An Assessment of the Influence of Dental Porcelain Slurry Preparation on Flexural Strength of Different Feldspathic Porcelains

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

2.2. Flexural Testing

2.3. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

- -

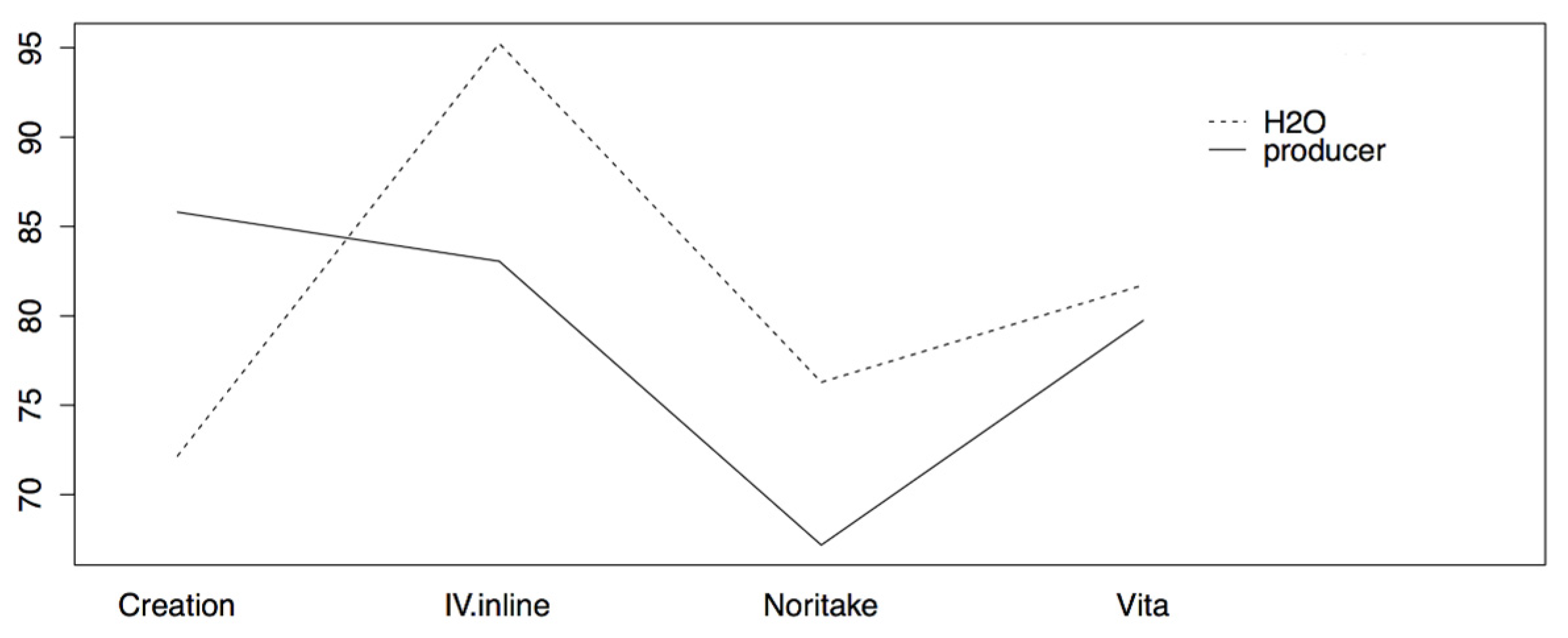

- The flexural strength of the ceramic Creation was better when mixed with the corresponding producer’s liquid while all other tested ceramics (Noritake, InLine, and Vita) achieved higher flexural results when mixed with H2O.

- -

- When the commercial modeling liquids were used, NRL resulted in a significantly lower flexural strength.

- -

- When different ceramic powders were mixed with distilled water, IV showed significantly highest flexural strength.

- -

- Overall, regardless of which mixing liquid was used, within each ceramic type, there was no statistically significant difference in flexural strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- International Organization for Standardization. Dentistry—Ceramic Materials, International Organization for Standards. ISO 6872. 2015. Available online: https://www.iso.org/standard/59936.html (accessed on 30 November 2020).

- Kelly, J.R.; Nishimura, I.; Campbell, S.D. Ceramics in dentistry: Historical roots and current perspectives. J. Prosthet. Dent. 1996, 75, 18–32. [Google Scholar] [CrossRef]

- Sadowsky, S.J. An overview of treatment considerations for esthetic restorations: A review of the literature. J. Prosthet. Dent. 2006, 96, 433–442. [Google Scholar] [CrossRef] [PubMed]

- Messer, R.L.; Lockwood, P.E.; Wataha, J.C.; Lewis, J.B.; Noris, S.; Bouillaguet, S. In vitro cytotoxicity of traditional versus contemporary dental ceramics. J. Prosthet. Dent. 2003, 90, 452–458. [Google Scholar] [CrossRef]

- Morimoto, S.; Albanesi, R.B.; Sesma, N.; Agra, C.M.; Braga, M.M. Main clinical outcomes of feldspathic porcelain and glass-ceramic laminate veneers: A systematic review and meta-analysis of survival and complication rates. Int. J. Prosthodont. 2016, 29, 38–49. [Google Scholar] [CrossRef] [PubMed]

- Jung, Y.G.; Wuttiphan, S.; Peterson, I.M.; Lawn, B.R. Damage modes in dental layer structures. J. Dent. Res. 1999, 78, 887–897. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Griggs, J.A.; Benham, A.W. Influence of powder/liquid mixing ratio on porosity and translucency of dental porcelains. J. Prosthet. Dent. 2004, 91, 128–135. [Google Scholar] [CrossRef] [PubMed]

- Pelaez-Vargas, A.; Dussan, J.A.; Restrepo-Tamayo, L.F.; Paucar, C.; Ferreira, J.A.; Monteiro, F.J. The effect of slurry preparation methods on biaxial flexural strength of dental porcelain. J. Prosthet. Dent. 2011, 105, 308–314. [Google Scholar] [CrossRef] [Green Version]

- Rasmussen, S.T.; Ngaji-Okumu, W.; Boenke, K.; O’Brien, W.J. Optimum size distribution for reduced sintering shrinkage of a dental porcelain. Dent. Mater. 1997, 13, 43–50. [Google Scholar] [CrossRef]

- Philips, R.W. Dental ceramics. In Skinner’s Science of Dental Materials, 12th ed.; Kenneth, J.A., Ed.; Elsevier: Amsterdam, The Netherlands, 1991; Volume 18, pp. 418–473. [Google Scholar]

- Sinmazişik, G.; Oveçoğlu, M.L. Physical properties and microstructural characterization of dental porcelains mixed with distilled water and modeling liquid. Dent. Mater. 2006, 22, 735–745. [Google Scholar] [CrossRef] [PubMed]

- Galhano, G.A.; Valandro, L.F.; De Melo, R.M.; Scotti, R.; Bottino, M.A. Evaluation of the flexural strength of carbon fiber-, quartz fiber-, and glass fiber-based posts. J. Endod. 2005, 31, 209–211. [Google Scholar] [PubMed] [Green Version]

- D’Arcangelo, C.; Cinelli, M.; De Angelis, F.; D’Amario, M. The effect of resin cement film thickness on the pullout strength of a fiber-reinforced post system. J. Prosthet. Dent. 2007, 98, 193–198. [Google Scholar] [CrossRef]

- Cheung, K.C.; Darvell, B.W. Sintering of dental porcelain: Effect of time and temperature on appearance and porosity. Dent. Mater. 2002, 18, 163–173. [Google Scholar] [CrossRef]

- Zhang, Z.; Yi, Y.; Wang, X.; Guo, J.; Li, D.; He, L.; Zahng, S. A comparative study of progressive wear of four dental monolithic, veneered glass-ceramics. J. Mech. Behav. Biomed. Mater. 2017, 74, 111–117. [Google Scholar] [CrossRef] [PubMed]

| Brand | Manufacturer | Ceramic Chemical Composition | Ceramic Modeling Liquid Chemical Composition (Weight %) |

|---|---|---|---|

| Creation CC (C) | Creation Willi Geller International GmbH, Meininge, Austria | Leucite-containing feldspathic porcelain SiO2 (55–65%); Al2O3 (12–18%); K2O (12–16%); Na2O (3–5%); TiO2 (<1%); ZrO2 (<1%); CaO (1–3%); LiO (<1%) MgO (<1%); B2O3(1–2%); BaO (1–2%); SnO2 (<1%); P2O5 (<1%) CeO2 CeF3 oxides (<0.1%); Pigments (0.1–0.3%) | Purified water (>99%); Propylene glycol (0–4%), Zinc chloride (<0.1%) |

| IV IPS InLine (IV) | Ivoclar Vivadent, Schaan, Liechtenstein | Leucite-containing feldspathic porcelain SiO2 (59.5–65.5%); Al2O3 (13.0–18.0%); K2O (10.0–14.0%); Na2O (4.0–8.0%); other oxides (<4.0%); pigment (<2.0%) | Water and/or glycol 90–99%, polymer (1–10%) |

| Noritake super porcelain EX (n) | Kuraray Noritake Dental Inc., Tokyo, Japan | Leucite-containing feldspathic porcelain SiO2 (64.5%); Al2O3 (14.4%) CaO (<1.0%); MgO (<1.0%) K2O (8.7%); Na2O (9.2%) Li2O (<1.0%); B2O3 (0%); pigments (<1%) | Polyethyleneglycol Water Additives % is not disclosed by the manufacturer |

| VITA VM13 (V) | VITA Zahnfabrik H. Rauter GmbH & Co. KG, Bad Sackingen, Germany | Leucite-containing feldspathic porcelain SiO2 (55–72%); Al2O3 (12–16%); K2O (8–10%); Na2O (4–6%); TiO2 (<1%); CeO2 (<1%); ZrO2 (<1%); CaO (1–2%); B2O3 (1–2%); BaO (1–3%); SnO2 (<1%); Mg, Fe, and P oxides (<0.1%) | Purified water (>99%); Inorganic components (<1%) |

| Ceramic | ST (°C) | DT (min) | TRI (°C/min) | Vacuum Pressure | FT (°C) | HT (min) |

|---|---|---|---|---|---|---|

| CR | 580 | 6 | 55 | Yes | 920 | 1 |

| IV | 403 | 4 | 60 | Yes | 910 | 1 |

| NR | 400 | 8 | 65 | Yes | 980 | 1 |

| VT | 400 °C | 6 | 55 | Yes | 880 °C | 1 |

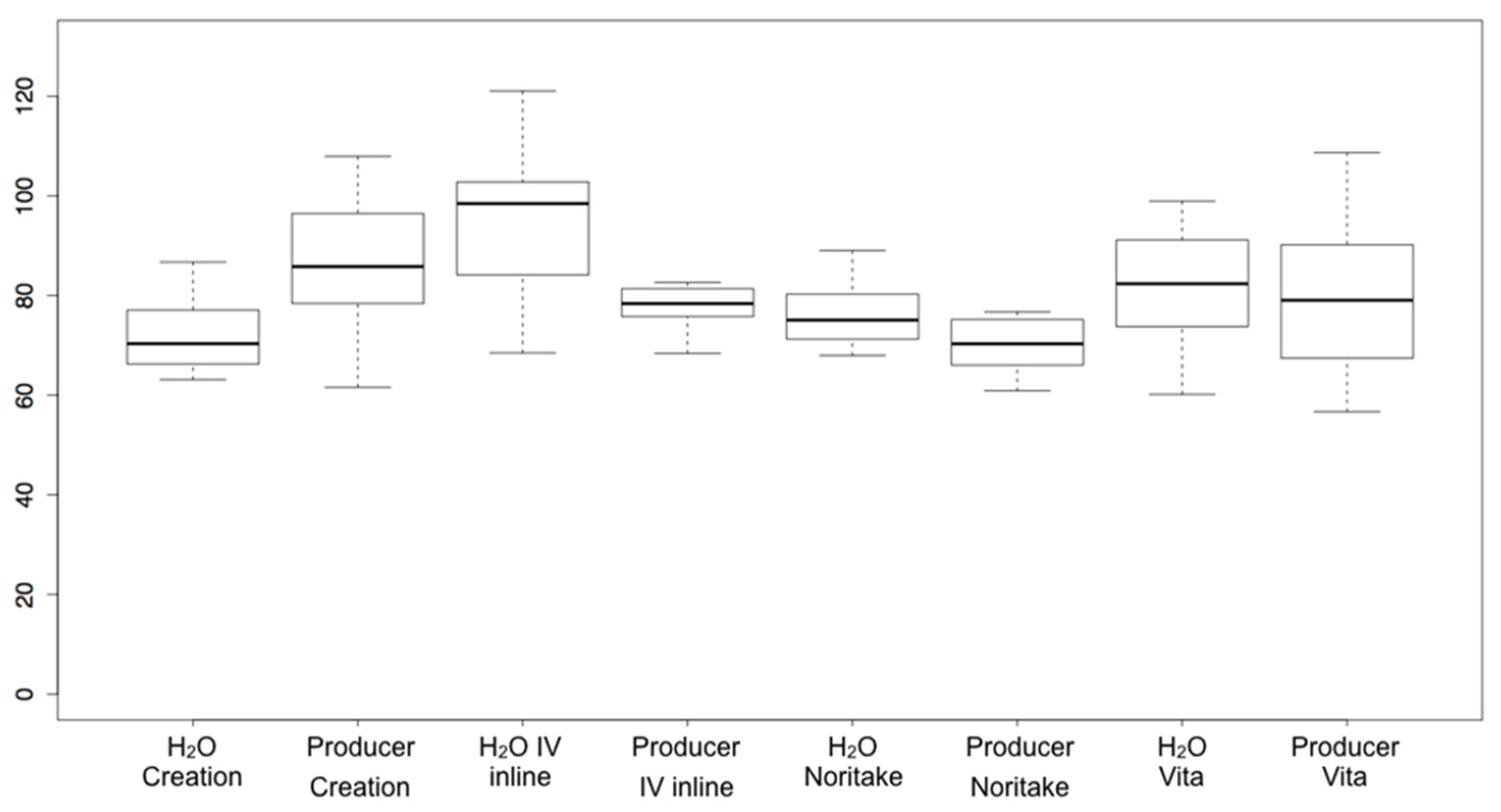

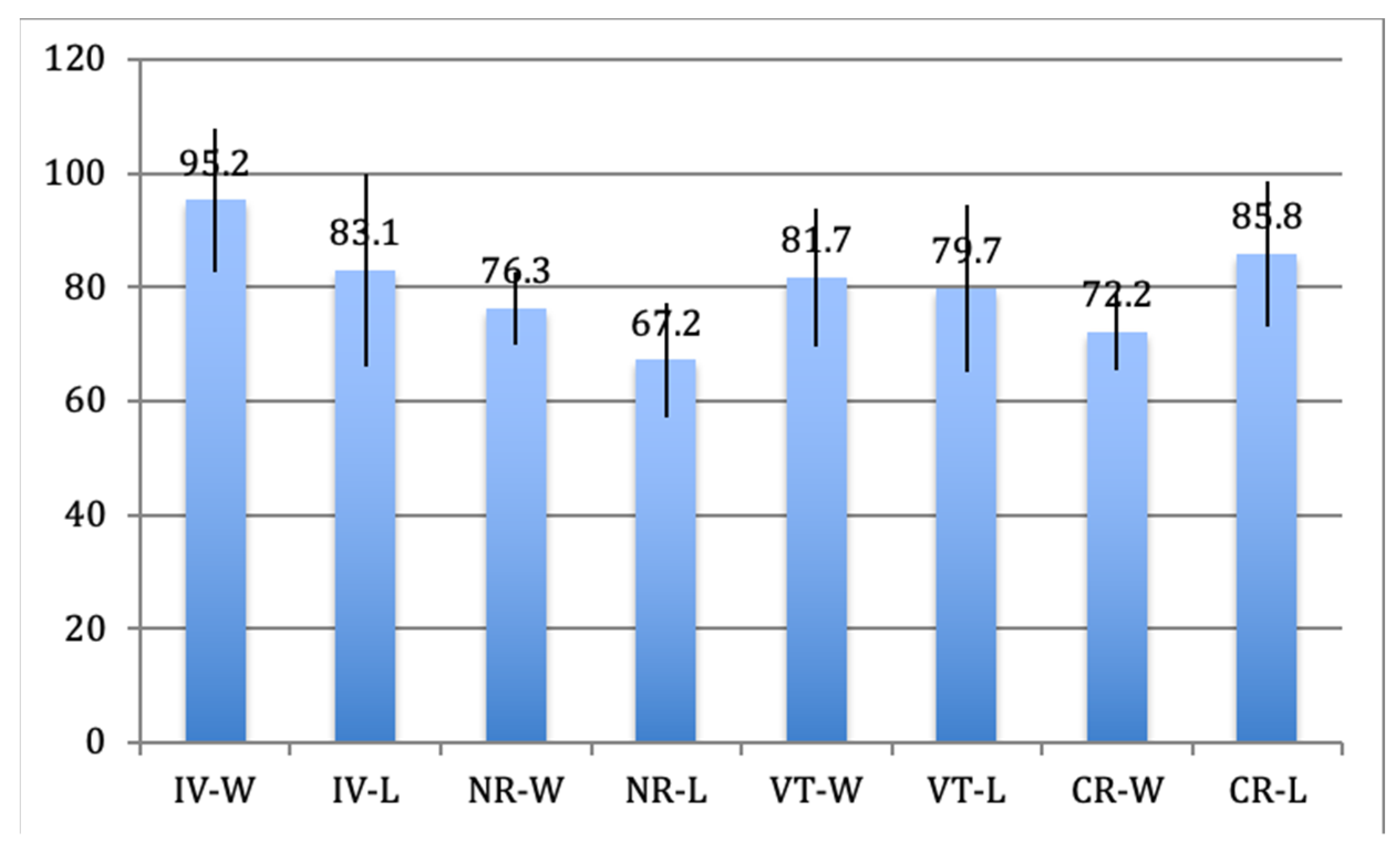

| Ceramic Type | Flexural Strength (Mean ± SD) Water (W) | Flexural Strength (Mean ± SD) Liquid (L) | Min–Max FS (95% CI) Water (W) | Min–Max FS (95% CI) Liquid (L) |

|---|---|---|---|---|

| CR | 72.2 ± 6.9 a,A | 85.8 ± 12.8 a,A | 67.3–107.9 (68.5–75.9) | 63.1–86.7 (79.0–92.6) |

| IV | 95.2 ± 12.7 b,c,B | 83.1 ± 16.9 a,c,B | 68.5–121.1 (88.4–102.1) | 45.6–132.8 (74.1–92.1) |

| NR | 76.3 ± 6.3 a,d,C | 67.2 ± 10.2 b,d,e,C | 45.9–89.0 (72.9–79.7) | 38.5–76.7 (61.8–72.6) |

| VT | 81.7 ± 12.1 a,c,D | 79.7 ± 14.6 a,c,e,D | 56.7–108.7 (75.3–88.1) | 60.2–98.9 (71.9–87.5) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alshihri, A.; Al-Haj Husain, N.; Vogeler, K.; Özcan, M. An Assessment of the Influence of Dental Porcelain Slurry Preparation on Flexural Strength of Different Feldspathic Porcelains. Appl. Sci. 2021, 11, 9385. https://doi.org/10.3390/app11209385

Alshihri A, Al-Haj Husain N, Vogeler K, Özcan M. An Assessment of the Influence of Dental Porcelain Slurry Preparation on Flexural Strength of Different Feldspathic Porcelains. Applied Sciences. 2021; 11(20):9385. https://doi.org/10.3390/app11209385

Chicago/Turabian StyleAlshihri, Abdulmonem, Nadin Al-Haj Husain, Kai Vogeler, and Mutlu Özcan. 2021. "An Assessment of the Influence of Dental Porcelain Slurry Preparation on Flexural Strength of Different Feldspathic Porcelains" Applied Sciences 11, no. 20: 9385. https://doi.org/10.3390/app11209385

APA StyleAlshihri, A., Al-Haj Husain, N., Vogeler, K., & Özcan, M. (2021). An Assessment of the Influence of Dental Porcelain Slurry Preparation on Flexural Strength of Different Feldspathic Porcelains. Applied Sciences, 11(20), 9385. https://doi.org/10.3390/app11209385