Analysis for the Knowledge Management Application in Maintenance Engineering: Perception from Maintenance Technicians

Abstract

1. Introduction

2. Instruments and Methods

- (a)

- Maintenance technicians operate with a high component of knowledge that is not registered in the company (tacit knowledge).

- (b)

- Tacit knowledge directly impacts on the resolution of critical actions and breakdowns in a shorter time (especially the non-cyclical ones), operational maneuver time reduction, and improvement in knowledge for detecting and improving energy efficiency.

- (c)

- The use of knowledge management techniques in maintenance activities, consequently, induces a reduction in the operational familiarization time of new staff.

- (d)

- Proper knowledge management by the maintenance organization positively influences the operability of the company and the connection of work teams.

- (a)

- First, using grounded theory, 76 people belonging to operational maintenance staff from different sections were interviewed (Table 1). At the same time, the direct observation technique was used, during this research phase, with access to the facilities, documentation, and equipment of the factory by the researcher, the real characteristics of the work carried out in maintenance, the study of their internal relations, and the characteristics of the information used by the maintenance teams were recorded, giving the researcher an insight into the phenomena in the research environment. With this, an attentive examination of the different aspects of a phenomenon is achieved, in order to study its characteristics and behaviour within the environment in which it develops.

- ▪

- Based on your experience in the field of industrial maintenance engineering, it is intended to study the strategic factors of maintenance, and their relationships and evolution with knowledge management processes, answer the following questions:

- ▪

- Q01. What do you consider to be the strategic activities of the maintenance activity that most affects the company?

- ▪

- Q02. To what extent do you think the experience of technical maintenance personnel affects these strategic activities?

- ▪

- Q03. What level of information/knowledge do you manage at your own level regarding maintenance activities (tacit knowledge, not registered), and what is precisely documented in the company (explicit knowledge)? Can you give an example?

- ▪

- Q04. From the explicit information that the company may have access to in order to carry out their work (computer programs, machinery, and equipment manuals, planimetry, work orders, etc.), to what extent is it useful and what deficiencies do you observe?

- ▪

- Q05. How do you document or transmit your daily jobs/experiences in your maintenance job, and how much time do you spend on it?

- ▪

- Q06. What is the usual way in which you capture the (important) operational experiences of your colleagues (through meetings, informal conversations, etc.), so that you can resolve such an action when it happens to you (example: operational manoeuvres in the event of breakdowns) or perform this task (example: maintenance work)?

- ▪

- Q07. Has a knowledge management program been implemented in your organization involving tactical maintenance actions? If yes, what opinion do you have of it?

- ▪

- Q08. What information/knowledge should be captured or made explicit, that helps you in the performance of your duties?

- ▪

- Q09. How should such information/knowledge, its accessibility (to share it), and its maintenance (how to collect and update it) be structured, so that it is easily usable and accessible to you?

- ▪

- Q10. What would be the benefit of the capture and conversion of tacit to explicit knowledge, personally and at the company level?

- ▪

- Q11. What would facilitate, in your opinion, the capture and conversion of tacit to explicit knowledge? How should such knowledge capture be done?

- ▪

- Q12. Which barriers do you consider most important for the implementation of a knowledge management program in the maintenance activity?

- ▪

- Q13. What would motivate you to support and be interested in capturing and recording your tacit knowledge and that of your colleagues, and which could improve the work of your colleagues and help improve the productivity and efficiency of the company?

- ▪

- Q14. What type of actions/experiences should be documented that affect the tactical actions of maintenance engineering, such as: Reliability of equipment and systems, Operation/operation of facilities, Energy efficiency, Maintainability?

- ▪

- Q15. How do you think it would affect the familiarization time of new personnel, and the action times of all maintenance technicians, if information structuring the and capture of tactical actions, as well as operational experiences lived, were based on experience?

- ▪

- Q16. What factors should be controlled quantitatively (measured), to see what affects the improvement of knowledge management in the tactical actions of maintenance?

- ▪

- Q17. Before a new installation, machinery, reform, etc., would it be convenient to introduce in the gant/pert diagrams of the duration of the works, a new activity in which the registration and collection of practical and useful knowledge is found, reflecting the actions or relevant information that would help in future installations?

- ▪

- Q18. What tools/techniques, means, etc., do you think would help you capture the important tactical and strategic information in your maintenance activity?

- ▪

- Q19. In your opinion, what consideration does the company’s management and maintenance clients (production, other areas of the company, etc.) have of the activities and missions of the maintenance department?

- ▪

- Q20. Do you need to know more about these topics, with reference to knowledge management of maintenance activity? What knowledge gaps do you have on these topics, which prevent you from getting more out of it?

- ▪

- Q21. What type of training would it be appropriate to receive, to what degree and in what way, that could improve your work efficiency?

- ▪

- Q22. Enter below any information or suggestions that you consider relevant, and that have not been addressed in the questionnaire.

- (b)

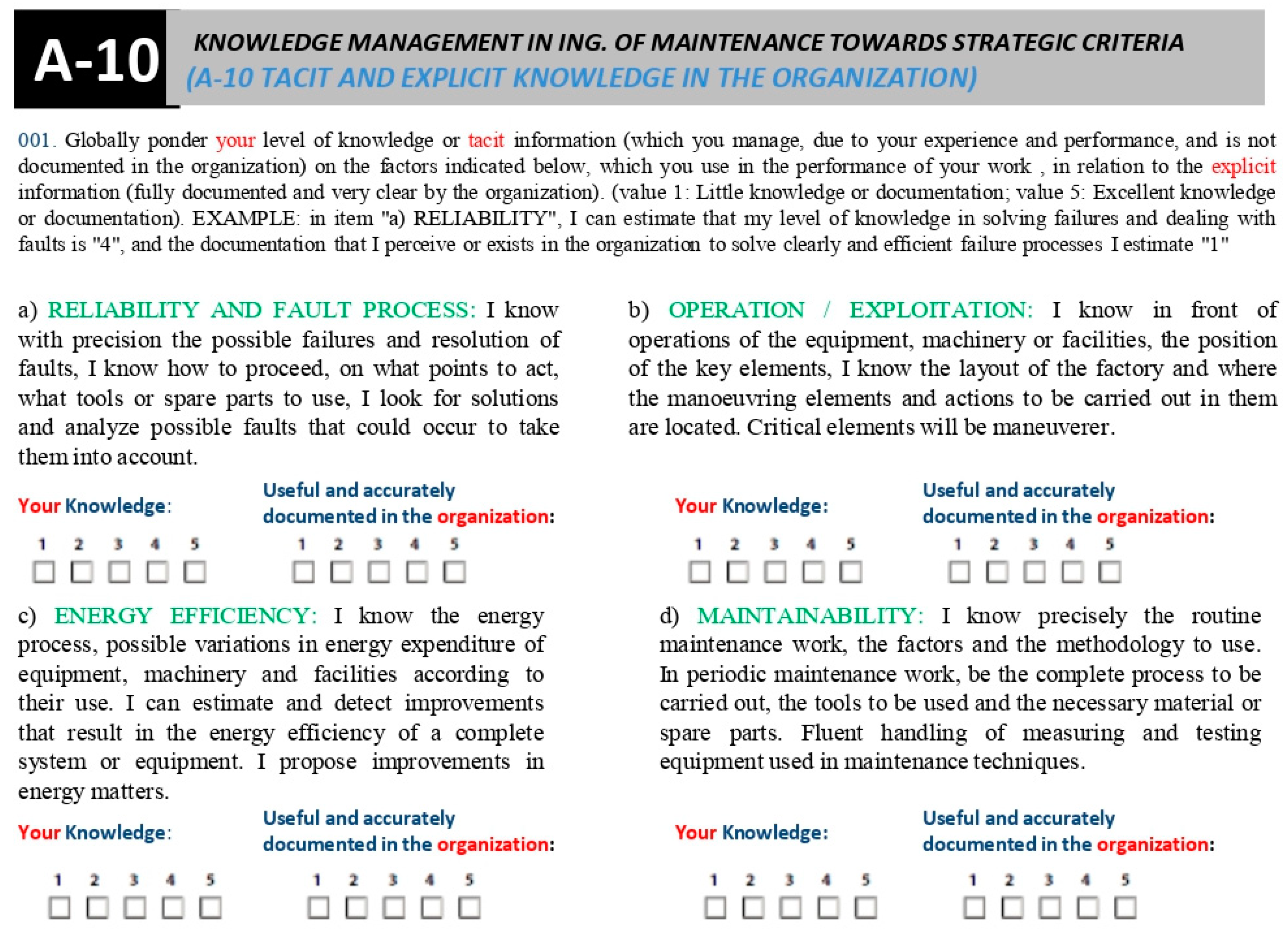

- With the aim of deepening the perception of knowledge management on the strategic actions of industrial maintenance engineering (reliability, operations, energy efficiency, and maintainability) by maintenance technicians, and allowing much greater access to it, by a greater number of members of the operative staff (Table 2), a survey (Figure 1) was passed to all the operative personnel (174 technicians) in order to identify and quantify their perceptions, about the personal knowledge they use (tacit) and the knowledge that they perceive as documented in a useful and precise way by the organization (explicit), regarding factors involved in the performance of their functions.

3. Results

3.1. Relation between Knowledge Management and Fundamental Strategic Maintenance Actions

- ▪

- Capture of the tacit strategic knowledge from operational maintenance technicians.

- ▪

- Resolution of critical failures in a short period of time (especially non-cyclical ones).

- ▪

- Reduction of operating manoeuvre times.

- ▪

- Facilitate the change of area or staff substitutions.

- ▪

- Decrease in the engagement times of new staff members.

- ▪

- Information capture and transfer of subcontracted companies.

- ▪

- Sharing of employee knowledge that can be used by others, who can detect new opportunities for improvement.

- ▪

- Improved knowledge of the reliability of equipment and facilities.

- ▪

- Improvement of knowledge for the detection and improvement of energy efficiency actions.

- ▪

- Time optimization, with effects on knowledge management and the reduction of maintenance costs.

3.2. Operators Involvement

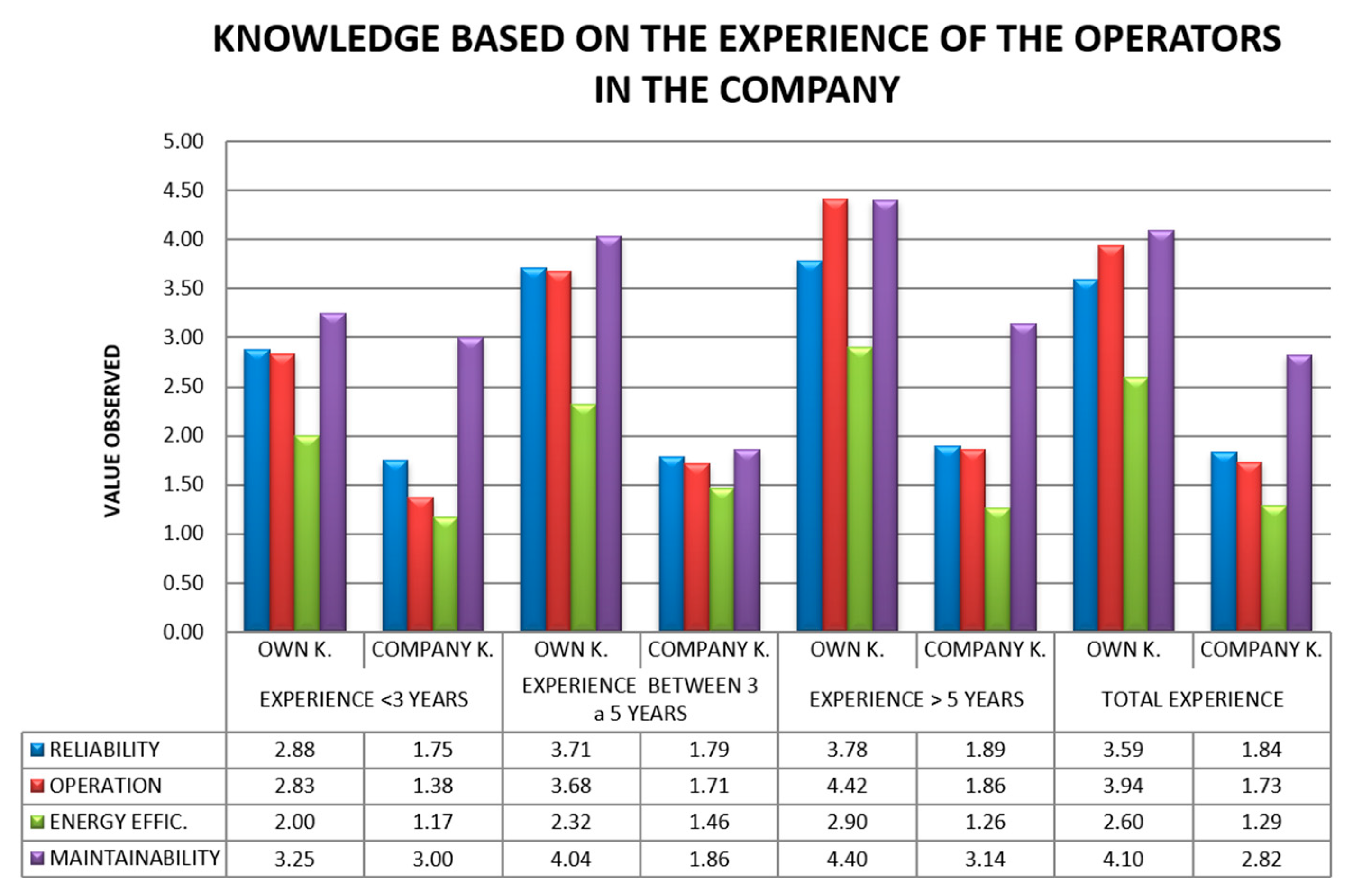

3.3. The Quantitative Perception of Maintenance Operators

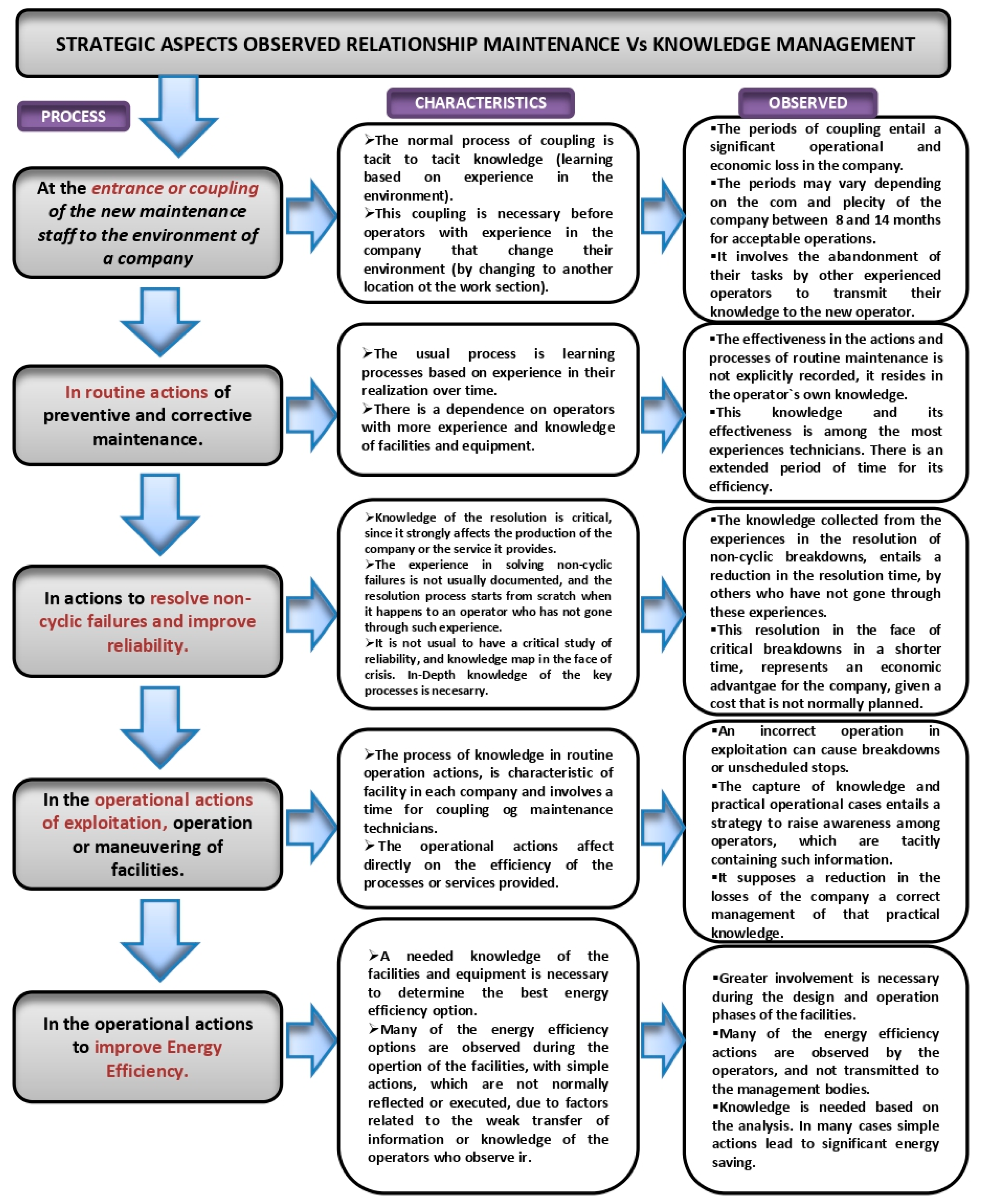

4. Discussion

- ➢

- The normal process of familiarizing the staff to the conditions of the company relies on tacit knowledge (learning based on experience in the environment), which involves this internal knowledge and the way to make it explicit to the entire organization [12].

- ➢

- This coupling is necessary before operators with experience in the company change their environment (by changing to another headquarters or changing the work section).

- ➢

- The usual process is to learn the actions based on others experience in carrying them out over time.

- ➢

- There is a unit of operators with more experience and knowledge of the facilities and equipment.

- ➢

- Knowledge about solving breakdowns is critical since it strongly affects the production of the company or the service it provides.

- ➢

- Experience in the resolution of non-cyclical breakdowns is not usually documented, and the resolution process starts from scratch when it happens to an operator who has not gone through such an experience.

- ➢

- There is usually no critical study of reliability or a crisis knowledge map. In-depth knowledge of key processes is required.

- ➢

- The knowledge process in the routine actions of operation, is characteristic of the facilities of each company and involves a familiarization time for maintenance technicians.

- ➢

- Such operational actions directly affect the efficiency of the processes or services provided.

- ➢

- In-depth knowledge of the facilities and equipment is necessary to determine the best energy efficiency options.

- ➢

- Many of the energy efficiency options are observed during the operation of the facilities, with simple implementations, which are not normally realized or executed, due to factors related to the poor transfer of information, or the knowledge of the operators who observe them.

5. Conclusions

- ▪

- The main facilitators/barriers detected are summarized based on the qualitative research carried out.

- ▪

- The main strategic aspects of maintenance that can increase its efficiency are confirmed by adopting a knowledge management model.

- ▪

- The high level of tacit knowledge used in this activity is confirmed, normally based on the high experience level required of the operators, and which requires high engagement times with new personnel.

- ▪

- The knowledge directly impacts on, the resolution of critical actions and breakdowns in a shorter time, operational maneuver time reduction, and the improvement in knowledge for detecting and improving energy efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEEE Std 493-2007. IEEE Recommended Practice for the Design of Reliable Industrial and Commercial Power Systems; IEEE-SA Standards Board: Washington, DC, USA, 2007. [Google Scholar]

- Koval, D.; Zhang, X.; Prost, J.; Coyle, T.; Arno, R.; Hale, R. Reliability Methodologies Applied to the IEEE Gold Book Standard Network. IEEE Ind. Appl. Mag. 2003, 9, 32–41. [Google Scholar] [CrossRef]

- Wang, W.; Loman, J.; Arno, R.; Vassiliou, P.; Furlong, E.; Ogden, D. Reliability block diagram simulation techniques applied to the IEEE std. 493 Standard Network. IEEE Trans. Ind. Appl. 2004, 40, 887–895. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications, and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Cacique, J. Diseño de un Programa Para Calcula la Confiabilidad en un Sistema de Distribución de Energía Eléctrica; UNEXPO: Bolívar, Venezuela, 2007; p. 138. [Google Scholar]

- Baeza, G.; Rodríguez, P.; Hernández, J. Evaluación de Confiabilidad de Sistemas de Distribución Eléctrica en Desregulación; Revista Facultad de Ingeniería: Santiago, Chile, 2003; Volume 11, pp. 33–39. [Google Scholar]

- McGranaghan, M. Quantifying Reliability and Service Quality for Distribution Systems. IEEE Trans. Ind. Appl. 2007, 43, 188–195. [Google Scholar] [CrossRef]

- Sexto, L. Confiabilidad integral del activo. In Proceedings of the Seminario Internacional de Mantenimiento Celebrado en Perú-Arequipa-Tecsup, Arequipa, Perú, 23–25 February 2005. [Google Scholar]

- Wilkesmann, M.; Wilkesmann, U. Industry 4.0—Organizing routines or innovations? VINE J. Inf. Knowl. Manag. Syst. 2018, 48, 238–254. [Google Scholar] [CrossRef]

- Cárcel-Carrasco, J.; Gómez-Gómez, C. Qualitative Analysis of the Perception of Company Managers in Knowledge Management in the Maintenance Activity in the Era of Industry 4.0. Processes 2021, 9, 121. [Google Scholar] [CrossRef]

- Isworowati, D.; Muhammad, F.; Kurniawati, A.; Kurniawan, M. Knowledge Management System for Maintenance Activity: Case Study at the Maintenance Department of XYZ Corporation. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Macao, China, 15–18 December 2019; pp. 139–143. [Google Scholar]

- Carcel-Carrasco, F.J.; Rodriguez-Mendez, M. Industrial maintenance and tacit knowledge: An introduction about its incidence. DYNA Manag. 2013, 1, 15. [Google Scholar] [CrossRef]

- Altmann, C. El Análisis de Causa Raíz, como herramienta en la mejora de la Confiabilidad. In Proceedings of the 2nd Congreso Uruguayo de Mantenimiento, Gestión de Activos y Confiabilidad, Montevideo, Uruguay, 16–18 August 2006. [Google Scholar]

- Amendola, L. Modelos Mixtos de Confiabilidad Projet Managament; PMM Institute for Learning: València, Spain, 2016; ISBN 978-84-943897-3-3. [Google Scholar]

- Amendola, L. Estrategias y Técnicas en la Dirección y Gestión de Proyectos. In ProjetManagament; Universitat Politècnica de València: València, Spain, 2004; ISBN 84-9705-522-5. [Google Scholar]

- Tavares, L. Administración Moderna de Mantenimiento; Novo Polo Publicacoes: Rio de Janeiro, Brasil, 2004. [Google Scholar]

- Ruiz-Sarmiento, J.; Monroy, J.; Moreno, F.-A.; Galindo, C.; Bonelo, J.-M.; Gonzalez-Jimenez, J. A predictive model for the maintenance of industrial machinery in the context of industry 4.0. Eng. Appl. Artif. Intell. 2020, 87, 103289. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Fathi, M. Corporate survival in Industry 4.0 era: The enabling role of lean-digitized manufacturing. J. Manuf. Technol. Manag. 2019, 31, 1–30. [Google Scholar] [CrossRef]

- Çınar, Z.M.; Nuhu, A.A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine Learning in Predictive Maintenance towards Sustainable Smart Manufacturing in Industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Jasiulewicz-Kaczmarek, M.; Legutko, S.; Kluk, P. Maintenance 4.0 Technologies—New Opportunities for Sustainability Driven Maintenance. Manag. Prod. Eng. Rev. 2020, 11, 74–87. [Google Scholar]

- Zonta, T.; da Costa, C.A.; da Rosa Righi, R.; de Lima, M.J.; da Trindade, E.S.; Li, G.P. Predictive Maintenance in the Industry 4.0: A Systematic Literature Review. Comput. Ind. Eng. 2020, 150, 106889. [Google Scholar] [CrossRef]

- Ceruti, A.; Marzocca, P.; Liverani, A.; Bil, C. Maintenance in aeronautics in an Industry 4.0 context: The role of Augmented Reality and Additive Manufacturing. J. Comput. Des. Eng. 2019, 6, 516–526. [Google Scholar] [CrossRef]

- Schumacher, A.; Nemeth, T.; Sihn, W. Roadmapping towards industrial digitalization based on an Industry 4.0 maturity model for manufacturing enterprises. Procedia CIRP 2019, 79, 409–414. [Google Scholar] [CrossRef]

- Bousdekis, A.; Lepenioti, K.; Apostolou, D.; Mentzas, G. Decision Making in Predictive Maintenance: Literature Review and Research Agenda for Industry 4.0. IFAC-PapersOnLine 2019, 52, 607–612. [Google Scholar] [CrossRef]

- Lee, S.M.; Lee, D.; Kim, Y.S. The quality management ecosystem for predictive maintenance in the Industry 4.0 era. Int. J. Qual. Innov. 2019, 5, 4. [Google Scholar] [CrossRef]

- Patalas-Maliszewska, J.; Kłos, S. An Approach to Supporting the Selection of Maintenance Experts in the Context of Industry 4.0. Appl. Sci. 2019, 9, 1848. [Google Scholar] [CrossRef]

- Sang, G.M.; Xu, L.; de Vrieze, P.T.; Bai, Y.; Pan, F. Predictive Maintenance in Industry 4.0. In Proceedings of the ICIST 2020: 10th International Conference on Information Systems and Technologies, Lecce, Italy, 4–5 June 2020. [Google Scholar]

- Bag, S.; Pretorius, J.H.C. Relationships between industry 4.0, sustainable manufacturing and circular economy: Proposal of a research framework. Int. J. Organ. Anal. 2020. [Google Scholar] [CrossRef]

- Manesh, M.F.; Pellegrini, M.M.; Marzi, G.; Dabić, M. Knowledge Management in the Fourth Industrial Revolution: Mapping the Literature and Scoping Future Avenues. IEEE Trans. Eng. Manag. 2021, 68, 289–300. [Google Scholar] [CrossRef]

- Pokojski, J.; Oleksiński, K.; Pruszyński, J. Conceptual and detailed design knowledge management in customized production—Industrial perspective. J. Comput. Des. Eng. 2019, 6, 479–506. [Google Scholar] [CrossRef]

- Emmanouilidis, C.; Pistofidis, P.; Bertoncelj, L.; Katsouros, V.; Fournaris, A.P.; Koulamas, C.; Ruiz-Carcel, C. Enabling the human in the loop: Linked data and knowledge in industrial cyber-physical systems. Annu. Rev. Control 2019, 47, 249–265. [Google Scholar] [CrossRef]

- Wan, S.; Li, D.; Gao, J.; Li, J. A knowledge based machine tool maintenance planning system using case-based reasoning techniques. Robot. Comput. Manuf. 2019, 58, 80–96. [Google Scholar] [CrossRef]

- Bravo-ibarra, E.; Herrera, L. Capacidad de innovación y configuración de recursos organizativos. Intang. Cap. 2009, 5, 301–320. [Google Scholar]

- Griffiths, P.; Remenyi, D. Aligning Knowledge Management with Competitive Strategy: A Framework. Electron. J. Knowl. Manag. 2008, 6, 125–134. [Google Scholar]

- Argote, L.; Ingram, P. Knowledge trasnfer: A basis for competitive advantage in firms. Organ. Behav. Hum. Decis. Process. 2000, 82, 150–169. [Google Scholar] [CrossRef]

- Claver, E.; Zaragoza, P. La dirección de recursos humanos en las organizaciones inteligentes. Una evidencia empírica desde la dirección del conocimiento. Investigaciones Europeas de Dirección y Economía de la Empresa 2007, 13, 55–73. [Google Scholar]

- Cárcel-Carrasco, F.-J.; Cárcel-Carrasco, J.-A.; Peñalvo-López, E. Factors in the Relationship between Maintenance Engineering and Knowledge Management. Appl. Sci. 2020, 10, 2810. [Google Scholar] [CrossRef]

- Pawlowski, J.; Bick, M. The Global Knowledge Management Framework: Towards a Theory for Knowledge Management in Globally Distributed Settings. Electron. J. Knowl. Manag. 2012, 10, 92–108. [Google Scholar]

- Pauleen, D. Personal knowledge management: Putting the “person” back into the knowledge equation. Online Inf. Rev. 2009, 33, 221–224. [Google Scholar] [CrossRef]

- Hoelzle, K.; Gemuenden, H.G. Cultural vs. structural aspects of Open Innovation—How to implement Open Innovation. In TUHH User and Open Innovation Workshop 2009; Workshop 2009 Hamburg, Germany, 3 June 2009; University of Hamburg: Hamburg, Germany, 2009. [Google Scholar]

- Cárcel Carrasco, F.J. La gestión del conocimiento en la ingeniería del mantenimiento industrial: Investigación sobre la incidencia en sus actividades estratégicas. Omnia Sci. 2014. [Google Scholar] [CrossRef]

- De Andrade, F.G.; Araújo, C.K.C.; Basso, S.; Przybysz, A.L.; De Francisco, A.C. The Perception of Knowledge Management by Small and Medium-Sized IT Companies, Campos Gerais, Brazil. In Proceedings of the International Joint Conference on Industrial Engineering and Operations Management, Novi Sad, Serbia, 21 March 2020; Springer: Cham, Switzerland, 2019; pp. 522–531. [Google Scholar]

- Martins, V.W.B.; Rampasso, I.S.; Anholon, R.; Quelhas, O.L.G.; Filho, W.L. Knowledge management in the context of sustainability: Literature review and opportunities for future research. J. Clean. Prod. 2019, 229, 489–500. [Google Scholar] [CrossRef]

- Nonaka, I.; Takeuchi, H. The Knowledge-Creating Company: How Japanese Companies Create the Dynamics of Innovation; Oxford University Press: New York, NY, USA, 1995. [Google Scholar]

- Nisar, T.M.; Prabhakar, G.P.; Strakova, L. Social media information benefits, knowledge management and smart organizations. J. Bus. Res. 2019, 94, 264–272. [Google Scholar] [CrossRef]

- Maxwell, J.A. Qualitative Research Design: An Interactive Approach; Sage Publications: Szende Oaks, CA, USA, 1996. [Google Scholar]

- Corbin, J.; Strauss, A. Basics of Qualitative Research: Techniques and Procedures for Developing Grounded Theory; Sage Publications: London, UK, 2015; ISBN 978-1-4129-9746-1. [Google Scholar]

- Charmaz, K. Constructing Grounded Theory: A Practical Guide through Qualitative Analysis; SAGE: London, UK, 2006. [Google Scholar]

- Glaser, B.G.; Strauss, A.L. The Discovery of Grounded Theory; Aldine deGruyter: New York, NY, USA, 1967. [Google Scholar]

- Pace, S. A grounded theory of the flow experiences of Web users. Int. J. Hum. Comput. Stud. 2004, 60, 327–363. [Google Scholar] [CrossRef]

- Cutcliffe, J. Adapt or Adopt: Developing and Transgressing the Methodological Boundaries of Grounded Theory. J. Adv. Nurs. 2005, 21, 42. [Google Scholar] [CrossRef] [PubMed]

- Passmore, J.; McGoldrick, S. Super-vision, Extra-vision, or Blind Faith? A Grounded Theory Study of the Efficacy of Coaching Supervision. In Coaching Researched: A Coaching Psychology Reader; Wiley Online Library: Hackensack, NJ, USA, 2020; pp. 145–165. [Google Scholar]

- Hwang, S. Utilizing qualitative data analysis software: A review of ATLAS.ti. Soc. Sci. Comput. Rev. 2007, 26, 519–527. [Google Scholar] [CrossRef]

- Gibbs, G.R. Media review: ATLAS.ti software to assist with the qualitative analysis of data. J. Mix. Methods Res. 2007, 1, 103–104. [Google Scholar] [CrossRef]

- Lewis, R.B. NVivo 2.0 and ATLAS.ti 5.0: A comparative review of two popular qualitative data-analysis programs. Field Methods 2004, 16, 439–464. [Google Scholar] [CrossRef]

| Labor Category | Work Experience (under 5 Years) | Work Experience (between 10 and 15 Years) | Work Experience (>15 Years) |

|---|---|---|---|

| operational maintenance technicians. (mechanics) | 6 | 12 | 9 |

| operational maintenance technicians. (electrical-systems) | 10 | 9 | 7 |

| operational maintenance technicians. (production) | 9 | 8 | 6 |

| subtotal | 25 | 29 | 22 |

| total | 76 | ||

| Technicians’ Work Experience (years) | Number of Surveys |

|---|---|

| <3 | 34 |

| 3 to 5 | 48 |

| >5 | 92 |

| total | 174 |

| Category of the Studied Phenomenon | Maintenance Operational Technicians |

|---|---|

| Tools for knowledge management | Information and knowledge maps. Agile and simple systems to capture experiences. Mobile computing tools to capture images, videos, and experiences. |

| Barriers in Knowledge Management | Little time available to properly document important actions. Cultural barriers. Culture based on “own knowledge”, not shared. Staff involvement. Greater use of informal knowledge transfer mechanisms. |

| Facilitators in Knowledge Management | Open and flexible proactive organizational culture. Participatory style of management. Employee’s personal motivation. Opportunity to learn. Organizational culture of the maintenance area. Management style. Media. Use of a manager of own knowledge of the maintenance activity. |

| Observations | A lot of strategic information, collected in a handwritten form disaggregated in personal notes and notebooks, annotations on plans, not shared with the rest of the organization, which hinders the transmission and use of the knowledge by the rest of the organization. |

| Results of Proper Management of Knowledge in Maintenance Activity | Capture of the tacit strategic knowledge of operational maintenance technicians. Resolving critical failures in less time (especially non-cyclical ones). Reduction of operating manoeuvre times. Facilitate the change of area or personnel substitutions. Reduction of familiarization times for new personnel. Capture of information and transfer of subcontractor companies. Sharing the knowledge of employees that can be used by others who can detect new opportunities for improvement. Improved knowledge of the reliability of equipment and facilities. Improvement of knowledge for the detection and improvement of energy efficiency actions. Optimization of time, which again results in knowledge management and the reduction of maintenance costs. Improvement in self-learning in order to solve problems in the factory itself. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cárcel-Carrasco, J.; Cárcel-Carrasco, J.-A. Analysis for the Knowledge Management Application in Maintenance Engineering: Perception from Maintenance Technicians. Appl. Sci. 2021, 11, 703. https://doi.org/10.3390/app11020703

Cárcel-Carrasco J, Cárcel-Carrasco J-A. Analysis for the Knowledge Management Application in Maintenance Engineering: Perception from Maintenance Technicians. Applied Sciences. 2021; 11(2):703. https://doi.org/10.3390/app11020703

Chicago/Turabian StyleCárcel-Carrasco, Javier, and José-Antonio Cárcel-Carrasco. 2021. "Analysis for the Knowledge Management Application in Maintenance Engineering: Perception from Maintenance Technicians" Applied Sciences 11, no. 2: 703. https://doi.org/10.3390/app11020703

APA StyleCárcel-Carrasco, J., & Cárcel-Carrasco, J.-A. (2021). Analysis for the Knowledge Management Application in Maintenance Engineering: Perception from Maintenance Technicians. Applied Sciences, 11(2), 703. https://doi.org/10.3390/app11020703