Influence of Soil Particle Size on the Engineering Properties and Microstructure of a Red Clay

Abstract

:1. Introduction

2. Materials and Methods

2.1. Research Materials

2.1.1. Exploration of Physical Properties of Sample Site

2.1.2. Material Composition of Soil Samples

2.2. Testing Methods

3. Results and Analysis

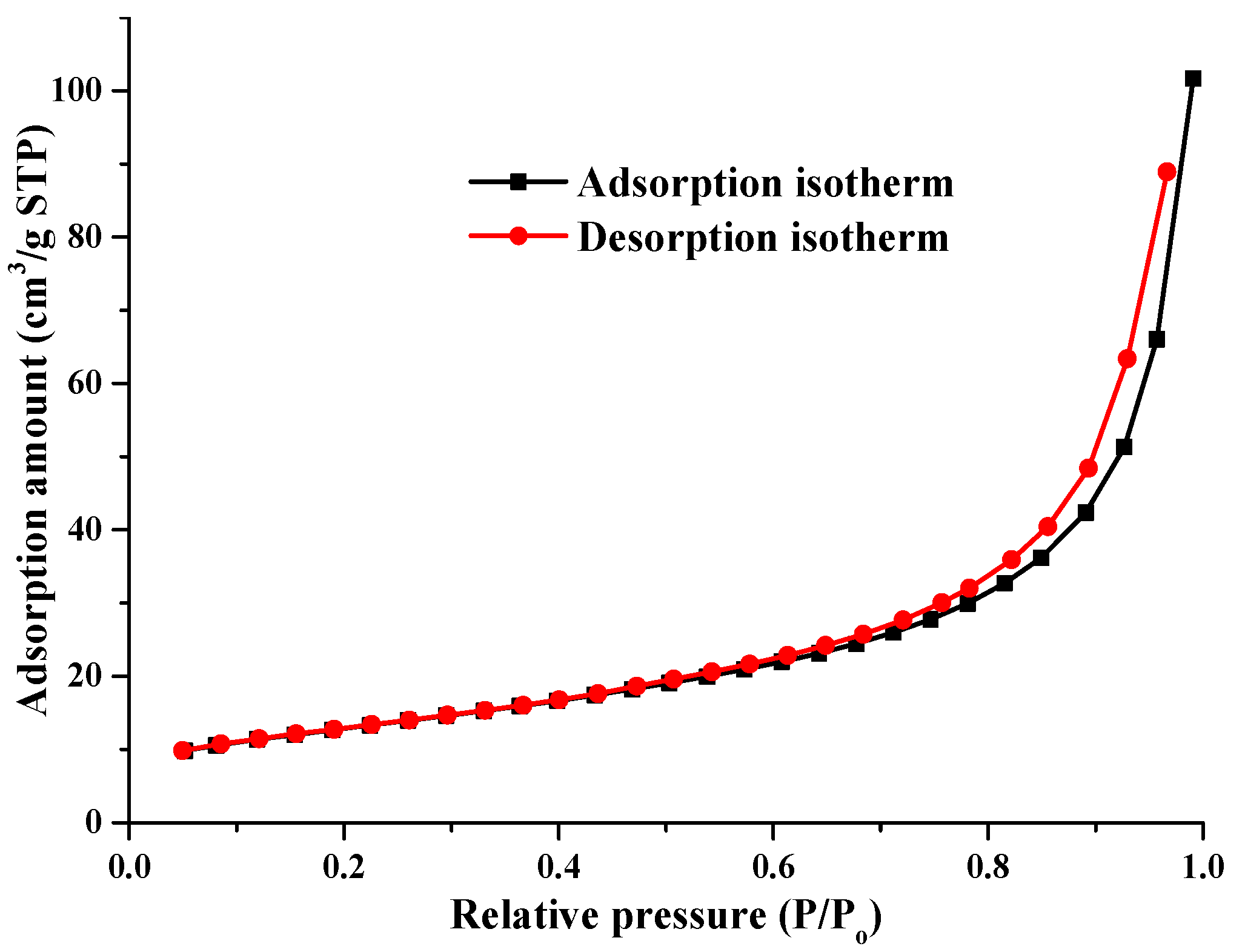

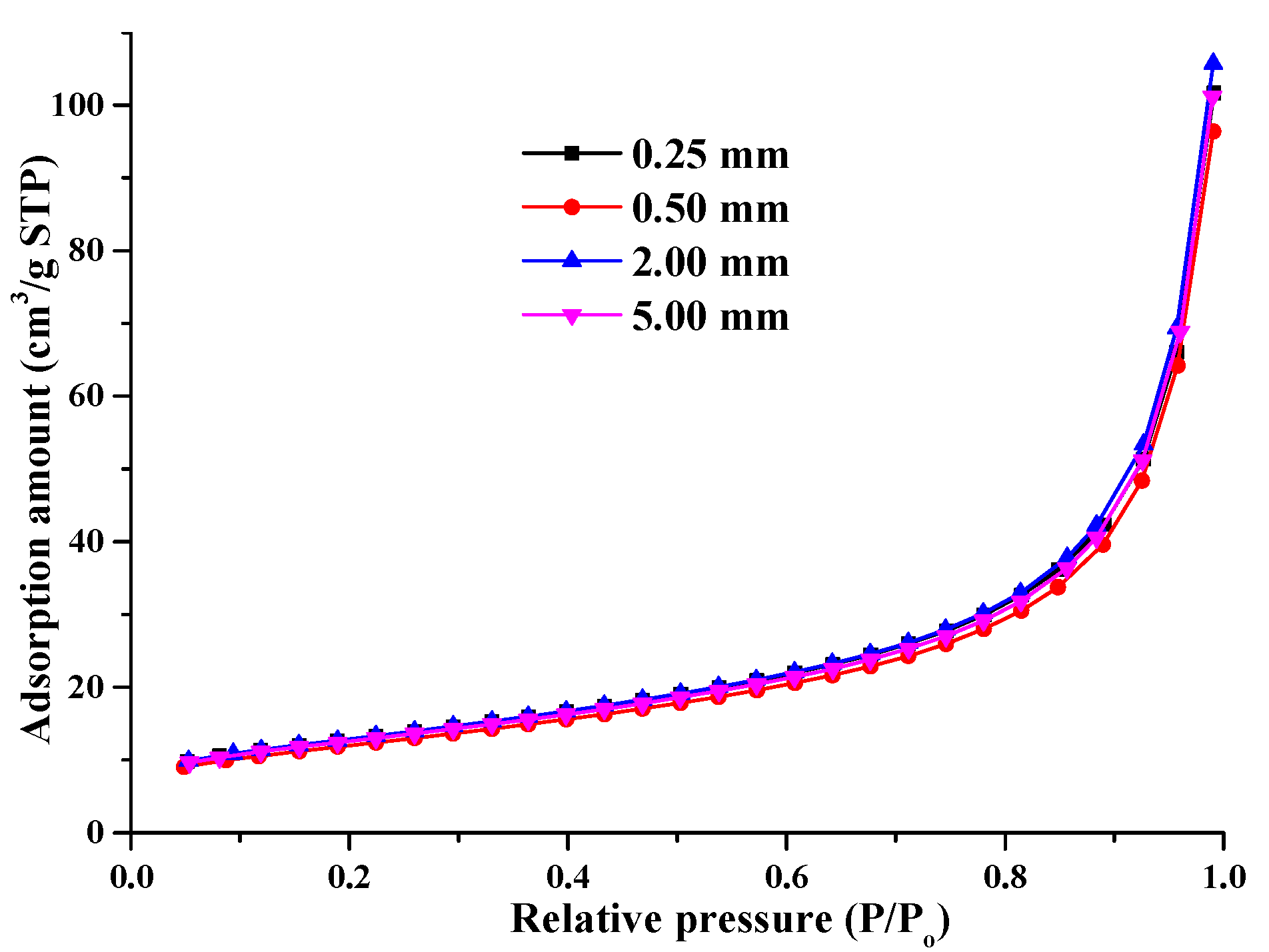

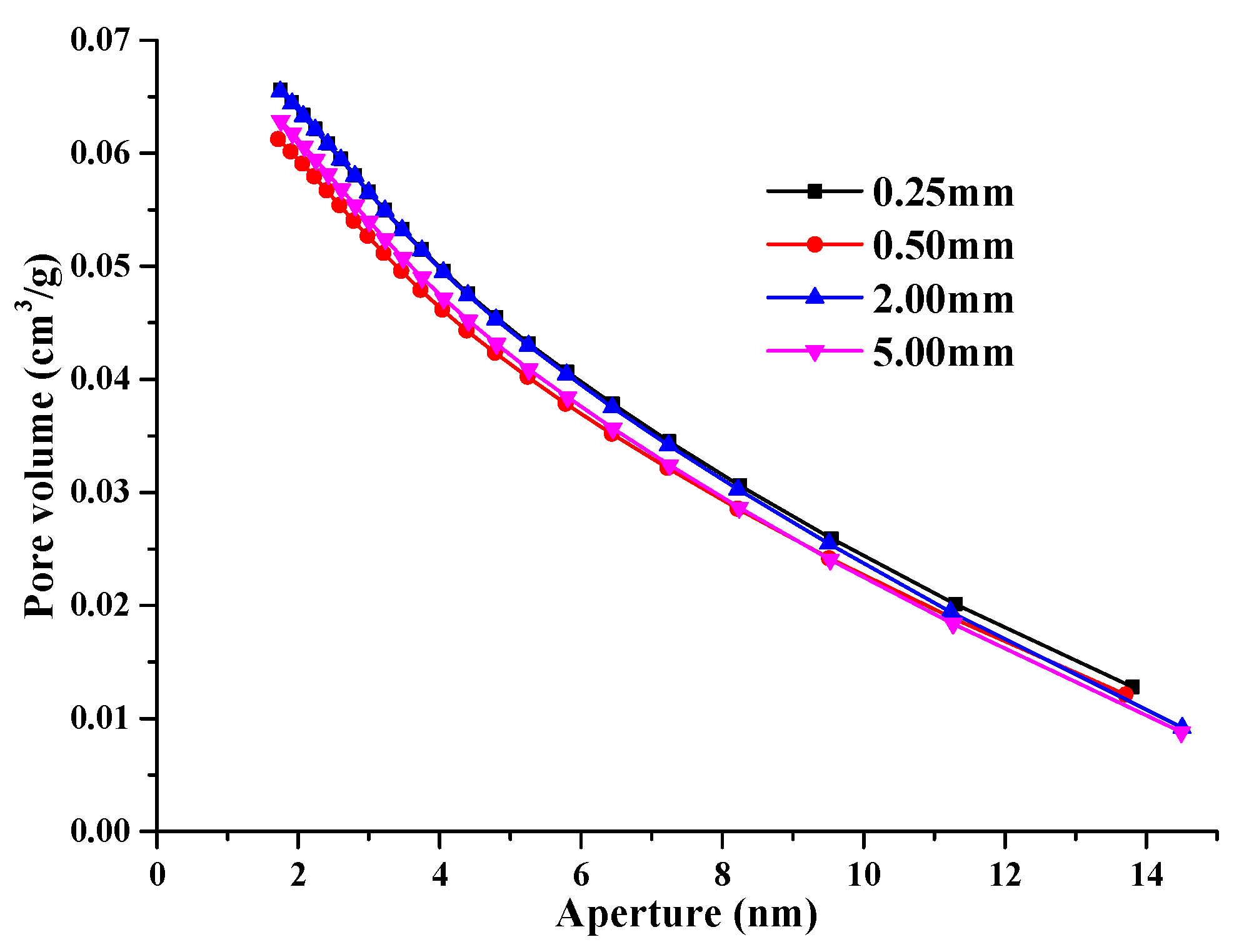

3.1. Analysis of Specific Surface Area and Pore

3.1.1. Specific Surface Area

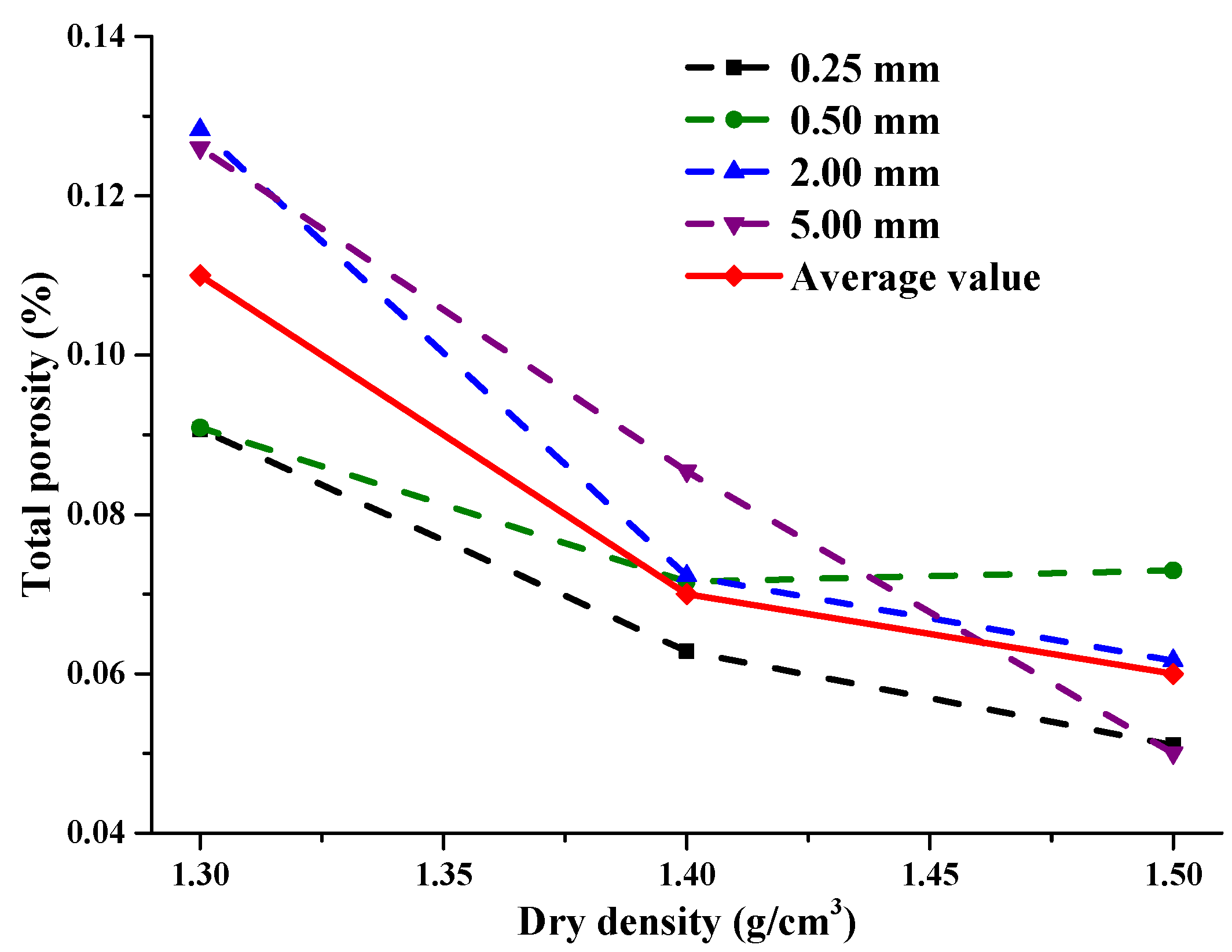

3.1.2. Porosity

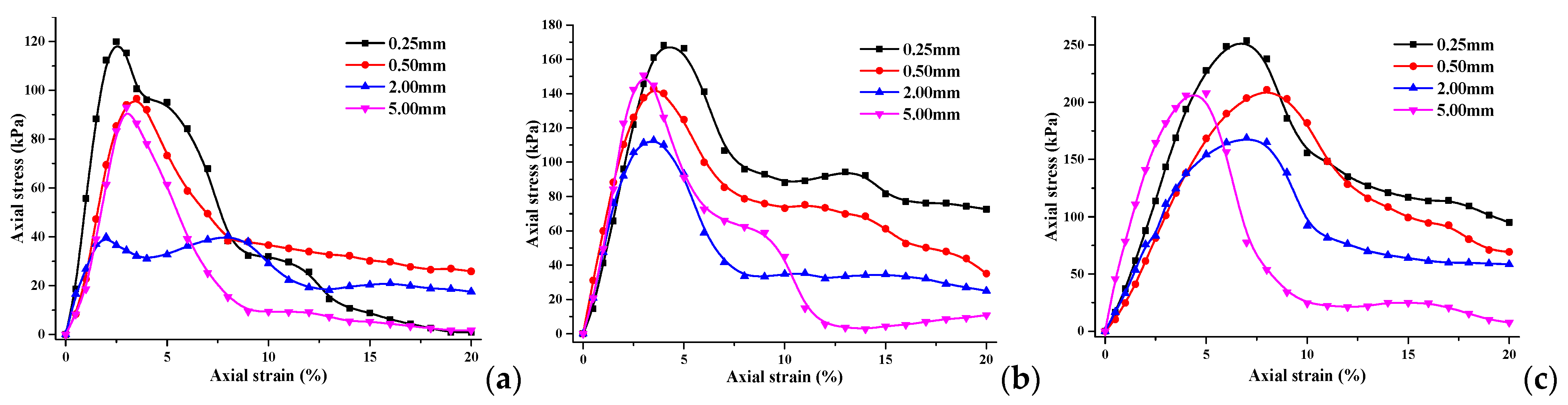

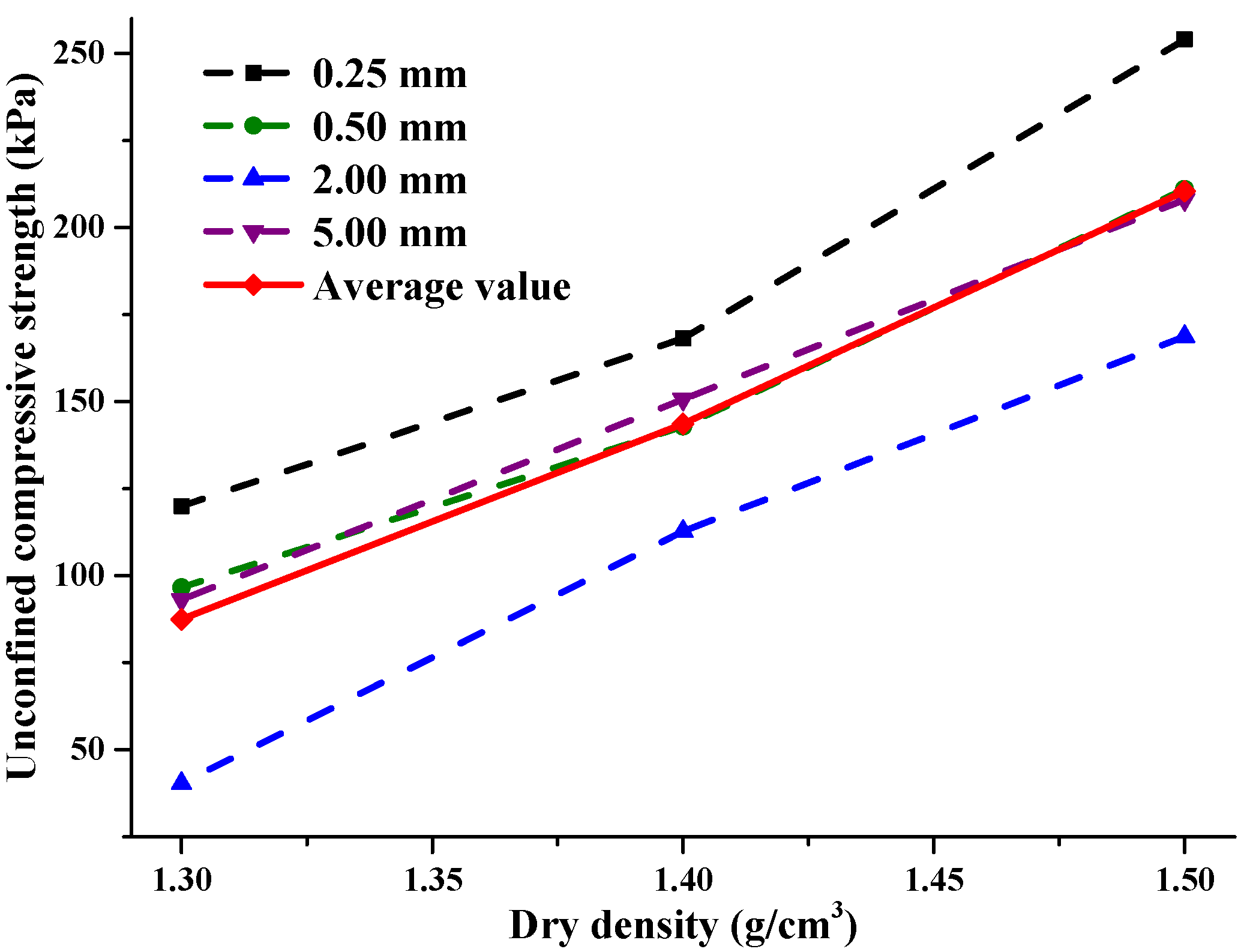

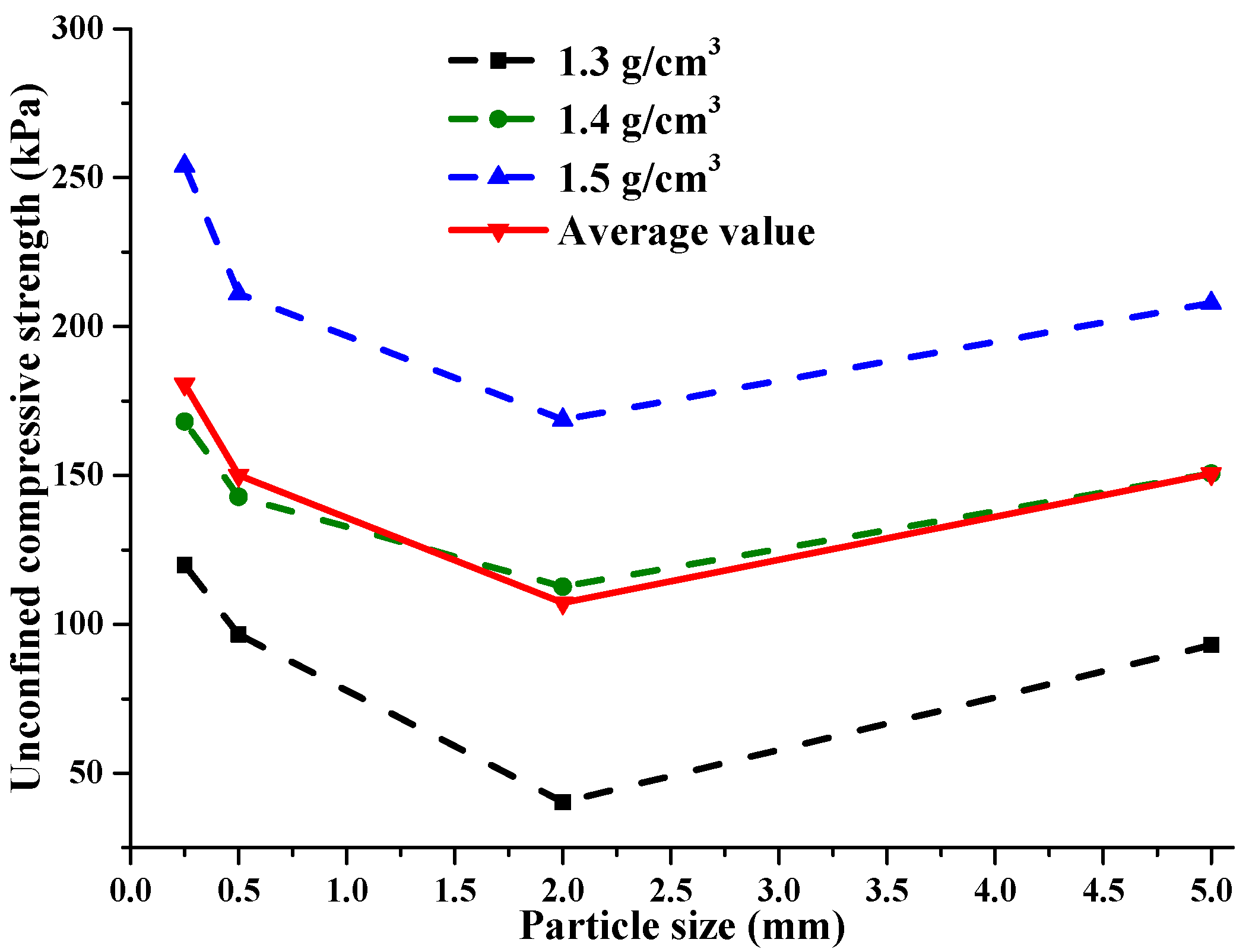

3.2. Results of UCS Test

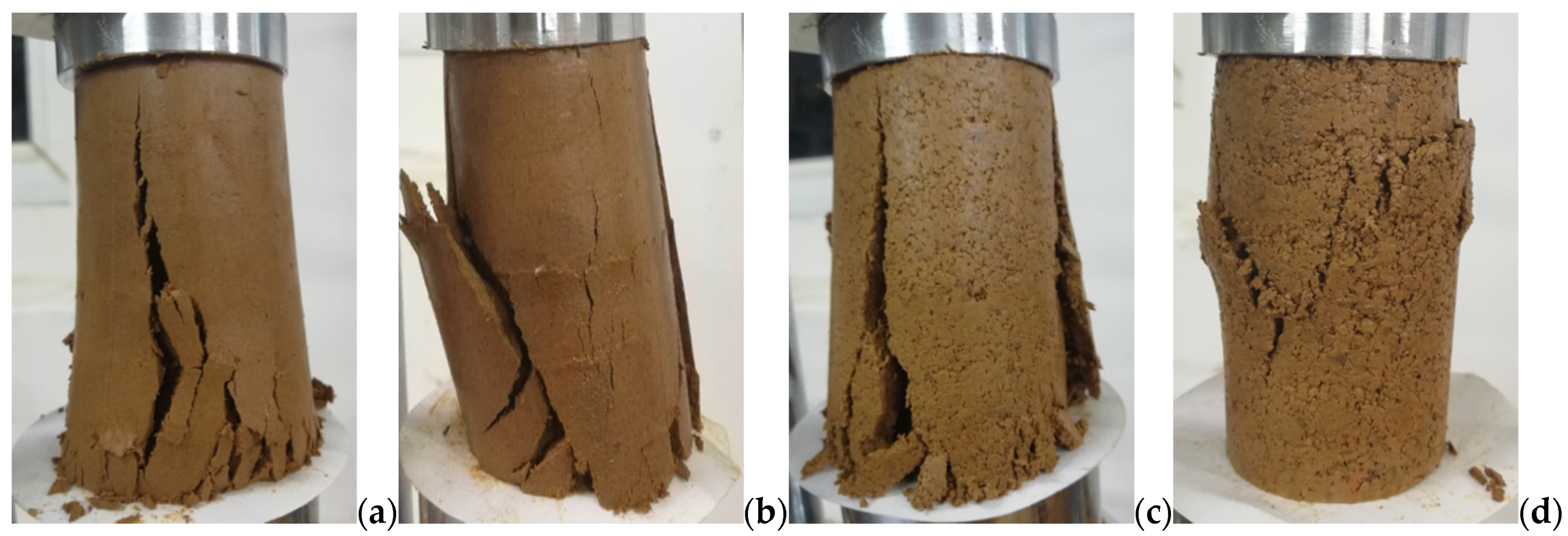

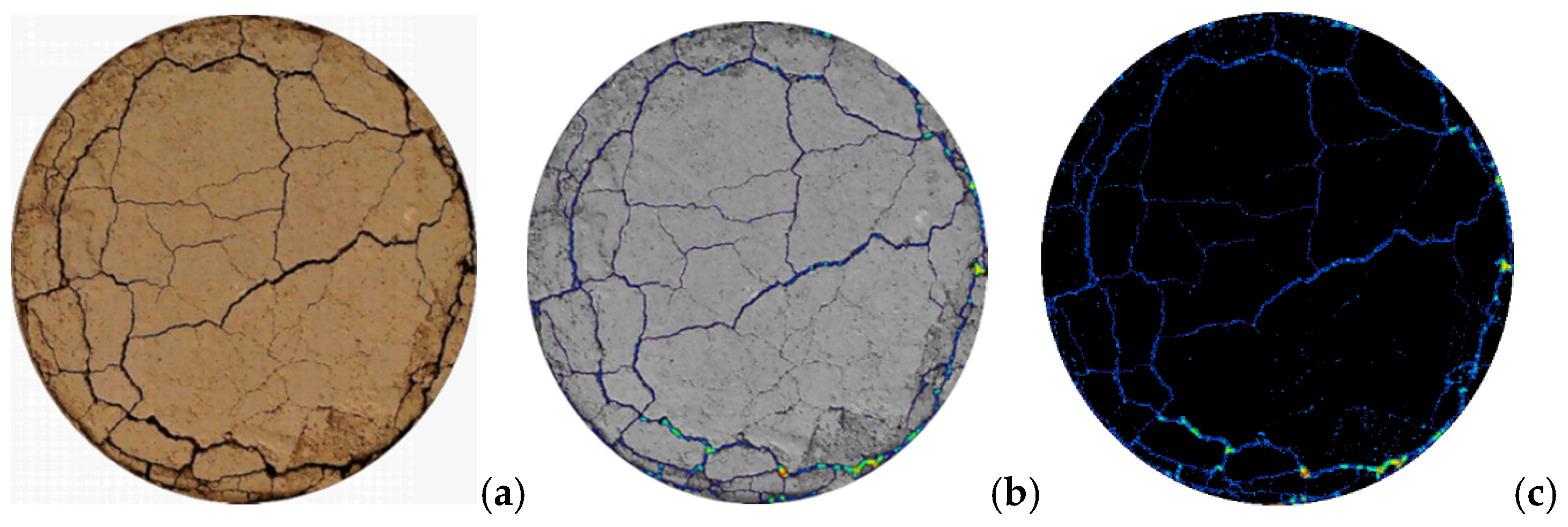

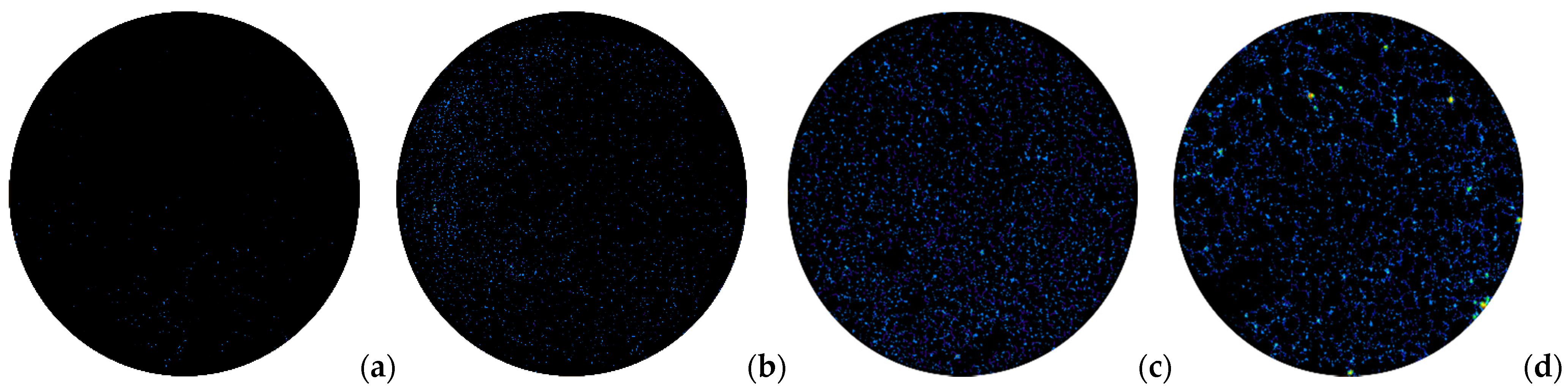

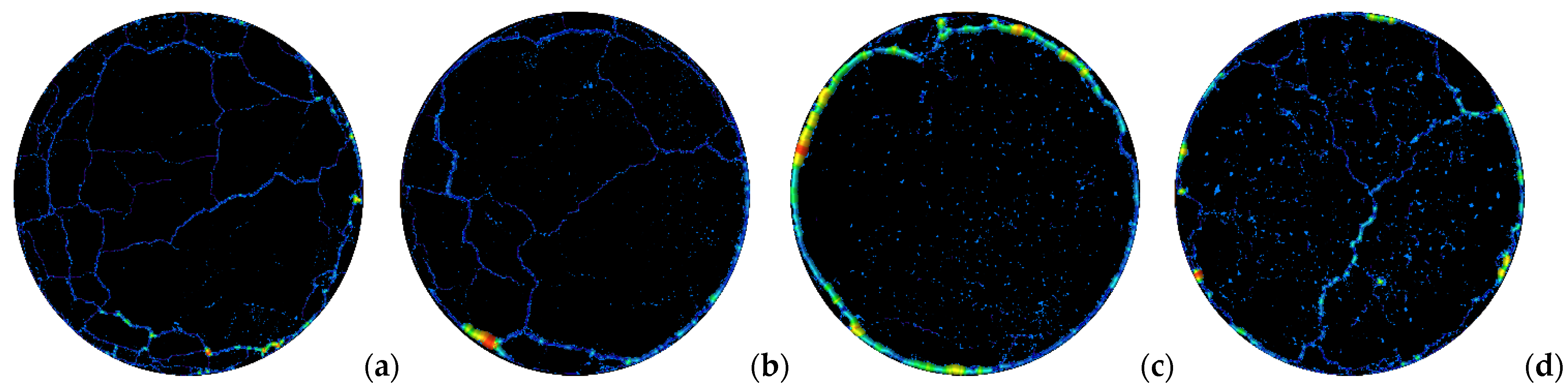

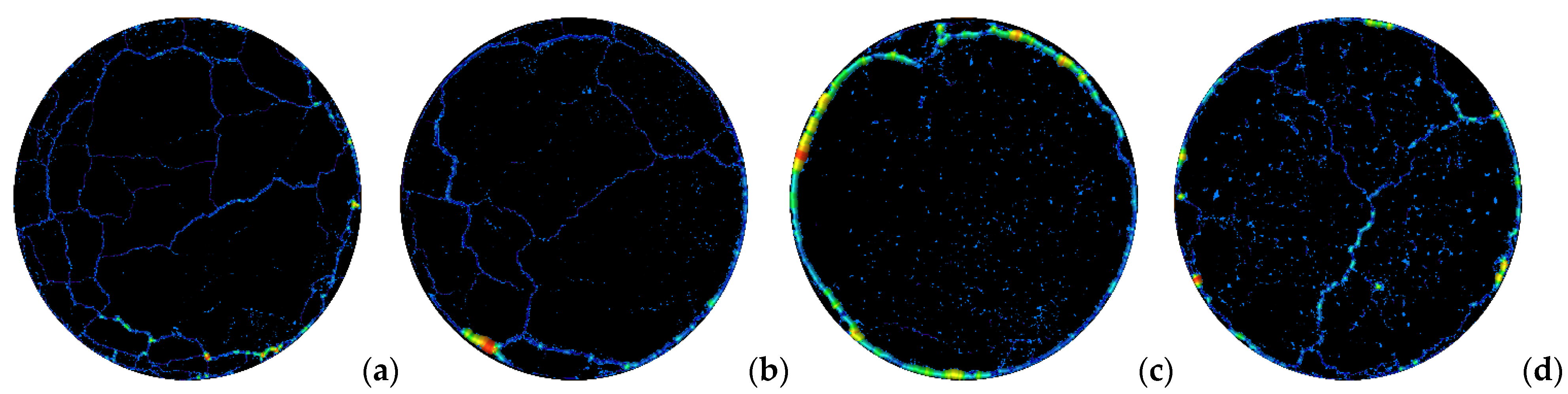

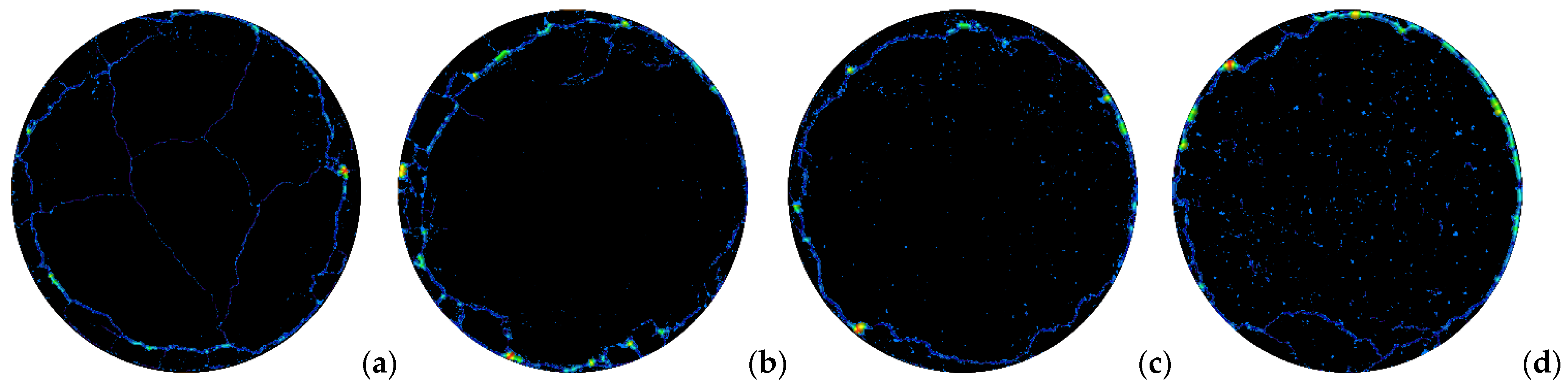

3.3. Results of Macro Cracks

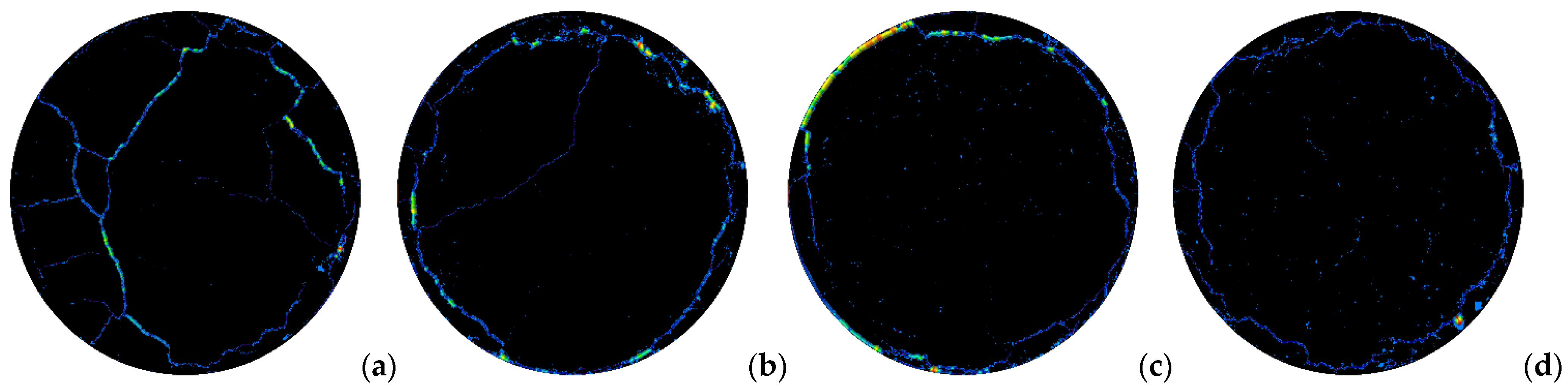

3.3.1. The Influence of WD Cycles on the Crack of Red Clay with Different Particle Sizes

3.3.2. The Impact of Dry Density on the Cracks of Red Clay with Different Particle Sizes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wei, X.; Ji, H.; Wang, S.; Song, C. The formation of representative lateritic weathering covers in south-central Guangxi (southern China). Catena 2014, 118, 55–72. [Google Scholar] [CrossRef]

- Lee, K.C.; Her, J.H.; Kwon, S.K. Red clay composites reinforced with polymeric binders. Constr. Build. Mater. 2008, 22, 2292–2298. [Google Scholar] [CrossRef]

- Li, J.; Tang, S.; Chen, X. Analysis of the Mechanical properties and mechanism of zinc ion-contaminated red clay. Adv. Mater. Sci. Eng. 2021, 2021, 6649691. [Google Scholar] [CrossRef]

- Mahinroosta, R.; Poorjafar, A. Effect of stress state and particle-size distribution on the stress reduction of sandy soils during saturation. Constr. Build. Mater. 2017, 150, 1–13. [Google Scholar] [CrossRef]

- Chen, L.; Chen, X.; Yang, X.; Bi, P.; Ding, X.; Huang, X.; Wang, H. Effect of calcium carbonate on the mechanical properties and microstructure of red clay. Adv. Mater. Sci. Eng. 2020, 2020, 5298186. [Google Scholar] [CrossRef]

- Zhang, Y.; Pu, S.; Li, R.Y.M.; Zhang, J. Microscopic and mechanical properties of undisturbed and remoulded red clay from Guiyang, China. Sci. Rep. 2020, 10, 18003. [Google Scholar] [CrossRef] [PubMed]

- Cho, G.; Dodds, J.; Santamarina, J. Particle shape effects on packing density, stiffness, and strength: Natural and crushed sands. J. Geotech. Geoenviron. 2006, 132, 591–602. [Google Scholar] [CrossRef] [Green Version]

- Santamarina, J.C.; Klein, A.; Fam, M.A. Soils and waves: Particulate materials behavior, characterization and process monitoring. J. Soils Sediments 2001, 1, 130. [Google Scholar] [CrossRef]

- Thornton, C. Numerical simulations of deviatoric shear deformation of granular media. Géotechnique 2000, 50, 43–53. [Google Scholar] [CrossRef]

- Wang, J.J.; Zhang, H.P.; Tang, S.C.; Liang, Y. Effects of Particle size distribution on shear strength of accumulation soil. J. Geotech. Geoenviron. Eng. 2013, 139, 1994–1997. [Google Scholar] [CrossRef]

- Qi, Z.; Chen, T.; Bai, S.; Yan, M.; Li, X. Effect of temperature and particle size on the thermal desorption of PCBs from contaminated soil. Environ. Sci. Pollut. Res. 2014, 21, 4697–4704. [Google Scholar] [CrossRef]

- Chang, C.S.; Deng, Y.B.; Yang, Z.N. Modeling of minimum void ratio for granular soil with effect of particle size distribution. J. Eng. Mech.-ASCE 2017, 143, 5092612. [Google Scholar] [CrossRef]

- Cubrinovski, M.; Ishihara, K. Maximum and minimum void ratio characteristics of sands. Soils Found. 2002, 42, 65–78. [Google Scholar] [CrossRef] [Green Version]

- Fuggle, A.R.; Roozbahani, M.M.; Frost, J.D. Size effects on the void ratio of loosely packed binary particle mixtures. In Geo-Congress 2014 Technical Papers; ASCE: Reston, VA, USA, 2014; pp. 129–138. [Google Scholar] [CrossRef]

- Islam, M.N.; Siddika, A.; Hossain, M.B.; Rahman, A.; Asad, M.A. Effect of particle size on the shear strength behavior of sands. arXiv 2019, arXiv:1902.09079. [Google Scholar]

- Cheraghi, M.; Jomaa, S.; Sander, G.; Barry, D. Hysteretic sediment fluxes in rainfall-driven soil erosion: Particle size effects. Water Resour. Res. 2016, 52, 8613–8629. [Google Scholar] [CrossRef]

- Rasti, A.; Adarmanabadi, H.R.; Pineda, M.; Reinikainen, J. Evaluating the effect of soil particle characterization on internal friction angle. Am. J. Eng. Appl. Sci. 2021, 14, 129–138. [Google Scholar] [CrossRef]

- Aberg, B. Void ratio of noncohesive soils and similar materials. J. Geotech. Eng. 1992, 118, 1315–1334. [Google Scholar] [CrossRef]

- Bobei, D.C.; Lo, S.R.; Wanatowski, D.; Gnanendran, C.T.; Rahman, M.M. Modified state parameter for characterizing static liquefaction of sand with fines. Can. Geotech. J. 2009, 46, 281–295. [Google Scholar] [CrossRef]

- Peters, J.F.; Berney, E.S. Percolation threshold of sand-clay binary mixtures. J. Geotech. Geoenviron. Eng. 2010, 136, 310–318. [Google Scholar] [CrossRef]

- Reiner, N.; Gabriel, E.; José, C.; Matheus, P. The mineral phase quantification of vermiculite and interstratified clay minerals-containing ores by X-ray diffraction and Rietveld method after K cation exchange. Miner. Eng. 2011, 24, 1323–1334. [Google Scholar] [CrossRef]

- Wang, Z.; Cheng, Y.; Qi, Y.; Wang, R.; Wang, L.; Jiang, J. Experimental study of pore structure and fractal characteristics of pulverized intact coal and tectonic coal by low temperature nitrogen adsorption. Powder Technol. 2019, 350, 15–25. [Google Scholar] [CrossRef]

- Qi, L.; Tang, X.; Wang, Z.; Peng, X. Pore characterization of different types of coal from coal and gas outburst disaster sites using low temperature nitrogen adsorption approach. Int. J. Min. Sci. Technol. 2017, 27, 371–377. [Google Scholar] [CrossRef]

- Sing, K. The use of nitrogen adsorption for the characterisation of porous materials. Colloids Surf. A Physicochem. Eng. Asp. 2001, 187–188, 3–9. [Google Scholar] [CrossRef]

| Unit Weight | Specific Gravity | Free Swelling Ratio | Plastic Limit | Liquid Limit | Plasticity Index | Optimum Moisture Content | Maximum Dry Unit Weight |

|---|---|---|---|---|---|---|---|

| 18.1 kN/m3 | 2.76 | 21% | 31.9% | 55.8% | 23.9 | 30.78% | 1.575 g·cm−3 |

| Element | MgK | AIK | SiK | KK | TiK | FeK | O | Total |

|---|---|---|---|---|---|---|---|---|

| Weight (%) | 0.90 | 19.54 | 22.34 | 1.32 | 1.36 | 7.72 | 46.81 | 100.00 |

| Mineral Composition | Semi-Quantitative (%) | Characteristic Peak | Interplanar Spacing d (Å) | Angle 2 Theta (°) | Relative Strength I (%) |

|---|---|---|---|---|---|

| Quartz | 38.00 | The first characteristic peak | 3.33 | 26.74 | 100 |

| The second characteristic peak | 4.23 | 20.97 | 21.9 | ||

| The third characteristic peak | 1.81 | 50.23 | 9.9 | ||

| Laumontite | 13.20 | The first characteristic peak | 9.42 | 9.38 | 100 |

| The second characteristic peak | 3.5 | 25.44 | 47.7 | ||

| The third characteristic peak | 4.15 | 21.39 | 43.8 | ||

| Montmorillonite | 1.10 | The first characteristic peak | 14.7 | 19.75 | 100 |

| The second characteristic peak | 4.93 | 35.06 | 60 | ||

| The third characteristic peak | 4.43 | 62.09 | 80 | ||

| Kaolinite | 4.20 | The first characteristic peak | 7.15 | 12.37 | 100 |

| The second characteristic peak | 3.57 | 24.9 | 80 | ||

| The third characteristic peak | 2.34 | 38.51 | 40 | ||

| Clinochlore | 23.10 | The first characteristic peak | 14.38 | 6.23 | 86.5 |

| The second characteristic peak | 7.1 | 12.38 | 100 | ||

| The third characteristic peak | 4.75 | 18.67 | 59.6 | ||

| Illite | 20.30 | The first characteristic peak | 9.9 | 8.9 | 61 |

| The second characteristic peak | 4.45 | 19.9 | 100 | ||

| The third characteristic peak | 3.5 | 25.38 | 60.3 |

| Grain Size (mm) | BET Surface Area (m2/g) | Langmuir Surface Area (m2/g) | Internal Surface Area (m2/g) | External Surface Area (m2/g) | BJH Adsorption Cumulative Surface Area (m2/g) | BJH Desorption Cumulative Surface Area (m2/g) |

|---|---|---|---|---|---|---|

| 0.25 | 45.6956 | 116.2331 | 2.8895 | 42.8061 | 46.950 | 48.4585 |

| 0.50 | 42.7188 | 109.0909 | 2.0696 | 40.6492 | 44.268 | 45.6784 |

| 2.00 | 45.8130 | 117.7344 | 2.9162 | 42.8968 | 47.143 | 48.8844 |

| 5.00 | 44.7118 | 113.1781 | 2.9628 | 41.7489 | 45.700 | 47.5564 |

| Grain Size (mm) | Micropore Volume (cm3/g) | BJH Adsorption Cumulative Volume (cm3/g) | BJH Desorption Cumulative Volume (cm3/g) | BJH Adsorption Average Pore Width (4 V/A) (nm) | BJH Desorption Average Pore Width (4 V/A) (nm) |

|---|---|---|---|---|---|

| 0.25 | 0.001210 | 0.065612 | 0.075129 | 5.5900 | 6.2015 |

| 0.50 | 0.000810 | 0.061253 | 0.072472 | 5.5348 | 6.3463 |

| 2.00 | 0.001235 | 0.065473 | 0.079685 | 5.5552 | 6.5203 |

| 5.00 | 0.001255 | 0.062868 | 0.077363 | 5.5028 | 6.5070 |

| Number of Cycles | 0.25 mm | 0.50 mm | 2.00 mm | 5.00 mm | ||||

|---|---|---|---|---|---|---|---|---|

| Total Porosity (%) | Fractal Dimension | Total Porosity (%) | Fractal Dimension | Total Porosity (%) | Fractal Dimension | Total Porosity (%) | Fractal Dimension | |

| 1 | 0.0025 | 0.8581 | 0.0129 | 1.3100 | 0.0500 | 1.4948 | 0.0645 | 1.4998 |

| 4 | 0.0875 | 1.3309 | 0.0982 | 1.3298 | 0.1586 | 1.3769 | 0.2035 | 1.5228 |

| 8 | 0.0745 | 1.2504 | 0.1085 | 1.1558 | 0.1312 | 1.3415 | 0.1419 | 1.4295 |

| 12 | 0.0907 | 1.3299 | 0.0909 | 1.2988 | 0.1283 | 1.2991 | 0.1260 | 1.3699 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Li, K.; Li, J.; Tang, S. Influence of Soil Particle Size on the Engineering Properties and Microstructure of a Red Clay. Appl. Sci. 2021, 11, 10887. https://doi.org/10.3390/app112210887

Wang Y, Li K, Li J, Tang S. Influence of Soil Particle Size on the Engineering Properties and Microstructure of a Red Clay. Applied Sciences. 2021; 11(22):10887. https://doi.org/10.3390/app112210887

Chicago/Turabian StyleWang, Yongwei, Kunyao Li, Jiaming Li, and Shibin Tang. 2021. "Influence of Soil Particle Size on the Engineering Properties and Microstructure of a Red Clay" Applied Sciences 11, no. 22: 10887. https://doi.org/10.3390/app112210887

APA StyleWang, Y., Li, K., Li, J., & Tang, S. (2021). Influence of Soil Particle Size on the Engineering Properties and Microstructure of a Red Clay. Applied Sciences, 11(22), 10887. https://doi.org/10.3390/app112210887