Reconstruction of Rice Drying Model and Analysis of Tempering Characteristics Based on Drying Accumulated Temperature

Abstract

:1. Introduction

2. Theory and Model Derivation

2.1. Effective Drying Accumulated Temperature Theory

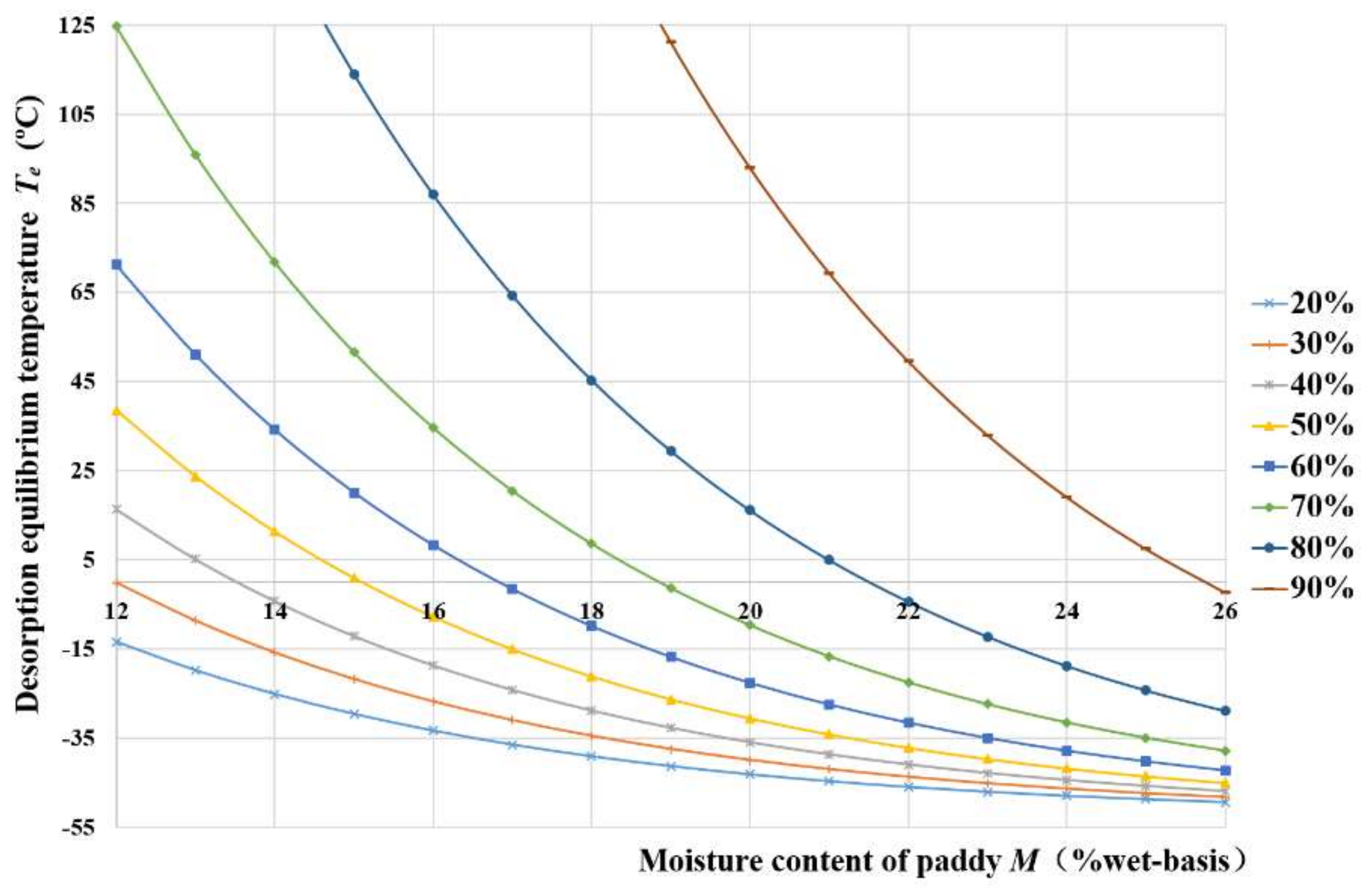

2.2. Derivation of Effective Drying Accumulated Temperature Model for Rice

3. Model Reconstruction

3.1. Test Review

3.2. Model Selection Method

3.3. Drying Accumulated Temperature–Moisture Ratio Model

3.4. Regression Equations of AT-MR Model Parameters

4. Materials and Methods

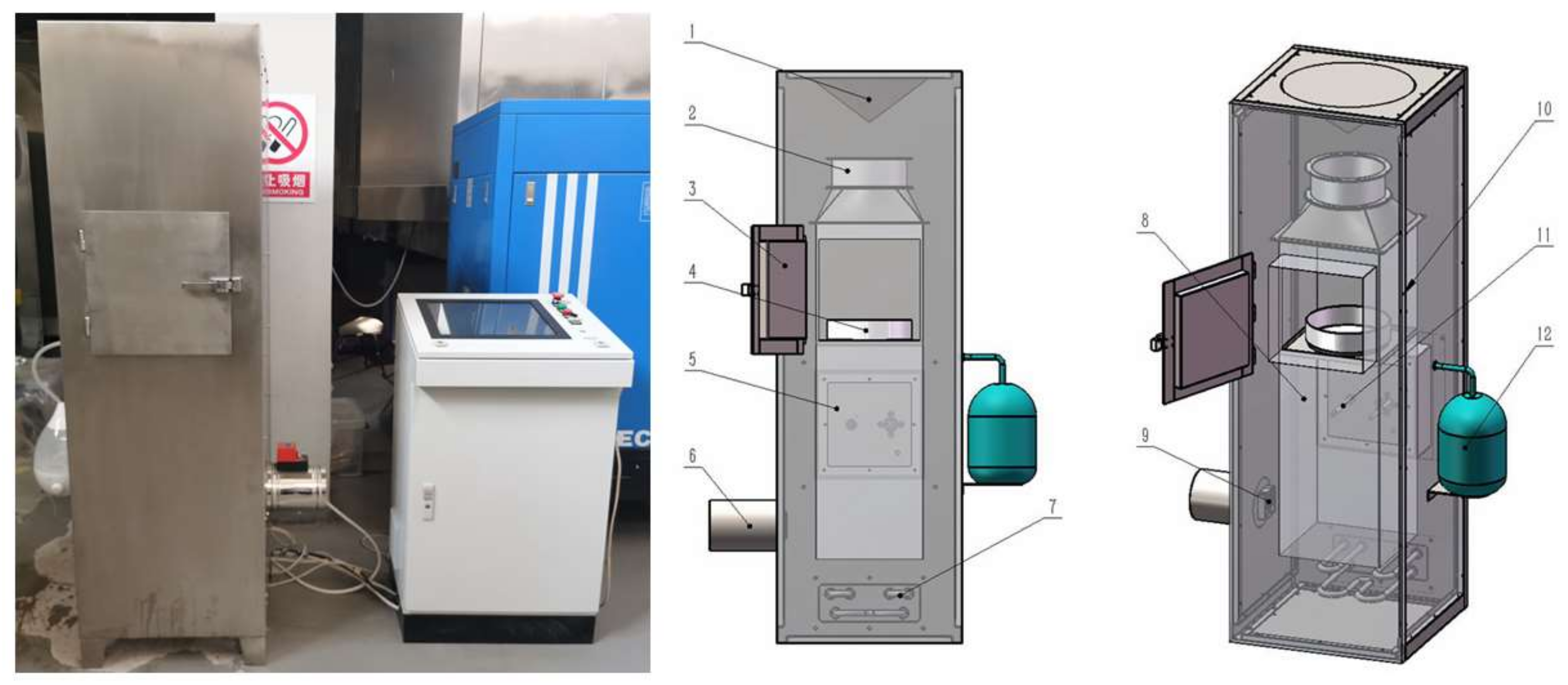

4.1. Equipment and Method

4.2. The Test Results

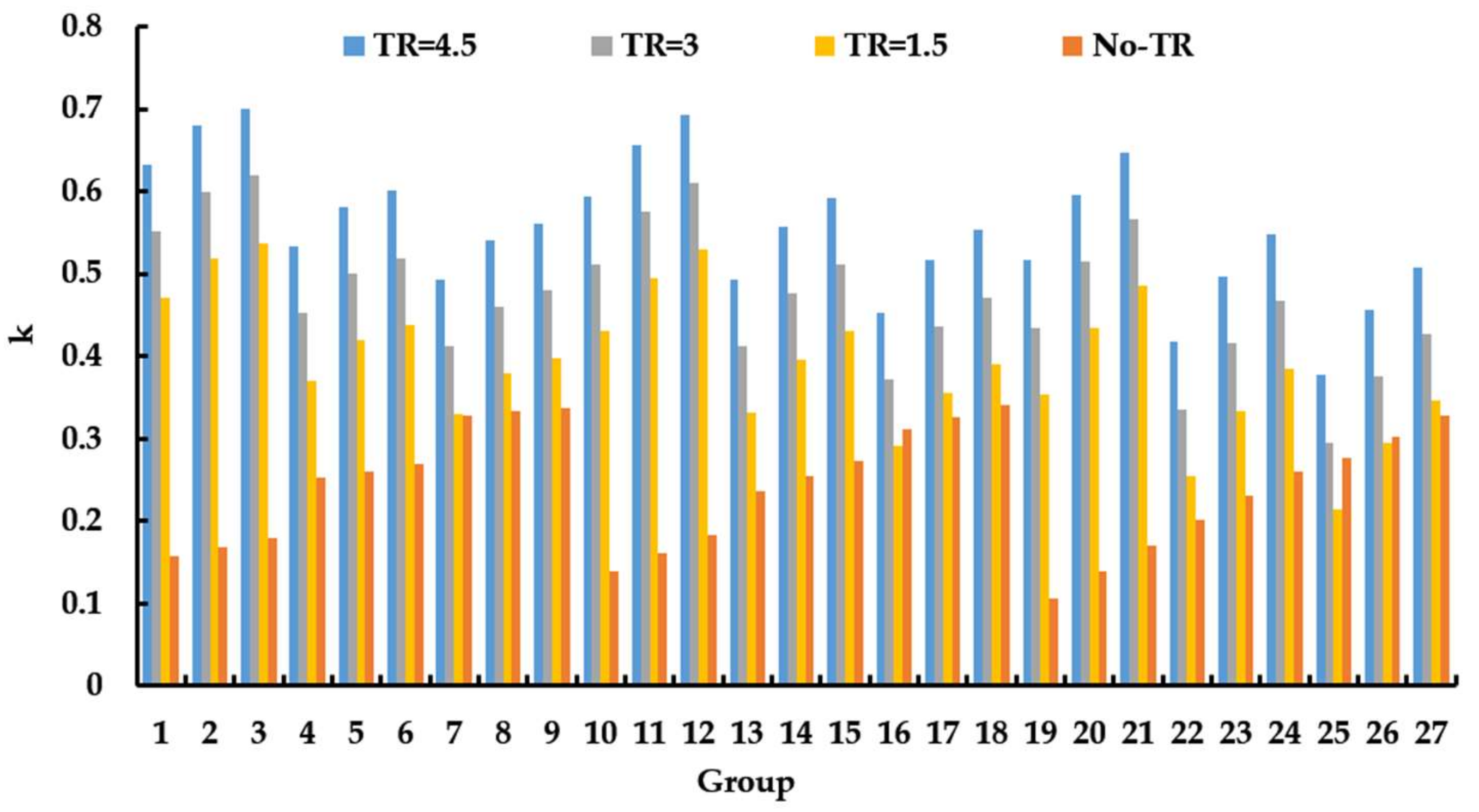

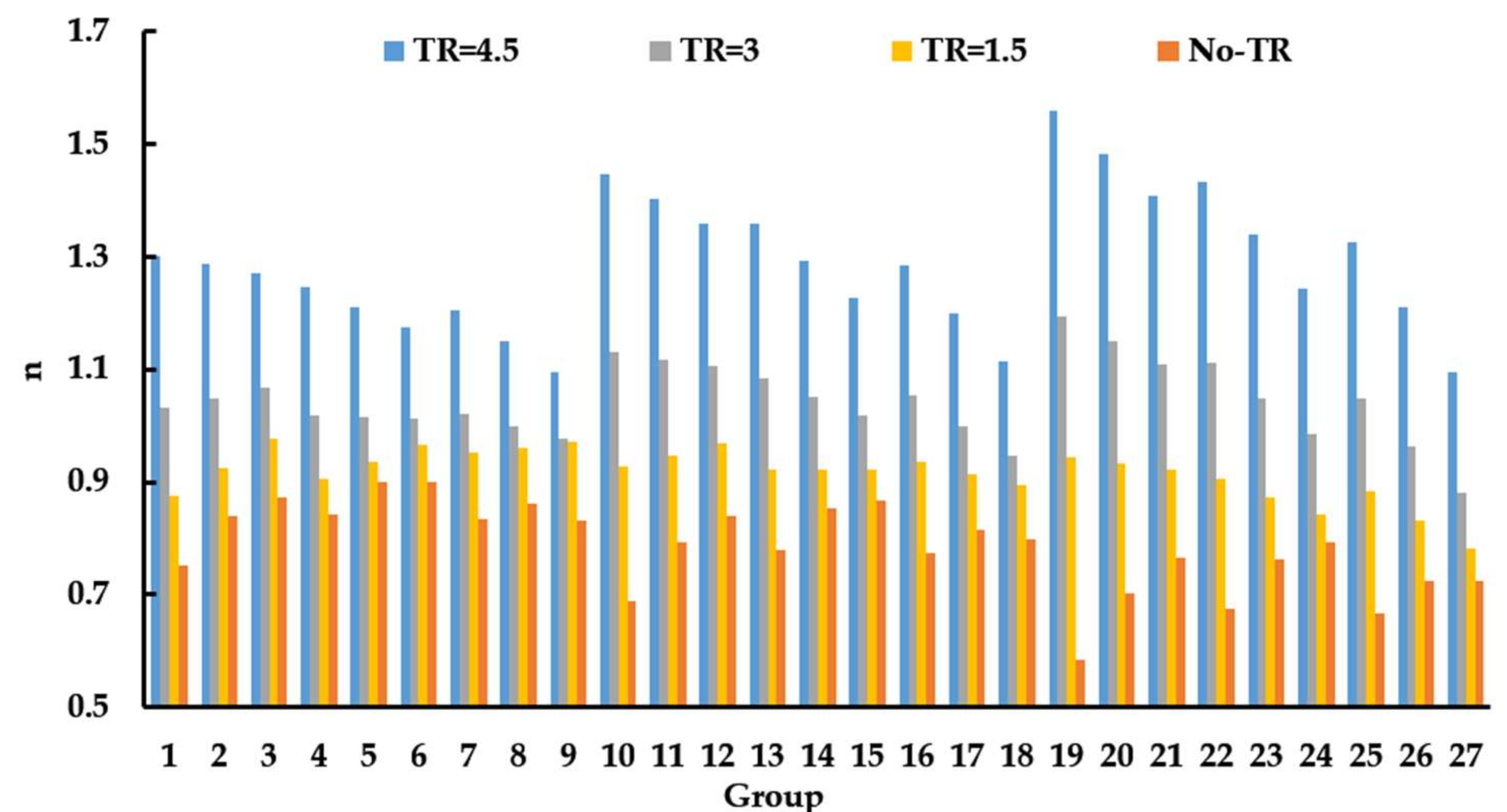

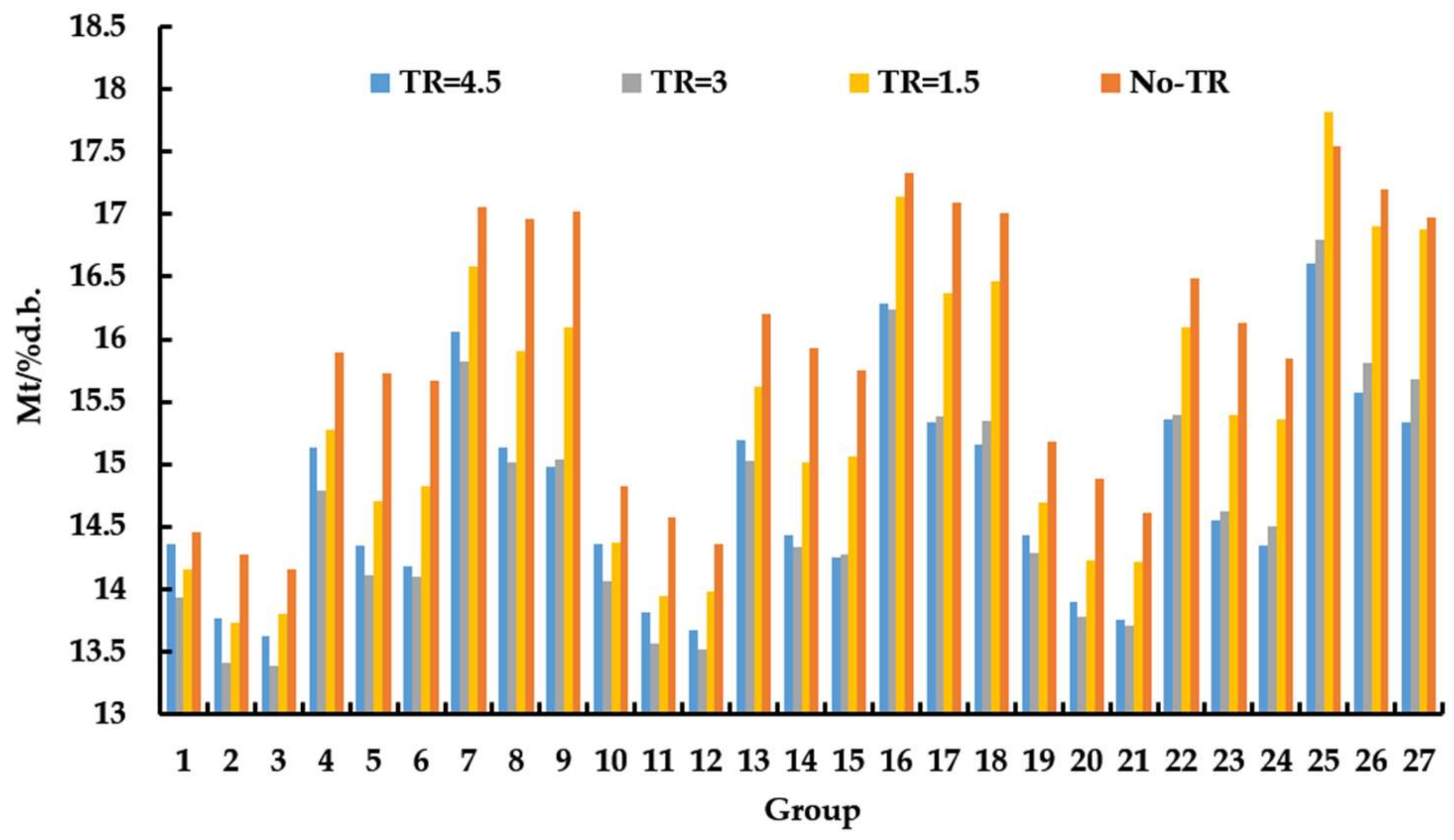

4.3. Analysis of the Effect of the Tempering Process on Rice Drying

5. Results

6. Conclusions

- The relationship between the drying accumulated temperature and the moisture ratio of rice was exponential, which made it possible to establish a mathematical model. Seven existing mathematical drying models were used to fit the non-tempering test results. After selecting the model with the best fitting degree, the model was reconstructed. The reconstructed model was named the AT-MR model.

- The AT-MR model was used to fit the test data both with tempering and without tempering, and the new evaluation parameters of the two model coefficients were obtained, as follows; Non-tempering test: R2 = 0.998615–0.999964, χ2(10−4) = 0.0280372–1.408121, and RMSE(10−4) = 0.0227802–1.106381; Tempering test: R2 = 0.997548–0.999979, χ2(10−4) = 0.016273–2.0163, and RMSE(10−4) = 0.014239–1.6979. Thus, the AT-MR model had high accuracy and achieved good predictive performance.

- The influence of the tempering process on the rice drying process was analyzed by comparing the AT-MR model fitting results of the non-tempering test (our previous experiment) and the tempering test (the experiment in this study). The results showed that the optimal tempering ratio was effectively three under the conditions of regular hot air intermittent drying.

- In our future research, we plan to model the batch drying process of rice in order to explore the changes in various indexes of rice during actual drying operations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lamidi, R.O.; Jiang, L.; Pathare, P.B.; Wang, Y.D.; Roskilly, A.P. Recent advances in sustainable drying of agricultural produce: A review. Appl. Energy 2019, 233–234, 367–385. [Google Scholar] [CrossRef] [Green Version]

- Tanaka, F.; Tanaka, F.; Tanaka, A.; Uchino, T. Mathematical modelling of thin-layer drying according to particle size distribution in crushed feed rice. Biosyst. Eng. 2015, 136, 87–91. [Google Scholar] [CrossRef]

- Jin, Y.; Wong, K.W.; Yang, D.; Zhang, Z.; Wu, W.; Yin, J. A neural network model used in continuous grain dryer control system. Dry. Technol. 2021, 8, 1–22. [Google Scholar] [CrossRef]

- Wang, N.; Brennan, J.G. A mathematical model of simultaneous heat and moisture transfer during drying of potato. J. Food Eng. 1995, 24, 47–60. [Google Scholar] [CrossRef]

- Franco, C.M.R.; de Lima, A.G.B.; Farias, V.S.O.; da Silva, W.P. Modeling and experimentation of continuous and intermittent drying of rough rice grains. Heat Mass Transf. 2019, 56, 1003–1014. [Google Scholar] [CrossRef]

- Rufino Franco, C.M.; Barbosa de Lima, A.G.; de Oliveira Farias, V.S.; Machado, E.A. Intermittent Drying of Rice Grains with Husk: Modelling and Experimentation. Diffus. Found. 2020, 25, 9–36. [Google Scholar] [CrossRef]

- Ertekin, C.; Firat, M.Z. A comprehensive review of thin-layer drying models used in agricultural products. Crit. Rev. Food Sci. Nutr. 2017, 57, 701–717. [Google Scholar] [CrossRef]

- PAGE, G.E. Factors Influencing the Maximum Rates of Air Drying Shelled Corn in Thin Layers. Ph.D. Thesis, Purdue University, Ann Arbor, MI, USA, 1949. [Google Scholar]

- Lewis, W.K. The Rate of Drying of Solid Materials. Indian Chem. Eng. 1921, 13, 427–432. [Google Scholar] [CrossRef]

- Midilli, A.; Kucuk, H.; Yapar, Z. A New Model for Single-layer Drying. Dry. Technol. 2002, 20, 1503–1513. [Google Scholar] [CrossRef]

- Prakash, B.; Siebenmorgen, T.J. Single-parameter Thin-layer Drying Equations for Long-grain Rice. Trans. ASABE 2018, 61, 733–742. [Google Scholar] [CrossRef]

- Chen, J.; Wu, W.; Cheng, R.; Jin, Y.; Liu, Z. Optimization of hot air drying process of corn using genetic algorithm and response surface methodology. Int. J. Food Prop. 2020, 23, 753–764. [Google Scholar] [CrossRef]

- Alves Pereira, J.C.; da Silva, W.P.; Gomes, J.P.; Queiroz, A.J.M.; de Figueirêdo, R.M.F.; de Melo, B.A.; Santiago, Â.M.; de Lima, A.G.B.; de Macedo, A.D.B. Continuous and Intermittent Drying of Rough Rice: Effects on Process Effective Time and Effective Mass Diffusivity. Agriculture 2020, 10, 282. [Google Scholar] [CrossRef]

- Kucuk, H.; Midilli, A.; Kilic, A.; Dincer, I. A Review on Thin-Layer Drying-Curve Equations. Dry. Technol. 2014, 32, 757–773. [Google Scholar] [CrossRef]

- Ghasemi, A.; Sadeghi, M.; Mireei, S.A. Multi-stage intermittent drying of rough rice in terms of tempering and stress cracking indices and moisture gradients interpretation. Dry. Technol. 2017, 36, 109–117. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, L.; Fu, P.; Lyu, F.; Zhang, J.; Gu, S.; Ding, Y. Effects of infrared radiation drying and heat pump drying combined with tempering on the quality of long-grain paddy rice. Int. J. Food Sci. Technol. 2018, 53, 2448–2456. [Google Scholar] [CrossRef]

- Aquerreta, J.; Iguaz, A.; Arroqui, C.; Vírseda, P. Effect of high temperature intermittent drying and tempering on rough rice quality. J. Food Eng. 2007, 80, 611–618. [Google Scholar] [CrossRef]

- Tohidi, M.; Sadeghi, M.; Torki-Harchegani, M. Energy and quality aspects for fixed deep bed drying of paddy. Renew. Sustain. Energy Rev. 2017, 70, 519–528. [Google Scholar] [CrossRef]

- Golmohammadi, M.; Assar, M.; Rajabi-Hamaneh, M.; Hashemi, S.J. Energy efficiency investigation of intermittent paddy rice dryer: Modeling and experimental study. Food Bioprod. Process. 2015, 94, 275–283. [Google Scholar] [CrossRef]

- Cihan, A.; Kahveci, K.; Hacıhafızoğlu, O. Modelling of intermittent drying of thin layer rough rice. J. Food Eng. 2007, 79, 293–298. [Google Scholar] [CrossRef]

- Dong, R.; Lu, Z.; Liu, Z.; Koide, S.; Cao, W. Effect of drying and tempering on rice fissuring analysed by integrating intra-kernel moisture distribution. J. Food Eng. 2010, 97, 161–167. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, W.; Han, F.; Zhang, Y.; Xu, Y. Intelligent Monitoring and Control of Grain Continuous Drying Process Based on Multi-parameter Corn Accumulated Temperature Model. In Proceedings of the 2017 International Conference on Smart Grid and Electrical Automation, Changsha, China, 27–28 May 2017; pp. 77–80. [Google Scholar] [CrossRef]

- Jin, Y.; Wong, K.W.; Wu, Z.; Qi, D.; Wang, R.; Han, F.; Wu, W. Relationship between accumulated temperature and quality of paddy. Int. J. Food Prop. 2019, 22, 19–33. [Google Scholar] [CrossRef] [Green Version]

- Hu, X.W.; Fan, Y.; Baskin, C.C.; Baskin, J.M.; Wang, Y.R. Comparison of the effects of temperature and water potential on seed germination of Fabaceae species from desert and subalpine grassland. Am. J. Bot. 2015, 102, 649–660. [Google Scholar] [CrossRef] [Green Version]

- Liu, D.; Xin, L.I.; Zheng, H.; Wang, Z.H.; University, N.A. Analysis on Changes of Earth Temperature and Spring Maize Sowing Time in Second Accumulated Temperature of Heilongjiang Province. J. Maize Sci. 2016, 24, 103–106. [Google Scholar] [CrossRef]

- Sun, L.L.; Li-Li, X.U.; Yuan-Peng, D.U.; Zhai, H. The relationship of effective accumulated temperature and bud burst in grapevine. Plant Physiol. J. 2016, 52, 1263–1270. [Google Scholar] [CrossRef]

- Zhao, D.; Wu, S. Spatial and temporal variability of key bio-temperature indicators on the Qinghai-Tibetan Plateau for the period 1961–2013. Int. J. Climatol. 2016, 36, 2083–2092. [Google Scholar] [CrossRef]

- Liu, Y.; Hou, P.; Xie, R.; Hao, W.; Li, S.; Mei, X. Spatial Variation and Improving Measures of the Utilization Efficiency of Accumulated Temperature. Crop Sci. 2015, 55, 1806–1807. [Google Scholar] [CrossRef]

- Ni, X.; Gunawan, G.; Brown, S.L.; Sumner, P.E.; Ruberson, J.R.; Buntin, G.D.; Holbrook, C.C.; Lee, R.D.; Streett, D.A.; Throne, J.E. Insect-Attracting and Antimicrobial Properties of Antifreeze for Monitoring Insect Pests and Natural Enemies in Stored Corn. J. Econ. Entomol. 2008, 101, 631. [Google Scholar] [CrossRef] [PubMed]

- Cинельшков, B.B. General Agricultural Meteorology; Higher Education Press: Beijing, China, 1959. [Google Scholar]

- Agrawal, K.K.; Clary, B.L.; Nelson, G.L. Investigation into the Theories of Desorption Isotherms for Rough Rice and Peanuts; Blackwell Publishing Ltd.: Hoboken, NJ, USA, 1971; Volume 36, pp. 919–924. [Google Scholar] [CrossRef]

- Li, X. Fiting Parameters of EMC/ERH Model for Chinese Rough Rice. J. Chin. Cereals Oils Assoc. 2010, 25, 1–8. [Google Scholar]

| Calculation Method | Calculation Method | ||

| 1 | 0 | ||

| 1 | |||

| …… | |||

| Factor | Level | ||||

|---|---|---|---|---|---|

| −2 | −1 | 0 | 1 | 2 | |

| Hot air temperature X1/°C | 27 | 31 | 35 | 39 | 43 |

| Relative humidity of hot air X2/% | 45 | 50 | 55 | 60 | 65 |

| Initial moisture content of rice X3/% | 17 | 19 | 21 | 23 | 25 |

| Velocity of hot air X4/m s−1 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 |

| Drying Time (h) | Wet-Basis Moisture Content (%) | Dry-Basis Moisture Content (%) | Desorption Equilibrium Temperature (°C) | Real-Time Drying Temperature Accumulation (°C·h) | Moisture Ratio of Rice | Total Drying Accumulated Temperature (°C·h) |

|---|---|---|---|---|---|---|

| 0 | 21.00 | 26.58 | −51.3148 | 0 | 1 | 0 |

| 0.25 | 20.80 | 26.27 | −50.3255 | 9.0555 | 0.9747 | 9.0555 |

| 0.5 | 20.45 | 25.71 | −49.4022 | 19.1005 | 0.9318 | 28.156 |

| 0.75 | 20.09 | 25.14 | −48.3732 | 18.8433 | 0.8885 | 46.9993 |

| 1 | 19.48 | 24.20 | −46.3953 | 36.6976 | 0.8161 | 83.697 |

| 1.25 | 18.92 | 23.34 | −44.2782 | 35.6391 | 0.7502 | 119.3361 |

| 1.5 | 18.39 | 22.54 | −42.0044 | 34.5022 | 0.6892 | 153.8383 |

| 1.75 | 17.90 | 21.80 | −39.5787 | 33.2893 | 0.6325 | 187.1276 |

| 2 | 17.42 | 21.09 | −36.9381 | 31.969 | 0.5784 | 219.0967 |

| 2.25 | 17.00 | 20.49 | −34.3969 | 30.6984 | 0.532 | 249.7951 |

| 2.5 | 16.64 | 19.96 | −31.9498 | 29.4749 | 0.4917 | 279.27 |

| 2.75 | 16.24 | 19.39 | −28.9984 | 27.9992 | 0.4477 | 307.2692 |

| 3 | 15.95 | 18.97 | −26.6788 | 26.8394 | 0.4161 | 334.1086 |

| 3.25 | 15.65 | 18.55 | −24.1059 | 25.5529 | 0.3835 | 359.6615 |

| 3.5 | 15.33 | 18.11 | −21.2302 | 24.1151 | 0.3499 | 383.7766 |

| 3.75 | 15.05 | 17.72 | −18.4833 | 22.7417 | 0.32 | 406.5183 |

| 4 | 14.80 | 17.37 | −15.8439 | 21.422 | 0.2932 | 427.9403 |

| 4.25 | 14.54 | 17.02 | −13.0109 | 20.0055 | 0.2662 | 447.9458 |

| 4.5 | 14.34 | 16.75 | −10.7278 | 18.8639 | 0.2456 | 466.8097 |

| 4.75 | 14.16 | 16.49 | −8.4869 | 17.7434 | 0.2263 | 484.5531 |

| 5 | 13.95 | 16.22 | −5.8789 | 16.4395 | 0.2049 | 500.9926 |

| 5.25 | 13.77 | 15.97 | −3.518 | 15.259 | 0.1864 | 516.2515 |

| 5.5 | 13.61 | 15.75 | −1.2572 | 14.1286 | 0.1694 | 530.3801 |

| 5.75 | 13.40 | 15.48 | 1.6521 | 12.6739 | 0.1485 | 543.0541 |

| Model No. | Name | Model Equation | Modified Equation |

|---|---|---|---|

| 1 | Linear equation | ||

| 2 | Polynomial equation | ||

| 3 | Page | ||

| 4 | Modified Page II | ||

| 5 | Simplified modified Page II | ||

| 6 | Weibull II | ||

| 7 | Midilli |

| Model No. | Range | ||

|---|---|---|---|

| R2 | χ2 (10−4) | RMSE (10−4) | |

| 1 | 0.973769–0.999161 | 0.5720432–19.53701 | 0.0444922–17.26623 |

| 2 | 0.99196–0.999697 | 0.0273277–7.422666 | 0.218622–5.832094 |

| 3 | 0.984013–0.998321 | 1.061333–14.11593 | 0.928666–12.50415 |

| 4 | 0.986226–0.998438 | 1.034447–12.90039 | 0.840489–10.42148 |

| 5 | 0.17752–0.330753 | 588.84853–879.66005 | 510.48454–787.06426 |

| 6 | 0.984013–0.998321 | 1.061333–14.11593 | 0.928666–12.50415 |

| 7 | 0.998632–0.999964 | 0.0301823–1.515054 | 0.0226367–1.082181 |

| Group | a | k | n | b |

|---|---|---|---|---|

| 1 | 1.00101 | 0.035269 | 0.715627 | −0.00205125 |

| 2 | 1.00139 | 0.00926442 | 0.692957 | −0.00102529 |

| 3 | 0.999012 | 0.00427439 | 0.783375 | −0.00196273 |

| 4 | 1.0009 | 0.00537334 | 0.530844 | −0.0038683 |

| 5 | 0.999496 | 0.00650352 | 0.847199 | −0.000580394 |

| 6 | 1.0001 | 0.00552916 | 0.835148 | −0.000493744 |

| 7 | 1.00039 | 0.00456589 | 0.751331 | −0.00242506 |

| 8 | 1.00139 | 0.00642331 | 0.68537 | −0.00204891 |

| 9 | 1.00164 | 0.00645302 | 0.762578 | −0.000657588 |

| 10 | 1.00057 | 0.00553006 | 0.788037 | −0.00074992 |

| 11 | 1.00109 | 0.00316241 | 0.780761 | −0.00237464 |

| 12 | 0.998202 | 0.00468692 | 0.766306 | −0.00130538 |

| 13 | 1.00257 | 0.00607272 | 0.72201 | −0.000390238 |

| 14 | 0.998687 | 0.00676858 | 0.83013 | −0.000344992 |

| 15 | 1.00164 | 0.00517981 | 0.754991 | −0.000539943 |

| 16 | 1.00153 | 0.0129326 | 0.757631 | −0.000539744 |

| 17 | 0.999883 | 0.00441983 | 0.916641 | −0.000969152 |

| 18 | 1.00005 | 0.00437859 | 0.854193 | −0.000567743 |

| 19 | 1.00343 | 0.00921075 | 0.742537 | −0.00208353 |

| 20 | 1.0017 | 0.00531923 | 0.688852 | −0.000702075 |

| 21 | 0.99793 | 0.0120082 | 0.640903 | −0.000764778 |

| 22 | 0.999311 | 0.00673804 | 0.704464 | −0.00312659 |

| 23 | 1.0017 | 0.006308 | 0.732581 | −0.000777213 |

| 24 | 1.00244 | 0.00926204 | 0.750457 | −0.00132015 |

| 25 | 1.00168 | 0.00542829 | 0.842068 | −0.000875988 |

| 26 | 1.00078 | 0.00575557 | 0.835284 | −0.000762651 |

| 27 | 1.00142 | 0.00563226 | 0.835448 | −0.0018802 |

| 28 | 1.00033 | 0.00944224 | 0.731882 | −0.00109802 |

| 29 | 1.001 | 0.00533085 | 0.849266 | −0.000780637 |

| 30 | 1.00249 | 0.00559346 | 0.831682 | −0.00102325 |

| 31 | 1.00158 | 0.00530231 | 0.843352 | −0.00199305 |

| 32 | 1.00199 | 0.0100175 | 0.700704 | −0.00158544 |

| 33 | 1.00002 | 0.00524587 | 0.864654 | −0.000709403 |

| 34 | 1.00075 | 0.00574093 | 0.847738 | −0.00067994 |

| 35 | 1.00024 | 0.00585991 | 0.831015 | −0.000714326 |

| 36 | 1.00081 | 0.0147862 | 0.673304 | −0.00126142 |

| Group | k | n | b |

|---|---|---|---|

| 1 | 0.0306137 | 0.722394 | −0.00205125 |

| 2 | 0.00573271 | 0.707736 | −0.00102529 |

| 3 | 0.00252274 | 0.775986 | −0.00196273 |

| 4 | 0.00485107 | 0.538049 | −0.0038683 |

| 5 | 0.00527444 | 0.83999 | −0.000580394 |

| 6 | 0.00590817 | 0.838778 | −0.000493744 |

| 7 | 0.00596193 | 0.754152 | −0.00242506 |

| 8 | 0.00977103 | 0.700251 | −0.00204891 |

| 9 | 0.00340685 | 0.778977 | −0.000657588 |

| 10 | 0.00385712 | 0.790293 | −0.00074992 |

| 11 | 0.0023295 | 0.790945 | −0.00237464 |

| 12 | 0.00600094 | 0.758982 | −0.00130538 |

| 13 | 0.0057322 | 0.729039 | −0.000390238 |

| 14 | 0.00875264 | 0.822986 | −0.000344992 |

| 15 | 0.00744517 | 0.771492 | −0.000539943 |

| 16 | 0.0173073 | 0.764295 | −0.000539744 |

| 17 | 0.00281839 | 0.913017 | −0.000969152 |

| 18 | 0.00608254 | 0.849176 | −0.000567743 |

| 19 | 0.00536611 | 0.760183 | −0.00208353 |

| 20 | 0.00762352 | 0.704859 | −0.000702075 |

| 21 | 0.00937648 | 0.641548 | −0.000764778 |

| 22 | 0.0102441 | 0.70608 | −0.00312659 |

| 23 | 0.00463416 | 0.741747 | −0.000777213 |

| 24 | 0.00982486 | 0.761552 | −0.00132015 |

| 25 | 0.00522365 | 0.851915 | −0.000875988 |

| 26 | 0.00560364 | 0.84138 | −0.000762651 |

| 27 | 0.00544327 | 0.843705 | −0.0018802 |

| 28 | 0.00928736 | 0.736501 | −0.00109802 |

| 29 | 0.00517718 | 0.855992 | −0.000780637 |

| 30 | 0.00534153 | 0.843632 | −0.00102325 |

| 31 | 0.00510717 | 0.853163 | −0.00199305 |

| 32 | 0.00950335 | 0.711821 | −0.00158544 |

| 33 | 0.00514296 | 0.868341 | −0.000709403 |

| 34 | 0.0055955 | 0.85349 | −0.00067994 |

| 35 | 0.00574205 | 0.83538 | −0.000714326 |

| 36 | 0.014516 | 0.678433 | −0.00126142 |

| Factor | Level | ||||

|---|---|---|---|---|---|

| −2 | −1 | 0 | 1 | 2 | |

| Hot air temperature X1/°C | 32.99 | 38.5 | 42.5 | 46.5 | 52.01 |

| Relative humidity of hot air X2/% | 41.11 | 48 | 53 | 58 | 64.89 |

| Initial moisture content of rice X3/% | 16.03 | 19.2 | 21.5 | 23.8 | 26.97 |

| Velocity of hot air X4/m s−1 | 0.36 | 0.5 | 0.6 | 0.7 | 0.84 |

| Tempering ratio X5 | 0 | 1.45 | 2.5 | 3.55 | 5 |

| Group | X1 (°C) | X2 (%) | X3 (%w.b.) | X4 (m/s) | X5 | Drying Accumulated Temperature (°C·h) |

|---|---|---|---|---|---|---|

| 1 | 38.5 | 48 | 19.2 | 0.5 | 1.45 | 412.53 |

| 2 | 46.5 | 48 | 19.2 | 0.5 | 1.45 | 345.73 |

| 3 | 38.5 | 58 | 19.2 | 0.5 | 1.45 | 525.72 |

| 4 | 46.5 | 58 | 19.2 | 0.5 | 1.45 | 369.68 |

| 5 | 38.5 | 48 | 23.8 | 0.5 | 1.45 | 659.89 |

| 6 | 46.5 | 48 | 23.8 | 0.5 | 1.45 | 466.16 |

| 7 | 38.5 | 58 | 23.8 | 0.5 | 1.45 | 825.44 |

| 8 | 46.5 | 58 | 23.8 | 0.5 | 1.45 | 592.29 |

| 9 | 38.5 | 48 | 19.2 | 0.7 | 1.45 | 368.45 |

| 10 | 46.5 | 48 | 19.2 | 0.7 | 1.45 | 377.58 |

| 11 | 38.5 | 58 | 19.2 | 0.7 | 1.45 | 493.96 |

| 12 | 46.5 | 58 | 19.2 | 0.7 | 1.45 | 354.42 |

| 13 | 38.5 | 48 | 23.8 | 0.7 | 1.45 | 522.83 |

| 14 | 46.5 | 48 | 23.8 | 0.7 | 1.45 | 385.02 |

| 15 | 38.5 | 58 | 23.8 | 0.7 | 1.45 | 698.01 |

| 16 | 46.5 | 58 | 23.8 | 0.7 | 1.45 | 446.63 |

| 17 | 38.5 | 48 | 19.2 | 0.5 | 3.55 | 600.22 |

| 18 | 46.5 | 48 | 19.2 | 0.5 | 3.55 | 435.47 |

| 19 | 38.5 | 58 | 19.2 | 0.5 | 3.55 | 892.62 |

| 20 | 46.5 | 58 | 19.2 | 0.5 | 3.55 | 628.91 |

| 21 | 38.5 | 48 | 23.8 | 0.5 | 3.55 | 919.96 |

| 22 | 46.5 | 48 | 23.8 | 0.5 | 3.55 | 674.48 |

| 23 | 38.5 | 58 | 23.8 | 0.5 | 3.55 | 1388.81 |

| 24 | 46.5 | 58 | 23.8 | 0.5 | 3.55 | 956.27 |

| 25 | 38.5 | 48 | 19.2 | 0.7 | 3.55 | 544.39 |

| 26 | 46.5 | 48 | 19.2 | 0.7 | 3.55 | 383.39 |

| 27 | 38.5 | 58 | 19.2 | 0.7 | 3.55 | 775.43 |

| 28 | 46.5 | 58 | 19.2 | 0.7 | 3.55 | 485.93 |

| 29 | 38.5 | 48 | 23.8 | 0.7 | 3.55 | 812.97 |

| 30 | 46.5 | 48 | 23.8 | 0.7 | 3.55 | 475.65 |

| 31 | 38.5 | 58 | 23.8 | 0.7 | 3.55 | 1051.05 |

| 32 | 46.5 | 58 | 23.8 | 0.7 | 3.55 | 694.71 |

| 33 | 32.99 | 53 | 21.5 | 0.6 | 2.5 | 806.94 |

| 34 | 52.01 | 53 | 21.5 | 0.6 | 2.5 | 396.84 |

| 35 | 42.5 | 41.11 | 21.5 | 0.6 | 2.5 | 442.64 |

| 36 | 42.5 | 64.89 | 21.5 | 0.6 | 2.5 | 845.54 |

| 37 | 42.5 | 53 | 16.03 | 0.6 | 2.5 | 216.11 |

| 38 | 42.5 | 53 | 26.97 | 0.6 | 2.5 | 726.54 |

| 39 | 42.5 | 53 | 21.5 | 0.36 | 2.5 | 1133.86 |

| 40 | 42.5 | 53 | 21.5 | 0.84 | 2.5 | 680.00 |

| 41 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 272.64 |

| 42 | 42.5 | 53 | 21.5 | 0.6 | 5 | 788.59 |

| 43 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 595.00 |

| 44 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 529.55 |

| 45 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 488.75 |

| 46 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 546.98 |

| 47 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 603.50 |

| 48 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 567.38 |

| 49 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 573.75 |

| 50 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 579.70 |

| 51 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 529.55 |

| 52 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 494.91 |

| 53 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 546.98 |

| 54 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 480.25 |

| 55 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 567.38 |

| 56 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 573.75 |

| 57 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 529.55 |

| 58 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 494.91 |

| 59 | 42.5 | 53 | 21.5 | 0.6 | 2.5 | 546.98 |

| Model No. | Range | ||

|---|---|---|---|

| R2 | χ2 (10−4) | RMSE (10−4) | |

| 1 | 0.924177–0.997569 | 2.3567–53.088 | 2.0425–51.157 |

| 2 | 0.996039–0.999912 | 0.061578–2.9869 | 0.049262–2.7069 |

| 3 | 0.982072–0.999526 | 0.32871–17.409 | 0.29740–16.017 |

| 4 | 0.985405–0.999576 | 0.26662–14.172 | 0.22853–12.472 |

| 5 | 0.164896–0.378380 | 474.41–985.24 | 435.69–821.04 |

| 6 | 0.982072–0.999526 | 0.32871–17.409 | 0.29740–16.017 |

| 7 | 0.997647–0.999979 | 0.016892–2.0295 | 0.014076–1.6023 |

| 8 | 0.997548–0.999979 | 0.016273–2.0163 | 0.014239–1.6979 |

| Group | k | n | b |

|---|---|---|---|

| 1 | 0.341389 | 0.834138 | −0.0489694 |

| 2 | 0.468729 | 0.978014 | −0.0377525 |

| 3 | 0.278803 | 0.907038 | −0.114835 |

| 4 | 0.396636 | 1.03552 | −0.107336 |

| 5 | 0.270643 | 0.952394 | −0.0309789 |

| 6 | 0.346402 | 0.983138 | −0.0416091 |

| 7 | 0.235325 | 0.901302 | −0.0569887 |

| 8 | 0.29801 | 0.938925 | −0.0709415 |

| 9 | 0.384782 | 0.96074 | −0.0261712 |

| 10 | 0.519735 | 1.07809 | −0.0129317 |

| 11 | 0.329509 | 0.92236 | −0.0956808 |

| 12 | 0.45681 | 1.0106 | −0.0969446 |

| 13 | 0.305711 | 0.973768 | −0.0319343 |

| 14 | 0.434421 | 1.03235 | −0.0327374 |

| 15 | 0.342004 | 0.781038 | −0.060188 |

| 16 | 0.445894 | 0.788397 | −0.0730112 |

| 17 | 0.43605 | 1.00398 | −0.0145096 |

| 18 | 0.666164 | 1.07885 | −0.00814848 |

| 19 | 0.32739 | 1.3173 | −0.0545716 |

| 20 | 0.401572 | 1.3462 | −0.0950719 |

| 21 | 0.352323 | 1.02753 | −0.0207138 |

| 22 | 0.430171 | 0.986659 | −0.0531129 |

| 23 | 0.255964 | 1.1299 | −0.0270968 |

| 24 | 0.319665 | 1.03021 | −0.0801716 |

| 25 | 0.4565 | 1.07825 | −0.0225678 |

| 26 | 0.57383 | 1.03232 | −0.0551755 |

| 27 | 0.404316 | 1.21928 | −0.0633263 |

| 28 | 0.550427 | 1.22649 | −0.082667 |

| 29 | 0.338439 | 1.02329 | −0.0380423 |

| 30 | 0.568301 | 0.926364 | −0.0633409 |

| 31 | 0.353745 | 0.903214 | −0.0706163 |

| 32 | 0.478514 | 0.803443 | −0.111609 |

| 33 | 0.319031 | 0.842192 | −0.0744975 |

| 34 | 0.469749 | 0.938362 | −0.120622 |

| 35 | 0.368043 | 0.885021 | −0.077033 |

| 36 | 0.174089 | 0.790303 | −0.223813 |

| 37 | 0.709576 | 1.19667 | −0.000305122 |

| 38 | 0.417963 | 0.930018 | −0.0186425 |

| 39 | 0.221123 | 1.02904 | −0.0177394 |

| 40 | 0.445099 | 0.964506 | −0.0252461 |

| 41 | 0.262261 | 1.01861 | −0.0255577 |

| 42 | 0.538269 | 1.298 | −0.00843418 |

| 43 | 0.454673 | 1.00279 | −0.0629393 |

| 44 | 0.353997 | 0.95054 | −0.0830329 |

| 45 | 0.439489 | 0.961908 | −0.0700671 |

| 46 | 0.423663 | 0.986718 | −0.0666787 |

| 47 | 0.412275 | 0.998257 | −0.0691629 |

| 48 | 0.393799 | 0.983384 | −0.0698121 |

| 49 | 0.385122 | 1.05931 | −0.0523508 |

| 50 | 0.38372 | 1.05168 | −0.0651892 |

| 51 | 0.408308 | 0.985089 | −0.0797404 |

| 52 | 0.370361 | 0.981359 | −0.0730344 |

| 53 | 0.391368 | 0.952122 | −0.0632013 |

| 54 | 0.439184 | 1.03834 | −0.0760649 |

| 55 | 0.427071 | 1.02673 | −0.0601507 |

| 56 | 0.385143 | 0.967961 | −0.0673409 |

| 57 | 0.414075 | 0.987404 | −0.059813 |

| 58 | 0.451924 | 0.967198 | −0.0665639 |

| 59 | 0.413357 | 1.03205 | −0.0790877 |

| Level | X1 (°C) | X2 (%) | X3 (%w.b.) | X4 (m/s) | X5 |

|---|---|---|---|---|---|

| −1 | 39 | 50 | 19 | 0.5 | 1.5 |

| 0 | 54 | 21 | 0.6 | 3 | |

| 1 | 58 | 23 | 0.7 | 4.5 |

| Group | X1 (°C) | X2 (%) | X3 (%w.b.) | X4 (m/s) | X5 |

|---|---|---|---|---|---|

| 1 | 39 | 50 | 19 | 0.5 | 1.5/3/4.5 |

| 2 | 39 | 50 | 19 | 0.6 | 1.5/3/4.5 |

| 3 | 39 | 50 | 19 | 0.7 | 1.5/3/4.5 |

| 4 | 39 | 50 | 21 | 0.5 | 1.5/3/4.5 |

| 5 | 39 | 50 | 21 | 0.6 | 1.5/3/4.5 |

| 6 | 39 | 50 | 21 | 0.7 | 1.5/3/4.5 |

| 7 | 39 | 50 | 23 | 0.5 | 1.5/3/4.5 |

| 8 | 39 | 50 | 23 | 0.6 | 1.5/3/4.5 |

| 9 | 39 | 50 | 23 | 0.7 | 1.5/3/4.5 |

| 10 | 39 | 54 | 19 | 0.5 | 1.5/3/4.5 |

| 11 | 39 | 54 | 19 | 0.6 | 1.5/3/4.5 |

| 12 | 39 | 54 | 19 | 0.7 | 1.5/3/4.5 |

| 13 | 39 | 54 | 21 | 0.5 | 1.5/3/4.5 |

| 14 | 39 | 54 | 21 | 0.6 | 1.5/3/4.5 |

| 15 | 39 | 54 | 21 | 0.7 | 1.5/3/4.5 |

| 16 | 39 | 54 | 23 | 0.5 | 1.5/3/4.5 |

| 17 | 39 | 54 | 23 | 0.6 | 1.5/3/4.5 |

| 18 | 39 | 54 | 23 | 0.7 | 1.5/3/4.5 |

| 19 | 39 | 58 | 19 | 0.5 | 1.5/3/4.5 |

| 20 | 39 | 58 | 19 | 0.6 | 1.5/3/4.5 |

| 21 | 39 | 58 | 19 | 0.7 | 1.5/3/4.5 |

| 22 | 39 | 58 | 21 | 0.5 | 1.5/3/4.5 |

| 23 | 39 | 58 | 21 | 0.6 | 1.5/3/4.5 |

| 24 | 39 | 58 | 21 | 0.7 | 1.5/3/4.5 |

| 25 | 39 | 58 | 23 | 0.5 | 1.5/3/4.5 |

| 26 | 39 | 58 | 23 | 0.6 | 1.5/3/4.5 |

| 27 | 39 | 58 | 23 | 0.7 | 1.5/3/4.5 |

| Group | Tempering Ratio = 3 | Non-Tempering | ||||||

|---|---|---|---|---|---|---|---|---|

| k | n | b | M (%) | k | n | b | M (%) | |

| 1 | 0.55137 | 1.03118 | −0.0239 | 13.928 | 0.15751 | 0.75148 | −0.2079 | 14.453 |

| 2 | 0.59933 | 1.04894 | −0.0433 | 13.413 | 0.16840 | 0.84077 | −0.2068 | 14.277 |

| 3 | 0.61868 | 1.06670 | −0.0379 | 13.379 | 0.17930 | 0.87214 | −0.2056 | 14.157 |

| 4 | 0.45204 | 1.01811 | −0.0447 | 14.793 | 0.25332 | 0.84195 | −0.1010 | 15.892 |

| 5 | 0.50000 | 1.01562 | −0.0641 | 14.114 | 0.26092 | 0.90013 | −0.0998 | 15.728 |

| 6 | 0.51935 | 1.01312 | −0.0587 | 14.092 | 0.26852 | 0.90040 | −0.0987 | 15.670 |

| 7 | 0.41191 | 1.02189 | −0.0427 | 15.822 | 0.32847 | 0.83558 | −0.0482 | 17.057 |

| 8 | 0.45987 | 0.99914 | −0.0621 | 15.014 | 0.33277 | 0.86266 | −0.0470 | 16.967 |

| 9 | 0.47922 | 0.97640 | −0.0567 | 15.032 | 0.33708 | 0.83182 | −0.0459 | 17.023 |

| 10 | 0.51172 | 1.13071 | −0.0518 | 14.059 | 0.13980 | 0.68940 | −0.2276 | 14.825 |

| 11 | 0.57560 | 1.11817 | −0.0713 | 13.561 | 0.16161 | 0.79366 | −0.2264 | 14.570 |

| 12 | 0.61086 | 1.10563 | −0.0658 | 13.516 | 0.18342 | 0.84002 | −0.2253 | 14.358 |

| 13 | 0.41239 | 1.08352 | −0.0660 | 15.030 | 0.23561 | 0.77986 | −0.1207 | 16.204 |

| 14 | 0.47627 | 1.05073 | −0.0854 | 14.333 | 0.25412 | 0.85302 | −0.1195 | 15.928 |

| 15 | 0.51153 | 1.01794 | −0.0800 | 14.274 | 0.27264 | 0.86827 | −0.1184 | 15.747 |

| 16 | 0.37225 | 1.05318 | −0.0572 | 16.242 | 0.31076 | 0.77349 | −0.0678 | 17.328 |

| 17 | 0.43613 | 1.00014 | −0.0767 | 15.385 | 0.32598 | 0.81555 | −0.0667 | 17.099 |

| 18 | 0.47140 | 0.94709 | −0.0713 | 15.342 | 0.34120 | 0.79969 | −0.0655 | 17.006 |

| 19 | 0.43513 | 1.19344 | −0.1003 | 14.289 | 0.10552 | 0.58413 | −0.2638 | 15.179 |

| 20 | 0.51493 | 1.15060 | −0.1198 | 13.780 | 0.13824 | 0.70337 | −0.2627 | 14.879 |

| 21 | 0.56611 | 1.10776 | −0.1143 | 13.708 | 0.17097 | 0.76470 | −0.2615 | 14.605 |

| 22 | 0.33580 | 1.11213 | −0.1078 | 15.389 | 0.20133 | 0.67459 | −0.1569 | 16.486 |

| 23 | 0.41560 | 1.04904 | −0.1272 | 14.625 | 0.23076 | 0.76273 | −0.1557 | 16.126 |

| 24 | 0.46678 | 0.98595 | −0.1218 | 14.505 | 0.26019 | 0.79296 | −0.1546 | 15.846 |

| 25 | 0.29567 | 1.04767 | −0.0924 | 16.791 | 0.27648 | 0.66822 | −0.1040 | 17.550 |

| 26 | 0.37547 | 0.96433 | −0.1118 | 15.815 | 0.30262 | 0.72526 | −0.1029 | 17.204 |

| 27 | 0.42665 | 0.88099 | −0.1064 | 15.680 | 0.32875 | 0.72438 | −0.1017 | 16.980 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, Y.; Yin, J.; Xie, H.; Zhang, Z. Reconstruction of Rice Drying Model and Analysis of Tempering Characteristics Based on Drying Accumulated Temperature. Appl. Sci. 2021, 11, 11113. https://doi.org/10.3390/app112311113

Jin Y, Yin J, Xie H, Zhang Z. Reconstruction of Rice Drying Model and Analysis of Tempering Characteristics Based on Drying Accumulated Temperature. Applied Sciences. 2021; 11(23):11113. https://doi.org/10.3390/app112311113

Chicago/Turabian StyleJin, Yi, Jun Yin, Huihuang Xie, and Zhongjie Zhang. 2021. "Reconstruction of Rice Drying Model and Analysis of Tempering Characteristics Based on Drying Accumulated Temperature" Applied Sciences 11, no. 23: 11113. https://doi.org/10.3390/app112311113

APA StyleJin, Y., Yin, J., Xie, H., & Zhang, Z. (2021). Reconstruction of Rice Drying Model and Analysis of Tempering Characteristics Based on Drying Accumulated Temperature. Applied Sciences, 11(23), 11113. https://doi.org/10.3390/app112311113