Drilling Fluid and Cement Slurry Design for Naturally Fractured Reservoirs

Abstract

1. Introduction

2. Determining the Location of the Thief Zone and the Classification of Fluid Loss

2.1. Location of the Thief Zone

2.2. The Classification of Fluid Loss

3. Prediction of Lost Circulation

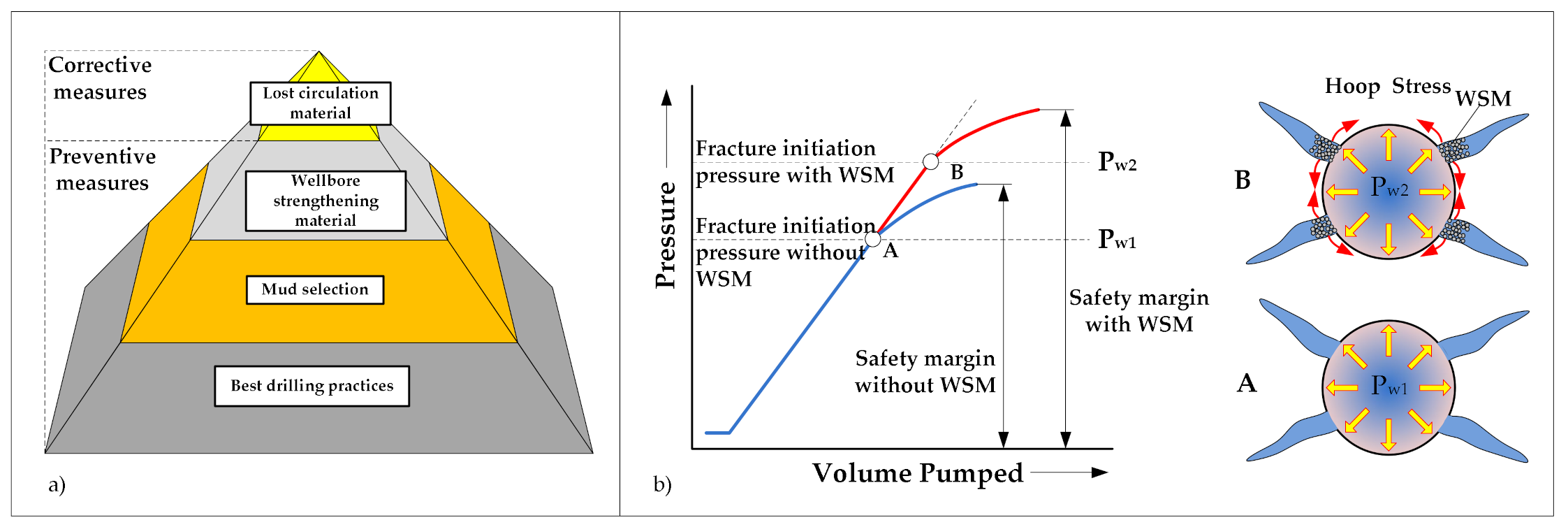

4. Preventive and Corrective Lost Circulation Measures

4.1. Preventive Measures to Avoid Lost Circulation during Drilling

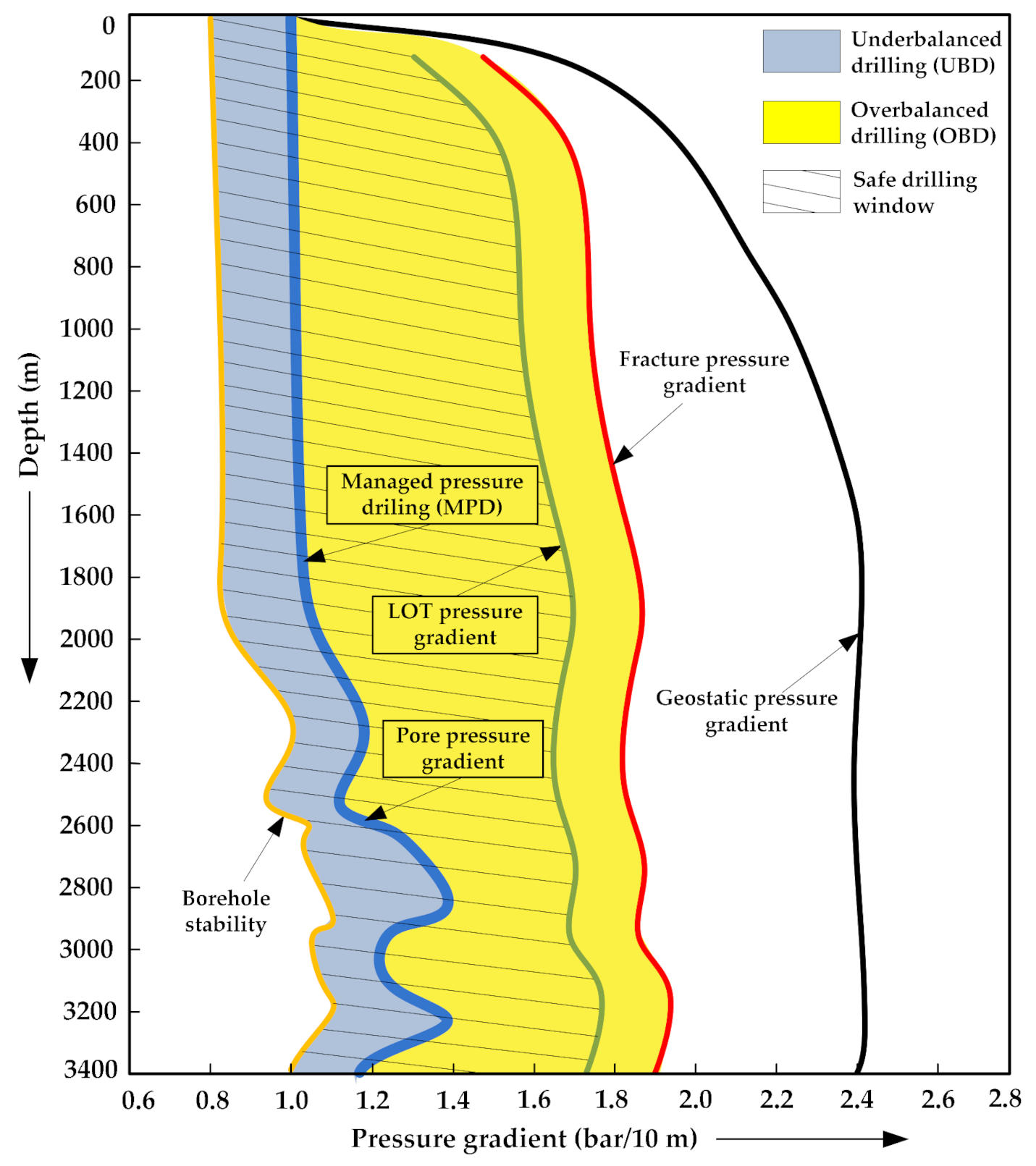

4.1.1. Underbalanced Drilling (UBD)

4.1.2. Managed Pressure Drilling (MPD)

4.1.3. Casing While Drilling (CwD)

4.1.4. Solid Expandable Tubulars (SET)

4.2. Corrective Measures to Mitigate Lost Circulation during Drilling

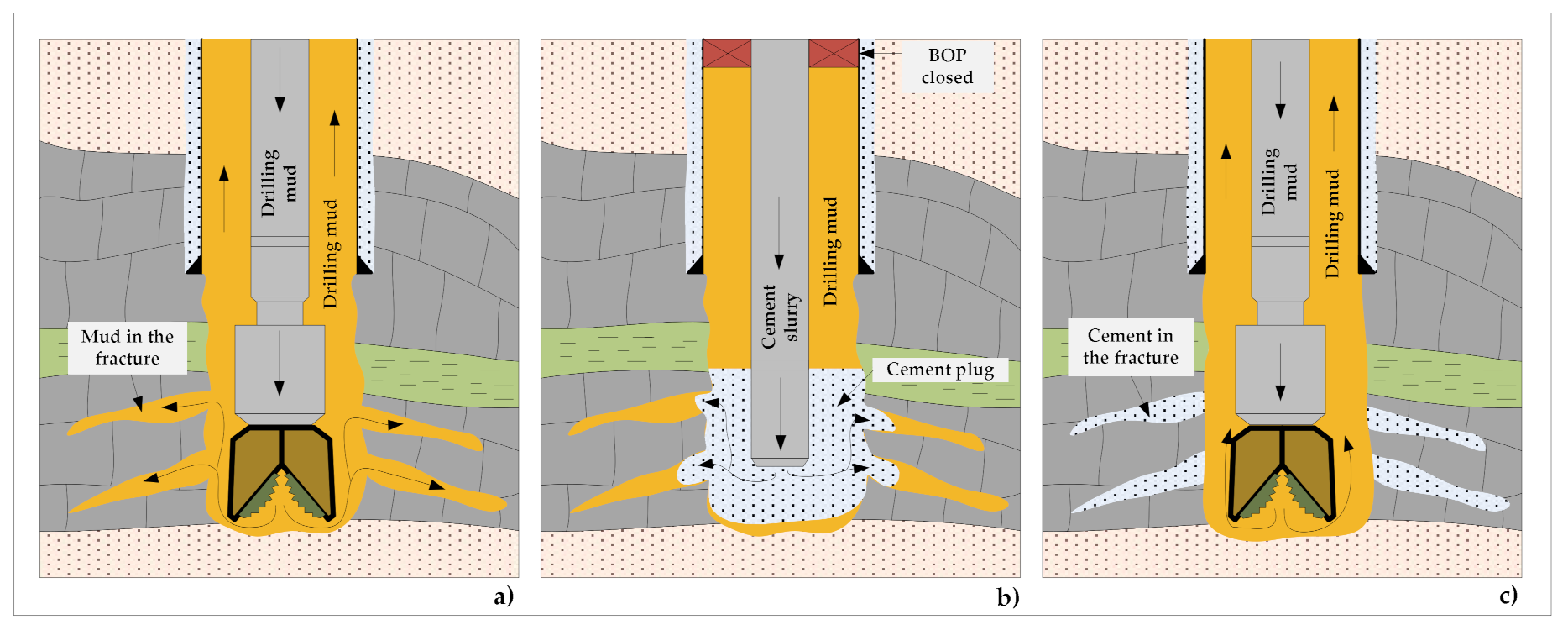

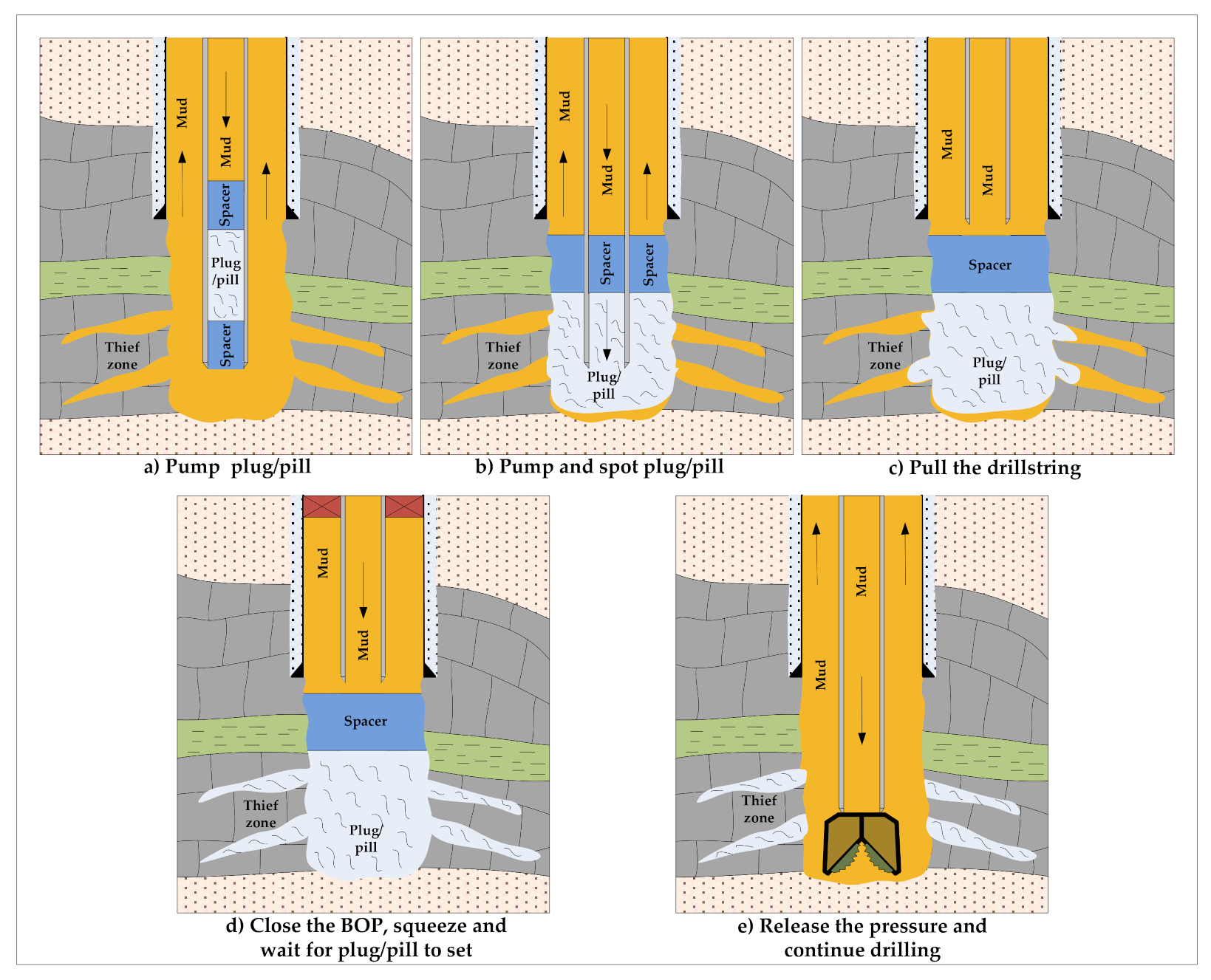

4.3. The Procedure of Spotting and Squeezing the Plug in the Thief Zone

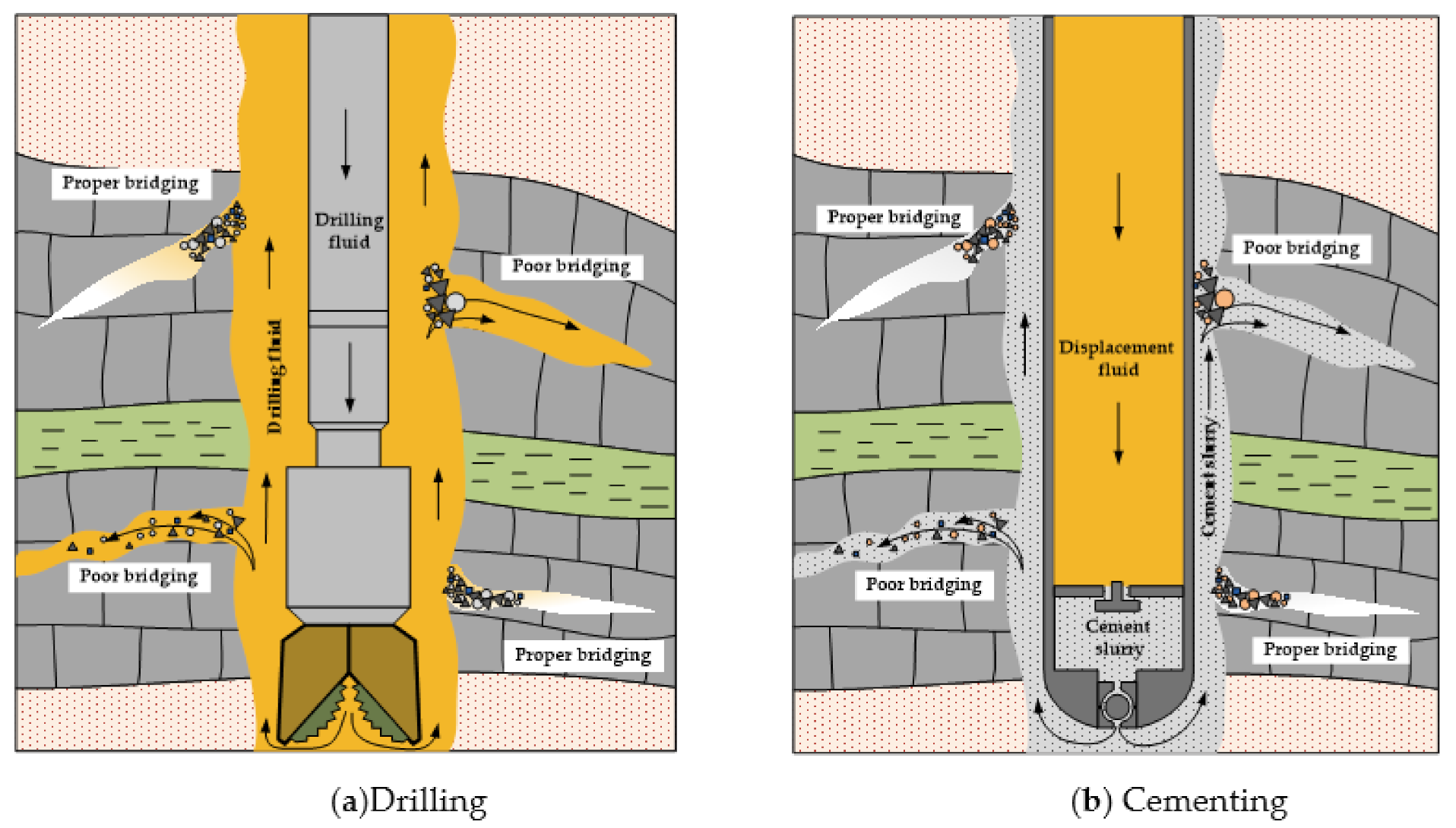

5. Lost Circulation While Cementing through Naturally Fractured Reservoirs

5.1. Cement Slurry and Set Cement Properties

5.1.1. Cement Slurry Density

5.1.2. Cement Slurry Viscosity and Thickening Time

5.1.3. Set Cement Compressive Strength

5.2. Two-Stage Cementing Technique

5.3. Cement Slurries for Primary Cementing through Fractured Formations

5.3.1. Cement Slurry with Microspheres

5.3.2. Thixotropic Cement Slurry

5.3.3. Cross-Linked Cement Slurry

5.3.4. Foamed Cement Slurry

5.3.5. Fiber-Cement Slurry

5.3.6. Gel-Cement Slurry

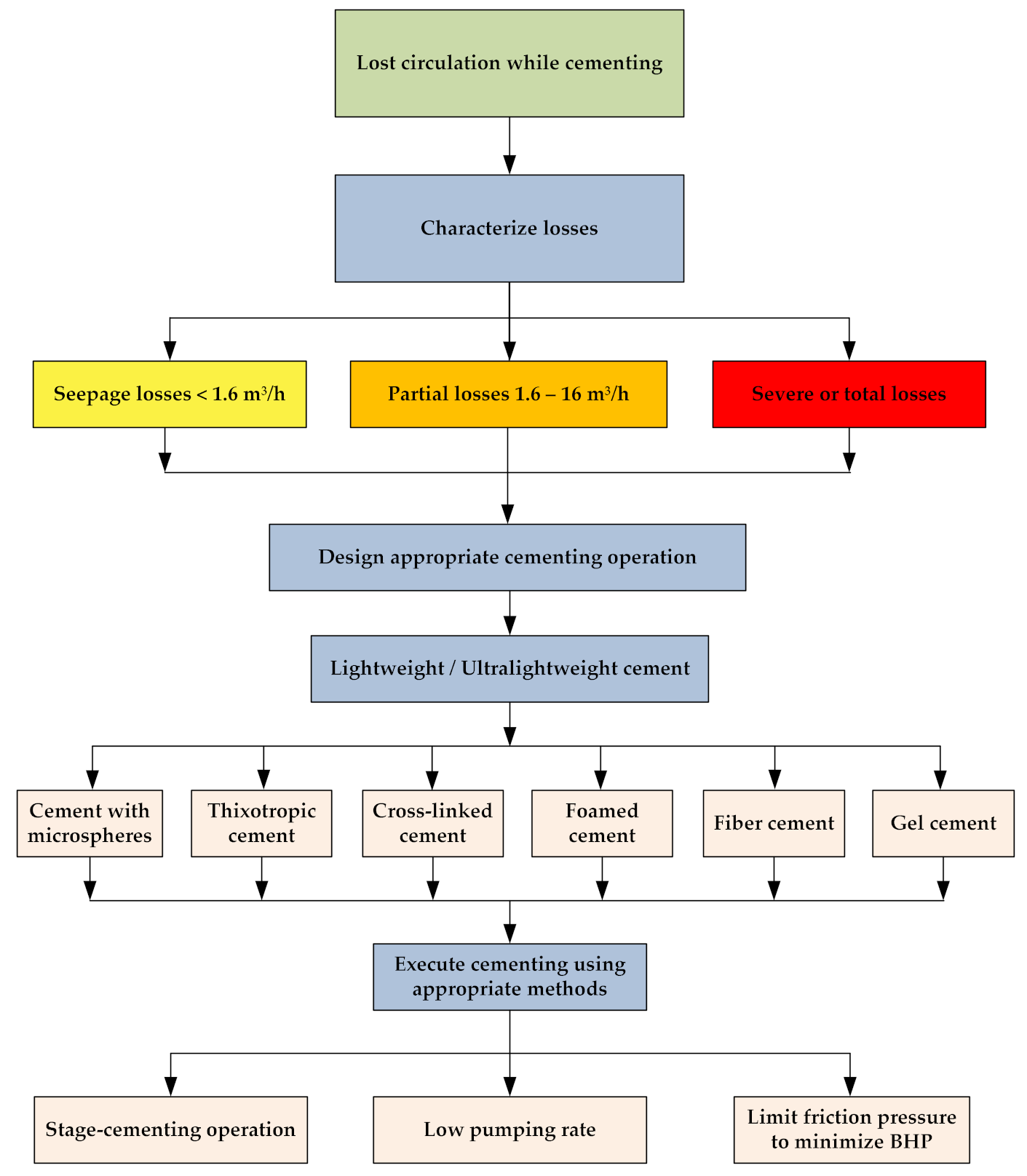

6. Procedures for Solving the Problem of Loss of Circulation during Casing Cementing

7. Discussion

8. Conclusions and Recommendations

- A strategy for managing lost circulation must be an integral part of well planning and should include the best drilling and cementing practice, drilling fluid and cement slurry selection, wellbore strengthening and lost circulation material selection, the appropriate corrective measures, as well as an adequate contingency plan.

- The key to success is proper planning, risk assessment to identify potential high-risk zones, quality materials and equipment, and experienced supervision.

- Drilling fluid and cement slurry losses into naturally fractured formations can be avoided or at least mitigated by managing the equivalent circulating density (ECD).

- In the vast majority of cases, losses were initiated prior to cementing, although cementing ECDs are typically higher than drilling ECDs, which is contrary to what is often perceived, and the reason lies in the fact that a cement slurry has the inherent ability to strengthen a well.

- Use artificial intelligence such as artificial neural networks (ANN), radial basis function (RBF) and support vector machine (SVM) to predict the occurrence of mud loss and lost circulation zones as well as to predict the fracture width and determine the particle sizes of lost circulation materials.

- Use available methods and tools to determine the location of the loss zone.

- Control bottom hole pressure (BHP) in static and dynamic conditions by applying new technologies and low-density fluids.

- Apply a wellbore strengthening strategy by adding WSMs to the mud to increase fracture pressure and avoid induced fractures or the re-opening of existing fractures.

- Close naturally fractured formations that are also oil and gas reservoirs, select acid-soluble or time and temperature degradable conventional lost circulation materials (LCMs) and/or special LCM pills/plugs (e.g., HFHS pills, polymer-based and fiber-based pills) to avoid permanent formation damage.

- The available materials and methods for solving the problem of lost circulation in naturally fractured reservoirs are not universal and, therefore, based on the collected well data for each specific situation, select the appropriate material and method that have proven successful in practice.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Elkatatny, S.; Gamal, H.; Ahmed, A.; Sarmah, P.; Sangaru, S.S.; Alohaly, M. A Novel Solution for Severe Loss Prevention While Drilling Deep Wells. Sustainability 2020, 12, 1339. [Google Scholar] [CrossRef]

- Caughron, D.E.; Renfrow, D.K.; Bruton, J.R.; Ivan, C.D.; Broussard, P.N.; Bratton, T.R.; Standifird, W.B. Unique Crosslinking Pill in Tandem With Fracture Prediction Model Cures Circulation Losses in Deepwater Gulf of Mexico. In Proceedings of the IADC/SPE Drilling Conference, Society of Petroleum Engineers (SPE), Dallas, TX, USA, 26–28 February 2002. [Google Scholar]

- Miller, M.; Scorsone, J.; Whitfill, D.L.; McDonald, M.; Miller, N. The Development of a Geopolymer-Based Pill as an Engineered Solution to Lost Circulation. In Proceedings of the SPE Annual Technical Conference and Exhibition, Society of Petroleum Engineers (SPE), New Orleans, LA, USA, 30 September–2 October 2013. [Google Scholar]

- Alsaba, M.; Nygaard, R.; Hareland, G.; Contreras, O. Review of Lost Circulation Materials and Treatments with an Updated Classification. In Proceedings of the AADE Fluids Technical Conference and Exhibition, Houston, TX, USA, 15–16 April 2014. [Google Scholar]

- Gaurina-Međimurec, N.; Pašić, B. Lost Circulation. In Risk Analysis for Prevention of Hazardous Situations in Petroleum and Natural Gas Engineering, 1st ed.; Matanović, D., Gaurina-Međimurec, N., Simon, K., Eds.; IGI Global: Hershey, PA, USA, 2014; pp. 73–95. [Google Scholar]

- Bychina, M.; Thomas, G.M.; Khandelwal, R.; Samuel, R. A Robust Model to Estimate the Mud Loss into Naturally Fractured Formations. In Proceedings of the SPE Annual Technical Conference and Exhibition, Society of Petroleum Engineers (SPE), San Antonio, TX, USA, 9–11 October 2017. [Google Scholar]

- Mahry, A.; Suryadi, D.; Sufiadi, E.; Hadinata, D.; Wahyudi, Y. Well Control in Carbonate Zone—Total Loss and Kick in Gas Reservoir. In Proceedings of the Offshore Technology Conference, Society of Petroleum Engineers (SPE), Houston, TX, 2–5 May 2016. [Google Scholar]

- Ramasamy, J.; Gooneratne, P.C.; Amanullah, M.D. Current Methods and Novel Solutions for Mitigating Lost Circulation. In Proceedings of the International Petroleum Technology Conference, Society of Petroleum Engineers (SPE), Beijing, China, 26–28 March 2019. [Google Scholar]

- Marinescu, P.; Oswald, R.J.; Vlasceanu, P. Uniquely Characteristics Mixed-Metal Oxide (MMO) Fluid Cure Lost Circulation While Meeting European Environmental Regulations. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Society of Petroleum Engineers (SPE), Jakarta, Indonesia, 30 October–1 November 2007. [Google Scholar]

- Sweatman, R.; Kessler, C.; Hillier, J. New Solutions to Remedy Lost Circulation, Crossflows, and Underground Blowouts. In Proceedings of the SPE/IADC Drilling Conference, Society of Petroleum Engineers (SPE), Amsterdam, The Netherlands, 4–6 March 1997. [Google Scholar]

- Ghalambor, A.; Salehi, S.; Shahri, M.P.; Karimi, M. Integrated Workflow for Lost Circulation Prediction. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Society of Petroleum Engineers (SPE), Lafayette, LA, USA, 26–28 February 2014. [Google Scholar]

- Ruzhnikov, A. Theoretical Aspects and Practical Implementation of Study of Drilling Fluid Level in the Annulus While Drilling with Total Losses. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Society of Petroleum Engineers (SPE), Abu Dhabi, UAE, 9–12 November 2020. [Google Scholar]

- Almetayev, R.; Al Hosani, M.; Al Ameri, S.; Al Mutawa, A.; Hussain, M.A.; Abraham, J.; Saleh, M.; Hadj-Moussa, A.; Le, K.P.D. First Nitrified Managed Pressure Drilling Application in United Arab Emirates. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Society of Petroleum Engineers (SPE), Abu Dhabi, UAE, 12–15 November 2018. [Google Scholar]

- Aneru, S.A.; Dosunmu, A.; Anyanwu, C.; Ekeinde, E.; Odagme, B. Optimizing the Drilling HPHT/Deep Offshore Wells Using Managed Pressure Drilling Techniques. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Society of Petroleum Engineers (SPE), Lagos, Nigeria, 5–7 August 2014. [Google Scholar]

- Ashraf, Q.; Khalid, A.; Luqman, K.; Hadj-Moussa, A.; Hamim, N. Underbalanced Well Intervention to Re-Enter a Dead Well Changed the Future Dynamics of the Largest Gas Field in Pakistan—A Successful Pilot Project. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Society of Petroleum Engineers (SPE), Abu Dhabi, UAE, 9–12 November 2020. [Google Scholar]

- Gaurina-Međiumurec, N.; Simon, K.; Matanović, D.; Pašić, B. Underbalanced Drilling Technology. Min. Geol. Pet. Eng. Bull. 2006, 18, 81–95. [Google Scholar]

- Fattah, K.A.; El-Katatney, S.; Dahab, A. Potential implementation of underbalanced drilling technique in Egyptian oil fields. J. King Saud Univ. Eng. Sci. 2011, 23, 49–66. [Google Scholar] [CrossRef]

- Savari, S.; Butcher, J.; Al-Hulail, M. Managing Lost Circulation in Highly Fractured, Vugular Formations: Engineered Usage of High Fluid Loss Squeeze and Reticulated Foam Lost Circulation Materials. In Proceedings of the IADC/SPE International Drilling Conference and Exhibition, Society of Petroleum Engineers (SPE), Galveston, TX, USA, 3–5 March 2020. [Google Scholar]

- Amanullah, M.; Alouhali, R.; AlArfaj, M. A Date Tree Fiber-Based LCM for Severe Loss Control. In Proceedings of the International Petroleum Technology Conference, Society of Petroleum Engineers (SPE), Dhahran, Saudi Arabia, 13–15 January 2020. [Google Scholar]

- Fidan, E.; Babadagli, T.; Kuru, E. Use of Cement As Lost Circulation Material—Field Case Studies. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition, Society of Petroleum Engineers (SPE), Kuala Lumpur, Malaysia, 13–15 September 2004. [Google Scholar]

- Fidan, E.; Babadagli, T.; Kuru, E. Use of Cement as Lost-Circulation Material: Best Practices. In Proceedings of the Canadian International Petroleum Conference, Society of Petroleum Engineers (SPE), Calgary, AB, Canada, 8–10 June 2004. [Google Scholar]

- Al-Azmi, B.; Al-Mayyan, H.; Al-Saleh, F.; Godara, V.; Panchal, R.; Kosandar, B.; Tobeh, S.; Jadhav, P.; Yadav, P.; Samir, A. A Cross-Link Polymer Sealant for Curing Severe Lost Circulation Events in Fractured Limestone Formations. In Proceedings of the SPE Asia Pacific Oil & Gas Conference and Exhibition, Society of Petroleum Engineers (SPE), Adelaide, Australia, 14–16 October 2014. [Google Scholar]

- Alkinani, H.H.; Al-Hameedi, A.T.; Flori, R.E.; Dunn-Norman, S.; Hilgedick, S.A.; Alsaba, M.T. Updated Classification of Lost Circulation Treatments and Materials with an Integrated Analysis and their Applications. In Proceedings of the SPE Western Regional Meeting, Society of Petroleum Engineers (SPE), Garden Grove, CA, USA, 22–27 April 2018. [Google Scholar]

- Bruton, J.R.; Ivan, C.D.; Heinz, T.J. Lost Circulation Control: Evolving Techniques and Strategies to Reduce Downhole Mud Losses. In Proceedings of the SPE/IADC Drilling Conference, Society of Petroleum Engineers (SPE), Amsterdam, The Netherlands, 27 February–1 March 2001. [Google Scholar]

- Canson, B. Lost Circulation Treatments for Naturally Fractured, Vugular, or Cavernous Formations. In Proceedings of the SPE/IADC Drilling Conference, Society of Petroleum Engineers (SPE), New Orleans, LA, USA, 5–8 March 1985. [Google Scholar]

- Savari, S.; Rolfson, J.; Williams, R.; Whitfill, D.L.; Wang, H.M. Reticulated Foam Enhanced High Fluid Loss Squeeze LCM for Severe Lost Circulation Management in Highly Fractured Formations. In Proceedings of the SPE Deepwater Drilling and Completions Conference, Society of Petroleum Engineers (SPE), Galveston, TX, USA, 14–15 September 2016. [Google Scholar]

- Solomon, O.; Adewale, D.; Anyanwu, C. Fracture Width Prediction and Loss Prevention Material Sizing in Depleted Formations Using Artificial Intelligence. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Society of Petroleum Engineers (SPE), Lagos, Nigeria, 31 July–2 August 2017. [Google Scholar]

- Moazzeni, A.; Nabaei, M.; Jegarluei, S.G. Prediction of Lost Circulation Using Virtual Intelligence in One of Iranian Oilfields. In Proceedings of the Nigeria Annual International Conference and Exhibition Society of Petroleum Engineers (SPE), Tinapa-Calabar, Nigeria, 31 July–7 August 2010. [Google Scholar]

- Abbas, A.K.; Alqatrani, G.; Mohammed, H.Q.; Dahm, H.H.; Alhumairi, M.A. Determination of Significant Parameters Affecting the Risk Level of Lost Circulation while Drilling. In Proceedings of the 54th US Rock Mechanics/Geomechanics Symposium, Golden, CO, USA, 28 June–1 July 2020. [Google Scholar]

- Abbas, A.K.; Al-Haideri, N.A.; Bashikh, A.A. Implementing artificial neural networks and support vector machines to predict lost circulation. Egypt. J. Pet. 2019, 28, 339–347. [Google Scholar] [CrossRef]

- Far, P.B.; Hosseini, P. Estimation of lost circulation amount occurs during under balanced drilling using drilling data and neural network. Egypt. J. Pet. 2017, 26, 627–634. [Google Scholar] [CrossRef]

- Toreifi, H.; Rostami, H.; Manshad, A.K. New method for prediction and solving the problem of drilling fluid loss using modular neural network and particle swarm optimization algorithm. J. Pet. Explor. Prod. Technol. 2014, 4, 371–379. [Google Scholar] [CrossRef]

- Cheraghian, G.; Wu, Q.; Mostofi, M.; Li, M.C.; Afrand, M.; Sangwai, J.S. Effect of a novel clay/silica nanocomposite on water-based drilling fluids: Improvements in rheological and filtration properties. Colloids Surf. A Physicochem. Eng. Asp. 2018, 555, 339–350. [Google Scholar] [CrossRef]

- Cheraghian, G.; Hemmati, M.; Bazgir, S. Application of TiO2 and fumed silica nanoparticles and improve the performance of drilling fluids. AIP Conf. Proc. 2014, 1590, 266–270. [Google Scholar] [CrossRef]

- Cheraghian, G. Application of Nano-Particles of Clay to Improve Drilling Fluid. Int. J. Nanosci. Nanotechnol. 2017, 13, 177–186. [Google Scholar]

- MI-Swaco. Prevention and Control of Lost Circulation. 2011. Available online: https://www.academia.edu/17116360/Manual_prevention_an_control_of_lost_circulation (accessed on 5 December 2020).

- Chen, Y.; Yu, M.; Ozbayoglu, M.E.; Takach, N. Numerical Model for Mapping Thief Zones in Directional Wells while Drilling. In Proceedings of the SPE Annual Technical Conference and Exhibition, Society of Petroleum Engineers (SPE), Amsterdam, The Netherlands, 27–29 October 2014. [Google Scholar]

- Wang, H.; Sweatman, R.E.; Engelman, R.E.; Deeg, W.F.; Whitfill, D.L. The Key to Successfully Applying Today’s Lost Circulation Solutions. In Proceedings of the SPE Annual Technical Conference and Exhibition, Society of Petroleum Engineers (SPE), Dallas, TX, USA, 9–12 October 2005. [Google Scholar]

- Akamine, A.Y.; Bratton, T.; Onyia, E.; Romanchock, M. Application of Real-Time Resistivity and Annular Pressure Data in Reducing Lost-Circulation Events. In Proceedings of the SPE/IADC Drilling Conference, Society of Petroleum Engineers (SPE), Amsterdam, The Netherlands, 19–21 February 2003. [Google Scholar]

- Bratton, T.; Rezmer-Cooper, I.; Desroches, J.; Gille, Y.E.; Li, Q.; Mcfayden, M. How to Diagnose Drilling Induced Fractures in Wells Drilled with Oil-Based Muds with Real-Time Resistivity and Pressure Measurements. In Proceedings of the SPE/IADC Drilling Conference, Society of Petroleum Engineers (SPE), Amsterdam, The Netherlands, 27 February–1 March 2001. [Google Scholar]

- Chilingarian, G.V.; Vorabutr, P. Lost Circulation. In Drilling and Drilling Fluids; Elsvier: Amsterdam, The Netherlands, 1981; pp. 537–557. [Google Scholar]

- Ahmed, A.; Elkatatny, S.; Abdulraheem, A.; Abughaban, M. Prediction of Lost Circulation Zones using Support Vector Machine and Radial Basis Function. In Proceedings of the International Petroleum Technology Conference, Society of Petroleum Engineers (SPE), Dhahran, Saudi Arabia, 13–15 January 2020. [Google Scholar]

- Nayberg, T. Laboratory Study of Lost Circulation Materials for Use in Both Oil-Based and Water-Based Drilling Muds. SPE Drill. Eng. 1987, 2, 229–236. [Google Scholar] [CrossRef]

- Nelson, E.B.; Guillot, D. Well Cementing, 2nd ed.; Schlumberger: Houston, TX, USA, 2006. [Google Scholar]

- Hitchcock, G. Additive Manufactured Shapes used to Cure Total Lost Circulation Events. In Proceedings of the Offshore Technology Conference, Society of Petroleum Engineers (SPE), Houston, TX, USA, 4–7 May 2020. [Google Scholar]

- Drilling Specialities Company Adevision of Chevron Phillips Chemical Company LP. Lost Circulation Guide. 2014. Available online: https://www.cpchem.com/sites/default/files/2020-04/LOSS%20OF%20CIRCULATION%20Guide.pdf (accessed on 8 January 2014).

- Olsen, M.; Lende, G.; Rehman, K.; Haugum, P.; Mo, J.; Smaaskjar, G.; Næss, R. Innovative and Established LCM Cementing Solutions Combined to Create Novel LCM Cementing Fluid Train. In Proceedings of the SPE Norway One Day Seminar, Society of Petroleum Engineers (SPE), Bergen, Norway, 14 May 2019. [Google Scholar]

- Therond, E.; Taoutaou, S.; James, S.G.; Way, P.W.; Gomes, P.; Dondale, A. Understanding Lost Circulation While Cementing: Field Study and Laboratory Research. SPE Drill. Complet. 2018, 33, 77–86. [Google Scholar] [CrossRef]

- Abbas, R.; Jarouj, H.; Dole, S.; Junaidi, E.H.; El-Hassan, H.; Francis, L.; Hornsby, L.; McCraith, S.; Shuttleworth, N.; van der Plas, K.; et al. A Safety Net for Controlling Lost Circulation. Oilfield Rev. Winter 2003, 15, 20–27. [Google Scholar]

- Al-Hameedi, A.T.T.; Alkinani, H.H.; Dunn-Norman, S.; Flori, R.E.; Hilgedick, S.A.; Amer, A.S.; Alsaba, M. Mud loss estimation using machine learning approach. J. Pet. Explor. Prod. Technol. 2018, 9, 1339–1354. [Google Scholar] [CrossRef]

- Efendiyev, G.; Mammadov, P.; Piriverdiyev, I.; Mammadov, V. Clustering of Geological Objects Using FCM-algorithm and Evaluation of the Rate of Lost Circulation. Procedia Comput. Sci. 2016, 102, 159–162. [Google Scholar] [CrossRef]

- Alkinani, H.H.; Al-Hameedi, A.T.T.; Dunn-Norman, S.; Alkhamis, M.M.; Mutar, R.A. Prediction of Lost Circulation Prior to Drilling for Induced Fractures Formations Using Artificial Neural Networks. In Proceedings of the SPE Oklahoma City Oil and Gas Symposium, Society of Petroleum Engineers (SPE), Oklahoma City, OK, USA, 9–10 April 2019. [Google Scholar]

- Whitfill, D.L. Lost Circulation Material Selection, Particle Size Distribution and Fracture Modeling with Fracture Simulation Software. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference, Society of Petroleum Engineers (SPE), Jakarta, Indonesia, 25–27 August 2008. [Google Scholar]

- Kumar, A.; Savari, S. Lost Circulation Control and Wellbore Strengthening: Looking Beyond Particle Size Distribution. In Proceedings of the AADE National Technical Conference and Exhibition, Houston, TX, USA, 12–14 April 2011. [Google Scholar]

- Gaurina-Međimurec, N.; Pašić, B.; Mijić, P. Risk Planning and Mitigation in Oil Well Fields. Int. J. Risk Conting. Manag. 2015, 4, 27–48. [Google Scholar] [CrossRef]

- Aston, M.; Alberty, M.; McLean, M.; De Jong, H.; Armagost, K. Drilling Fluids for Wellbore Strengthening. In Proceedings of the IADC/SPE Drilling Conference, Society of Petroleum Engineers (SPE), Dallas, TX, USA, 2–4 March 2004. [Google Scholar]

- Wang, H.; Sweatman, R.E.; Engelman, R.; Deeg, W.F.; Whitfill, D.L.; Soliman, M.Y.; Towler, B.F. Best Practice in Understanding and Managing Lost Circulation Challenges. SPE Drill. Complet. 2008, 23, 168–175. [Google Scholar] [CrossRef]

- Fan, X.; Zhang, Q.; Wang, J.; Xu, L.; Zhang, P.; Jia, W.; Chen, X.; Yu, G.; Yang, Y. Mathematical methods for evaluating a reservoir based on gas dynamic monitoring during underbalanced drilling. J. Nat. Gas Sci. Eng. 2015, 26, 1068–1079. [Google Scholar] [CrossRef]

- Wu, H.; Chen, P.; Fan, X.; Xia, H.; Wang, J.; Wang, J.; Wu, J. Research on Rapid Identification and Evaluation Technology for Gas Formation during Underbalanced Drilling. Geofluids 2017, 2017, 1–8. [Google Scholar] [CrossRef]

- Pedersen, T.; Godhavn, J.-M.; Schubert, J. Supervisory control for underbalanced drilling operations. IFAC PapersOnLine 2015, 48, 120–127. [Google Scholar] [CrossRef]

- Ladmia, A.; Culen, M.; Al Katheeri, A.B.; Al Hosani, F.M.A.; Edmonstone, G.F.J.; Mantilla, A.; Baslaib, M.A.; Nabil, I.M.; Yousfi, F.Z.; Al Hosani, M.A.; et al. Underbalance Coiled Tubing Drilling in Tight Gas Reservoir Study Case Onshore Field, Abu Dhabi. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Society of Petroleum Engineers (SPE), Abu Dhabi, UAE, 9–12 November 2020. [Google Scholar]

- Salehi, S.; Hareland, G.; Nygaard, R. Numerical simulations of wellbore stability in under-balanced-drilling wells. J. Pet. Sci. Eng. 2010, 72, 229–235. [Google Scholar] [CrossRef]

- Fossli, B.; Sangesland, S. Controlled Mud-Cap Drilling for Subsea Applications: Well-Control Challenges in Deep Waters. SPE Drill. Complet. 2006, 21, 133–140. [Google Scholar] [CrossRef]

- Emam, S.S.; Brand, P.R.; Gabaldon, O.R.; Vityk, M.; El Leithy, A.; Shanab, M.A.; Hamdy, B.; Abdel-Moniem, M.; El-Desouky, W.; El-Azm, H.A. Use of Managed Pressure Drilling Paved the Way to a Massive Gas Field Discovery in Egypt Western Desert: Case History. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference and Exhibition, Society of Petroleum Engineers (SPE), Abu Dhabi, UAE, 29–31 January 2018. [Google Scholar]

- Gedge, B.J.; Tan, C.Y.; Rao, J.; Singh, H.K.D.; Oracion, J.; Quoc, B.T.; Nguyen, V.B.; Tran, N.H.; Minh, T.L.T.; Buitenhuis, R.J.; et al. The Deployment of Managed Pressure Drilling Technology, to Assist in the Development of Offshore HPHT Gas Condensate Fields in Vietnam—Planning, Engineering, and Implementation. In Proceedings of the SPE Asia Pacific Oil & Gas Conference and Exhibition, Society of Petroleum Engineers (SPE), Adelaide, Australia, 14–16 October 2014. [Google Scholar]

- Goodwin, B.; Nauduri, S.; Medley, G. MudCap Drilling: New Variations, Drivers, Limitations, and Lessons Learned–Case Histories. In Proceedings of the SPE/IADC Managed Pressure Drilling & Underbalanced Operations Conference & Exhibition, Society of Petroleum Engineers (SPE), Madrid, Spain, 8–9 April 2014. [Google Scholar]

- Kurbanov, V.; Rotaru, A.; Gribanov, V.; Bakhitov, R.; Sidorov, Y. Managed Pressure Drilling Overcomes Drilling Challenges and Enhances Oil Production of Naturally Fractured Carbonate Reservoir of East Siberia. In Proceedings of the SPE Russian Petroleum Technology Conference, Society of Petroleum Engineers (SPE), Moscow, Russia, 22–24 October 2019. [Google Scholar]

- Grijalva, O.; Holzmann, J.; Oppelt, J.; Perozo, N.; Paz, C.; Asgharzadeh, A. OCTG Advancements in Casing Drilling: Where We Have Been and Where Are We Going? In Proceedings of the SPE Oklahoma City Oil and Gas Symposium, Oklahoma City, OK, USA, 27–31 March 2017. [Google Scholar] [CrossRef]

- Gaurina-Međimurec, N. Casing Drilling Technology. Min. Geol. Pet. Eng. Bull. 2005, 17, 19–26. [Google Scholar]

- Ofei, T.N.; Jalaludin, A.N.; Habte, A.D.; Lemma, T.A.; Ben-Awuah, J. Investigation of Plastering Effect in Casing-while-Drilling—A CFD Study. IOP Conf. Ser. Mater. Sci. Eng. 2019, 495, 012071. [Google Scholar] [CrossRef]

- Kiran, R.; Karimi, M.; Salehi, S. Finite Element Analysis of Casing Drilling Smearing Effect. In Proceedings of the SPE Deepwater Drilling and Completions Conference, Society of Petroleum Engineers (SPE), Galveston, TX, USA, 10–11 September 2014. [Google Scholar]

- Naveen, V.; Babu, V. Experimental Study of Plastering Effect During Casing While Drilling. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Society of Petroleum Engineers (SPE), Abu Dhabi, UAE, 10–13 November 2014. [Google Scholar]

- Chima, J.; Zhou, S.; Al-Hajji, A.; Okot, M.; Sharif, Q.J.; Clark, D.; Oveson, D.; Moellendick, E.; Holt, C.; Neidhardt, D. Casing Drilling Technology Application: Case Histories from Saudi Arabia. In Proceedings of the SPE Saudi Arabia Section Technical Symposium and Exhibition, Al-Khobar, Saudi Arabia, 8–11 April 2012. [Google Scholar] [CrossRef]

- Karimi, M.; Ghalambor, A.; Montgomery, M.; Moellendick, T.E. Formation Damage and Fluid Loss Reduction due to Plastering Effect of Casing Drilling. In Proceedings of the SPE European Formation Damage Conference, Society of Petroleum Engineers (SPE), Noordwijk, The Netherlands, 7–10 June 2011. [Google Scholar]

- Meza, O.G.; Yaqoob, T.; Bello, O.; Boulakhrif, F.; Holzmann, J.; Oppelt, J. Combined Investigation of Effects of Contact Stresses, Pore Size and Rotary Dynamics on Mud Plastering in Prevention of Lost Circulation in Weak Zones during Casing Drilling. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Society of Petroleum Engineers (SPE), Abu Dhabi, UAE, 13–16 November 2017. [Google Scholar]

- Ezeakacha, C.; Salehi, S.; Ghalambor, A.; Karimi, M. An Integrated Study of Mud Plastering Effects for Reducing Filtrate’s Invasion. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Society of Petroleum Engineers (SPE), Lafayette, LA, USA, 24–26 February 2016. [Google Scholar]

- Grant, T.; Bullock, M. The Evolution Of Solid Expandable Tubular Technology: Lessons Learned Over Five Years. In Proceedings of the Offshore Technology Conference, Society of Petroleum Engineers (SPE), Huston, TX, USA, 2–5 May 2005. [Google Scholar]

- Gusevik, R.; Cooper, B.; Cameron, J.R. Expandable Solid-Steel Liner Applications in the Marcellus. In Proceedings of the SPE Eastern Regional Meeting, Pittsburgh, PA, USA, 20–22 August 2013. [Google Scholar] [CrossRef]

- Park, M.; Teasdale, P.; Cowling, M. Application of Uncemented Solid Expandable Liner for Combined Openhole Isolation and Casing Repair. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Society of Petroleum Engineers (SPE), London, UK, 17–19 March 2015. [Google Scholar]

- Rahman, R.A.; Zulkafly, A.H. Issues and Solutions for Cementing Expandable Liners: A Case History. In Proceedings of the IADC/SPE Drilling Conference, Society of Petroleum Engineers (SPE), Dallas, TX, USA, 2–4 March 2004. [Google Scholar]

- Stringer, J.A.; Farley, D.B. The Evolution of Expandables: A New Era of. In Proceedings of the SPE Middle East Oil & Gas Show and Conference, Society of Petroleum Engineers (SPE), Manama, Baherin, 10–13 March 2013. [Google Scholar]

- Luzardo, J.; Oliveira, E.P.; Derks, P.W.J.; Nascimento, R.V.; Pérez-Gramatges, A.; Valle, R.; Pantano, I.G.; Sbaglia, F.; Inderberg, K. Alternative Lost Circulation Material for Depleted Reservoirs. OTC Brasil 2015. [Google Scholar] [CrossRef]

- Droger, N.; Eliseeva, K.; Todd, L.; Ellis, C.; Salih, O.; Silko, N.; Fu, D.; Meyer, A.; Bermudez, R. Degradable Fiber Pill for Lost Circulation in Fractured Reservoir Sections. In Proceedings of the IADC/SPE Drilling Conference, Society of Petroleum Engineers (SPE), Fort Worth, TX, USA, 4–6 March 2014. [Google Scholar]

- Fomenkov, A.; Pinigin, I.; Mikliayev, M.; Fedyanin, A. Using Thixotropic Cement Slurry for Lost Circulation Control: Case History, Volga-Urals Region. In Proceedings of the SPE Russian Petroleum Technology Conference, Society of Petroleum Engineers (SPE), Moscow, Russia, 22–24 October 2019. [Google Scholar]

- Whitfill, D.L.; Hemphill, T. All Lost-Circulation Materials and Systems Are Not Created Equal. In Proceedings of the SPE Annual Technical Conference and Exhibition, Society of Petroleum Engineers (SPE), Denver, CO, USA, 5–18 October 2003. [Google Scholar]

- Available online: https://www.slb.com/drilling/drilling-fluids-and-well-cementing/drilling-fluids/drilling-fluid-additives/wellbore-strengthening-materials/optiseal-wellbore-strengthening-material-blend (accessed on 5 December 2020).

- Jeennakorn, M.; Alsaba, M.; Nygaard, R.; Saasen, A.; Nes, O.M. The effect of testing conditions on the performance of lost circulation materials: Understandable sealing mechanism. J. Pet. Explor. Prod. Technol. 2018, 9, 823–836. [Google Scholar] [CrossRef]

- Zhong, H.; Shen, G.; Yang, P.; Qiu, Z.; Jin, J.; Xing, X. Mitigation of Lost Circulation in Oil-Based Drilling Fluids Using Oil Absorbent Polymers. Materials 2018, 11, 2020. [Google Scholar] [CrossRef]

- Kulkarni, S.D.; Savari, S.; Gupta, N.; Whitfill, D. Designing Lost Circulation Material LCM Pills for High Temperature Applications. In Proceedings of the SPE Deepwater Drilling and Completions Conference, Society of Petroleum Engineers (SPE), Galveston, TX, USA, 14–15 September 2016. [Google Scholar]

- Amanullah, M.D. Characteristics, Behavior and Performance of ARC Plug—A Date Seed-Based Sized Particulate LCM. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 25–28 April 2016. [Google Scholar] [CrossRef]

- Murray, D.; Sanders, M.W.; Houston, K.; Hogg, H.; Wylie, G. Case Study—ECD Management Strategy Solves Lost Circulation Issues On Complex Salt Diapirs/Paleocene Reservoir. In Proceedings of the SPE Annual Technical Conference and Exhibition, Society of Petroleum Engineers (SPE), New Orleans, LA, USA, 30 September–2 October 2013. [Google Scholar]

- Sanders, W.W.; Williamson, R.N.; Ivan, C.D.; Powell, D. Lost Circulation Assessment and Planning Program: Evolving Strategy to Control Severe Losses in Deepwater Projects. In Proceedings of the SPE/IADC Drilling Conference, Society of Petroleum Engineers (SPE), Amsterdam, The Netherlands, 19–21 February 2003. [Google Scholar]

- DuPriest, F.E.; Smith, M.V.; Zeilinger, S.C.; Shoykhet, N. Method To Eliminate Lost Returns and Build Integrity Continuously With High-Filtration-Rate Fluid. In Proceedings of the IADC/SPE Drilling Conference, Society of Petroleum Engineers (SPE), Orlando, FL, USA, 4–6 March 2008. [Google Scholar]

- Oliveira, J.A.A.; Zago, J.; Fontes, C.; Waldmann, A.T.A.; Martins, A.L. Modeling Drilling Fluid Losses in Fractured Reservoirs. In Proceedings of the SPE Latin America Petroleum Engineering Conference, Society of Petroleum Engineers (SPE), Mexico City, Mexico, 16–18 April 2012. [Google Scholar]

- Savari, S.; Whitfill, D.L. Managing Losses in Naturally Fractured Formations: Sometimes Nano is too Small. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Society of Petroleum Engineers (SPE), London, UK, 17–19 March 2015. [Google Scholar]

- Savari, S.; Whitfill, D.L.; Walker, J. Lost Circulation Management in Naturally Fractured Reservoirs. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference and Exhibition, Society of Petroleum Engineers (SPE), Abu Dhabi, UAE, 26–28 January 2016. [Google Scholar]

- Ivan, C.; Bruton, J.; Bloys, B. How can we best manage lost circulation? In Proceedings of the AADE National Technology Conference “Practical Solutions for Drilling Challenges”, Houston, TX, USA, 1–3 April 2003. [Google Scholar]

- Mofunlewi, S.S.; Okoto, F. Curing Lost Circulation with an Engineered Spacer During Cement Placement. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Society of Petroleum Engineers (SPE), Lagos, Nigeria, 2–4 August 2016. [Google Scholar]

- Apourvari, S.N.; Schaffie, M.; Farazmand, R. A new formulation for lightweight oil well cement slurry using a natural pozzolan. Adv. Geo. Energy Res. 2019, 3, 242–249. [Google Scholar] [CrossRef]

- Veisi, M.S.; Taoutaou, S.; Steven, A.; Pasteris, M.; Wedhaswari, V.R.; Awalt, M.; Kadrie, M.; Permata, E. Engineered Highly Crush-Resistant Cement Slurry to Prevent Lost Circulation. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Society of Petroleum Engineers (SPE), Nusa Dua, Bali, Indonesia, 20–22 October 2015. [Google Scholar]

- Mata, F.; Veiga, M. Crosslinked Cements Solve Lost Circulation Problems. In Proceedings of the SPE Annual Technical Conference and Exhibition, Society of Petroleum Engineers (SPE), Houston, TX, USA, 26–29 September 2004. [Google Scholar]

- Yuan, B.; Yang, Y.; Tang, X.; Xie, Y. A starting pressure prediction of thixotropic cement slurry: Theory, model and example. J. Pet. Sci. Eng. 2015, 133, 108–113. [Google Scholar] [CrossRef]

- Effendhy, J.H.; Abbas, R.; Malik, B. Fibers in Cement Form Network to Cure Lost Circulation. World Oil Mag. 2003, 48–50. [Google Scholar]

- Putra, T.; Steven, A.; Wedhaswari, V.R.; Awalt, M.S.; Natanagara, B.B.; Pasteris, M.; Jaffery, M.F.; Veisi, M.S.; Rudiantoro, A. Novel Cementing Solutions to Impede Lost Circulation with Highly Crush-Resistant Lightweight Cement System and Engineered Fibers. In Proceedings of the SPE Asia Pacific Oil & Gas Conference and Exhibition, Society of Petroleum Engineers (SPE), Perth, Australia, 25–27 October 2016. [Google Scholar]

- Pavić, V.; Gaurina-Međimurec, N.; Ružić, M. Foam Cement Slurry in Petroleum Industry (In Croatian: Pjenocementne kaše u naftnoj industriji). Nafta 1989, 40, 753–761. [Google Scholar]

- Fomenkov, A.; Pinigin, I.; Velikiy, D.; Denisov, I. Positive Experience Using Foam Cementing Technology for Production Casing Cementing in the Volga-Ural Field. In Proceedings of the SPE Russian Petroleum Technology Conference, Society of Petroleum Engineers (SPE), Moscow, Russia, 26–29 October 2020. [Google Scholar]

- Fomenkov, A.; Pinigin, I.; Zyryanov, V.; Fedyanin, A. Foam Cementing in the Volga-Ural Region: Case Study. In Proceedings of the SPE Russian Petroleum Technology Conference, Society of Petroleum Engineers (SPE), Moscow, Russia, 15–17 October 2018. [Google Scholar]

- Nayberg, T.; Petty, B. Laboratory Study of Lost Circulation Materials for Use in Oil-Base Drilling Muds. In Proceedings of the SPE Deep Drilling and Production Symposium, Amarillo, TX, USA, 6–8 April 1986. [Google Scholar] [CrossRef]

- El-Hassan, H.I.; Abbas, R.; Jarouj, H.; Munk, T. Using a Novel Fiber Cement System to Control Lost Circulation: Case Histories from the Middle East and the Far East. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference and Exhibition, Society of Petroleum Engineers (SPE), Abu Dhabi, UAE, 20–22 October 2003. [Google Scholar]

- Low, N.; Daccord, G.; Bedel, J.P. Designing Fibered Cement Slurries for Lost Circulation Applications: Case Histories. In Proceedings of the SPE Annual Technical Conference and Exhibition, Society of Petroleum Engineers (SPE), Denver, CO, USA, 5–8 October 2003. [Google Scholar]

- Ahmed, A.; Elkatatny, S.; Gajbhiye, R.; Rahman, M.K.; Sarmah, P.; Yadav, P. Effect of Polypropylene Fibers on Oil-Well Cement Properties at HPHT Condition. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Damman, Saudi Arabia, 23–26 April 2018. [Google Scholar]

| Thief zone is “on bottom” if: | Thief zone is “off bottom” if: |

|---|---|

| Fluid loss first occurs while drilling ahead. Fluid loss is accompanied by a notable change in the rate of penetration (ROP), torque, or drilling vibration. Fluid loss is due to natural fractures, faults, caverns, vugs or high permeability sands and gravels (well site geology data, drilling break with increase in torque and kelly free falls while drilling coupled with an instant loss in circulation). | Fluid loss first occurs while tripping, drilling fast or increasing mud weight. Fluid loss is the result of shutting the well in and killing the well. A annular loading is such as to increase the return apparent mud weight higher than the last casing shoe fracture gradient. |

| Severity of Loss | Rate of Loss | Type of Formation |

|---|---|---|

| Seepage | 0.16 to 1.6 m3/h | Any permeable formation type when the bridging agents are not large enough to form a seal, or when there are no fine particles to complete the seal. |

| Partial | 1.6 m3/h to 16 m3/h | Highly porous or fractured formations, gravel, small natural fractures and barely opened induced fractures. |

| Complete | mud level at 61 to 152 m below wellhead | Long, open sections of gravel, long intervals of small natural fractures, large natural fractures (caverns, vugs) or open induced fractures. |

| Severe complete | mud level at 152 to 305+ m below wellhead | Large, open natural fractures, caverns, and open induced fractures. |

| Source | Severity of Loss | |||

|---|---|---|---|---|

| Seepage (Minor) | Partial (Moderate/Medium) | Severe (Massive/Complete) | Total (Complete) | |

| Typical Loss Rate (m3/h) | ||||

| Hitchock, 2020 [45]; Drilling Specialties Company, 2014 [46] | Water-based mud | |||

| <4 | 4 to 16 | >16 | no returns | |

| Oil-based mud | ||||

| <1.6 | 1.6 to 4.8 | >4.8 | no returns | |

| Ramasamy et al., 2019 [8] | <1.6 | 1.6 to 3.2 | 3.2 to 32 | no returns |

| Olsen et al., 2019 [47] | - | - | >25 | no returns |

| Therond et al., 2018 [48] | <1.6 | 1.6 to 16 | 16 to 80 | no returns |

| MI-Swaco, 2011 [36] | <1.6 | 1.6 to 16 | - | no returns |

| Mahry et al., 2016 [7] | - | 1.6 to 8 | - | no returns |

| Ghalambor et al., 2014 [11]; Marinescu et al., 2007 [9] | - | 1.6 to 8 (s.c.) 10 to 20% of the mud (d.c.) | 8 to 24 (s.c.) 50 to 100% of the mud (d.c.) | no returns |

| Nayberg, 1987 [43]; Nelson, 2006 [44]; Alsaba et al., 2014 [4] | 0.16 to 1.6 | 1.6 to 80 | >80 | no returns |

| Jarouj et al., 2003/2004 [49] | <1.6 | >1.6, but some fluid returns | - | no returns |

| Sweatman et al., 1997 [10] | 1.6 to 3.2 (s. c.); 0.16 to 1.6 (d. c.) | - | 8 to 24 (s. c.); 50 to 100% of the mud (d. c.) | no returns |

| Al-Hameedi et al., 2018 [50] | <1 | 1 to 10 | >15 | no returns |

| Preventive Measures | |

|---|---|

| 1. Controlling bottom hole pressure (BHP) |

|

| 2. Wellbore pressure containment improvement (WPCI) (WPCI treatment with a required amount of sealant volume is used to increase the pressure-containment integrity of the entire open hole and to allow an increase in the mud weight without loss in the continuation of drilling to the total depth.) | |

| 3. Running intermediate casing in the transition zones (Setting casing to protect upper weaker formations within a transition zone.) | |

| 4. Setting Solid Expandable Tubulars (SET) (Installation of clad liner with external seals and other external attachment for covering the lost circulation and depleted zone in open hole section.) | |

| 5. Wellbore strengthening (Increasing the fracture resistance by increasing the hoop stress in the near wellbore region.) | |

| Lost Circulation Materials (LCMs) | ||

|---|---|---|

| Conventional LCM | Specially Designed LCM | |

| Flaky LCM | flaked calcium carbonate, mica, cellophane, vermiculite, and corncobs | Cement Plug Ultra-thixotropic and thixotropic cement slurries including calcium carbonate, flakes, and mica for mechanical bridging. |

| Granular LCM | calcium carbonate, nutshells, gilsonite, graphite, asphalt, perlite, and course bentonite | Polyurethane Grouting Mixtures or solutions that react to produce a gel or foam.(Single component prepolymerized polyurethanes that require water to react and two component polyurethanes that are mixed and react with each other). |

| Fibrous LCM | sawdust, cellulose fibers, shredded paper, mineral fibers, and nylon fibers | Geopolymer-Based Pill Chemically reactive pill based on aqueous alkali alumino silicates. |

| Blended LCM | a mixture of two or more types of LCM | Settable Plug A plug is utilized for slurry, which is a gel or solidified; keeps fluid at low viscosity and reacts at certain bottom hole temperature. |

| Water-/Acid-Soluble LCM | calcium carbonate, fiber, ground marble and salts | Cross-linked Gel A high-viscosity gel formed by the development of cross-linked bonds between polymer chains making the polymer network. |

| Hydratable/Swellable LCM | A mixture of different LCM with a highly reactive polymer | Viscoelastic Surfactant It is made of surfactants that self-assemble into worm-like micellar structures that act as polymers, raising the viscosity of the mud at low shear rates. |

| Nanoparticles LCM | iron hydroxide, calcium carbonate, and silica nanoparticles | Degradable Fiber Pill A fiber pill maintains stability for required time, but eventually self-degrade within desired time frame over a broad Bottomhole Temperature (BHT) range. |

| Category | Composition | Mechanism of Reaction |

|---|---|---|

| Extender (Benefit: lower slurry density; higher slurry yield) | Bentonite | Absorption of water |

| Sodium silicates | Formation of C-S-H gel and absorption of water | |

| Pozzolans (Diatomaceous earth, Fly ash, Fume silica) | Lower density than cement | |

| Gilsonite | ||

| Powdered coal | ||

| Microspheres | ||

| Nitrogen | Foamed cement | |

| Lost-circulation control agent (Benefit: prevent loss of slurry to formation) | Gilsonite | Bridging effect across formation |

| Granular coal | ||

| Cellophane flake | ||

| Nut Shells | ||

| Fibrous Additives | ||

| Gypsum | Induce thixotropic behavior of cement slurry | |

| Soluble sulfate salts | ||

| Bentonite | ||

| Crosslinked cellulosic polymers |

| Extender | Minimum Achievable Density of Cement Slurry (kg/m3) | Common Concentration |

|---|---|---|

| Active Extenders | ||

| Bentonite | 1380 | Up to 20% BWOC |

| Diatomaceous Earth | 1320 | Up to 40% BWOC |

| Silica | 1200 | Up to 28% BWOC |

| Fly Ashes | 1572 | Fly Ash/Cement ratio is 1:3 to 3:1 (+2% bentonite) |

| Sodium Silicates | 1332 | Solid sodium silicate (Sodium metasilicate): 0.2% to 3.0% BWOC Liquid sodium silicate (water glass): 0.8 to 2.3 l/sk |

| Inert Extenders | ||

| Expanded perlite (Volcanic Glass) | 1440 | Cement/Perlite ratio is (sk:kg) 1:14 to 1:56 (+2 to 4% bentonite BWOC) |

| Gilsonite | 1440 | Up to 23 kg of gilsonite/sk of cement |

| Powdered (ground) coal | 1430 | 5.8 to 11,3 kg of powdered coal/sk of cement (+up to 12% bentonite BWOC) |

| Microspheres (glass and ceramic) | 960 (840) | Up to 150% BWOC |

| Nitrogen | 720 | As required |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaurina-Međimurec, N.; Pašić, B.; Mijić, P.; Medved, I. Drilling Fluid and Cement Slurry Design for Naturally Fractured Reservoirs. Appl. Sci. 2021, 11, 767. https://doi.org/10.3390/app11020767

Gaurina-Međimurec N, Pašić B, Mijić P, Medved I. Drilling Fluid and Cement Slurry Design for Naturally Fractured Reservoirs. Applied Sciences. 2021; 11(2):767. https://doi.org/10.3390/app11020767

Chicago/Turabian StyleGaurina-Međimurec, Nediljka, Borivoje Pašić, Petar Mijić, and Igor Medved. 2021. "Drilling Fluid and Cement Slurry Design for Naturally Fractured Reservoirs" Applied Sciences 11, no. 2: 767. https://doi.org/10.3390/app11020767

APA StyleGaurina-Međimurec, N., Pašić, B., Mijić, P., & Medved, I. (2021). Drilling Fluid and Cement Slurry Design for Naturally Fractured Reservoirs. Applied Sciences, 11(2), 767. https://doi.org/10.3390/app11020767