In this section, we will describe the testing of the Baseline Engine (identical to the RLE but with a conventional cylinder) and the RLE prototype described above. By comparing the combustion characteristics, we are quantifying the friction reduction experimentally under low-speed and peak cylinder pressure (PCP) conditions. This section is rather long for the two following reasons. We cannot accurately obtain the iMEP of the two engines and we cannot control the mechanical fuel injection well. A measurement of iMEP for the two engines would have been a very direct way of comparing the idle fMEP, but unfortunately, this is not feasible. An electronically controlled fuel injection would have allowed us to easily compare cases. Instead, a relatively complicated methodology that generates an even comparison of operating conditions between the BSL and RLE is presented, which accomplishes the same, but unfortunately is lengthy.

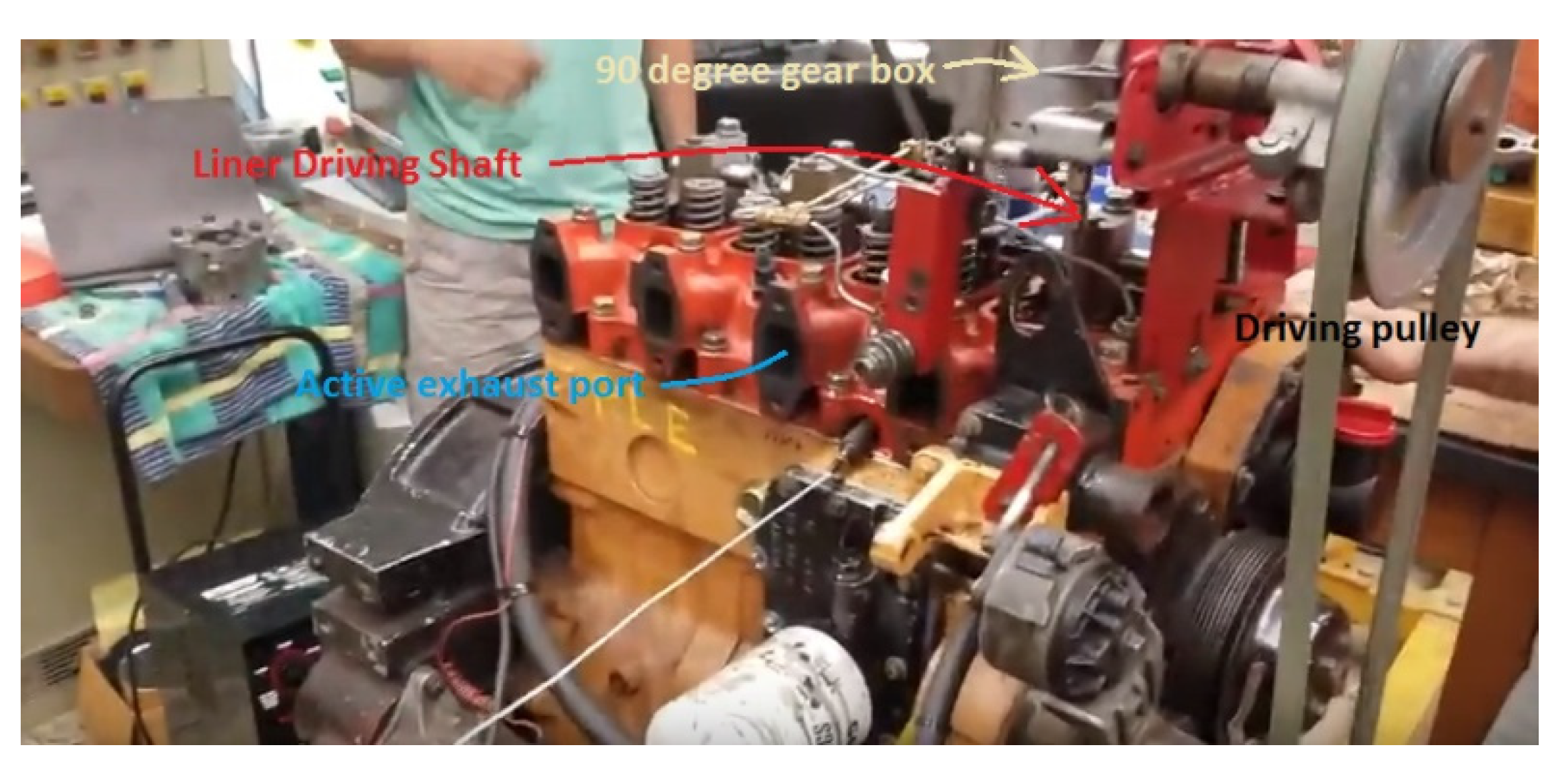

Given the fact that both engines are powered by an approximately 1 L single cylinder which drives a 5-bearing crankshaft and accessories sized for a 5.9 L 6-cylinder engine (water pump and oil pump are identical to the 6BT), and given that we have focused on 750 rpm, the operating conditions presented here represent a loaded idle (i.e., engine is driving an AC compressor or other accessories) rather than a totally unloaded idle condition of a full engine. The reason why we chose 750 rpm is because the minimum idle of the two engines is on the order of 630 to 680 rpm, and is not entirely consistent. Therefore, we are focusing on an idle condition where the fueling lever of the injection pump needs to be slightly advanced instead of resting at its minimum stop. These old-style injection pumps operate like speed regulators in the idle range. Additionally, we have focused on 70 °C because the original BSL data are at that oil/coolant temperature, and we have not yet obtained high resolution pressure data for the BSL at a higher temperature. Additionally, all the data are with the 15w40 grade lubricant.

3.1. Preliminary Testing from Prior Publication

The fuel economy at idle of the prototype was compared to a baseline engine, also single-cylinder, where all the characteristics were almost identical to the RLE except for the liner rotation (Dardalis 2019). The condition focused on at that time was 750 rpm idle and 71 °C coolant and oil temperature. For that condition, the RLE was estimated to have slightly under 20% lower fuel consumption. This estimation was achieved via comparing the pressure rise between the peak motoring pressure (PMP) and peak cylinder pressure during firing pressure (PCP), which is essentially proportional to the total heat release per cycle, as long as the combustion phasing is similar. The assumption here is that the indicated thermal efficiency of the two engines is identical, which is reasonable since the engines are almost completely identical with similar compression ratio. The validity of this comparison was also made possible by the fact that injection timing was substantially advanced and peak firing pressure was around the TDC, which meant that the majority of the heat release was complete by TDC. This is not an efficient way to run an engine, but we are not attempting to achieve a record in thermal efficiency; instead, we are estimating the percentage of friction reduction of the RLE concept by comparing the amount of heat release needed to sustain the idle in the BSL and RLE. The difference between PCP and PMP was adjusted by the ratio of clearance volumes between the two engines (which unfortunately were not exactly the same, but also varied, as shown in the sections below) in order to comply with the ideal gas equation, and the corrected value is what is used for the final comparison (the correction factor is relatively small). This yielded about a 19% reduction in fuel consumption at idle for the RLE (Dardalis 2019). However, these tests were very preliminary and had the following limitations.

Difficulty in obtaining the proper TDC location.

Difficulty in obtaining the accurate IMEP.

Uncertainty in injection timing.

Baseline had a slightly higher compression ratio.

The Rotating Liner gearbox was an inefficient unit with grease bushings rather than roller element bearings, which increased gearbox parasitic losses.

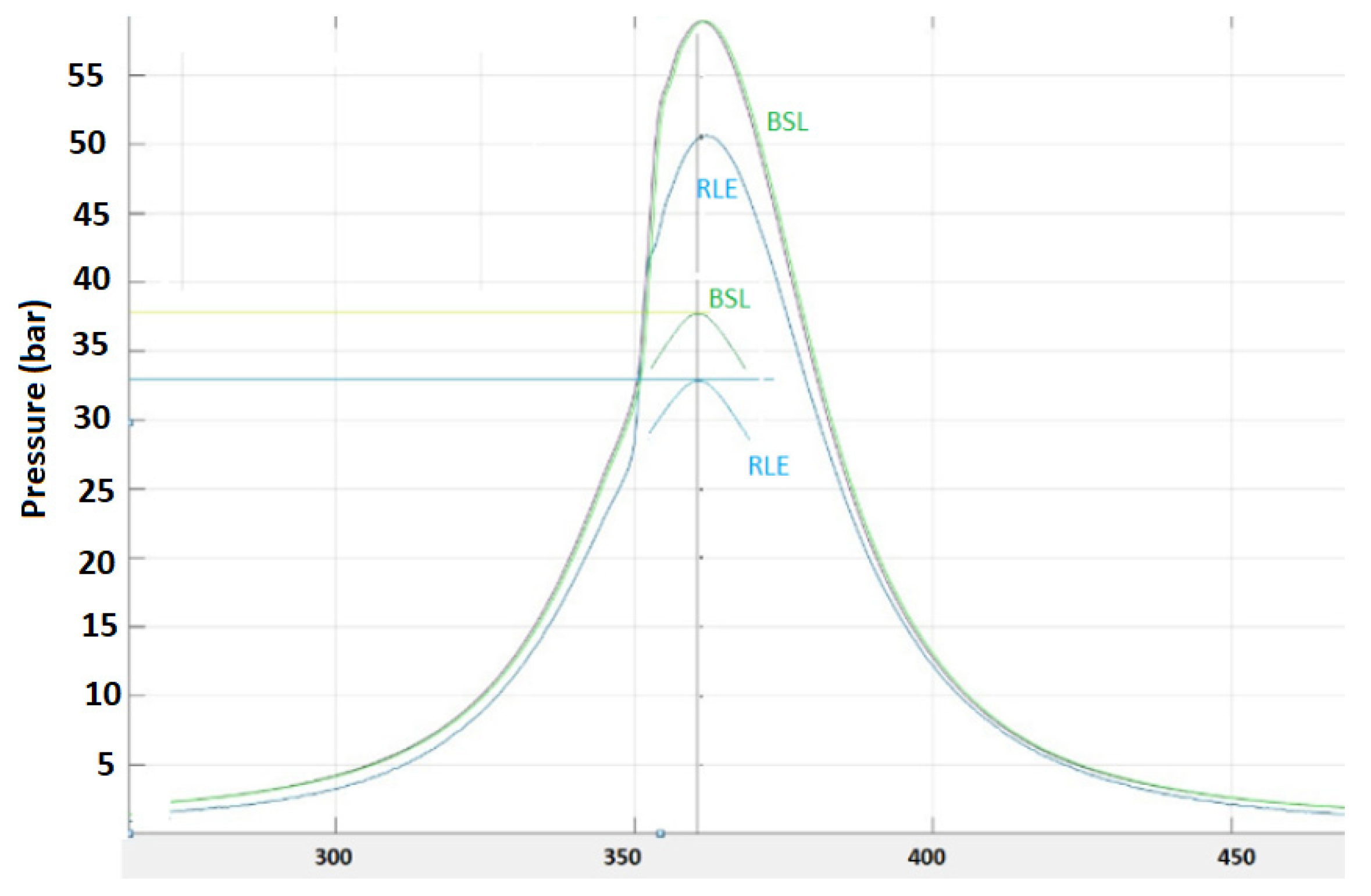

Figure 9 shows the pressure vs. crank angle graphs from the two prototypes from the prior publication. In this graph, the CA axis is slightly shifted in order to align the premixed combustion events, which seem to be fairly close anyway. However, it is fairly evident that both cases have a substantially over-advanced timing and that most of the heat release has been completed by the TDC. In both cases, the peak pressure was within one degree from the TDC. In the analyses presented in this paper, not only did we confirm that, but we also showed that the BSL was slightly more retarded, and a fraction of its heat release had taken place after the TDC, changing the numbers somewhat.

Firstly, we reduced the compression ratio of the BSL to the point where the motoring pressure was slightly lower than the motoring pressure on the RLE. Even though we have not perfectly matched the two compression ratios, we were at least able to bracket the RLE compression ratio with the two BSL cases. In the work presented in this paper, we were able to locate the TDC with better precision in both engines. However, we were still not able to obtain repeatable IMEP measurements. We identified the root of this problem to be the crankshaft torsional vibrations that take place due to the conversion from a four-cylinder configuration into a single-cylinder engine. The reasonably precise location of the TDC, however, allowed us to better define the location of the premixed combustion with respect to the TDC (which is the effective injection timing). The potential error caused by the torsional vibration is negligible compared to the potential error in the iMEP calculation. This allowed us to better refine our relative gross heat release rate (PCP minus PMP). Additionally, we were able to calculate the adiabatic instantaneous heat release rate, which is also relatively insensitive to the exact TDC location, especially if the majority of the heat input takes place during the premixed combustion phase (due to the low-pressure fuel system modified for single-cylinder operation), and if that event is substantially before the TDC where the combustion chamber volume is relatively large. We were also able to obtain some limited exhaust CO2 concentrations of the two engines.

3.3. Comparison of High Compression Ratio BSL with the RLE

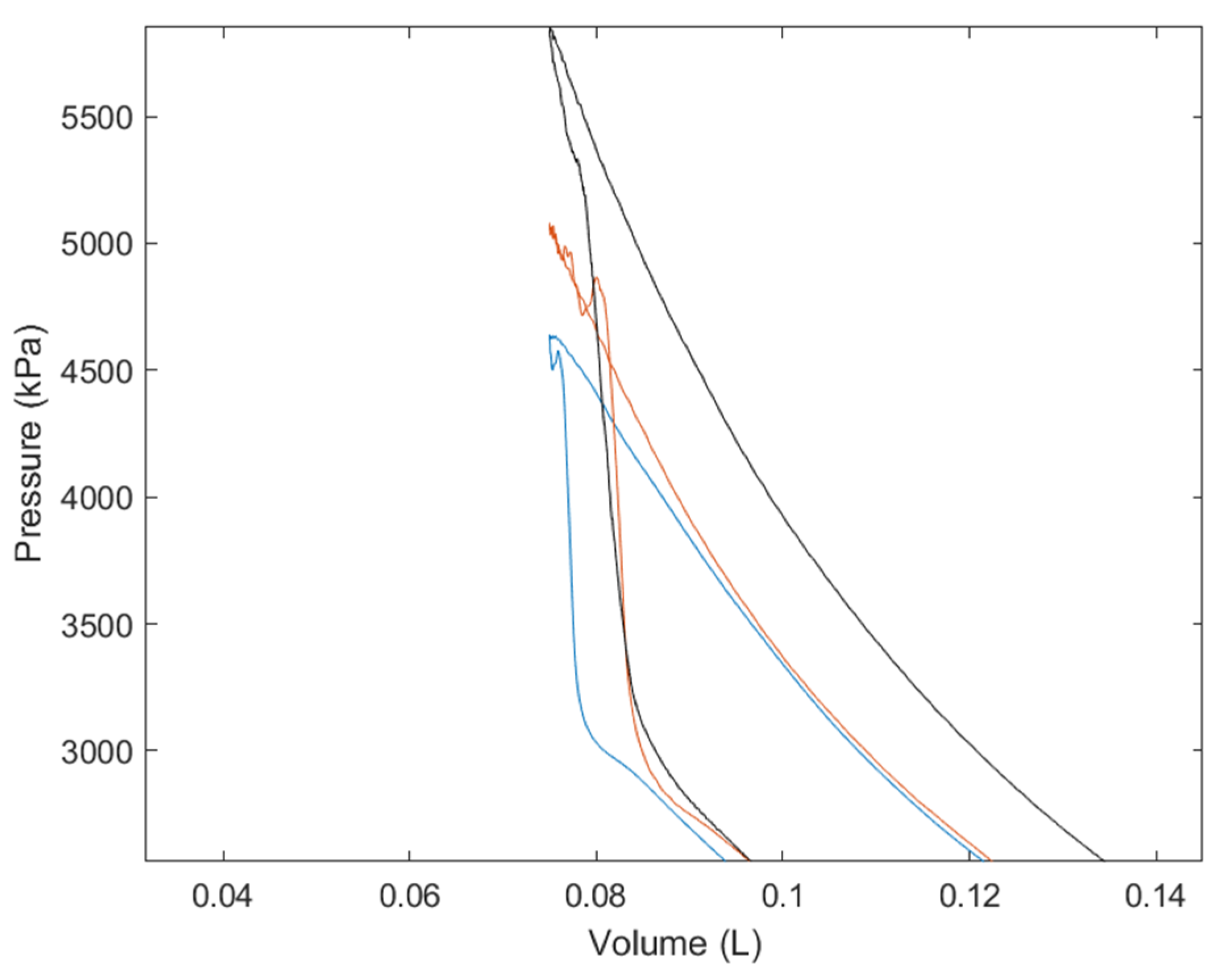

In this subsection, we show some P-V diagrams that help us analyze the combustion characteristics of the various cases that we are presenting. If the pressure rise due to combustion has the slope shown by the black and red curves of

Figure 11, it means that the volume was still decreasing when combustion occurred; therefore, the combustion took place before TDC. In the case of the blue curve, the pressure rise is almost vertical, meaning that there was no appreciable volume change during combustion, so the premixed combustion took place at the TDC. If the slope was reversed, then the pressure rise would have been taking place while the volume was increasing, and it would have taken place after TDC (this is the typical way diesel engines are set up to run). Additionally, a portion of the top of the compression and expansion curves, as in the red graph of

Figure 11, overlaps. This means that the combustion had ended before the minimum volume was reached, so the pressure followed the corresponding adiabatic curve from the end of combustion, to the minimum volume, and back over the early expansion. In the black curve of

Figure 11, some degree of combustion continued until the minimum volume or slightly after; the expansion followed a slightly higher adiabatic curve than the late compression.

As discussed above, the RLE has been upgraded with a new gearbox and also with a proper TDC location. The data of

Figure 11 (red line) were taken before ever modifying the injection pump timing, and with the same injector. Additionally, we are still using the exact same injection pump as we had in the original BSL experiments. It is obvious from

Figure 11 that the injection timing in the RLE was substantially over-advanced and all combustion was complete prior to the TDC, whereas for the BSL, even though the premixed combustion was clearly taking place prior to the TDC, some combustion and increase in pressure continued after the TDC. The RLE red line graph also shows a pressure oscillation that was not present in the data presented by Dardalis [

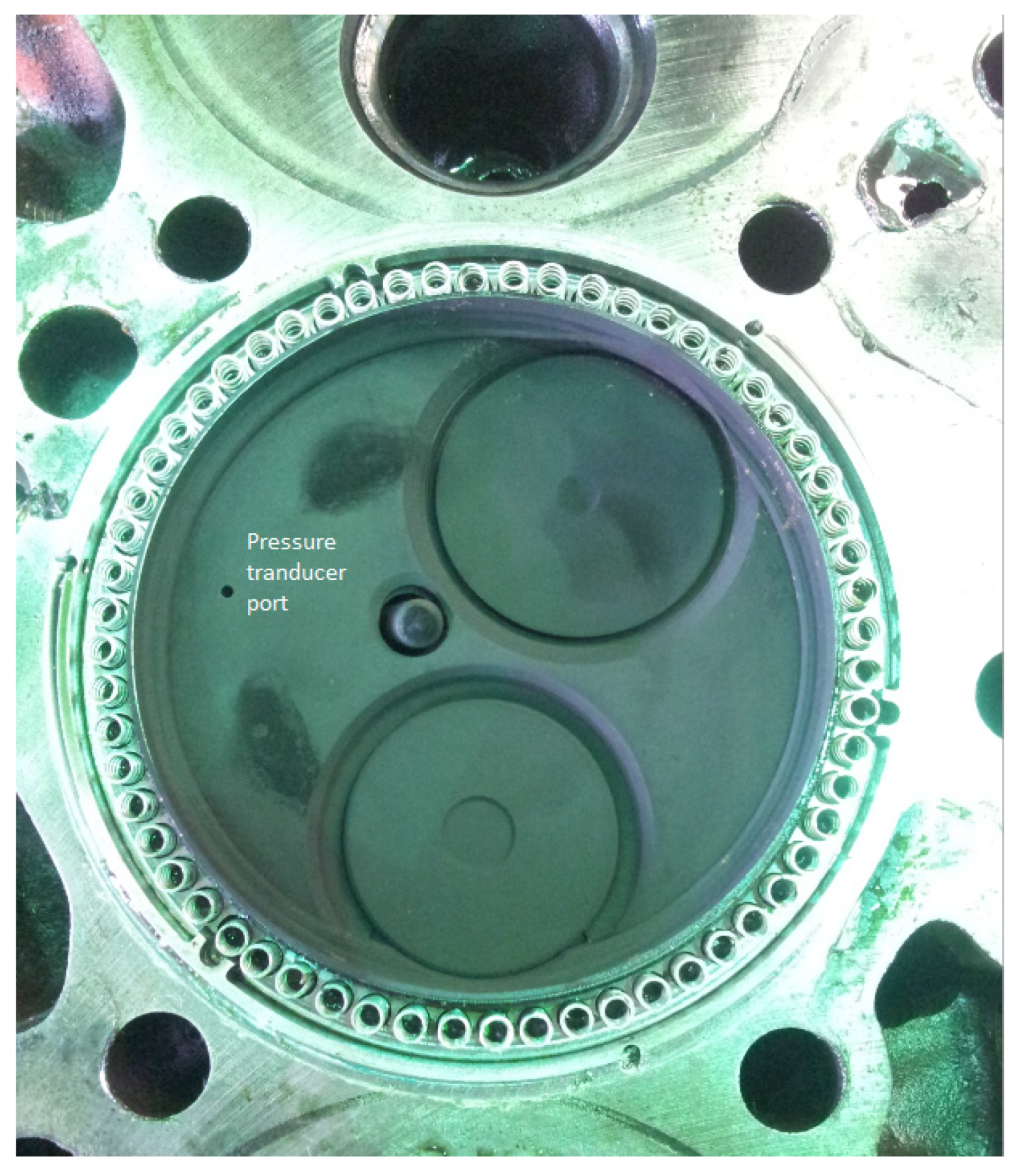

7]. It seems that we are having some abnormal combustion along with the pressure wave in the channel that connects the combustion chamber to the pressure transducer (a channel of approximately 20 mm is connecting our transducer to the combustion chamber, see

Figure A2; under certain conditions, a pressure oscillation is seen in the signal). In the blue case in

Figure 11, the injection timing was retarded (still on the RLE). As expected, the peak pressure was reduced, making it a more fair comparison; however, some pressure noise towards the very top is still visible (this is even more apparent on the Pressure vs. Crank Angle graph).

The blue graph in

Figure 11 appears to be a much better comparison to the old BSL data (black). However, the combustion still appears to be faster. We are not exactly sure as to why, other than the fact that we were forced to service the injector between the two tests due to contamination, and the cracking pressure may have increased. As we said above, the obsolete mechanical fuel system cannot be controlled directly; instead, we tried different operating parameters in a trial and error mode and observed the results in the pressure signal.

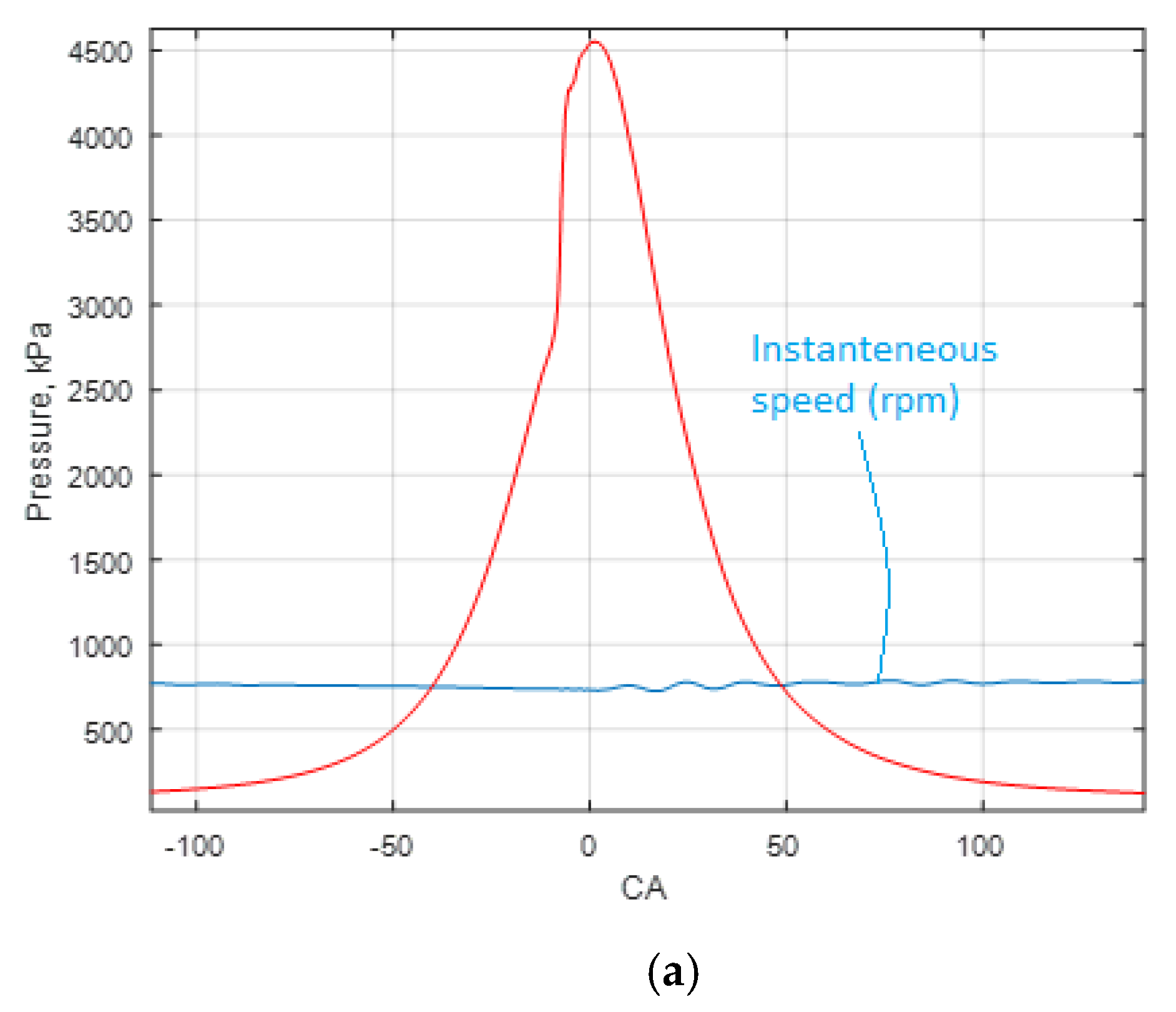

We had a new injector prepared with a lower cracking pressure and tested it in the RLE. The result was a slower combustion event (the combustion duration and location with respect to the TDC is presented later with the instantaneous heat release rate calculations, see

Section 3.7). Again, we are focusing on the conditions of 750 rpm and 71 °C coolant and oil temperature. The results are shown in

Figure 12a and

Figure 13b.

Figure 12a shows the pressure vs. crank angle graph, where the slower combustion also minimized the pressure wave that we obtain on the signal right at the end of the premixed combustion.

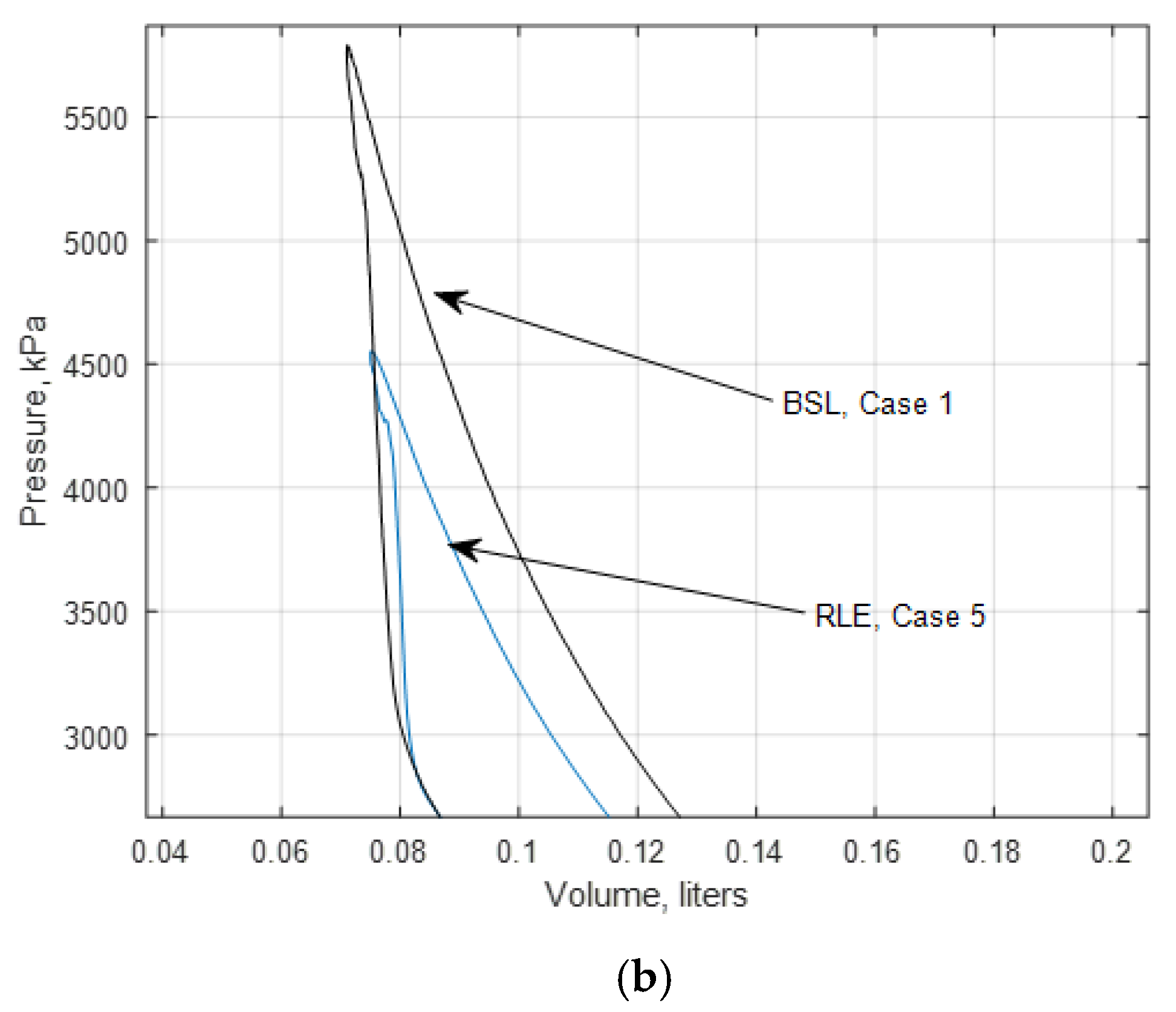

Figure 12b shows the top of the P-V diagram of the same case, which also looks remarkably identical to the BSL in

Figure 11 (which is the same case as

Figure 9 for BSL). Therefore, it can be concluded that the case in

Figure 12 is a much better match to the original BSL cases in terms of percentage of fuel burnt at the TDC. The comparison of PCP minus PMP of these two cases is therefore more relevant.

The revised estimates for fuel reduction to sustain idle and therefore, friction reduction, are presented in

Section 3.6 below. The purpose of the above discussion was to justify the comparison of the BSL Case 1 data to that of the RLE Case 5 data for both heat release and PCP/PMP analysis.

3.4. BSL Testing under Reduced Compression Ratio

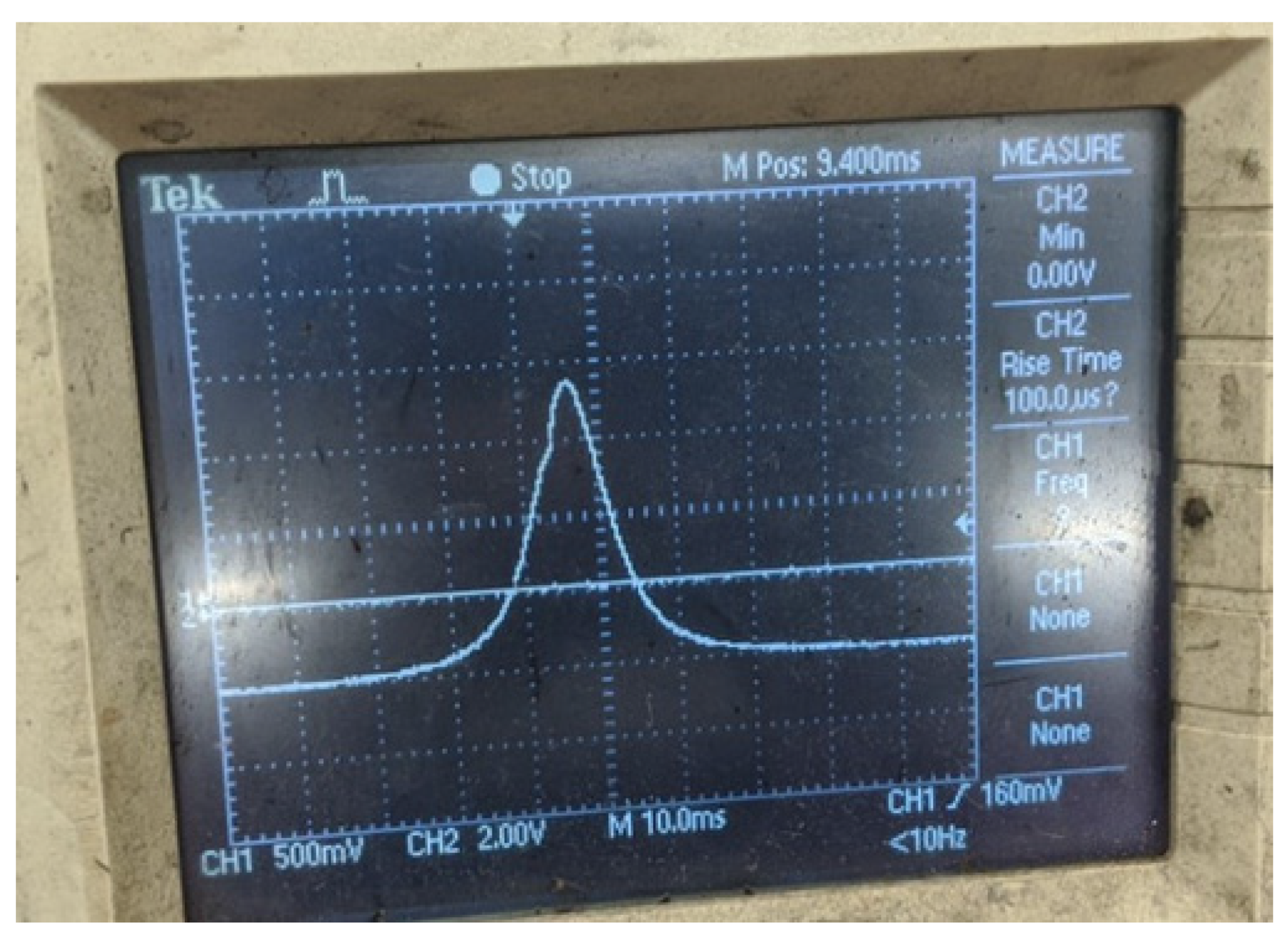

We decided to conduct a few more tests with the BSL and obtain some preliminary CO2 exhaust concentrations from it. The BSL revival was performed without the crankshaft encoder, since we did not want to move this from the RLE and upset our TDC position. However, we could still take cylinder pressure data via the oscilloscope, which are presented in this subsection.

Prior to reviving the BSL, we also decided to reduce its compression ratio, so it would be a better match to the RLE; the correction factor due to differences in clearance volume would hopefully become 1 or closer to 1. As it turned out, the compression ratio of the BSL became slightly lower, so the correction factor was still needed, but the correction factor now amplified the difference in PCP-PMP rather than reducing it. The variation of compression ratio was performed by replacing the original thick copper head gasket with a stock gasket, but apparently, given that we did not know exactly the extent to which each gasket crushes, the compression ratio did not end up at the exact value of the RLE (we used a copper head gasket in the RLE as well, but the head bolts were torqued down to a lower torque than the BSL, since the combustion gases were contained by our RLE hydrodynamic face seal). The compression ratio comparison was performed via our motoring test. This motoring test is not exactly a motoring test, since we do not have a motoring dynamometer. Instead, we rev the engines up, turn off the injection pump, and record pressure and speed. This can be conducted with the data acquisition system, or simply by the oscilloscope. This process is shown in the

Appendix A. The process yielded 28 bar absolute (27 bar gage) at around 1080 rpm (the sensitivity of the peak pressure on rpm is very low for both engines; it used to be slightly more pronounced for the BSL when it operated with a higher compression ratio).

The comparison in terms of CO

2 concentration is shown in

Table 1 and

Table 2. Comparing the cases with advanced injection timing, the RLE exhibited about 20% lower CO

2 concentration for the idle condition in question. With the retarded timing, the difference became substantially wider at a 45% difference. This margin is larger than the pressure data suggest, and we cannot explain this large difference yet.

During these tests, it was discovered that some further correlations between PCP-PMP can be made, and the injection timing can be used as a variable. Specifically, we know that as the injection timing is retarded, the PCP will be reduced. We wanted to capture this effect and compare it to how the RLE responds to similar injection timing. This allowed us to group cases with similar combustion characteristics, and make more refined comparisons, thus eliminating the uncertainty of injection timing. Even though we can no longer define the exact position of the premixed combustion with respect to the TDC (given the absence of the crankshaft encoder from the BSL), the changes in the combustion characteristics are fairly large, and solid conclusions can be made, even in the absence of an encoder.

In this next series of experiments, the new injector with reduced cracking pressure was used with the BSL as was the case of the RLE data given in

Figure 12b. In this case, it has a rather advanced injection timing. This is evident by the fact that the sharp pressure rise of the premixed combustion takes place at a compression pressure of at least 3 bar below the maximum motoring pressure and of course, prior to any local maxima of the pressure. When the temperature actually reached 71 °C, the peak pressure was about 44.5 bar abs. The combustion behavior of this case is shown in the

Appendix A (

Figure A4). This case is called Case 2.

Now, let us explore the PCP response when the timing is retarded by 4 degrees. The combustion characteristics are again shown in the

Appendix A (

Figure A5). The fact that these conditions are of a retarded injection timing can be concluded by the fact that the premixed combustion started at a pressure about identical to PMP, indicating that combustion started around the TDC and most of the heat release took place after TDC. For some reason, the premixed combustion is not as well defined in this case, possibly due to the reduced compression ratio. The combustion seems to be slower than other cases. The PCP for that case was about 39.0 bar absolute. This case, which we call Case 3, is also shown in the

Appendix A. Obviously, we cannot use the difference of PCP-PMP to compare this case with, for example, the RLE cases of

Figure 11 or

Figure 12, since in these cases, most of the heat release was completed by TDC. However, an RLE case with similarly retarded timing is presented in

Section 3.5 in order to show that the trend of lower PCP-PMP in the RLE persists.

3.6. The PCP-PMP Comparison Method, and First Estimate of RLE Friction Reduction

The above cases set the stage for meaningful comparisons of PCP minus PMP of comparable RLE and BSL cases in order to establish the total heat release needed to sustain the engine. It can be assumed that the indicated thermal efficiency of both engines is about identical, and since the only load on the engine at idle is its own internal friction, the fMEP is directly proportional to the heat needed to sustain the engines. This total heat release per cycle is proportional to the PCP-PMP, as long as the comparison is made for cases where about the same percentage of the total heat release is complete at the TDC, and/or as long as the peak cycle pressure is around the TDC (in other words, as long as the combustion phasing with respect to the TDC is identical). The only case where peak pressure is substantially after the TDC is Case 3 (see

Figure A5 in the

Appendix A). We collected enough information to justify meaningful comparisons. For the cases shown in

Table 1 and

Table 2, we can compare Cases 1 and 4 (favorable for the BSL as discussed), 1 and 5, 2 and 5, and 3 and 6. The CO

2 measurements are not complete, but appear consistent with the PCP-PMP comparison method. The most important corroboration is actually via the integrated adiabatic heat release calculations, which will be discussed in

Section 3.7; they show where in the cycle the heat release is taking place.

Overall, the comparison in

Table 1 and

Table 2 is consistent with the trends. The lowest margin of RLE improvement in fuel economy is when comparing Cases 1 and 4, which is 18%. RLE Case 4 is considerably over-advanced as shown by its P-V diagram (

Figure 11, red curve). This over-advancing was also apparently causing excessive heat loss, and the actual indicated thermal efficiency was low, as indicated by the higher (compared to RLE Case 5) exhaust CO

2 concentration. However, when the timing was retarded one step (Case 5), and the combustion of the RLE was a lot closer to BSL Case 1, we obtained a 38% reduction in PCP-PMP compared to Case 1. However, we are comparing the RLE with a higher compression ratio BSL, where it can be argued that the pressure loading on the BSL piston rings creates an excessive fMEP loss for the BSL (the RLE piston rings and skirt are operating hydrodynamically, so their fMEP contribution is not sensitive to pressure loading). However, when we compare RLE Case 5 with BSL Case 2, where the compression ratio is actually lower than the RLE, we are still obtaining a 32% reduction in fuel consumption. When the timing is considerably retarded on both engines, the margin is reduced to 23%. This is reasonable, based on the fact that the retarded timing reduces the pressure loading on the BSL piston rings, but also, it needs to be reiterated that this comparison favors the BSL where the peak pressure is considerably past the TDC (

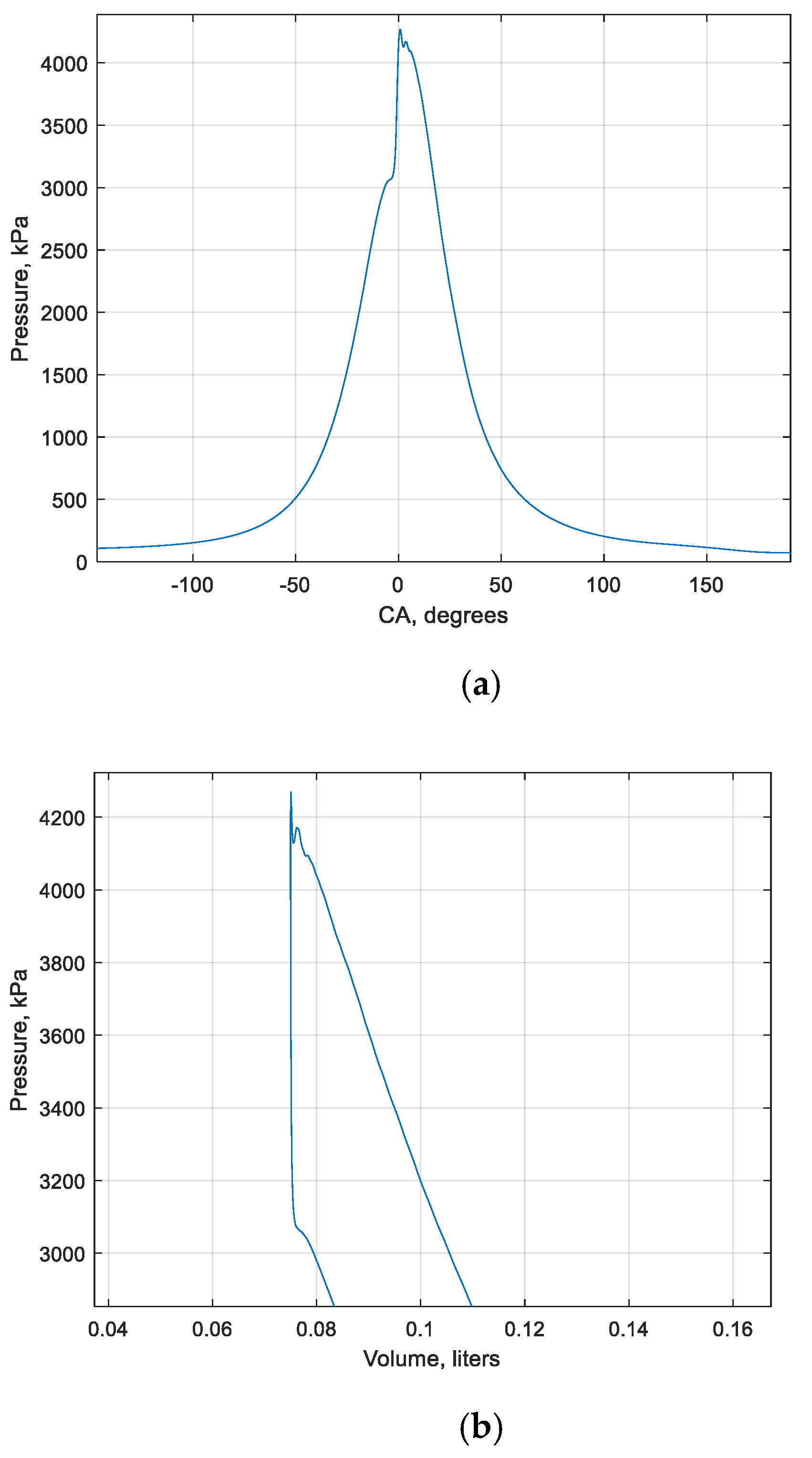

Figure 13a for the RLE and

Figure A5 for the BSL).

Some readers may wonder about the validity of the PCP-PMP method, by suggesting that the leakage from the face seal reduces the peak pressure on the RLE. This was expanded upon by Dardalis et al. 2019 [

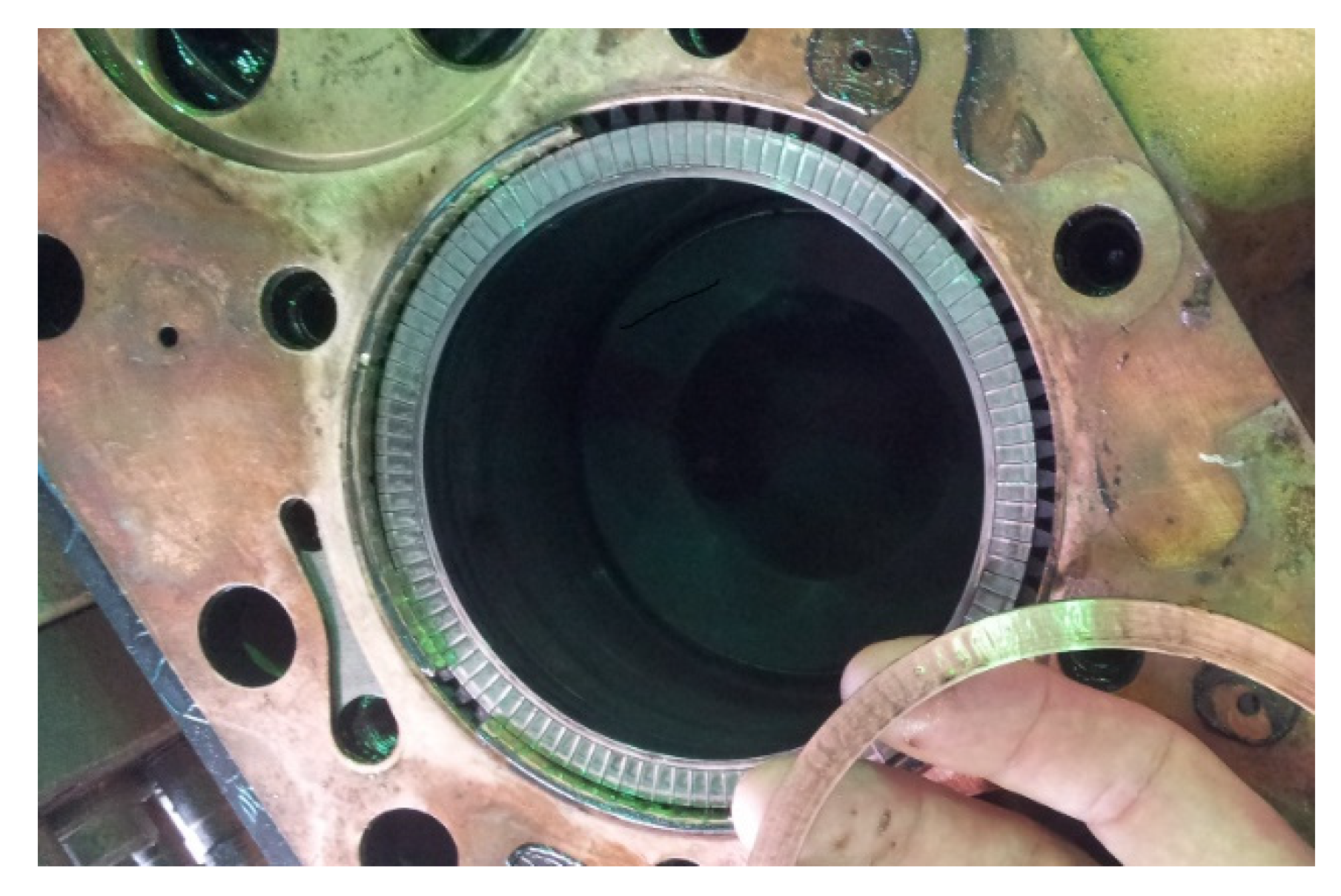

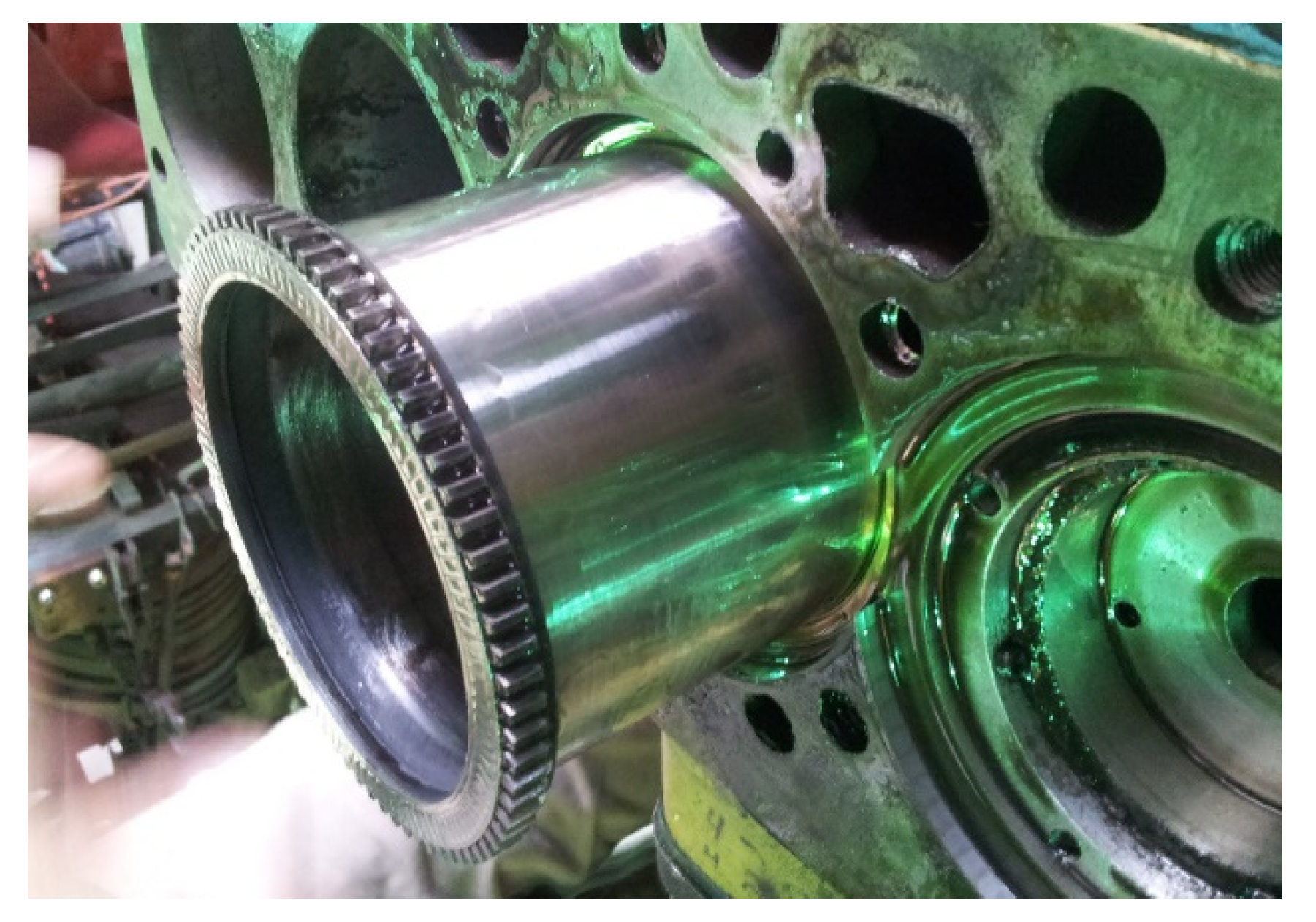

7], but it will be briefly mentioned here. The combustion with this low-pressure injection system is very sooty and leaves heavy traces where there is blowby. When the engine is disassembled and inspected, it is typically observed that the area of the seal is clean from soot, and in fact, the area where the soot never enters in the seal gland is very well defined (See

Figure A2 in the

Appendix A). This is in contrast to the piston ring lands, for example, where soot is clearly defining the leakage path, especially in the RLE where the rings are pinned, and the end-gaps are always in the same position. Second, the RLE face seal area is directly connected to the gear area (

Figure 4 or

Figure A1), which is in turn isolated from the main crankcase. We had leaks occur occasionally due to malfunctions, caused either by an error during assembly, or on one occasion, by debris from a proximity sensor that collided with the piston and packed in the gland, interfering with the face seal function. When a leak happened, the sound was clearly heard from the open port of cylinder #1. This is the only time when signs of soot are observed in the seal area during disassembly. Finally, a gas leakage is a direct energy loss, which will require a larger quantity of fuel to be burned to compensate. As will be seen in

Section 3.7, most of the heat release takes place during a very brief portion of the cycle when there would be very little time for gas leakage. A significant energy loss due to leakage would show itself as a higher amount of total heat released per cycle needed to sustain the engine. However, the overall heat release follows the same trends as the PCP-PMP method, as shown in

Section 3.7.

Based on the results of this section, it is reasonable to conclude that the RLE fMEP is approximately 20–35% less than the BSL, as it takes about 20–30% less fuel to run, given approximately identical thermal efficiencies. Additionally, given that each of the single cylinders has to rotate a 5-bearing crankshaft, and the oil and water pumps are sized for complete 6-cylinder engines, it can be concluded that the fMEP reduction for a complete engine would likely be much higher than 30%. This is expanded on in

Section 3.8.

3.7. Instantaneous and Integrated Total Heat Release Comparison

We have high-resolution cylinder pressure data with a crankshaft encoder for many cases for the RLE and one case for the BSL, Case 1 having a high compression ratio. These were analyzed to obtain the instantaneous adiabatic heat release rate. This information can be used to confirm the statements of previous sections with respect to the heat release distribution in the cycle, and specifically with respect to the TDC. For example, was Case 4 of

Table 1 and

Table 2 really more advanced than Case 1, and is Case 5 indeed a better match to Case 1 to the position of the combustion event with respect to the TDC?

The equation used to calculate the instantaneous heat release rate was borrowed from Brunt and Platts [

8] and is shown here as Equation (1).

where

Qhr is the heat input by combustion,

γ is the ratio of specific heats (function of temperature),

p is the pressure, and

V is the volume. Note that we ignored heat loss; we are only considering the adiabatic heat release in order to be consistent with the prior PCP-PMP method. For all the graphs shown in this section, the dQ plotted is for 1/20th of a crank angle, which is our encoder resolution.

Figure 14 shows the heat release rate for BSL Case 1. This confirms the prior statements that most of the heat release was prior to the TDC, but some combustion continued after the TDC. Additionally, it confirms that the bulk of the combustion takes place in the premixed section.

Figure 15 describes Case 4 for the RLE, which had a more advanced combustion. This calculation indicates that while the combustion started at about the same time, virtually all the heat was released in the premixed stage, and all prior to the TDC. Note also that the maximum heat release rate around crank angle −8.5 is very high in Case 4, which is responsible for creating the pressure wave noise right at the end of the premixed phase. This pressure wave also causes a local calculated negative heat release rate at about crank angle −6.5, but this noise does not affect the average calculation. The heat release history confirms that the comparisons of PCP-PMP between Cases 1 (BSL, high compression ratio) and 4 (RLE most advanced) were not entirely fair for the RLE because the combustion characteristics of Case 4 will generate a higher PCP for the same total heat released per cycle. The comparison of the total heat released per cycle of 487 J for the BSL to 328 J for the RLE indeed shows a larger margin for the RLE, a reduction in total heat input by 33%, while the simplified PCP-PMP method only yields 18%.

Figure 16 shows the heat release rates for both RLE Case 5 and Case 6 (retarded yet another 4 degrees). The first lesson from

Figure 16 is the effect that the combustion retardation has on PCP. As expected, as the injection timing is retarded, the PCP drops. This will obviously happen on both BSL and RLE. Therefore, in the PCP-PMP method, it is important to compare cases with similar injection timing as expressed by the location of the heat release with respect to the TDC.

Now, we consider if, indeed, RLE Case 5 (retarded by about 4 degrees) is a more fair comparison with BSL Case 1. Further examining

Figure 16, we note that in Case 5, we can see that the maximum rate of combustion is much reduced compared to Case 4 (

Figure 15), causing a reduction in the pressure wave noise, which also reduced the negative heat release just after the premixed combustion, and that some combustion continues after the TDC, much like Case 1 of the BSL shown in

Figure 14 or

Figure 11. The phasing of the maximum heat release rate, the beginning and end of the premixed combustion (starts at −10, ends at −5), and the small tail end of heat release that stretches to just after the TDC, all match between the two cases. Case 4, in contrast (

Figure 15), has a much higher maximum rate of heat release, and the premixed event was just about over at −7.5 crank angle degrees. This confirms that Cases 1 and 5 are better matched for the PCP-PMP method comparison. The simplified PCP-PMP method yields a 38% reduction in fueling, while the integrated heat release comparison (319 vs. 487 J) yields 34.5%.

If we compare RLE Cases 4 (over-advanced) and 5, given that we have identical integrated heat release (heat per cycle), one would expect that the CO

2 emissions would also be about identical. However,

Table 1 and

Table 2 show a large difference in CO

2 concentration. This discrepancy is caused by the fact that our heat release calculation is adiabatic and does not consider the loss in indicated thermal efficiency caused by the excess heat loss of Case 4 (in Case 4, we know that the heat loss is greater due to the longer exposure of the combustion chamber walls to high temperature and pressure). In other words, our analysis only considers the heat release that was directly used to raise the cylinder pressure and perform mechanical work, and not the heat lost to the combustion chamber walls. The indicated thermal efficiency with respect to expansion ratio, however, is identical, which is consistent with the similar values to the total adiabatic heat release. We can differentiate, however, between the friction reduction and fuel consumption reduction. The friction reduction is likely directly proportional to the adiabatic total heat release. However, the reduction in fuel consumption at idle will be proportional to the total heat release (which includes the heat lost to the combustion chamber walls). Brunt and Pratts [

9] suggest that the actual heat release is about 15% higher than the adiabatic heat release. Therefore, the percentage reduction in fuel consumption may prove to be 15% higher (i.e., a 30% value would be 34.5%). We are planning on performing fuel flow measurements in the future.

Given that the PCP-PMP method is corroborated by the more sophisticated heat release rate calculation, we can also compare Case 5 with Case 2 (28% benefit for the RLE), as well as Case 3 with Case 6 (20% benefit for the RLE even though Case 6 is not entirely warmed up). It is only reasonable for the RLE margin to be reduced when the timing is retarded, as the pressure loading on the BSL piston assembly is relieved (but also, the RLE was not fully warmed up). However, even with a reduced compression ratio for the BSL compared to the RLE, the substantial friction reduction persists. The trend of greater fMEP reduction at increasing pressure loading (i.e., higher loads) will likely persist (based also on the SVE experience), but unfortunately, the testing precision will have to be improved, since a smaller fraction of the fuel energy will be expended towards overcoming internal friction.

A sensitivity analysis of this heat release calculation was conducted to compare the estimated magnitude of the friction reduction of the RLE at idle with the potential error. As discussed above, it was calculated that BSL Case 1 had approximately 4 cc lower clearance volume (the relatively large difference in peak pressure was partly due to valve timing and excessive valve lash that caused an early intake valve closing, plus slightly different camshaft specs). Additionally, there is approximately +/−0.25 crank angle error on the TDC of the BSL for Case 1, plus some errors in the real piston location as opposed to the encoder position, due to the torsional vibrations mentioned earlier (these are more pronounced in the RLE, where the liner driving mechanism adds a torsional spring and flywheel upstream of the encoder, see

Figure 10). Therefore, we did a test calculation of the BSL total heat release, assuming extreme errors of 1 full degree TDC shift (towards the direction where the heat release would decrease), plus a reduction in clearance volume of 10 cc instead of 4 cc, which would also reduce the total heat released per cycle (if the clearance volume was that much lower in the BSL, we would not have had reduced the motoring pressure via the minor changes performed prior to resurrecting the BSL unit). Even at this extreme range of parameters, which is far outside the confidence level, the BSL heat release is still 396 J per cycle, or 24% higher than RLE Case 5. The main reason why the heat release calculation is insensitive to the TDC location is that even in Case 1, most of the heat release occurred substantially before TDC. If the premixed combustion took place near TDC, then it is very likely that the calculation would show more sensitivity to TDC location and clearance volume. In other words, given the nature of combustion for both engines for most cases, the integrated heat release calculation is equivalent to the PCP-PMP method. The margin of error on the simpler method is obviously very low as the experimental error is very low compared to the difference.

Again, it is unfortunate that we do not have an electronic fuel injection system so that we can directly control the fuel injection rate and timing. However, this heat release rate analysis explores the direct results of fuel injected, and therefore, more than compensates for the above defect. A lot of trial and error is required to obtain comparable cases, but we have proven that we have accomplished that. Our methods may lack precision, but the margins calculated are substantially higher than the margin of error.

Comparing BSL Case 3 and RLE Case 5 based on the CO2 emissions yields a larger margin for the RLE. We cannot explain the variation, (other than the possibility that the increased adiabatic heat release also generates increased heat loss and amplifies some of the fuel consumption of the BSL, but this is not sufficient to explain the difference). We took the CO2 numbers twice for both cases. Given some variations in the valve timing and volumetric efficiency of the two engines, we tend to believe the pressure data more.

3.8. Extrapolation to a Complete Engine

In this section, we will describe a friction energy accounting scenario, in order to extrapolate the potential reduction in the idle fuel economy of a complete 4BT, if we had indeed converted all cylinders, and we were comparing the 4-cylinder RLE to a complete 4-cylinder baseline engine.

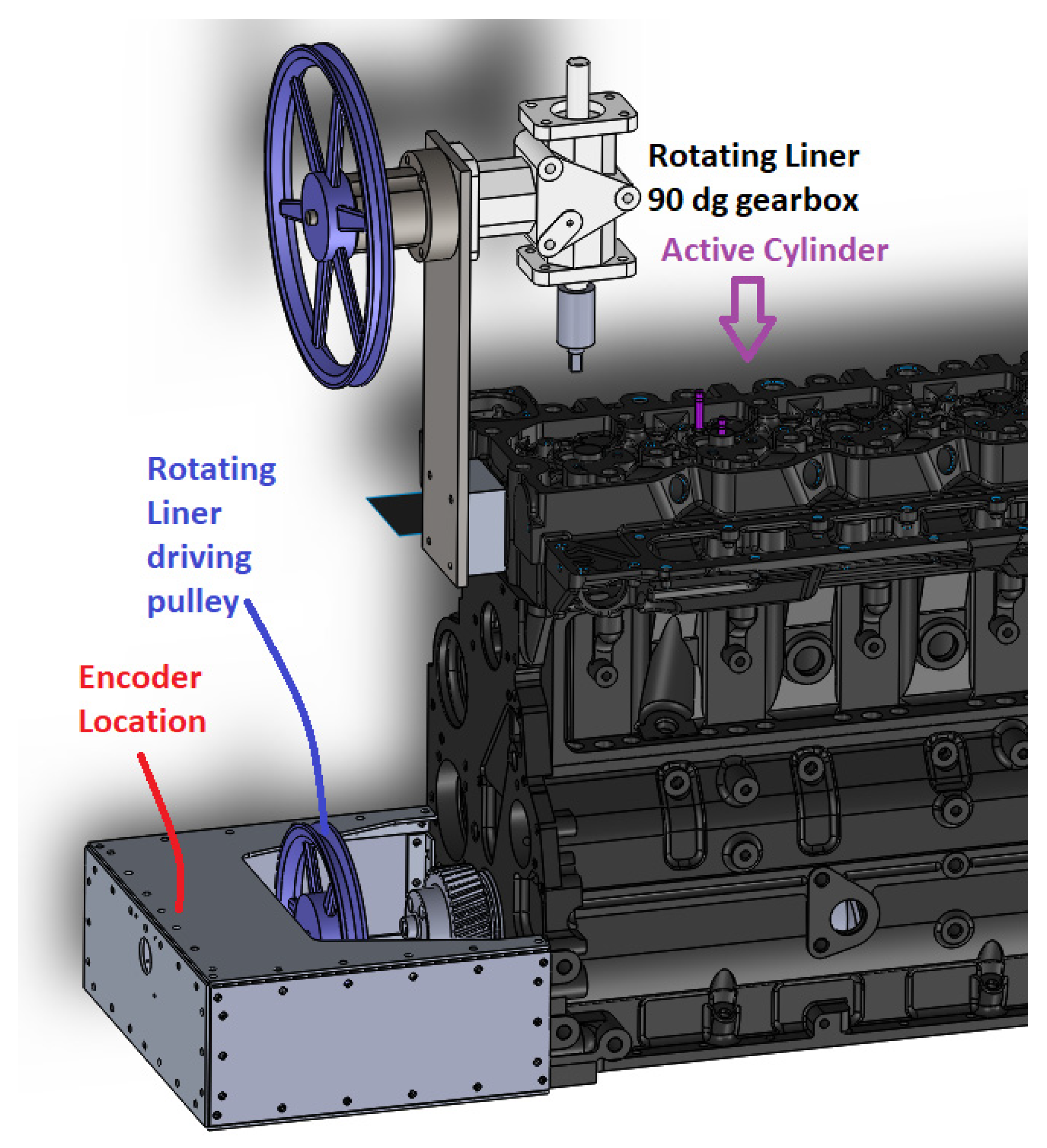

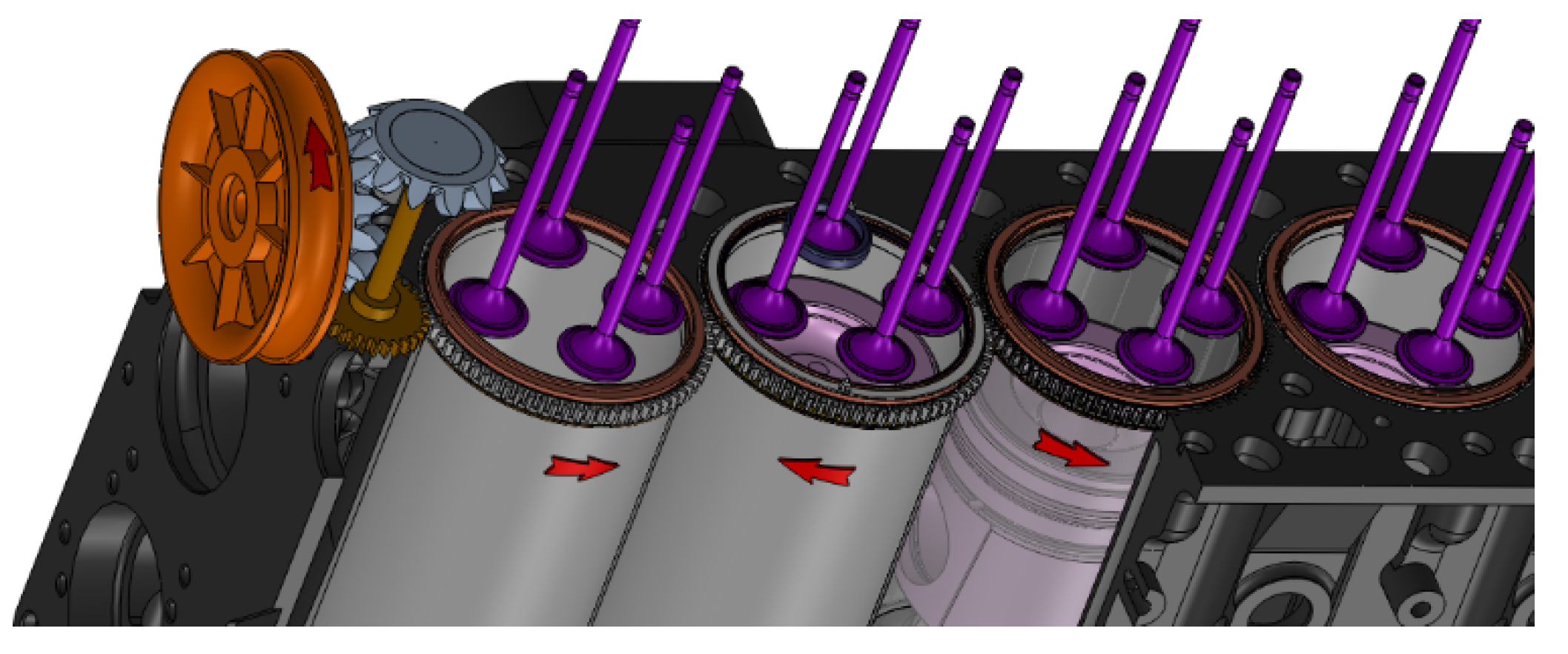

Figure 17 shows the conceptual CAD of a multi-cylinder RLE. In this CAD representation, all the design features of the rotating liner components as fabricated for this prototype are reproduced so that the performance characteristics of this prototype would be perfectly duplicated without any changes, and would fit in the existing block.

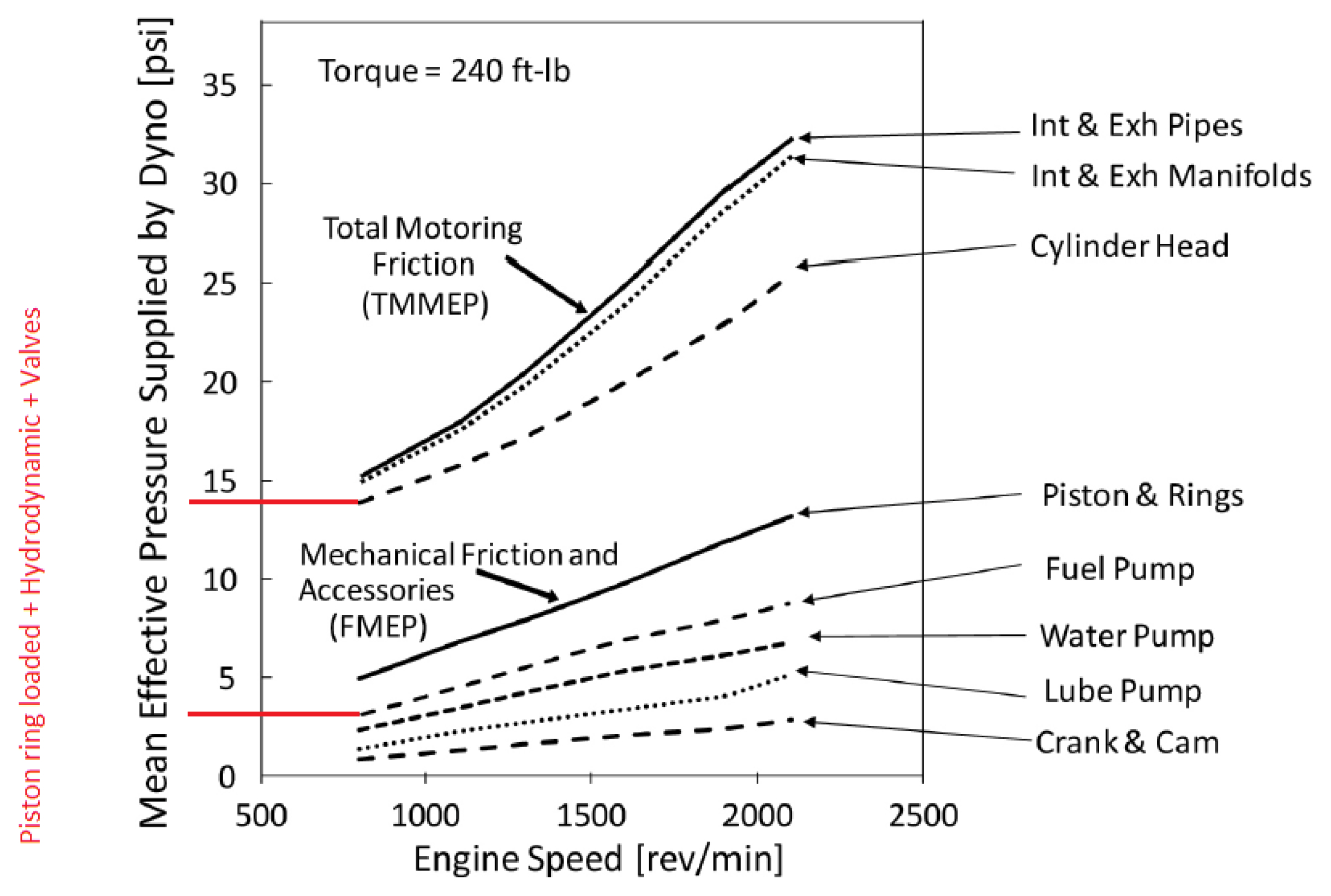

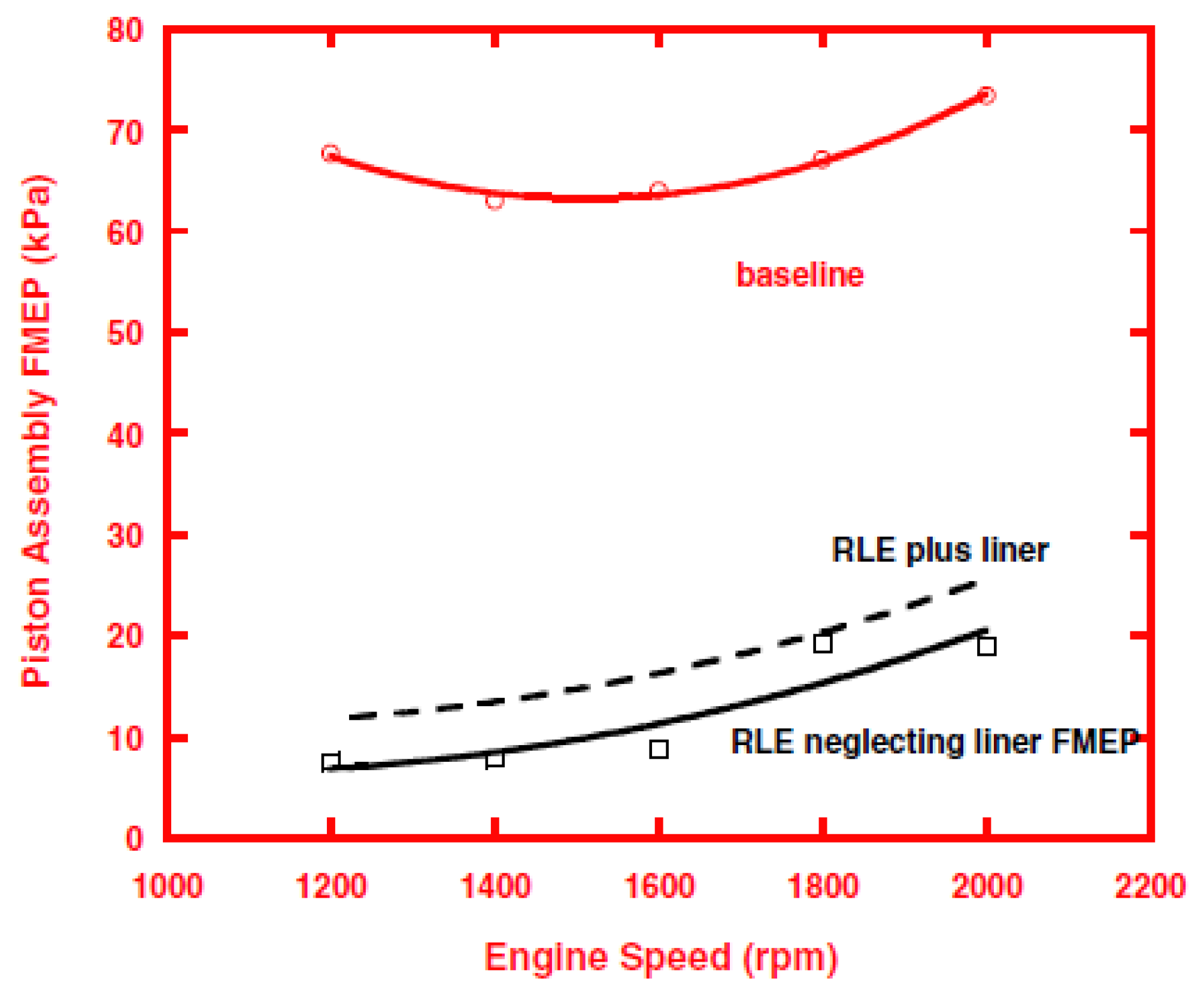

Table 3 shows a likely percentage distribution of component friction for the original Cummins 4BT, and how the RLE reduces it, in order to approximate the measured friction reduction via analysis of the combustion characteristics of the two single cylinder engines. The numbers assigned fit general friction distributions that are reported in the literature. Note also, according to a motoring tear down friction test of a diesel engine published by Stanton (2013), at 750 rpm, the piston assembly (plus valves, but the valvetrain is a small contributor) was the dominant source of friction by about 75% of the total, so the

Table 3 numbers may be a bit conservative concerning the piston assembly’s contribution (note, Stanton’s graph does not properly assign the removal of the cylinder head to the piston assembly; this is a typical error in published tear down tests, which are often performed in the wrong order, Dardalis 2019). The units in

Table 3 are arbitrary, adjusted to give 100% for the 4-cylinder BSL.

In the column that corresponds to the 4-cylinder BSL, the crank 10 + 10 corresponds to 10% for the connecting rod bearings and 10% for the main bearings. The accessories include the injection pump, which will have a substantially reduced power requirement when operating on one cylinder. All injection pump pistons accept fuel during engine operation, but only one piston compresses the fuel against the injector—the other three pistons just return the fuel to the tank without compressing it. The piston assembly contribution for the RLE single cylinder was reduced until the RLE single-cylinder total friction was about 25% reduced from the single cylinder BSL and so as to be consistent with the measurements presented above. The result is a total friction reduction of over 40%. The numbers in

Table 3 illustrate that the measured 25% friction reduction in the single-cylinder RLE will receive a considerable amplification when a complete four-engine is converted. The dramatic piston assembly friction reduction in

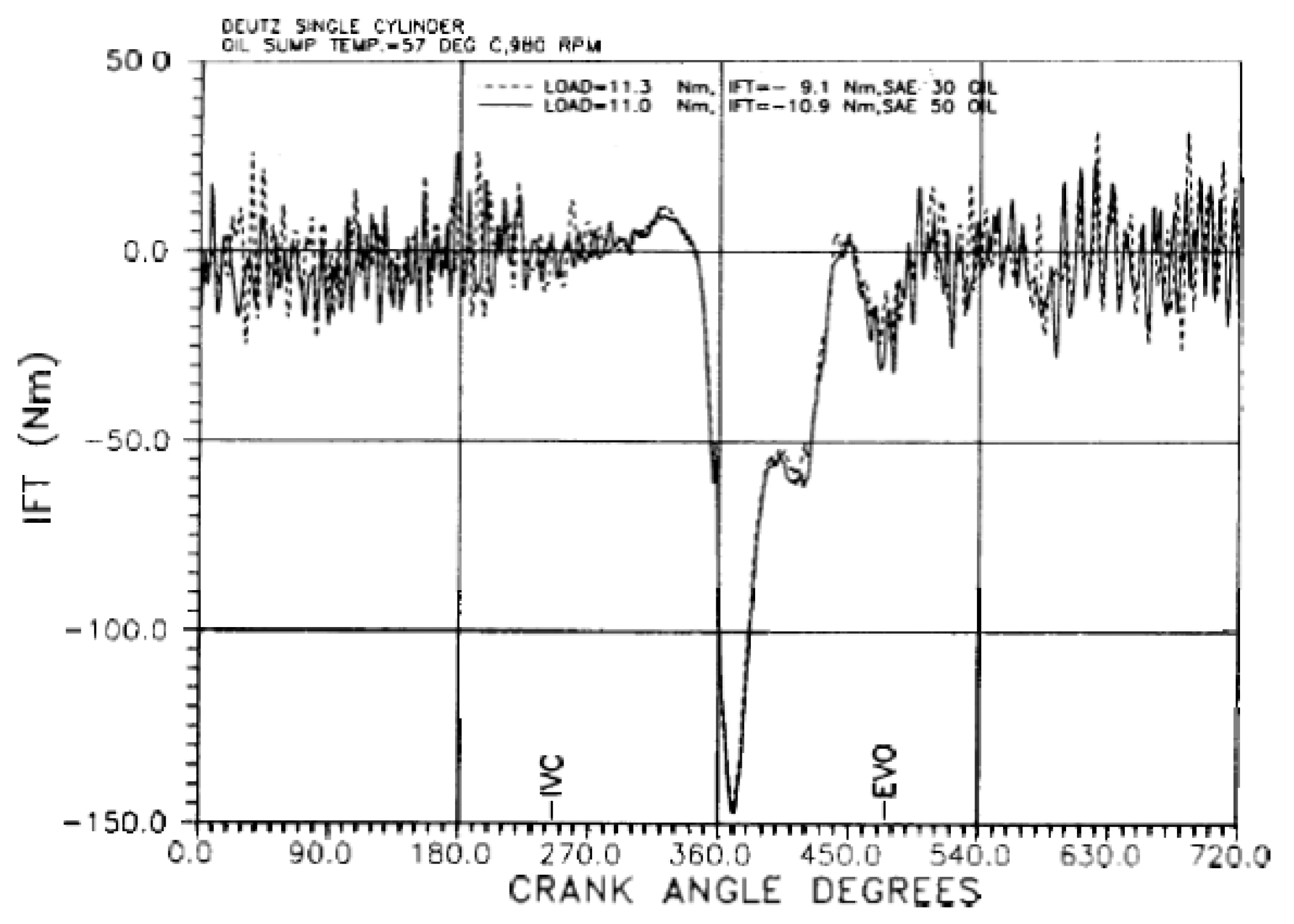

Table 3 from 14.25 to 5.0 is consistent with the tear down presented by Dardalis et al. (2005), where a similarly dramatic friction reduction was recorded for the light-duty RLE under motoring conditions.

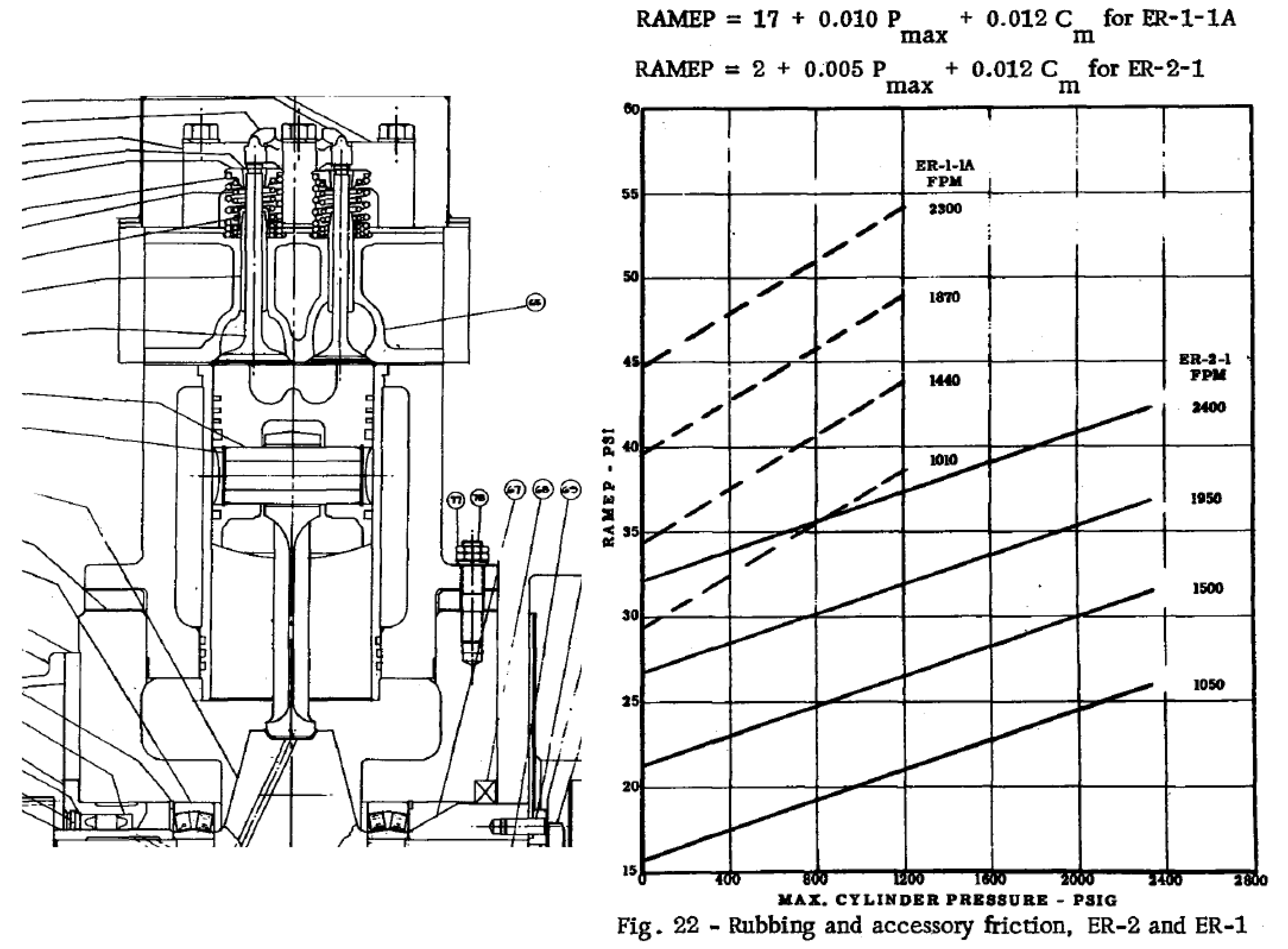

The fMEP shown by Stanton (2013) is about 105 kPa, but this is a motored condition which is known to yield reduced fMEP. The fMEP of a regular diesel at firing idle at the above coolant temperature is about 137 kPa, based on the friction model by Chen and Flynn (1965) and presented again by Dardalis (2012), updated with coefficients that are a better match for modern engines. The calculation used the mid-range of all coefficients except for the hydrodynamic term, which we used the highest value, justified by the relatively low coolant and oil temperature. The above friction model is semi-empirical and calibrated to match a large number of experimental datasets by Southwest Research Institute. The calibration was performed in the late 1990s when the Cummins 4BT engines were being tested and built. Based on our information, Cummins is currently using a similar model with coefficients of about similar values. If we assume that the total friction energy of the four-cylinder BSL in

Table 3 is distributed among all 4 cylinders, and that the 100 units of friction energy corresponds to 137 kPa, one can calculate the predicted burden for the single cylinder BSL and RLE. The operating IMEP of the single cylinder BSL would be 137 kPa/100 × 36.75 × 4 = 201 kPa. The IMEP for the RLE would be 137/100 kPa × 27.5 × 4 = 150.7 kPa. Indeed, our IMEP calculation for BSL Case 1 is 208 kPa, while the RLE cases vary between 155 and 180 kPa. As discussed in

Section 3.2, the IMEP numbers are not reliable due to the torsional vibrations that upset the volume calculation (likely more so for the RLE with the additional shaft portion that drives the rotating liner), but the order of magnitude IMEP seems to be in general agreement. The RLE seems to reduce the fMEP by about 50 kPa at idle. Since the boundary friction assembly term that the RLE minimizes increases at higher loads, the fMEP reduction will increase at these higher loads. We expect that future research will confirm that.

Some researchers may find it difficult to believe that a piston friction reduction method can reduce total engine friction by 50 kPa or more. Part of the reason for this resistance is the many erroneous test results reported by the literature. While usually, the researchers mention that confidence in the absolute numbers of their reported fMEP is low and only the reported trends and margins are useful, nevertheless, readers tend to accept the numbers as given. Stanton et al. (2013) show (once corrected) that the piston assembly-loaded friction, plus unloaded piston assembly friction (boundary oil control rings and the hydrodynamic terms) and the valvetrain contribute 69 kPa for motoring conditions at the lowest rpm range. This graph is reproduced as

Figure A6 in the

Appendix A. Kim et al. (2005) [

6], in a similar motoring tear down of the light-duty RLE and BSL engines, showed a friction reduction of 50+ kPa under motoring conditions. These motoring tests are relatively simple, so the confidence level in the absolute numbers is high. Fedden et al. [

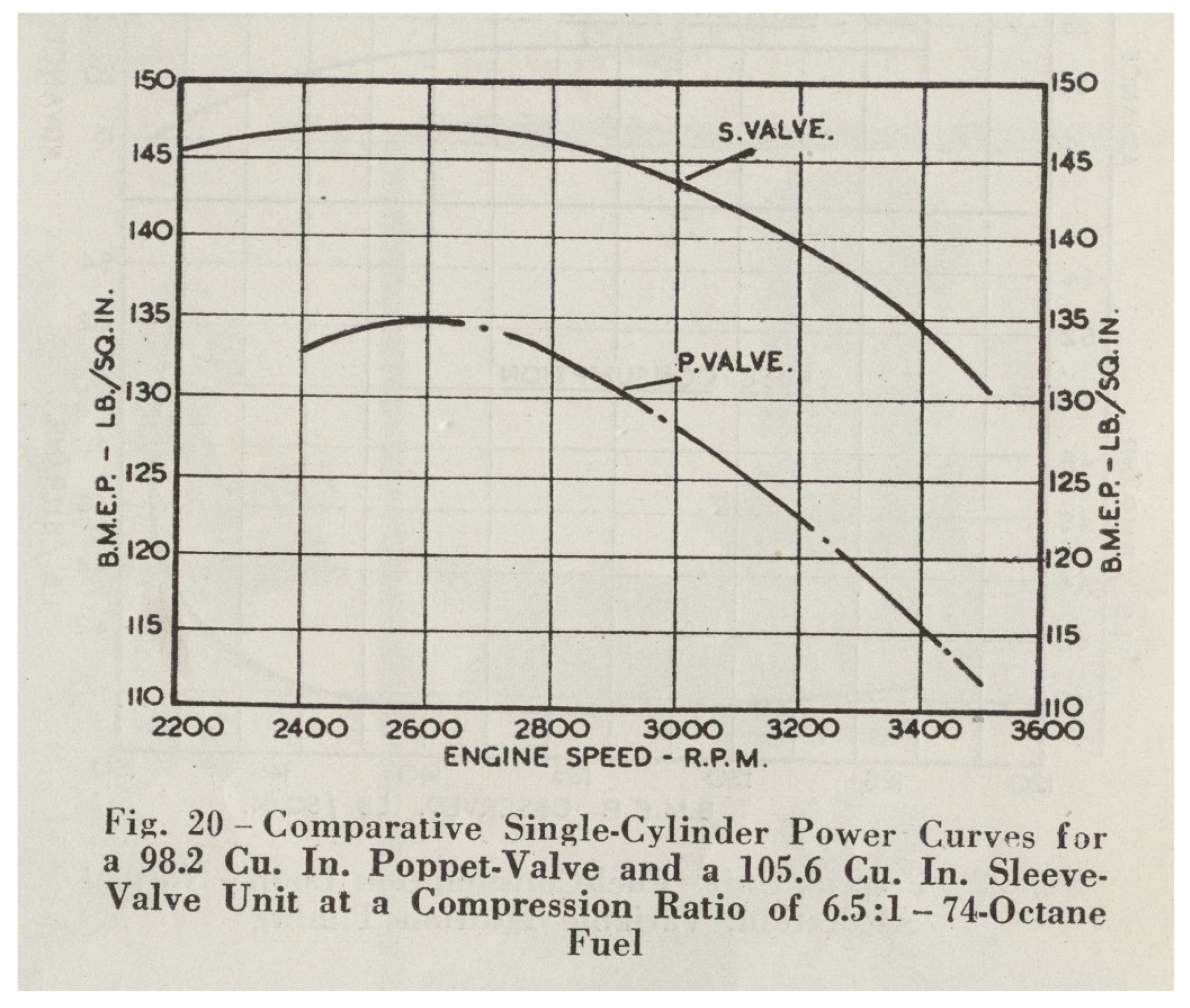

7] presented two naturally aspirated spark ignition engines, one a conventional poppet valve, DOHC (dual overhead cam), and 4 valves per cylinder with stationary liners, and one a sleeve valve (rotating cylinders close to TDC), both operating at a compression ratio of 6.5:1 and at wide open throttle (shown in

Figure A8 in the

Appendix A). The sleeve valve unit produced about 100 kPa more BMEP, even at a low engine speed where any possible advantage in volumetric efficiency of the sleeve valve cannot be significant. Note that the pressure loading of the piston rings of these two engines is not too far from our idling diesels, due to their very low compression ratio, even though they were operating at full throttle. Therefore, friction reduction of this order of magnitude, if indeed the boundary friction terms are minimized, is possible and consistent with the prior literature. Additionally, as discussed above, if the boundary friction via liner rotation was not indeed nearly entirely removed, the total friction of the RLE would have been substantially higher than the BSL, simply because the high friction coefficient of metallic contact would have burdened not only the piston axial motion (from about 30 degrees before TDC to about 45 after TDC) but also the rotating liner during that period (which travelled about 6.6 cm during that time period, unlike the piston which only travelled about 2.5 cm).

Based on the friction model presented by Dardalis et al. (2012) [

5], the friction reduction at idle was expected to be about 25%, but the testing showed that it is 40% or more. Therefore, it may be logical to assume that the 3.5% fuel economy benefit at full load and the 6.8% benefit over the Heavy-Duty FTP derived by the assumptions by Dardalis (2012) may both prove conservative. While the fuel economy percentage improvement will reduce by increasing load because the mechanical efficiency of the baseline naturally increases, the fMEP reduction at increasing load will likely increase, and likely more than the prior modeling suggested. There is a proportionality between the boundary portion of the fMEP that the RLE is reducing/eliminating to the peak cylinder pressure, as the Chenn and Flynn [

2] friction model suggests (see

Figure A7 in the

Appendix A). Furthermore, the 6.8% benefit over the HD FTP (Heavy Duty Federal Test Procedure) was calculated by Dardalis based on data from pre-EGR engines with lower cylinder pressures. Therefore, an RLE applied to a modern heavy-duty truck engine will likely produce much larger benefits than anticipated back in 2012.