Thin Film Gas Sensors Based on Planetary Ball-Milled Zinc Oxide Nanoinks: Effect of Milling Parameters on Sensing Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

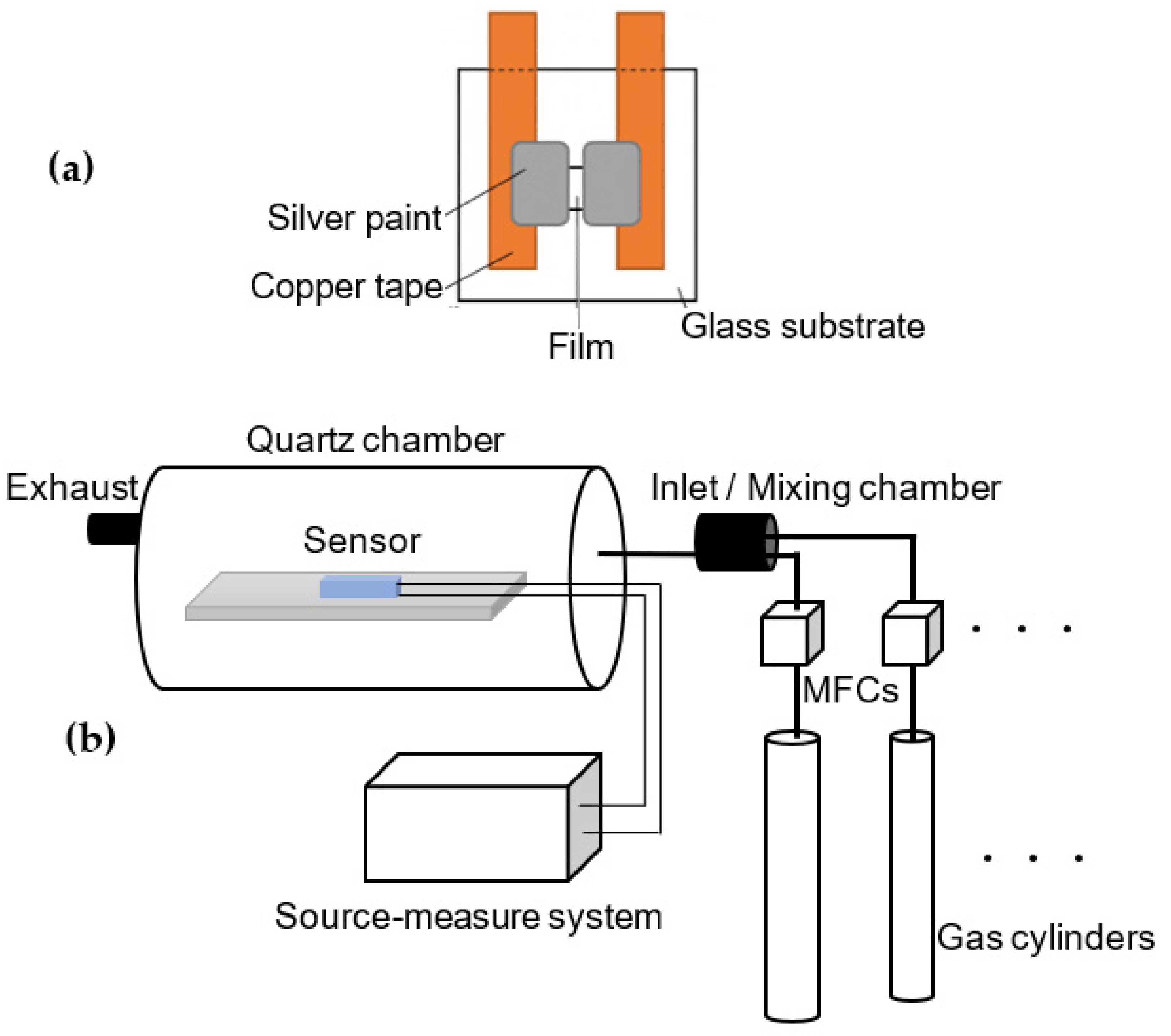

2.2. Preparation of Nanostructured Thin Films and Sensor Fabrication

2.3. Sensor Characterization

3. Results and Discussion

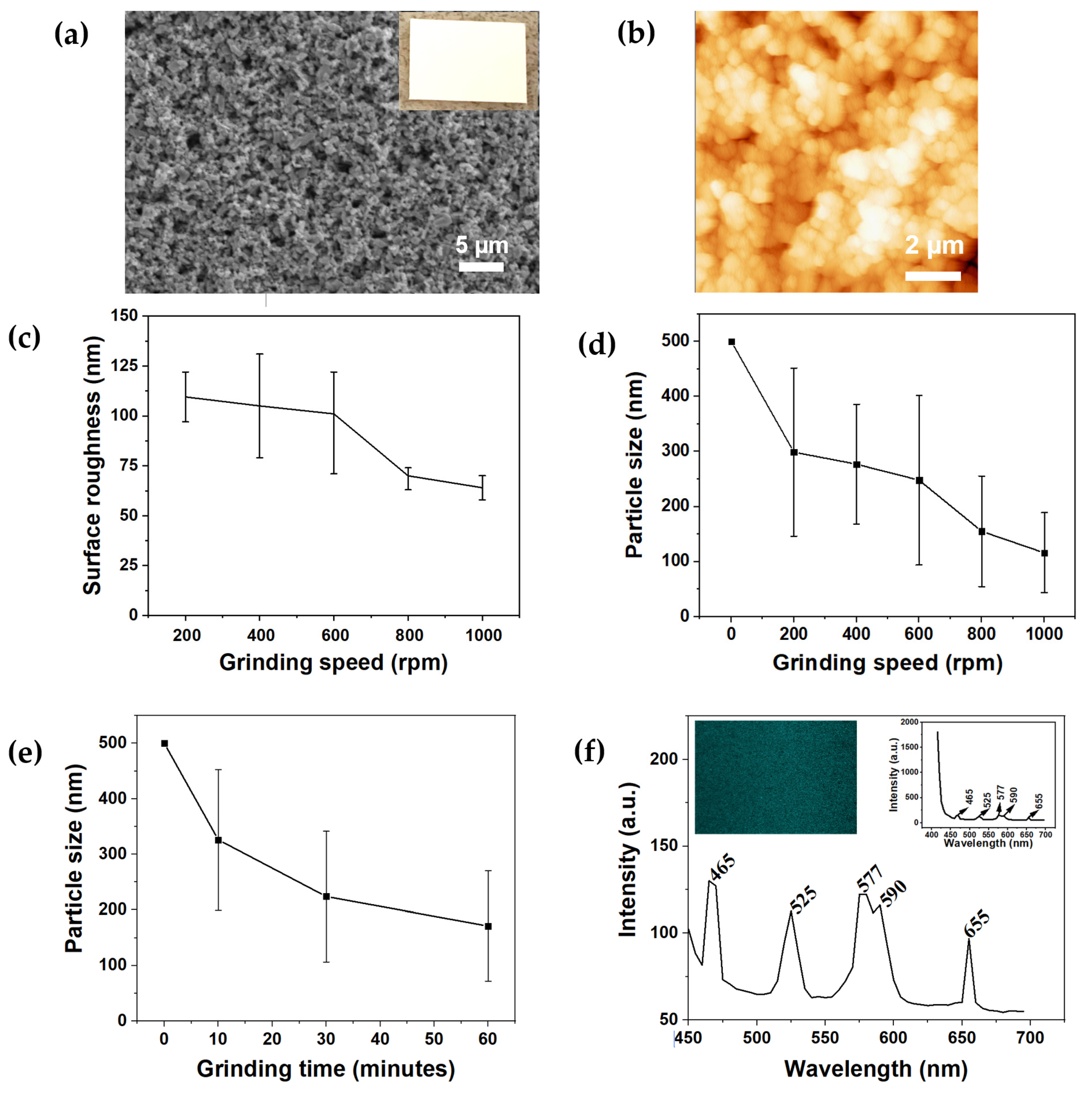

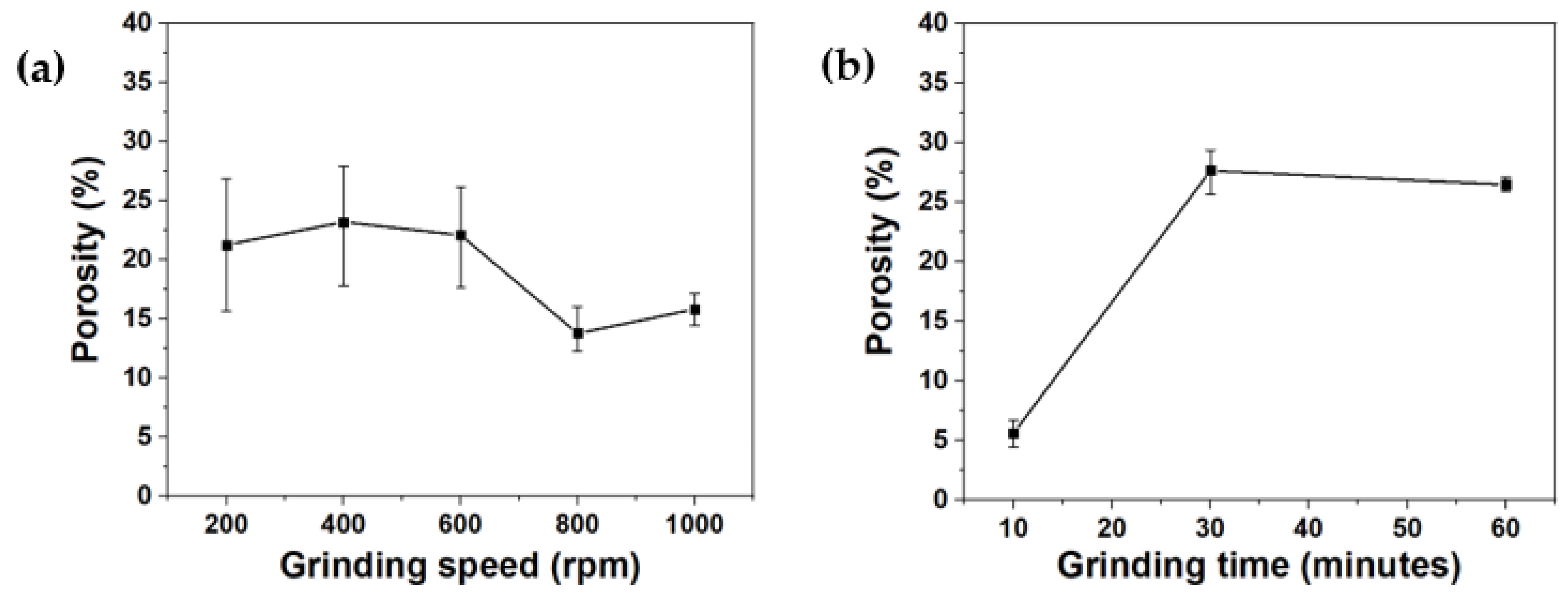

3.1. Film Morphology and Material Characterization

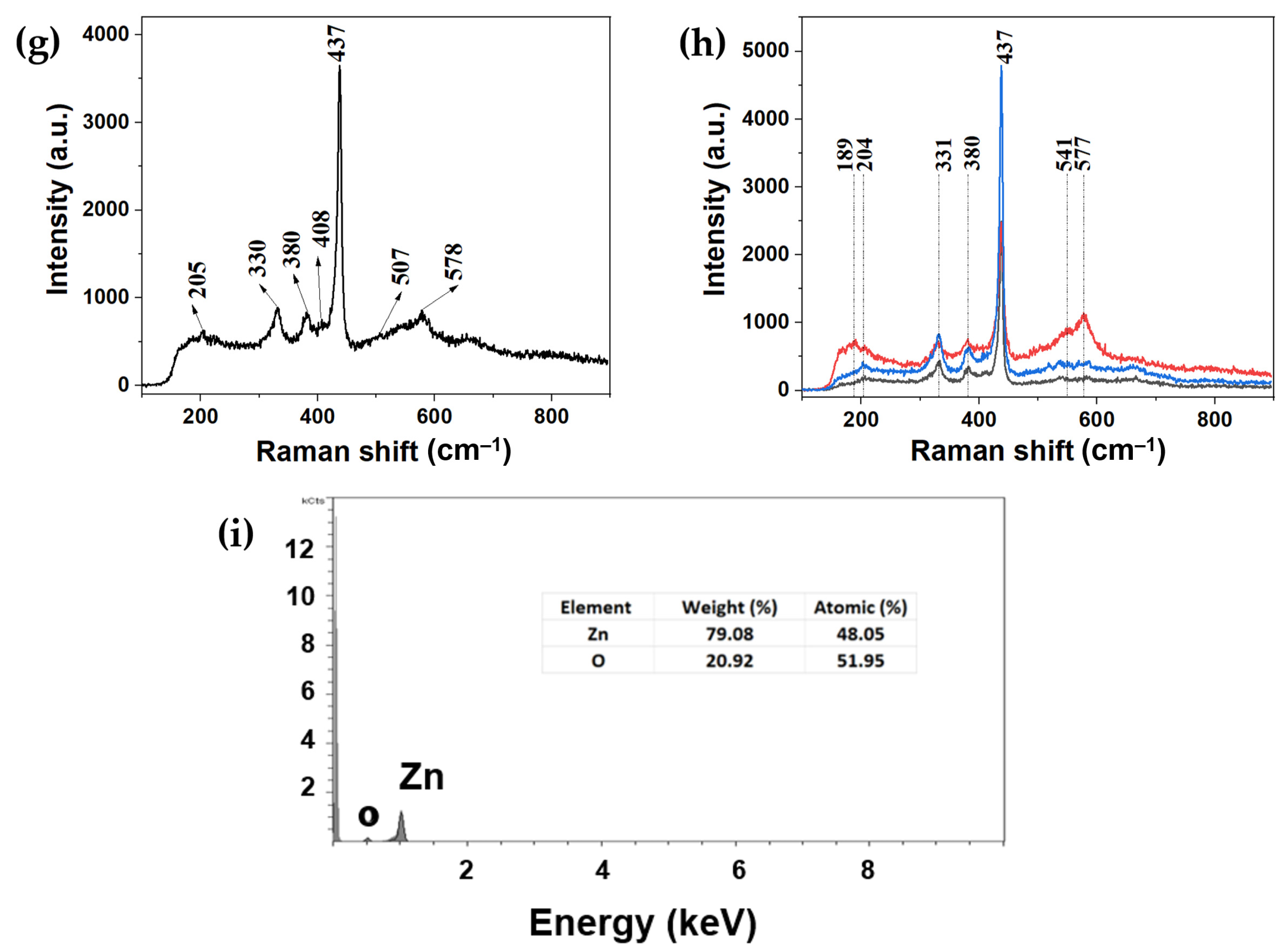

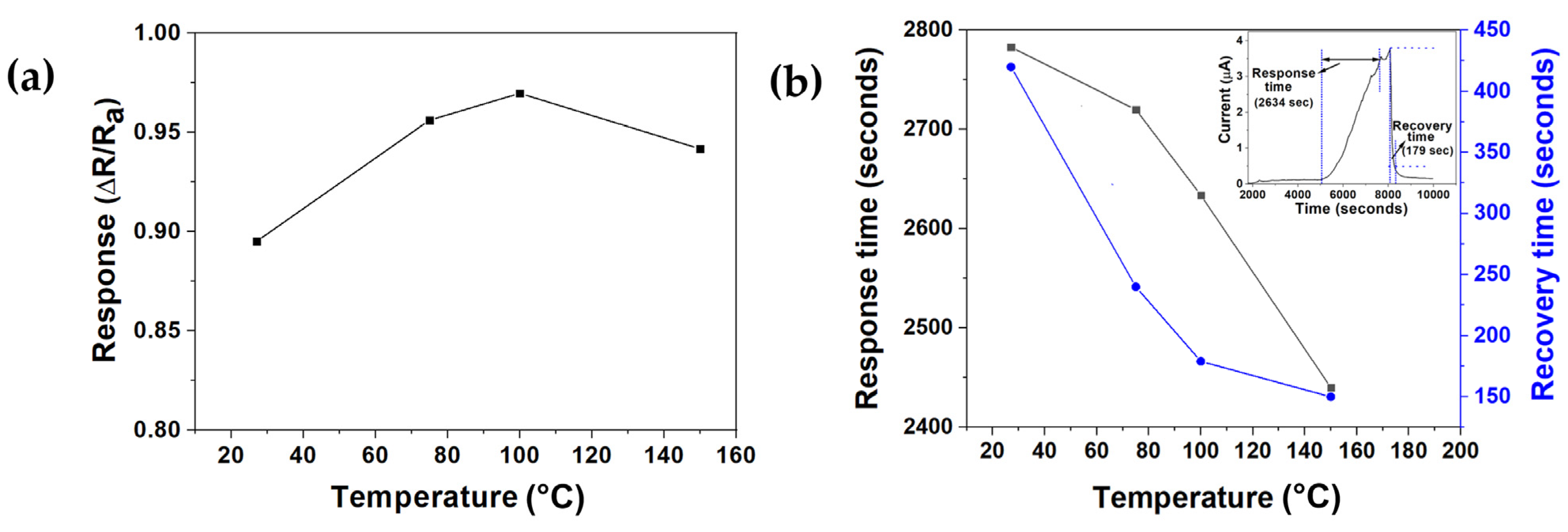

3.2. Gas Sensing Results

3.3. Gas Sensing Mechanisms and Data Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fernando, R.H. Nanocomposite and Nanostructured Coatings: Recent Advancements. In Nanotechnology Applications in Coatings; American Chemical Society: Washington, DC, USA, 2009; pp. 2–21. [Google Scholar]

- Levashov, E.A.; Shtansky, D.V. Multifunctional nanostructured films. Russ. Chem. Rev. 2007, 76, 463–470. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, G.; Al-Dossary, O.; Umar, A. ZnO nanostructured thin films: Depositions, properties applications—A review. Mater. Express 2015, 5, 3–23. [Google Scholar] [CrossRef]

- Rao, T.P.; Santhosh Kumar, M.C. Effect of thickness on structural, optical and electrical properties of nanostructured ZnO thin films by spray pyrolysis. Appl. Surf. Sci. 2009, 255, 4579–4584. [Google Scholar] [CrossRef]

- Mao, S.; Lu, G.; Chen, J. Nanocarbon-based gas sensors: Progress and challenges. J. Mater. Chem. A 2014, 2, 5573–5579. [Google Scholar] [CrossRef]

- Ali, S.; Gupta, A.; Shafiei, M.; Langford, S.J. Recent Advances in Perylene Diimide-Based Active Materials in Electrical Mode Gas Sensing. Chemosensors 2021, 9, 30. [Google Scholar] [CrossRef]

- Mao, S.; Cui, S.; Yu, K.; Wen, Z.; Lu, G.; Chen, J. Ultrafast hydrogen sensing through hybrids semiconducting single-walled carbon nanotubes tin oxide nanocrystals. Nanoscale 2012, 4, 1275–1279. [Google Scholar] [CrossRef]

- Ali, S.; Jameel, M.A.; Gupta, A.; Langford, S.J.; Shafiei, M. Capacitive humidity sensing performance of naphthalene diimide derivatives at ambient temperature. Synth. Met. 2021, 275, 116739. [Google Scholar] [CrossRef]

- Kong, J.; Franklin, N.R.; Zhou, C.; Chapline, M.G.; Peng, S.; Cho, K.; Dai, H. Nanotube Molecular Wires as Chemical Sensors. Science 2000, 287, 622–625. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.-J.; Choi, Y.-K. Chemical sensors based on nanostructured materials. Sens. Actuators B 2007, 122, 659–671. [Google Scholar] [CrossRef]

- Dey, A. Semiconductor metal oxide gas sensors A Review. Mater. Sci. Eng. B 2018, 229, 206–217. [Google Scholar] [CrossRef]

- Jiménez-Cadena, G.; Riu, J.; Rius, F.X. Gas sensors based on nanostructured materials. Analyst 2007, 132, 1083–1099. [Google Scholar] [CrossRef]

- Vollath, D. Nanomaterials an Introduction to Synthesis, Properties and Applications, 2nd ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2013. [Google Scholar]

- Mirzaei, A.; Kim, J.-H.; Kim, H.W.; Kim, S.S. How shell thickness can affect the gas sensing properties of nanostructured materials: Survey of literature. Sens. Actuators B 2018, 258, 270–294. [Google Scholar] [CrossRef]

- Eranna, G.; Joshi, B.C.; Runthala, D.P.; Gupta, R.P. Oxide Materials for Development of Integrated Gas Sensors—A Comprehensive Review. Crit. Rev. Solid State Mater. Sci. 2004, 29, 111–188. [Google Scholar] [CrossRef]

- Sun, Y.-F.; Liu, S.-B.; Meng, F.-L.; Liu, J.-Y.; Jin, Z.; Kong, L.-T.; Liu, J.-H. Metal oxide nanostructures and their gas sensing properties: A review. Sensors 2012, 12, 2610–2631. [Google Scholar] [CrossRef]

- Cerjak, H. Nanomaterials: An introduction to synthesis, properties and applications. Mater. Technol. 2009, 24, 74. [Google Scholar] [CrossRef]

- Koo, W.-T.; Cho, H.-J.; Kim, D.-H.; Kim, Y.H.; Shin, H.; Penner, R.M.; Kim, I.-D. Chemiresistive Hydrogen Sensors: Fundamentals, Recent Advances, and Challenges. ACS Nano 2020, 14, 14284–14322. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Liu, X.; Zhou, M.; Zhang, S.; Cao, S.; Lei, G.; Lou, C.; Zhang, J. Plasma-induced oxygen vacancies enabled ultrathin ZnO films for highly sensitive detection triethylamine. J. Hazard. Mater. 2021, 415, 125757. [Google Scholar] [CrossRef]

- Hastir, A.; Kohli, N.; Singh, R.C. Ag doped ZnO Nanowires as highly sensitive ethanol gas sensor. Mater. Today:. Proc. 2017, 4, 9476–9480. [Google Scholar] [CrossRef]

- Majhi, S.M.; Rai, P.; Yu, Y.-T. Facile Approach to Synthesize Au@ZnO Core–Shell Nanoparticles and TheirApplication for Highly Sensitive and Selective Gas Sensors. ACS Appl. Mater. Interfaces 2015, 7, 9462–9468. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, J.; Zhu, M.; Ju, D.; Xu, H.; Cao, B. High performance gas sensor based on ZnO nanowires functionalized by Au nanoparticles. Sens. Actuators B 2014, 199, 339–345. [Google Scholar] [CrossRef]

- Barsan, N.; Koziej, D.; Weimar, U. Metal oxide- based gas sensor research: How to? Sens. Actuators B 2007, 121, 18–35. [Google Scholar] [CrossRef]

- Lu, H.F.; Li, F.; Liu, G.; Chen, Z.-G.; Wang, D.-W.; Fang, H.-T.; Lu, G.Q.; Jiang, Z.H.; Cheng, H.-M. Amorphous TiO2 nanotube arrays for low-temperature oxygen sensors. Nanotechnology 2008, 19, 405504. [Google Scholar] [CrossRef] [PubMed]

- Tiburcio-Silver, A.; Sánchez-Juárez, A. SnO2: Ga thin films as oxygen gas sensor. Mater. Sci. Eng., B. 2004, 110, 268–271. [Google Scholar] [CrossRef]

- Gupta, S.; Joshi, A.; Kaur, M. Development of gas sensors using ZnO nanostructures. J. Chem. Sci. 2010, 122, 57–62. [Google Scholar] [CrossRef]

- Chaabouni, F.; Abaab, M.; Rezig, B. Metrological characteristics of ZnO oxygen sensor at room temperature. Sens. Actuators B 2004, 100, 200–204. [Google Scholar] [CrossRef]

- Khosravi, Y.; Sasar, M.; Abdi, Y. Light-induced oxygen sensing using ZnO/GO based gas sensor. Mater. Sci. Semicond. Process. 2018, 85, 9–14. [Google Scholar] [CrossRef]

- Zhu, L.; Zeng, W. Room-temperature gas sensing of ZnO-based gas sensor: A review. Sens. Actuators A 2017, 267, 242–261. [Google Scholar] [CrossRef]

- Mukae, K.; Tsuda, K.; Nagasawa, I. Capacitance-vs-voltage characteristics of ZnO varistors. J. Appl. Phys. 1979, 50, 4475–4476. [Google Scholar] [CrossRef]

- Dongale, T.D.; Khot, K.V.; Mali, S.S.; Patil, P.S.; Gaikwad, P.K.; Kamat, R.K.; Bhosale, P.N. Development of Ag/ZnO/FTO thin film memristor using aqueous chemical route. Mater. Sci. Semicond. Process. 2015, 40, 523–526. [Google Scholar] [CrossRef]

- Biswas, C.; Ma, Z.; Zhu, X.; Kawaharamura, T.; Wang, K.L. Atmospheric growth of hybrid ZnO thin films for inverted polymer Solar cells. Sol. Energy Mater. Sol. Cells 2016, 157, 1048–1056. [Google Scholar] [CrossRef]

- Choi, M.-Y.; Choi, D.; Jin, M.-J.; Kim, I.; Kim, S.-H.; Choi, J.-Y.; Lee, S.Y.; Kim, J.M.; Kim, S.-W. Mechanically powered transparent flexible charge-generating nanodevices with piezoelectric ZnO nanorods. Adv. Mater. 2009, 21, 2185–2189. [Google Scholar] [CrossRef]

- Ryu, Y.; Lee, T.-S.; Lubguban, J.A.; White, H.W.; Kim, B.-J.; Park, Y.-S.; Youn, C.-J. Next generation of oxide photonic devices: ZnO-based ultraviolet light emitting diodes. Appl. Phys. Lett. 2006, 88, 241108. [Google Scholar] [CrossRef]

- Wang, X.; Summers, C.J.; Wang, Z.L. Large-scale hexagonal patterned growth of aligned ZnO nanorods for nano-optoelectronics and nanosensor arrays. Nano Lett. 2004, 4, 423–426. [Google Scholar] [CrossRef]

- Mao, Y.Z.; Ma, S.Y.; Li, W.Q.; Luo, J.; Cheng, L.; Gengzang, D.J.; Xu, X.L. Synthesis of porous small-sized ZnO nanoparticles and their gas-sensing performance. Mater. Lett. 2015, 157, 151–154. [Google Scholar] [CrossRef]

- Liewhiran, C.; Phanichphant, S. Doctor-bladed thick films of flame-made Pd/ZnO nanoparticles for ethanol sensing. Curr. Appl Phys. 2008, 8, 336–339. [Google Scholar] [CrossRef]

- Koshizaki, N.; Oyama, T. Sensing characteristics of ZnO-based NOx sensor. Sens. Actuators B 2000, 66, 119–121. [Google Scholar] [CrossRef]

- Khan, S.B.; Faisal, M.; Rahman, M.M.; Jamal, A. Low-temperature growth of ZnO nanoparticles: Photocatalyst and acetone sensor. Talanta 2011, 85, 943–949. [Google Scholar] [CrossRef]

- Wagh, M.S.; Jain, G.H.; Patil, D.R.; Patil, S.A.; Patil, L.A. Modified zinc oxide thick film resistors as NH3 gas sensor. Sens. Actuators B 2006, 115, 128–133. [Google Scholar] [CrossRef]

- Ryu, H.-W.; Park, B.-S.; Akbar, S.A.; Lee, W.-S.; Hong, K.-J.; Seo, Y.-J.; Shin, D.-C.; Park, J.-S.; Choi, G.-P. ZnO sol–gel derived porous film for CO gas sensing. Sens. Actuators B 2003, 96, 717–722. [Google Scholar] [CrossRef]

- Li, B.S.; Liu, Y.C.; Chu, Z.S.; Shen, D.Z.; Lu, Y.M.; Zhang, J.Y.; Fan, X.W. High quality ZnO thin films grown by plasma enhanced chemical vapor deposition. J. Appl. Phys. 2002, 91, 501–505. [Google Scholar] [CrossRef]

- Lou, C.; Wang, K.; Mei, H.; Xie, J.; Zheng, W.; Liu, X.; Zhang, J. ZnO nanoarrays via a thermal decomposition–deposition method for sensitive and selective NO2 detection. Cryst. Eng. Comm. 2021, 23, 3654–3663. [Google Scholar] [CrossRef]

- Xu, Y.; Zheng, W.; Liu, X.; Zhang, L.; Zheng, L.; Yang, C.; Pinna, N.; Zhang, J. Platinum single atoms on tin oxide ultrathin films for extremely sensitive gas detection. Mater. Horiz. 2020, 7, 1519–1527. [Google Scholar] [CrossRef]

- Stambolova, I.; Konstantinov, K.; Vassilev, S.; Peshev, P.; Tsacheva, T. Lanthanum doped SnO2 and ZnO thin films sensitive to ethanol and humidity. Mater. Chem. Phys. 2000, 63, 104–108. [Google Scholar] [CrossRef]

- Ohshima, T.; Thareja, R.K.; Yamagata, Y.; Ikegami, T.; Ebihara, K.; Narayan, J. Laser-ablated plasma for deposition of ZnO thin films on various substrates. Sci. Technol. Adv. Mater. 2001, 2, 517–523. [Google Scholar] [CrossRef]

- Erol, A.; Okur, S.; Comba, B.; Mermer, Ö.; Arıkan, M.Ç. Humidity sensing properties of ZnO nanoparticles synthesized by sol–gel process. Sens. Actuators B 2010, 145, 174–180. [Google Scholar] [CrossRef]

- Omerovic, N.; Radovic, M.; Savic, S.M.; Katona, J. Preparation of TiO2 and ZnO dispersions for inkjet printing of flexible sensing devices. Process. Appl. Ceram. 2018, 12, 326–334. [Google Scholar] [CrossRef]

- Liu, H.-Y.; Kong, H.; Ma, X.-M.; Shi, W.-Z. Microstructure and electrical properties of ZnO-based varistors prepared by high-energy ball milling. J. Mater. Sci. 2007, 42, 2637–2642. [Google Scholar] [CrossRef]

- Takehana, M.; Nishino, T.; Sugawara, K.; Sugawara, T. Preparation of zinc oxide varistor by a wet chemical method. Mater. Sci. Eng. B 1996, 41, 186–189. [Google Scholar] [CrossRef]

- Salah, N.; Habib, S.S.; Khan, Z.H.; Memic, A.; Azam, A.; Alarfaj, E.; Zahed, N.; Al-Hamedi, S. High energy Ball milling technique for ZnO nanoparticles as antibacterial material. Int. J. Nanomed. 2011, 6, 863. [Google Scholar] [CrossRef] [PubMed]

- Qi, Q.; Zhang, T.; Yu, Q.; Wang, R.; Zeng, Y.; Liu, L.; Yang, H. Properties of humidity sensing ZnO nanorods-base sensor fabricated by Screen printing. Sens. Actuators B 2008, 133, 638–643. [Google Scholar] [CrossRef]

- Wang, C.-T.; Huang, K.-Y.; Lin, D.T.; Liao, W.-C.; Lin, H.-W.; Hu, Y.-C. A flexible proximity sensor fully fabricated inkjet printing. Sensors 2010, 10, 5054–5062. [Google Scholar] [CrossRef]

- Deng, Y.; Peng, E.; Shao, Y.; Xiao, Z.; Dong, Q.; Huang, J. Scalable fabrication of efficient organolead trihalide perovskite solar cells with doctor-bladed active layers. Energy Environ. Sci. 2015, 8, 1544–1550. [Google Scholar] [CrossRef]

- Giri, P.K.; Bhattacharyya, S.; Singh, D.K.; Kesavamoorthy, R.; Panigrahi, B.K.; Nair, K.G.M. Correlation between microstructure and optical properties of ZnO nanoparticles synthesized by ball milling. J. Appl. Phys. 2007, 102, 093515. [Google Scholar] [CrossRef]

- Fokina, E.; Budim, N.; Kochnev, V.; Chernik, G. Planetary mills of periodic and continuous action. J. Mater. Sci. 2004, 39, 5217–5221. [Google Scholar] [CrossRef]

- Mio, H.; Kano, J.; Saito, F. Scale-up method of planetary ball Mill. Chem. Eng. Sci. 2004, 59, 5909–5916. [Google Scholar] [CrossRef]

- Baláž, P.; Achimovičová, M.; Baláž, M.; Billik, P.; Cherkezova-Zheleva, Z.; Criado, J.M.; Delogu, F.; Dutková, E.; Gaffet, E.; Gotor, F.J.; et al. Hallmarks of mechanochemistry: From nanoparticles to technology. Chem. Soc. Rev. 2013, 42, 7571–7637. [Google Scholar] [CrossRef] [PubMed]

- Bruckmann, A.; Krebs, A.; Bolm, C. Organocatalytic reactions: Effects of ball milling, microwave and ultrasound irradiation. Green Chem. 2008, 10, 1131–1141. [Google Scholar] [CrossRef]

- Sapkota, R.; Zou, J.; Dawka, S.; Bobak, J.E.; Papadopoulos, C. Multifunctional thin film coatings formed via nanogrinding. Appl. Nanosci. 2018, 8, 1437–1444. [Google Scholar] [CrossRef]

- Huang, L.; Kramer, G.; Wieldraaijer, W.; Brands, D.; Poels, E.; Castricum, H.; Bakker, H. Methanol synthesis over Cu/ZnO catalysts prepared by ball milling. Catal. Lett. 1997, 48, 55–59. [Google Scholar] [CrossRef]

- Yong, H.E.; Krishnamoorthy, K.; Hyun, K.T.; Kim, S.J. Preparation of ZnO nanopaint for marine antifouling applications. J. Ind. Eng. Chem. 2015, 29, 39–42. [Google Scholar] [CrossRef]

- Yu, M.; Shao, D.; Lu, F.; Sun, X.; Sun, H.; Hu, T.; Wang, G.; Sawyer, S.; Qiu, H.; Lian, J. ZnO/graphene nanocomposite fabricated by high energy ball milling with greatly enhanced lithium storage capability. Electrochem. Commun. 2013, 34, 312–315. [Google Scholar] [CrossRef]

- Radoi, R.; Fernández, P.; Piqueras, J.; Wiggins, M.S.; Solis, J. Luminescence properties of mechanically milled and laser irradiated ZnO. Nanotechnology 2003, 14, 794–798. [Google Scholar] [CrossRef]

- Xie, C.; Xiao, L.; Hu, M.; Bai, Z.; Xia, X.; Zeng, D. Fabrication and formaldehyde gas-sensing property of ZnO–MnO2 coplanar gas sensor arrays. Sens. Actuators B 2010, 145, 457–463. [Google Scholar] [CrossRef]

- Choi, J.D.; Choi, G.M. Electrical and CO gas sensing properties of layered ZnO–CuO Sensor. Sens. Actuators B 2000, 69, 120–126. [Google Scholar] [CrossRef]

- Chen, H.; Liu, Y.; Xie, C.; Wu, J.; Zeng, D.; Liao, Y. A comparative study on UV light activated porous TiO2 and ZnO film sensors for gas sensing at room temperature. Ceram. Int. 2012, 38, 503–509. [Google Scholar] [CrossRef]

- Yu, J.H.; Choi, G.M. Selective CO gas detection CuO-and ZnO-doped SnO2 gas sensor. Sens. Actuators B 2001, 75, 56–61. [Google Scholar] [CrossRef]

- Xiang, X.; Zhu, D.; Wang, D. Enhanced formaldehyde gas sensing properties of La-doped SnO2 nanoparticles prepared by ball-milling solid chemical reaction method. J. Mater. Sci. Mater. Electron. 2016, 27, 7425–7432. [Google Scholar] [CrossRef]

- Hu, Y.; Tan, O.K.; Cao, W.; Zhu, W. A low temperature nanostructured SrTiO3 thick film oxygen gas sensor. Ceram. Int. 2004, 30, 1819–1822. [Google Scholar] [CrossRef]

- Wagh, M.; Patil, L.; Seth, T.; Amalnerkar, D. Surface cupricated SnO2–ZnO thick films as a H2S gas sensor. Mater. Chem. Phys. 2004, 84, 228–233. [Google Scholar] [CrossRef]

- Chang, S.-P.; Chen, K.-J. Zinc oxide nanoparticle photodetector. J. Nanomater. 2012, 2012, 1–5. [Google Scholar] [CrossRef]

- Gimenez, A.J.; Yáñez-Limón, J.M.; Seminario, J.M. ZnO–cellulose composite UV sensing. IEEE Sens.J. 2012, 13, 1301–1306. [Google Scholar] [CrossRef]

- Hsiao, Y.-J.; Fang, T.-H.; Ji, L.-W.; Yang, B.-Y. Red-shift effect and sensitive responsivity of MoS2/ZnO flexible photodetectors. Nanoscale Res. Lett. 2015, 10, 1–5. [Google Scholar] [CrossRef][Green Version]

- Rasband, W.S.; ImageJ, U.S. National Institutes of Health, Bethesda, Maryland, USA, 1997–2016. Available online: https://imagej.nih.gov/ij/ (accessed on 16 September 2021).

- Saikia, L.; Bhuyan, D.; Saikia, M.; Malakar, B.; Dutta, D.K.; Sengupta, P. Photocatalytic performance of ZnO nanomaterials for self sensitized degradation of malachite green dye under solar light. App. Catal. A: Gen 2015, 490, 42–49. [Google Scholar] [CrossRef]

- Amutha, A.; Amirthapandian, S.; Sundaravel, B.; Panigrahi, B.K.; Saravanan, K.; Thangadurai, P. Low-temperature photoluminescence behaviour of Ag decorated ZnO Nanorods. J. Appl. Phys 2016, 120, 205104. [Google Scholar] [CrossRef]

- Zhang, W.C.; Wu, X.L.; Chen, H.T.; Zhu, J.; Huang, G.S. Excitation wavelength dependence of the visible photoluminescence from amorphous ZnO Granular films. J. Appl. Phys 2008, 103, 093718. [Google Scholar] [CrossRef]

- Damen, T.C.; Porto, S.P.S.; Tell, B. Raman Effect in Zinc Oxide. Phys. Rev. 1966, 142, 570–574. [Google Scholar] [CrossRef]

- Cuscó, R.; Alarcón-Lladó, E.; Ibáñez, J.; Artús, L.; Jiménez, J.; Wang, B.; Callahan, M.J. Temperature dependence of Raman scattering in ZnO. Phys. Rev. B 2007, 75, 165202. [Google Scholar] [CrossRef]

- Choi, Y.I.; Jung, H.J.; Shin, W.G.; Sohn, Y. Band-gap engineered ZnO and Ag/ZnO by ball milling method and their photocatalytic and Fenton-like photocatalytic activities. Appl. Surf. Sci. 2015, 356, 615–625. [Google Scholar] [CrossRef]

- Šćepanović, M.; Grujić-Brojčin, M.; Vojisavljević, K.; Bernik, S.; Srećković, T. Raman study of structural disorder in ZnO nanopowders. J. Raman Spectrosc. 2010, 41, 914–921. [Google Scholar] [CrossRef]

- Vojisavljevic, K.; Šcepanovic, M.; Sreckovic, T.; Grujic-Brojcin, M.; Brankovic, Z.; Brankovic, G. Structural characterization of mechanically milled ZnO: Influence of zirconia milling media. J. Phys. Condens. Matter 2008, 20, 475202. [Google Scholar] [CrossRef]

- Singh, J.; Sharma, S.; Soni, S.; Sharma, S.; Singh, R.C. Influence of different milling media on structural, morphological and optical properties of the ZnO nanoparticles synthesized by ball milling process. Mater. Sci. Semicond. Process. 2019, 98, 29–38. [Google Scholar] [CrossRef]

- Jung, H.J.; Sohn, Y.; Sung, H.G.; Hyun, H.S.; Shin, W.G. Physicochemical properties of ball milled boron particles: Dry vs wet ball milling process. Powder Technol. 2015, 269, 548–553. [Google Scholar] [CrossRef]

- Ou, J.Z.; Ge, W.; Carey, B.; Daeneke, T.; Rotbart, A.; Shan, W.; Wang, Y.; Fu, Z.; Chrimes, A.F.; Wlodarski, W.; et al. Physisorption-Based Charge Transfer in Two-Dimensional SnS2 for Selective and Reversible NO2 Gas Sensing. ACS Nano 2015, 9, 10313–10323. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Wu, J.; Wang, Z.M.; Jiang, Y. Nanoscale Sensors; Lecture Notes in Nanoscale Science and Technology; Springer International Publishing: Berlin/Heidelberg, Germany, 2013; ISBN 9783319027722. [Google Scholar]

- Kumar, R.; Al-Dossary, O.; Kumar, G.; Umar, A. Zinc oxide nanostructures for NO2 gas–sensor applications: A review. Nanomicro Lett. 2015, 7, 97–120. [Google Scholar] [CrossRef] [PubMed]

- Ahn, M.-W.; Park, K.-S.; Heo, J.-H.; Park, J.-G.; Kim, D.-W.; Choi, K.J.; Lee, J.-H.; Hong, S.-H. Gas sensing properties of defect-controlled ZnO-nanowire gas sensor. Appl. Phys. Lett. 2008, 93, 263103. [Google Scholar] [CrossRef]

- Yu, L.; Guo, F.; Liu, S.; Yang, B.; Jiang, Y.; Qi, L.; Fan, X. Both oxygen vacancies defects and porosity facilitated NO2 gas sensing response in 2D ZnO nanowalls at room temperature. J. Alloys Compd. 2016, 682, 352–356. [Google Scholar] [CrossRef]

- Yuan, Z.; Li, R.; Meng, F.; Zhang, J.; Zuo, K.; Han, E. Approaches enhancing gas sensing properties: A review. Sensors 2019, 19, 1495. [Google Scholar] [CrossRef]

- Abe, S.; Choi, U.-S.; Shimanoe, K.; Yamazoe, N. Influences of ball-milling time on gas sensing properties of Co3O4–SnO2 composites. Sens. Actuators B 2005, 107, 516–522. [Google Scholar] [CrossRef]

- Viswanathan, R.; Gupta, R.B. Formation of zinc oxide nanoparticles in supercritical water. J. Supercrit. Fluids 2003, 27, 187–193. [Google Scholar] [CrossRef]

- Matsoukas, T.; Friedlander, S.K. Dynamics of aerosol agglomerate formation. J. Colloid Interface Sci. 1991, 146, 495–506. [Google Scholar] [CrossRef]

- Medina, J.; Bolaños, H.; Mosquera-Sanchez, L.P.; Rodriguez-Paez, J. Controlled synthesis of ZnO nanoparticles and evaluation of their toxicity in Mus musculus mice. Int. Nano Lett. 2018, 8, 165–179. [Google Scholar] [CrossRef]

- Wang, C.; Yin, L.; Zhang, L.; Xiang, D.; Gao, R. Metaloxide gas sensors: Sensitivity and influencing factors. Sensors 2010, 10, 2088–2106. [Google Scholar] [CrossRef]

- Göpel, W.; Lampe, U. Influence of defects on the electronic structure of zinc oxide surfaces. Phys. Rev. B 1980, 22, 6447–6462. [Google Scholar] [CrossRef]

- Aggelopoulos, C.A.; Dimitropoulos, M.; Govatsi, A.; Sygellou, L.; Tsakiroglou, C.D.; Yannopoulos, S.N. Influence of the surface-to-bulk defects ratio of ZnO and TiO2 on their UV-mediated photocatalytic activity. Appl. Catal. B 2017, 205, 292–301. [Google Scholar] [CrossRef]

- Tsukazaki, A.; Ohtomo, A.; Kawasaki, M. High-mobility electronic transport in ZnO thin films. Appl. Phys. Lett. 2006, 88, 152106. [Google Scholar] [CrossRef]

- Wal, R.L.V.; Hunter, G.W.; Xu, J.C.; Kulis, M.J.; Berger, G.M.; Ticich, T.M. Metal oxide nanostructure and gas-sensing performance. Sens. Actuators B 2009, 138, 113–119. [Google Scholar] [CrossRef]

- Hong, R.; Pan, T.; Qian, J.; Li, H. Synthesis and surface modification of ZnO nanoparticles. Chem. Eng. J. 2006, 119, 71–81. [Google Scholar] [CrossRef]

- Ozcan, S.; Can, M.M.; Ceylan, A. Single step synthesis of nanocrystalline ZnO via wet milling. Mater. Lett. 2010, 64, 2447–2449. [Google Scholar] [CrossRef]

- Faure, B.; Salazar-Alvarez, G.; Ahniyaz, A.; Villaluenga, I.; Berriozabal, G.; Miguel, Y.R.D.; Bergström, L. Dispersion and surface functionalization of oxide nanoparticles for transparent photocatalytic and UV protecting coatings and sunscreens. Sci. Technol. Adv. Mater. 2013, 14, 023001. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Yee, S.S.; Carey, W.P. Transition between neck-controlled grain-boundary-controlled sensitivity of metal-oxide gas sensors. Sens. Actuators B 1995, 25, 454–457. [Google Scholar] [CrossRef]

- Jacobs, C.B.; Maksov, A.B.; Muckley, E.S.; Collins, L.; Mahjouri-Samani, M.; Ievlev, A.; Rouleau, C.M.; Moon, J.-W.; Graham, D.E.; Sumpter, B.G.; et al. UV activated ZnO films flexible substrate Room temperature O2 H2O sensing. Sci. Rep. 2017, 7, 6053. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.-H.; Kim, J.-Y.; Mirzaei, A.; Kim, H.; Kim, S. Significant enhancement of hydrogen-sensing properties of ZnO nanofibers through NiO loading. Nanomaterials 2018, 8, 902. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, Y.; Kanamori, M.; Kondoh, A.; Minoura, H.; Ohya, Y. Photoconductivity of Ultrathin Zinc Oxide Films. Jpn. J. Appl. Phys 1994, 33, 6611–6615. [Google Scholar] [CrossRef]

- Scolfaro, D.; Onofre, Y.; Teodoro, M.D.; Godoy, M. de Atmosphere-Dependent Photoconductivity of ZnO in the Urbach Tail. Int. J. Photoenergy 2018, 2018. [Google Scholar] [CrossRef]

- Kulwicki, B.M. Humidity Sensors. J. Am. Ceram. Soc. 1991, 74, 697–708. [Google Scholar] [CrossRef]

- Chen, Z.; Lu, C. Humidity sensors review of materials and mechanisms. Sens. Lett. 2005, 3, 274–295. [Google Scholar] [CrossRef]

- Gupta, S.P.; Pawbake, A.S.; Sathe, B.R.; Late, D.J.; Walke, P.S. Superior humidity sensor and photodetector of mesoporous ZnO nanosheets at room temperature. Sens. Actuators B 2019, 293, 83–92. [Google Scholar] [CrossRef]

- Jiao, M.; Van Duy, N.; Hoa, N.D.; Van Hieu, N.; Hjort, K.; Nguyen, H. Comparison NO2 gas-sensing properties of three different ZnO nanostructures synthesized by on-Chip low-temperature hydrothermal growth. J. Electron. Mater. 2018, 47, 785–793. [Google Scholar] [CrossRef]

- Khatibani, A.B. Investigation of gas sensing property of Zinc oxide thinfilms deposited by Sol-Gel method: Effects of molarity and annealing temperature. Indian J. Phys. 2021, 95, 243–252. [Google Scholar] [CrossRef]

- Hjiri, M.; Bahanan, F.; Aida, M.; El Mir, L.; Neri, G. High performance CO Gas Sensor Based on ZnO Nanoparticles. J. Inorg. Organomet. Polym. Mater. 2020, 30, 4063–4071. [Google Scholar] [CrossRef]

- Moon, W.J.; Yu, J.H.; Choi, G.M. The CO and H2 gas selectivity of CuO-doped SnO2–ZnO composite gas sensor. Sens. Actuators B 2002, 87, 464–470. [Google Scholar] [CrossRef]

- Huang, B.-R.; Lin, J.-C. A facile synthesis of ZnO nanotubes and their hydrogen sensing properties. Appl. Surf. Sci. 2013, 280, 945–949. [Google Scholar] [CrossRef]

- Yoon, D.H.; Yu, J.H.; Choi, G.M. CO gas sensing properties of ZnO–CuO composite. Sens. Actuators B: Chem. 1998, 46, 15–23. [Google Scholar] [CrossRef]

- Phan, D.-T.; Chung, G.-S. Effects of different morphologies of ZnO films on hydrogen sensing properties. J. Electroceramics 2014, 32, 353–360. [Google Scholar] [CrossRef]

- Khan, R.; Ra, H.-W.; Kim, J.T.; Jang, W.S.; Sharma, D.; Im, Y.H. Nanojunction effects in multiple ZnO nanowire gas sensor. Sens. Actuators B 2010, 150, 389–393. [Google Scholar] [CrossRef]

- Mirzaei, A.; Leonardi, S.; Neri, G. Detection of hazardous volatile organic compounds (VOCs) by metal-oxide nanostructures-based gas sensors A review. Ceram. Int. 2016, 42, 15119–15141. [Google Scholar] [CrossRef]

- Dobrokhotov, V.; Oakes, L.; Sowell, D.; Larin, A.; Hall, J.; Kengne, A.; Bakharev, P.; Corti, G.; Cantrell, T.; Prakash, T.; et al. Toward the nanospring-based artificial olfactory system for trace-detection of flammable explosive vapors. Sens. Actuators B 2012, 168, 138–148. [Google Scholar] [CrossRef]

| Material | Target Gas | LOD | Response/Temperature | Response Time/Recovery Time | References |

|---|---|---|---|---|---|

| Present work | H2 (5000 ppm) | 500 ppm | 21% b/RT | - | - |

| CuO coated ZnO using ball milling method | H2 (200 ppm) | - | ~15 a/300 °C | - | [115] |

| ZnO nanotube using chemical etching process | H2 (500 ppm) | 5 ppm | ~29.6% b/RT | ~540 s/- | [116] |

| SnO2-doped ZnO using ball milling method | CO (200 ppm) | - | ~5 a/450 °C | - | [66] |

| ZnO-CuO composite via ball milling process | CO (200 ppm) | - | ~12.2 a/180 °C | - | [117] |

| Pt-doped ZnO using RF sputtering | H2 (1000 ppm) | 250 ppm | ~5.5 a/200 °C | 36 s/112 s | [118] |

| ZnO nanowires by thermal evaporation | H2 (100 ppm) | 50 ppm | ~5.5 a/200 °C | 30 s/- | [119] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sapkota, R.; Duan, P.; Kumar, T.; Venkataraman, A.; Papadopoulos, C. Thin Film Gas Sensors Based on Planetary Ball-Milled Zinc Oxide Nanoinks: Effect of Milling Parameters on Sensing Performance. Appl. Sci. 2021, 11, 9676. https://doi.org/10.3390/app11209676

Sapkota R, Duan P, Kumar T, Venkataraman A, Papadopoulos C. Thin Film Gas Sensors Based on Planetary Ball-Milled Zinc Oxide Nanoinks: Effect of Milling Parameters on Sensing Performance. Applied Sciences. 2021; 11(20):9676. https://doi.org/10.3390/app11209676

Chicago/Turabian StyleSapkota, Raju, Pengjun Duan, Tanay Kumar, Anusha Venkataraman, and Chris Papadopoulos. 2021. "Thin Film Gas Sensors Based on Planetary Ball-Milled Zinc Oxide Nanoinks: Effect of Milling Parameters on Sensing Performance" Applied Sciences 11, no. 20: 9676. https://doi.org/10.3390/app11209676

APA StyleSapkota, R., Duan, P., Kumar, T., Venkataraman, A., & Papadopoulos, C. (2021). Thin Film Gas Sensors Based on Planetary Ball-Milled Zinc Oxide Nanoinks: Effect of Milling Parameters on Sensing Performance. Applied Sciences, 11(20), 9676. https://doi.org/10.3390/app11209676