Modeling and Experimental Verification of Induction Heating of Thin Molybdenum Sheets

Abstract

1. Introduction

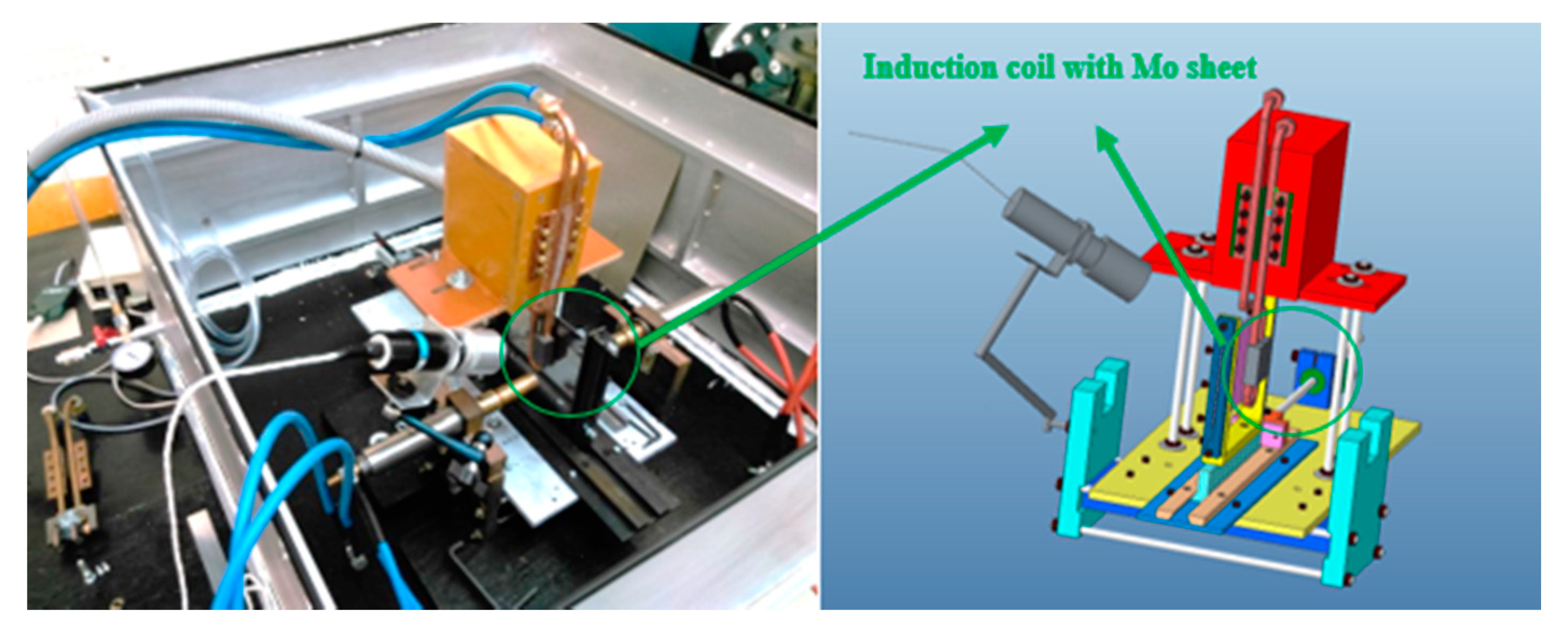

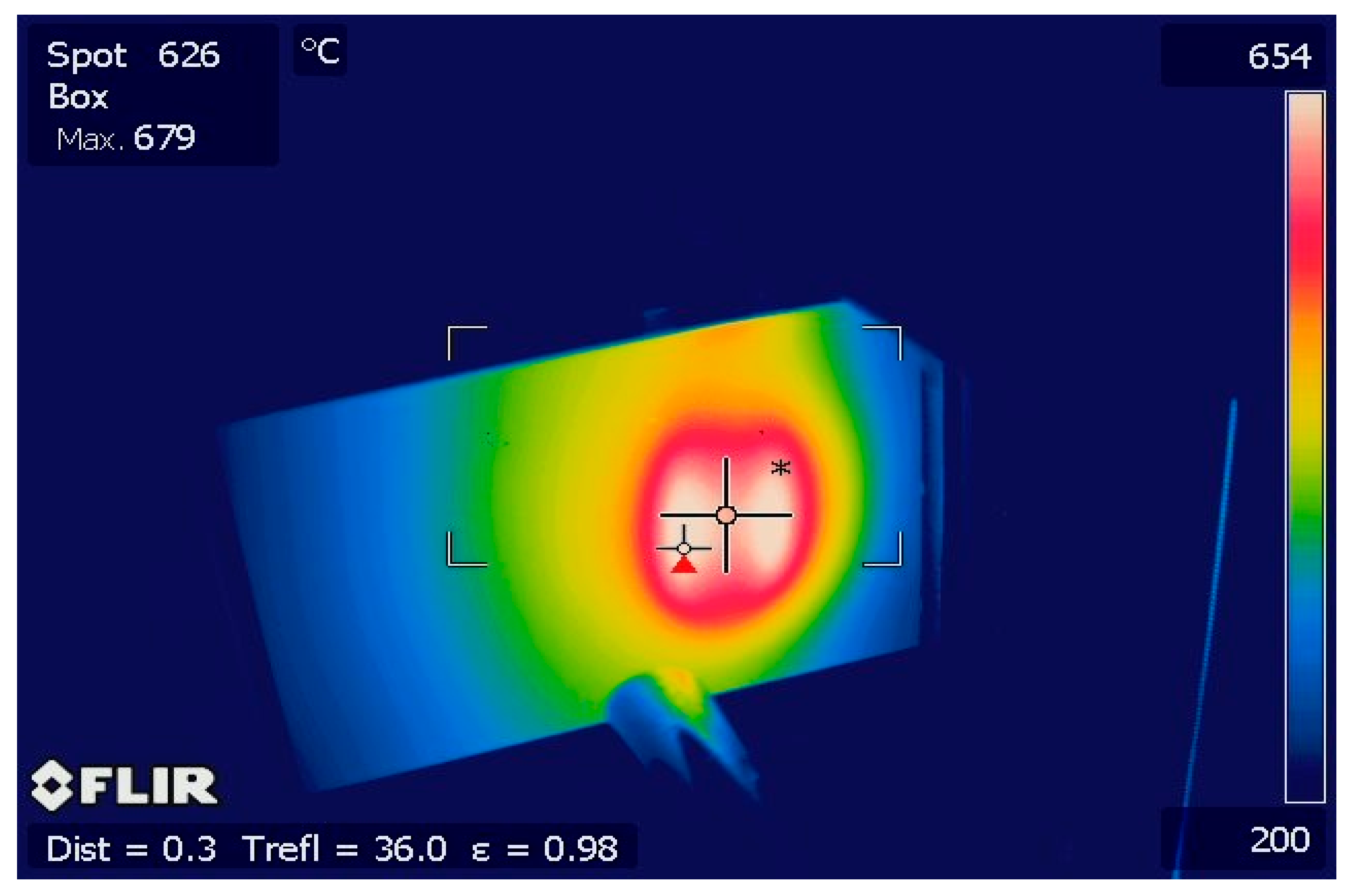

2. Contactless—Induction Heating of Thin Molybdenum Sheet

- the operating frequency of the electromagnetic field

- value of the coil’s current

- distance (gap) between the heating coil and Mo sheet

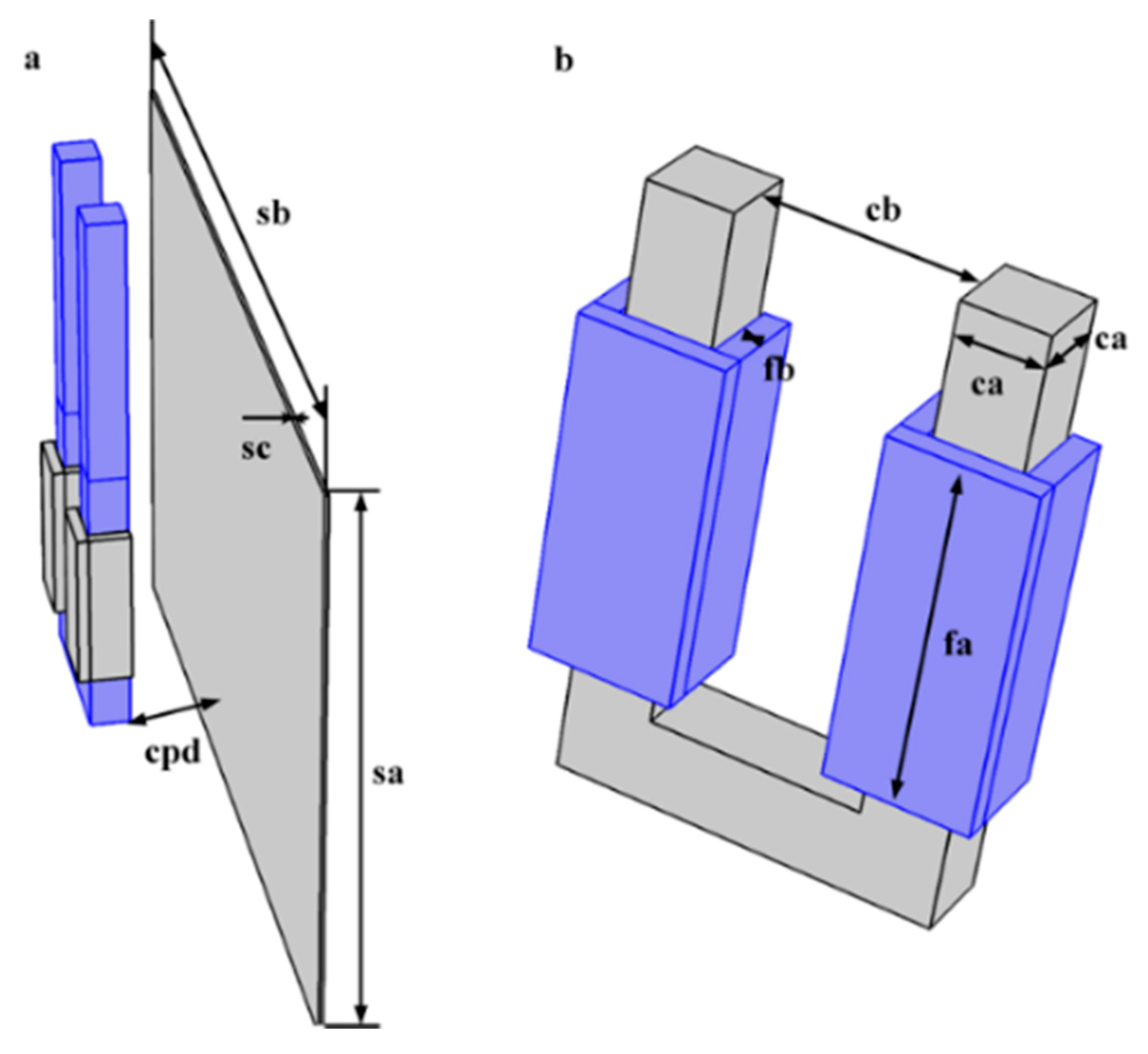

3. Design of Electro-Thermal Simulation Model of Induction Heating

- the mutual position between the induction coil and the Mo sheet,

- the coil material properties as well as the coil geometry

- the frequency and intensity of the applied electromagnetic field.

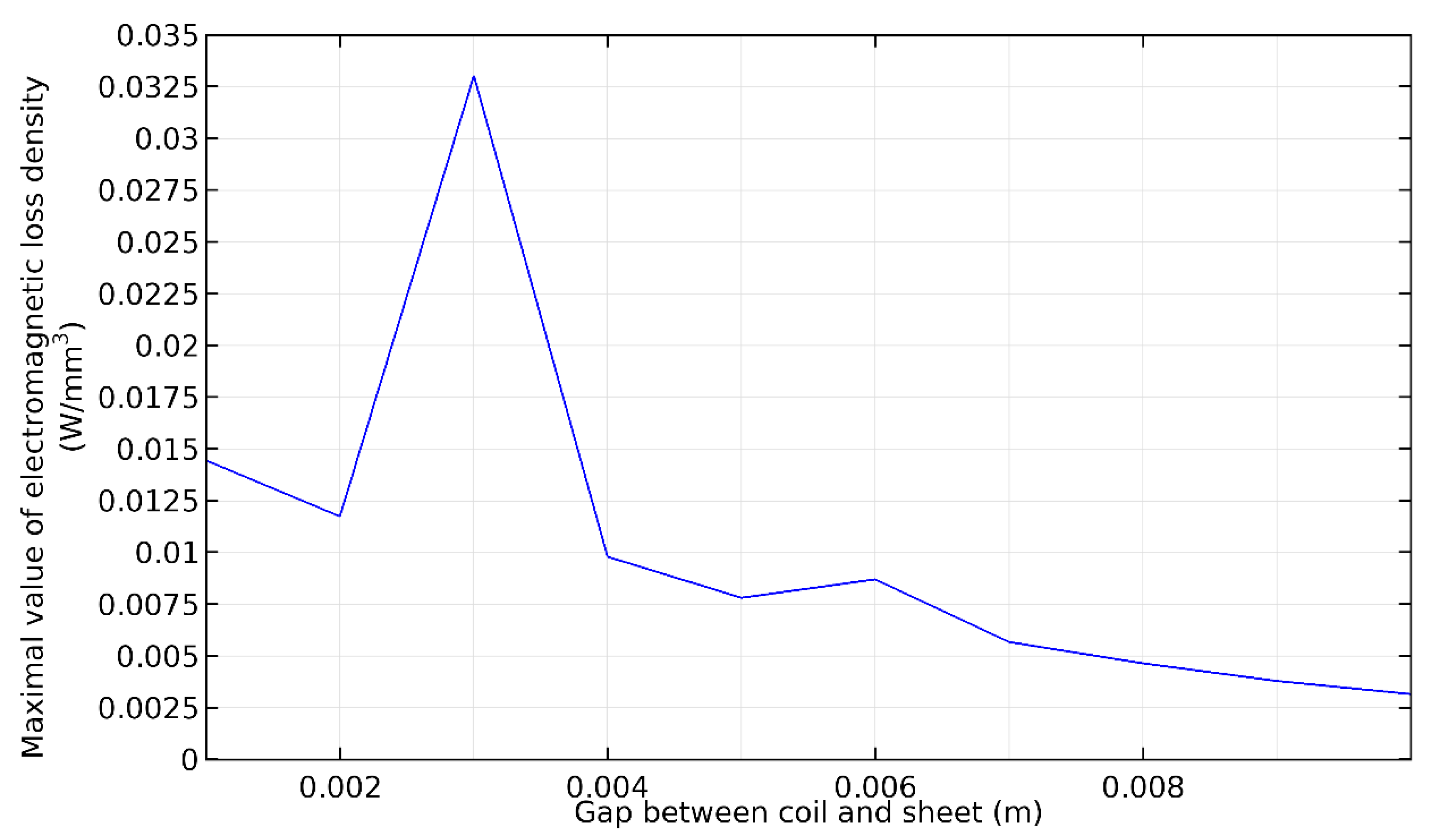

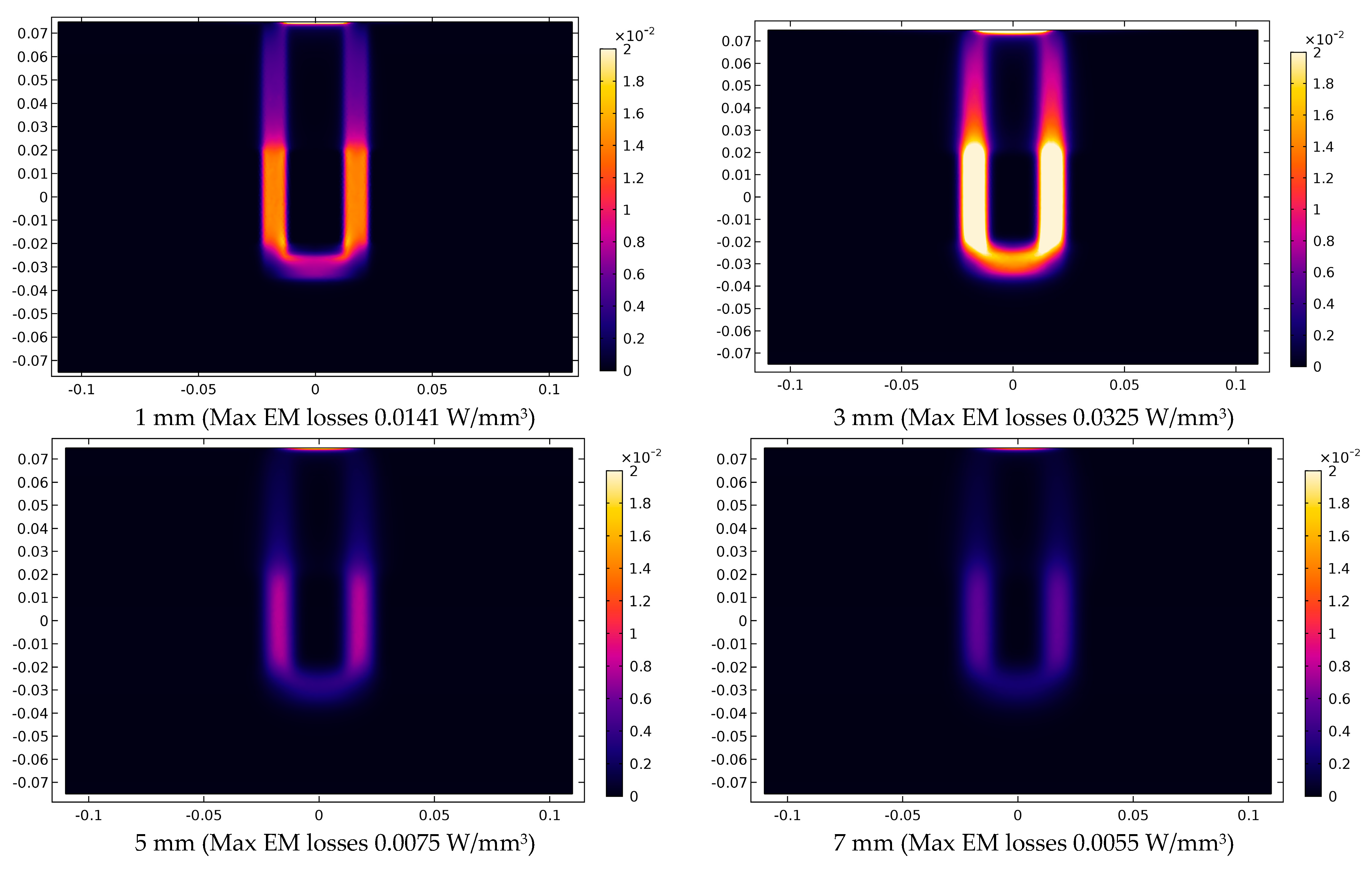

3.1. Parametric Simulation for the Determination of the Optimal Operating Conditions of the Induction Heating

- The current flowing through the coil is 150 A.

- The thickness of the ferrite core is 10 mm.

- The operating frequency of the applied voltage generating EM field is 25 kHz.

- Distance (gap) between sheet and heating element is 1:1:10 [mm], i.e., initial distance is 1 mm, step is 1 mm, and the final distance is 10 mm.

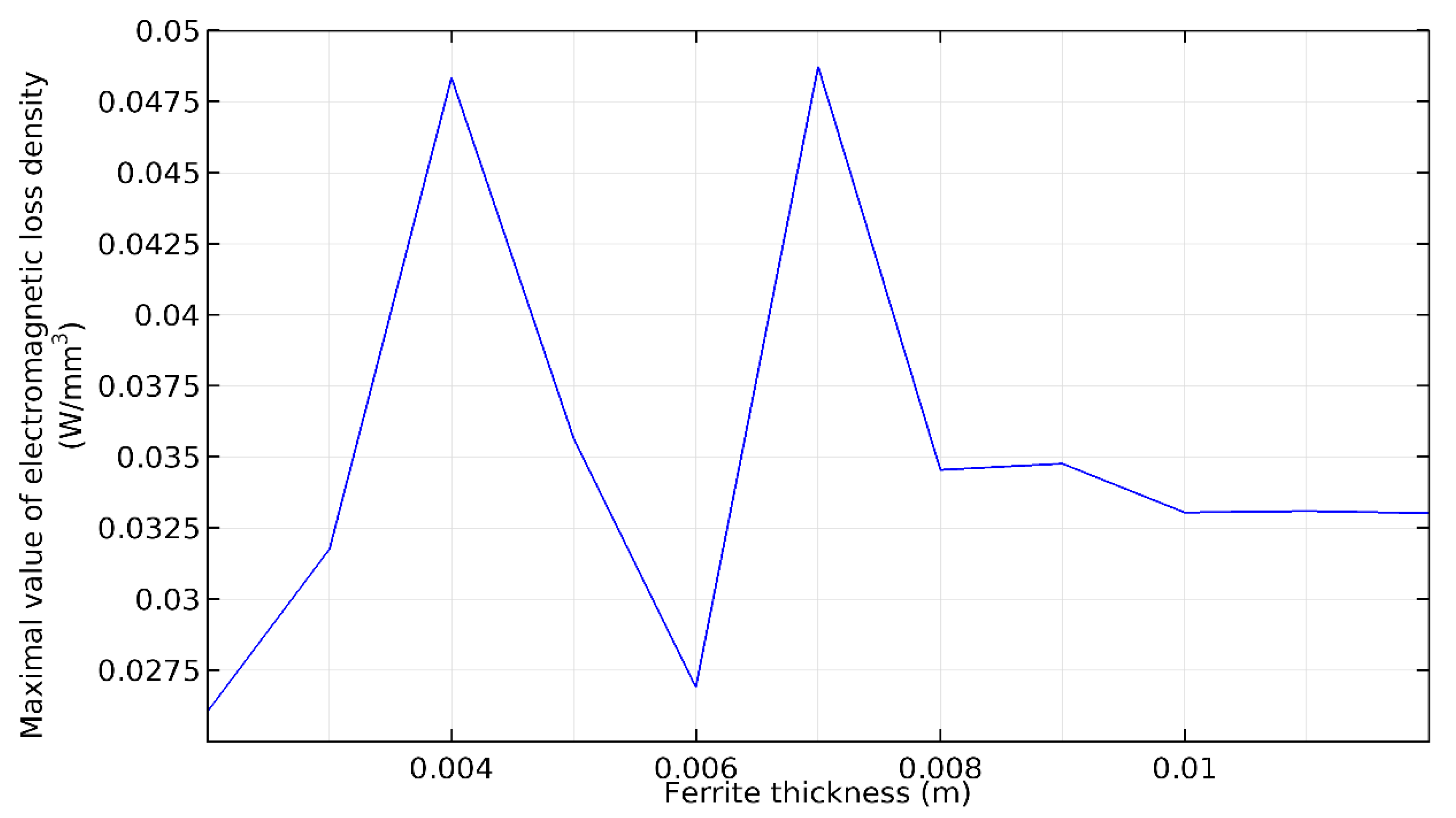

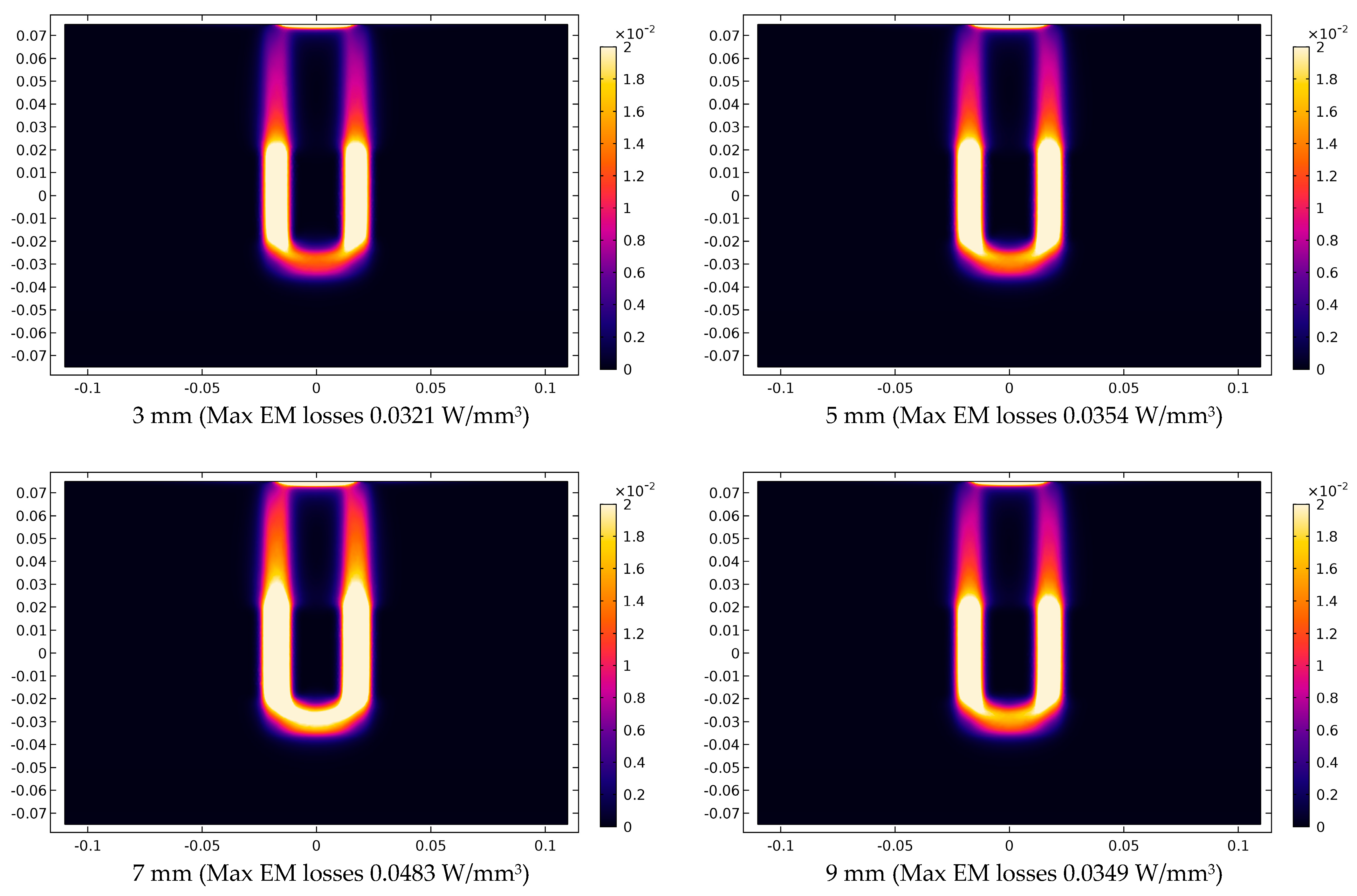

- The current flowing through the coil is 150 A

- The thickness of the ferrite core is 2:1:12 mm

- The operating frequency of the applied field is 25 kHz

- Distance (gap) Between sheet and heating element is 3 mm

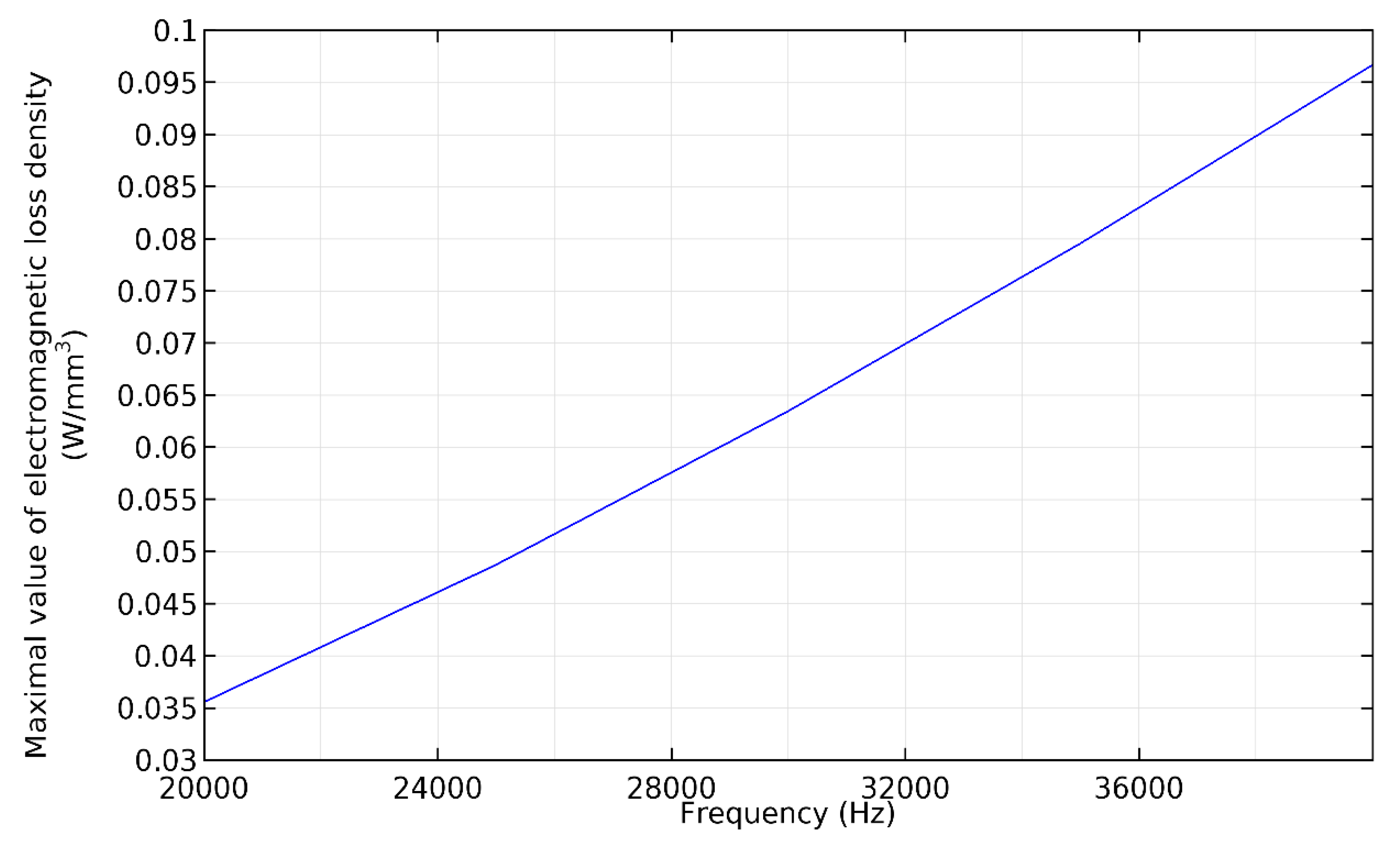

- The current flowing through the coil is 150 A.

- The thickness of the ferrite core is 7 mm.

- The applied field’s operating frequency is 20:5:40 kHz (initial frequency 20 kHz, step-change 5 kHz, and final frequency 40 kHz).

- Distance (gap) between sheet and heating element is 3 mm.

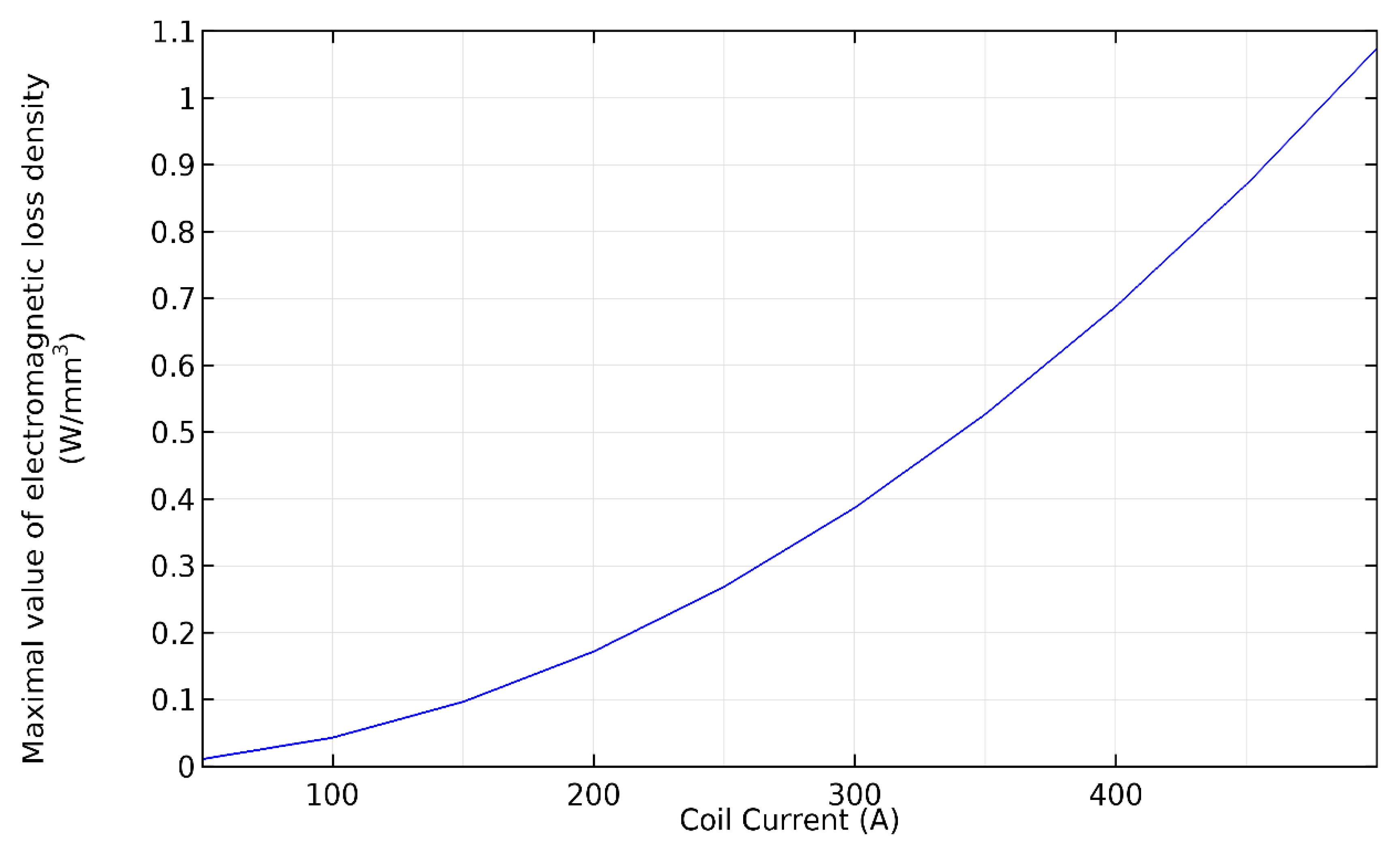

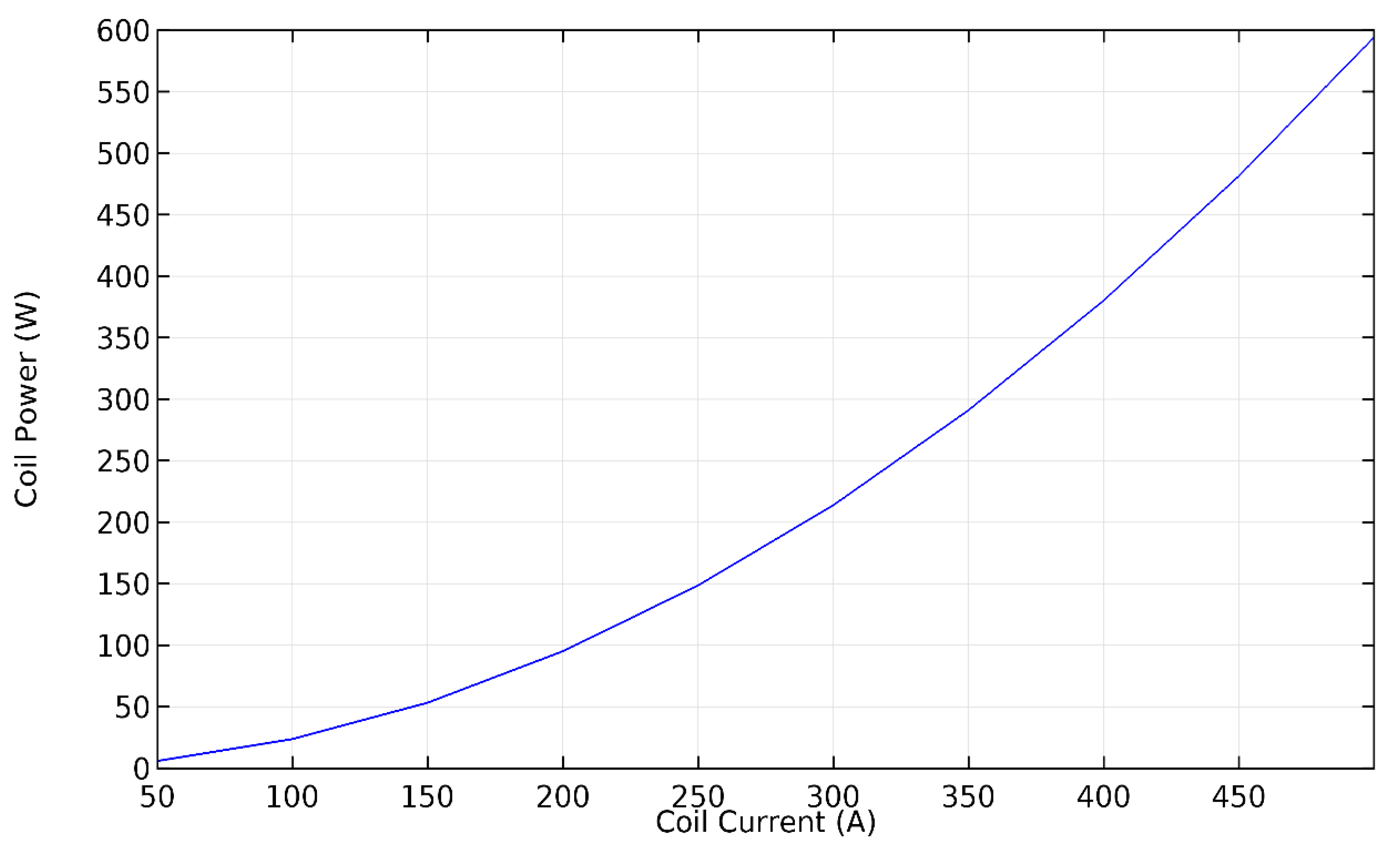

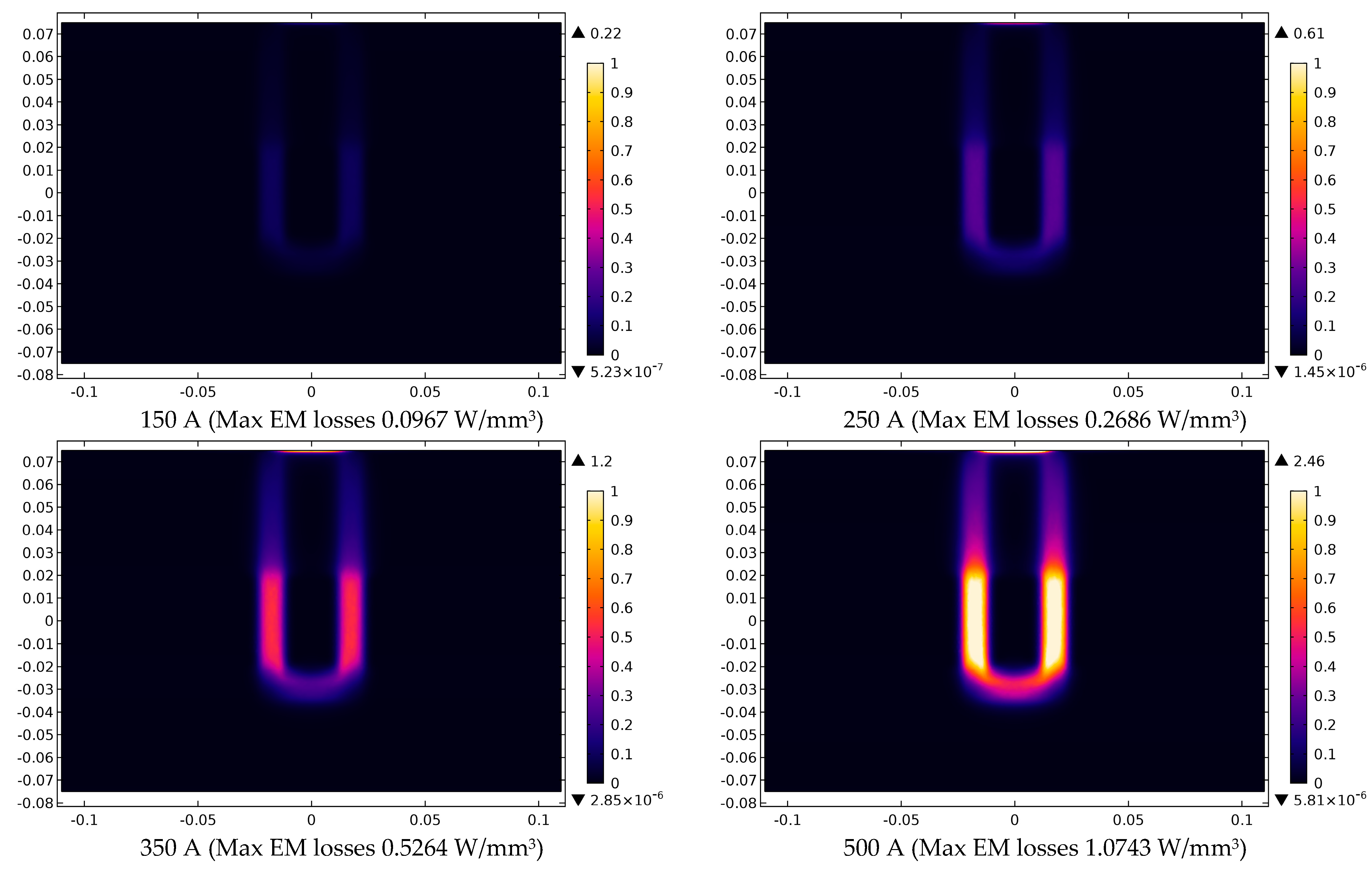

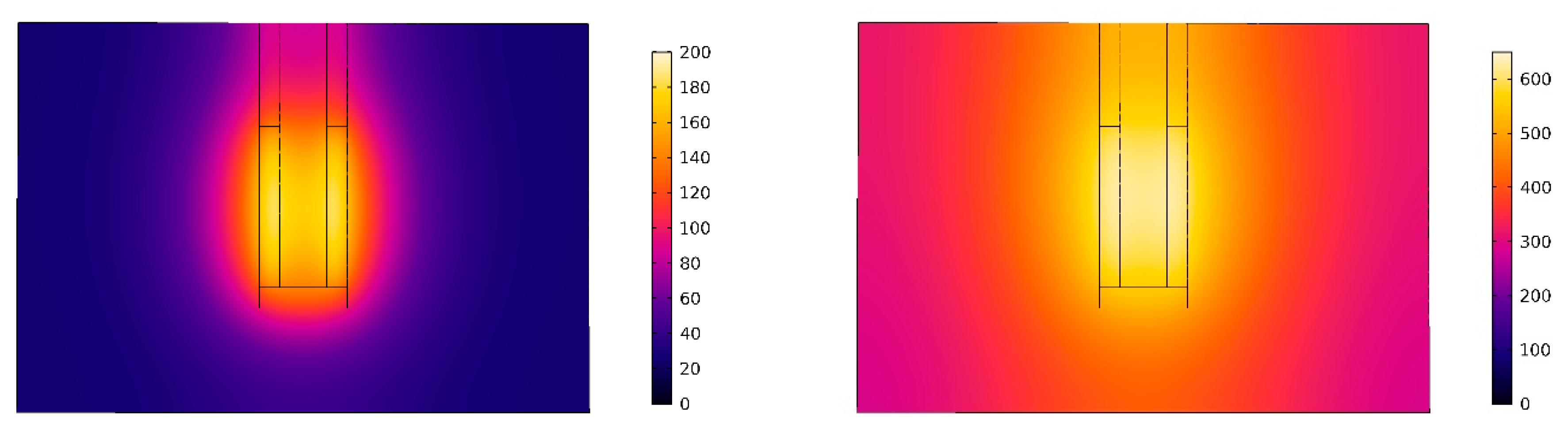

3.2. Heat Distribution and Heat Performance for Optimal Parameter Settings of Induction Heating

- The current flowing through the coil is 50:50:500 A.

- The thickness of the ferrite core is 7 mm.

- The operating frequency of the applied field is 40 kHz.

- Distance (gap) between sheet and heating element is 3 mm.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pepper, I.; Gerba, C.; Gentry, T. Enviromental Microbiology, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Griffiths, A.; Miller, J.; Suzuki, D. An Introduction to Genetic Analysis, 7th ed.; W.H. Freeman: New York, NY, USA, 2000. [Google Scholar]

- Fasihi, Z.; Zakeri-Milani, P.; Nokhodchi, A.; Akbari, J.; Barzegar-Jalali, M.; Loebenberg, R.; Valizadeh, H. Thermodynamic approaches for the prediction of oral drug absorption. J. Therm. Anal. Calorim. 2017, 130, 1371–1382. [Google Scholar] [CrossRef]

- Guihong, T.M.; Christopher, F.; Change, T. Temperature-Sensitive Mutations Made Easy: Generating Conditional Mutations by Using Temperature-Sensitive Inteins That Function within Different Temperature. Genetics 2009, 183, 13–22. [Google Scholar]

- Koniar, D.; Hargas, L.; Stofan, S. High Speed Video System for Tissue Measurement Based on PWM Regulated Dimming and Virtual Instrumentation. Elektron. Elektrotech. 2010, 10, 169–172. [Google Scholar]

- Kuo-Chi, L. Thermal propagation analysis for living tissue with surface heating. Int. J. Ther. Sci. 2008, 47, 507–513. [Google Scholar]

- Verma, R. Challenges in education in thermal analysis and calorimetry. J. Therm. Anal. Calorim. 2013, 113, 1675–1679. [Google Scholar] [CrossRef]

- Agrawal, M.; Pardasani, K.R.; Adlakha, N. Finite element model to study the thermal effect of tumors in dermal regions of irregular tapered shaped human limbs. Int. J. Ther. Sci. 2015, 98, 287–295. [Google Scholar] [CrossRef]

- Su, C.-H.; Wu, S.-H.; Shen, S.-J.; Shiue, G.-Y.; Wang, Y.-W.; Shu, C.-M. Thermal characteristics and regeneration analyses of adsorbents by differential scanning calorimetry and scanning electron microscope. J. Therm. Anal. Calorim. 2009, 96, 765–769. [Google Scholar] [CrossRef]

- Kéri, O.; Bárdos, P.; Boyadjiev, S.; Igricz, T.; Nagy, Z.K.; Szilágyi, I.M. Thermal properties of electrospun polyvinylpyrrolidone/titanium tetraisopropoxide composite nanofibers. J. Therm. Anal. Calorim. 2019, 137, 1249–1254. [Google Scholar] [CrossRef]

- Shunmugam, M.S.; Kanthababu, M. Advances in Simulation, Product Design and Development. In Advances in Simulation, Product Design and Development, Proceedings of the AIMTDR 2018, Berlin/Heidelberg, Germany, 6 November 2018; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 978-981-329-487-5. [Google Scholar]

- Veeman, D. Finite Element simulation of Temperature Distribution and Residual Stress in Single Bead on Plate Weld Trial using Double Ellipsoidal Heat Source Model. Int. J. Recent Technol. Eng. 2019, 8, 133–138. [Google Scholar]

- Hyoe, T.; Colegrove, P.A.; Shercliff, H. Thermal and microstructure modelling in thick plate aluminium alloy 7075 friction stir welds. In Friction Stir Welding and Processing II, Proceedings of the 2nd International Conference on Friction Stir Welding and Processing, San Diego, CA, USA, 13–16 September 2003; The Minerals, Metals and Materials Society: Pittsburgh, PA, USA, 2003; pp. 33–42. [Google Scholar]

- Ubaid, M.; Bajaj, D.; Mukhopadhyay, A.K.; Siddiquee, A.N. Friction Stir Welding of Thick AA2519 Alloy: Defect Elimination, Mechanical and Micro-Structural Characterization. Met. Mater. Int. 2019, 26, 1841–1860. [Google Scholar] [CrossRef]

- Yuan, W.-J.; Wu, Y.-X. Coupled thermal-mechanical simulation on quenching of aluminum alloy thick-plate based on ANSYS. J. Cent. South Univ. Sci. Technol. 2010, 41, 2207–2212. [Google Scholar]

- Colegrove, P.; Shercliff, H.R. CFD modelling of friction stir welding of thick plate 7449 aluminium alloy. Sci. Technol. Weld. Join. 2006, 11, 429–441. [Google Scholar] [CrossRef]

- Hargas, L.; Koniar, D.; Hrianka, M. Adjusting and Conditioning of High Speed Videosequences for Diagnostic Purposes in Medicine. In Proceedings of the 10th International Conference ELEKTRO 2014, Rajecké Teplice, Slovakia, 19–20 May 2014; pp. 548–552. [Google Scholar]

- Nomoto, T.; Imajo, S.; Yamashita, S.; Akutsu, H.; Nakazawa, Y.; Krivchikov, A.I. Construction of a thermal conductivity measurement system for small single crystals of organic conductors. J. Therm. Anal. Calorim. 2018, 135, 2831–2836. [Google Scholar] [CrossRef]

- Ge, M.Y.; Shu, C.; Chua, K.J.; Yang, W.M. Numerical analysis of a clinically-extracted vascular tissue during cryo-freezing using immersed boundary method. Int. J. Ther. Sci. 2016, 110, 109–118. [Google Scholar] [CrossRef]

- Chen, M.; Dongxu, O.; Cao, S.; Liu, J.; Wang, Z.; Wang, J. Effects of heat treatment and SOC on fire behaviors of lithium-ion batteries pack. J. Therm. Anal. Calorim. 2018, 136, 2429–2437. [Google Scholar] [CrossRef]

- Hruska, K.; Kindl, V.; Pechanek, R. Design and FEM Analyses of an Electrically Excited Automotive Synchronous Motor. In Proceedings of the 15th International Power Electronics and Motion Control Conference and Exposition (EPE-PEMC ECCE Europe), Novi Sad, Serbia, 4–6 September 2012. [Google Scholar]

- Rafajdus, P.; Peniak, A.; Peter, D.; Makyś, P.; Szabó, L. Optimization of Switched Reluctance Motor Design Procedure for Electrical Vehicles. In Proceedings of the International Conference on Optimization of Electrical and Electronic Equipment (OPTIM), Brasov, Romania, 22–24 May 2014. [Google Scholar]

- Koniar, D.; Hargas, L.; Loncova, Z. Visual system-based object tracking using image segmentation for biomedical applications. Electr. Eng. 2017, 99, 1349–1366. [Google Scholar] [CrossRef]

- Frivaldsky, M.; Donic, T.; Vavrus, V.; Pavelek, M. Experimental research of optimization methodology for local, resistive—Heating of thin molybdenum plates. Int. J. Ther. Sci. 2017, 121, 111–123. [Google Scholar] [CrossRef]

- Zhu, J.; Fu, S.; Li, K.; Zeng, X.; Chen, S. Thermal stability assessment of a new energetic Ca(II) compound with ZTO ligand by DSC and ARC. J. Therm. Anal. Calorim. 2018, 134, 1873–1882. [Google Scholar] [CrossRef]

- Mashayekhi, R.; Khodabandeh, E.; Akbari, O.A.; Toghraie, D.; Bahiraei, M.; Gholami, M. CFD analysis of thermal and hydrodynamic characteristics of hybrid nanofluid in a new designed sinusoidal double-layered microchannel heat sink. J. Therm. Anal. Calorim. 2018, 134, 2305–2315. [Google Scholar] [CrossRef]

- Hațiegan, C.; Răduca, M.; Frunzaverde, D.; Răduca, E.; Pop, N.; Gillich, G.-R. The modeling and simulation of the thermal analysis on the hydrogenerator stator winding insulation. J. Therm. Anal. Calorim. 2013, 113, 1217–1221. [Google Scholar] [CrossRef]

- Balek, V.; Zelenák, V.; Mitsuhashi, T.; Beckman, I.N.; Haneda, H.; Bezdička, P. Thermal Behaviour of Titania Based Materials: Mathematical modeling of emanation thermal analysis results. J. Therm. Anal. Calorim. 2002, 67, 63–72. [Google Scholar] [CrossRef]

- Barewar, S.D.; Tawri, S.; Chougule, S.S. Experimental investigation of thermal conductivity and its ANN modeling for glycol-based Ag/ZnO hybrid nanofluids with low concentration. J. Therm. Anal. Calorim. 2019, 139, 1779–1790. [Google Scholar] [CrossRef]

- Kozlov, A.; Svishchev, D.; Donskoy, I.; Keiko, A.V. Thermal analysis in numerical thermodynamic modeling of solid fuel conversion. J. Therm. Anal. Calorim. 2012, 109, 1311–1317. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Operating frequency [kHz] | 80 |

| Coil’s current [A] | 150 |

| Gap [mm] | 6 |

| Mo thickness [mm] | 7 |

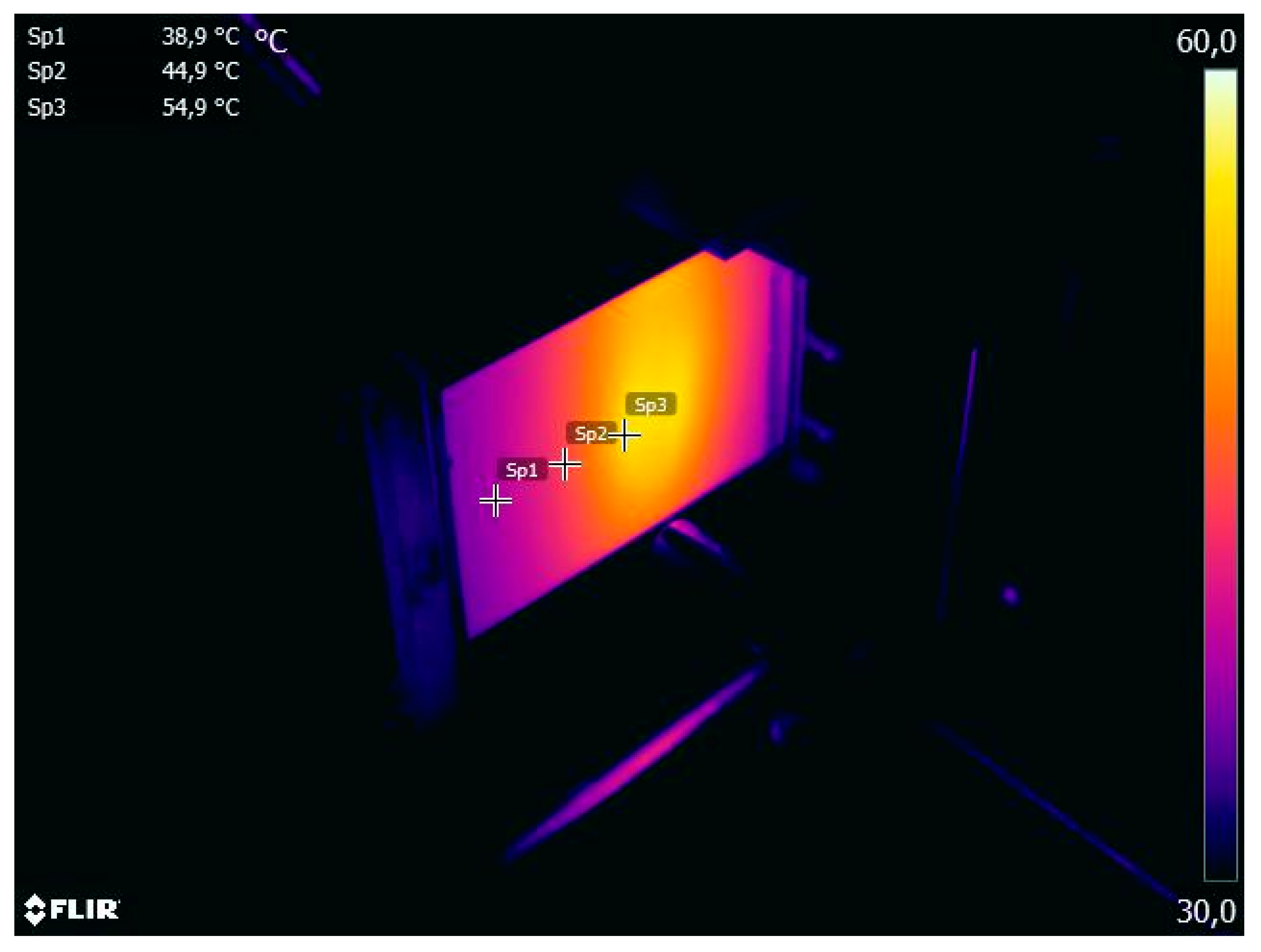

| Reference Point | The Temperature at the Reference Point [°C] (Experimental) | The Temperature at the Reference Point [°C] (Simulation) | Relative Error [%] |

|---|---|---|---|

| Sp1 | 38.9 | 39.88 | −2.52 |

| Sp2 | 44.9 | 45.73 | −1.85 |

| Sp3 | 54.9 | 55.59 | −1.26 |

| Parameter/Domain | Molybdenum Sheet | Coil | Magnetic Part | Environment |

|---|---|---|---|---|

| Material | Molybdenum | Copper | Alloy ferrite powder | Air |

| Electrical conductivity [S/m] | 17.9 × 106 | 5.5 × 107 | 1 × 10−12 | 1 × 10−15 |

| Density [kg/m3] | 10,280 | 8700 | 4980 | 1.2 |

| Relative permittivity [-] | 1 | 1 | 1 | 1 |

| Relative permeability [-] | 1.00012 | 1 | 3000 | 1 |

| Ampere’s Law | YES | YES | YES | YES |

| Magnetic insulation | NO | NO | NO | YES |

| Coil domain | NO | YES | NO | NO |

| Domain | Material | Domain Settings | Domain Equations |

|---|---|---|---|

| Environment | Air | Fluid, Initial Values [25 °C] | (1), (3) |

| Environment Boundary | Air | Fluid, Initial Values [25 °C], Thermal Insulation | (1), (3), (4) |

| Molybdenum Plate | Molybdenum | Solid, Initial Values [25 °C] | (2), (3) |

| Heat Source in Molybdenum Plate | Molybdenum | Solid, Initial Values [25 °C], Heat Source | (2), (3), (5) |

| Coil | Copper | Solid, Initial Values [25 °C] | (2), (3) |

| Magnetics | Ferrite | Solid, Initial Values [25 °C] | (2), (3) |

| Maximum Element Size [m] | Minimum Element Size [m] | Maximum Element Grow [-] | Curvature Factor [-] | Resolution of Narrow Regions |

|---|---|---|---|---|

| 8.75 × 10−3 | 3.75 × 106 | 1.35 | 0.3 | 0.85 |

| Parameter | Coil’s Current [A] | Frequency [kHz] | GAP [mm] | Mo Thickness [mm] |

|---|---|---|---|---|

| Value | 500 | 40 | 3 | 7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frivaldsky, M.; Pavelek, M.; Donic, T. Modeling and Experimental Verification of Induction Heating of Thin Molybdenum Sheets. Appl. Sci. 2021, 11, 647. https://doi.org/10.3390/app11020647

Frivaldsky M, Pavelek M, Donic T. Modeling and Experimental Verification of Induction Heating of Thin Molybdenum Sheets. Applied Sciences. 2021; 11(2):647. https://doi.org/10.3390/app11020647

Chicago/Turabian StyleFrivaldsky, Michal, Miroslav Pavelek, and Tibor Donic. 2021. "Modeling and Experimental Verification of Induction Heating of Thin Molybdenum Sheets" Applied Sciences 11, no. 2: 647. https://doi.org/10.3390/app11020647

APA StyleFrivaldsky, M., Pavelek, M., & Donic, T. (2021). Modeling and Experimental Verification of Induction Heating of Thin Molybdenum Sheets. Applied Sciences, 11(2), 647. https://doi.org/10.3390/app11020647