Degradation of Mechanical Behavior of Sandstone under Freeze-Thaw Conditions with Different Low Temperatures

Abstract

:1. Introduction

2. Materials and Methods

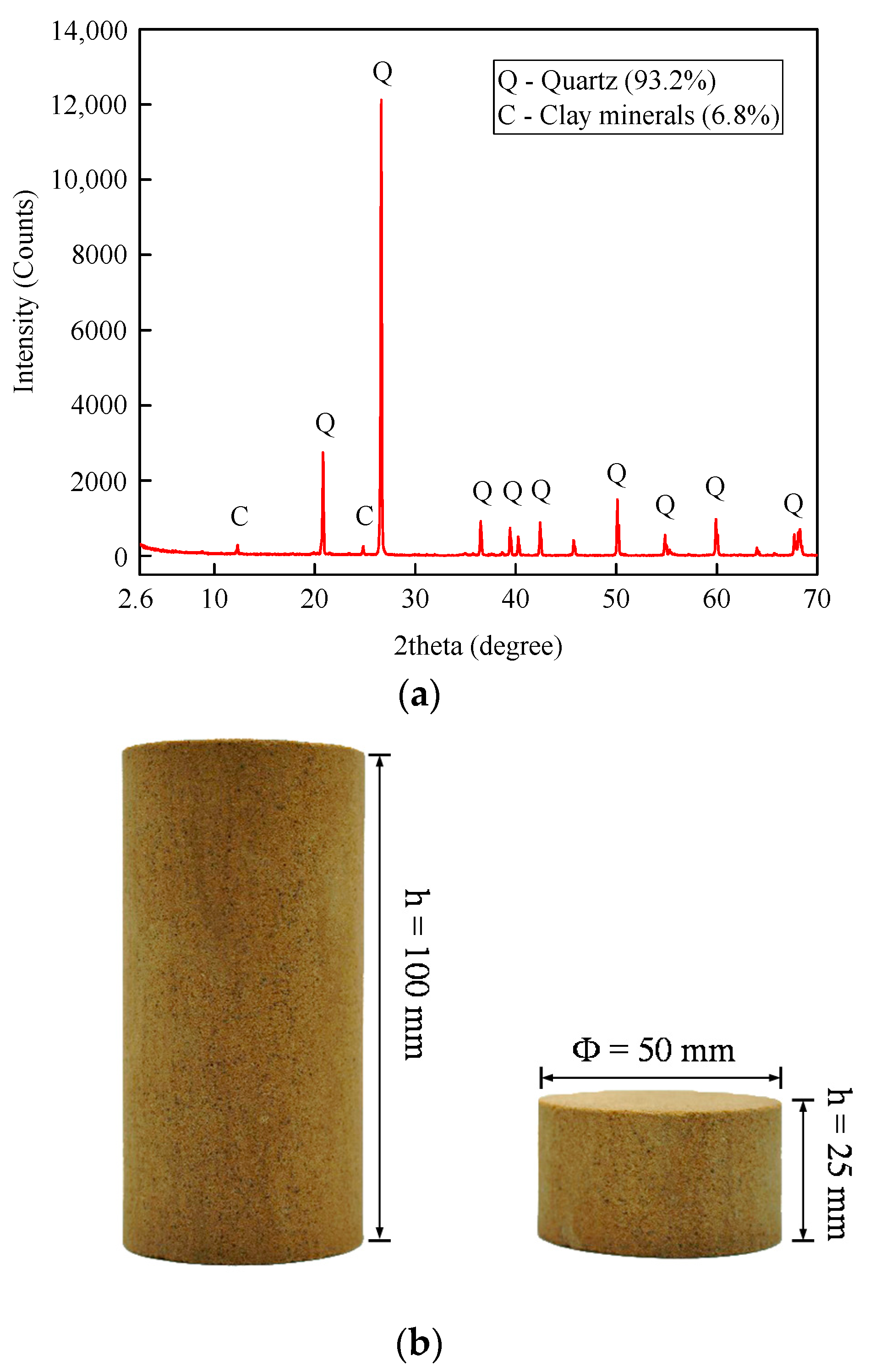

2.1. Specimen Preparation

2.2. Freeze-Thaw Cycling Treatments

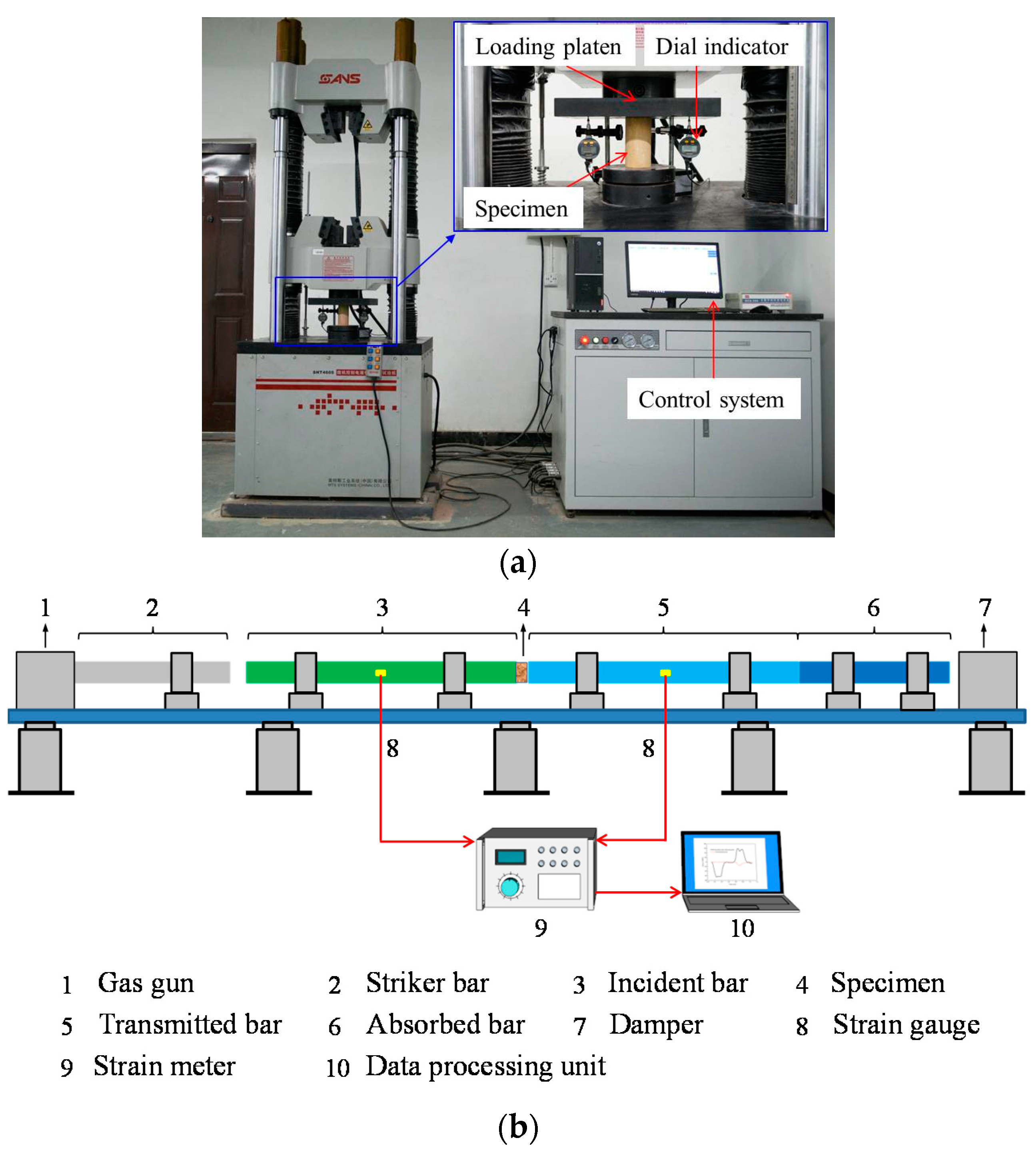

2.3. Static Uniaxial Compression Tests

2.4. SHPB Tests

3. Results

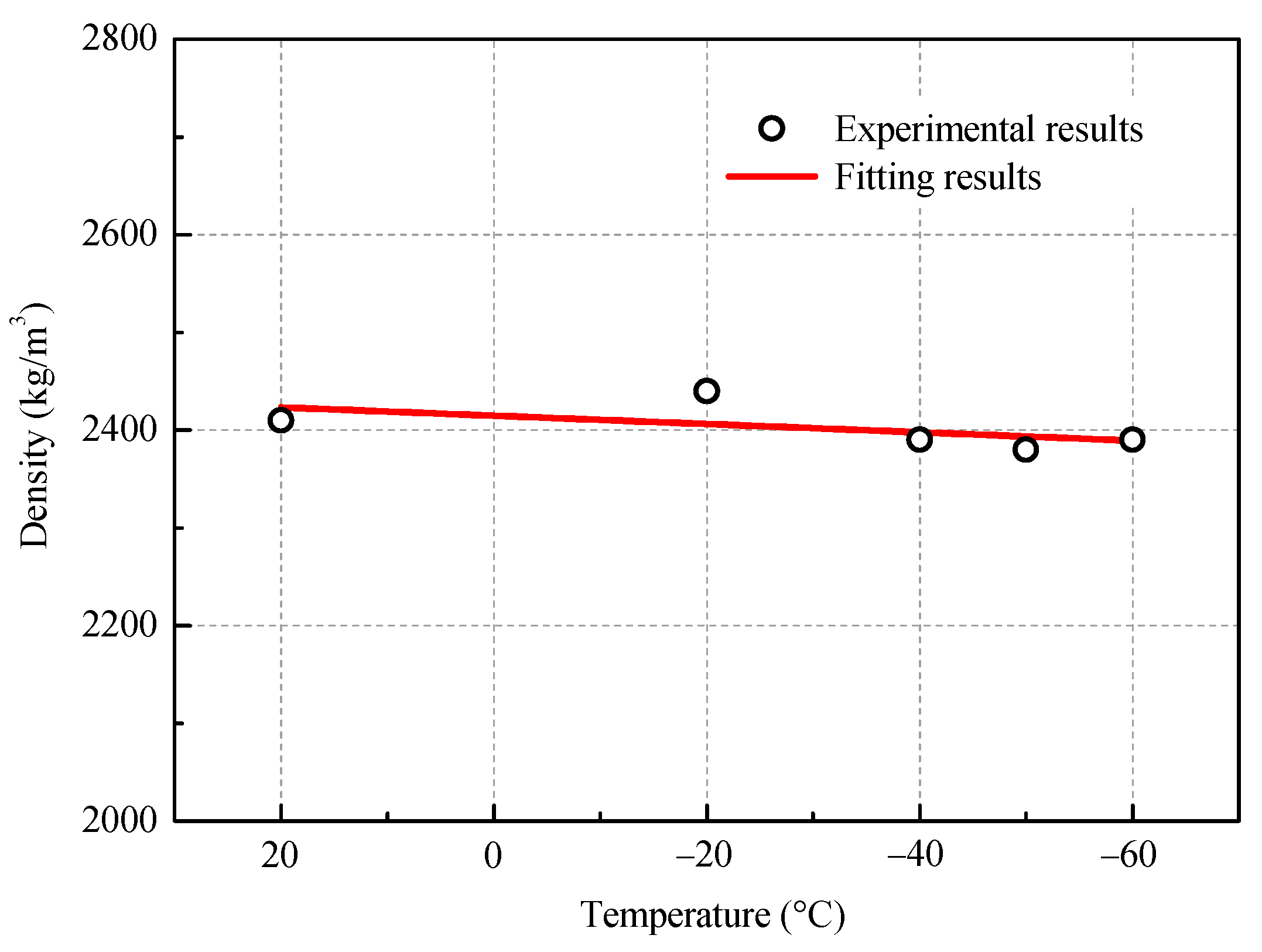

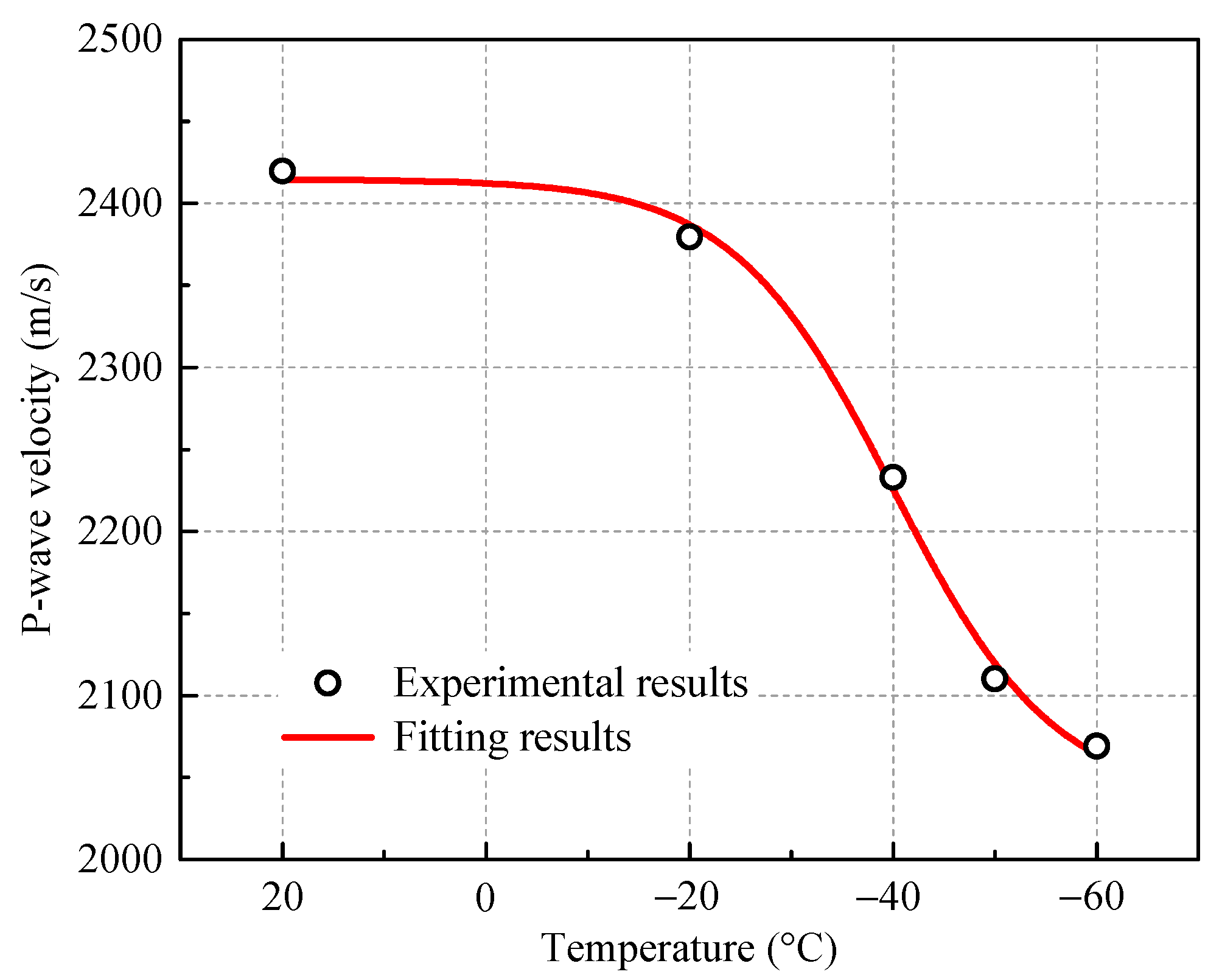

3.1. Effects of Freezing Temperature on Density and P-Wave Velocity

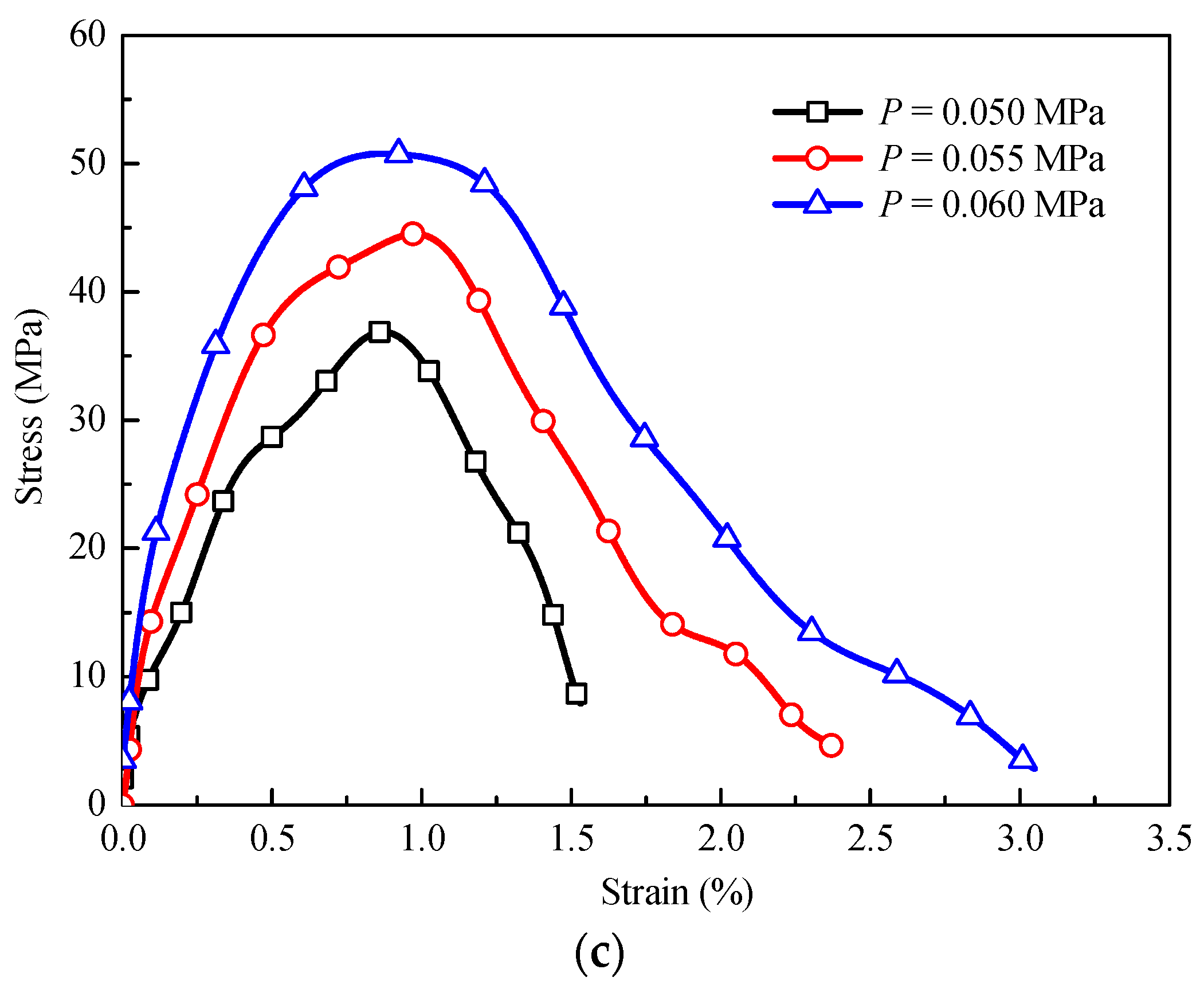

3.2. Effects of Freezing Temperature and Impact Pressure on the Stress–Strain Curve

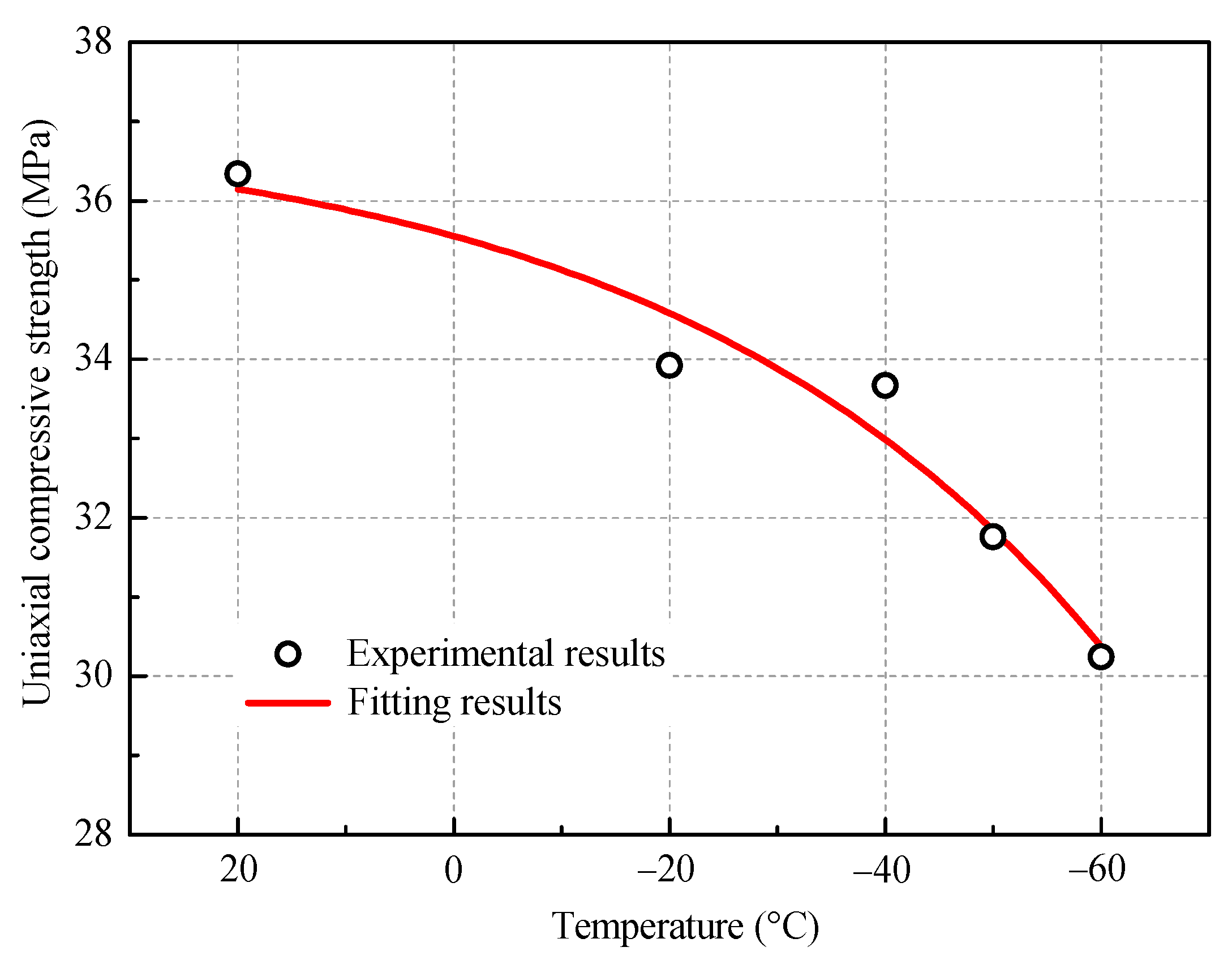

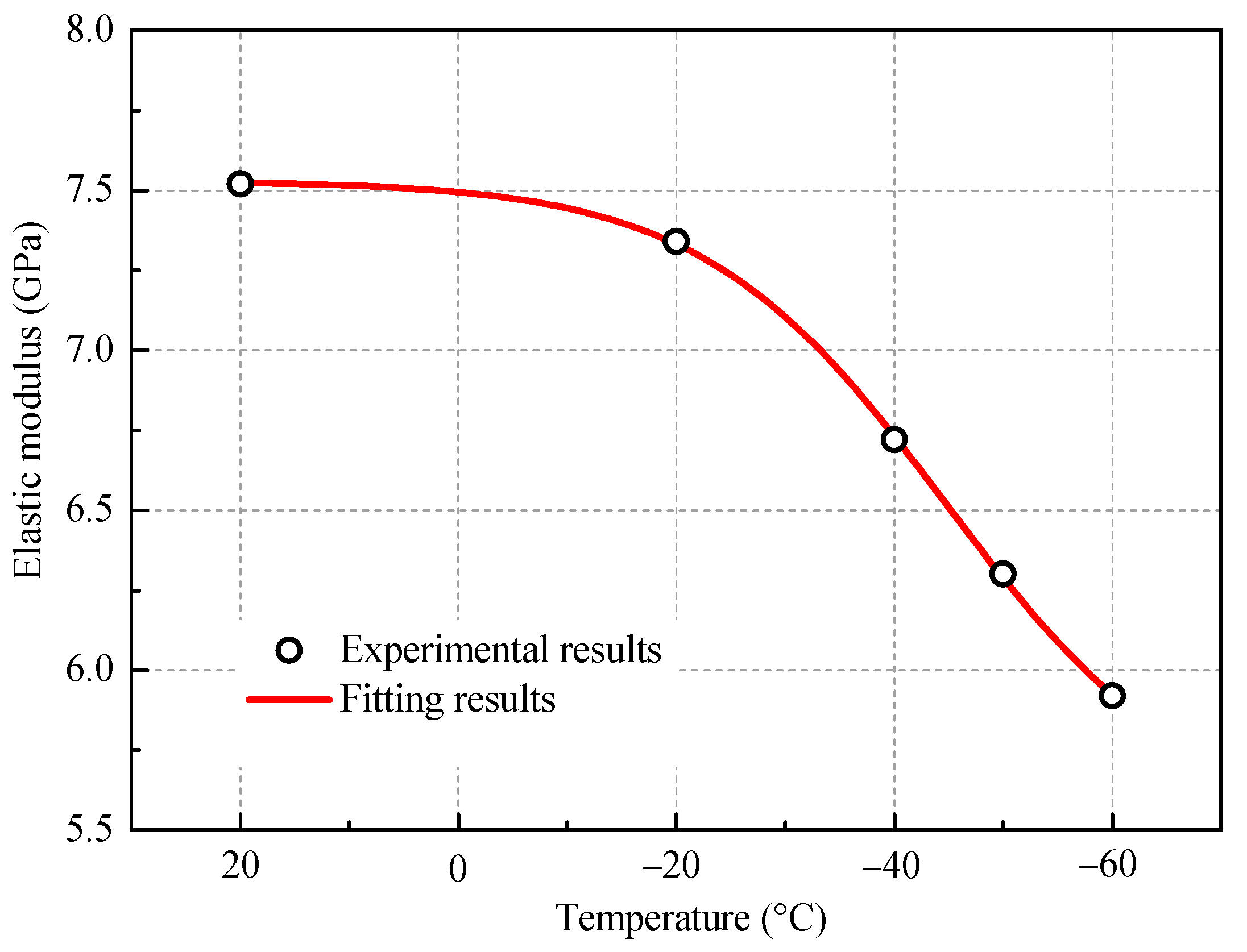

3.3. Effects of Freezing Temperature on Static Uniaxial Compressive Strength and Static Elastic Modulus

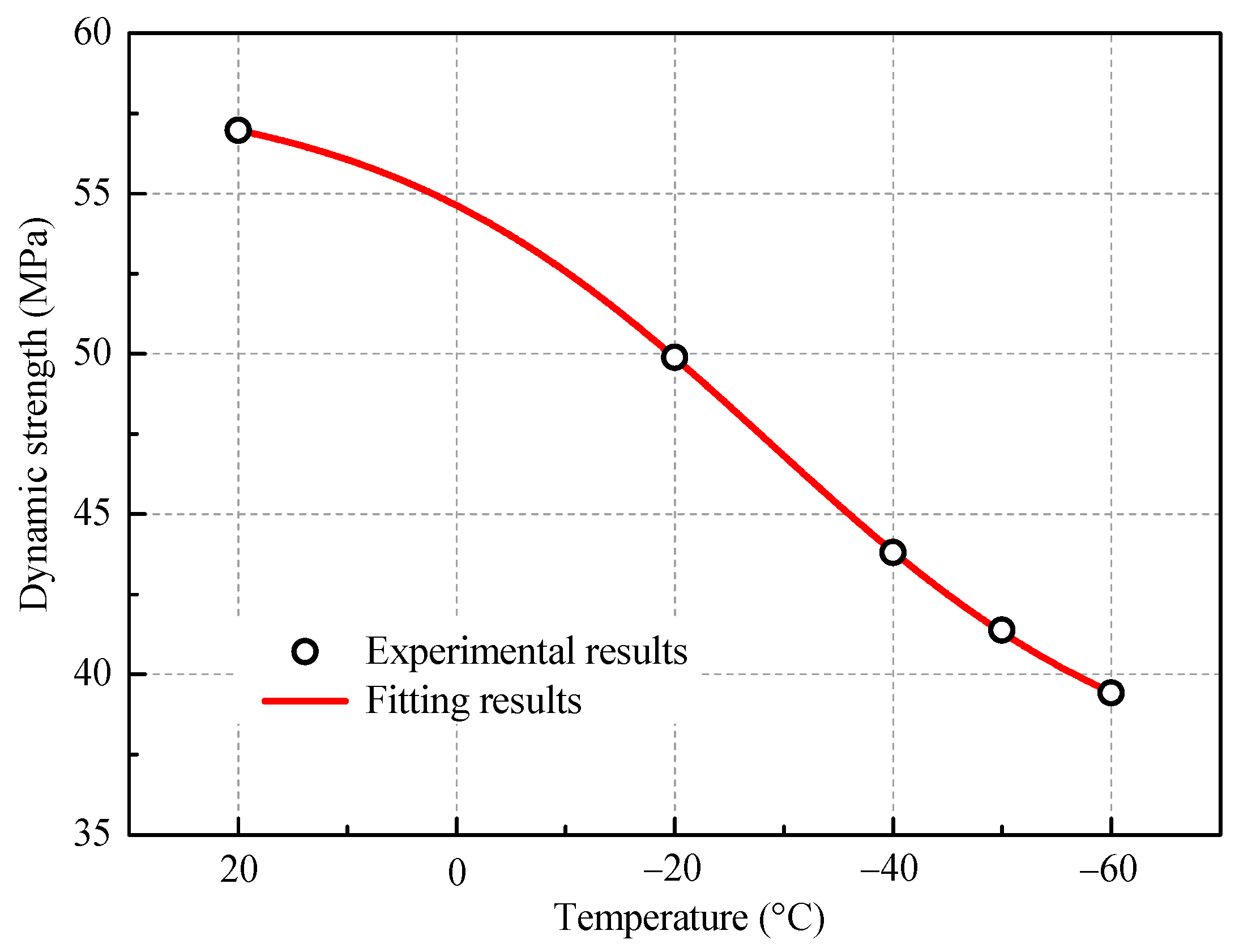

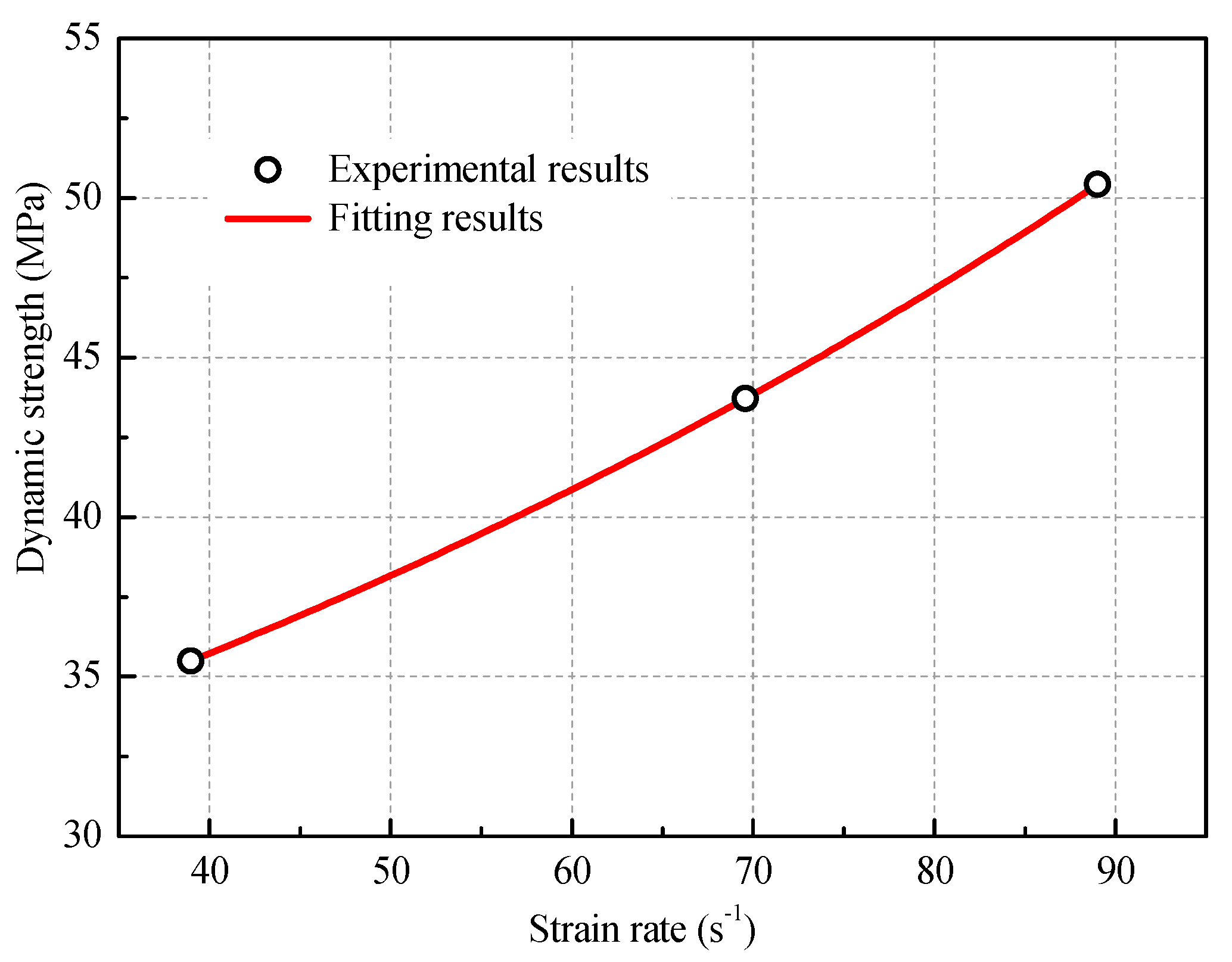

3.4. Effects of Freezing Temperature and Strain Rate on Dynamic Strength

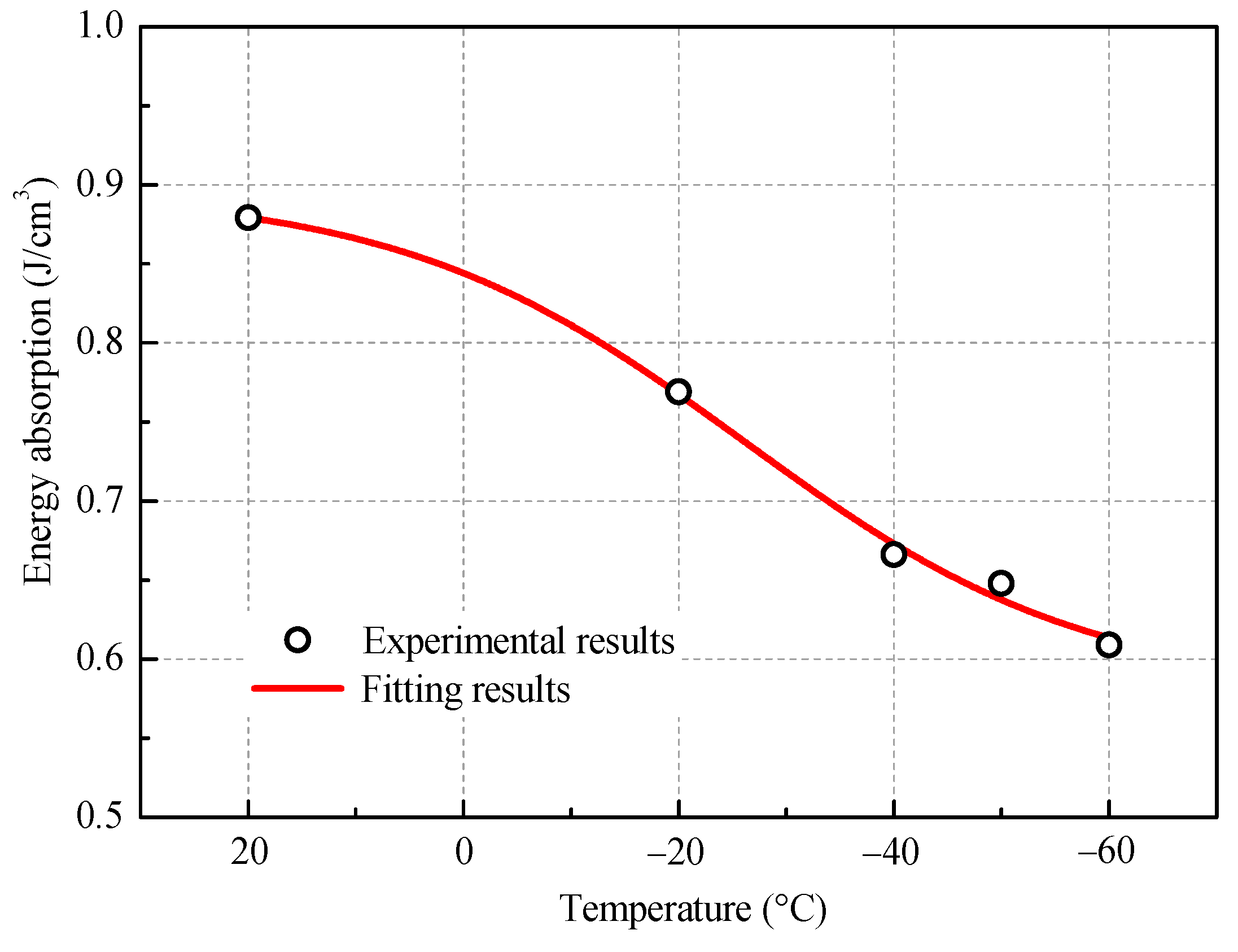

3.5. Effects of Freezing Temperature and Strain Rate on Dynamic Energy Absorption

4. Conclusions

- (1)

- The density of sandstone decreases as the freezing temperature decreases from 20 to −60 °C, and the decreasing extent of density approximately reaches 1.0% at −60 °C. The P-wave velocity first shows a slightly decreasing trend as the freezing temperature decreases, and then rapidly decreases after −20 °C.

- (2)

- Under the same freeze-thaw cycling number, the static uniaxial compressive strength, static elastic modulus, dynamic strength, and dynamic energy absorption of sandstone all decrease non-linearly as the freezing temperature decreases from 20 to −60 °C. However, the dynamic mechanical behavior is more sensitive to the freezing temperature during freeze-thawing cycling compared with the static mechanical behavior.

- (3)

- The strain rate significantly influences the dynamic mechanical responses of sandstone after low-temperature treatments. The dynamic strength and dynamic energy absorption increase monotonically as the strain rate increases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Wang, P.; Xu, J.Y.; Liu, S.; Wang, H.Y.; Liu, S.H. Static and dynamic mechanical properties of sedimentary rock after freeze-thaw or thermal shock weathering. Eng. Geol. 2016, 210, 148–157. [Google Scholar] [CrossRef] [Green Version]

- Deprez, M.; De Kock, T.; De Schutter, G.; Cnudde, V. A review on freeze-thaw action and weathering of rocks. Earth-Sci. Rev. 2020, 203, 103143. [Google Scholar] [CrossRef]

- Luo, Y.; Qu, D.X.; Wang, G.; Li, X.P.; Zhang, G. Degradation model of the dynamic mechanical properties and damage failure law of sandstone under freeze-thaw action. Soil Dyn. Earthq. Eng. 2020, 132, 106094. [Google Scholar] [CrossRef]

- Luo, X.D.; Jiang, N.; Zuo, C.Q.; Dai, Z.W.; Yan, S.T. Damage characteristics of altered and unaltered diabases subjected to extremely cold freeze-thaw cycles. Rock Mech. Rock Eng. 2014, 47, 1997–2004. [Google Scholar] [CrossRef]

- Fang, X.Y.; Xu, J.Y.; Wang, P.X. Compressive failure characteristics of yellow sandstone subjected to the coupling effects of chemical corrosion and repeated freezing and thawing. Eng. Geol. 2018, 233, 160–171. [Google Scholar] [CrossRef]

- Inada, Y.; Yokota, K. Some studies of low temperature rock strength. Int. J. Rock Mech. Min. Sci. 1984, 21, 145–153. [Google Scholar] [CrossRef]

- Yamabe, T.; Neaupane, K.M. Determination of some thermo-mechanical properties of Sirahama sandstone under subzero temperature condition. Int. J. Rock Mech. Min. Sci. 2001, 38, 1029–1034. [Google Scholar] [CrossRef]

- Kodama, J.; Goto, T.; Fujii, Y.; Hagan, P. The effects of water content, temperature and loading rate on strength and failure process of frozen rocks. Int. J. Rock Mech. Min. Sci. 2013, 62, 1–13. [Google Scholar] [CrossRef]

- Bai, Y.; Shan, R.L.; Ju, Y.; Wu, Y.X.; Sun, P.F.; Wang, Z.E. Study on the mechanical properties and damage constitutive model of frozen weakly cemented red sandstone. Cold Reg. Sci. Technol. 2020, 171, 102980. [Google Scholar] [CrossRef]

- Dwivedi, R.D.; Soni, A.K.; Goel, R.K.; Dube, A.K. Fracture toughness of rocks under sub-zero temperature conditions. Int. J. Rock Mech. Min. Sci. 2000, 37, 1267–1275. [Google Scholar] [CrossRef]

- Yang, R.S.; Fang, S.Z.; Guo, D.M.; Li, W.Y.; Mi, Z.Z. Study on dynamic tensile strength of red sandstone under impact loading and negative temperature. Geotech. Geol. Eng. 2019, 37, 4527–4537. [Google Scholar] [CrossRef]

- Yang, R.S.; Fang, S.Z.; Li, W.Y.; Yang, Y.; Yue, Z.W. Experimental study on the dynamic properties of three types of rock at negative temperature. Geotech. Geol. Eng. 2019, 37, 455–464. [Google Scholar] [CrossRef]

- Weng, L.; Wu, Z.J.; Liu, Q.S. Dynamic mechanical properties of dry and water-saturated siltstones under sub-zero temperatures. Rock Mech. Rock Eng. 2020, 53, 4381–4401. [Google Scholar] [CrossRef]

- Mardoukhi, A.; Mardoukhi, Y.; Hokka, M.; Kuokkala, V.T. Effects of test temperature and low temperature thermal cycling on the dynamic tensile strength of granitic rocks. Rock Mech. Rock Eng. 2021, 54, 443–454. [Google Scholar] [CrossRef]

- Kurilko, A.S.; Novopashin, M.D. Features of low temperature effect upon strength of enclosing rock and kimberlite in the “Udachnaya” pipe. J. Min. Sci. 2005, 41, 119–122. [Google Scholar] [CrossRef]

- Zakharov, E.V.; Kurilko, A.S. Effects of low temperatures on strength and power input into rock failure. Sci. Cold Arid. Reg. 2014, 6, 455–460. [Google Scholar] [CrossRef]

- Vasarhelyi, B. Statistical analysis of the influence of water content on the strength of the miocene limestone. Rock Mech. Rock Eng. 2005, 38, 69–76. [Google Scholar] [CrossRef]

- Weng, L.; Wu, Z.J.; Liu, Q.S.; Wang, Z.Y. Energy dissipation and dynamic fragmentation of dry and water-saturated siltstones under sub-zero temperatures. Eng. Fract. Mech. 2019, 220, 106659. [Google Scholar] [CrossRef]

- Jia, H.L.; Zi, F.; Yang, G.S.; Li, G.Y.; Shen, Y.J.; ·Sun, Q.; ·Yang, P.Y. Influence of pore water (ice) content on the strength and deformability of frozen argillaceous siltstone. Rock Mech. Rock Eng. 2020, 53, 967–974. [Google Scholar] [CrossRef]

- Tan, X.J.; Chen, W.Z.; Yang, J.P.; Cao, J.J. Laboratory investigations on the mechanical properties degradation of granite under freeze–thaw cycles. Cold Reg. Sci. Technol. 2011, 68, 130–138. [Google Scholar] [CrossRef]

- Mu, J.Q.; Pei, X.J.; Huang, R.Q.; Rengers, N.; Zou, X.Q. Degradation characteristics of shear strength of joints in three rock types due to cyclic freezing and thawing. Cold Reg. Sci. Technol. 2017, 138, 91–97. [Google Scholar] [CrossRef]

- Celik, M.Y. Water absorption and P-wave velocity changes during freeze-thaw weathering process of crosscut travertine rocks. Environ. Earth Sci. 2017, 76, 409. [Google Scholar] [CrossRef]

- Liu, C.J.; Deng, H.W.; Zhao, H.T.; Zhang, J. Effects of freeze-thaw treatment on the dynamic tensile strength of granite using the Brazilian test. Cold Reg. Sci. Technol. 2018, 155, 327–332. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, H.W.; Taheri, A.; Ke, B.; Liu, C.J.; Yang, X.R. Degradation of physical and mechanical properties of sandstone subjected to freeze-thaw cycles and chemical erosion. Cold Reg. Sci. Technol. 2018, 155, 37–46. [Google Scholar] [CrossRef]

- Weng, L.; Wu, Z.J.; Taheri, A.; Liu, Q.S.; Lu, H. Deterioration of dynamic mechanical properties of granite due to freeze-thaw weathering: Considering the effects of moisture conditions. Cold Reg. Sci. Technol. 2020, 176, 103092. [Google Scholar] [CrossRef]

- Ma, Q.Y.; Ma, D.D.; Yao, Z.M. Influence of freeze-thaw cycles on dynamic compressive strength and energy distribution of soft rock specimen. Cold Reg. Sci. Technol. 2018, 153, 10–17. [Google Scholar] [CrossRef]

- Fan, L.F.; Xu, C.; Wu, Z.J. Effects of cyclic freezing and thawing on the mechanical behavior of dried and saturated sandstone. Bull. Eng. Geol. Environ. 2020, 79, 755–765. [Google Scholar] [CrossRef]

- Park, J.; Hyun, C.U.; Park, H.D. Changes in microstructure and physical properties of rocks caused by artificial freeze-thaw action. Bull. Eng. Geol. Environ. 2015, 74, 555–565. [Google Scholar] [CrossRef]

- Liu, B.; Ma, Y.J.; Liu, N.; Han, Y.H.; Li, D.Y.; Deng, H.L. Investigation of pore structure changes in Mesozoic water-rich sandstone induced by freeze-thaw process under different confining pressures using digital rock technology. Cold Reg. Sci. Technol. 2019, 161, 137–149. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, H.W.; Deng, J.R.; Guo, H.Q. Influence of freeze-thaw cycles on the degradation of sandstone after loading and unloading. Bull. Eng. Geol. Environ. 2020, 79, 1967–1977. [Google Scholar] [CrossRef]

- Hall, K. The role of thermal stress fatigue in the breakdown of rock in cold regions. Geomorphology 1999, 31, 47–63. [Google Scholar] [CrossRef]

- Ishikawa, M.; Kurashige, Y.; Hirakawa, K. Analysis of crack movements observed in an alpine bedrock cliff. Earth Surf. Proc. Land. 2004, 29, 883–891. [Google Scholar] [CrossRef]

- Liu, C.J.; Deng, J.R.; Yu, S.T.; Li, P.; Lin, Y. Effect of freezing and thawing on microstructure damage and dynamic flexural tension of granite. Rock Mech. Rock Eng. 2020, 53, 3853–3858. [Google Scholar] [CrossRef]

- Liu, Y.Z.; Cai, Y.T.; Huang, S.B.; Guo, Y.L.; Liu, G.F. Effect of water saturation on uniaxial compressive strength and damage degree of clay-bearing sandstone under freeze-thaw. Bull. Eng. Geol. Environ. 2020, 79, 2021–2036. [Google Scholar] [CrossRef]

- Luo, X.D.; Zhou, S.T.; Huang, B.; Jiang, N.; Xiong, M.X. Effect of freeze-thaw temperature and number of cycles on the physical and mechanical properties of marble. Geotech. Geol. Eng. 2020, 39, 567–582. [Google Scholar] [CrossRef]

- Abdolghanizadeh, K.; Hosseini, M.; Saghafiyazdi, M. Effect of freezing temperature and number of freeze-thaw cycles on mode I and mode II fracture toughness of sandstone. Theor. Appl. Fract. Mech. 2020, 105, 102428. [Google Scholar] [CrossRef]

- Fan, L.F.; Wang, M.; Wu, Z.J. Effect of nonlinear deformational macrojoint on stress wave propagation through a double-scale discontinuous rock mass. Rock Mech. Rock Eng. 2021, 54, 1077–1090. [Google Scholar] [CrossRef]

- Fan, L.F.; Yang, K.C.; Wang, M.; Wang, L.J.; Wu, Z.J. Experimental study on wave propagation through granite after high-temperature treatment. Int. J. Rock Mech. Min. Sci. 2021, 148, 104946. [Google Scholar] [CrossRef]

- Bieniawski, Z.T.; Bernede, M.J. Suggested methods for determining the uniaxial compressive strength and deformability of rock materials. 1. Suggested method for determination of the uniaxial compressive strength of rock materials. Int. J. Rock Mech. Min. Sci. 1979, 16, 137–138. [Google Scholar] [CrossRef]

- Zhou, Y.X.; Xia, K.; Li, X.B.; Li, H.B.; Ma, G.W.; Zhao, J.; Zhou, Z.L.; Dai, F. Suggested methods for determining the dynamic strength parameters and mode-I fracture toughness of rock materials. Int. J. Rock Mech. Min. Sci. 2012, 49, 105–112. [Google Scholar] [CrossRef]

- Yang, S.Q.; Huang, Y.H.; Tian, W.L.; Ying, P.F.; Jing, H.W. Effect of high temperature on deformation failure behavior of granite specimen containing a single fissure under uniaxial compression. Rock Mech. Rock Eng. 2019, 52, 2087–2107. [Google Scholar] [CrossRef]

- Fan, L.F.; Gao, J.W.; Wu, Z.J.; Yang, S.Q.; Ma, G.W. An investigation of thermal effects on micro-properties of granite by X-ray CT technique. Appl. Therm. Eng. 2018, 140, 505–519. [Google Scholar] [CrossRef]

- Sun, H.; Sun, Q.; Deng, W.N.; Zhang, W.Q.; Lv, C. Temperature effect on microstructure and P-wave propagation in Linyi sandstone. Appl. Therm. Eng. 2017, 115, 913–922. [Google Scholar] [CrossRef]

- Zhou, Z.L.; Li, X.B.; Ye, Z.Y.; Liu, K.W. Obtaining constitutive relationship for rate-dependent rock in SHPB tests. Rock Mech. Rock Eng. 2010, 43, 697–706. [Google Scholar] [CrossRef]

- Li, Y.B.; Zhai, Y.; Wang, C.S.; Meng, F.D.; Lu, M. Mechanical properties of Beishan granite under complex dynamic loads after thermal treatment. Eng. Geol. 2020, 267, 105481. [Google Scholar] [CrossRef]

- Gao, J.W.; Xi, Y.; Fan, L.F.; Du, X.L. Real-time visual analysis of the microcracking behavior of thermally damaged granite under uniaxial loading. Rock Mech. Rock Eng. 2021, 1–16. [Google Scholar] [CrossRef]

- Li, J.L.; Kaunda, R.B.; Zhou, K.P. Experimental investigations on the effects of ambient freeze-thaw cycling on dynamic properties and rock pore structure deterioration of sandstone. Cold Reg. Sci. Technol. 2018, 154, 133–141. [Google Scholar] [CrossRef]

- Fan, L.F.; Gao, J.W.; Du, X.L.; Wu, Z.J. Spatial gradient distributions of thermal shock-induced damage to granite. J. Rock Mech. Geotech. 2020, 12, 917–926. [Google Scholar] [CrossRef]

- Ma, G.W.; Fan, L.F.; Li, J.C. Evaluation of equivalent medium methods for stress wave propagation in jointed rock mass. Int. J. Numer. Anal. Methods Geomech. 2013, 37, 701–715. [Google Scholar] [CrossRef]

- Fan, L.F.; Wu, Z.J.; Wan, Z.; Gao, J.W. Experimental investigation of thermal effects on dynamic behavior of granite. Appl. Therm. Eng. 2017, 125, 94–103. [Google Scholar] [CrossRef]

- Qin, Y.; Tian, H.; Xu, N.X.; Chen, Y. Physical and mechanical properties of granite after high-temperature treatment. Rock Mech. Rock Eng. 2020, 53, 305–322. [Google Scholar] [CrossRef]

- Xu, J.C.; Pu, H.; Sha, Z.H. Mechanical behavior and decay model of the sandstone in Urumqi under coupling of freeze-thaw and dynamic loading. Bull. Eng. Geol. Environ. 2021, 80, 2963–2978. [Google Scholar] [CrossRef]

- Feng, S.W.; Zhou, Y.; Wang, Y.; Lei, M.D. Experimental research on the dynamic mechanical properties and damage characteristics of lightweight foamed concrete under impact loading. Int. J. Impact Eng. 2020, 140, 103558. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, J.; Xu, C.; Xi, Y.; Fan, L. Degradation of Mechanical Behavior of Sandstone under Freeze-Thaw Conditions with Different Low Temperatures. Appl. Sci. 2021, 11, 10653. https://doi.org/10.3390/app112210653

Gao J, Xu C, Xi Y, Fan L. Degradation of Mechanical Behavior of Sandstone under Freeze-Thaw Conditions with Different Low Temperatures. Applied Sciences. 2021; 11(22):10653. https://doi.org/10.3390/app112210653

Chicago/Turabian StyleGao, Jingwei, Chao Xu, Yan Xi, and Lifeng Fan. 2021. "Degradation of Mechanical Behavior of Sandstone under Freeze-Thaw Conditions with Different Low Temperatures" Applied Sciences 11, no. 22: 10653. https://doi.org/10.3390/app112210653

APA StyleGao, J., Xu, C., Xi, Y., & Fan, L. (2021). Degradation of Mechanical Behavior of Sandstone under Freeze-Thaw Conditions with Different Low Temperatures. Applied Sciences, 11(22), 10653. https://doi.org/10.3390/app112210653