Optimization Design of the Lower Rocker Arm of a Vertical Roller Mill Based on ANSYS Workbench

Abstract

:1. Introduction

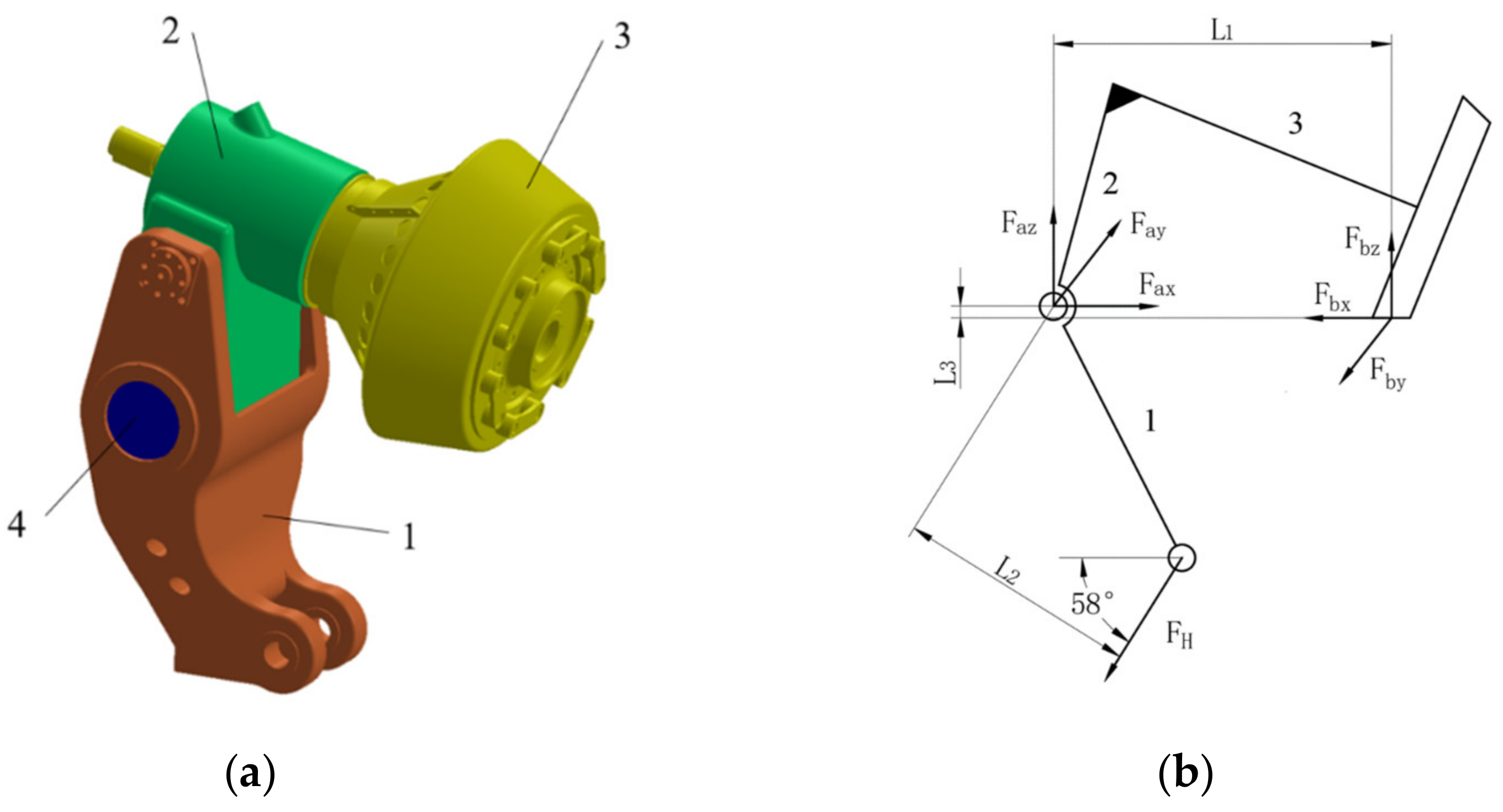

2. Finite Element Analysis

2.1. Modeling and Meshing

2.2. Load Calculation

2.3. Applying Boundary Conditions

2.4. Static Analysis

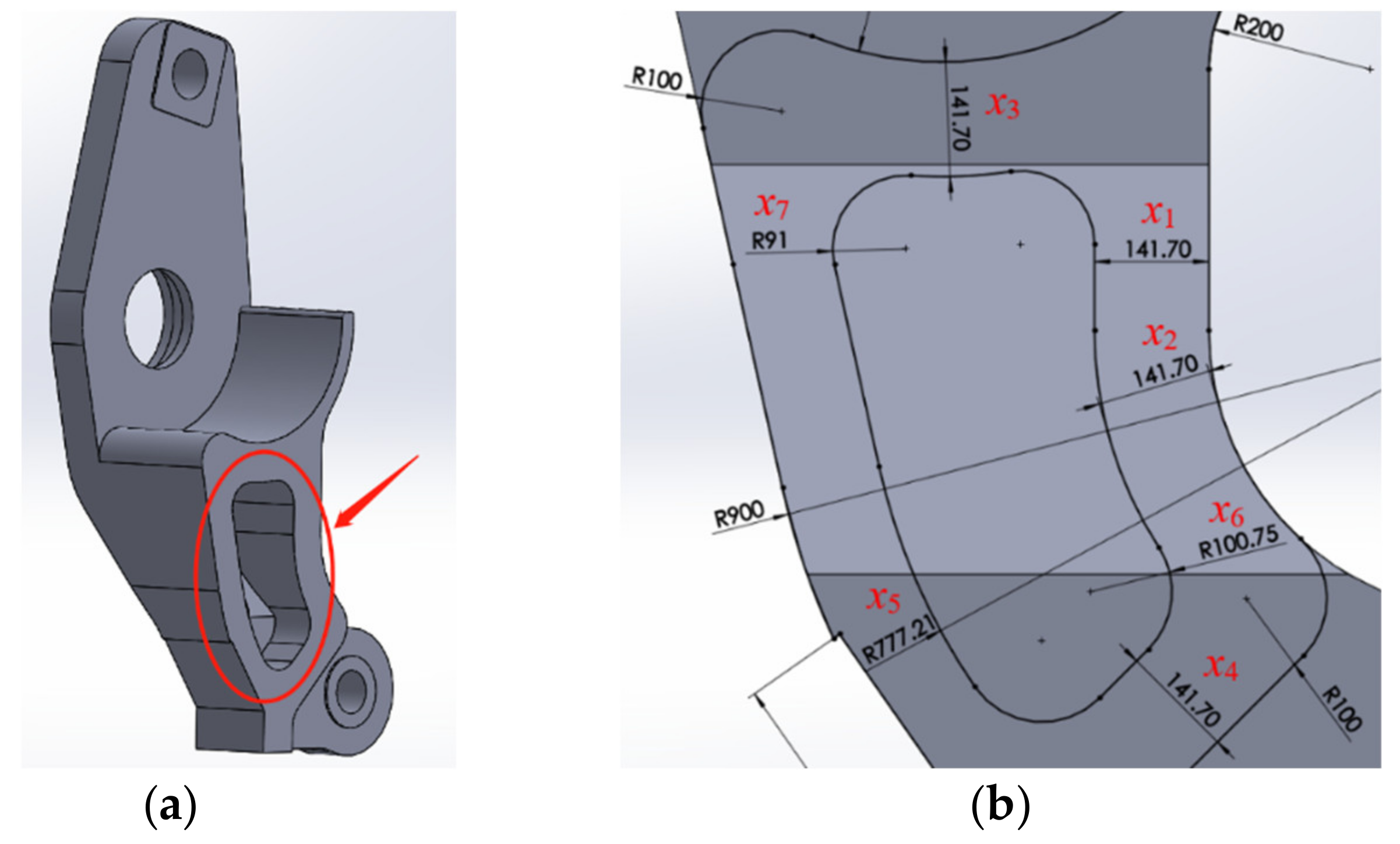

3. Optimum Design of Response Surface Analysis Method

3.1. Mathematical Model of Optimal Design

705.0 mm ≤ x5 ≤ 849.4 mm

94.5 mm ≤ x6 ≤ 107.0 mm

163.8 mm ≤ x7 ≤ 200.2 mm

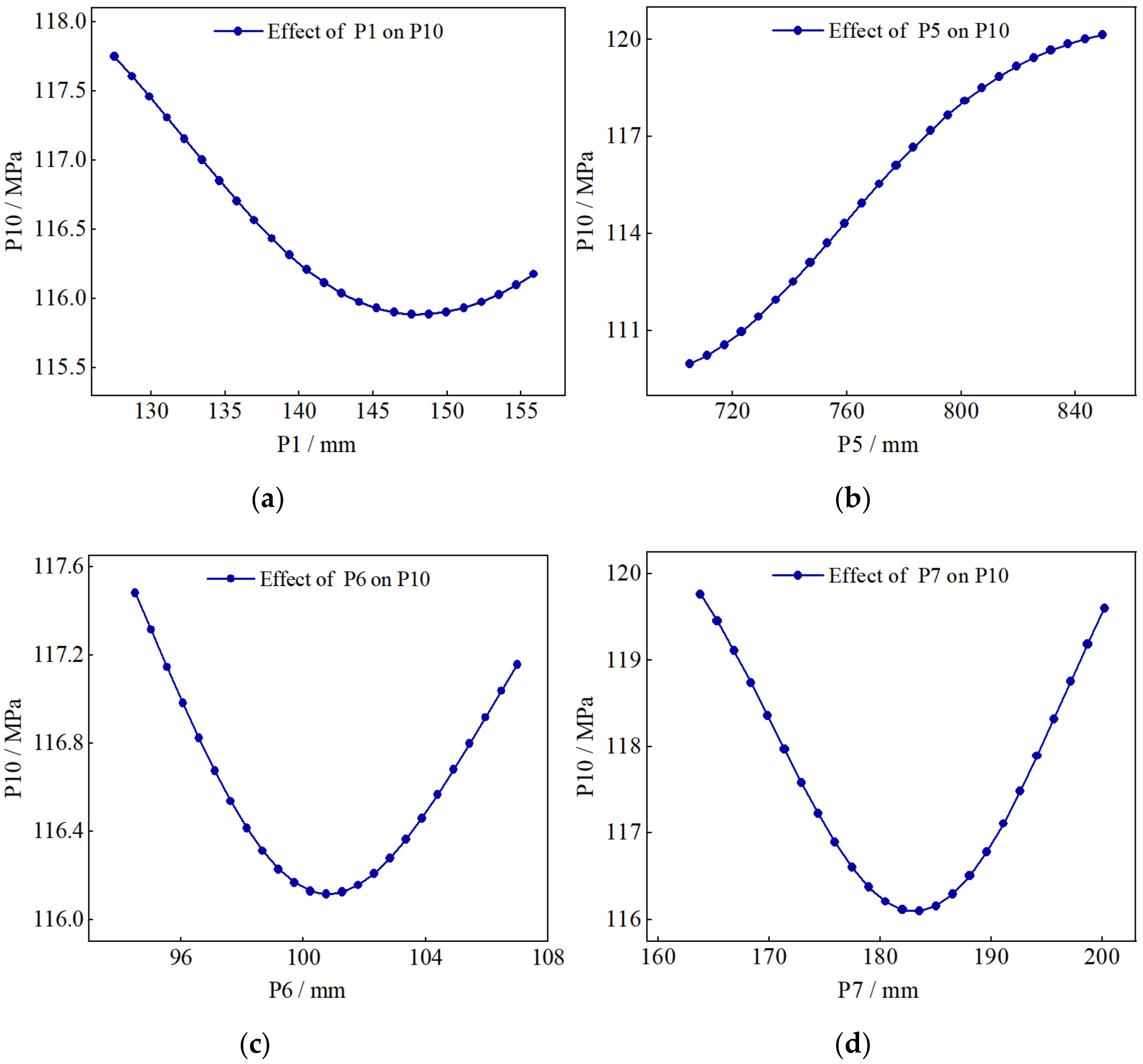

3.2. Optimization of the Response Surface

3.3. Selection of the Optimized Scheme

3.4. Comparison of Results before and after Optimization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schaefer, H.U. Loesche vertical roller mills for the comminution of ores and minerals. Miner. Eng. 2001, 14, 1155–1160. [Google Scholar] [CrossRef]

- Altun, D.; Benzer, H.; Aydogan, N.; Gerold, C. Operational parameters affecting the vertical roller mill performance. Miner. Eng. 2017, 103, 67–71. [Google Scholar] [CrossRef]

- Tontu, M. An investigation of performance characteristics and energetic efficiency of vertical roller coal mill. Int. J. COAL Prep. Util. 2021, 41, 248–262. [Google Scholar] [CrossRef]

- Wei, W.; Peng, Y.; Du, L.; Li, Y.; Cai, Y.; Chen, Z. Finite element analysis of the rolling ring and riding wheel for cement rotary kiln. UPB Sci. Bull. Ser. D Mech. Eng. 2019, 81, 253–266. [Google Scholar]

- Li, C.; Wang, Y.; Chen, J.; You, J.; Rajnathsing, H. Fault diagnosis in a gyroscope-based six-axis accelerometer. Trans. FAMENA 2018, 42, 103–114. [Google Scholar] [CrossRef]

- Wei, W.; Zhu, H.; Li, Y.; Jin, P. Finite element analysis of the vertical roller mill based on ANSYS Workbench. Int. J. Eng. Syst. Model. Simul. 2019, 11, 102–111. [Google Scholar] [CrossRef]

- Chen, J.; Jiang, H.; Fu, Y.; Qian, N. Heat Transfer Performance of an Axially Rotating Heat Pipe for Cooling of Grinding. Energy 2020, 13, 5745. [Google Scholar] [CrossRef]

- Zhang, Z.; Ibhadode, O.; Ali, U.; Dibia, C.F.; Rahnama, P.; Bonakdar, A.; Toyserkani, E. Topology optimization parallel-computing framework based on the inherent strain method for support structure design in laser powder-bed fusion additive manufacturing. Int. J. Mech. Mater. Des. 2020, 16, 897–923. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, R.; Jin, M. Experimental study of ZG 270–500 material characteristics under strain control modes. J. Yanshan Univ. 2019, 43, 449–454. (In Chinese) [Google Scholar] [CrossRef]

- Xu, X.; Quan, L.; Li, B.; Guo, J. Modeling, Simulation and Experiment of Electro-hydraulic Screw Down Servo System of Seamless Tube Rolling Mill. Chin. J. Mech. Eng. 2011, 24, 113–120. [Google Scholar] [CrossRef]

- Heidari, A.; Forouzan, M.R.; Akbarzadeh, S. Effect of Friction on Tandem Cold Rolling Mills Chattering. ISIJ Int. 2014, 54, 2349–2356. [Google Scholar] [CrossRef] [Green Version]

- Zhao, D. Finite Element Analysis on Rocker Arms of Vertical Roller Mill. Sci. Technol. Rev. 2013, 31, 53–56. [Google Scholar] [CrossRef]

- Hoon, H.; Ho, K.S. Optimum Process Design in Sheet-Metal Forming with Finite Element Analysis. J. Eng. Mater. Technol. 2001, 123, 476–481. [Google Scholar] [CrossRef]

- Feng, R.; Wang, T.; Dai, S.; Chen, Y.; Qiu, L. Comparison of Four Methods on Optimizing Conditions by Using the Central Composite Design. Chin. J. Health Stat. 2014, 31, 387–389. (In Chinese) [Google Scholar]

- Kitayama, S.; Yamazaki, K. Sequential approximate robust design optimization using radial basis function network. Int. J. Mech. Mater. Des. 2014, 10, 313–328. [Google Scholar] [CrossRef]

- Ismail, A.Y.; Na, G.; Koo, B. Topology and Response Surface Optimization of a Bicycle Crank Arm with Multiple Load Cases. Appl. Sci. 2020, 10, 2201. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.; Hsieh, C. Influence analysis in response surface methodology. J. Stat. Plan. Inference 2014, 147, 188–203. [Google Scholar] [CrossRef]

- Serageldin, A.A.; Radwan, A.; Katsura, T.; Sakata, Y.; Nagasaka, S.; Nagano, K. Parametric analysis, response surface, sensitivity analysis, and optimization of a novel spiral-double ground heat exchanger. Energy Convers. Manag. 2021, 240, 114251. [Google Scholar] [CrossRef]

- Lee, D.; Lee, J. Structural optimization concept for the design of an aluminium control arm. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2003, 217, 647–656. [Google Scholar] [CrossRef]

- Meziane-Tani, I.; Métris, G.; Lion, G.; Deschamps, A.; Bendimerad, F.T.; Bekhti, M. Optimization of small satellite constellation design for continuous mutual regional coverage with multi-objective genetic algorithm. Int. J. Comput. Intell. Syst. 2016, 9, 627–637. [Google Scholar] [CrossRef] [Green Version]

- Balaguru, S.; Natarajan, E.; Ramesh, S.; Muthuvijayan, B. Structural and modal Analysis of Scooter Frame for Design Improvement. Mater. Today Proc. 2019, 16, 1106–1116. [Google Scholar] [CrossRef]

| Name | P1/mm | P5/mm | P6/mm | P7/mm |

|---|---|---|---|---|

| Initial value | 142 | 777 | 100 | 182 |

| Constraint range | [127.5, 155.8] | [705, 849.4] | [94.5, 107.0] | [163.8, 200.2] |

| P1/mm | P5/mm | P6/mm | P7/mm | P8/kg | P9/MPa | P10/mm |

|---|---|---|---|---|---|---|

| 141.70 | 777.21 | 100.75 | 182.00 | 6552.52 | 1.08 | 116.29 |

| 127.53 | 777.21 | 100.75 | 182.00 | 6468.43 | 1.10 | 117.92 |

| 155.87 | 777.21 | 100.75 | 182.00 | 6634.06 | 1.08 | 116.35 |

| 141.70 | 705.00 | 100.75 | 182.00 | 6791.69 | 1.08 | 106.32 |

| 141.70 | 849.42 | 100.75 | 182.00 | 6293.10 | 1.12 | 120.32 |

| 141.70 | 777.21 | 94.50 | 182.00 | 6551.01 | 1.09 | 117.66 |

| 141.70 | 777.21 | 107.00 | 182.00 | 6554.16 | 1.09 | 117.33 |

| 141.70 | 777.21 | 100.75 | 163.80 | 6545.18 | 1.09 | 119.94 |

| 141.70 | 777.21 | 100.75 | 200.20 | 6560.37 | 1.10 | 119.78 |

| 131.72 | 726.36 | 96.35 | 169.18 | 6662.58 | 1.10 | 116.65 |

| 151.68 | 726.36 | 96.35 | 169.18 | 6769.89 | 1.07 | 121.33 |

| 131.72 | 828.06 | 96.35 | 169.18 | 6301.74 | 1.14 | 121.14 |

| 151.68 | 828.06 | 96.35 | 169.18 | 6428.00 | 1.11 | 125.95 |

| 131.72 | 726.36 | 105.15 | 169.18 | 6664.81 | 1.09 | 119.11 |

| 151.68 | 726.36 | 105.15 | 169.18 | 6772.20 | 1.08 | 120.06 |

| 131.72 | 828.06 | 105.15 | 169.18 | 6303.89 | 1.12 | 116.16 |

| 151.68 | 828.06 | 105.15 | 169.18 | 6430.20 | 1.11 | 120.12 |

| 131.72 | 726.36 | 96.35 | 194.82 | 6672.33 | 1.09 | 120.10 |

| 151.68 | 726.36 | 96.35 | 194.82 | 6779.55 | 1.08 | 120.43 |

| 131.72 | 828.06 | 96.35 | 194.82 | 6313.55 | 1.12 | 116.71 |

| 151.68 | 828.06 | 96.35 | 194.82 | 6439.76 | 1.11 | 108.72 |

| 131.72 | 726.36 | 105.15 | 194.82 | 6674.57 | 1.09 | 118.98 |

| 151.68 | 726.36 | 105.15 | 194.82 | 6781.86 | 1.08 | 109.79 |

| 131.72 | 828.06 | 105.15 | 194.82 | 6315.70 | 1.12 | 125.58 |

| 151.68 | 828.06 | 105.15 | 194.82 | 6441.96 | 1.11 | 125.87 |

| Parameter | First Group | Second Group | Third Group |

|---|---|---|---|

| P1/mm | 129.03 | 129.01 | 129 |

| P5/mm | 848.34 | 848.16 | 848.16 |

| P6/mm | 98.441 | 98.446 | 101.52 |

| P7/mm | 168.48 | 168.32 | 168.35 |

| P8/kg | 6206.2 | 6206.2 | 6207.4 |

| P9/mm | 1.1469 | 1.1474 | 1.1404 |

| P10/MPa | 119.86 | 119.93 | 117.77 |

| Input Variable | Value before Optimization/mm | Optimized Initial Value/mm | Optimized Rounded Value/mm |

|---|---|---|---|

| P1 | 142 | 129.03 | 129 |

| P5 | 777 | 848.34 | 848 |

| P6 | 100 | 98.441 | 98 |

| P7 | 182 | 168.48 | 168 |

| Variable | Value before Optimization | Initial Value after Optimization | Actual Value after Optimization | Amplitude of Change |

|---|---|---|---|---|

| P8/kg | 6552.5 | 6206.2 | 6206.2 | −5.285% |

| P9/MPa | 116.29 | 119.86 | 119.18 | +2.485% |

| P10/mm | 1.0802 | 1.1469 | 1.1475 | +6.230% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, W.; Shen, J.; Yu, H.; Chen, B.; Wei, Y. Optimization Design of the Lower Rocker Arm of a Vertical Roller Mill Based on ANSYS Workbench. Appl. Sci. 2021, 11, 10408. https://doi.org/10.3390/app112110408

Wei W, Shen J, Yu H, Chen B, Wei Y. Optimization Design of the Lower Rocker Arm of a Vertical Roller Mill Based on ANSYS Workbench. Applied Sciences. 2021; 11(21):10408. https://doi.org/10.3390/app112110408

Chicago/Turabian StyleWei, Weihua, Jicheng Shen, Haipeng Yu, Bingrui Chen, and Yu Wei. 2021. "Optimization Design of the Lower Rocker Arm of a Vertical Roller Mill Based on ANSYS Workbench" Applied Sciences 11, no. 21: 10408. https://doi.org/10.3390/app112110408

APA StyleWei, W., Shen, J., Yu, H., Chen, B., & Wei, Y. (2021). Optimization Design of the Lower Rocker Arm of a Vertical Roller Mill Based on ANSYS Workbench. Applied Sciences, 11(21), 10408. https://doi.org/10.3390/app112110408