1. Introduction

Construction machinery has a pivotal role in the building and mining industry, which makes a great contribution to the world economy [

1]. The wheel loader is one of the most common mobile construction machinery and is often used to transport different materials at production sites [

2].

The automation of wheel loaders, which has received great attention over the past three decades, can improve safety and reduce costs. Dadhich et al. [

3] proposed five steps to full automation of wheel loaders: manual operation, in-sight tele-operation, tele-remote operation, assisted tele-remote operation, and fully autonomous operation. Despite extensive research in this field, fully automated systems for wheel loaders have never been demonstrated. Remote operation is considered a step towards fully automated equipment, but it has led to a reduction in productivity and fuel efficiency [

4].

In the working process of wheel loaders, bucket-filling is a crucial part, as it determines the weight of the loaded materials. Bucket-filling is a relatively repetitive task for the operators of wheel-loaders and is suitable for automation. Automatic bucket-filling is also required for efficient remote operation and the development of fully autonomous solutions [

5]. The interaction condition between the bucket and the pile strongly affects the bucket-filling. However, due to the complexity of the working environment, the interaction condition is unknown and constantly changing. The difference in working materials also influences the bucket-filling. A general automatic bucket-filling solution is still a challenge for different piles.

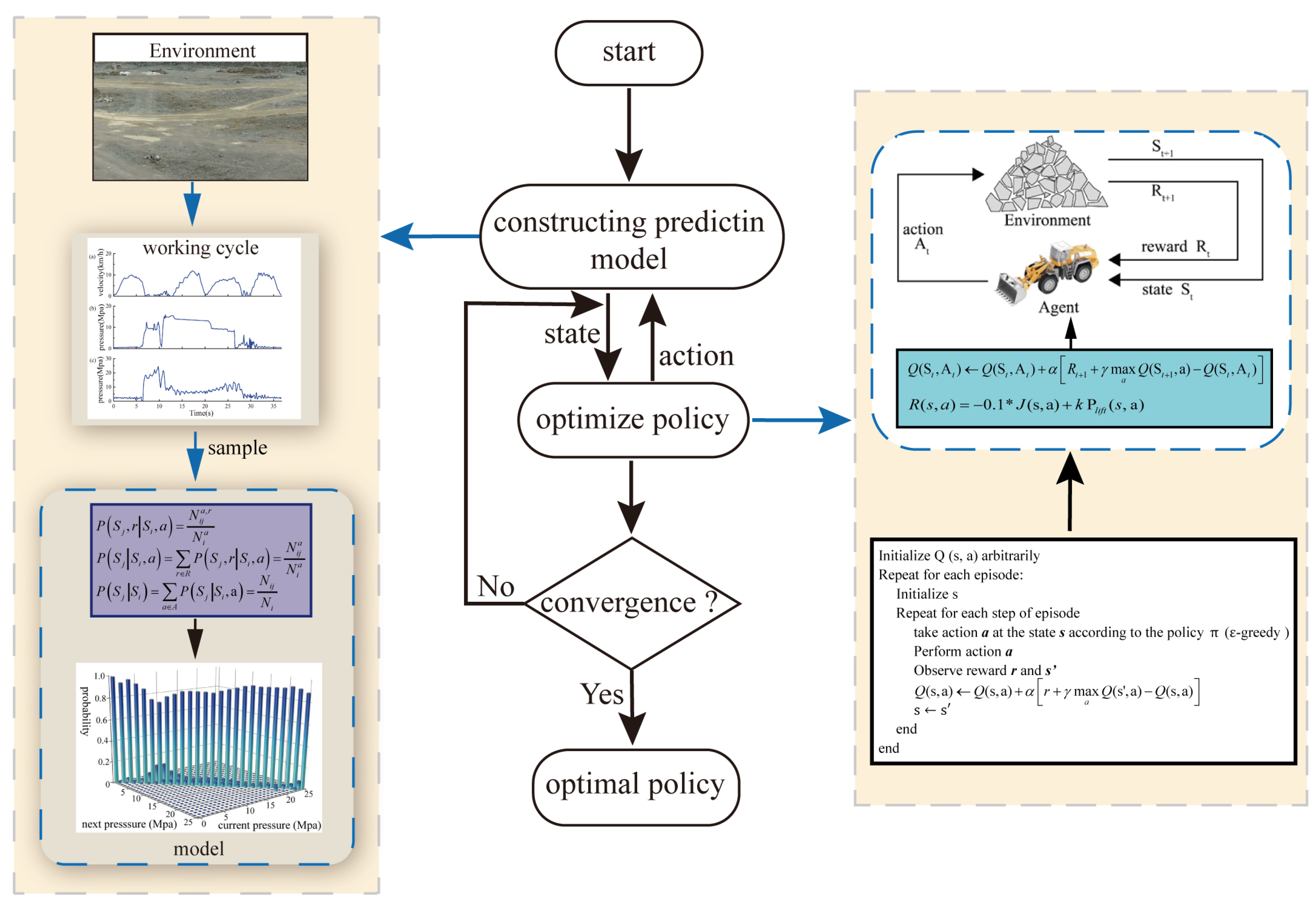

In this paper, a data-driven RL-based approach is proposed for automatic bucket-filling of wheel loaders to achieve low costs and adapt to changing conditions. The Q-learning algorithm can learn from different conditions and is used to learn the optimal action in different states by maximizing the expected sum of rewards. Aiming to achieve low costs, an indirect RL is employed. Indirect RL requires a virtual environment constructed from data or the known knowledge, and the agent learns from interacting with the virtual environment instead of the real environment. Direct RL needs to interact with the real environment, and the agent of direct RL learns from interacting with the real environment. Compared to direct RL, indirect RL can more efficiently take advantage of samples by planning [

6]. In addition, the parameters of Q-learning in source tasks are partially transferred to the Q-learning of target tasks to demonstrate the transfer learning capability of the proposed approach. Considering the nonlinearity and complexity of interactions between the bucket and pile [

7], the data obtained from field tests are utilized to build a nonlinear, non-parametric statistical model for predicting the state of the loader bucket in the bucket-filling process. The prediction model is used to train the Q-learning algorithm to validate the proposed algorithm.

The main contributions of this paper are summarized as follows:

- (1)

A data-based prediction model for the wheel loader is developed.

- (2)

A general automatic bucket-filling algorithm based on Q-learning is presented and the transfer ability of the algorithm is demonstrated. The proposed automatic bucket-filling algorithm does not require a dynamic model and can adapt for different changing conditions with low costs.

- (3)

The performance of the automatic bucket-filling algorithm and expert operators on loading two different materials is compared.

The rest of this paper is summarized below.

Section 2 presents the related existing research.

Section 3 states the problem and develops the prediction model.

Section 4 details the experimental setup and data processing.

Section 5 explains the automatic bucket-filling algorithm based on Q-learning and presents the state and reward.

Section 6 discusses the experimental results and evaluates the performance of our model by comparing it with real operators. Lastly, the conclusions are drawn in

Section 7.

2. Related Works

Numerous researchers have attempted to use different methods to achieve automatic bucket-filling. These studies can be summarized into the following three categories, which are: (1) physical model-based, (2) neural networks-based, and (3) reinforcement learning (RL)-based. This section will review related works in these three aspects, respectively.

Most relevant research attempted to realize automatic bucket-filling via physical-model-based control [

8]. Meng et al. [

9] applied Coulomb’s passive earth pressure theory to establish a model of bucket force during the scooping process for load-haul-dump machines. The purpose of developing the model was to calculate energy consumption, and the trajectory was determined through optimizing the minimum energy consumption in theory. Shen and Frank [

10,

11] used the dynamic programming algorithm to solve the optimal control of variable trajectories based on the model of construction machinery. The control results are compared to an extensive empirical measurement done on a wheel loader. The results show that the fuel efficiency is higher compared to the fuel efficiency measured among real operators. These works require accurate machine models, so they are prone to collapse under conditions of modeling errors, wear, and change. An accurate model of the bucket-pile interaction is difficult to build because the working condition is unpredictable, and the interaction forces between the bucket and material are uncertain and changing. When the machine and materials change, the model needs to be rebuilt. Therefore, the model-based approach is not a generic automatic bucket-filling solution for various the bucket-pile environments.

In recent years, non-physical-model-based approaches [

12] have been employed in the autonomous excavation of loaders and excavators. With the development of artificial intelligence, neural networks have been used in non-model-based approaches. A time-delayed neural network trained on expert operator data has been applied to execute the bucket-filling task automatically [

13]. The results show that time-delayed neural network (TDNN) architecture with input data obtained from the wheel loader successfully performs the bucket-filling operation after an initial period (100 examples) of imitation learning from an expert operator. The TDNN algorithm is used to compare with the expert operator and performs slightly worse than the expert operator with 26% longer bucket-filling time. Park et al. [

14] utilized an Echo-State Networks-based online learning technique to control the position of hydraulic excavators and compensate for the dynamics changes of the excavators over time. Neural network-based approaches do not require any machine and material models. However, these approaches require a large amount of labeled data obtained from expert operators for training, which is too costly.

Reinforcement learning (RL) is capable of learning effectively through interaction with complex environments without labeled data. The learning procedure of RL includes perceiving the environmental state, taking related actions to influence the environment, and evaluating an action by the reward from the environment [

15]. Reinforcement learning not only achieved surprising performance in GO [

16] and Atari games [

17], but has also been widely used for autonomous driving [

18] and energy management [

19]. The application of RL in construction machinery automation is mainly based on real-time interaction with the real or simulation environment. Hodel et al. [

20] applied RL-based simulation methods to control the excavator to perform the bucket-leveling task. Kurinov et al. [

21] investigated the application of an RL algorithm for excavator automation. In the proposed system, the agent of the excavator can learn a policy by interacting with the simulated model. Because simulation models are not derived from the real world, RL-based simulation cannot learn features of the real world well. Dadhich et al. [

5] used RL to achieve the automatic bucket-filling of wheel loaders through real-time interaction with the real environment. However, interacting with the real environment to train the RL algorithm is costly and time-consuming.

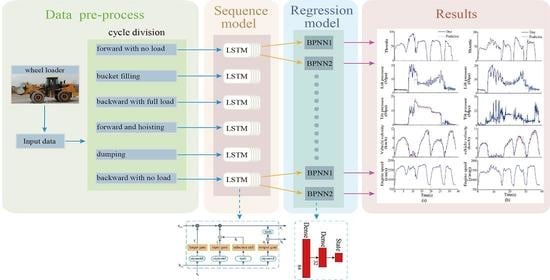

3. Background and Modeling

3.1. Working Cycle

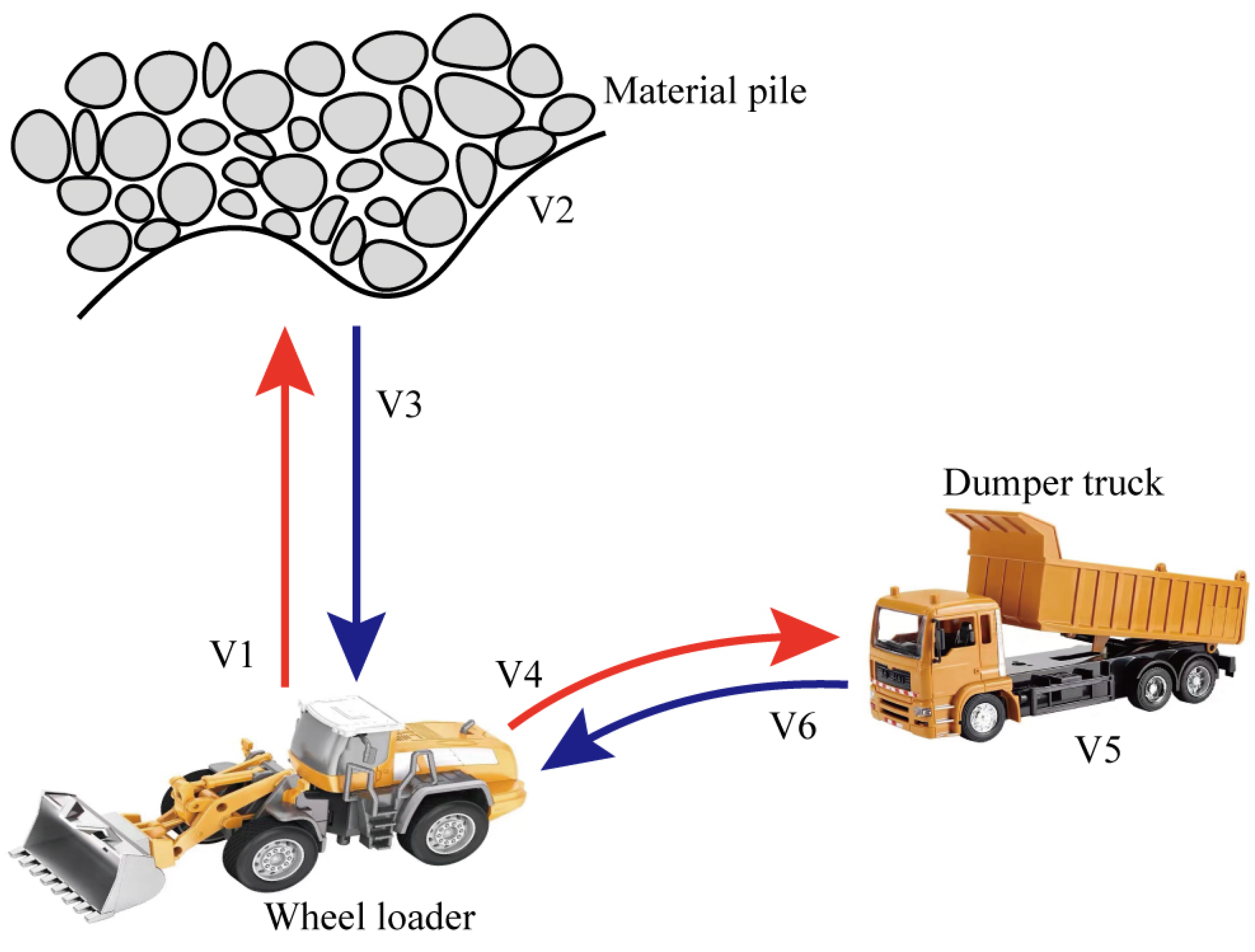

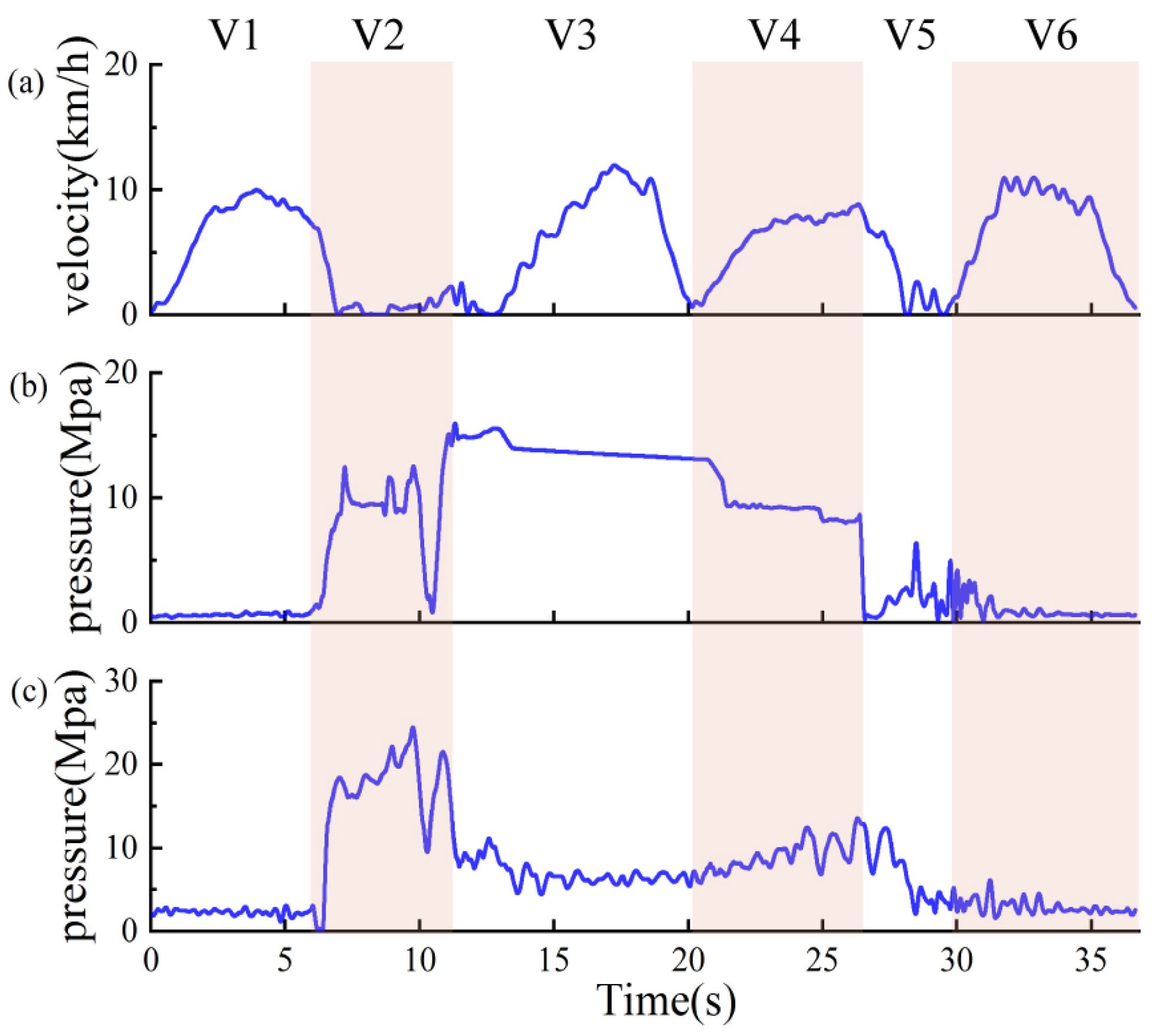

Wheel loaders are used to remove material (sand, gravel, etc.) from one site to another or an adjacent load receiver (dump truck, conveyor belt, etc.). Although there are many repetitive operation modes in the working process of wheel loaders, the different working cycles increase the complexity of data analysis. For wheel loaders, the representative short loading cycle, sometimes also dubbed the V-cycle, is adopted in this experiment, as illustrated in

Figure 1. The single V-cycle is divided into six phases, namely, V1 forward with no load (start and approach the pile), V2 bucket-filling (penetrates the pile and load), V3 backward with full load (Retract from the pile), V4 forward and hoisting (approach to the dumper), V5 dumping, and V6 backward with no load (Retract from the dumper), as shown in

Table 1. This article only focuses on the automation of the bucket-filling process (V2), which highly affected the overall energy efficiency and productivity of a complete V-cycle. The bucket-filling process (V2) accounts for 35–40% of the total fuel consumption per cycle [

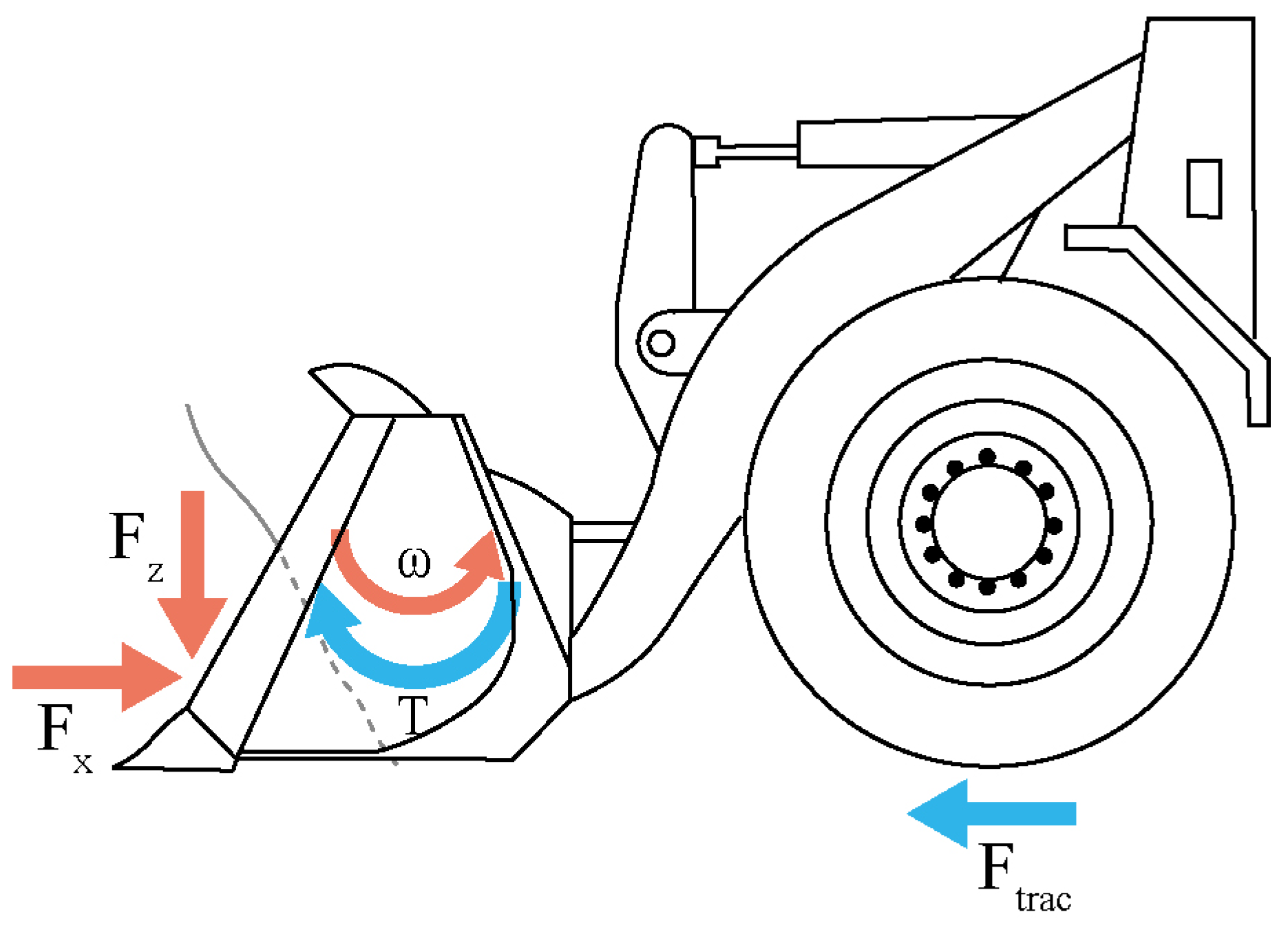

22]. In the bucket-filling process, the operator needs to modulate three actions simultaneously: a forward action (throttle), an upward action (lift), and a rotating action of the bucket (tilt) to obtain a large bucket weight.

3.2. Problem Statement

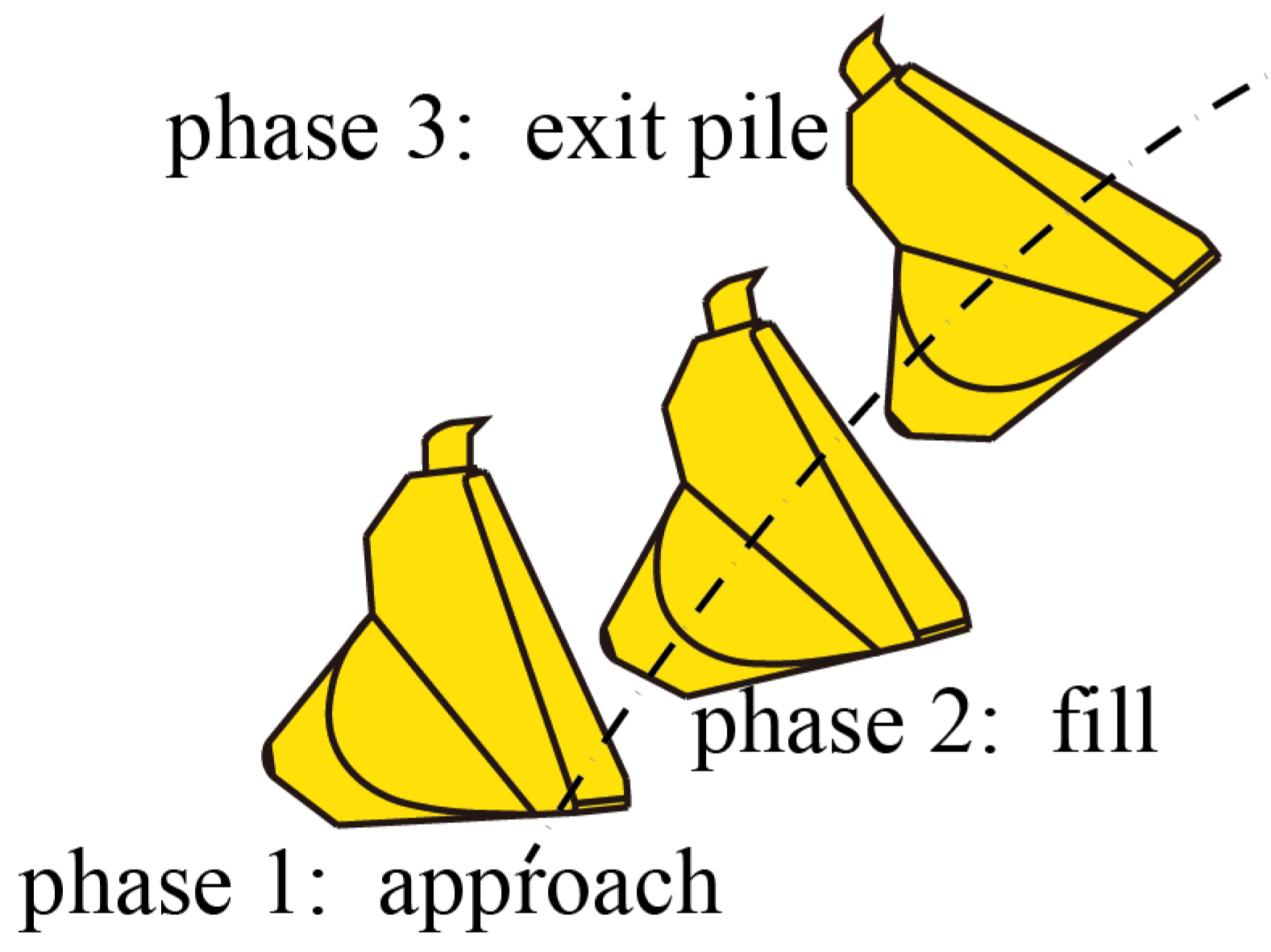

The working process of scooping can be split into three stages: approach, fill, and exit the pile, as shown in

Figure 2. In the first stage, wheel loaders move towards the pile of earth and the bucket penetrates the soil. In the second stage, the operator simultaneously adjusts the lift, tilt, and throttle to navigate the bucket tip through the earth pile and load as much material as possible within a short period. The throttle controls the engine speed, while the lift and tilt levers command valves in the hydraulics system that ultimately control the motion of the linkage’s lift and tilt cylinder, respectively. In the third phase, the bucket is tilted until the breakout is involved and the bucket exits the pile. The scoop phase is treated as a stochastic process where the input is the wheel loader state, and the output is the action. The goal is to find a policy using RL that maps the wheel loader state to action.

3.3. Prediction Model

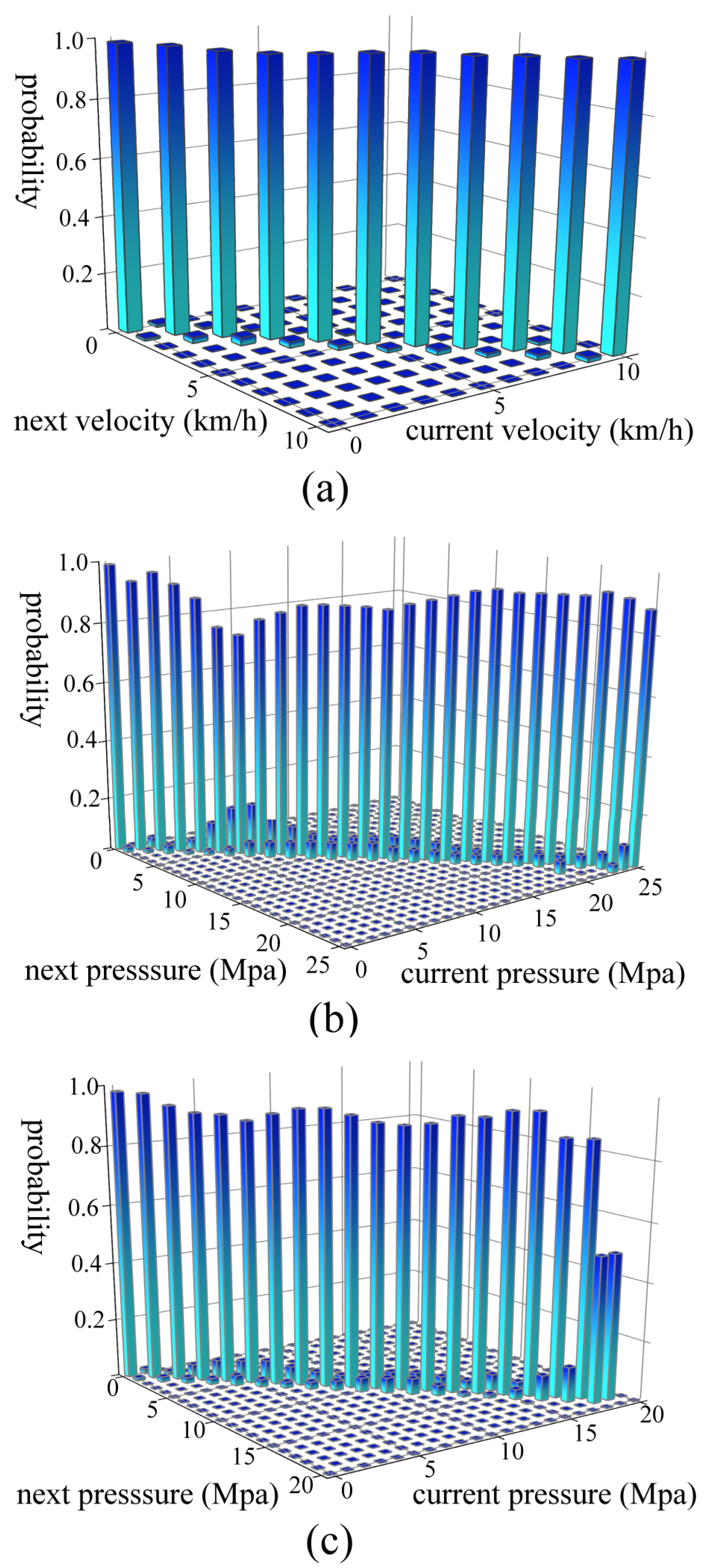

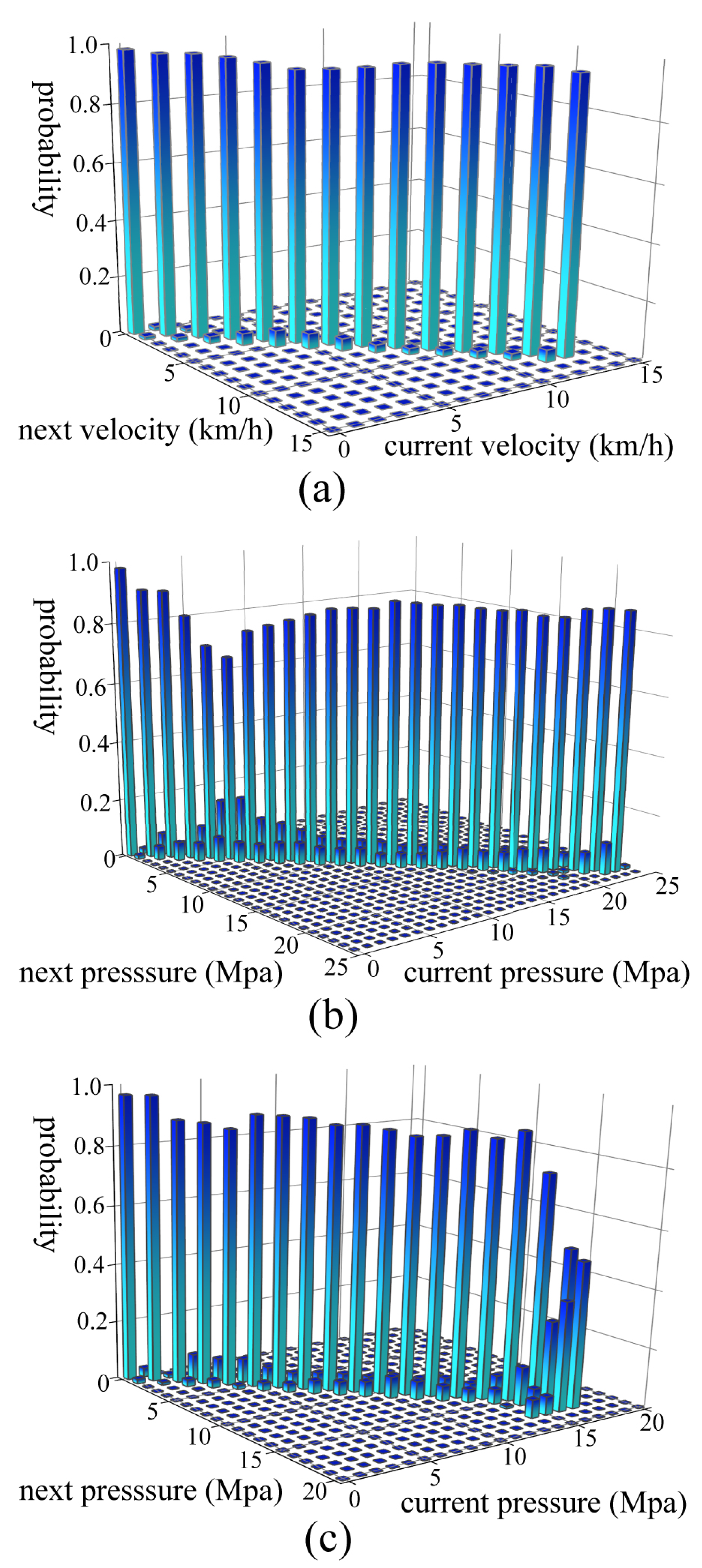

The Markov property is a prerequisite for reinforcement learning. In the actual operation process, the operator mainly executes the next actions according to the current state of the loader. Thus, the wheel loader state of the scooping process at the next moment is considered not to be related to the past, but to the current state, which satisfies the Markov property. Therefore, the interaction between the wheel loader bucket and the continuously changing pile can be modeled as a Finite Markov decision process (FMDP) which is expressed by a quadruple , consisting of the set of possible states S, the set of available actions A, the transition probability P, and the reward R. The state includes the velocity, the tilt cylinder pressure, and the lift cylinder pressure. The actions consist of lift, tilt, and throttle commands which are all discrete. The ranges of lift, tilt, and throttle commands are from 0 to 160, 0 to 230, and 0 to 100, respectively. Besides, as the pile’s shape and loaded material vary randomly, the change of the pile is considered as a stochastic process, which also satisfies the Markov property. Therefore, the problem of automatic bucket-filling for wheel loaders is considered as a finite Markov decision process (FMDP).

To achieve indirect RL, a prediction model needs to be constructed to predict the wheel loader state at the next moment according to the current state and action during the scooping phase. In this paper, changes in the wheel loader state are regarded as a series of discrete dynamic stochastic events and described with a Markov chain. The transition probability can be expressed as:

where

is the number of times the wheel loader state transits from

to

, and

is the total number of times the wheel loader state transits from

to all possible states.

The prediction model of the wheel loader state can be expressed as:

where

denotes the probability of state transits from

to

and to get a reward r when action

a is taken in state

,

is the total number of times the wheel loader state transits from

to all possible states when action

a is taken, and

is the total number of times the wheel loader state transits from

to

when action

a is taken and gets the reward

r.

Python is used to construct the prediction model. We read the experimental data in sequence. The current state and action a are stored as a key of the Python dictionary, and the value corresponding to the key is another dictionary whose keys are the next state and reward r, and values are . According to the current state and action a, the next state and reward r are selected randomly with probability.

The prediction model can approximate the real working environment, as it is built using the real data obtained from tests. Besides, the prediction model not only covers the working information of wheel loaders, but also reflects the environmental effect. The sampling frequency is important because the complexity of the model can be controlled by adjusting the sampling frequency. The high sampling frequency will increase the complexity of the model and the computation load, while the low sampling frequency might cause model distortion.

6. Results and Discussions

In this section, the proposed automatic bucket-filling algorithm is utilized to learn the policy on prediction models and present the results. We choose 0.15 as the learning rate of Q-learning, in the greedy policy is 0.1, and the discount factor = 0.15.

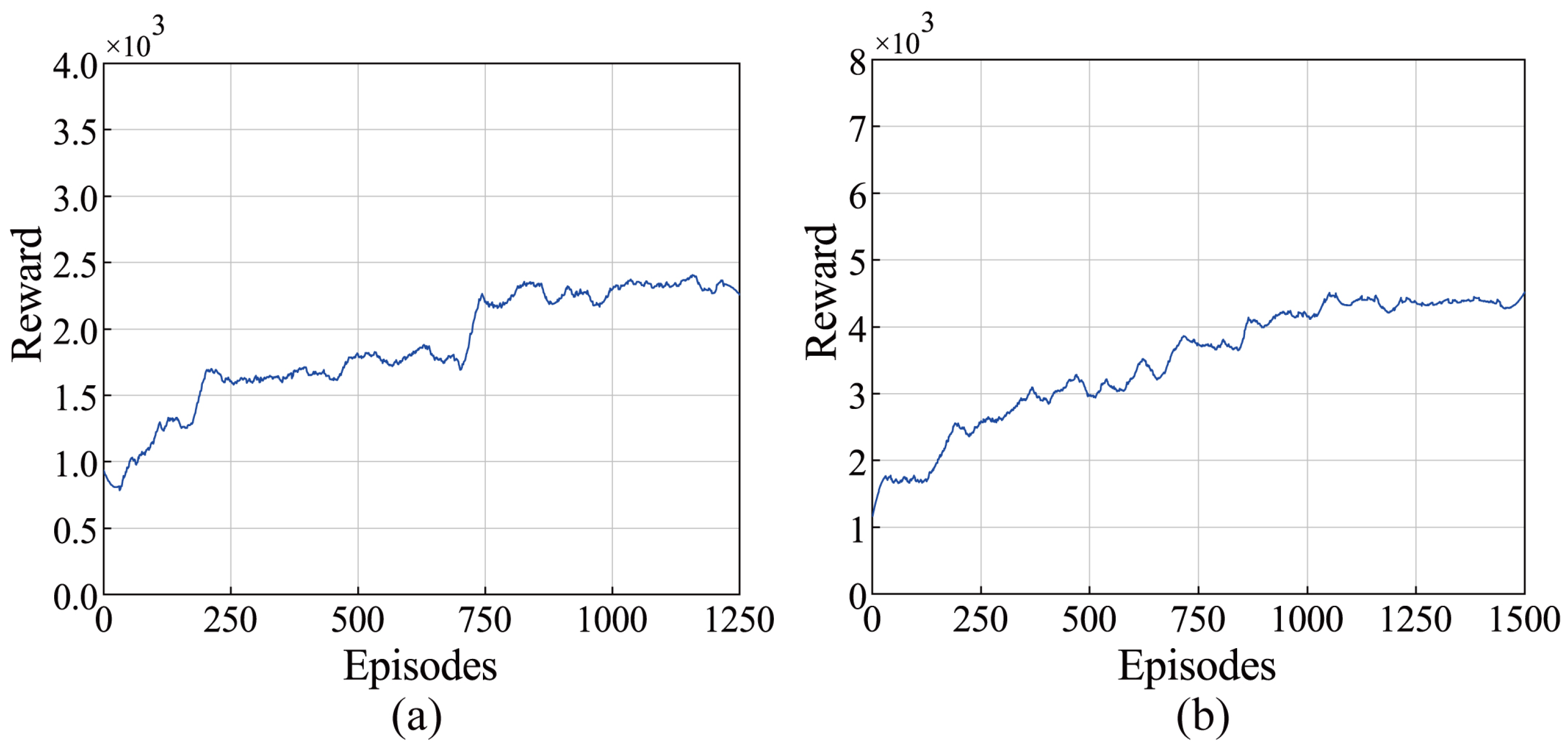

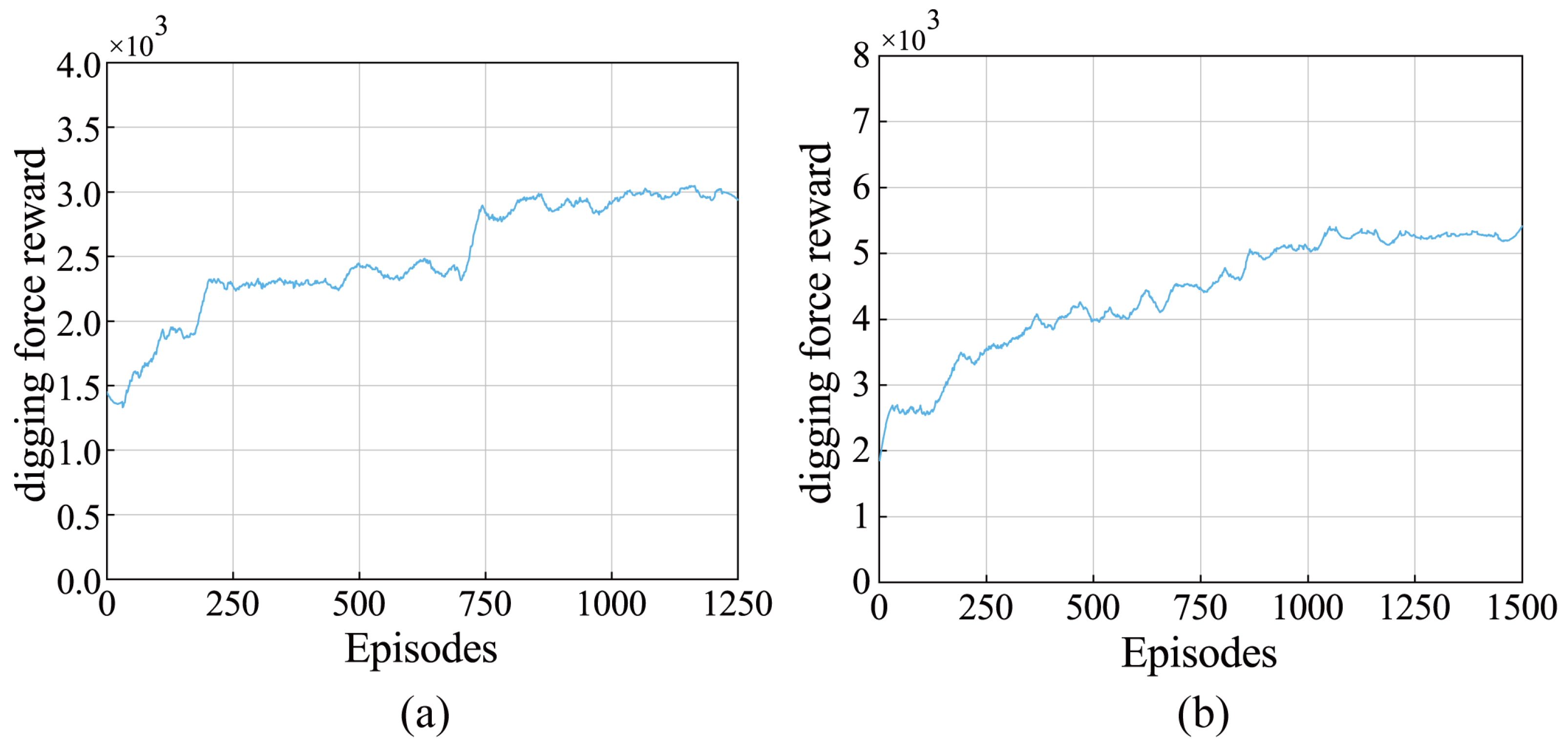

Wheel loaders have a complicated working environment and are used to transport different materials. In order to verify the convergence of the algorithm on the diverse environment, the reward curves based on different prediction models are depicted in

Figure 12. It can be observed that the proposed automatic bucket-filling algorithm can converge to the optimal policy that maximizes reward, indicating that the agent was learning the policy correctly under different prediction models. This shows that the proposed algorithm can be adapted to different bucket-pile models, thus dealing with the complex and changing working environment of wheel loaders in the absence of a complex dynamic model.

The digging force reward per episode is obtained by accumulating the lift cylinder pressure of each step and is used to approximate the change of digging force. As can be seen from

Figure 13, compared with the algorithm interacting with the small coarse gravel model, the algorithm interacting with the medium coarse gravel model can converge to a smaller value of digging force reward. A larger digging force usually leads to higher fuel consumption. Thus, loading small coarse gravel has higher fuel consumption compared to medium coarse gravel on this data-based prediction model, as shown in

Figure 14. This finding suggests that the prediction model can truly reflect the interaction between the bucket and the material to a certain extent.

The results of fuel consumption of the agent in different models are shown in

Figure 14. The data used to build the model come from the real environment. The wheel loader operated by a human operator is the same as the wheel loader used to obtain the data. In addition, the working environment of the wheel loader is also the same. Therefore, the agent we trained has the same operating object and operating environment as the human operator. A comparison with humans is used as a generally accepted method of machine learning algorithm testing [

11,

13]. Physical-model-based methods require a physical model. However, the diversity between the physical model and the wheel loader used to obtain the data is great. In addition, the environment constructed for the physical model is also very different from the environment constructed in the article. Therefore, physical-model-based methods and the method proposed in this article have different operating objects and environments. In addition, deep learning-based methods mainly predict actions based on previous actions and states. As deep learning-based methods mainly solve the prediction problem, root mean square error (RMSE) is used as the evaluation indicator, which is different from our paper. Therefore, the fuel consumption measured by the human operator is used to compare with the fuel consumption of the agent.

Table 2 shows the average fuel consumption of loading different piles and the variance of fuel consumption in the recorded bucket-filling phase. In

Figure 14b, there is a relatively stable convergence, while in

Figure 14a, the curve fluctuates violently. A possible explanation for this is that the prediction model built by data with higher variance is more complex and variable. Therefore, the agent will encounter more situations in each episode, resulting in the oscillation of the convergence curve. In addition to this, the convergence values of fuel consumption of agents on medium coarse gravel model and small coarse gravel model are around 33.3 mL and 45.6 mL, respectively, and improve by 8.0% and 10.6% compared to the average fuel consumption measured by real operators because Q-learning can learn the optimal action in different states.

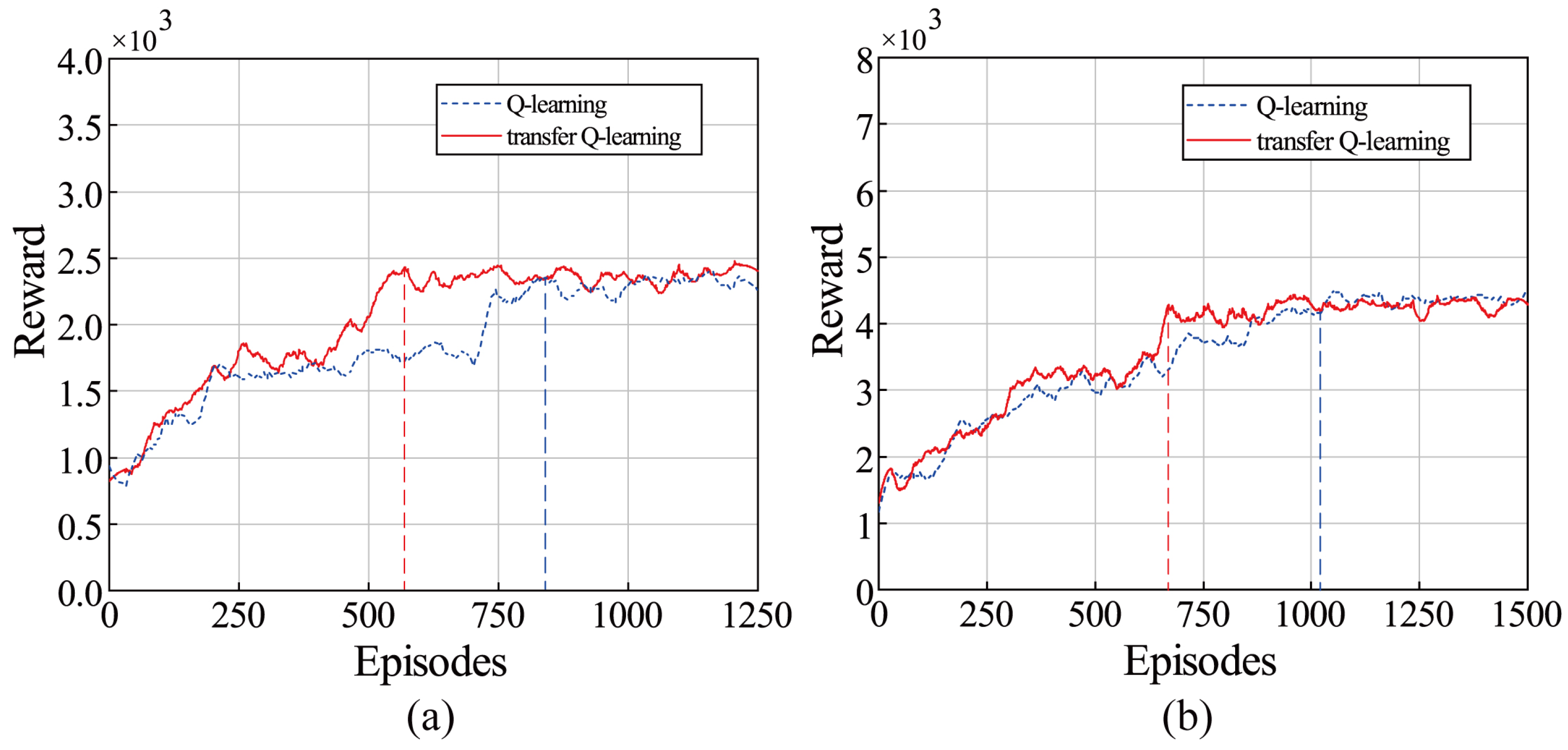

The transfer learning ability can help the algorithm to improve the learning performance on new bucket-filling tasks, thereby saving training costs. In this paper, transfer Q-learning refers to the Q-learning that has been trained in other tasks and learned relevant knowledge.

Figure 15 shows the convergence curve of rewards for Q-learning and transfer Q-learning in the different bucket-pile interaction models. In

Figure 15a, Q-learning is only trained on the MCG-pile model, and transfer Q-learning is first trained on the SCG-pile model and then trained on the MCG-pile model. In

Figure 15b, Q-learning is only trained on the SCG-pile model, and transfer Q-learning is first trained on the MCG-pile model and then trained on the SCG-pile model. The convergence rate (learning rate efficient) of Q-learning and transfer Q-learning in two bucket-pile interaction models are compared, as presented in

Table 3. Using Q-learning as the benchmark, the convergence speed of transfer Q-learning in the medium coarse gravel and small coarse gravel model is improved by 30.3% and 34.1%, respectively. This means that the proposed algorithm has a good transfer learning capability. This improvement can be ascribed to the fact that Q-learning stores the learned knowledge in the Q-function and the transfer Q-learning transfers the Q-function learned from the source task to the Q-function of the target task. Therefore, the agent no longer needs to learn the basic action characteristics in the bucket-filling phase.

When the two piles have similar characteristics, such as in category and shape, transfer Q-learning might have better performance in the new bucket-filling task due to the similarity of the optimal Q-function in two tasks [

24]. Finally, the amount of data used to build the interaction model also has an impact on the performance of transfer Q-learning on the prediction model. The more data there is, the more states and actions the developed prediction model contains. Therefore, different prediction models have more identical states and actions, and the Q-function of the target task can learn more knowledge from the Q-function of the source task. However, the transfer learning method potentially does not work or even harm the new tasks [

25] when the piles or environment are greatly different.