Effect of Micro-Textured Surfaces and Sliding Speed on the Lubrication Mechanism and Friction-Wear Characteristics of CF/PEEK Rubbing against 316L Stainless Steel under Seawater Lubrication

Abstract

:1. Introduction

2. Numerical Approach

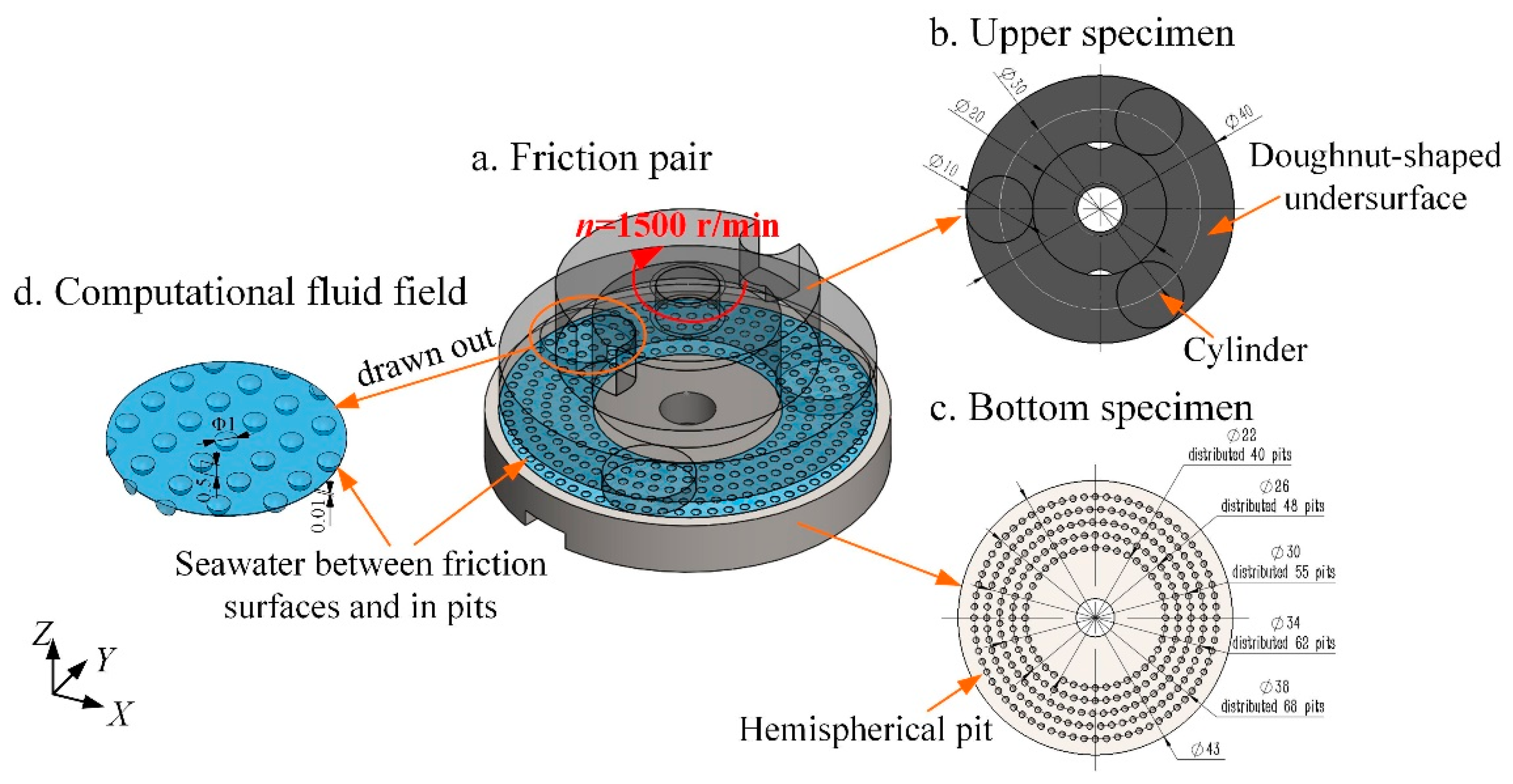

2.1. Model Description

2.2. Governing Equation

2.3. Simulation Strategy

3. Experimental Details

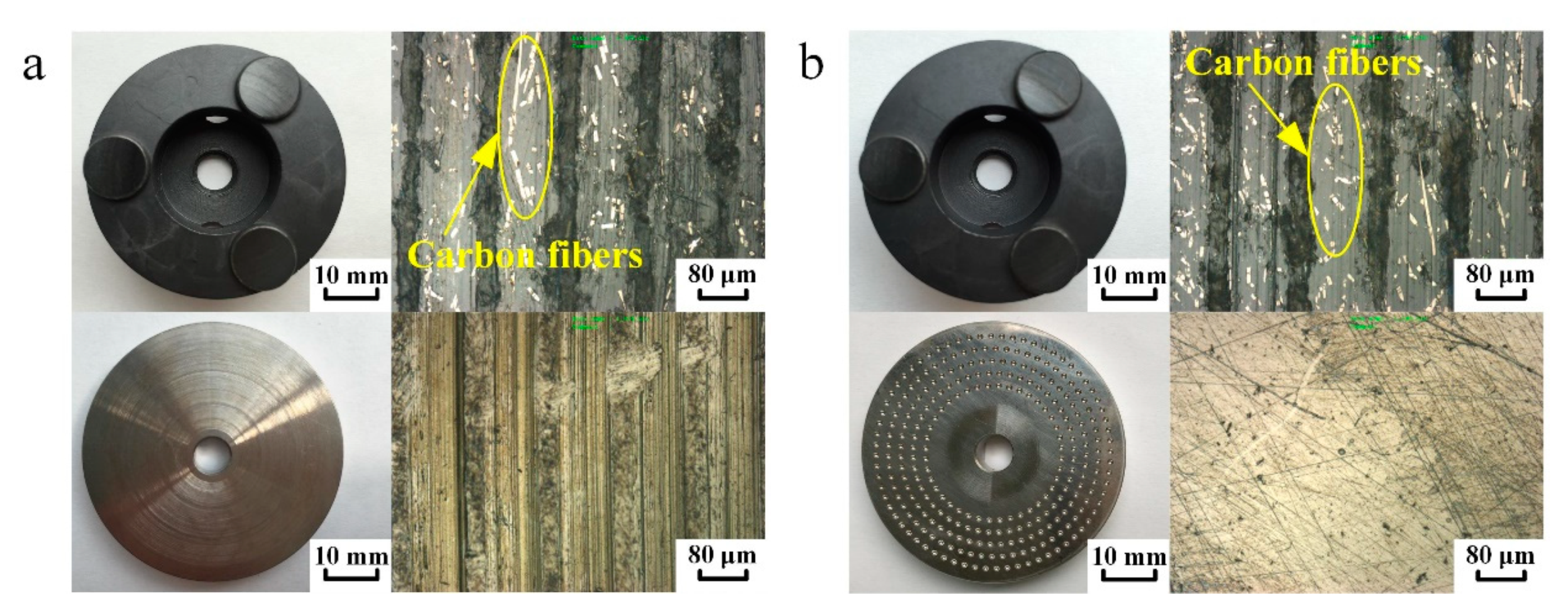

3.1. Materials and Specimens

3.2. Lubricating Medium

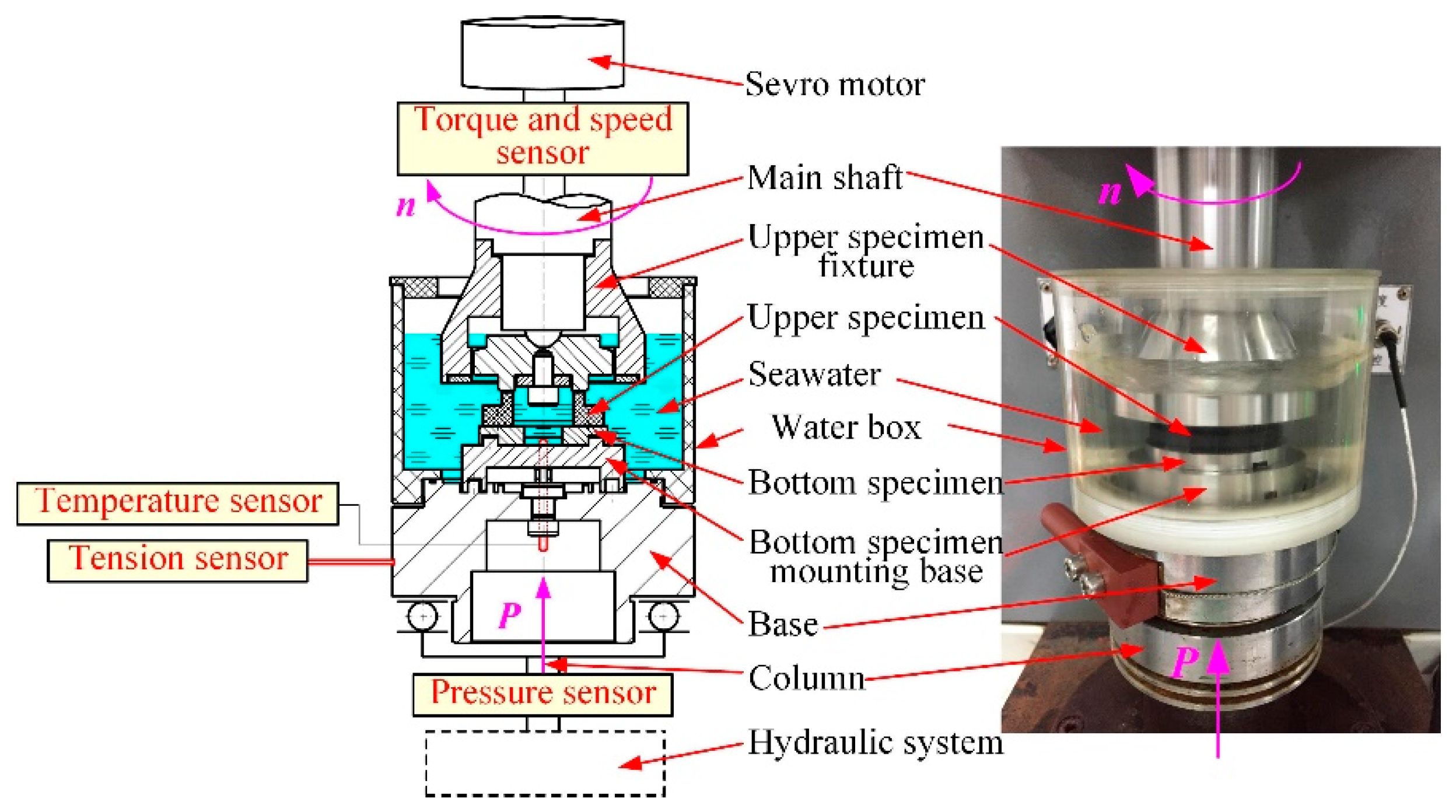

3.3. Experimental Setup and Principle

3.4. Working Conditions and Testing Program

4. Results and Discussion

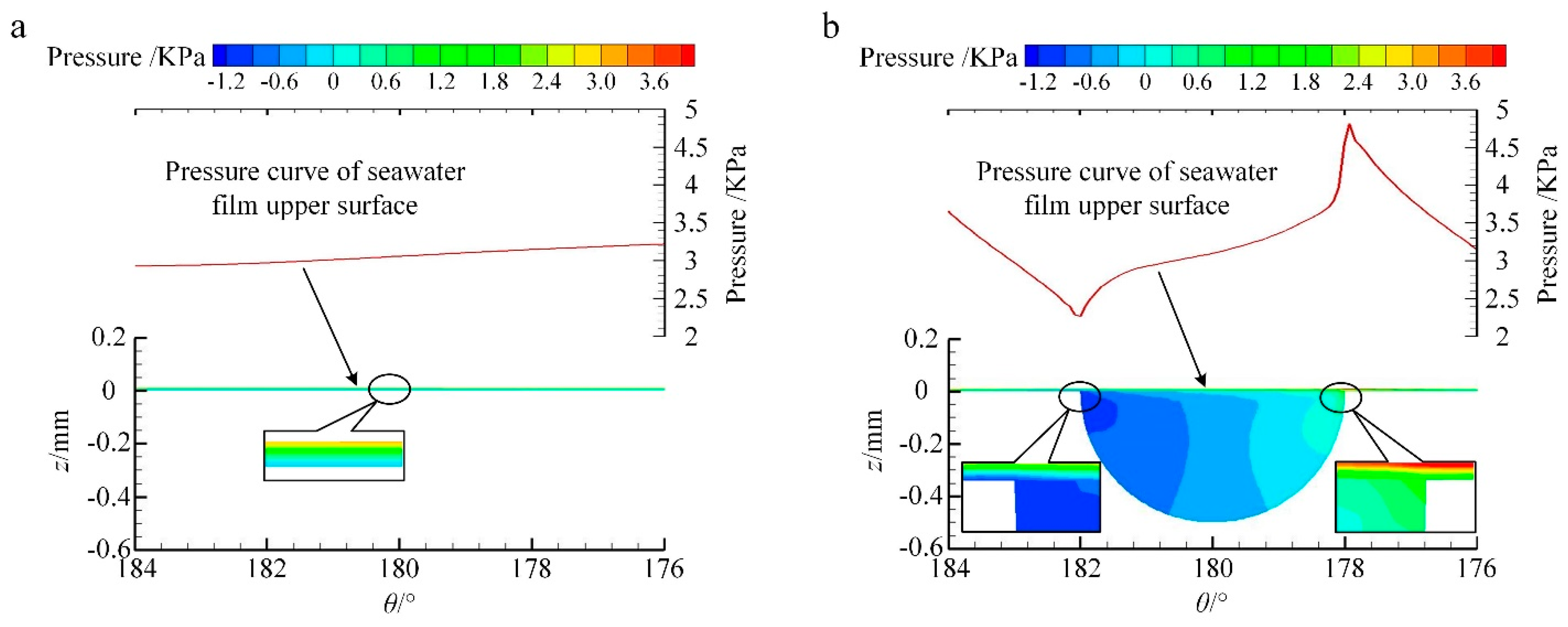

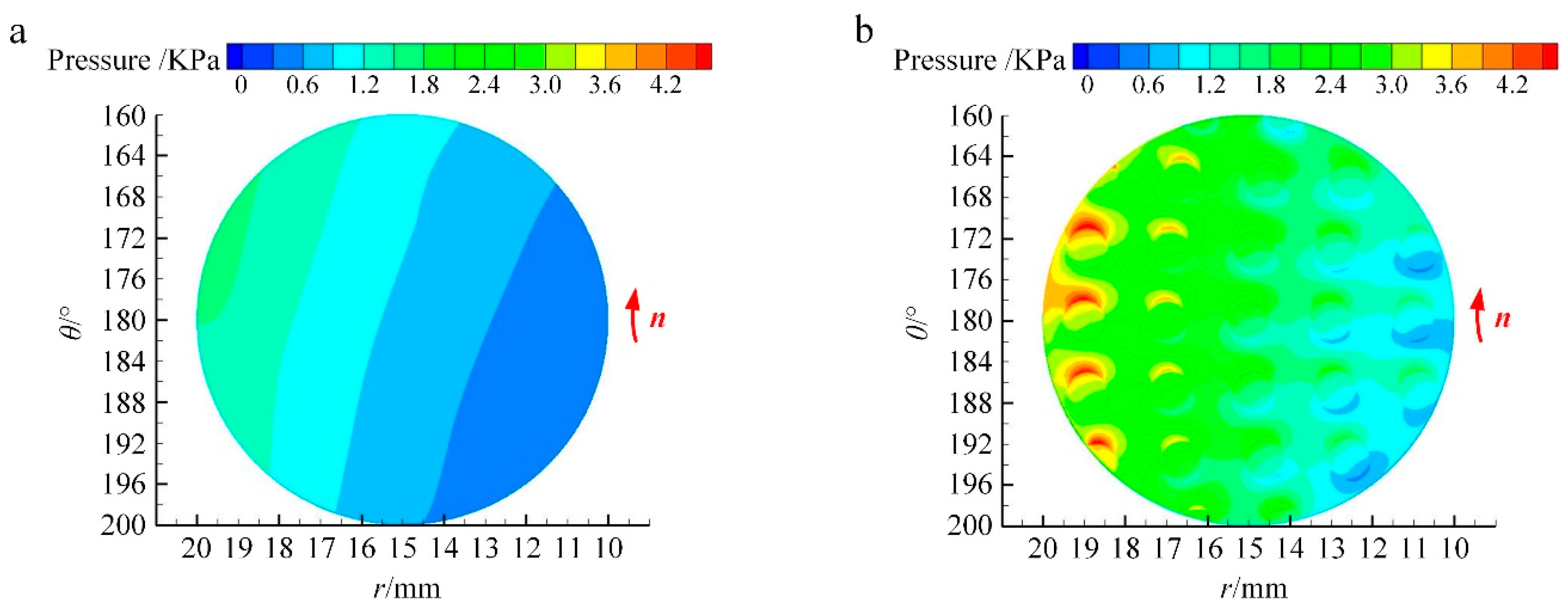

4.1. Analysis of the Lubrication Mechanism

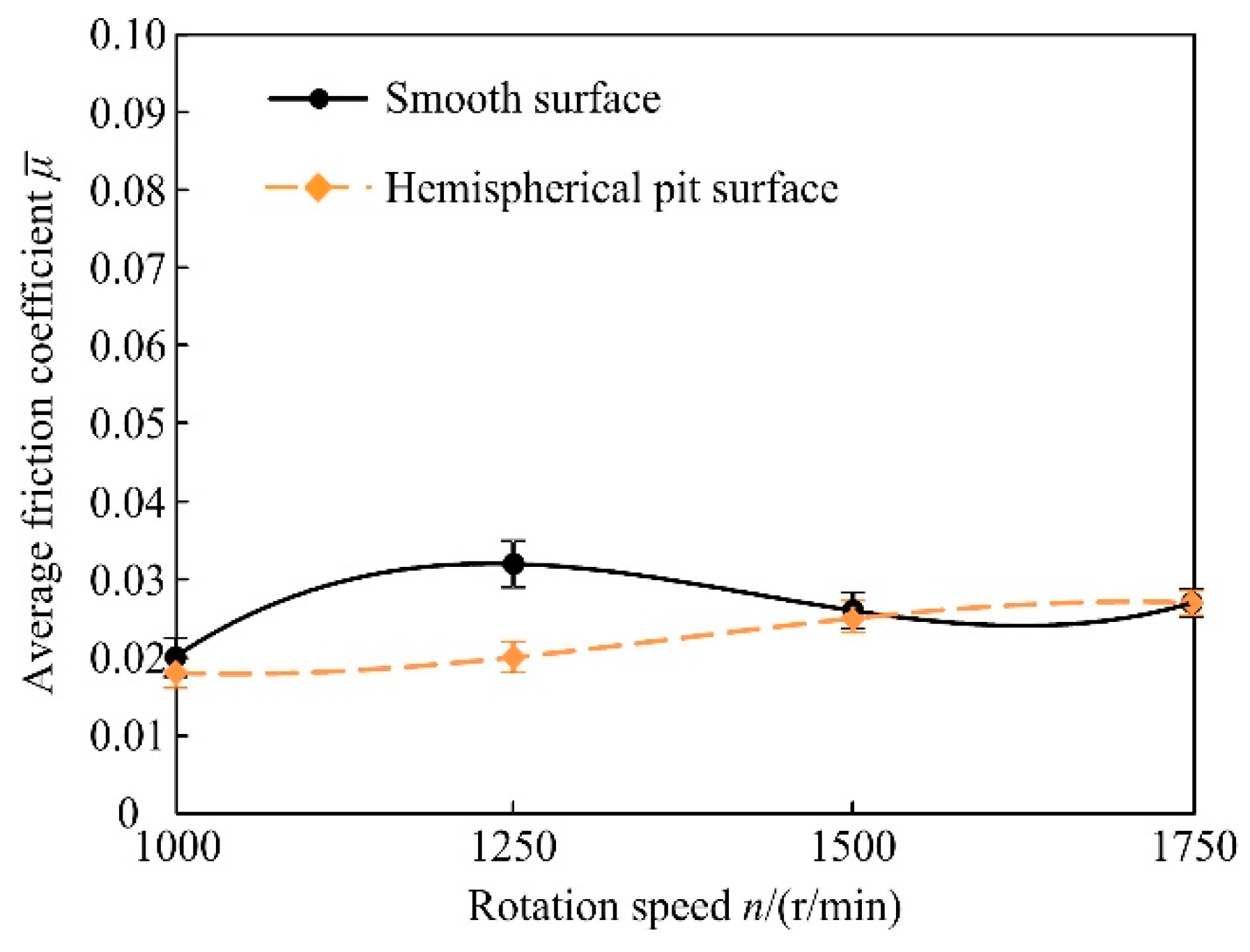

4.2. Analysis of the Friction Coefficient

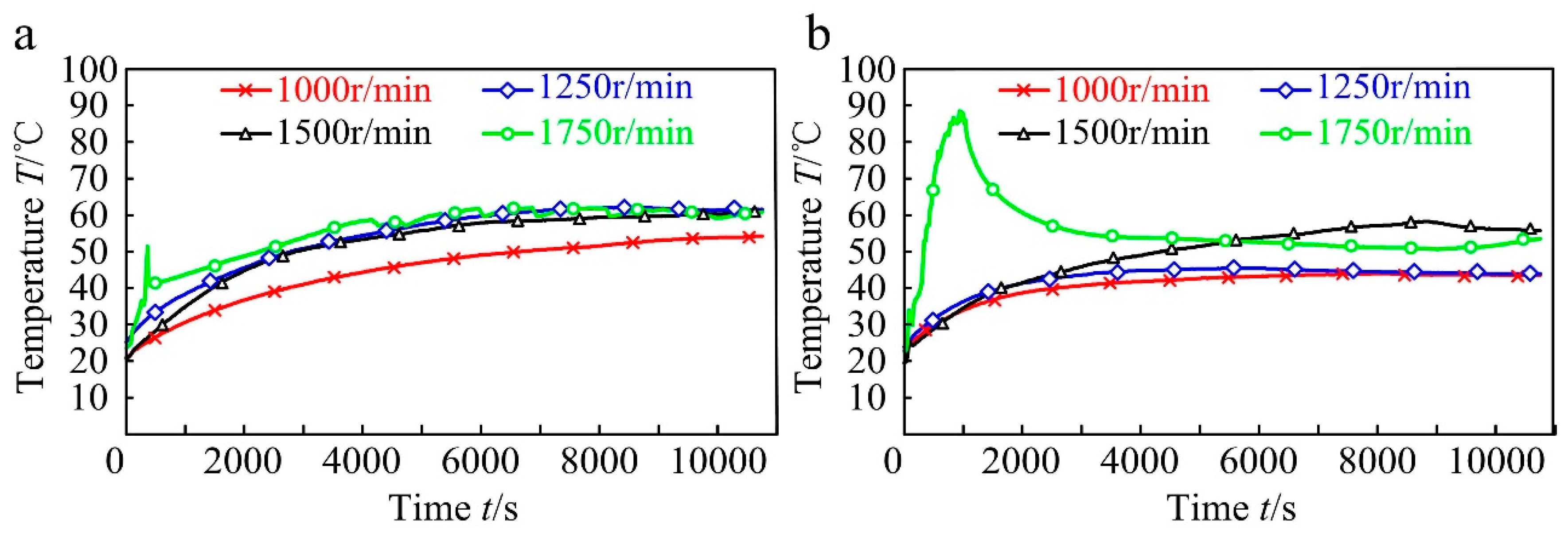

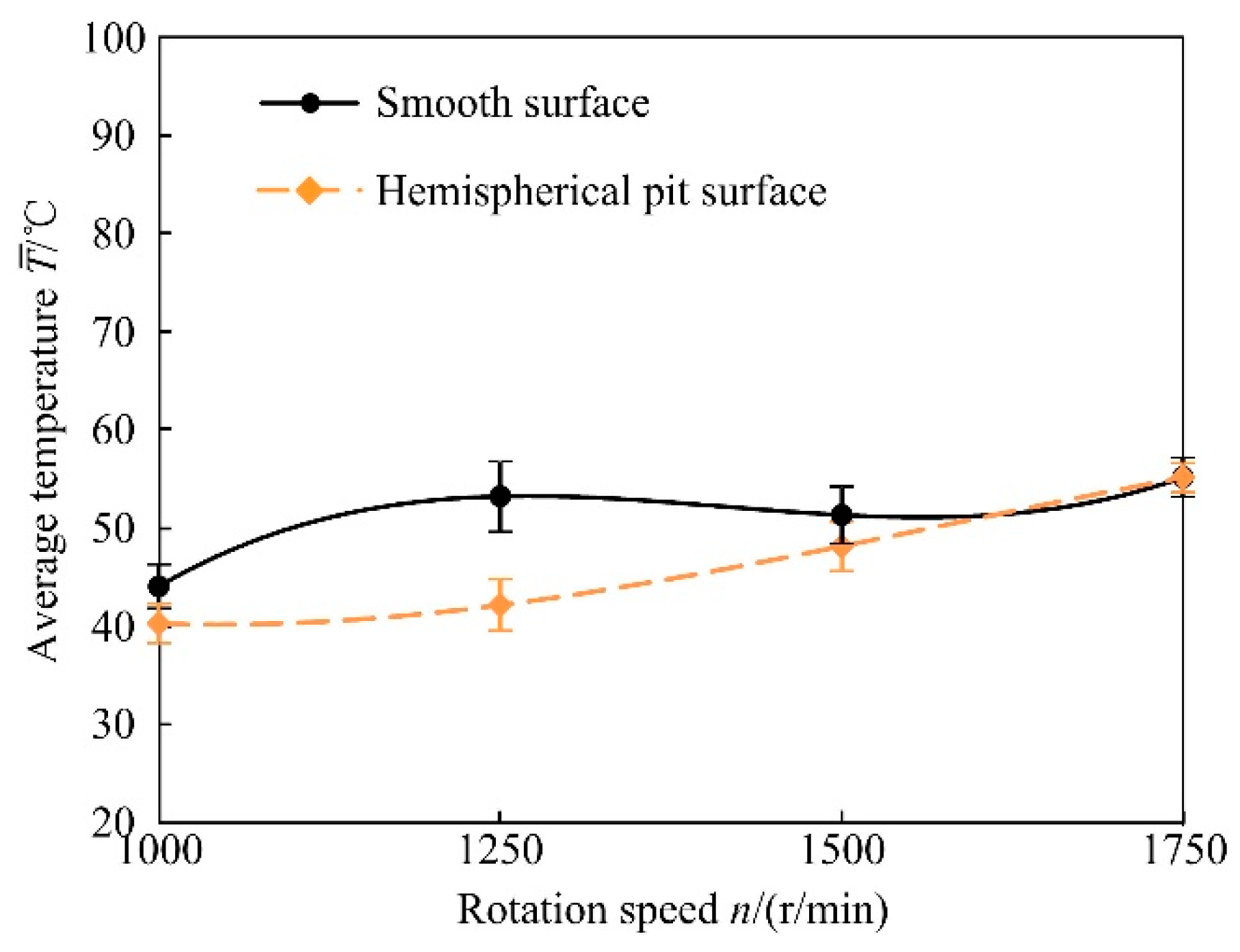

4.3. Analysis of the Specimen Contact Temperature

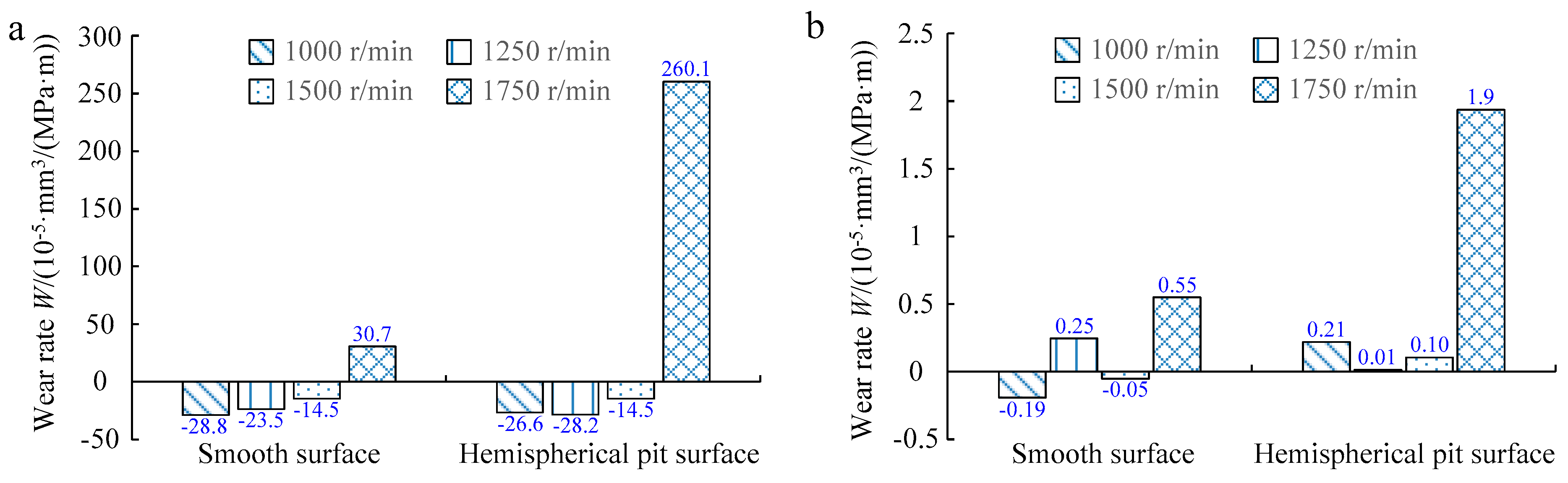

4.4. Analysis of the Wear Rate

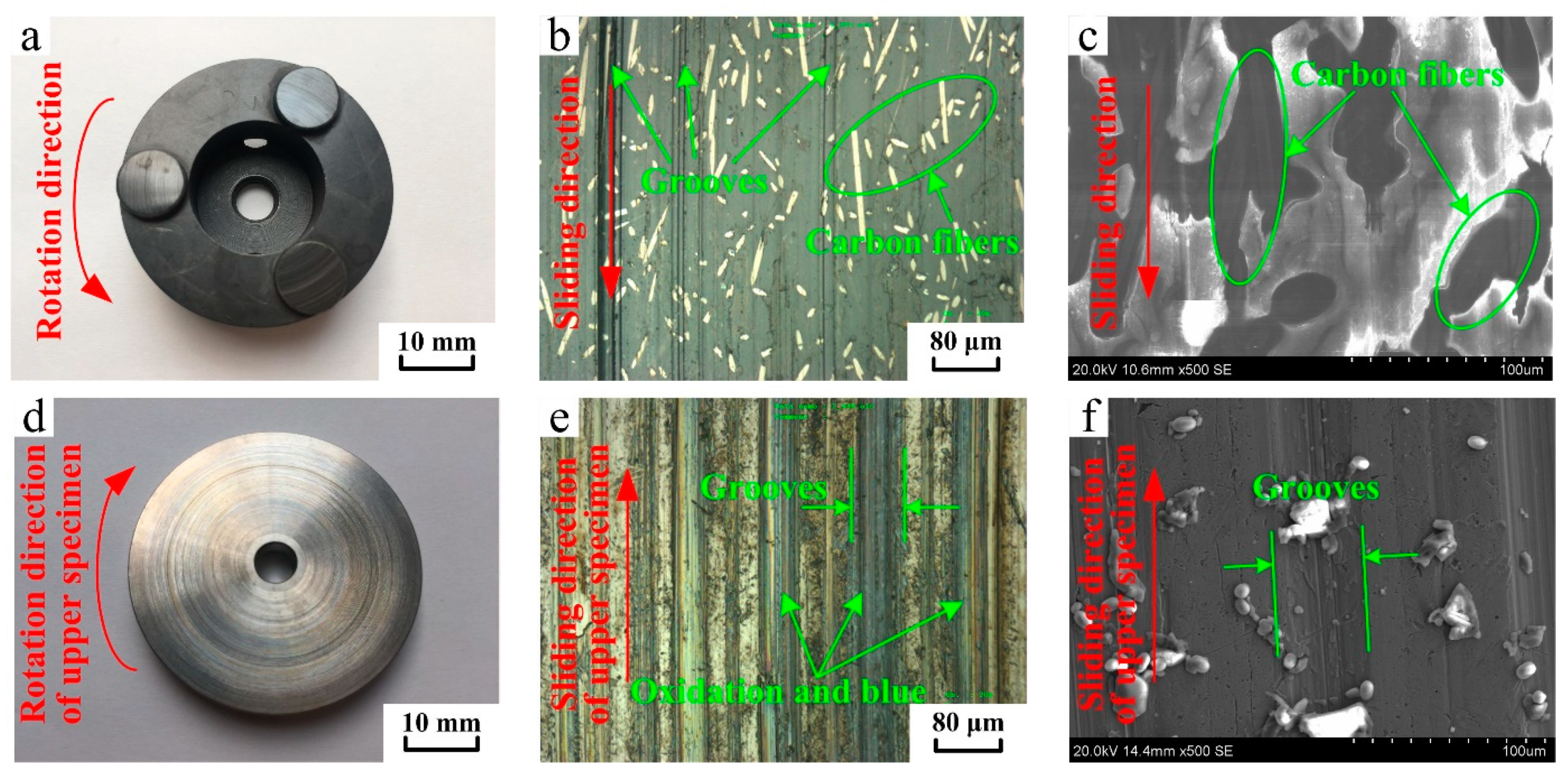

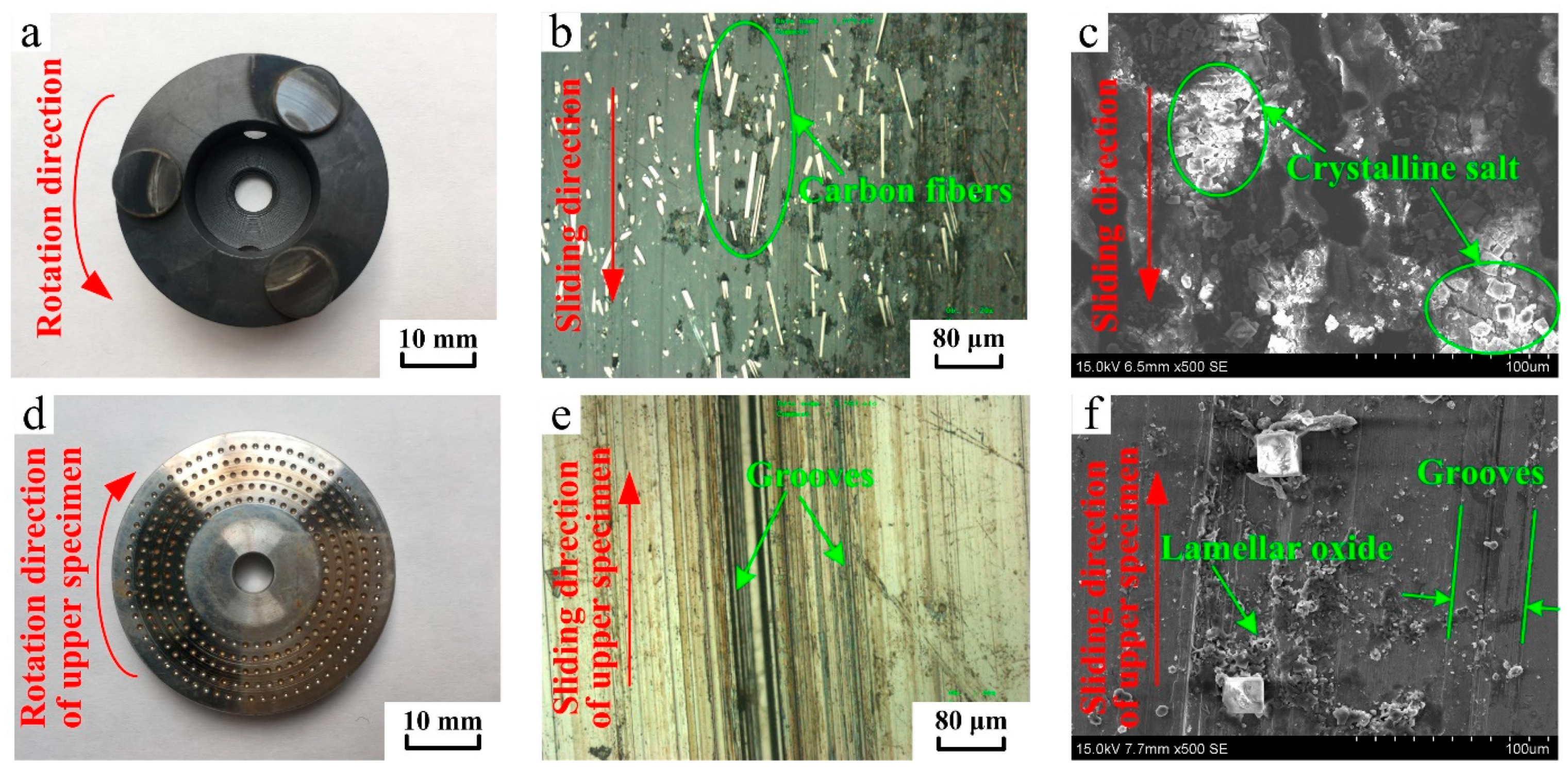

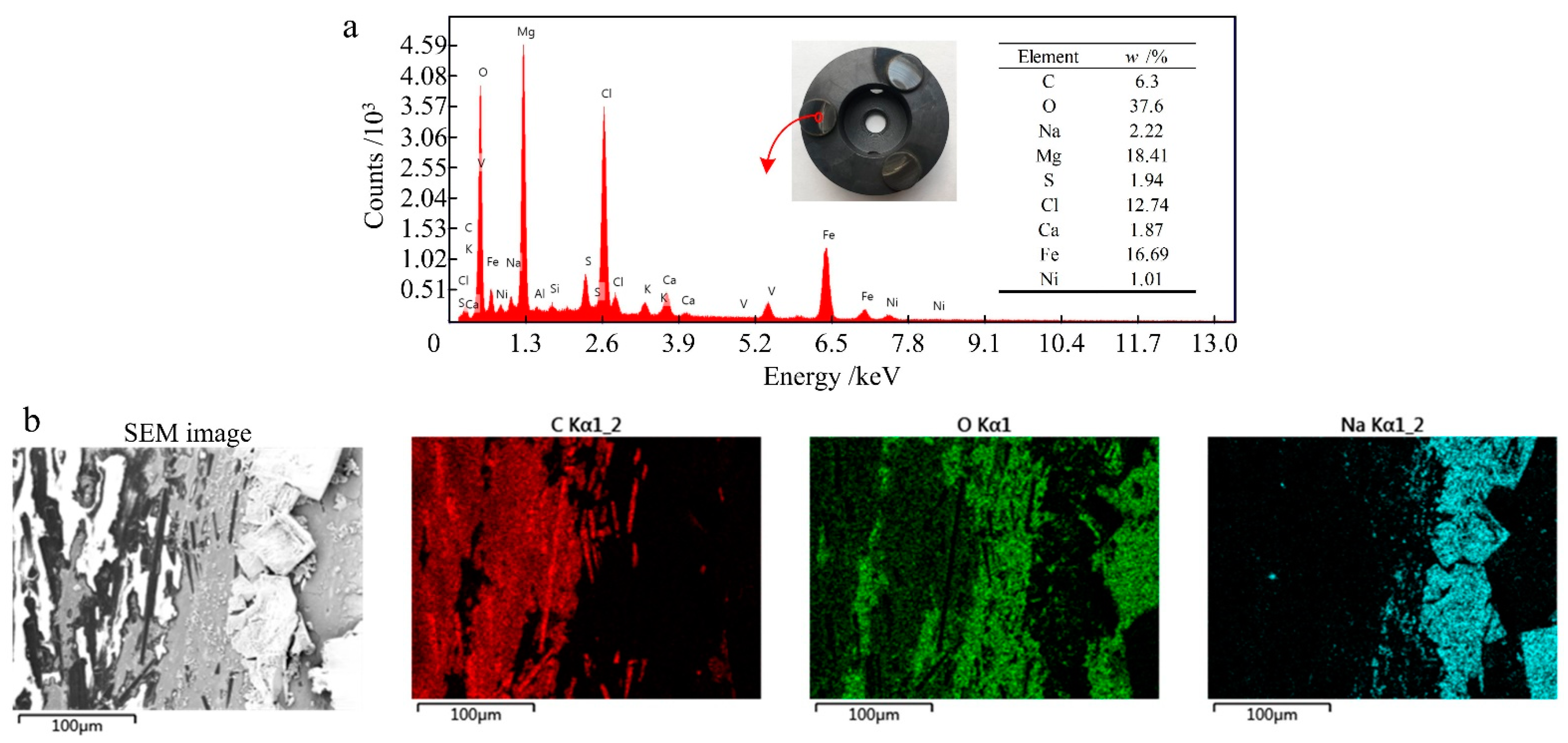

4.5. Effect of Micro-Hemispherical Pit-Textured Surfaces on Friction and Wear Behaviors

4.6. Effect of the Sliding Speed on the Friction and Wear Characteristics

5. Conclusions

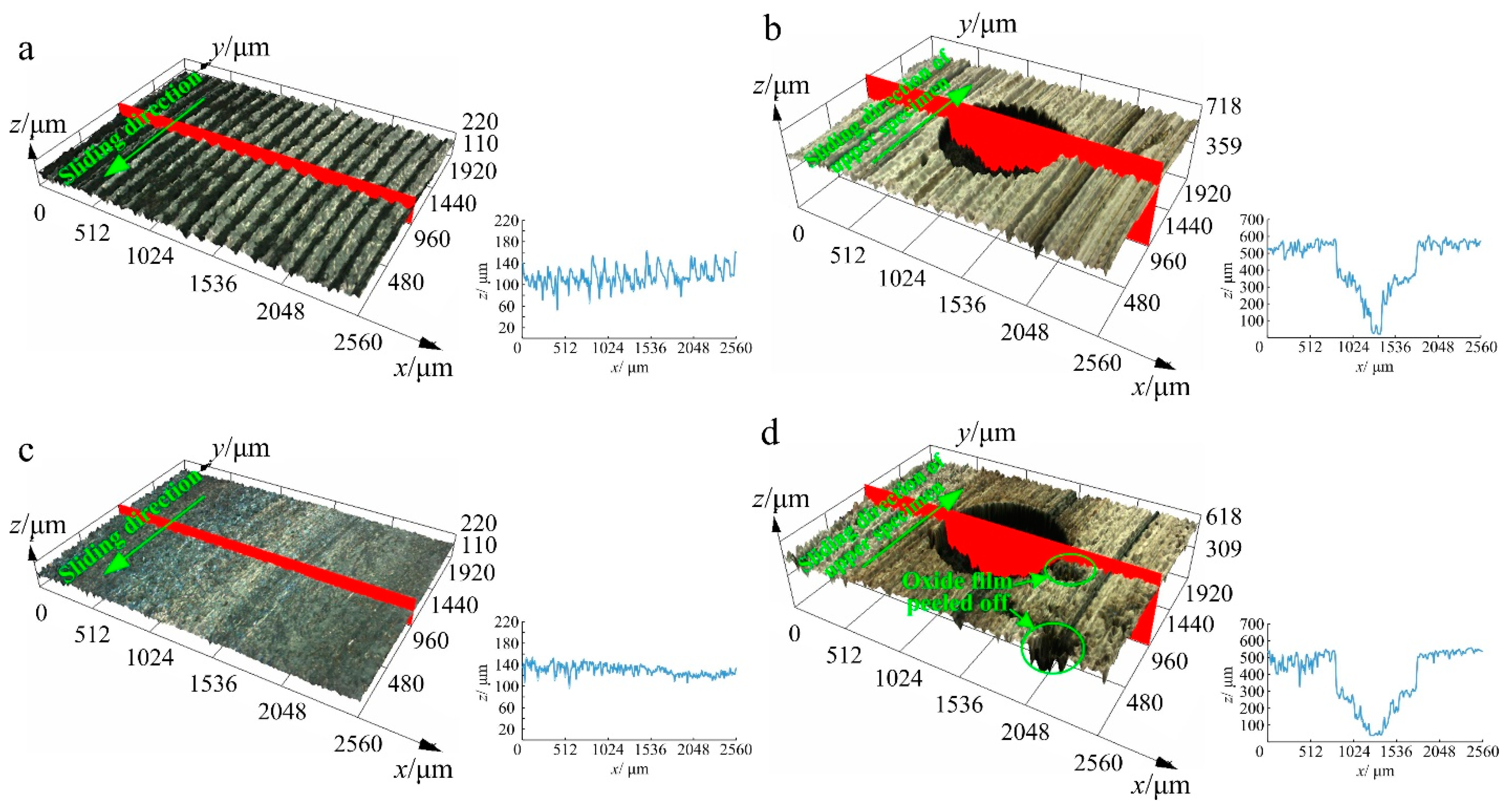

- When the upper specimen rotates relative to the bottom specimen, seawater between the friction surfaces follows the movement, forms a vortex ring flow in the hemispherical pit of the bottom specimen, uses the convergent gap to generate a hydrodynamic effect, produces the bearing capacity, and realizes fluid lubrication. For the smooth-surface friction pair as the compared group, the sliding speed of the upper specimen is only transferred downwards layer by layer in the thickness direction of the seawater film, and no hydrodynamic effect is produced.

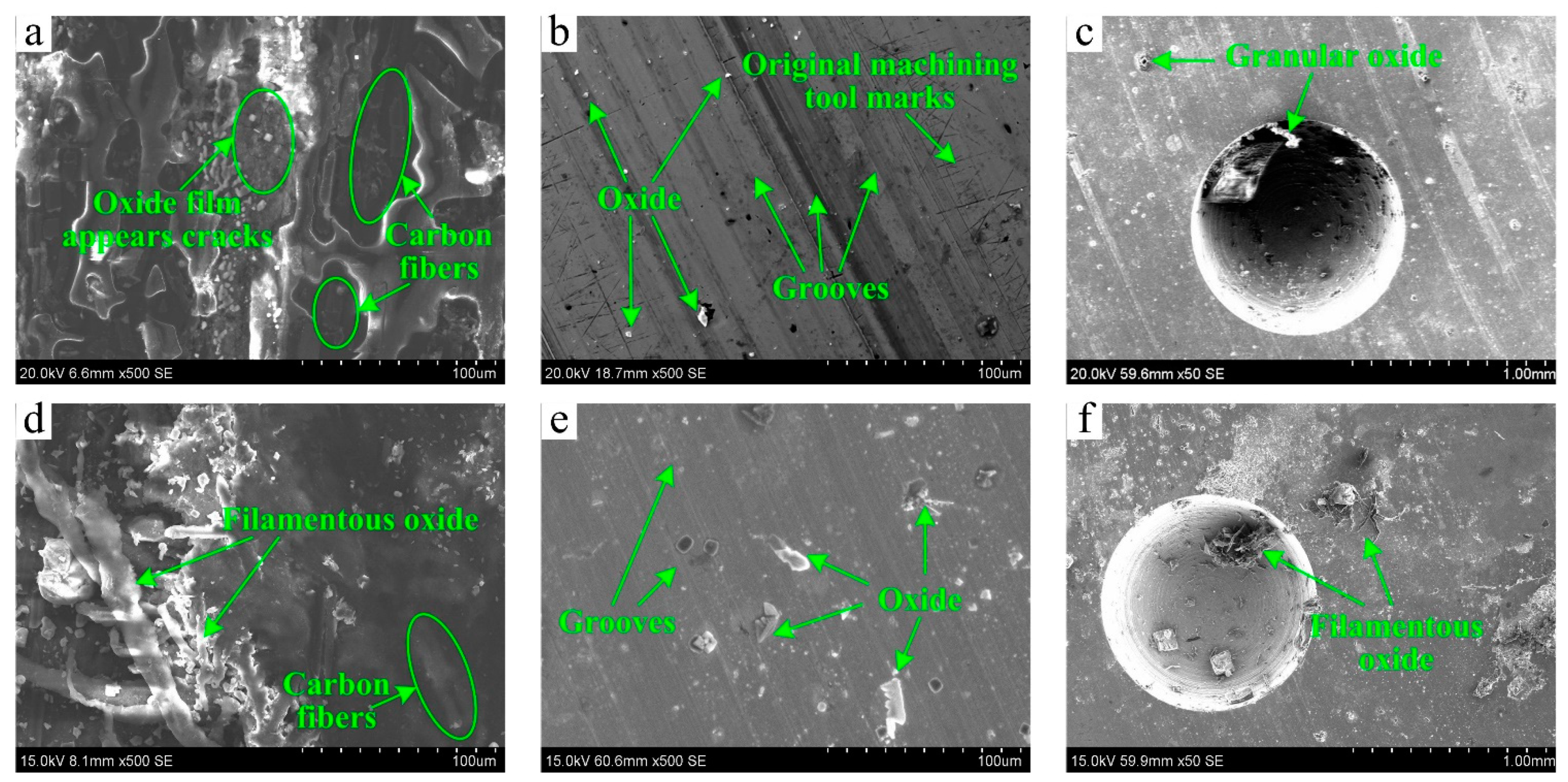

- The hemispherical pits diminish the abrasive wear during the friction process by storing the wear debris, and the main wear forms of the hemispherical-pit surface friction pair are oxidative wear and adhesive wear. The friction coefficient of the hemispherical-pit surface friction pair is 0.018–0.027, and the specimen contact temperature is 40.2–55.1 °C. The effect of drag reduction and anti-wear is significantly improved compared with the smooth-surface friction pair under the same working conditions.

- The hemispherical-pit surface friction pair is in the hydrodynamic lubrication state at rotation speeds ranging from 1000 r/min to 1750 r/min. The total friction coefficient is only determined by the fluid friction coefficient, which increases with the increase of the sliding velocity gradient. As the sliding speed increases, the specimen contact temperature climbs, and the oxidation reaction gradually becomes full. Oxidative wear and adhesive wear alternately play a dominant role in the friction, and the wear rate first decreases and then increases sharply.

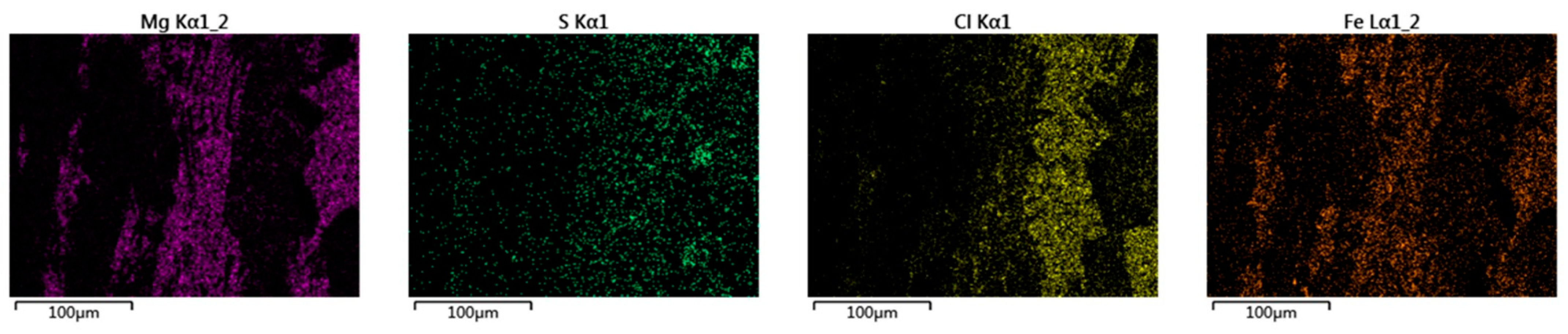

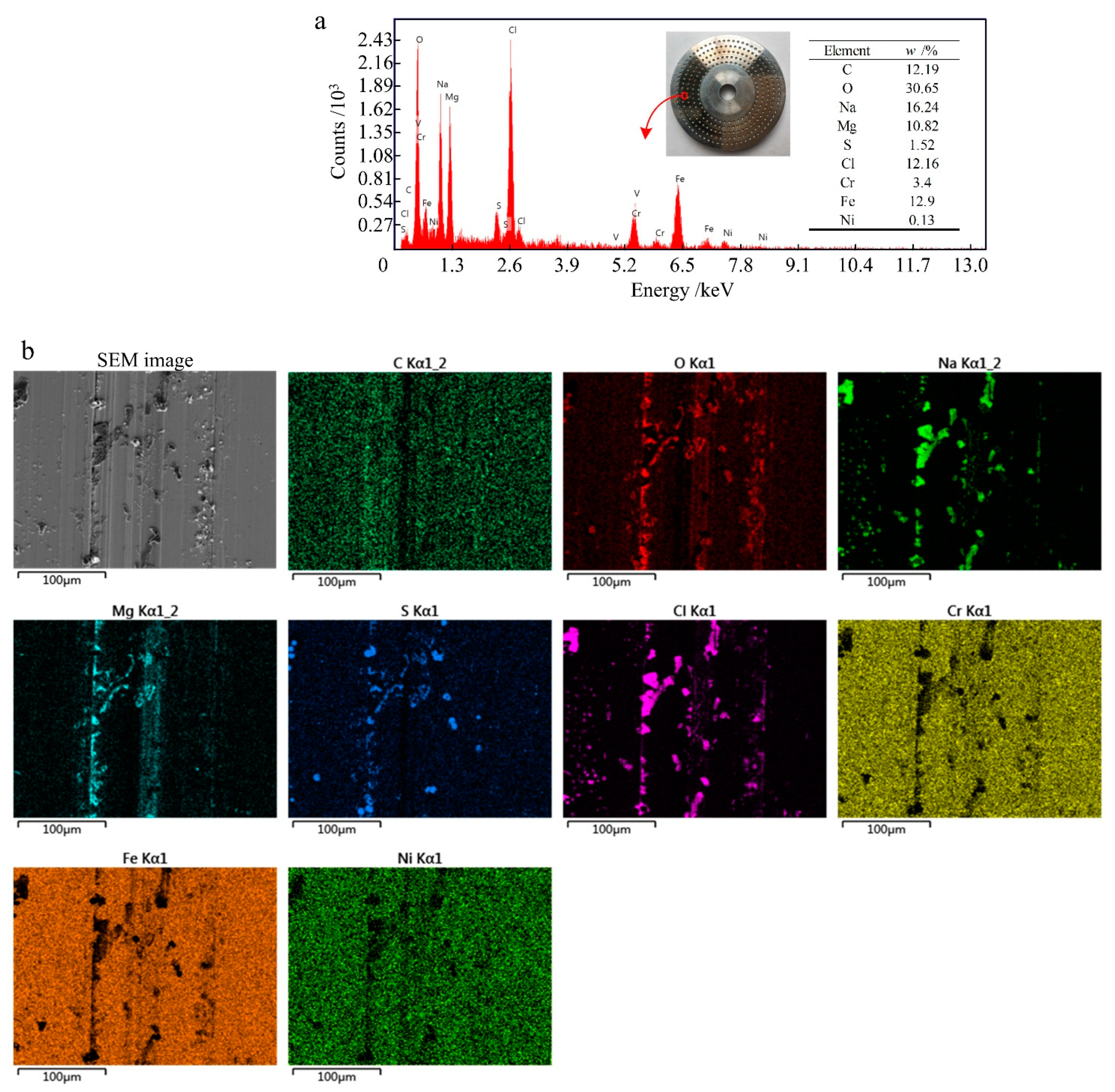

- As the friction progresses and the temperature rises, the surface material of the upper specimen of CF/PEEK undergoes plastic deformation, falls off, and transfers to the surface of the bottom specimen of 316L stainless steel. The temperature rise also induces the oxidation of the 316L stainless steel surface, and a continuous transfer film and oxide film are gradually formed on the surface. The film avoids the direct contact of the friction surface and realizes the self-lubrication of the textured surfaces. Therefore, the friction coefficient of the upper CF/PEEK–bottom 316L friction pair is 41.9–54.5% lower than that of the upper 316L–bottom CF/PEEK friction pair.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, J.R.; Dai, Z.D. Bionics of non-smooth surface (I). Prog. Nat. Sci. 2008, 18, 241–246. [Google Scholar]

- Sun, J.R.; Dai, Z.D. Bionics of non-smooth surface (II). Prog. Nat. Sci. 2008, 18, 727–733. [Google Scholar]

- Andersson, P.; Koskinen, J.; Varjus, S.; Gerbig, Y.; Haefke, H.; Georgiou, S.; Zhmud, B.; Buss, W. Microlubrication effect by laser-textured steel surfaces. Wear 2007, 262, 369–379. [Google Scholar] [CrossRef]

- Costa, H.L.; Hutchings, I.M. Hydrodynamic lubrication of textured steel surfaces under reciprocating sliding conditions. Tribol. Int. 2007, 40, 1227–1238. [Google Scholar] [CrossRef]

- Tang, W.; Zhou, Y.K.; Zhu, H.; Yang, H.F. The effect of surface texturing on reducing the friction and wear of steel under lubricated sliding contact. Appl. Surf. Sci. 2013, 273, 199–204. [Google Scholar] [CrossRef]

- Gu, Y.Q.; Zhao, G.; Zheng, J.X.; Li, Z.Y.; Liu, W.B.; Muhammad, F.K. Experimental and numerical investigation on drag reduction of non-smooth bionic jet surface. Ocean Eng. 2014, 81, 50–57. [Google Scholar] [CrossRef]

- Uddin, M.S.; Liu, Y.W. Design and optimization of a new geometric texture shape for the enhancement of hydrodynamic lubrication performance of parallel slider surfaces. Biosurface Biotribol. 2016, 2, 59–69. [Google Scholar] [CrossRef] [Green Version]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372–373, 21–41. [Google Scholar] [CrossRef]

- Codrignani, A.; Frohnapfel, B.; Magagnato, F.; Schreiber, P.; Schneider, J.; Gumbsch, P. Numerical and experimental investigation of texture shape and position in the macroscopic contact. Tribol. Int. 2018, 122, 46–57. [Google Scholar] [CrossRef]

- Salama, M.E. The Effect of Microroughness on the Performance of Parallel Thrust Bearing; Institute of Mechanical Engineers: London, UK, 1952; pp. 149–158. [Google Scholar]

- Kramer, M.O. Boundary layer stabilization by distributed damping. J. Am. Soc. Nav. Eng. 1960, 74, 25–33. [Google Scholar]

- Hamilton, D.B.; Walowit, J.A.; Allen, C.M. A theory of lubrication by micro-irregularities. Fluids Eng. 1966, 88, 177–185. [Google Scholar]

- Anno, J.N.; Walowit, J.A.; Allen, C.M. Microasperity lubrication. Tribology 1968, 90, 351–355. [Google Scholar] [CrossRef]

- Anno, J.N.; Walowit, J.A.; Allen, C.M. Load support and leakage from microasperity-lubricated face seals. Tribology 1969, 91, 726–731. [Google Scholar] [CrossRef]

- Etsion, I.; Burstein, L. A model for mechanical seals with regular microsurface structure. Tribol. Trans. 1996, 39, 677–683. [Google Scholar] [CrossRef]

- Etsion, I.; Halperin, G.; Greenberg, Y. Increasing mechanical seal life with laser-textured seal faces. In Proceedings of the 15th Internationnal Conference, Maastricht, The Netherlands, 16–18 September 1997; pp. 3–11. [Google Scholar]

- Etsion, I.; Kligerman, Y.; Halperin, G. Analytical and experimental investigation of laser-textured mechanical seal faces. Tribol. Trans. 1999, 42, 511–516. [Google Scholar] [CrossRef]

- Etsion, I. Improving tribological performance of mechanical seals by laser surface texturing. In Proceedings of the 17th International Pump Users Symposium, Houston, TX, USA, 6–9 March 2000; pp. 17–22. [Google Scholar]

- Etsion, I. State of the art in laser surface texturing. J. Tribol. 2005, 127, 248–253. [Google Scholar] [CrossRef]

- Brizmer, V.; Kligerman, Y.; Etsion, I. A laser surface textured parallel thrust bearing. Tribol. Trans. 2003, 46, 397–403. [Google Scholar] [CrossRef]

- Etsion, I.; Sher, E. Improving fuel efficiency with laser surface textured piston rings. Tribol. Int. 2009, 42, 542–547. [Google Scholar] [CrossRef]

- Ren, L.Q.; Wang, Z.Z.; Han, Z.W. Experimental research on sliding wear of bionic nonsmoothed surface. Trans. Chin. Soc. Agric. Mach. 2003, 34, 86–92. [Google Scholar]

- Wakuda, M.; Yamauchi, Y.; Kanzaki, S.; Yasuda, Y. Effect of surface texturing on friction reduction between ceramic and steel materials under lubricated sliding contact. Wear 2003, 254, 356–363. [Google Scholar] [CrossRef]

- Yang, Z.J.; Han, Z.W.; Ren, L.Q. Friction and wear behavior of bionic non-smooth surfaces at high temperature. Tribology 2005, 25, 374–378. [Google Scholar]

- Wang, X.L.; Adachi, K.; Otsuka, K.; Kato, K. Optimization of the surface texture for silicon carbide sliding in water. Appl. Surf. Sci. 2006, 253, 1282–1286. [Google Scholar] [CrossRef]

- Chen, K.; Wang, Y.; Cao, K.Y.; Song, X.W. Analysis of aerodynamic drag reduction on automobile by using bionic non-smooth surface. China Mech. Eng. 2011, 23, 1001–1006. [Google Scholar]

- Wang, Z.Q.; Gao, D.R. Friction and wear properties of stainless steel sliding against polyetheretherketone and carbon-fiber-reinforced polyetheretherketone under natural seawater lubrication. Mater. Des. 2014, 53, 881–887. [Google Scholar] [CrossRef]

- Wu, S.F.; Gao, D.R.; Liang, Y.N.; Chen, B. Influence of non-smooth surface on tribological properties of glass fiber-epoxy resin composite sliding against stainless steel under natural seawater lubrication. Chin. J. Mech. Eng. 2015, 28, 1171–1176. [Google Scholar] [CrossRef]

- Yang, H.Y.; Zhou, H. Some key problems of the water hydraulics. Chin. J. Mech. Eng. 2002, 38, 96–100. [Google Scholar] [CrossRef]

- Lachner, H. Hydrostatic lagerungen in axialkolbenmachine. Hydraul. Pneum. 1974, 18, 605–611. [Google Scholar]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China; Standardization Administration of the People’s Republic of China. GB 17378.4-2007. The Specifications for Marine Monitoring-Part 4: Seawater Analysis; Standards Press of China: Beijing, China, 2008.

- Wen, S.Z.; Huang, P.; Tian, Y.; Ma, L.R. Principles of Tribology; Tsinghua University Press: Beijing, China, 2018. [Google Scholar]

- Liang, Y.N.; Gao, D.R.; Zhao, J.H. Tribological properties of friction pair between 316L stainless steel and CF/PEEK with nonsmooth surface under seawater lubrication. Tribol. Trans. 2020, 63, 658–671. [Google Scholar] [CrossRef]

- Liang, Y.N.; Gao, D.R.; Chen, B.; Zhao, J.H. Friction and wear study on friction pairs with a biomimetic non-smooth surface of 316L relative to CF/PEEK under a seawater lubricated condition. Chin. J. Mech. Eng. 2019, 32, 66. [Google Scholar] [CrossRef] [Green Version]

| Property | Standard | Value |

|---|---|---|

| Density ρ/(g/cm3) | ISO 1183 | 1.4 |

| Water absorption (25 °C, 24 h) W/% | ISO 62 | 0.06 |

| Rockwell hardness HRR | ASTM D785 | 107 |

| Heat deflection temperature HDT/°C | ASTM D648 | 315 |

| Thermal expansion coefficient α/(10–5/°C) | ASTM D696 | 1.5 |

| Tensile strength (23 °C) σb/MPa | ISO 527-2/1B/50 | 220 |

| Bending strength (23 °C) σbb/MPa | ISO 178 | 298 |

| Compression strength (23 °C) σbc/MPa | ASTM D695 | 240 |

| Element | C | Si | Mn | S | P | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|---|

| w/% | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.03 | ≤0.045 | 16.0–18.0 | 10.0–14.0 | 2.0–3.0 |

| Property | Standard | Value |

|---|---|---|

| Density ρ/(g/cm3) | GB/T 20878-2007 | 8.03 |

| Elastic modulus E/GPa | 206 | |

| Brinell hardness HB | 230 | |

| Elongation δ/% | 30 | |

| Thermal conductivity λ/(W/(m·k)) | 16.3 | |

| Thermal expansion coefficient α/(10–6/°C) | 16.0 | |

| Tensile strength σb/MPa | 620 | |

| Yield strength σs/MPa | 310 |

| Element | Average Concentration /(g/kg Seawater) | Element | Average Concentration /(g/kg Seawater) |

|---|---|---|---|

| Na | 10.77 | Cl | 19.354 |

| K | 0.399 | S | 0.904 |

| Ca | 0.412 | Br | 0.067 |

| Mg | 1.29 | C | 0.0276 |

| Sr | 0.0079 | F | 0.0013 |

| Friction Pair | Rotation Speed n/(r/min) | Sliding Speed v/(m/s) | Load P/N | Time t/s | Temperature T/°C | |

|---|---|---|---|---|---|---|

| 1 | Bottom specimen with smooth surface Bottom specimen with hemispherical-pit surface | 1000 | 1.57 | 300 | 10,800 | 22–26 (room) |

| 2 | 1250 | 1.96 | ||||

| 3 | 1500 | 2.36 | ||||

| 4 | 1750 | 2.75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Y.; Gao, J.; Gao, D.; Sun, Y.; Zhang, Z.; Zhao, J. Effect of Micro-Textured Surfaces and Sliding Speed on the Lubrication Mechanism and Friction-Wear Characteristics of CF/PEEK Rubbing against 316L Stainless Steel under Seawater Lubrication. Appl. Sci. 2021, 11, 9915. https://doi.org/10.3390/app11219915

Liang Y, Gao J, Gao D, Sun Y, Zhang Z, Zhao J. Effect of Micro-Textured Surfaces and Sliding Speed on the Lubrication Mechanism and Friction-Wear Characteristics of CF/PEEK Rubbing against 316L Stainless Steel under Seawater Lubrication. Applied Sciences. 2021; 11(21):9915. https://doi.org/10.3390/app11219915

Chicago/Turabian StyleLiang, Yingna, Jianxin Gao, Dianrong Gao, Yanan Sun, Zongyi Zhang, and Jianhua Zhao. 2021. "Effect of Micro-Textured Surfaces and Sliding Speed on the Lubrication Mechanism and Friction-Wear Characteristics of CF/PEEK Rubbing against 316L Stainless Steel under Seawater Lubrication" Applied Sciences 11, no. 21: 9915. https://doi.org/10.3390/app11219915

APA StyleLiang, Y., Gao, J., Gao, D., Sun, Y., Zhang, Z., & Zhao, J. (2021). Effect of Micro-Textured Surfaces and Sliding Speed on the Lubrication Mechanism and Friction-Wear Characteristics of CF/PEEK Rubbing against 316L Stainless Steel under Seawater Lubrication. Applied Sciences, 11(21), 9915. https://doi.org/10.3390/app11219915