Physical Properties of Modern Reciprocal Endodontic Systems and Fatigue Failure Testing in Simulated Clinical Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

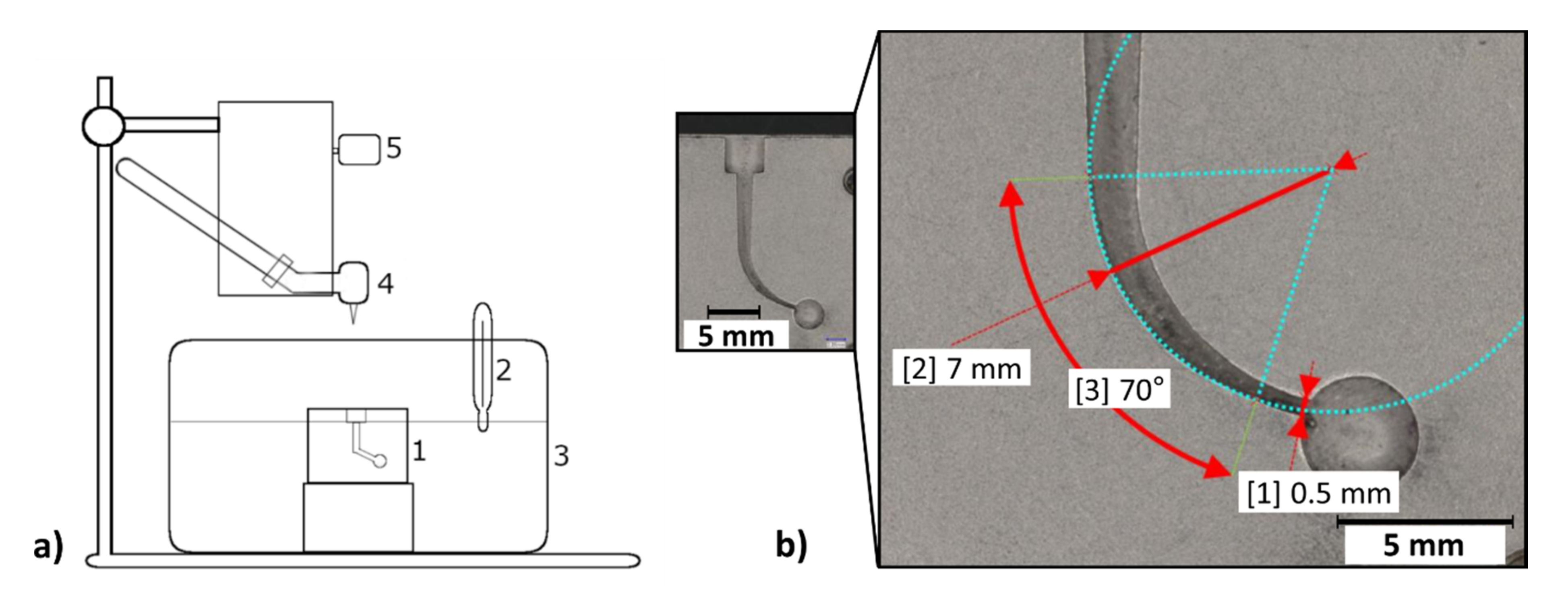

2.2. Cyclic Fatigue

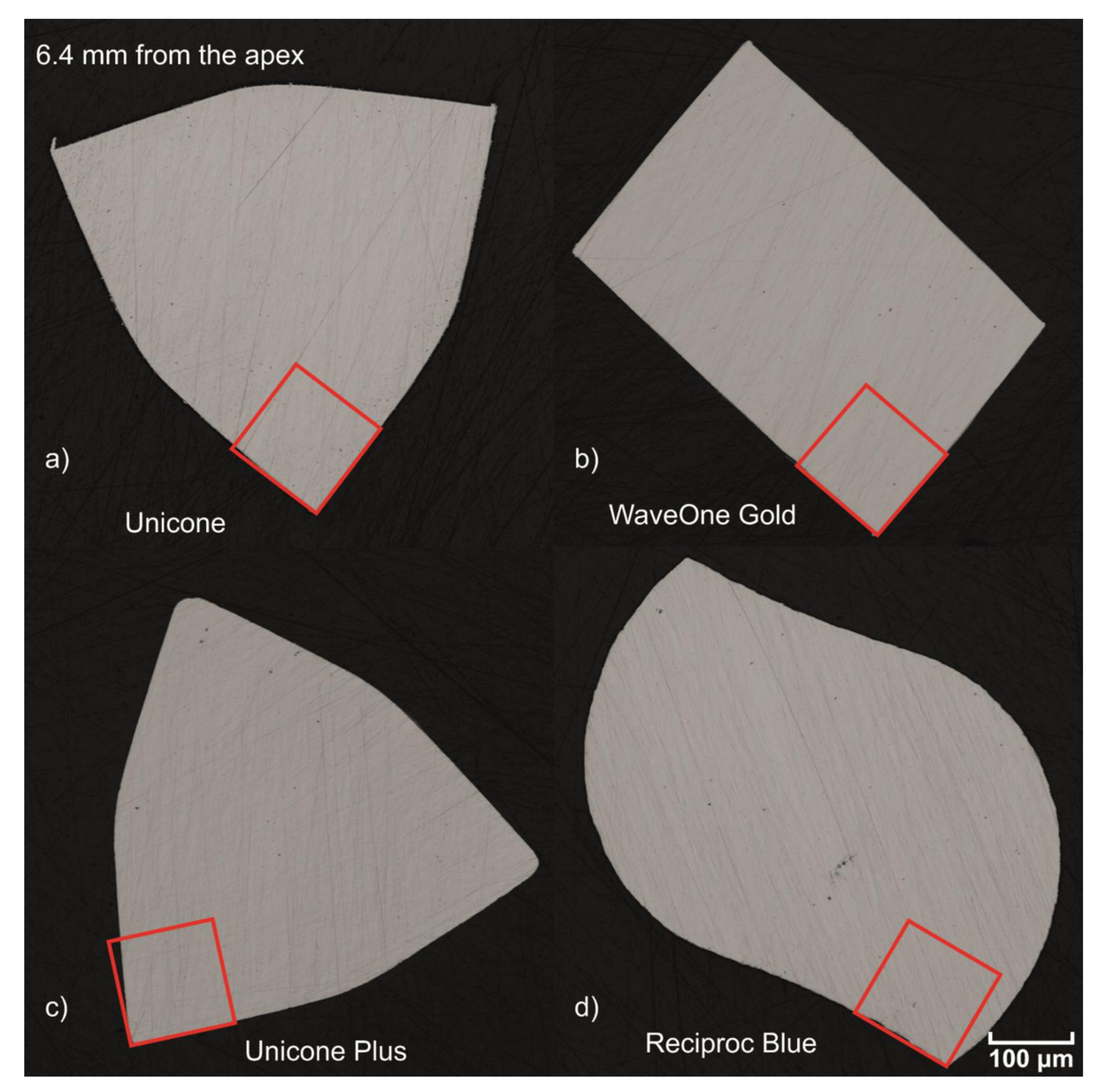

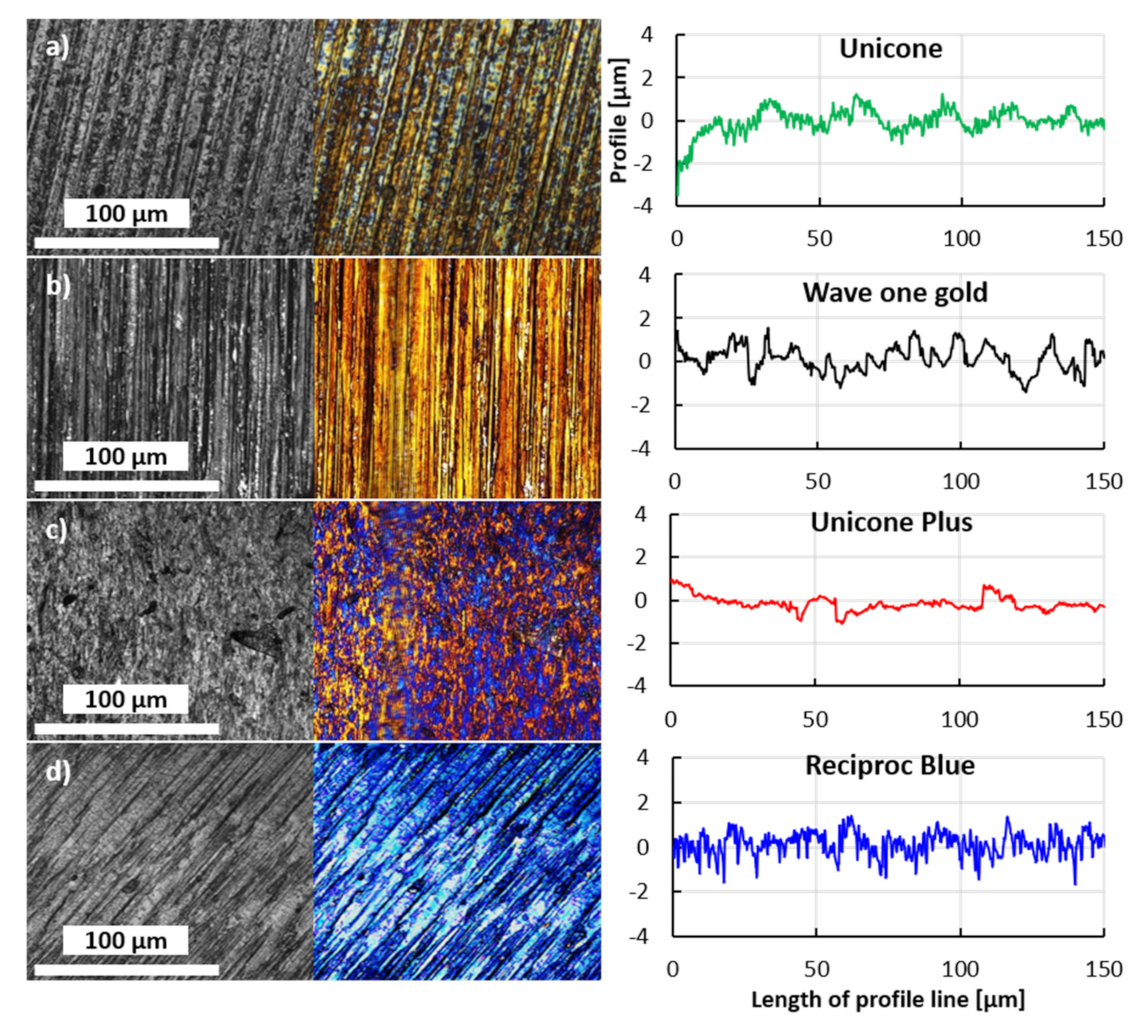

2.3. Local Mechanical Properties

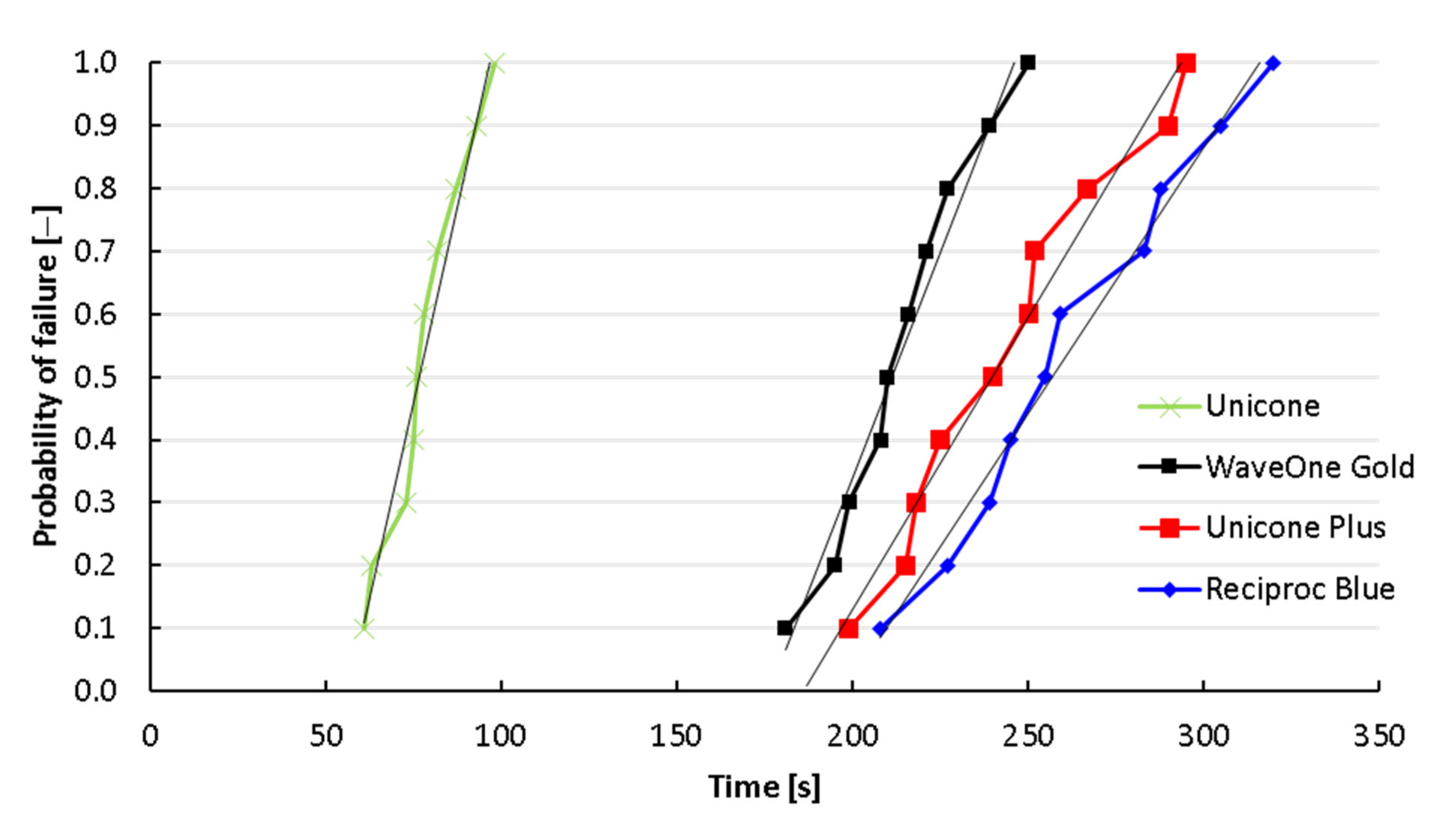

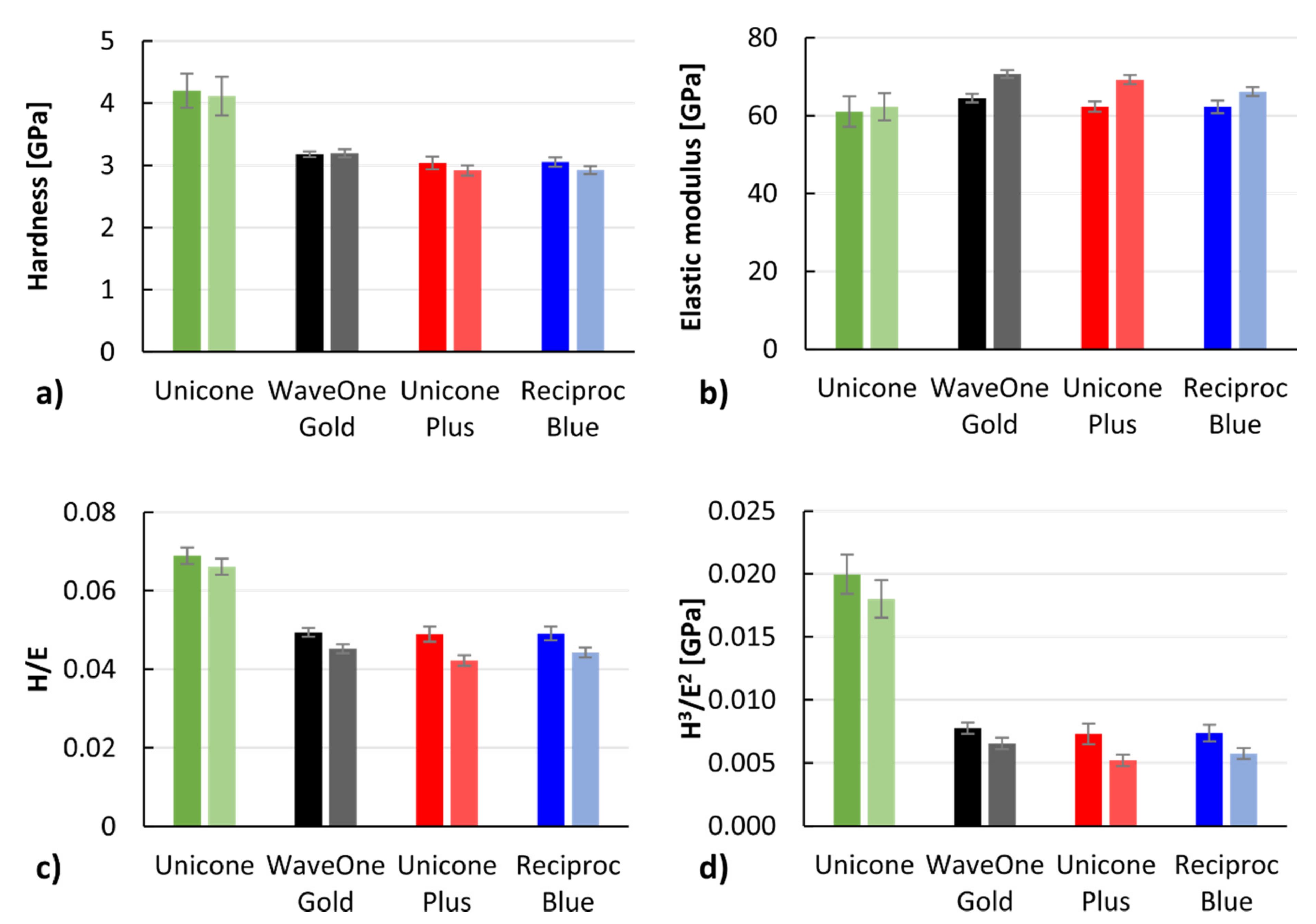

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Parashos, P.; Messer, H.H. Rotary NiTi Instrument Fracture and its Consequences. J. Endod. 2006, 32, 1031–1043. [Google Scholar] [CrossRef] [PubMed]

- Sattapan, B.; Nervo, G.J.; Palamara, J.E.A.; Messer, H.H. Defects in Rotary Nickel-Titanium Files After Clinical Use. J. Endod. 2000, 26, 161–165. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peng, B.; Shen, Y.; Cheung, G.S.P.; Xia, T.J. Defects in ProTaper S1 instruments after clinical use: Longitudinal examination. Int. Endod. J. 2005, 38, 550–557. [Google Scholar] [CrossRef]

- Shen, Y.; Cheung, G.S.-P.; Peng, B.; Haapasalo, M. Defects in Nickel-Titanium Instruments after Clinical Use. Part 2: Fractographic Analysis of Fractured Surface in a Cohort Study. J. Endod. 2009, 35, 133–136. [Google Scholar] [CrossRef] [PubMed]

- Parashos, P.; Gordon, I.; Messer, H.H. Factors Influencing Defects of Rotary Nickel-Titanium Endodontic Instruments After Clinical Use. J. Endod. 2004, 30, 722–725. [Google Scholar] [CrossRef]

- Cheung, G.S.P.; Darvell, B.W. Fatigue testing of a NiTi rotary instrument. Part 2: Fractographic analysis. Int. Endod. J. 2007, 40, 619–625. [Google Scholar] [CrossRef]

- Alapati, S.B.; Brantley, W.A.; Svec, T.A.; Powers, J.M.; Nusstein, J.M.; Daehn, G.S. SEM Observations of Nickel-Titanium Rotary Endodontic Instruments that Fractured During Clinical Use. J. Endod. 2005, 31, 40–43. [Google Scholar] [CrossRef]

- Thompson, S.A. An overview of nickel–titanium alloys used in dentistry. Int. Endod. J. 2000, 33, 297–310. [Google Scholar] [CrossRef] [Green Version]

- Zhou, H.; Peng, B.; Zheng, Y.-F. An overview of the mechanical properties of nickel–titanium endodontic instruments. Endod. Top. 2013, 29, 42–54. [Google Scholar] [CrossRef]

- Miyazaki, S.; Otsuka, K. Deformation and transition behavior associated with theR-phase in Ti-Ni alloys. Metall. Trans. A 1986, 17, 53–63. [Google Scholar] [CrossRef]

- Larsen, C.M.; Watanabe, I.; Glickman, G.N.; He, J. Cyclic Fatigue Analysis of a New Generation of Nickel Titanium Rotary Instruments. J. Endod. 2009, 35, 401–403. [Google Scholar] [CrossRef]

- Kuhn, G.; Jordan, L. Fatigue and Mechanical Properties of Nickel-Titanium Endodontic Instruments. J. Endod. 2002, 28, 716–720. [Google Scholar] [CrossRef]

- Zupanc, J.; Vahdat-Pajouh, N.; Schäfer, E. New thermomechanically treated NiTi alloys—A review. Int. Endod. J. 2018, 51, 1088–1103. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Plotino, G.; Grande, N.M.; Testarelli, L.; Gambarini, G.; Castagnola, R.; Rossetti, A.; Özyürek, T.; Cordaro, M.; Fortunato, L. Cyclic Fatigue of Reciproc and Reciproc Blue Nickel-titanium Reciprocating Files at Different Environmental Temperatures. J. Endod. 2018, 44, 1549–1552. [Google Scholar] [CrossRef] [PubMed]

- Lopes, H.P.; Elias, C.N.; Vieira, M.V.B.; Vieira, V.T.L.; de Souza, L.C.; dos Santos, A.L. Influence of Surface Roughness on the Fatigue Life of Nickel-Titanium Rotary Endodontic Instruments. J. Endod. 2016, 42, 965–968. [Google Scholar] [CrossRef] [PubMed]

- Oh, S.; Kum, K.-Y.; Kim, H.-J.; Moon, S.-Y.; Kim, H.-C.; Chaniotis, A.; Perinpanayagam, H.; Pedullá, E.; Chang, S.W. Bending resistance and cyclic fatigue resistance of WaveOne Gold, Reciproc Blue, and HyFlex EDM instruments. J. Dent. Sci. 2020, 15, 472–478. [Google Scholar] [CrossRef] [PubMed]

- Di Nardo, D.; Gambarini, G.; Seracchiani, M.; Mazzoni, A.; Zanza, A.; Giudice, A.; Angelo, M.; Testarelli, L. Influence of different cross-section on cyclic fatigue resistance of two nickel-titanium rotary instruments with same heat treatment: An in vitro study. Saudi Endod. J. 2020, 10, 221. [Google Scholar]

- Zinelis, S.; Darabara, M.; Takase, T.; Ogane, K.; Papadimitriou, G.D. The effect of thermal treatment on the resistance of nickel-titanium rotary files in cyclic fatigue. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2007, 103, 843–847. [Google Scholar] [CrossRef]

- Zinelis, S.; Eliades, T.; Eliades, G. A metallurgical characterization of ten endodontic Ni-Ti instruments: Assessing the clinical relevance of shape memory and superelastic properties of Ni-Ti endodontic instruments. Int. Endod. J. 2010, 43, 125–134. [Google Scholar] [CrossRef]

- Keskin, C.; Inan, U.; Demiral, M.; Keleş, A. Cyclic Fatigue Resistance of Reciproc Blue, Reciproc, and WaveOne Gold Reciprocating Instruments. J. Endod. 2017, 43, 1360–1363. [Google Scholar] [CrossRef]

- Özyürek, T. Cyclic Fatigue Resistance of Reciproc, WaveOne, and WaveOne Gold Nickel-Titanium Instruments. J. Endod. 2016, 42, 1536–1539. [Google Scholar] [CrossRef]

- Gao, Y.; Gutmann, J.L.; Wilkinson, K.; Maxwell, R.; Ammon, D. Evaluation of the Impact of Raw Materials on the Fatigue and Mechanical Properties of ProFile Vortex Rotary Instruments. J. Endod. 2012, 38, 398–401. [Google Scholar] [CrossRef]

- Keleş, A.; Eymirli, A.; Uyanık, O.; Nagas, E. Influence of static and dynamic cyclic fatigue tests on the lifespan of four reciprocating systems at different temperatures. Int. Endod. J. 2019, 52, 880–886. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-C.; Kwak, S.-W.; Cheung, G.S.-P.; Ko, D.-H.; Chung, S.-M.; Lee, W. Cyclic Fatigue and Torsional Resistance of Two New Nickel-Titanium Instruments Used in Reciprocation Motion: Reciproc Versus WaveOne. J. Endod. 2012, 38, 541–544. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Plotino, G.; Grande, N.M.; Melo, M.C.; Bahia, M.G.; Testarelli, L.; Gambarini, G. Cyclic fatigue of NiTi rotary instruments in a simulated apical abrupt curvature. Int. Endod. J. 2010, 43, 226–230. [Google Scholar] [CrossRef] [PubMed]

- Plotino, G.; Testarelli, L.; Al-Sudani, D.; Pongione, G.; Grande, N.M.; Gambarini, G. Fatigue resistance of rotary instruments manufactured using different nickel–titanium alloys: A comparative study. Odontology 2014, 102, 31–35. [Google Scholar] [CrossRef]

- Plotino, G.; Grande, N.M.; Testarelli, L.; Gambarini, G. Cyclic fatigue of Reciproc and WaveOne reciprocating instruments. Int. Endod. J. 2012, 45, 614–618. [Google Scholar] [CrossRef] [PubMed]

- Grande, N.M.; Plotino, G.; Pecci, R.; Bedini, R.; Malagnino, V.A.; Somma, F. Cyclic fatigue resistance and three-dimensional analysis of instruments from two nickel–titanium rotary systems. Int. Endod. J. 2006, 39, 755–763. [Google Scholar] [CrossRef]

- De Hemptinne, F.; Slaus, G.; Vandendael, M.; Jacquet, W.; De Moor, R.J.; Bottenberg, P. In Vivo Intracanal Temperature Evolution during Endodontic Treatment after the Injection of Room Temperature or Preheated Sodium Hypochlorite. J. Endod. 2015, 41, 1112–1115. [Google Scholar] [CrossRef]

- Huang, X.; Shen, Y.; Wei, X.; Haapasalo, M. Fatigue Resistance of Nickel-titanium Instruments Exposed to High-concentration Hypochlorite. J. Endod. 2017, 43, 1847–1851. [Google Scholar] [CrossRef]

- De Vasconcelos, R.A.; Murphy, S.; Carvalho, C.A.T.; Govindjee, R.G.; Govindjee, S.; Peters, O.A. Evidence for Reduced Fatigue Resistance of Contemporary Rotary Instruments Exposed to Body Temperature. J. Endod. 2016, 42, 782–787. [Google Scholar] [CrossRef] [Green Version]

- Grande, N.M.; Plotino, G.; Silla, E.; Pedullà, E.; DeDeus, G.; Gambarini, G.; Somma, F. Environmental Temperature Drastically Affects Flexural Fatigue Resistance of Nickel-titanium Rotary Files. J. Endod. 2017, 43, 1157–1160. [Google Scholar] [CrossRef]

- Pedullà, E.; Lo Savio, F.; Boninelli, S.; Plotino, G.; Grande, N.M.; La Rosa, G.; Rapisarda, E. Torsional and Cyclic Fatigue Resistance of a New Nickel-Titanium Instrument Manufactured by Electrical Discharge Machining. J. Endod. 2016, 42, 156–159. [Google Scholar] [CrossRef] [PubMed]

- Plotino, G.; Grande, N.M.; Cotti, E.; Testarelli, L.; Gambarini, G. Blue Treatment Enhances Cyclic Fatigue Resistance of Vortex Nickel-Titanium Rotary Files. J. Endod. 2014, 40, 1451–1453. [Google Scholar] [CrossRef]

- Plotino, G.; Grande, N.M.; Mercadé Bellido, M.; Testarelli, L.; Gambarini, G. Influence of Temperature on Cyclic Fatigue Resistance of ProTaper Gold and ProTaper Universal Rotary Files. J. Endod. 2017, 43, 200–202. [Google Scholar] [CrossRef] [PubMed]

- Hülsmann, M. Research that matters: Studies on fatigue of rotary and reciprocating NiTi root canal instruments. Int. Endod. J. 2019, 52, 1401–1402. [Google Scholar] [CrossRef]

- Aoun, C.; Nehme, W.; Naaman, A.; Khalil, I. Review and classification of endodontic heat treatment procedures. Int. J. Curr. Res. 2017, 9, 51300–51306. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Standardization, I.O.F. Geometrical Product Specifications (GPS)—Surface texture: Profile method—Terms, definitions and surface texture parameters. In 01.040.17 Metrology and Measurement. Physical Phenomena (Vocabularies) 17.040.20 Properties of Surfaces; ISO 4287; ISO—International Organization for Standardization: Geneve, Switzerland, 1997; p. 25. [Google Scholar]

- Özyürek, T.; Gündoğar, M.; Yılmaz, K.; Uslu, G. Bending resistance and cyclic fatigue life of Reciproc Blue, WaveOne Gold, and Genius files in a double (S-shaped) curved canal. J. Dent. Res. Dent. Clin. Dent. Prospect. 2017, 11, 241–246. [Google Scholar] [CrossRef]

- Pedullà, E.; Grande, N.M.; Plotino, G.; Gambarini, G.; Rapisarda, E. Influence of continuous or reciprocating motion on cyclic fatigue resistance of 4 different nickel-titanium rotary instruments. J. Endod. 2013, 39, 258–261. [Google Scholar] [CrossRef]

- Plotino, G.; Grande, N.M.; Mazza, C.; Petrovic, R.; Testarelli, L.; Gambarini, G. Influence of size and taper of artificial canals on the trajectory of NiTi rotary instruments in cyclic fatigue studies. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2010, 109, e60–e66. [Google Scholar] [CrossRef]

- Plotino, G.; Costanzo, A.; Grande, N.M.; Petrovic, R.; Testarelli, L.; Gambarini, G. Experimental Evaluation on the Influence of Autoclave Sterilization on the Cyclic Fatigue of New Nickel-Titanium Rotary Instruments. J. Endod. 2012, 38, 222–225. [Google Scholar] [CrossRef] [PubMed]

- Plotino, G.; Grande, N.M.; Cordaro, M.; Testarelli, L.; Gambarini, G. A Review of Cyclic Fatigue Testing of Nickel-Titanium Rotary Instruments. J. Endod. 2009, 35, 1469–1476. [Google Scholar] [CrossRef]

- Pereira, É.S.J.; Viana, A.C.D.; Buono, V.T.L.; Peters, O.A.; Azevedo Bahia, M.G.d. Behavior of Nickel-Titanium Instruments Manufactured with Different Thermal Treatments. J. Endod. 2015, 41, 67–71. [Google Scholar] [CrossRef]

- Martins, J.N.R.; Silva, E.J.N.L.; Marques, D.; Belladonna, F.; Simões-Carvalho, M.; Vieira, V.T.L.; Antunes, H.S.; Braz Fernandes, F.M.B.; Versiani, M.A. Design, metallurgical features, mechanical performance and canal preparation of six reciprocating instruments. Int. Endod. J. 2021, 54, 1623–1637. [Google Scholar] [CrossRef] [PubMed]

- Bahia, M.G.A.; Buono, V.T.L. Decrease in the fatigue resistance of nickel-titanium rotary instruments after clinical use in curved root canals. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2005, 100, 249–255. [Google Scholar] [CrossRef] [PubMed]

- Ninan, E.; Berzins, D.W. Torsion and Bending Properties of Shape Memory and Superelastic Nickel-Titanium Rotary Instruments. J. Endod. 2013, 39, 101–104. [Google Scholar] [CrossRef] [PubMed]

- Ha, J.H.; Cheung, G.S.P.; Versluis, A.; Lee, C.J.; Kwak, S.W.; Kim, H.C. ‘Screw-in’ tendency of rotary nickel–titanium files due to design geometry. Int. Endod. J. 2015, 48, 666–672. [Google Scholar] [CrossRef]

- Callister, W.D. Materials Science and Engineering, 8th ed.; John Wiley and Sons Ltd.: Chichester, UK, 2010; p. 1000. [Google Scholar]

- Getsov, L.B.; Rybinkov, A.I.; Malashenko, I.S. Cyclic strength of high-temperature alloys with coatings. Strength Mater. 1988, 20, 1576–1581. [Google Scholar] [CrossRef]

- Casagrande, A.; Cammarota, G.P.; Micele, L. Relationship between fatigue limit and Vickers hardness in steels. Mater. Sci. Eng. A 2011, 528, 3468–3473. [Google Scholar] [CrossRef]

- Wang, R.-J.; Shang, D.-G. Low-cycle fatigue life prediction of spot welds based on hardness distribution and finite element analysis. Int. J. Fatigue 2009, 31, 508–514. [Google Scholar] [CrossRef]

- Keryvin, V.; Hoang, V.H.; Shen, J. Hardness, toughness, brittleness and cracking systems in an iron-based bulk metallic glass by indentation. Intermetallics 2009, 17, 211–217. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Pintaude, G. Introduction of the Ratio of the Hardness to the Reduced Elastic Modulus for Abrasion. In Tribology—Fundamentals and Advancements; Gegner, J., Ed.; IntechOpen: Rijeka, Croatia, 2013. [Google Scholar]

- Ni, W.; Cheng, Y.-T.; Lukitsch, M.J.; Weiner, A.M.; Lev, L.C.; Grummon, D.S. Effects of the ratio of hardness to Young’s modulus on the friction and wear behavior of bilayer coatings. Appl. Phys. Lett. 2004, 85, 4028–4030. [Google Scholar] [CrossRef]

- Tsui, T.Y.; Pharr, G.M.; Oliver, W.C.; Chung, Y.W.; Cutiongco, E.C.; Bhatia, C.S.; White, R.L.; Rhoades, R.L.; Gorbatkins, S.M. Nanoindentation and nanoscratching of hard coating materials for magnetic disks. MSEng 1995, 356, 767–772. [Google Scholar]

- Beake, B.D.; Isern, L.; Bhattacharyya, D.; Endrino, J.L.; Lawson, K.; Walker, T. Nano- and micro-scale impact testing of zirconia, alumina and zirconia-alumina duplex optical coatings on glass. Wear 2020, 462, 203499. [Google Scholar] [CrossRef]

- Silva, E.J.N.L.; Martins, J.N.R.; Lima, C.O.; Vieira, V.T.L.; Braz Fernandes, F.M.; De-Deus, G.; Versiani, M.A. Mechanical Tests, Metallurgical Characterization, and Shaping Ability of Nickel-Titanium Rotary Instruments: A Multimethod Research. J. Endod. 2020, 46, 1485–1494. [Google Scholar] [CrossRef] [PubMed]

| WaveOne Gold | Reciproc Blue | Unicone Plus | Unicone | |

|---|---|---|---|---|

| Time to fracture (s) | 214.6 ± 20.7 | 262.9 ± 35.5 | 245.1 ± 32.1 | 78.6 ± 11.9 |

| Fracture position (mm) | 5.5 ± 0.4 | 5.7 ± 0.5 | 5.8 ± 0.5 | 5.4 ± 0.4 |

| Ra [µm] | Rq [µm] | Rz [µm] | Rc [µm] | Rt [µm] | |

|---|---|---|---|---|---|

| Unicone | 0.29 ± 0.08 | 0.39 ± 0.12 | 2.22 ± 0.64 | 1.28 ± 0.35 | 3.47 ± 1.54 |

| WaveOne gold | 0.54 ± 0.05 | 0.67 ± 0.06 | 3.34 ± 0.30 | 2.01 ± 0.27 | 4.16 ± 0.55 |

| Unicone Plus | 0.19 ± 0.03 | 0.26 ± 0.05 | 1.63 ± 0.36 | 0.78 ± 0.20 | 2.46 ± 0.62 |

| Reciproc Blue | 0.36 ± 0.10 | 0.45 ± 0.13 | 2.62 ± 0.80 | 1.56 ± 0.49 | 3.41 ± 0.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jusku, A.; Tomáštík, J.; Václavek, L.; Jirásek, P.; Harvan, Ľ.; Holík, P.; Čtvrtlík, R. Physical Properties of Modern Reciprocal Endodontic Systems and Fatigue Failure Testing in Simulated Clinical Conditions. Appl. Sci. 2021, 11, 11160. https://doi.org/10.3390/app112311160

Jusku A, Tomáštík J, Václavek L, Jirásek P, Harvan Ľ, Holík P, Čtvrtlík R. Physical Properties of Modern Reciprocal Endodontic Systems and Fatigue Failure Testing in Simulated Clinical Conditions. Applied Sciences. 2021; 11(23):11160. https://doi.org/10.3390/app112311160

Chicago/Turabian StyleJusku, Alexandr, Jan Tomáštík, Lukáš Václavek, Petr Jirásek, Ľuboš Harvan, Pavel Holík, and Radim Čtvrtlík. 2021. "Physical Properties of Modern Reciprocal Endodontic Systems and Fatigue Failure Testing in Simulated Clinical Conditions" Applied Sciences 11, no. 23: 11160. https://doi.org/10.3390/app112311160

APA StyleJusku, A., Tomáštík, J., Václavek, L., Jirásek, P., Harvan, Ľ., Holík, P., & Čtvrtlík, R. (2021). Physical Properties of Modern Reciprocal Endodontic Systems and Fatigue Failure Testing in Simulated Clinical Conditions. Applied Sciences, 11(23), 11160. https://doi.org/10.3390/app112311160