Effect of Aging and Moisture Damage on Fatigue Cracking Properties in Asphalt Mixtures

Abstract

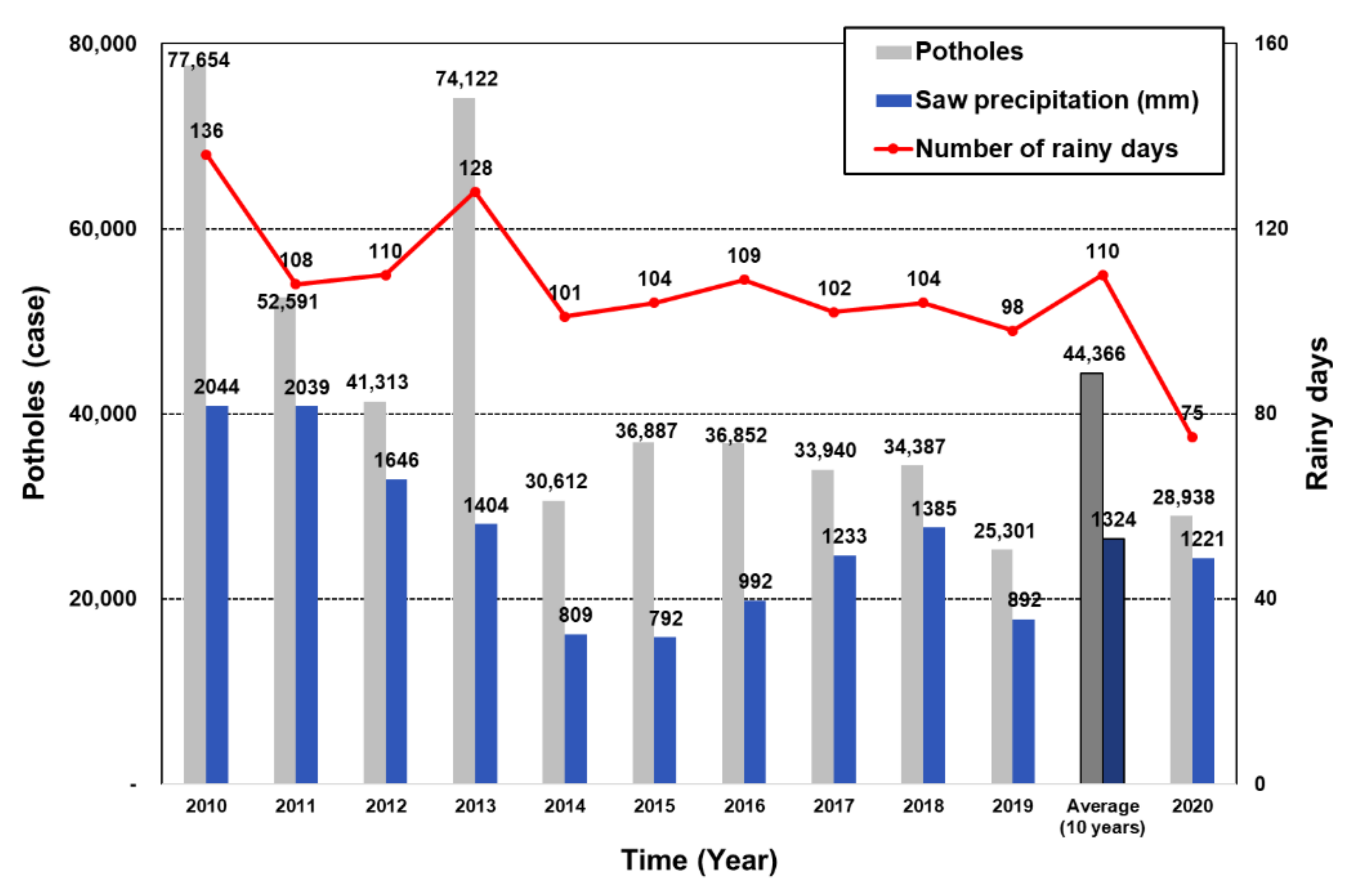

:1. Introduction

2. Materials and Mix Design

2.1. Materials

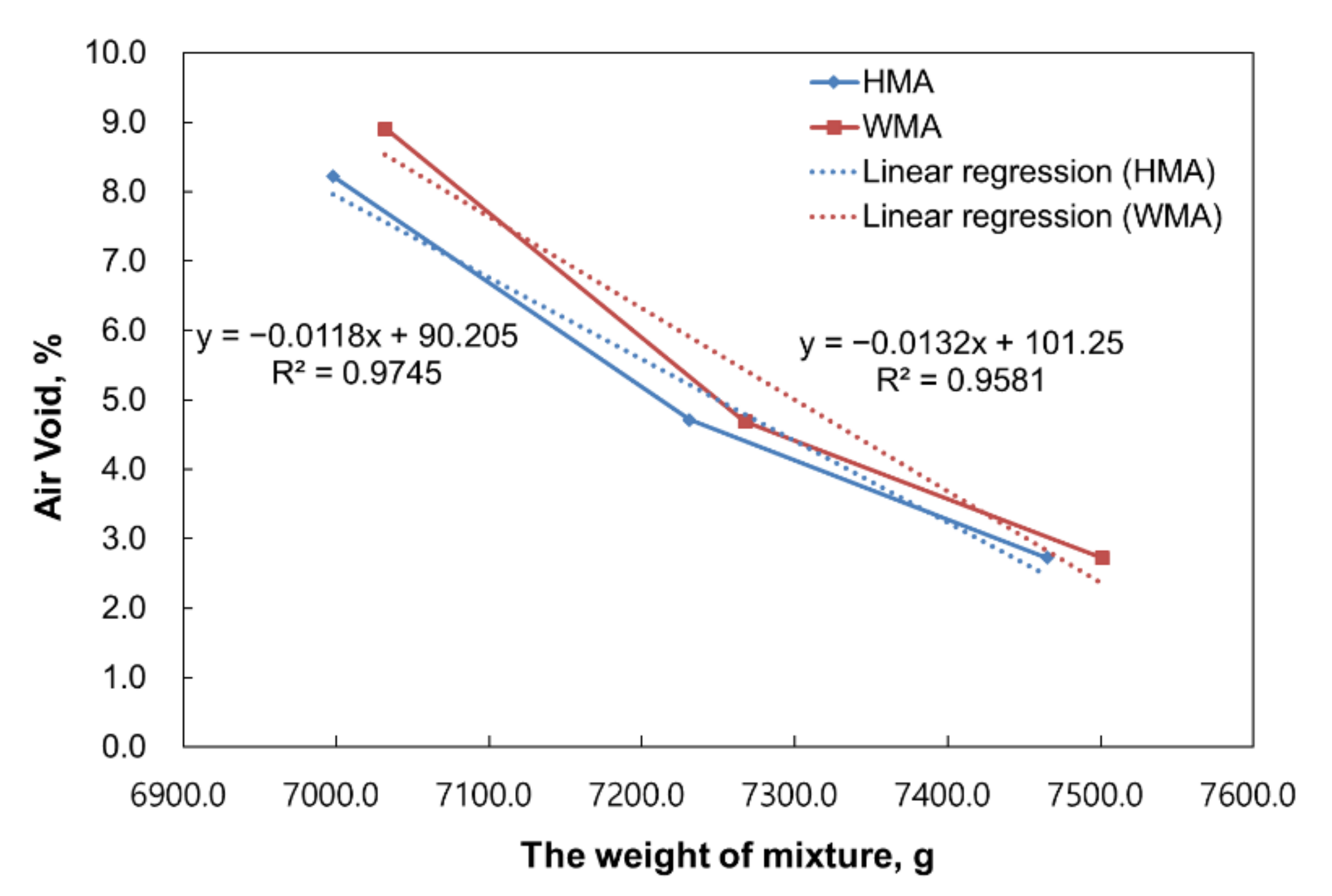

2.2. Mix Design

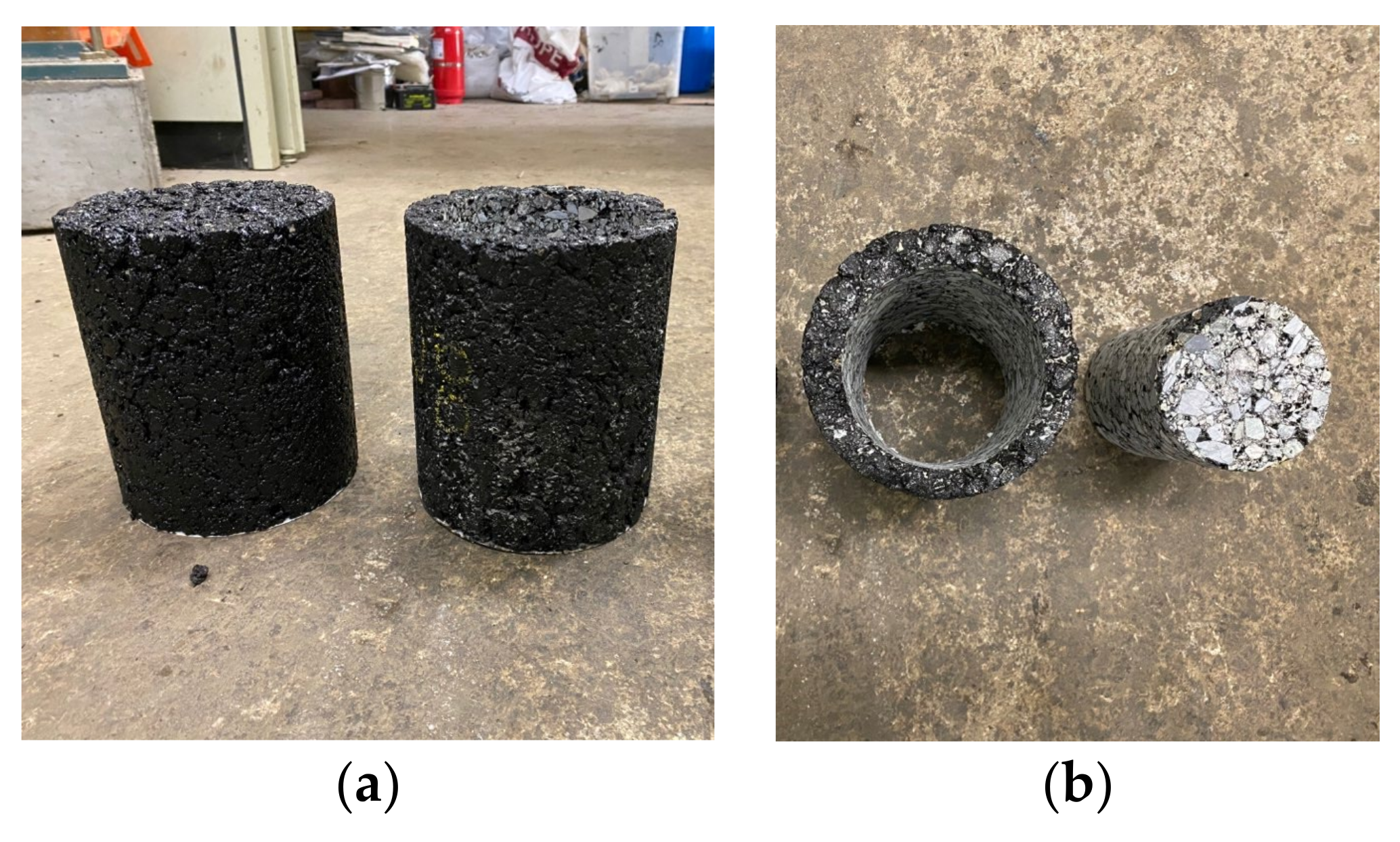

2.3. Fabrication of Specimens

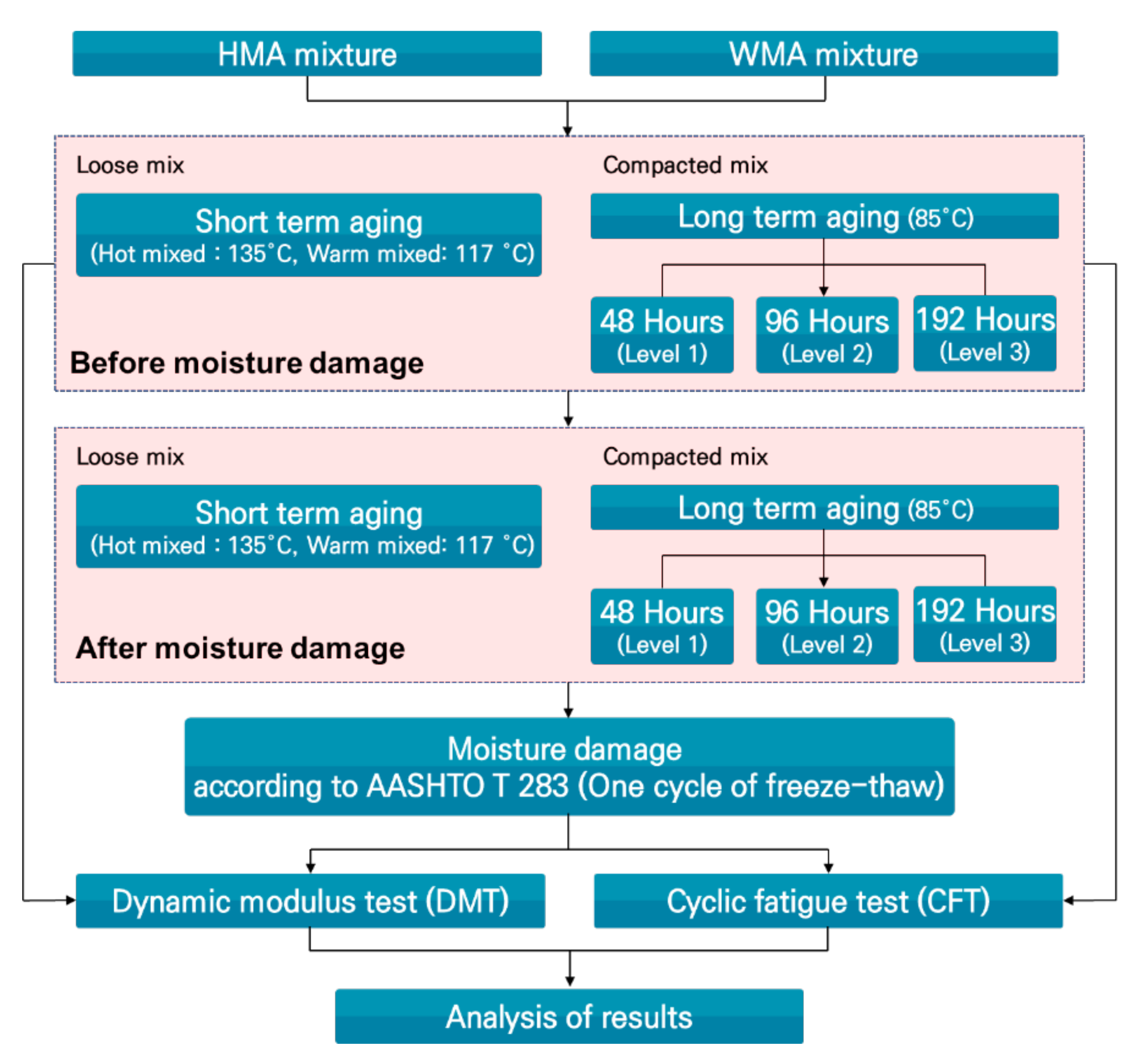

3. Experimental Program

3.1. Aging Method

3.2. Moisture Damage Method

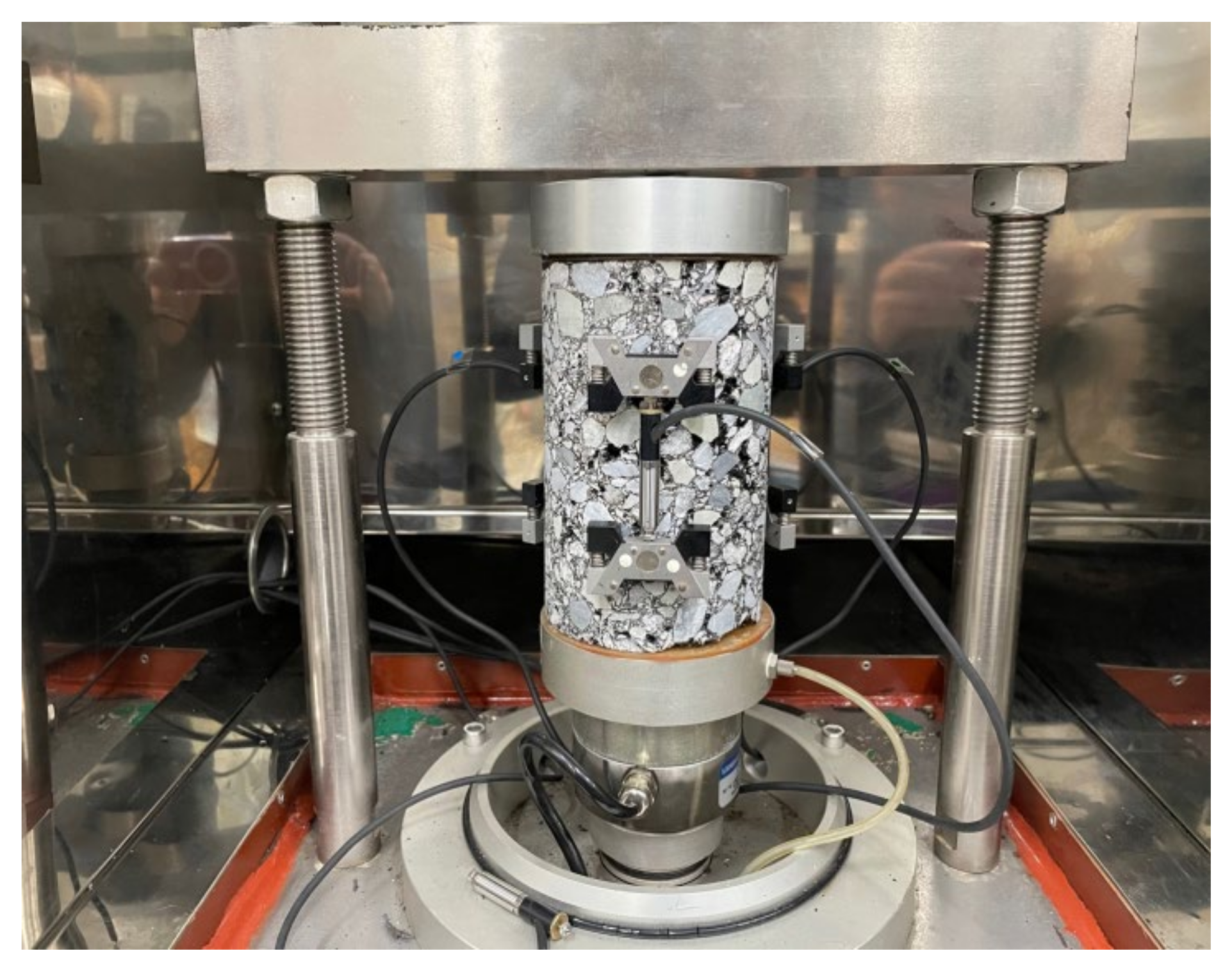

3.3. Dynamic Modulus Test

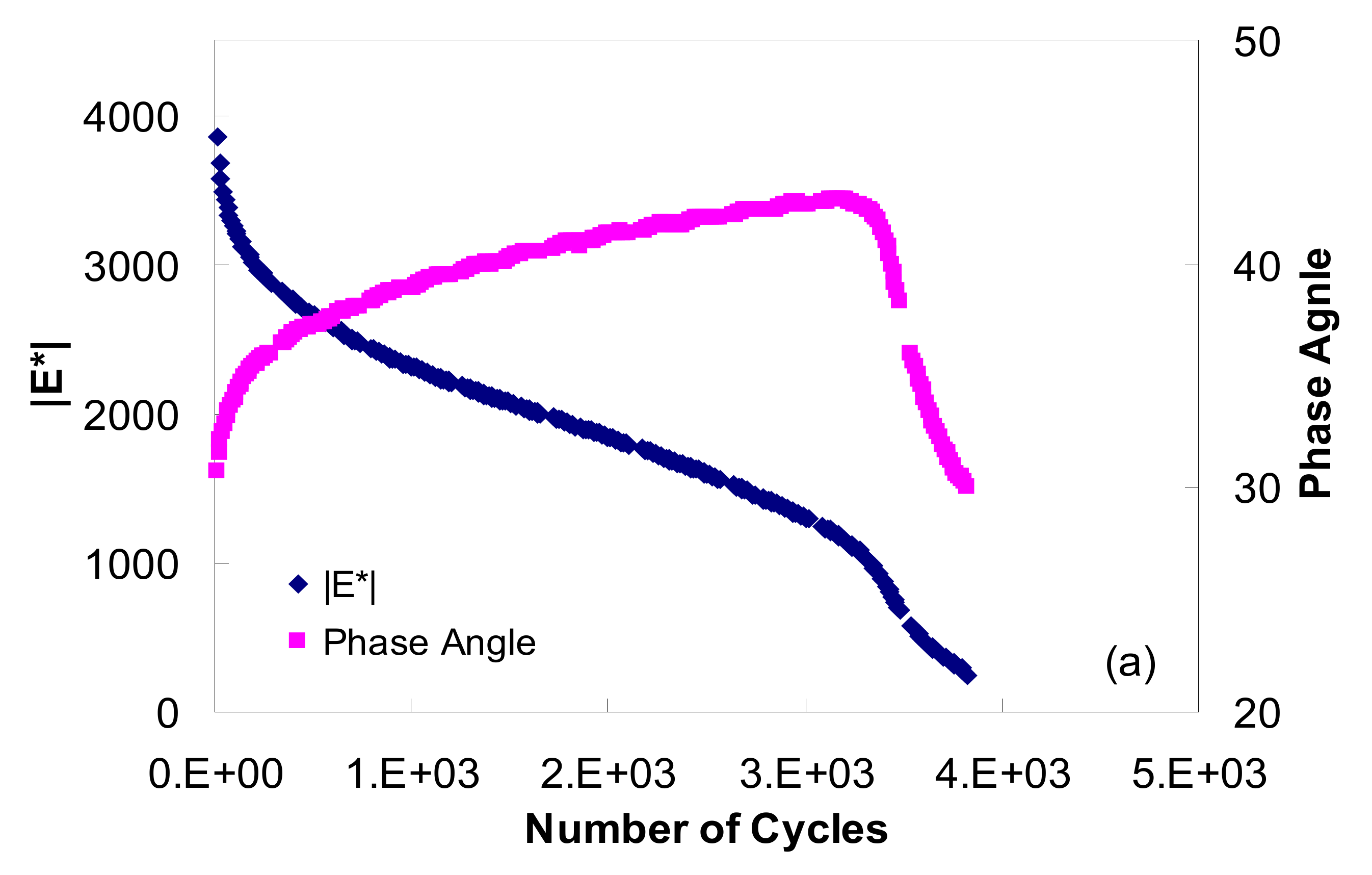

3.4. Fatigue Cracking Resistance Test

4. Test Results

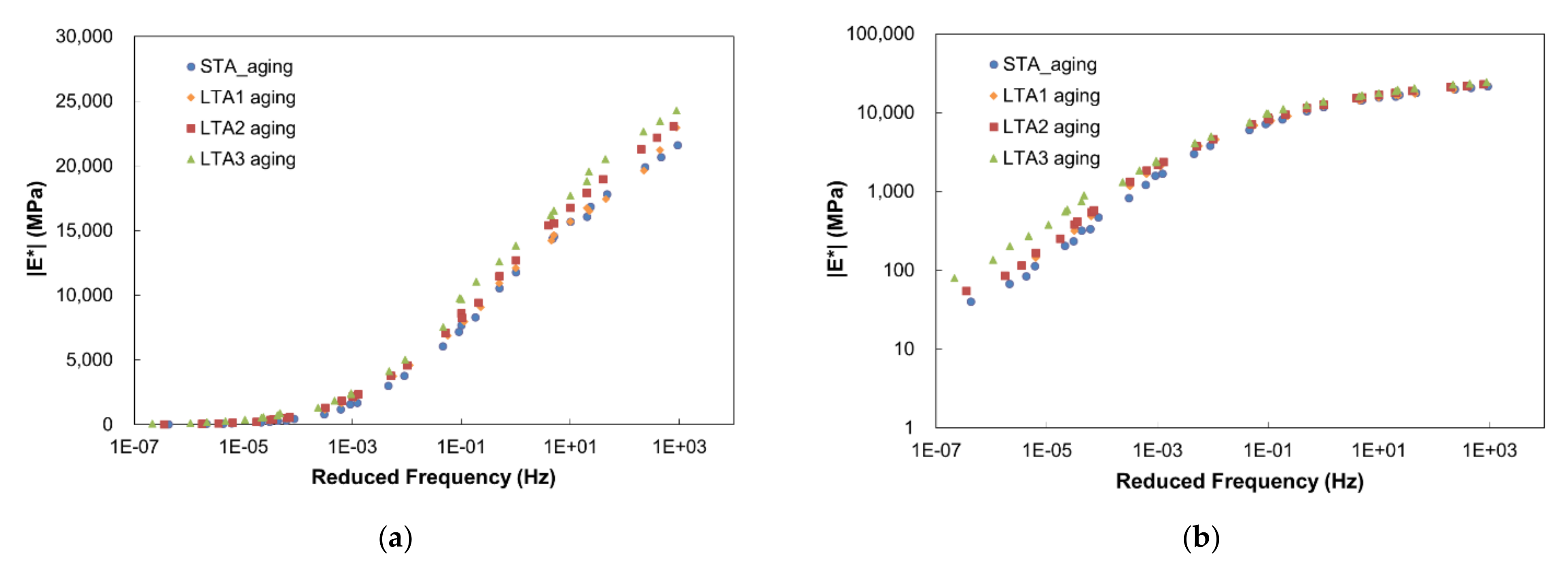

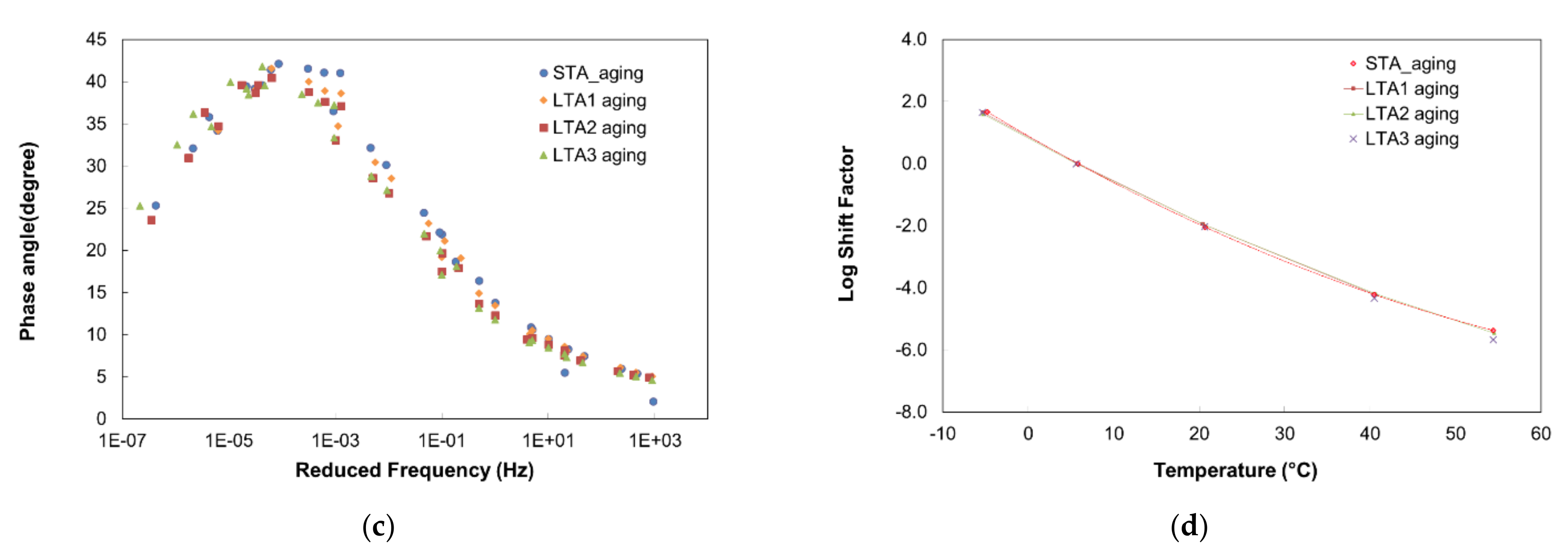

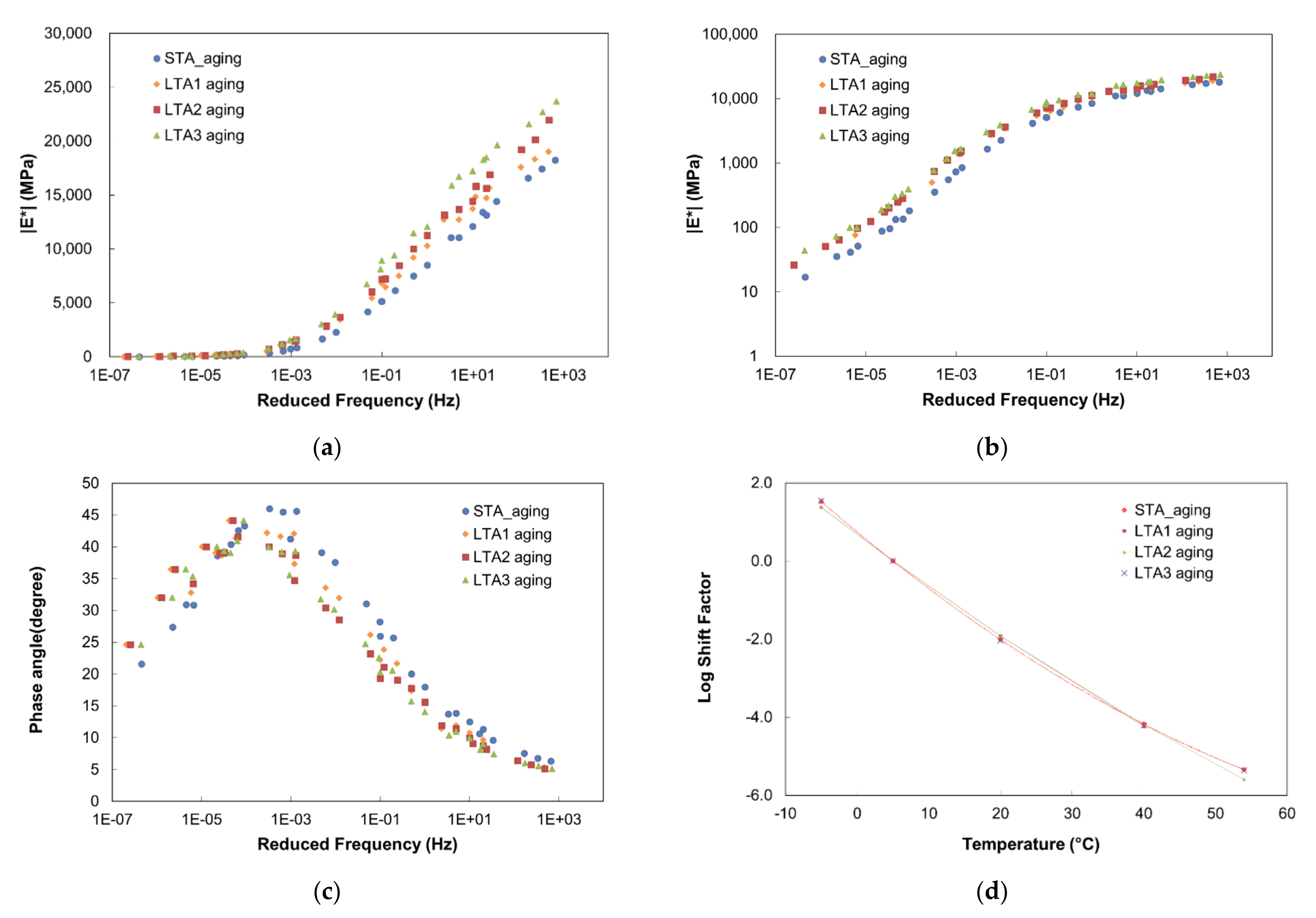

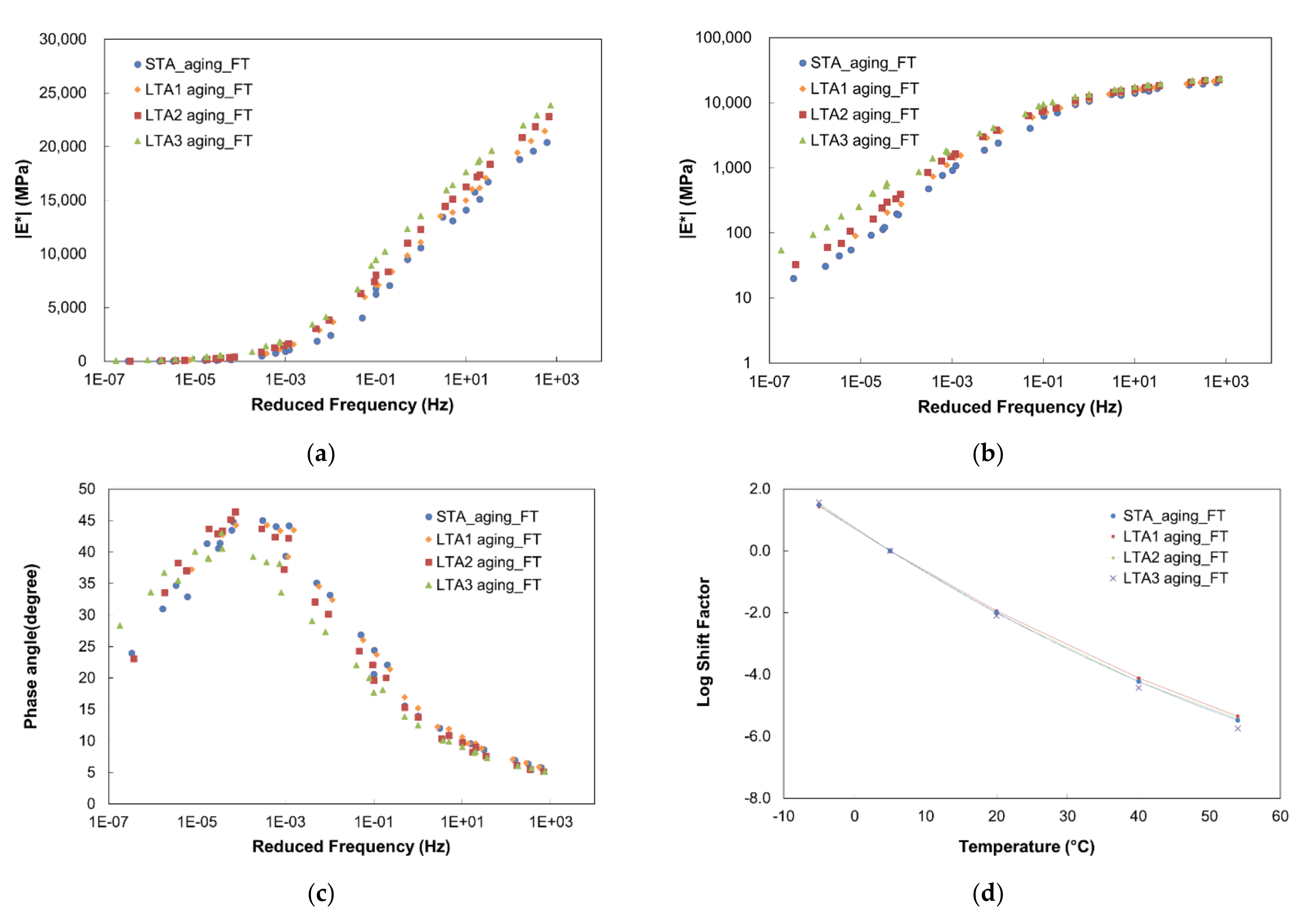

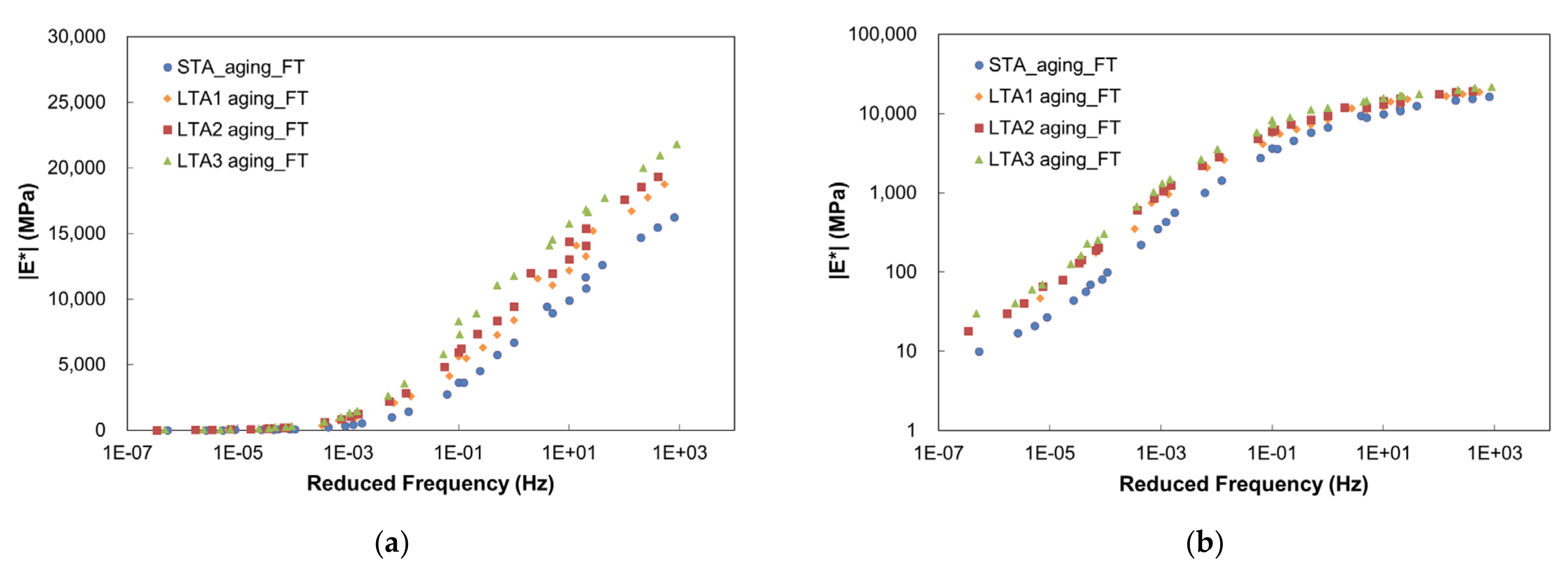

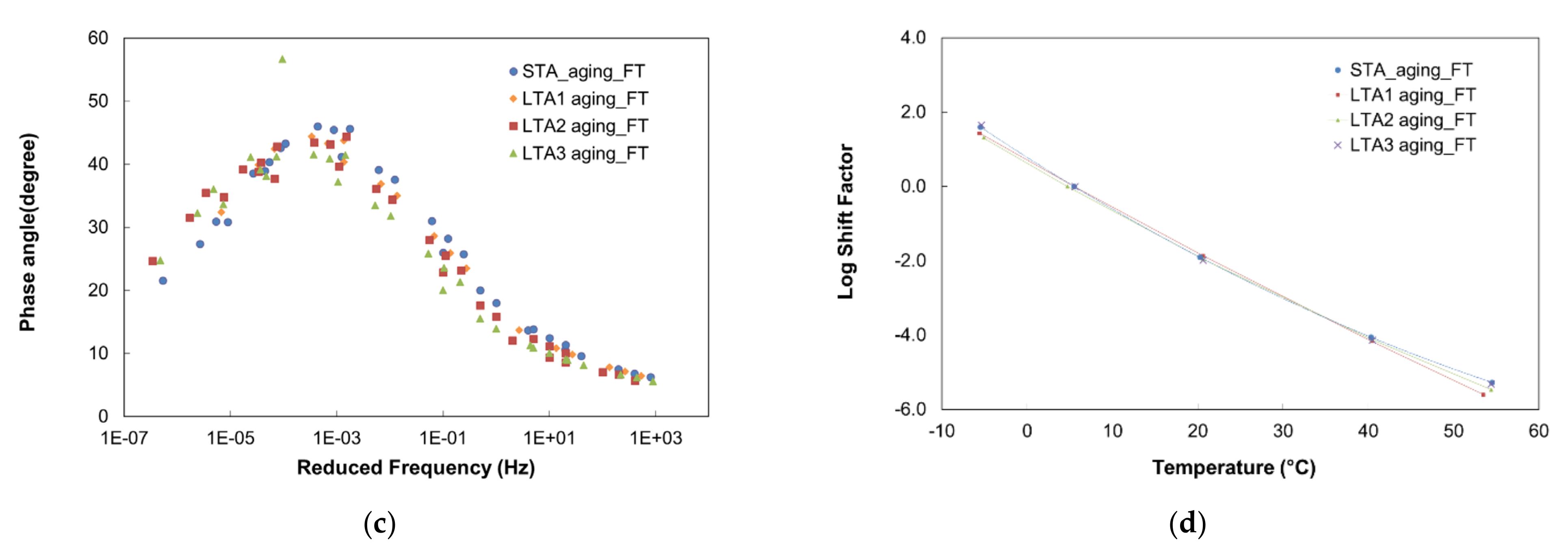

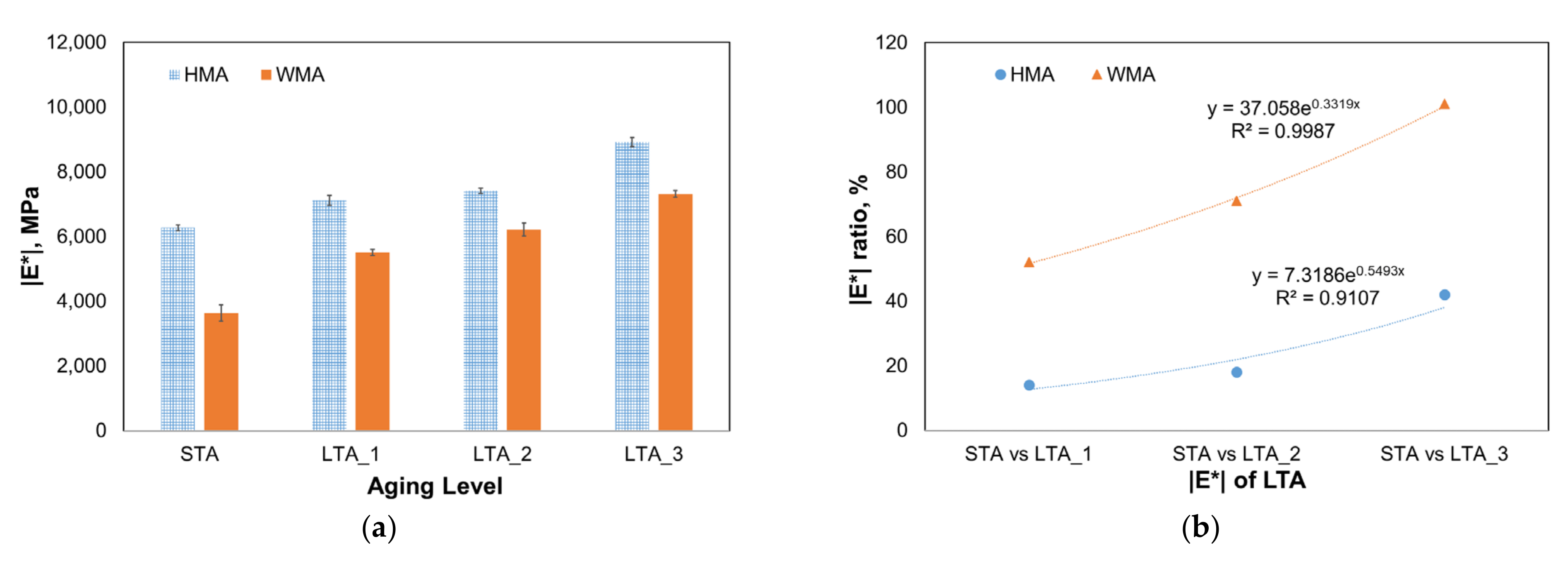

4.1. Dynamic Modulus Test Results

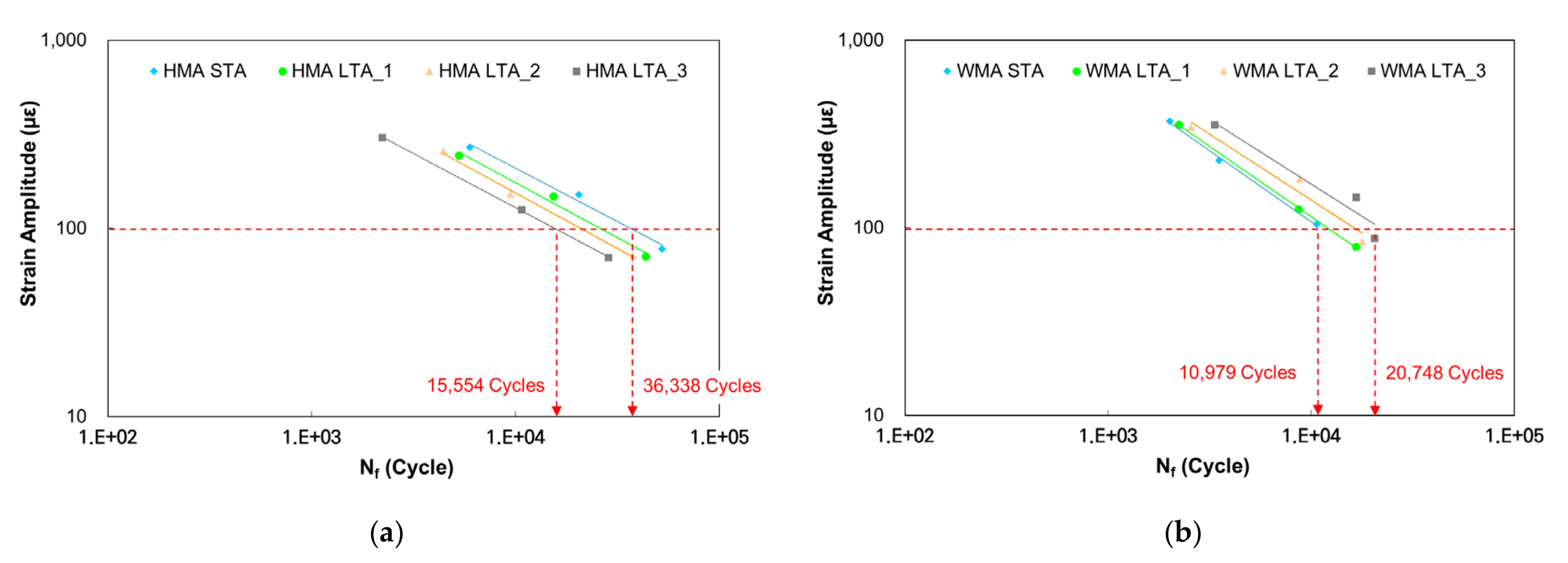

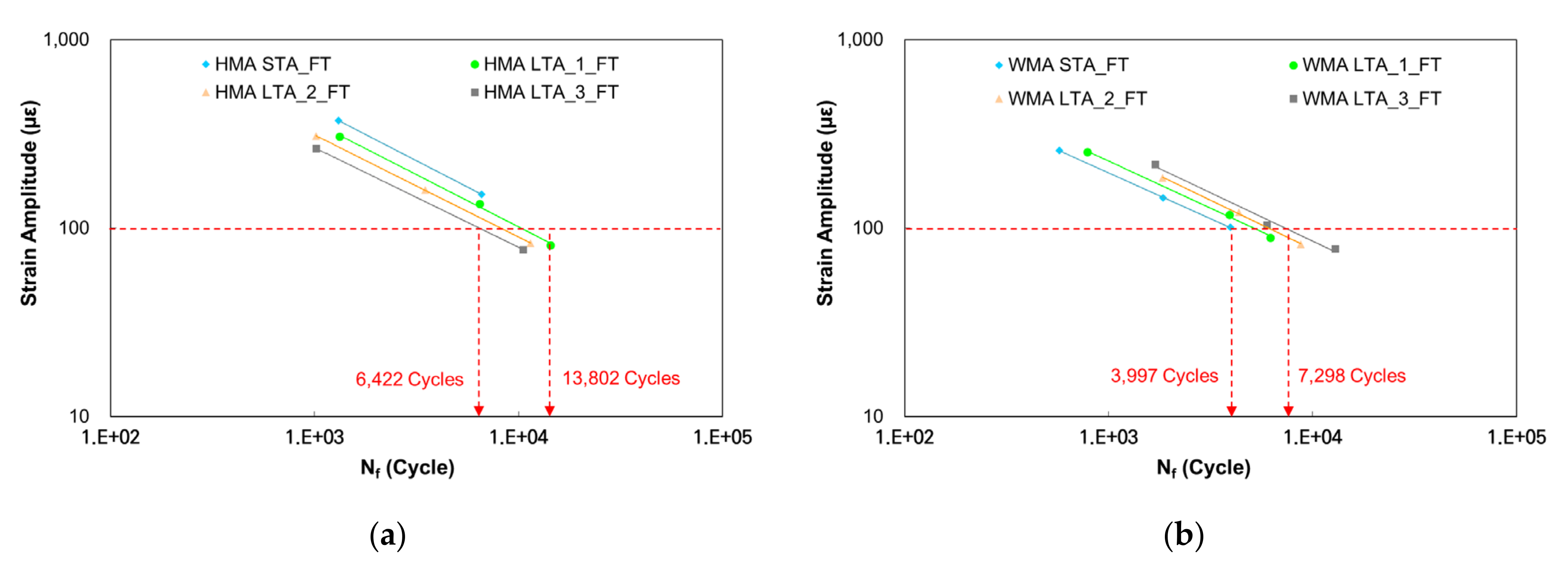

4.2. Fatigue Cracking Resistance Test Results of Asphalt Mixtures

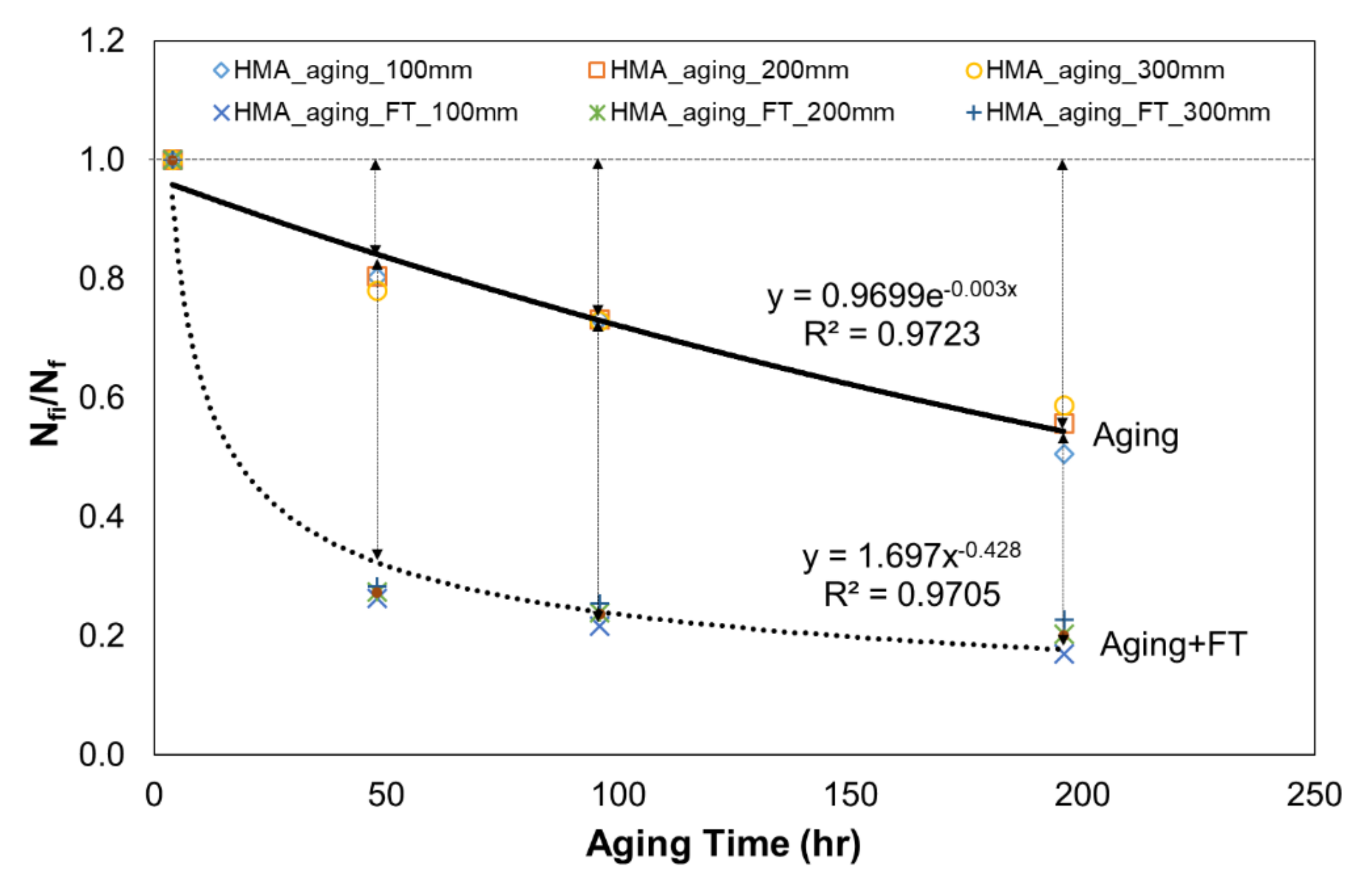

4.3. Analysis of Fatigue Effects Due to Aging and Moisture Damage

5. Conclusions

- The elastic modulus of HMA and WMA mixtures increased with aging. For the HMA mixture, elastic modulus increased by approximately 35% as the aging time progressed from the initial stage, whereas that of the WMA mixture increased by approximately 50%, suggesting that the WMA mixture has a higher sensitivity to aging according to time and temperature;

- The change in elastic modulus induced by moisture damage after aging was analyzed for both the mixtures. It was observed that the value of elastic modulus significantly reduced compared to that before moisture damage. In particular, in the WMA mixture, the initial modulus of elasticity was reduced by approximately 50%, owing to moisture damage. This was because of the initial aging time and temperature considering the nature of the WMA mixture, which required a certain period of time (approximately 48 h) to develop a certain stiffness (elastic modulus). The experimental coefficient values (k1, k2, and k3) of the fatigue model to predict the fatigue cracking cycles caused by aging and moisture damage after aging of HMA and WMA mixtures were calculated and presented for each condition. Additionally, the prediction of fatigue cracking cycles due to aging and moisture damage after aging of HMA and WMA mixtures was conducted through indoor experiments;

- Based on fatigue life prediction results using the coefficient values and tensile strain for each condition through the fatigue test, the fatigue life of the HMA mixture decreased with aging, whereas the fatigue life of the WMA mixture increased with aging;

- The fatigue lives of both the mixtures decreased rapidly after the moisture damage. The fatigue life of the HMA mixture was reduced by 60–70%, and that of the WMA mixture was reduced by 80% or more after moisture damage compared to that before moisture damage. Moisture damage had a greater effect on the change in fatigue life than the aging properties;

- In the HMA mixture, the fatigue life before and after moisture damage decreased as aging progressed, indicating that the effect of aging gradually increased with an increase in the service period. As the service period progressed, it was more vulnerable to fatigue damage caused by moisture such as potholes;

- In this study, short-term and long-term aging were carried out step-by-step, after which it was subjected to water treatment. By this, the moisture damage of the asphalt mixture while it aged was simulated through water treatment. Unlike the water treatment level suggested by AASHTO T 283, the specimen was subjected to water damage in advance while short-term and long-term aging were performed to evaluate the aging and moisture damage according to the common years of packaging. The results of this evaluation revealed that moisture damage in the aged packaging can rapidly shorten its life and cause significant damage.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Little, D.N.; Jones, D.R. Chemical and Mechanical Processes of Moisture Damage in Hot-Mix Asphalt Pavements. In Proceedings of the Moisture Sensitivity of Asphalt Pavements National Seminar, San Diego, CA, USA, 4–6 February 2003. [Google Scholar]

- Hicks, R.G.; Santucci, L.; Aschenbrener, T. Introduction and seminar objectives. In Proceedings of the Moisture Sensitivity of Asphalt Pavements National Seminar, San Diego, CA, USA, 4–6 February 2003. [Google Scholar]

- He, J.; Liu, L.; Yang, H.; Aliha, M.R.M.; Karimi, H.R. Contribution of interface fracture mechanism on fracture propagation trajectory of heterogeneous asphalt composites. Appl. Sci. 2021, 11, 3013. [Google Scholar] [CrossRef]

- Yang, D.; Karimi, H.R.; Aliha, M.R.M. Comparison of testing method effects on cracking resistance of asphalt concrete mixtures. Appl. Sci. 2021, 11, 5094. [Google Scholar] [CrossRef]

- Shaker, S.; Aliha, M.R.M.; Keymanesh, M.R. Aging effect on combined mode fracture resistance of bitumen. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1609–1621. [Google Scholar] [CrossRef]

- Zhu, J.; Ma, T.; Fan, J.; Fang, Z.; Chen, T.; Zho, Y. Experimental study of high modulus asphalt mixture containing reclaimed asphalt pavement. J. Clean. Prod. 2020, 263, 121447. [Google Scholar] [CrossRef]

- Zhou, Y.; Hou, D.; Manzano, H.; Orozco, C.A.; Geng, G.; Monteiro, P.J.M.; Liu, J. Interfacial connection mechanisms in calcium–silicate–hydrates/polymer nanocomposites: A molecular dynamics study. ACS Appl. Mater. Interfaces 2017, 9, 41014–41025. [Google Scholar] [CrossRef]

- Brown, S.F.; Scholz, T.V. Development of laboratory protocols for the aging of asphalt mixtures. In Proceedings of the 2nd Eurasphalt and Eurobitume Congress, Barcelona, Spain, 20–22 September 2000. [Google Scholar]

- AASHTO. Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014. [Google Scholar]

- Lee, J.; Moon, S.J.; Im, J.; Yang, S. Evaluation of moisture susceptibility of asphalt mixtures using dynamic modulus. J. Test. Eval. 2016, 45, 1280–1288. [Google Scholar] [CrossRef]

- Saad, I.; Sarsam, I.; Lutfi, A.-Z. Resistance to moisture damage of recycled asphalt concrete pavement. J. Eng. 2015, 21, 45–54. [Google Scholar]

- Das, P.K.; Birgisson, B.; Jelagin, D.; Kringos, N. Investigation of the asphalt mixture morphology influence on its ageing susceptibility. Mater. Struct. 2015, 48, 987–1000. [Google Scholar] [CrossRef]

- Seoul Institute of Technology. Maintenance Methods Depending on Pavement Deterioration Types; SIT: Seoul, Korea, 2020. [Google Scholar]

- Seoul Metropolitan Government. Available online: https://opengov.seoul.go.kr/press/18456873 (accessed on 30 October 2021).

- Ministry of Land, Infrastructure and Transport. Asphalt Mixture Production and Construction Guidelines; MOLIT: Sejong City, Korea, 2017.

- Dougan, C.E.; Stephens, J.E.; Mahoney, J.; Hansen, G. E*-Dynamic Modulus Test Protocol—Problems and Solutions; Federal Highway Administration: Washington, DC, USA, 2003. [Google Scholar]

- Baek, C.M. Investigation of Top-Down Cracking Mechanisms Using the Viscoelastic Continuum Damage Finite Element Program. Ph.D. Thesis, North Carolina University, Chapel Hill, NC, USA, 2010. [Google Scholar]

- Bell, C.A.; Wieder, A.J.; Fellin, M.J. Laboratory Aging of Asphalt-Aggregate Mixtures: Field Validation; Strategic Highway Research Program: Washington, DC, USA, 1994. [Google Scholar]

- Kim, Y.R.; Hintz, C.; Rad, F.Y.; Elwardany, M.; Underwood, S. Long-Term Aging of Asphalt Mixtures for Performance Testing and Prediction; National Cooperative Highway Research Program: Washington, DC, USA, 2015. [Google Scholar]

- AASHTO. Standard Practice for Mixture Conditioning of Hot Mix Asphalt; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2002. [Google Scholar]

- Bonaquest, R. Mix Design Practices for Warm Mix Asphalt; National Cooperative Highway Research Program: Washington, DC, USA, 2009. [Google Scholar]

- AASHTO. Method of Test for Determining Dynamic Modulus of Hot Mix Asphalt (HMA); Association of State Highway and Transportation Officials: Washington, DC, USA, 2007. [Google Scholar]

- Reese, R. Properties of aged asphalt binder related to asphalt concrete fatigue life. J. Assoc. Asph. Paving Technol. 1997, 66, 604–632. [Google Scholar]

- Safaeia, F.; Lee, J.; do Nascimento, L.A.H.; Hintz, C.; Kim, Y.R. Implications of warm-mix asphalt on long-term oxidative ageing and fatigue performance of asphalt binders and mixtures. Road Mater. Pavement Des. 2014, 15, 45–61. [Google Scholar] [CrossRef]

- Kim, Y.R.; Baek, C.M. Evaluation of moisture susceptibility in a warm mix asphalt pavement: US 157, Hurdle Mills, NC. In Proceedings of the 2nd International Warm-Mix Conference, St. Louis, MI, USA, 13 October 2011. [Google Scholar]

- Das, B.P.; Das, S.; Siddagangaiah, A.K. Probabilistic modeling of fatigue damage in asphalt mixture. Constr. Build. Mater. 2020, 269, 121300. [Google Scholar] [CrossRef]

| Contents | Test | HMA | WMA | |

|---|---|---|---|---|

| Original (Before short-term aging) | Penetration (0.1 mm) | 73 | 69 | |

| Flash point (°C) | Over 300 | Over 300 | ||

| Softening point (°C) | 44.2 | 46.3 | ||

| Viscosity at 135 °C(cP) | 482 | 416 | ||

| G*/sinδ(kPa) | 1.221 | 1.304 | ||

| (64 °C) | (64 °C) | |||

| RTFO (Short-term aging) | G*/sinδ(kPa) | 2.535 | 2.419 | |

| (64 °C) | (64 °C) | |||

| PAV (Long-term aging) | Bending beam rheometer (BBR) | Stiffness (MPa) | 201.44 | 187.32 |

| (−12 °C) | (−12 °C) | |||

| m-value | 0.31 | 0.32 | ||

| (−12 °C) | (−12 °C) | |||

| Performance grade | 64-22 | 64-22 | ||

| Contents | Spec. | Test Result | ||

|---|---|---|---|---|

| Coarse Agg. | Fine Agg. | Filler | ||

| Specific gravity | ≥2.5 | 2.89 | 2.77 | 2.68 |

| Water absorption (%) | ≤3.0 | 0.33 | 0.65 | - |

| LA abrasion coefficient (%) | ≤35 | 12.2 | - | - |

| The Size of Agg. | FE Rate (%, of Weight) | Specification (%) |

|---|---|---|

| 20 mm | 4.8 | ≤Under |

| 13 mm | 7.6 | ≤Under |

| Item | Asphalt Content (%) | Air Void (%) | Density (g/cm3) | VMA (%) | VFA (%) | Stability (kgf) | Flow Value (0.1 mm) | |

|---|---|---|---|---|---|---|---|---|

| Division | ||||||||

| Hot mix asphalt (HMA) binder | 5.1 | 4.0 | 2.377 | 15.58 | 74.2 | 1488 | 31 | |

| Warm mix asphalt (WMA) binder | 5.1 | 4.1 | 2.361 | 15.33 | 73.7 | 1662 | 34 | |

| Mix ID | No. | Tension Stress Amplitude (kPa) | Peak-to-Peak Strain (Microstrain) | Cycle at Failure |

|---|---|---|---|---|

| HMA STA | 1 | 987 | 78 | 52,423 |

| 2 | 1222 | 151 | 20,423 | |

| 3 | 1427 | 270 | 5975 | |

| HMA LTA_1 | 1 | 877 | 71 | 43,442 |

| 2 | 1127 | 148 | 15,373 | |

| 3 | 1348 | 244 | 5269 | |

| HMA LTA_2 | 1 | 882 | 72 | 37,468 |

| 2 | 1172 | 152 | 9394 | |

| 3 | 1488 | 258 | 4430 | |

| HMA LTA_3 | 1 | 818 | 70 | 28,487 |

| 2 | 1255 | 126 | 10,687 | |

| 3 | 1685 | 304 | 2215 | |

| WMA STA | 1 | 788 | 104 | 10,624 |

| 2 | 1124 | 229 | 3512 | |

| 3 | 1561 | 371 | 2016 | |

| WMA LTA_1 | 1 | 896 | 79 | 16,624 |

| 2 | 1075 | 126 | 8624 | |

| 3 | 1530 | 355 | 2224 | |

| WMA LTA_2 | 1 | 949 | 84 | 17,868 |

| 2 | 1332 | 182 | 8774 | |

| 3 | 1527 | 344 | 2563 | |

| WMA LTA_3 | 1 | 884 | 88 | 20,487 |

| 2 | 1165 | 146 | 16,624 | |

| 3 | 1509 | 355 | 3338 |

| Mix | Coefficients | ||

|---|---|---|---|

| k1 | k2 | k3 | |

| HMA_STA | 3.71 × 102 | 1.74 | 1.28 |

| HMA_LTA1 | 4.89 × 102 | 1.69 | 1.28 |

| HMA_LTA2 | 4.62 × 102 | 1.68 | 1.28 |

| HMA_LTA3 | 2.05 × 102 | 1.74 | 1.28 |

| WMA_STA | 3.21 × 103 | 1.32 | 1.28 |

| WMA_LTA1 | 4.50 × 103 | 1.33 | 1.28 |

| WMA_LTA2 | 5.34 × 103 | 1.36 | 1.28 |

| WMA_LTA3 | 8.49 × 103 | 1.36 | 1.28 |

| Mix ID | No. | Tension Stress Amplitude (kPa) | Peak-to-Peak Strain (Microstrain) | Cycle at Failure |

|---|---|---|---|---|

| HMA STA_FT | 1 | 1141 | 151 | 6597 |

| 2 | 1384 | 372 | 1312 | |

| 3 | - | - | - | |

| HMA LTA_1_FT | 1 | 924 | 81 | 14,284 |

| 2 | 1090 | 135 | 6448 | |

| 3 | 1168 | 307 | 1323 | |

| HMA LTA_2_FT | 1 | 945 | 83 | 11,437 |

| 2 | 1145 | 160 | 3483 | |

| 3 | 1309 | 308 | 1016 | |

| HMA LTA_3_FT | 1 | - | - | - |

| 2 | 1076 | 77 | 10,530 | |

| 3 | 1289 | 265 | 1016 | |

| WMA STA_FT | 1 | 788 | 101 | 3942 |

| 2 | 913 | 145 | 1844 | |

| 3 | 971 | 258 | 573 | |

| WMA LTA_1_FT | 1 | 722 | 89 | 6193 |

| 2 | 879 | 118 | 3914 | |

| 3 | 983 | 254 | 788 | |

| WMA LTA_2_FT | 1 | 742 | 82 | 8724 |

| 2 | 874 | 121 | 4354 | |

| 3 | 999 | 185 | 1837 | |

| WMA LTA_3_FT | 1 | 879 | 78 | 12,914 |

| 2 | 1041 | 104 | 5952 | |

| 3 | 1118 | 218 | 1688 |

| Mix | Coefficients | ||

|---|---|---|---|

| k1 | k2 | k3 | |

| HMA_STA_FT | 7.04 × 101 | 1.80 | 1.28 |

| HMA_LTA1_FT | 6.03 × 101 | 1.80 | 1.28 |

| HMA_LTA2_FT | 3.39 × 101 | 1.85 | 1.28 |

| HMA_LTA3_FT | 1.89 × 101 | 1.90 | 1.28 |

| WMA_STA_FT | 8.94 × 10−1 | 2.05 | 1.28 |

| WMA_LTA1_FT | 3.61 | 1.99 | 1.28 |

| WMA_LTA2_FT | 9.78 | 1.92 | 1.28 |

| WMA_LTA3_FT | 1.42 × 101 | 1.92 | 1.28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.L.; Baek, C.; Park, H.B. Effect of Aging and Moisture Damage on Fatigue Cracking Properties in Asphalt Mixtures. Appl. Sci. 2021, 11, 10543. https://doi.org/10.3390/app112210543

Yang SL, Baek C, Park HB. Effect of Aging and Moisture Damage on Fatigue Cracking Properties in Asphalt Mixtures. Applied Sciences. 2021; 11(22):10543. https://doi.org/10.3390/app112210543

Chicago/Turabian StyleYang, Sung Lin, Cheolmin Baek, and Hee Beom Park. 2021. "Effect of Aging and Moisture Damage on Fatigue Cracking Properties in Asphalt Mixtures" Applied Sciences 11, no. 22: 10543. https://doi.org/10.3390/app112210543

APA StyleYang, S. L., Baek, C., & Park, H. B. (2021). Effect of Aging and Moisture Damage on Fatigue Cracking Properties in Asphalt Mixtures. Applied Sciences, 11(22), 10543. https://doi.org/10.3390/app112210543