Research Concerning the Bending Properties of Reconstituted Spruce Lumber Boards, Obtained by Edge-Cutting at 45° and Gluing

Abstract

1. Introduction

- -

- Uses the existing technology while requiring only a supplementary circular saw with inclinable blade (to perform the cutting at 45°);

- -

- Allows valorizing sideboards with variable width (which is not possible in any other way);

- -

- Allows for obtaining directly prismatic products from these sideboards; and

- -

- Ensures good dimensional stability of the reconstituted boards due to the mirrored position of the sideboards.

2. Materials and Methods

2.1. Materials

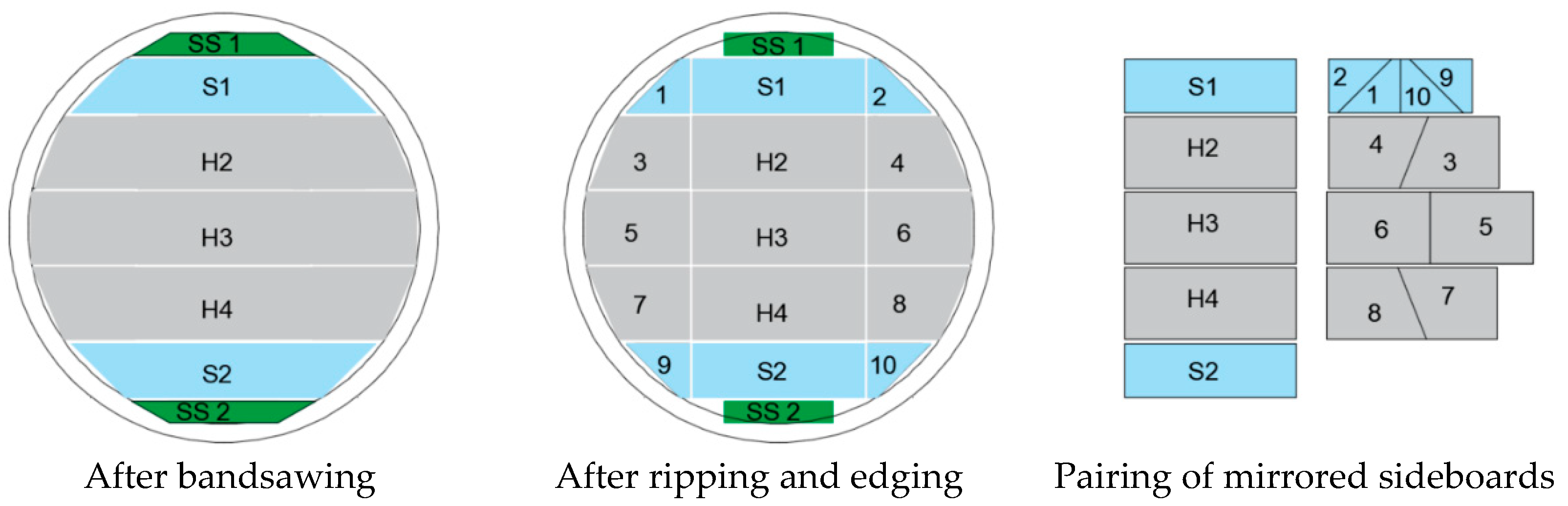

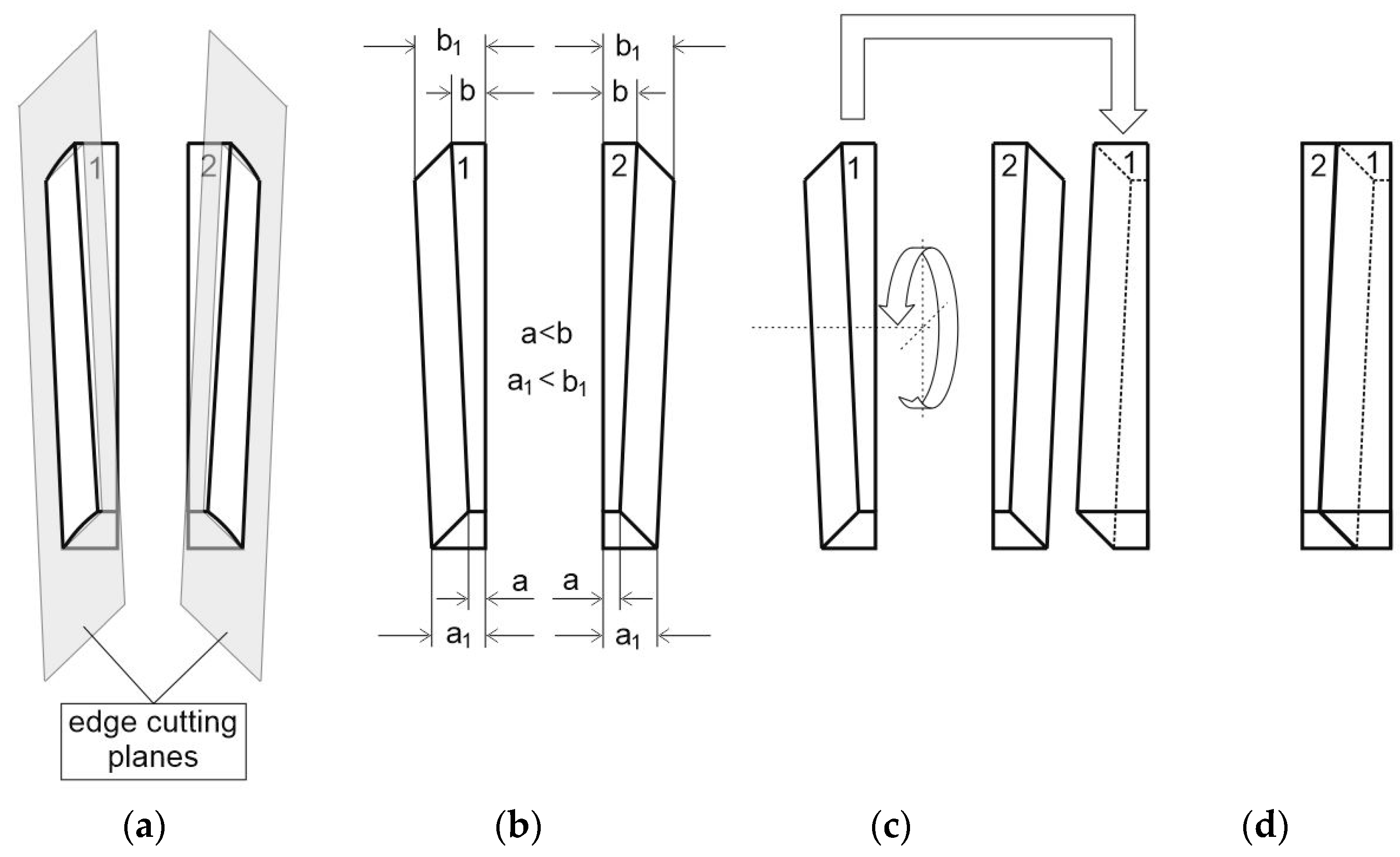

2.1.1. Material Preparation

2.1.2. Sampling

2.2. The Bending Test

3. Results and Discussion

- The values obtained within this research for the solid wood samples are in good accordance with the values from reference literature (given in Table 1); the density of solid wood increases from core to outer zone due to the fact that the annual rings become narrower, and the proportion of earlywood decreases;

- The comparative results concerning the influence of the load direction relative to the annual rings (tangential load vs. radial load—see Table 4 and Table 5) for the solid wood samples shows that the tangential load leads to 10% higher values of MOE and MOR compared to the radial loading; this can be explained by the much lower number of pits in the tangential than in the radial walls of the tracheids, which makes resinous wood more resistant to tangential loads;

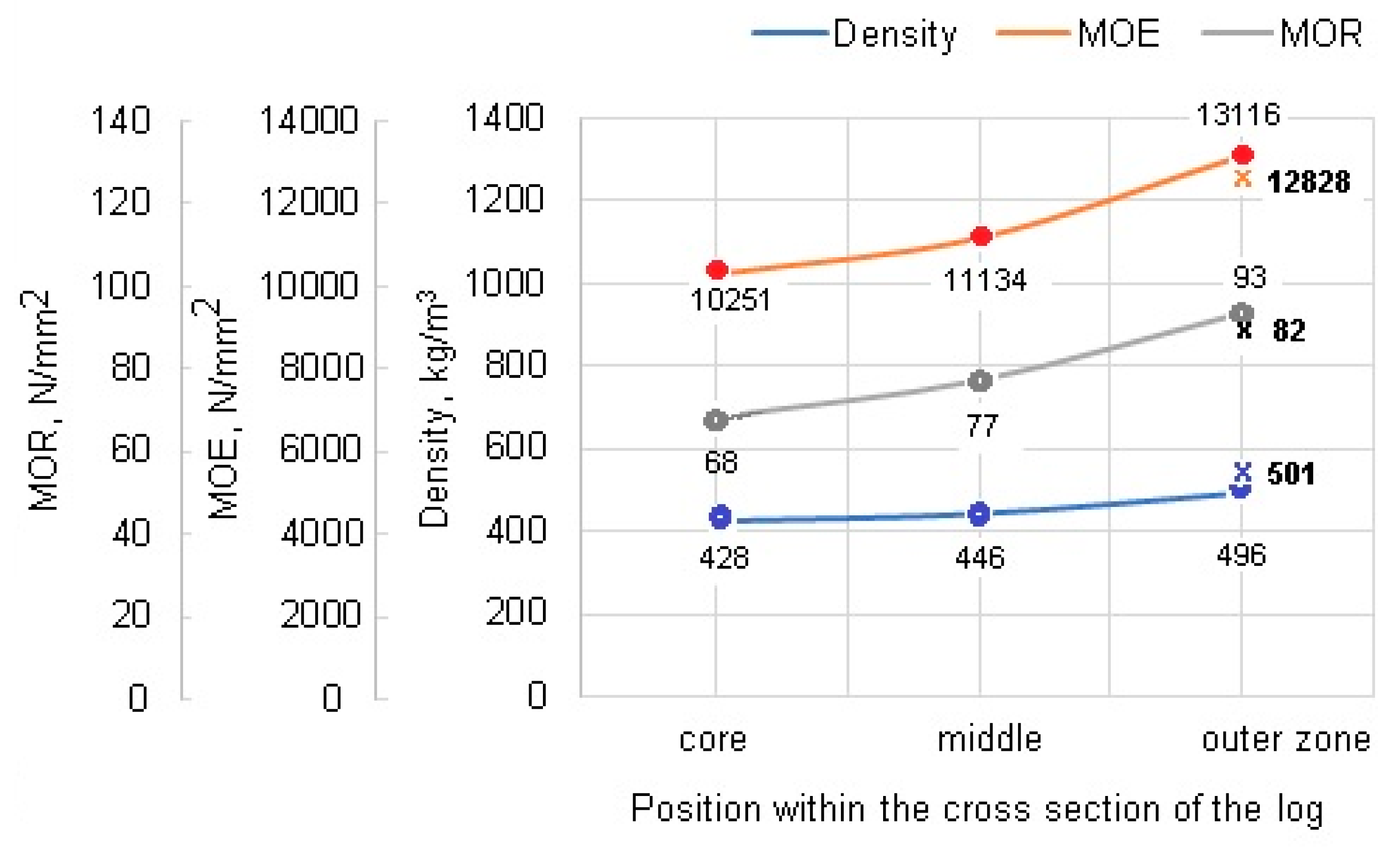

- A good correlation between the density and the bending properties of the solid wood samples was noticed, as mentioned in reference [7]: the bending properties increased with increasing density from the central part of the log towards the outer area, as illustrated in the example given in Figure 7, based on the data obtained from Log N°1 samples, tangentially loaded; dissimilarly, the glued samples (represented with “x” and bold values in Figure 7) had lower bending properties despite having higher density (due to the presence of the adhesive);

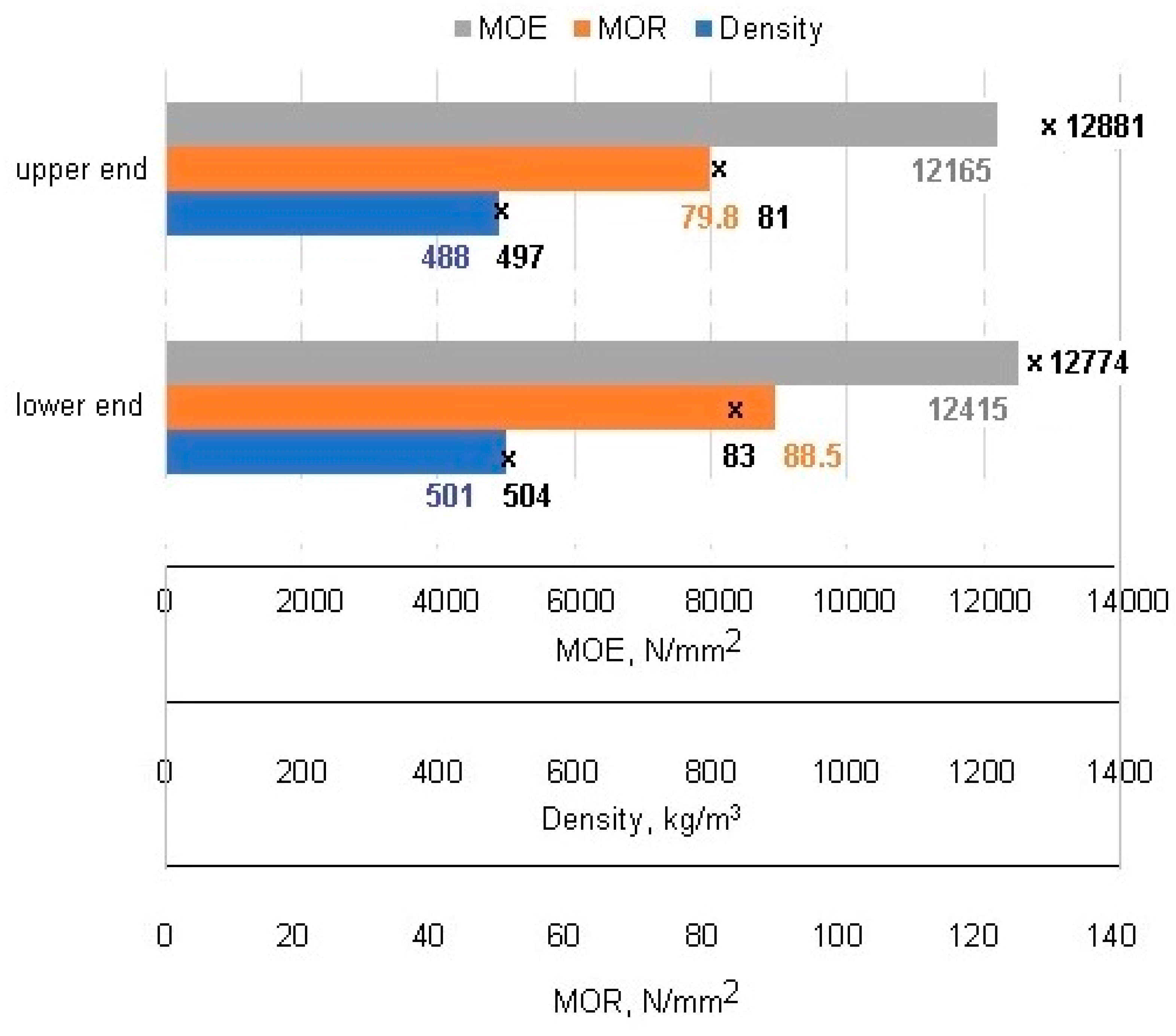

- As far as the influence of the position within the tree height is concerned, no major difference was noticed between the values obtained from the butt logs compared to the top logs for the density of the solid wood samples, which is also in good accordance with data from reference [7]; the MOR and MOE values for solid wood are less uniform; there is a clear decreasing tendency of both parameters from butt to top, as illustrated in the example given in Figure 8, based on the data obtained from Log N°1 samples, radially loaded; the glued samples obtained from the same log (represented with “x” in Figure 8) showed very close density, lower MOR and MOE at the butt, and visibly higher MOR and MOE at the top, compared to the solid wood samples.

- There is a reasonable accordance between the values obtained from the two different logs;

- The density of the glued elements is higher than the density of the solid wood elements from the same (outer area) of the logs;

- There is no significant difference in the MOE values of the bonded boards compared to the solid wood boards from the same area, with only one exception (for Log N° 1 when the load was radially applied);

- There is no significant difference in the MOR values of the bonded boards compared to the solid wood boards from the same area, with only one exception (for Log N° 1 when the load was tangentially applied).

4. Conclusions

- The density, MOR, and MOE of the bonded elements are comparable to the values obtained for the solid wood samples from the outer area;

- Generally, the MOR and MOE values obtained for the glued samples were smaller than for the tangentially loaded solid wood samples, but slightly higher (or comparable) to the radially loaded ones;

- With average values MOR = 82 N/mm2 and MOE = 12,300…12,800 N/mm2, the bonded elements can be considered as suitable for CLT products, where usually the minimum required MOR is 24 N/mm2 and the average MOE is 11,000 N/mm2 (according to CEN EN 338) [19].

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Steele, P.H. Factors Determining Lumber Recovery in Sawmilling; USDA Forest Service: Madison, WI, USA, 1984. [Google Scholar]

- Stangle, S.M.; Bruchert, F.; Heikkila, A.; Usenius, T.; Sauter, U. Potentially Increased Sawmill Yield from Hardwoods Using X-Ray Computed Tomography for Knot Detection. Ann. For. Sci. 2015, 72, 57–65. [Google Scholar] [CrossRef]

- Brandstetter, M.; Zeleniuc, O.; Pei, G.; Campean, M. Conversion Efficiency of Fir Roundwood into Sawlogs. BioResources 2020, 15, 5653–5665. [Google Scholar] [CrossRef]

- Panshin, A.J.; de Zeeuw, C. Textbook of Wood Technology; McGraw-Hill, Inc.: New York, NY, USA, 1980. [Google Scholar]

- Tsoumis, G. Science and Technology of Wood: Structure, Properties, Utilization. Structure, Properties, Utilization; Chapman & Hall: New York, NY, USA, 1991. [Google Scholar]

- Holzatlas. In Fachbuchverlag Leipzig; Wagenführ, R., Ed.; Carl Hanser Verlag Munchen-Wien: Munich, Germany, 2008. [Google Scholar]

- Kollmann, F. Technologie des Holzes und der Holzwerkstoffe; 2 Auflage; Springer: Berlin/Heidelberg, Germany; Göttingen, Germany, 1951. [Google Scholar]

- Olesen, P.O. The Variation of the Basic Density Level and Tracheid Width within the Juvenile and Mature Wood of Norway spruce. For. Tree Improv. 1977, 12, 1–21. [Google Scholar]

- Petty, J.A.; Macmillan, D.C.; Steward, C.M. Variation of Density and Growth Ring Width in Stems of Sitka and Norway spruce. Forestry 1990, 63, 39–49. [Google Scholar] [CrossRef]

- Saranpää, P. Wood Density and Growth. In Wood Quality and Its Biological Basis; Barnett, J.R., Jeronimidis, G., Eds.; Biological Sciences Series; Blackwell Publishing: Bodmin, UK; CRC Press: Bodmin, UK, 2009. [Google Scholar]

- Bardak, T.; Tankut, A.N.; Tankut, N.; Aydemir, D.; Szoen, E. The Bending and Tension Strength of Furniture Joints Bonded with Polyvinyl Acetate Nanocomposites. Maderas. Cienc. Tecnol. 2017, 19, 51–62. [Google Scholar] [CrossRef]

- Kumar, V.S.; Sharma, C.M.; Gupta, S. Compression and Flexural Properties of Finger Jointed Mango Wood Sections. Maderas. Cienc. Tecnol. 2015, 17, 151–160. [Google Scholar] [CrossRef]

- Watson, P.; Clauss, S.; Ammann, S.; Niemz, P. Fracture Properties of Adhesive Joints Under Mechanical Stress. Wood Res. 2013, 58, 43–56. [Google Scholar]

- Cao, G.; Shmulsky, R.; Liu, M.; Entsminger, E.D.; Via, B.K.; Wan, H. Characterizing Star-sawn Pattern Produced and Orthogonally Glued Specimens of Southern Pine. For. Prod. J. 2019, 69, 53–60. [Google Scholar]

- ISO 3129. Wood—Sampling Methods and General Requirements for Physical and Mechanical Testing of Small Clear Wood Specimens; ISO: Genève, Switzerland, 2012. [Google Scholar]

- ISO 13061-3. Determination of Ultimate Strength in Static Bending; ISO: Genève, Switzerland, 2016. [Google Scholar]

- ISO 13061-4. Determination of Modulus of Elasticity in Static Bending; ISO: Genève, Switzerland, 2016. [Google Scholar]

- Hu, W.; Zhang, J. Bolt-Bearing Yield Strength of Three-Layered Cross-Laminated Timber Treated with Phenol Formaldehyde Resin. Forests 2020, 11, 551. [Google Scholar] [CrossRef]

- CEN EN 338. Structural Timber—Strength Classes; European Committee for Standardization (CEN): Brussels, Belgium, 2016. [Google Scholar]

| Density (ρ12–15%), kg/m3 | MOE, N/mm2 | MOR, N/mm2 |

|---|---|---|

| 330–470–680 | 7300–11,000–21,400 | 49–78–136 |

| Top Diameter, mm | Diameter at Mid Length, mm | Butt Diameter, mm | Length, m | Wood Volume, m3 | |

|---|---|---|---|---|---|

| Log Nr. 1 | 237 | 240 | 258.5 | 3.1 | 0.14 |

| Log Nr. 2 | 227.5 | 230 | 247.5 | 3.1 | 0.13 |

| Log/Type of Samples | Position within Cross Section * | Position over Tree Length | Cummulated Mean and STDEV | |

|---|---|---|---|---|

| Lower Part | Upper Part | |||

| Log N° 1 | ||||

| Solid wood (tangentially loaded) | Core zone | 420.33 ± 1.15 | 436.67 ± 22.01 | 428.50 ± 11.58 |

| Middle zone | 449.67 ± 19.83 | 442.67 ± 22.78 | 446.17 ± 22.64 | |

| Outer zone | 495.55 ± 20.55 | 495.53 ± 43.39 | 495.54 ± 32.35 | |

| Mean and STDEV | 462.50 ± 34.79 | 462.57 ± 41.37 | 462.53 ± 38.08 | |

| Solid wood (radially loaded) | Core zone | 416.85 ± 6.80 | 400.67 ± 7.43 | 408.76 ± 7.12 |

| Middle zone | 428.39 ± 16.18 | 464.27 ± 15.09 | 446.33 ± 15.64 | |

| Outer zone | 501.24 ± 18.58 | 488.95 ± 27.72 | 495.09 ± 23.40 | |

| Mean and STDEV | 455.22 ± 41.89 | 461.42 ± 38.50 | 458.32 ± 40.19 | |

| Edge-bonded boards (at 45°) | Outer zone | 504.14 ± 18.94 | 496.85 ± 13.76 | 500.50 ± 16.49 |

| Log N° 2 | ||||

| Solid wood (tangentially loaded) | Core zone | 411.33 ± 13.01 | 407.33 ± 33.50 | 409.33 ± 23.26 |

| Middle zone | 433.83 ± 12.32 | 427.00 ± 35.22 | 430.42 ± 23.77 | |

| Outer zone | 517.02 ± 25.73 | 469.20 ± 9.86 | 493.11 ± 17.80 | |

| Mean and STDEV | 462.62 ± 50.01 | 439.85 ± 36.13 | 451.24 ± 43.07 | |

| Solid wood (radially loaded) | Core zone | 407.20 ± 10.14 | 396.36 ± 17.37 | 401.78 ± 13.76 |

| Middle zone | 423.33 ± 12.33 | 438.19 ± 25.16 | 430.76 ± 18.75 | |

| Outer zone | 492.31 ± 41.10 | 472.58 ± 12.02 | 482.45 ± 26.56 | |

| Mean and STDEV | 447.70 ± 46.16 | 443.58 ± 34.22 | 445.64 ± 40.19 | |

| Edge-bonded boards (at 45°) | Outer zone | 518.12 ± 22.40 | 508.38 ± 24.91 | 513.75 ± 23.55 |

| Log/Type of Samples | Position within Cross Section * | Position over Tree Length | Cummulated Mean and STDEV | |

|---|---|---|---|---|

| Lower Part | Upper Part | |||

| Log N° 1 | ||||

| Solid wood (tangentially loaded) | Core zone | 9490.00 ± 933.92 | 11,011.33 ± 721.69 | 10,250.67 ± 827.81 |

| Middle zone | 11,480.83 ± 922.26 | 10,787.67 ± 1056.90 | 11,134.25 ± 989.58 | |

| Outer zone | 13,211.55 ± 1167.09 | 13,021.41 ± 1136.27 | 13,116.48 ± 1151.68 | |

| Mean and STDEV | 11,774.99 ± 1719.06 | 11,725.93 ± 1463.01 | 11,750.46 ± 1591.04 | |

| Solid wood (radially loaded) | Core zone | 8612.17 ± 728.33 | 8732.53 ± 363.55 | 8672.35 ± 518.98 |

| Middle zone | 9534.50 ± 3721.91 | 10,629.95 ± 527.30 | 10,082.23 ± 953.13 | |

| Outer zone | 12,414.60 ± 974.53 | 12,165.43 ± 773.24 | 12,290.02 ± 848.76 | |

| Mean and STDEV | 10,502.07 ± 1872.56 | 10,864.66 ± 1433.39 | 10,683.37 ± 1648.84 | |

| Edge-bonded boards (at 45°) | Outer zone | 12,773.58 ± 757.49 | 12,881.45 ± 513.75 | 12,827.52 ± 635.36 |

| Log N° 2 | ||||

| Solid wood (tangentially loaded) | Core zone | 8521.33 ± 656.18 | 8343.33 ± 269.52 | 8432.33 ± 462.85 |

| Middle zone | 9738.50 ± 726.32 | 10,337.00 ± 1459.98 | 10,037.75 ± 1093.15 | |

| Outer zone | 13,947.61 ± 726.34 | 11,554.44 ± 916.20 | 12,751.03 ± 1477.61 | |

| Mean and STDEV | 11,178.71 ± 2425.11 | 10,425.20 ± 1596.86 | 10,801.96 ± 2010.99 | |

| Solid wood (radially loaded) | Core zone | 8211.22 ± 462.32 | 8897.74 ± 640.04 | 8554.48 ± 551.18 |

| Middle zone | 9722.33 ± 931.89 | 10,130.42 ± 488.50 | 9926.38 ± 710.20 | |

| Outer zone | 12,620.16 ± 1395.89 | 11,424.44 ± 812.06 | 12,022.30 ± 1103.96 | |

| Mean and STDEV | 10,579.24 ± 2082.79 | 10,401.49 ± 1159.21 | 10,490.37 ± 1621.00 | |

| Edge-bonded boards (at 45°) | Outer zone | 12,258.38 ± 844.76 | 12,374.44 ± 1232.62 | 12,306.41 ± 1004.02 |

| Log/Type of Samples | Position within Cross Section * | Position over Tree Length | Cummulated Mean and STDEV | |

|---|---|---|---|---|

| Lower Part | Upper Part | |||

| Log N° 1 | ||||

| Solid wood (tangentially loaded) | Core zone | 65.27 ± 3.00 | 70.47 ± 9.22 | 67.87 ± 6.11 |

| Middle zone | 80.82 ± 4.56 | 72.73 ± 6.67 | 76.78 ± 5.62 | |

| Outer zone | 94.34 ± 3.55 | 91.72 ± 10.97 | 93.03 ± 7.26 | |

| Mean and STDEV | 83.1 ± 11.73 | 81.21 ± 12.25 | 82.16 ± 11.99 | |

| Solid wood (radially loaded) | Core zone | 61.09 ± 3.65 | 58.68 ± 6.39 | 59.89 ± 5.02 |

| Middle zone | 65.52 ± 4.44 | 70.46 ± 5.63 | 67.99 ± 5.04 | |

| Outer zone | 88.49 ± 6.78 | 79.82 ± 4.62 | 84.16 ± 5.70 | |

| Mean and STDEV | 73.82 ± 13.48 | 71.83 ± 9.47 | 72.83 ± 11.48 | |

| Edge-bonded boards (at 45°) | Outer zone | 82.98 ± 5.63 | 81.12 ± 4.82 | 82.05 ± 5.23 |

| Log N° 2 | ||||

| Solid wood (tangentially loaded) | Core zone | 61.28 ± 2.67 | 61.14 ± 0.73 | 61.21 ± 1.70 |

| Middle zone | 65.34 ± 6.89 | 71.14 ± 8.87 | 68.24 ± 7.88 | |

| Outer zone | 94.89 ± 3.94 | 81.34 ± 6.35 | 88.12 ± 5.15 | |

| Mean and STDEV | 76.35 ± 16.44 | 73.27 ± 10.12 | 74.81 ± 13.28 | |

| Solid wood (radially loaded) | Core zone | 61.01 ± 0.96 | 61.94 ± 3.68 | 61.48 ± 2.32 |

| Middle zone | 66.63 ± 4.01 | 69.38 ± 5.67 | 60.97 ± 4.84 | |

| Outer zone | 85.04 ± 4.33 | 75.45 ± 7.22 | 80.24 ± 5.78 | |

| Mean and STDEV | 72.87 ± 11.08 | 70.32 ± 7.66 | 71.59 ± 18.74 | |

| Edge-bonded boards (at 45°) | Outer zone | 85.85 ± 9.22 | 77.76 ± 4.68 | 81.81 ± 6.95 |

| Log Number | Loading Direction | MOR (N/mm2) | |

|---|---|---|---|

| Solid Wood | Glued | ||

| #1 | Tangential | 93 (12) (7.93) A * | 82 (24) (5.21) B |

| Radial | 84 (12) (7.16) A | 82 (24) (5.21) A | |

| #2 | Tangential | 88 (12) (8.60) A | 82 (29) (8.58) A |

| Radial | 80 (12) (7.57) A | 82 (29) (8.58) A | |

| #1 + #2 | Tangential | 91 (24) (8.45) A | 82 (53) (7.19) B |

| Radial | 82.19 (24) (7.47) A | 82 (53) (7.19) A | |

| Log Number | Loading Direction | MOE (N/mm2) | |

|---|---|---|---|

| Solid Wood | Glued | ||

| #1 | Tangential | 13,116 (12) (1102.66) A * | 12,828 (24) (635.36) A |

| Radial | 12,290 (12) (848.76) A | 12,828 (24) (635.36) B | |

| #2 | Tangential | 12,751 (12) (1477.61) A | 12,306 (29) (1004.02) A |

| Radial | 12,022 (12) (1255.13) A | 12,306 (29) (1004.02) A | |

| #1 + #2 | Tangential | 12,934 (24) (1288.62) A | 12,542 (53) (888.78) A |

| Radial | 12,156 (24) (1056.72) A | 12,542 (53) (888.78) A | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Porojan, M.; Brandstetter, M.; Ispas, M.; Bedelean, B.; Campean, M. Research Concerning the Bending Properties of Reconstituted Spruce Lumber Boards, Obtained by Edge-Cutting at 45° and Gluing. Appl. Sci. 2021, 11, 9937. https://doi.org/10.3390/app11219937

Porojan M, Brandstetter M, Ispas M, Bedelean B, Campean M. Research Concerning the Bending Properties of Reconstituted Spruce Lumber Boards, Obtained by Edge-Cutting at 45° and Gluing. Applied Sciences. 2021; 11(21):9937. https://doi.org/10.3390/app11219937

Chicago/Turabian StylePorojan, Mihaela, Markus Brandstetter, Mihai Ispas, Bogdan Bedelean, and Mihaela Campean. 2021. "Research Concerning the Bending Properties of Reconstituted Spruce Lumber Boards, Obtained by Edge-Cutting at 45° and Gluing" Applied Sciences 11, no. 21: 9937. https://doi.org/10.3390/app11219937

APA StylePorojan, M., Brandstetter, M., Ispas, M., Bedelean, B., & Campean, M. (2021). Research Concerning the Bending Properties of Reconstituted Spruce Lumber Boards, Obtained by Edge-Cutting at 45° and Gluing. Applied Sciences, 11(21), 9937. https://doi.org/10.3390/app11219937