Evaluations of All-in-One, Polycarboxylate-Based Superplasticizer with Viscosity Modifying Agents for the Application of Normal-Strength, High-Fluidity Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Cement and Mineral Admixtures

2.1.2. Aggregates

2.1.3. Superplasticizer

2.1.4. VMA (Viscosity Modifying Agent)

2.2. Experimental Methods

2.2.1. Preparation of the Polycarboxylate-Based Superplasticizers (NPCE)

2.2.2. Concrete Mix

2.2.3. Fluidity

2.2.4. Rheology

2.2.5. Compressive Strength

3. Results and Discussion

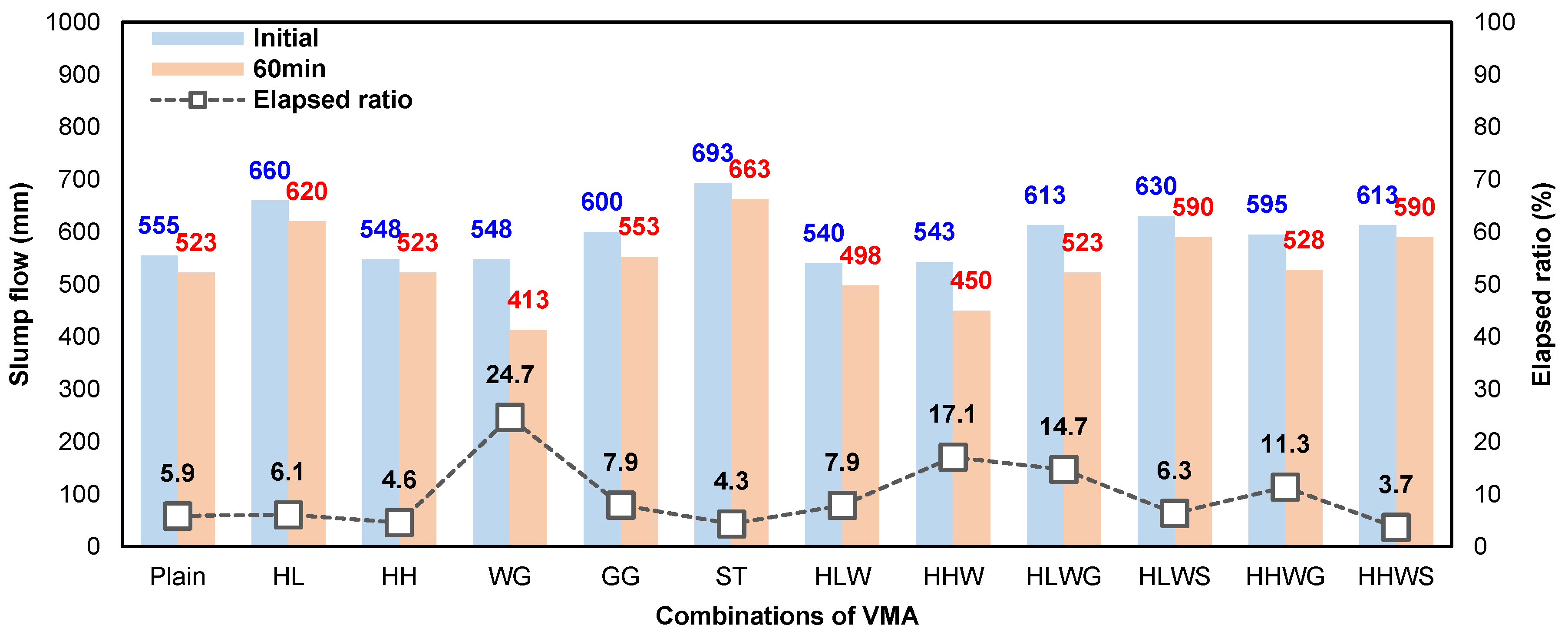

3.1. Workability

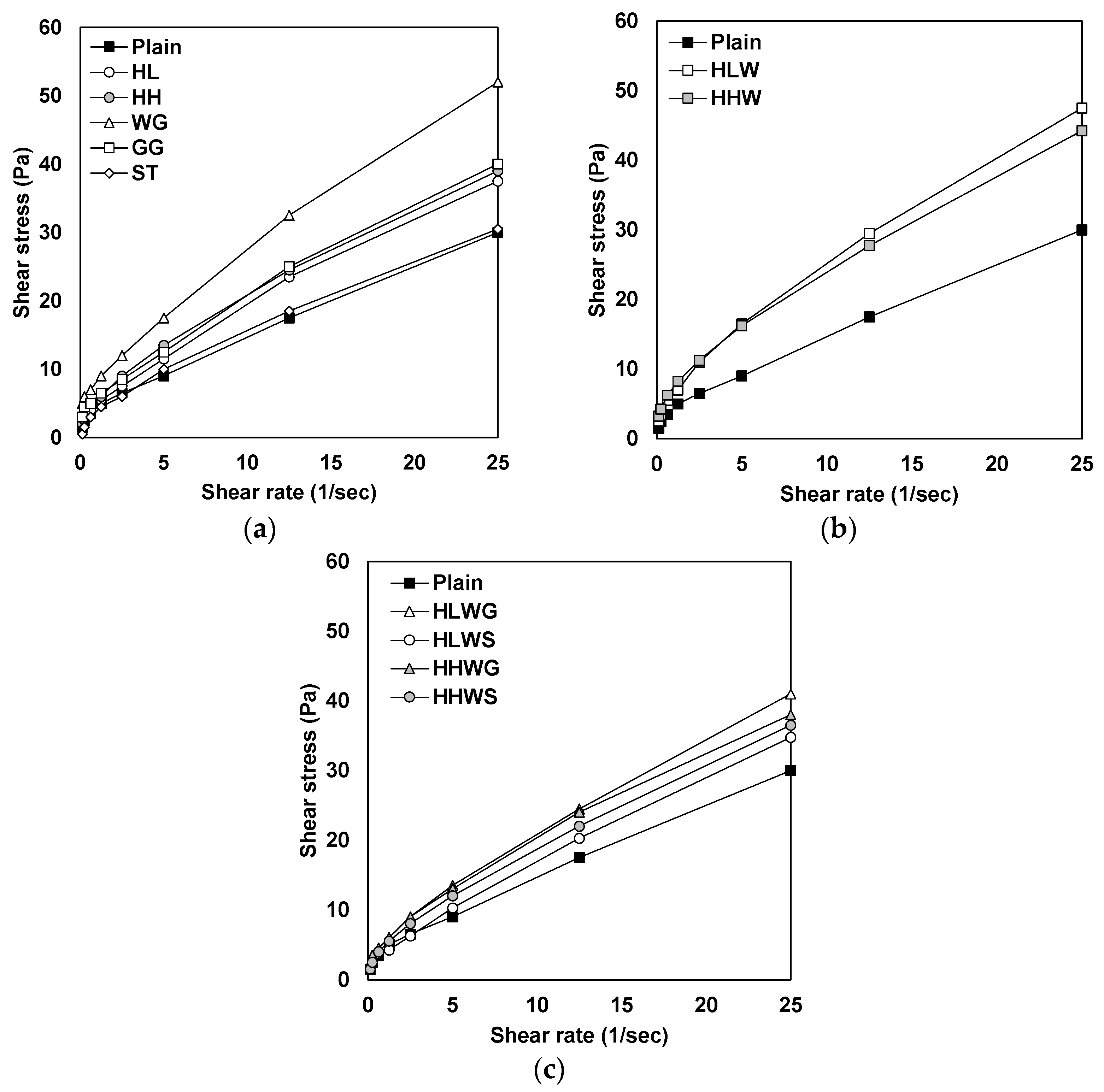

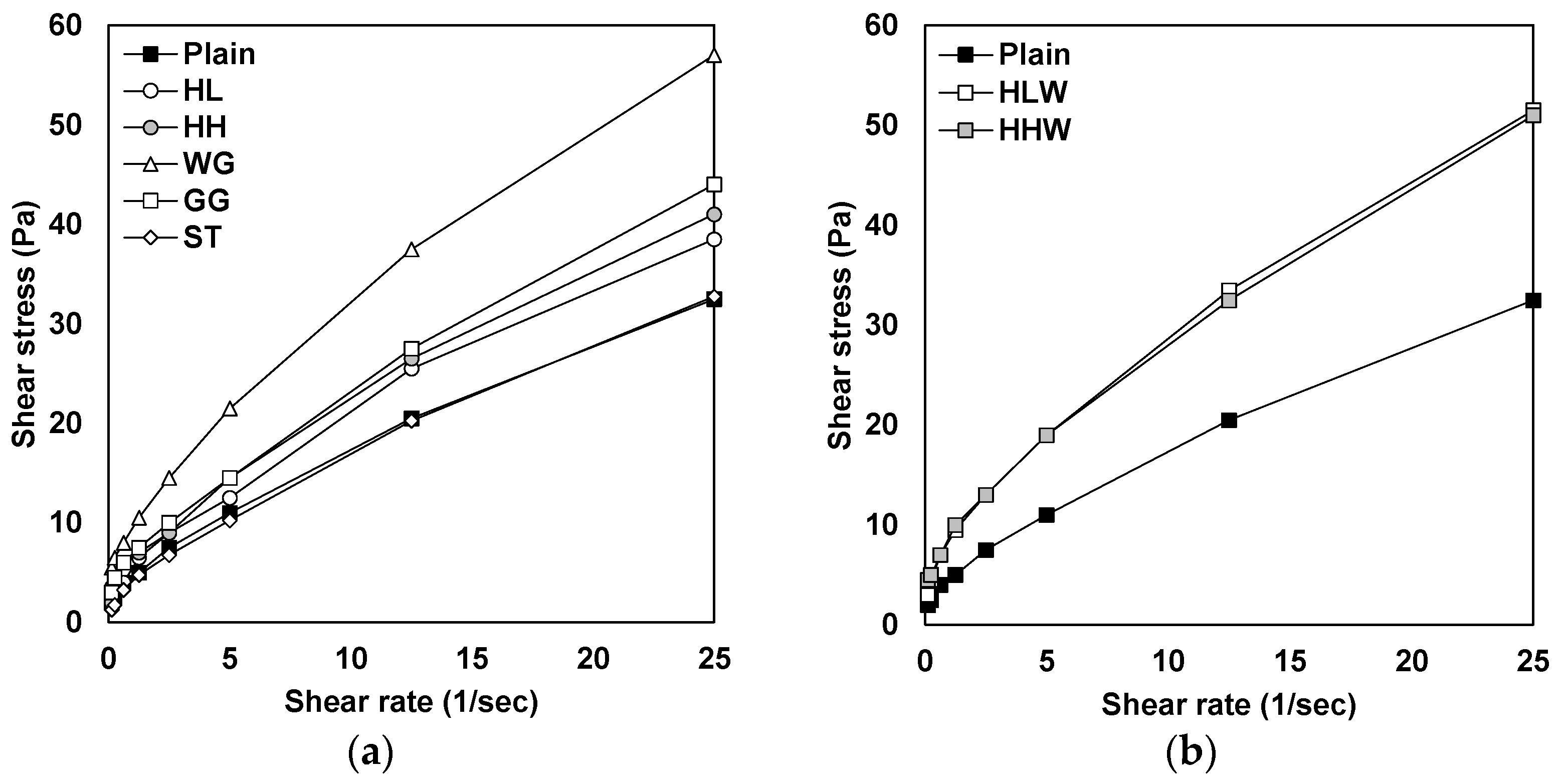

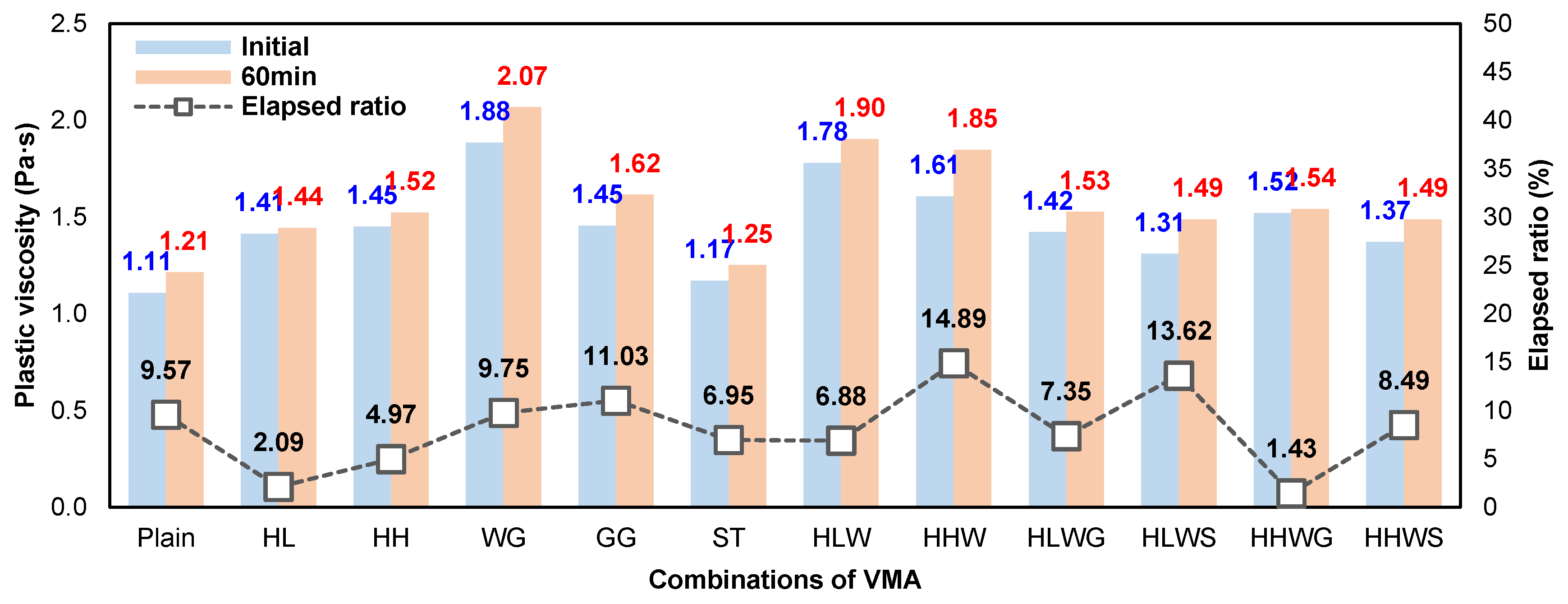

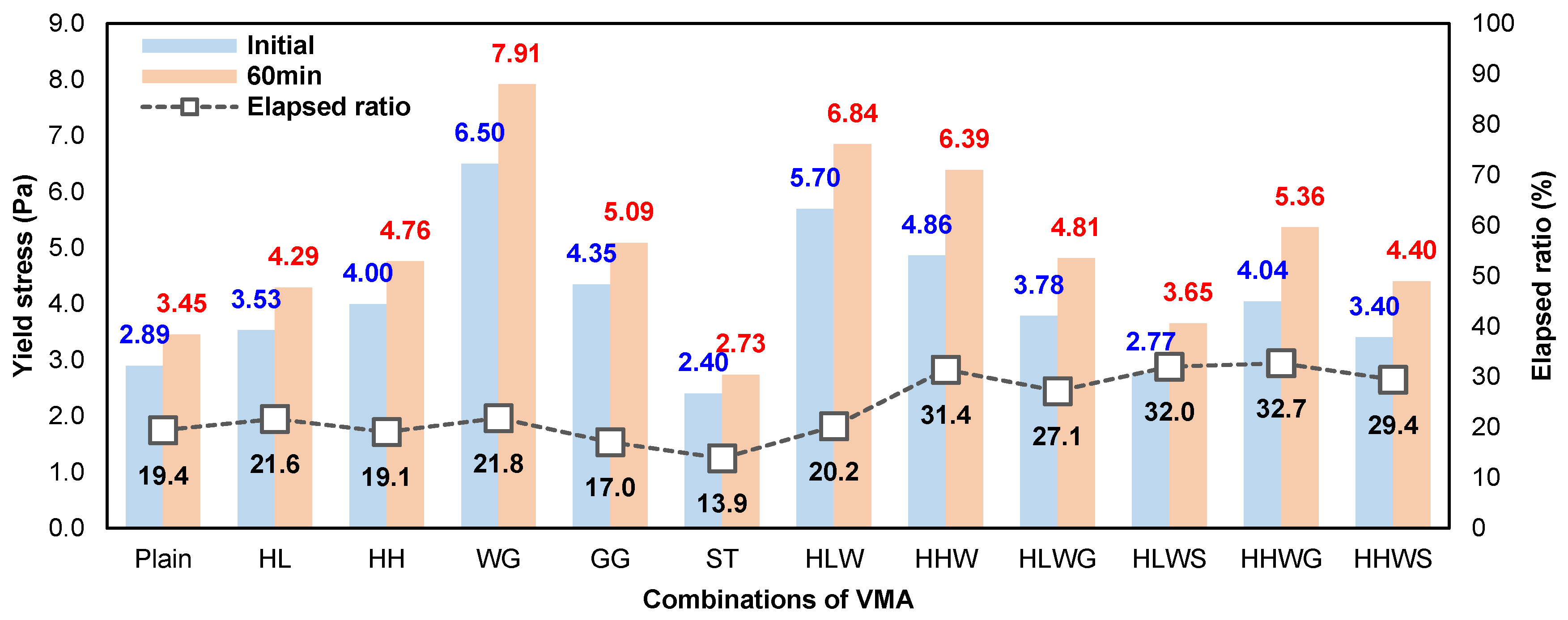

3.2. Rheological Performance

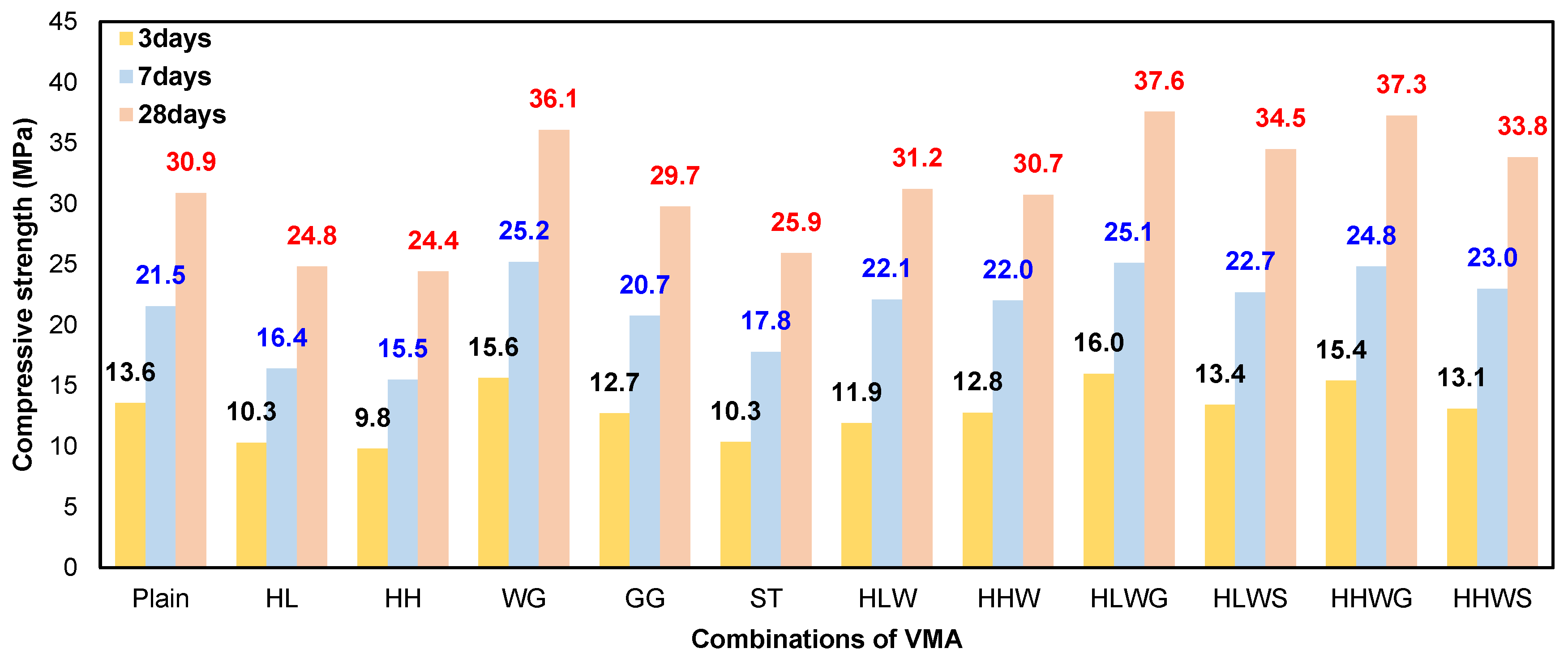

3.3. Compressive Strength

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ozawa, K.; Maekawa, K.; Okamura, H. Development of high performance concrete. J. Fac. Eng. Univ. Tokyo Ser. B 1992, 41, 381–439. [Google Scholar]

- Chen, Y.; Veer, F.; Copuroglu, O. A critical review of 3D concrete printing as a low CO2 concrete approach. Heron 2017, 62, 167–194. [Google Scholar]

- Safawi, M.I.; Iwaki, I.; Miura, T. A Study on the Applicability of Vibration in Fresh High-Fluidity Concrete. 2004. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0008884604004867 (accessed on 16 November 2021).

- Shi, Y.-X.; Matsui, I.; Guo, Y.-J. A study on the effect of fine mineral powders with distinct vitreous contents on the fluidity and rheological properties of concrete. Cem. Concr. Res. 2004, 34, 1381–1387. [Google Scholar] [CrossRef]

- Choi, Y.-W.; Chung, J.-S.; Moon, D.-J.; Shin, H.-C. A Study on Proportion of Normal-Strength Self-Compacting Concrete Using Ground Calcium Carbonate. J. Korean Soc. Civ. Eng. 2003, 23, 627–637. [Google Scholar]

- Choi, Y.-W.; Moon, J.-H.; Eom, J.-H. Chloride Ion Penetration Properties of Normal Strength High-Fluidity Concrete Using Lime Stone Powder. J. Korea Inst. Struct. Maint. Insp. 2010, 14, 160–168. [Google Scholar]

- Billberg, P. The effect of mineral and chemical admixtures on fine mortar rheology. Spec. Publ. 1997, 173, 301–320. [Google Scholar]

- Wasserman, R.I. The performance of high-fluidity concrete for normal strength structures. Constr. Build. Mater. 2017, 133, 285–300. [Google Scholar] [CrossRef]

- Pelisser, F.; Vieira, A.; Bernardin, A.M. Efficient self-compacting concrete with low cement consumption. J. Clean. Prod. 2018, 175, 324–332. [Google Scholar] [CrossRef]

- Yammine, J.; Chaouche, M.; Guerinet, M.; Moranville, M.; Roussel, N. From ordinary rhelogy concrete to self compacting concrete: A transition between frictional and hydrodynamic interactions. Cem. Concr. Res. 2008, 38, 890–896. [Google Scholar] [CrossRef]

- ACI PRC-237-07. Self-Consolidating Concrete. 2007. Available online: https://documents.pub/document/aci-237r-07-self-consolidating-concrete-1.html (accessed on 16 November 2021).

- Peng, Y.; Jacobsen, S. Influence of water/cement ratio, admixtures and filler on sedimentation and bleeding of cement paste. Cem. Concr. Res. 2013, 54, 133–142. [Google Scholar] [CrossRef]

- Peng, Y.; Lauten, R.A.; Reknes, K.; Jacobsen, S. Bleeding and sedimentation of cement paste measured by hydrostatic pressure and Turbiscan. Cem. Concr. Compos. 2017, 76, 25–38. [Google Scholar] [CrossRef]

- Tang, C.-W.; Yen, T.; Chang, C.-S.; Chen, K.-H. Optimizing mixture proportions for flowable high-performance concrete via rheology tests. Mater. J. 2001, 98, 493–502. [Google Scholar]

- Assaad, J.; Khayat, K.H.; Daczko, J. Evaluation of static stability of self-consolidating concrete. Mater. J. 2004, 101, 207–215. [Google Scholar]

- Bilgil, A.; Ozturk, B.; Bilgil, H. A numerical approach to determine viscosity-dependent segregation in fresh concrete. Appl. Math. Comput. 2005, 162, 225–241. [Google Scholar] [CrossRef]

- Winnefeld, F.; Becker, S.; Pakusch, J.; Götz, T. Effects of the molecular architecture of comb-shaped superplasticizers on their performance in cementitious systems. Cem. Concr. Compos. 2007, 29, 251–262. [Google Scholar] [CrossRef]

- Yamada, K.; Takahashi, T.; Hanehara, S.; Matsuhisa, M. Effects of the chemical structure on the properties of polycarboxylate-type superplasticizer. Cem. Concr. Res. 2000, 30, 197–207. [Google Scholar] [CrossRef]

- Palacios, M.; Flatt, R.J.; Puertas, F.; Sanchez-Herencia, A. Compatibility between polycarboxylate and viscosity-modifying admixtures in cement pastes. ACI Spec. Publ. 2012, 288, 29–42. [Google Scholar]

- Jang, H.-O.; Jee, N.-Y. An experimental study on the mixing of normal strength and high-fluidity concrete using ground granulated blast furnace slag. J. Archit. Inst. Korea Struct. Constr. 2013, 29, 81–88. [Google Scholar]

- Khayat, K.H. Viscosity-enhancing admixtures for cement-based materials—An overview. Cem. Concr. Compos. 1998, 20, 171–188. [Google Scholar] [CrossRef]

- Rols, S.; Ambroise, J.; Pera, J. Effects of different viscosity agents on the properties of self-leveling concrete. Cem. Concr. Res. 1999, 29, 261–266. [Google Scholar] [CrossRef]

- Lachemi, M.; Hossain, K.; Lambros, V.; Nkinamubanzi, P.-C.; Bouzoubaa, N. Performance of new viscosity modifying admixtures in enhancing the rheological properties of cement paste. Cem. Concr. Res. 2004, 34, 185–193. [Google Scholar] [CrossRef]

- Leemann, A.; Winnefeld, F. The effect of viscosity modifying agents on mortar and concrete. Cem. Concr. Compos. 2007, 29, 341–349. [Google Scholar] [CrossRef]

- Yen, T.; Tang, C.-W.; Chang, C.-S.; Chen, K.-H. Flow behaviour of high strength high-performance concrete. Cem. Concr. Compos. 1999, 21, 413–424. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Q.; Liu, C.; Zhou, M. Properties comparison of mortars with welan gum or cellulose ether. Constr. Build. Mater. 2016, 102, 648–653. [Google Scholar] [CrossRef]

- Ma, B.; Peng, Y.; Tan, H.; Jian, S.; Zhi, Z.; Guo, Y.; Qi, H.; Zhang, T.; He, X. Effect of hydroxypropyl-methyl cellulose ether on rheology of cement paste plasticized by polycarboxylate superplasticizer. Constr. Build. Mater. 2018, 160, 341–350. [Google Scholar] [CrossRef]

- Sakata, N.; Maruyama, K.; Minami, M. Basic properties and effects of welan gum on self-consolidating concrete. In Production Methods and Workability of Concrete; CRC Press: Boca Raton, FL, USA, 2004; pp. 249–266. [Google Scholar]

- Teng, L.; Zhu, J.; Khayat, K.H.; Liu, J. Effect of welan gum and nanoclay on thixotropy of UHPC. Cem. Concr. Res. 2020, 138, 106238. [Google Scholar] [CrossRef]

- Govin, A.; Bartholin, M.-C.; Biasotti, B.; Giudici, M.; Langella, V.; Grosseau, P. Modification of water retention and rheological properties of fresh state cement-based mortars by guar gum derivatives. Constr. Build. Mater. 2016, 122, 772–780. [Google Scholar] [CrossRef]

- Govin, A.; Bartholin, M.-C.; Schmidt, W.; Grosseau, P. Combination of superplasticizers with hydroxypropyl guar, effect on cement-paste properties. Constr. Build. Mater. 2019, 215, 595–604. [Google Scholar] [CrossRef]

- Lee, D.K.; Shin, J.H.; Yoo, B.H.; Son, H.J.; Han, H.S. Development of specialized viscosity agent for high-fluidity concrete using normal binders. Korea Concr. Inst. 2019, 31, 337–338. [Google Scholar]

- ASTM C150/C150 9M-20b. Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2020; Available online: https://shop.bsigroup.com/products/standard-specification-for-portland-cement (accessed on 16 November 2021).

- KS L 5405. Fly Ash; Korean Standards Association: Seoul, Korea, 2018. [Google Scholar]

- KS F 2563. Ground Granulated Blast—Furnace Slag for use in Concrete; Korean Standards Association: Seoul, Korea, 2018. [Google Scholar]

- KS F 2527. Concrete Aggregate; Korean Standards Association: Seoul, Korea, 2020. [Google Scholar]

- ASTM C39-21. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Coshohocken, PA, USA, 2021. [Google Scholar]

- KS F 2403. Standard Test Method for Making and Curing Concrete Specimens; Korean Standards Association: Seoul, Korea, 2019. [Google Scholar]

- Plank, J.; Lummer, N.R.; Dugonjić-Bilić, F. Competitive adsorption between an AMPS®-based fluid loss polymer and Welan gum biopolymer in oil well cement. J. Appl. Polym. Sci. 2010, 116, 2913–2919. [Google Scholar] [CrossRef]

- Khayat, K.; Saric-Coric, M. Effect of Welan Gum SuperplasticizerCombinations on Properties of Cement Grouts. Spec. Publ. 2000, 195, 249–268. [Google Scholar]

- Okamura, H.; Ouchi, M. Self-compacting concrete. J. Adv. Concr. Technol. 2003, 1, 5–15. [Google Scholar] [CrossRef]

- Varela, H.; Barluenga, G.; Palomar, I. Influence of nanoclays on flowability and rheology of SCC pastes. Constr. Build. Mater. 2020, 243, 118285. [Google Scholar] [CrossRef]

- Wallevik, J.E. Relationship between the Bingham parameters and slump. Cem. Concr. Res. 2006, 36, 1214–1221. [Google Scholar] [CrossRef]

- Knapen, E.; Van Gemert, D. Cement hydration and microstructure formation in the presence of water-soluble polymers. Cem. Concr. Res. 2009, 39, 6–13. [Google Scholar] [CrossRef]

- Figueiredo, S.C.; Çopuroğlu, O.; Schlangen, E. Effect of viscosity modifier admixture on Portland cement paste hydration and microstructure. Constr. Build. Mater. 2019, 212, 818–840. [Google Scholar] [CrossRef] [Green Version]

| Contents (wt.%) | ||||

|---|---|---|---|---|

| Cement | Fly Ash | Blast Furnace Slag | ||

| Physical properties | Density (g/cm3) | 3.15 | 2.24 | 2.90 |

| Blaine (cm2/g) | 3590 | 3350 | 4130 | |

| Chemical properties | CaO | 62.51 | 3.12 | 42.11 |

| SiO2 | 21.46 | 55.59 | 31.86 | |

| Al2O3 | 6.44 | 23.54 | 14.43 | |

| SO3 | 2.32 | 0.41 | 2.12 | |

| Fe2O3 | 3.03 | 7.79 | 0.75 | |

| MgO | 2.75 | 1.20 | 3.81 | |

| Ig.loss (%) | 1.21 (950 ± 50 °C) | 1.81 (975 ± 25 °C) | 0.56 (700 ± 25 °C) | |

| Fine Aggregate | Coarse Aggregate | |

|---|---|---|

| Density (g/cm3) | 2.58 | 2.69 |

| Fineness modulus | 2.12 | 6.64 |

| Water absorption ratio (%) | 0.86 | 0.53 |

| Passing ratio of 0.08 mm sieve (%) | 2.95 | 0.77 |

| Types | Appearances | Description |

|---|---|---|

| Water reduction type | Light yellow liquid |

|

| Hybrid type | Yellowish-brown liquid |

|

| Retention type | Faint light yellow |

|

| HPMC | WG (Welan Gum) | GG (Guar Gum) | ST (Starch) | |

|---|---|---|---|---|

| Appearance |  |  |  |  |

| Phase | Liquid | Liquid | Liquid | Liquid |

| Color | Light brown | Medium opaque | Dark brown | Light opacity |

| Molecular weight (g/mol) | 324.3 | 168.2 | 535.2 | 342.3 |

| Viscosity (cps) | 55,500 (sol.2%) | 15,300 (sol.2%) | 4700 (sol.2%) | 7900 (sol.5%) |

| Specific gravity | 1.210 | 1.460 | 1.246 | 1.466 |

| pH | 7 ± 1 | 7 ± 1 | 7 ± 1 | 11 ± 1 |

| % | kg/m3 | NPCE (Binders × wt.%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W/B | S/a | W | Binders | S | G | PCE | HPMC | WG | GG | ST | |||

| C | FA | BS | |||||||||||

| Plain | 43.5 | 55.0 | 152 | 228 | 53 | 70 | 983 | 811 | 2.0 | ||||

| HL | 43.9 | 55.0 | 154 | 228 | 53 | 70 | 981 | 809 | 2.0 | 0.3 | - | - | - |

| HH | 2.0 | 0.6 | - | - | - | ||||||||

| WG | 2.0 | - | 0.1 | - | - | ||||||||

| GG | 2.0 | - | - | 0.1 | - | ||||||||

| ST | 2.0 | - | - | - | 0.1 | ||||||||

| HLW | 44.3 | 55.0 | 155 | 228 | 53 | 70 | 979 | 807 | 2.0 | 0.3 | 0.1 | - | - |

| HHW | 2.0 | 0.6 | 0.1 | - | - | ||||||||

| HLWG | 45.6 | 55.0 | 160 | 228 | 53 | 70 | 973 | 802 | 2.0 | 0.3 | 0.1 | 0.1 | - |

| HLWS | 2.0 | 0.3 | 0.1 | - | 0.1 | ||||||||

| HHWG | 2.0 | 0.6 | 0.1 | 0.1 | - | ||||||||

| HHWS | 2.0 | 0.6 | 0.1 | - | 0.1 | ||||||||

| Plain | HL | HH | WG | GG | ST | |

| Initial |  |  |  |  |  |  |

| 565 mm × 545 mm | 660 mm × 660 mm | 540 mm × 555 mm | 555 mm × 540 mm | 600 mm × 600 mm | 695 mm × 690 mm | |

| 60 min |  |  |  |  |  |  |

| 555 mm × 490 mm | 620 mm × 620 mm | 530 mm × 515 mm | 415 mm × 410 mm | 565 mm × 540 mm | 670 mm × 655 mm | |

| HLW | HHW | HLWG | HLWS | HHWG | HHWS | |

| Initial |  |  |  |  |  |  |

| 550 mm × 535 mm | 550 mm × 530 mm | 615 mm × 610 mm | 635 mm × 625 mm | 615 mm × 575 mm | 615 mm × 610 mm | |

| 60 min |  |  |  |  |  |  |

| 465 mm × 435 mm | 500 mm × 495 mm | 530 mm × 515 mm | 590 mm × 590 mm | 530 mm × 525 mm | 590 mm × 590 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kong, T.-W.; Yang, H.-M.; Lee, H.-S.; Yoon, C.-B. Evaluations of All-in-One, Polycarboxylate-Based Superplasticizer with Viscosity Modifying Agents for the Application of Normal-Strength, High-Fluidity Concrete. Appl. Sci. 2021, 11, 11141. https://doi.org/10.3390/app112311141

Kong T-W, Yang H-M, Lee H-S, Yoon C-B. Evaluations of All-in-One, Polycarboxylate-Based Superplasticizer with Viscosity Modifying Agents for the Application of Normal-Strength, High-Fluidity Concrete. Applied Sciences. 2021; 11(23):11141. https://doi.org/10.3390/app112311141

Chicago/Turabian StyleKong, Tae-Woong, Hyun-Min Yang, Han-Seung Lee, and Chang-Bok Yoon. 2021. "Evaluations of All-in-One, Polycarboxylate-Based Superplasticizer with Viscosity Modifying Agents for the Application of Normal-Strength, High-Fluidity Concrete" Applied Sciences 11, no. 23: 11141. https://doi.org/10.3390/app112311141

APA StyleKong, T.-W., Yang, H.-M., Lee, H.-S., & Yoon, C.-B. (2021). Evaluations of All-in-One, Polycarboxylate-Based Superplasticizer with Viscosity Modifying Agents for the Application of Normal-Strength, High-Fluidity Concrete. Applied Sciences, 11(23), 11141. https://doi.org/10.3390/app112311141