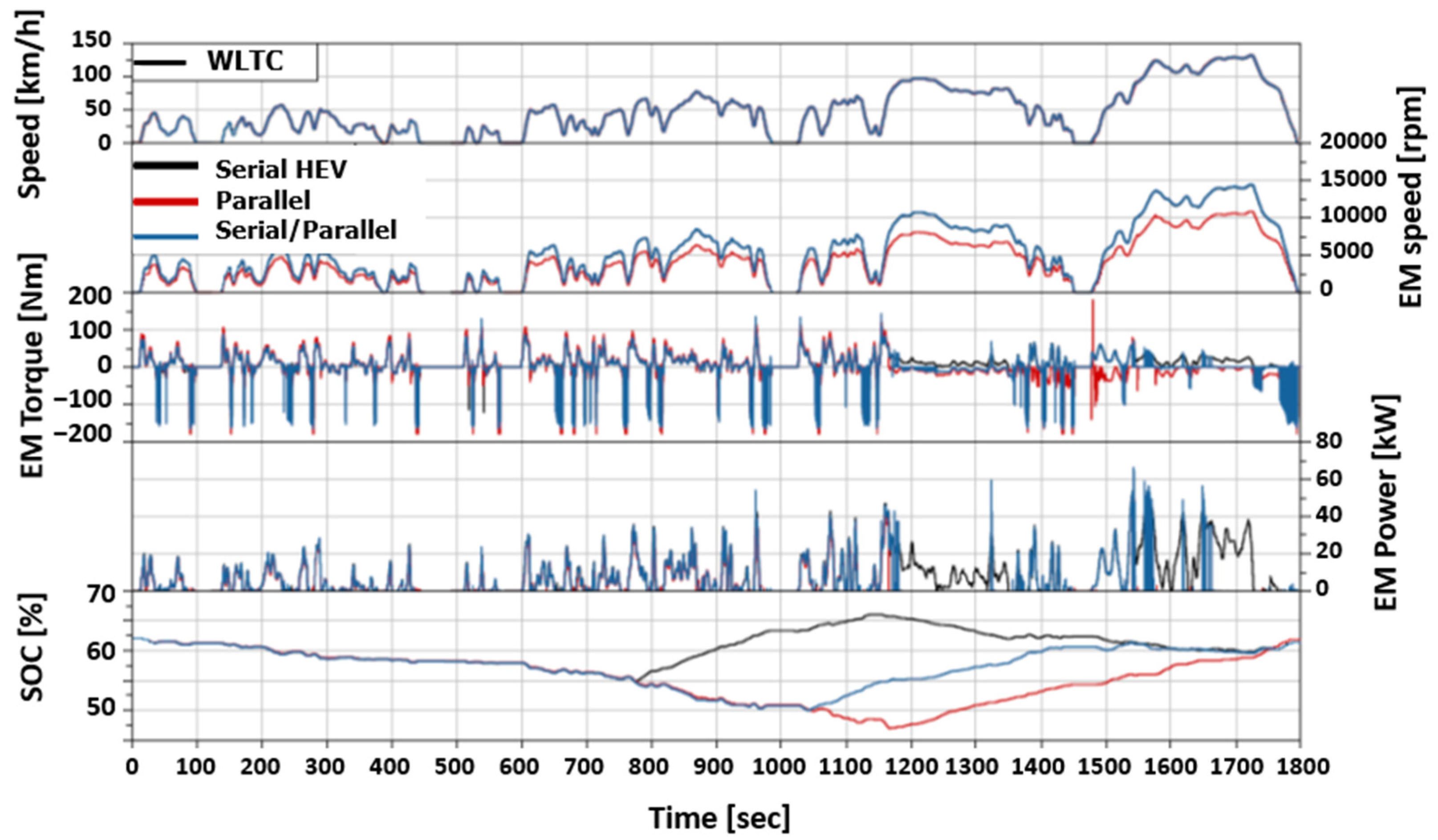

In the control strategy, the tool considers these control parameters as inputs for the system to move for one transition to another over the driving cycle power demand. These values can be modified accordingly to achieve the best results. A rule-based control topology is introduced in this paper, and it determines the transition of variable driving modes on the HEV simulation. The output of the supervisor block is the active drive mode of the vehicle during the given driving cycle. The supervisor is the master controller, and it controls the other subcomponents of the vehicle, such as ICE, power devices, transmission, etc. In total, nine different states are available in the simulation, as shown in

Figure 2.

IDLE mode is the stationary position of the vehicle. This state describes the behavior of the vehicle when not moving, meaning the ICE with generator and the EMs, the two power sources, are at rest. The entire system is at rest, with no generation of power. ICE (GEN) mode is also the stationary position of vehicle. This state describes the behavior of the vehicle when not moving, but the ICE with generator is switched on to charge the battery when the SOC of the battery is depleted. Meanwhile, the electrical machine remains switched off or in a resting position. This state remains active until one of two conditions is met: until the battery reaches a nominal SOC, or until there is a power request from the driving cycle. EV (short for Electric Vehicle) mode is the behavior of the vehicle when there is a power demand from the driving cycle, so the vehicle launches from a state of rest through the power supplied by the battery to the electrical machine, while the ICE and generator remain in the state of rest. This state is only available in HEV or BEV, and is called e-drive mode or battery-only mode; this is the state where only power from a battery is supplied to the EM. When the EM is used as a generator to recuperate this negative power available, and this in turn is used to charge the battery, this is called Braking (GEN) mode. This state also describes the behavior of the vehicle when decelerating. If the braking power is not sufficient to stop the vehicle, it will additionally use mechanical brakes to stop. In ICE + GEN mode and ICE + EM mode cases, the ICE with an EM is mechanically coupled to the wheels to provide power to the vehicle in parallel hybrids. In this state, the excess power generated by the ICE is used to charge the battery (ICE + GEN mode), and the extra power needed is supplied by the battery through EM (ICE + EV mode), in case the power request from the driving cycle is higher than the power from ICE. In serial hybrids, ICE (GEN) mode is active when the power request from the driving cycle is higher than that possible to deliver by battery. Since ICE and the generator are coupled on the same shaft, the power from the generator is delivered to the electrical machine to drive the vehicle. Both the ICE and the generator are run in their most efficient areas. ICE (GEN) + EV mode is the state when the power request from the driving cycle is very high compared to that of which the individual power sources are capable; therefore, a combination of the power sources is used to drive the cycle. The maximum power by the ICE (GEN) is used, and the remaining power that is needed is supplied from the battery. ICE (only) mode is the state in which the vehicle runs like a conventional ICE vehicle.

Depending on the hybrid architectures, the used hybrid modes can be represented by 6 or 7 states among the 9 total modes described above. For example, 7 modes (1−7) are used in parallel hybrids, 6 modes (1−4, 8 and 9) are for serial hybrids, and serial/parallel (2 mode) hybrids use 7 modes (1−4, 5, 6 and 9).

2.2.2. Rule-Based Control Strategies

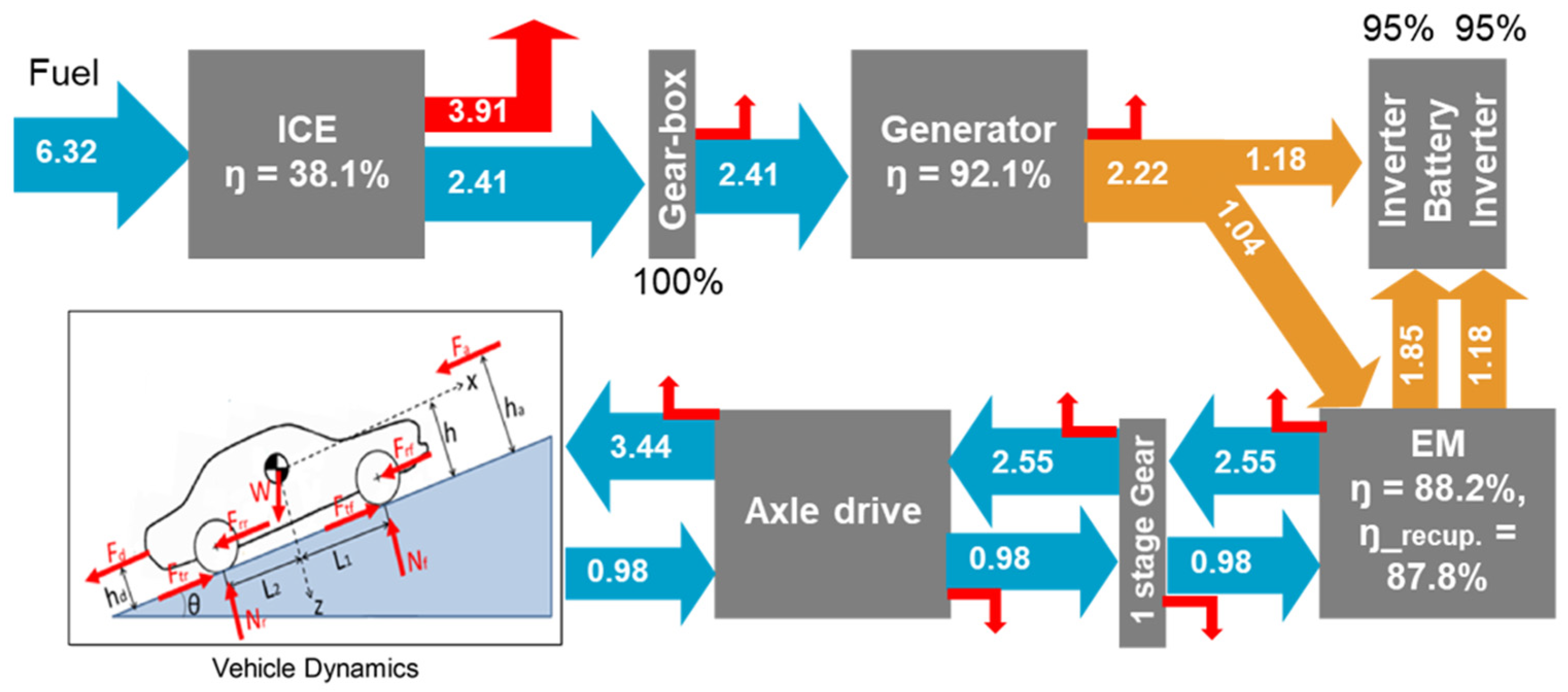

Rule-based control topologies are introduced in this section for serial, parallel and serial/parallel hybrids. Serial hybrids allow a complete decoupling of the ICE from the powertrain, which makes it easier to implement efficiency-increasing ICE measures that react sensitively to transient behavior. Such hybrid concepts show a high degree of freedom regarding the charging process of the battery. It can easily be charged at vehicle stop and at low vehicle speeds, for instance. An additional positive effect of the serial hybrid powertrain is its electrical driving experience. In contrast, there is the long efficiency chain from the ICE to the wheel. The overall losses of this mechanical/electrical path cannot be neglected, although the ICE can be operated at optimum efficiency. This becomes particularly clear at high vehicle speeds, as the high speeds of the EMs cause the efficiency of the machines to drop sharply. In comparison, a parallel concept has a significantly lower degree of freedom in the charging process of the battery. Likewise, the customer’s desired electric driving experience cannot be achieved in every driving situation. Although the ICE cannot be operated with optimum efficiency at every point due to the mechanical coupling, this can be approximated by a large number of gear stages combined with an operating point shift by charging/discharging the battery while driving. The efficiency chain from the ICE to the wheel is significantly shorter compared to the serial concept. Part of the mechanical power generated by the ICE is always fed directly to the output, bypassing the electrical path. A fuel consumption advantage over the serial approach can be expected. In case of serial/parallel hybrids, it is able to combine the advantages of both approaches. Due to the dynamical coupling and structural complexity, the serial/parallel hybrid driving system possesses multiple working modes to adapt to different driving conditions. As an example, in this paper, the author introduces a simple logic control for rule-base strategies in the following sections. This is to show the flexibility of the tool in adapting any logic algorithm by the user.

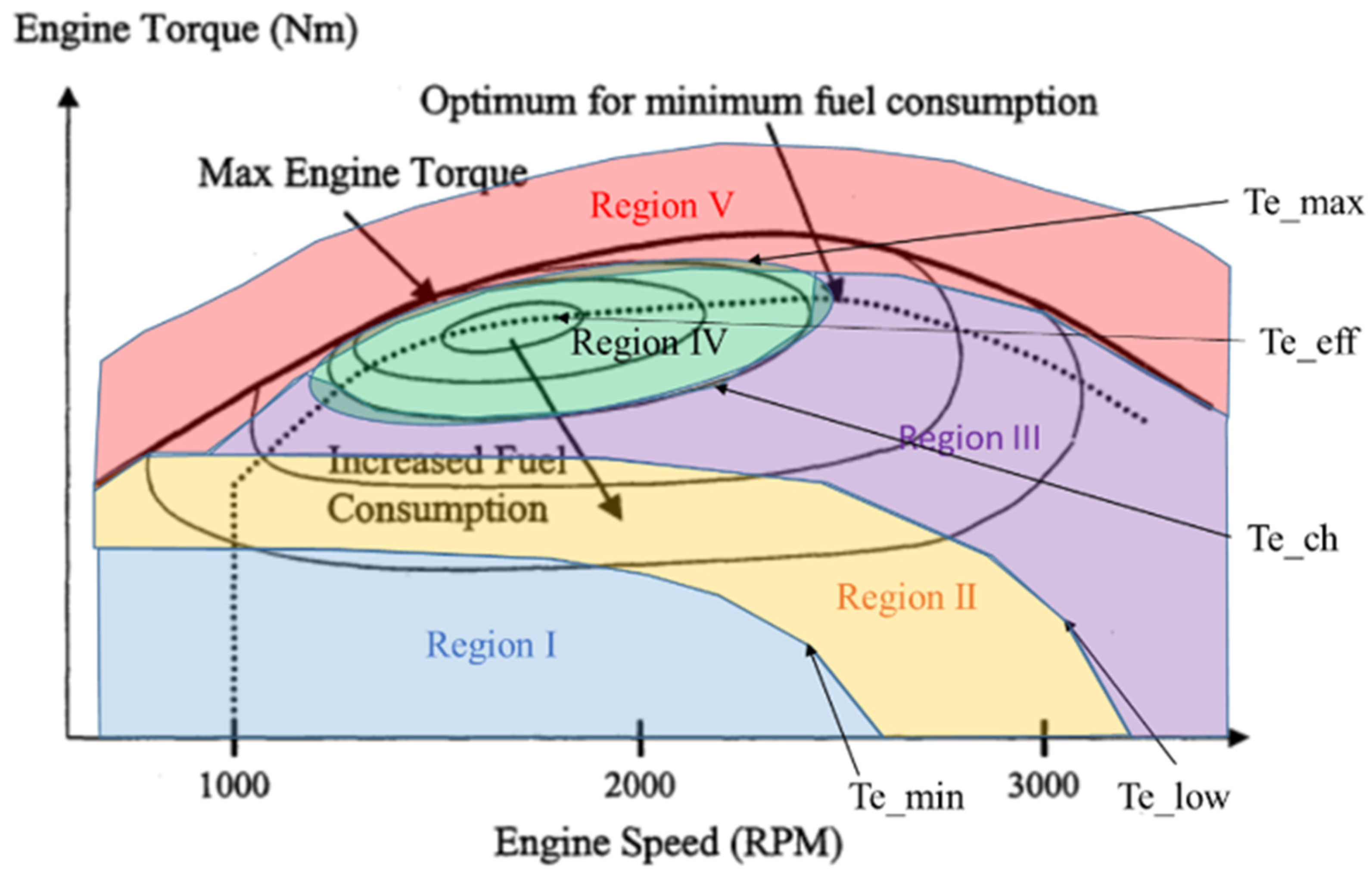

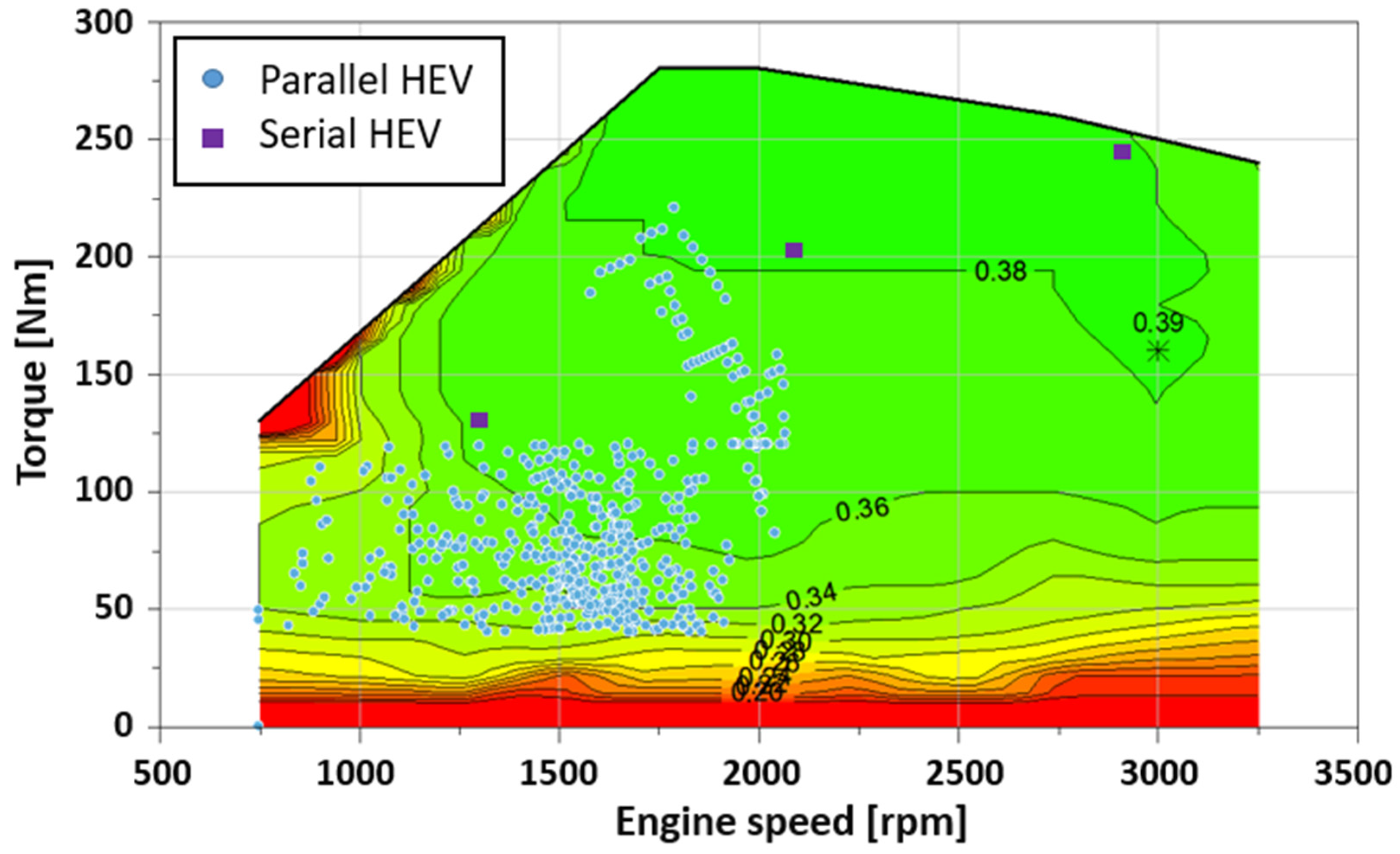

Among 9 different modes (the different modes described in

Section 2.2.1), 7 different operating modes are selected for parallel hybrids in the HEV simulation tool, so it is necessary to divide the different states into operating ranges, because the torque demand from the ICE will be a major control parameter, since the ICE is directly connected to the wheels in parallel HEVs. To clarify the system of mode switching, a rule-based control topology for the parallel hybrids is proposed for optimal system efficiency. The operation regions are divided according to the test data of the engine [

7], as shown in

Figure 3. As shown in this figure, the line “Te_min” is the very low torque curve, with a relatively poor efficiency of ICE, “Te_low” is the minimum torque, and “Te_ch” is the limit of torque of charging mode. Region IV (in green) is the area with minimum fuel consumption, based on the example of test data of an engine. The dash line “Te_eff” represents the optimum area for minimum fuel consumption at a given engine speed and “Te_max” is the expected limit of engine torque in this hybrid simulation, which is close to the solid line for full loads of the engine. Above the line, a combination of the power sources, ICE and EMs, is required to carry out very high power requests. Based on the different regions, the operating system is divided into five parts, which are: e-driving mode (Region I), e-driving or engine driving mode (Region II), charging mode (Region III), engine driving mode (Region IV), and engine and EM hybrid mode (Region V). To formulate the control strategy of the parallel hybrids, two other parameters are considered, which are battery SOC and vehicle speed. The vehicle speed is just used to realize the IDEL mode, and the SOC is the other main parameter for the control logic. As a control parameter, the SOC is divided into five levels: “SOC_min” is the minimum level of SOC for the battery function, “SOC_low” is a variable level to represent the relatively low level of SOC based on the driver’s opinion for the optimization. “SOC_initial” is the SOC at the beginning of the simulation, and “SOC_high” is again a variable SOC representing a high level of SOC, which can set by the driver. “SOC_max” is the maximum SOC of the given battery.

In principle, the drivers are able to design their own control topology by themselves in the HEV simulation tool (e.g., state-flow box or Fuzzy logic toolbox). According to

Figure 3, the judgment conditions of each working state are set, and the target torque of the motor and engine can be varied upon driver request. Region I is the economic zone, in which EV mode is mostly used to minimize fuel consumption. The engine runs only when the low limitation of SOC is reached. Region II is the area where the e-driving mode is slightly reduced, depending on the SOC, and the engine runs to charge the battery when the SOC is lower than SOC_low. In Region III, the engine is operated mainly near the optimum point in the minimum fuel consumption area to manage the required torque from the wheel while the battery is charged. The EV mode can only be handled when the SOC is above SOC_high in the region. In Region IV, the vehicle runs mostly like a conventional ICE vehicle, with the highest efficiency from the engine map. The engine cannot achieve the very high torque requirements from the wheels, like in Region V, and thus the EM and the ICE are coupled to deliver very high torque in hybrid mode if the SOC is sufficient. The engine runs with the highest torque to minimize the drop of SOC in this region. In all cases, the vehicle is basically not in a stationary position, and from the figure, the parameters in black (e.g., SOC_min, SOC_initial, SOC_max) are a fixed value, while the red parameters (e.g., SOC_low, SOC_high, Te_min, Te_low, Te_ch, etc.) are varied for the optimization process (

Section 3).

- 2.

Serial hybrid topology

In the serial hybrids, the power demand of the EM will be a main parameter, since the EM is directly connected, and the SOC is the variable that determines the power from the EM and the ICE for hybrids. In a similar way to parallel hybrids, the different operating modes of the serial hybrids (six modes in the serial hybrids in

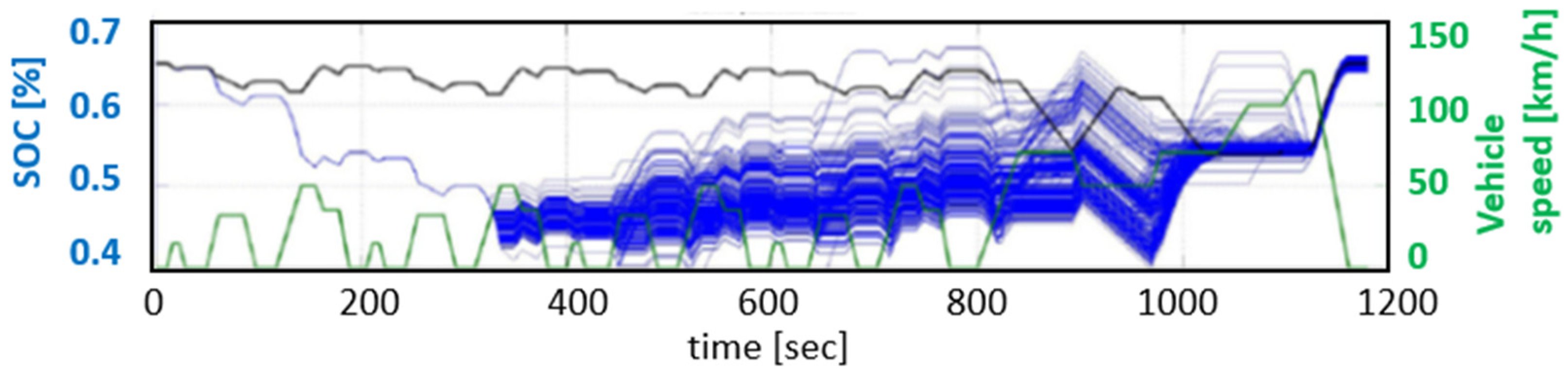

Section 2.2.1) are used for the control topology, with different modes being selected in different regions. The vehicle speed is just used to realize the IDEL, i.e., in all the cases, the vehicle speed is not in the stationary position. The SOC is divided into five levels, like the parallel hybrids, i.e., SOC_min, SOC_low, SOC_initial, SOC_high and SOC_max, and SOC_low and SOC_high are again the flexible values for the optimization process. According to the power demand of the wheels, the operation modes have been divided by the different levels of power from the EMs, and it also depends on the number of engine OPs from single OP to multiple OPs.

Figure 4 shows examples of the engine OPs for serial hybrids with single OP (the symbol with the red star) and multiple OPs (the symbols with blue stars).

The control strategy for a single OP for serial hybrids is relatively simple. As long as the SOC is above the threshold value, depending on the power demand of the EM, the ICE will be at rest. The ICE with generator is switched on to charge the battery when the SOC of the battery is depleted. Both the ICE and generator run in their most efficient areas. The serial hybrids with a single engine OP are ideal for serial hybrids with large battery sizes, like range-extender hybrids. Mostly, EV mode is used until “Pm_eff” (Pm_eff is the calculated power of the engine at the OP to transfer the power demanded by the EM), while the engine runs to charge the battery according to the SOC. In case of high power demand from the EM, the engine and EM run mostly together in hybrid mode to avoid high battery discharge in this region.

In the case of the traditional serial hybrid topology with multiple engine OPs, three engine OPs (blue symbols in

Figure 5, for example) are used in the case of the serial hybrid; OP2 is the most efficient operating condition in the given engine map, and OP1 is a relatively highly efficient point with low torque and speed. OP3 is the maximum power from the engine. The ICE power command depends on the threshold value of SOC at different levels of total power demand of the EMs. The power demands of the EMs is divided across the range from “Pm_min” to “Pm_OP3”. “Pm_min”, “Pm_low” and “Pm_high” are variable values based on driver inputs, and “Pm_OP1”, “Pm_OP2” and “Pm_OP3” are calculated values that determine the combination of torque and speed of the ICE at the OPs for the generated power demand. The EV mode is mostly used to minimize the fuel consumption below Pm_OP1 (e.g., SOC_min, SOC_low or SOC_initial, depending on the power demand of the EM), and the ICE runs only to charge the battery when the SOC is lower than the threshold values set as low limitations. Above Pm_OP1, the EV mode will be limited only to cases where the SOC is high. When the SOC is below the threshold, the combination of the power sources (ICE and EM) will be used, and the operating regions of the ICE (OP1 or OP2) and the operating modes (ICE (GEN) + EV mode or ICE (GEN) mode) will be varied depending on the SOC. Above Pm_OP2, the system mostly runs in hybrid mode and charging mode, with maximum power coming from the ICE to minimize the discharge of battery, and very limited EV mode. The objective of the topology with multiple OPs is to keep the ICE operation in the sweet spot of relatively low fuel consumption, and further increase in demand essentially keeps the system operating in hybrid mode to maintain a reasonable level of SOC. The present study uses a 1-speed transmission concept, as less emphasis is placed on the vehicle’s ability to climb and accelerate. The main lever here is the most cost-effective concept with minimal fuel consumption. The use of a higher number of gears is also possible in this simulation tool.

The operating parameters can be controlled by the topology using a state-flow or a Fuzzy logic tool in the simulation. The control strategy of hybrids decides on the instantaneous power request from the different energy sources while respecting numerous constraints. For this reason, the combination of the parameters and the energy management strategies is very important for the HEV optimization for energy consumption. In this simulation, the Fuzzy logic controller is proposed. In case of a serial hybrid model, for example, the power demand, SOC and vehicle speed are generally used as the control parameters. The required power for EMs is generated by a combination of a generator for an ICE and an EM. They are very simple, conceptually, consisting of an input stage, a processing stage and an output stage. The input stage maps the parameters to the appropriate membership functions and the truth values. The processing stage invokes each appropriate rule and generates results for each, then combines the results of the rules. Finally, the output stage converts the combined results back into a specific control output value. The advantage of the Fuzzy logic is helping the user to view systematic validation of each interaction. The result of simulation shows the excellent effect of the optimal control strategy to share the required power between the ICE and the electric motor. Through the simulation, it can be proved that the fuzzy logic controller is useful for improving driving performance, and the Fuzzy logic technique is suitable for hybrid electric vehicles [

17].

- 3.

Serial/parallel hybrid topology

In multi-configuration hybrids, clutches or power-split gear sets make it possible to switch from one configuration to another (i.e., between serial and parallel systems). The serial/parallel configuration has a similar control topology to the one described before, for serial hybrids. The difference arises from its flexibility, which allows the mechanical connection of the ICE to the wheels in parallel hybrid mode or the combination of the power sources (the EM and the ICE with a generator) as in serial hybrid mode. The increased flexibility allows a combination of the advantages of each hybrid architecture. All nine operating modes (

Section 2.2.1) are able to be used in the serial/parallel hybrid topology. Here, the vehicle acts as a serial hybrid at low speeds and as a parallel hybrid for highway cruising. At low speed and torque (below Pm_OP1, like serial hybrid), the vehicle works either in serial mode or in pure electric (EV) mode, and the status of the ICE is determined by the SOC values. At medium power demand (between Pm_OP1 and Pm_OP2, like for the serial hybrid), the serial and parallel systems are used depending on SOC. With a further increase in the power demand of wheels (above Pm_OP2, like serial hybrid), the parallel system will mainly be used. In this configuration, all the machines can directly act on the gearbox input shaft to meet the torque demand of the vehicle. The energy management determines what fraction of torque is generated by the EM and the ICE.