A Method for the Design of Concrete with Combined Steel and Basalt Fiber

Abstract

:1. Introduction

2. Research Aims, Scope and Novelty

3. Experimental Program

3.1. Concrete Composition and Mix Preparation Technology

3.2. Tested Specimens, Equipment and Procedure

3.3. Experiments Planning Using Regression Modeling

4. Experimental Results

4.1. Influence of Steel and Basalt Fiber Contents on Concrete Strength

4.2. Influence of Steel and Polypropylene Fiber Contents on Concrete Strength

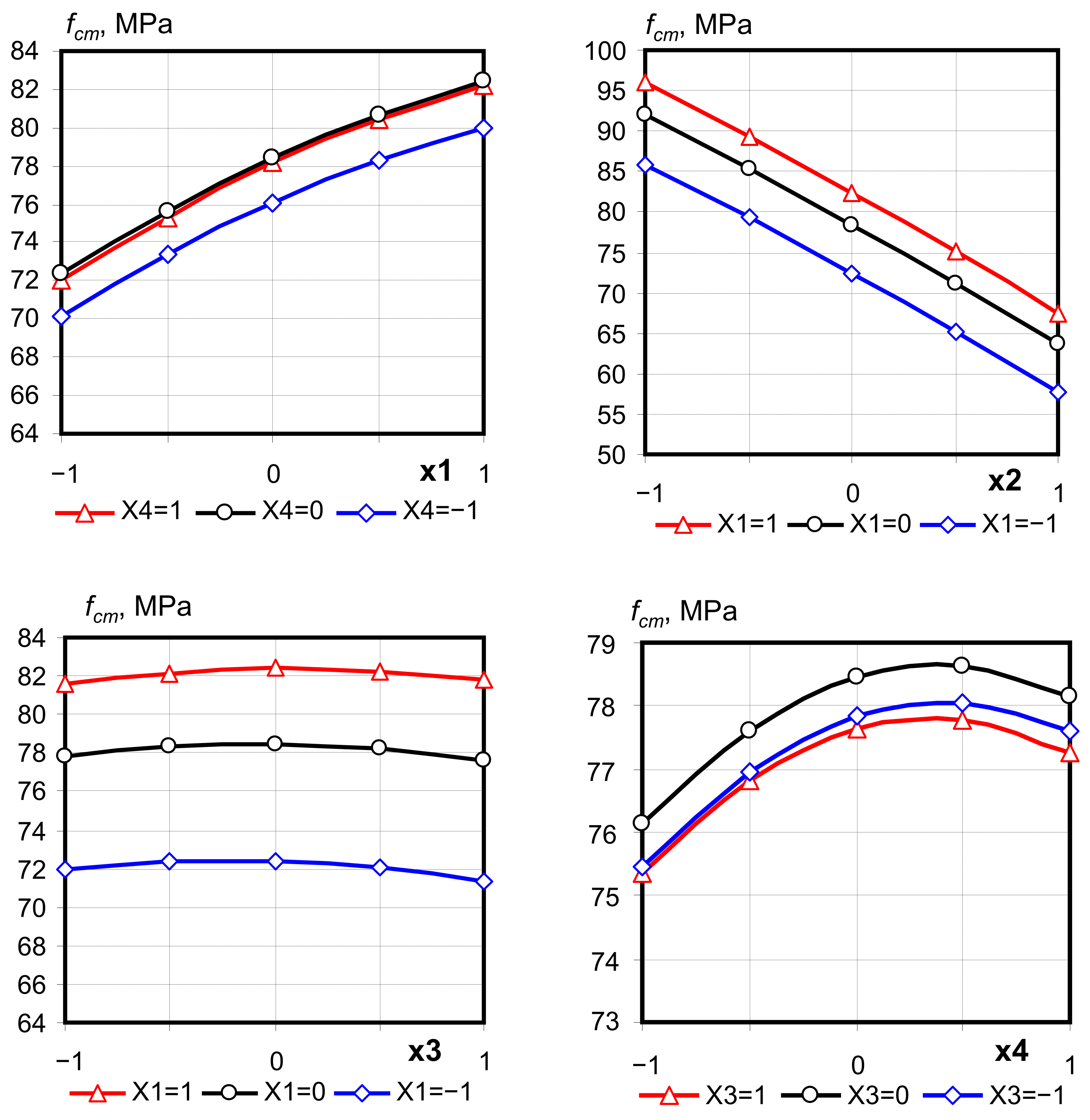

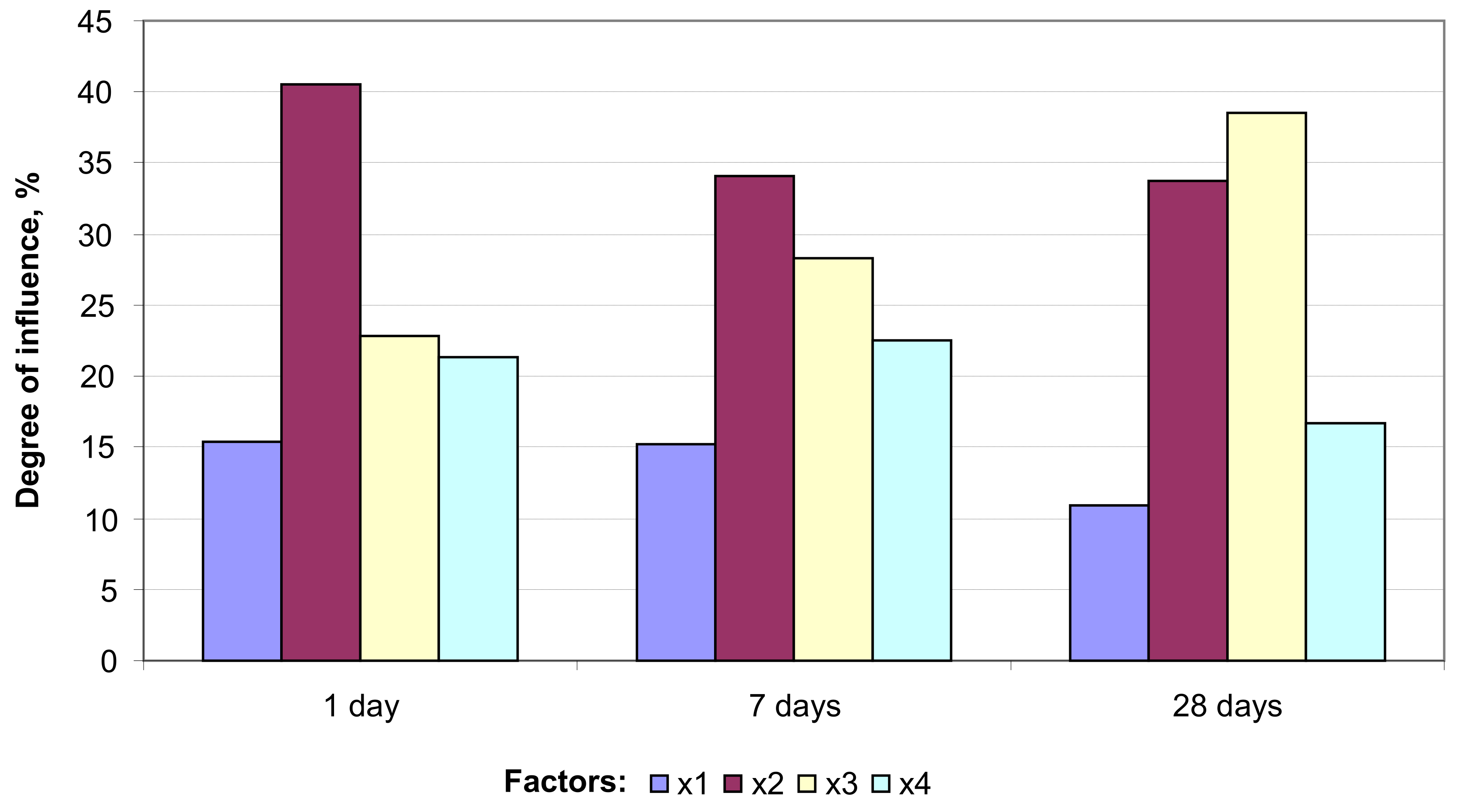

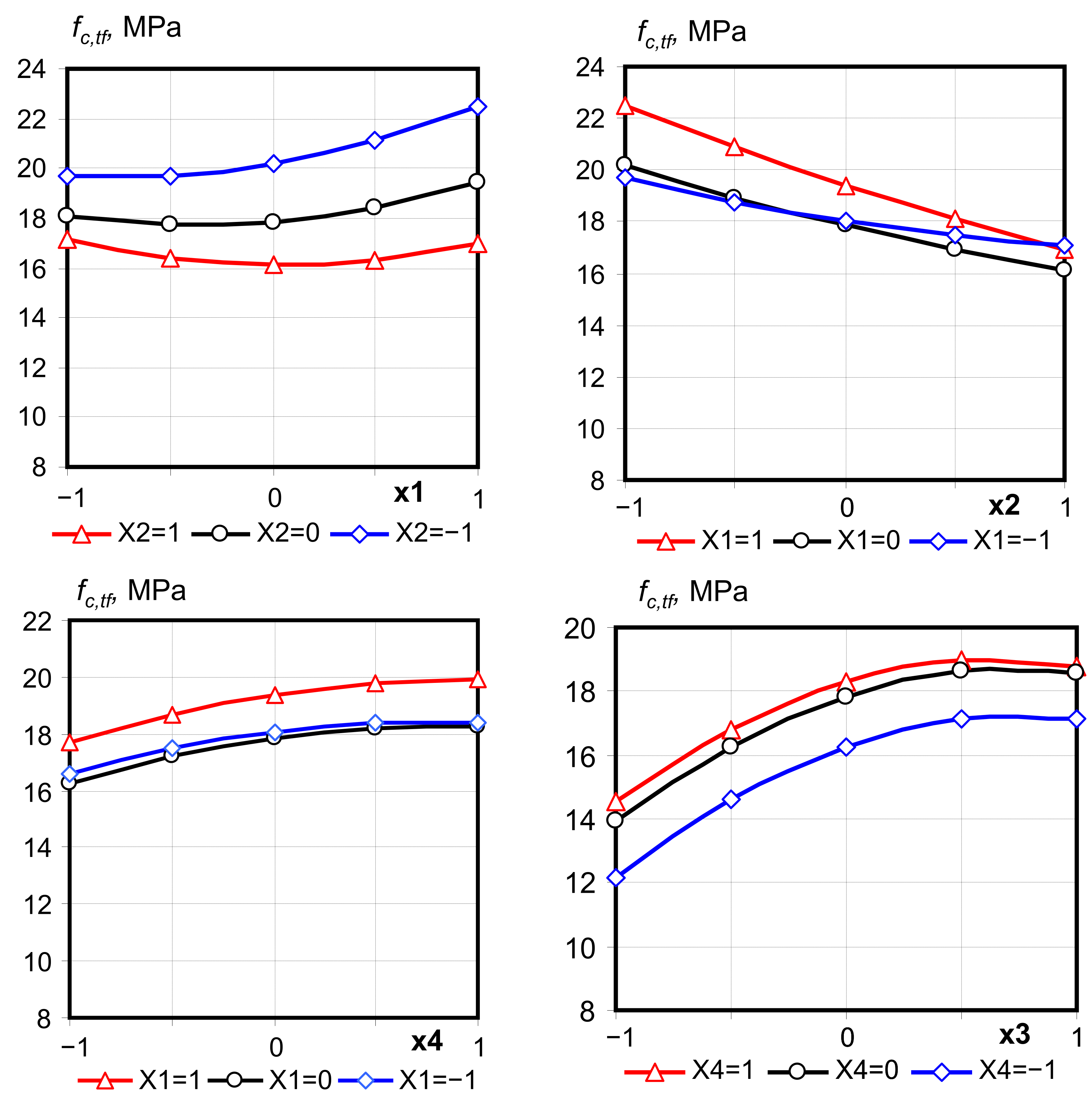

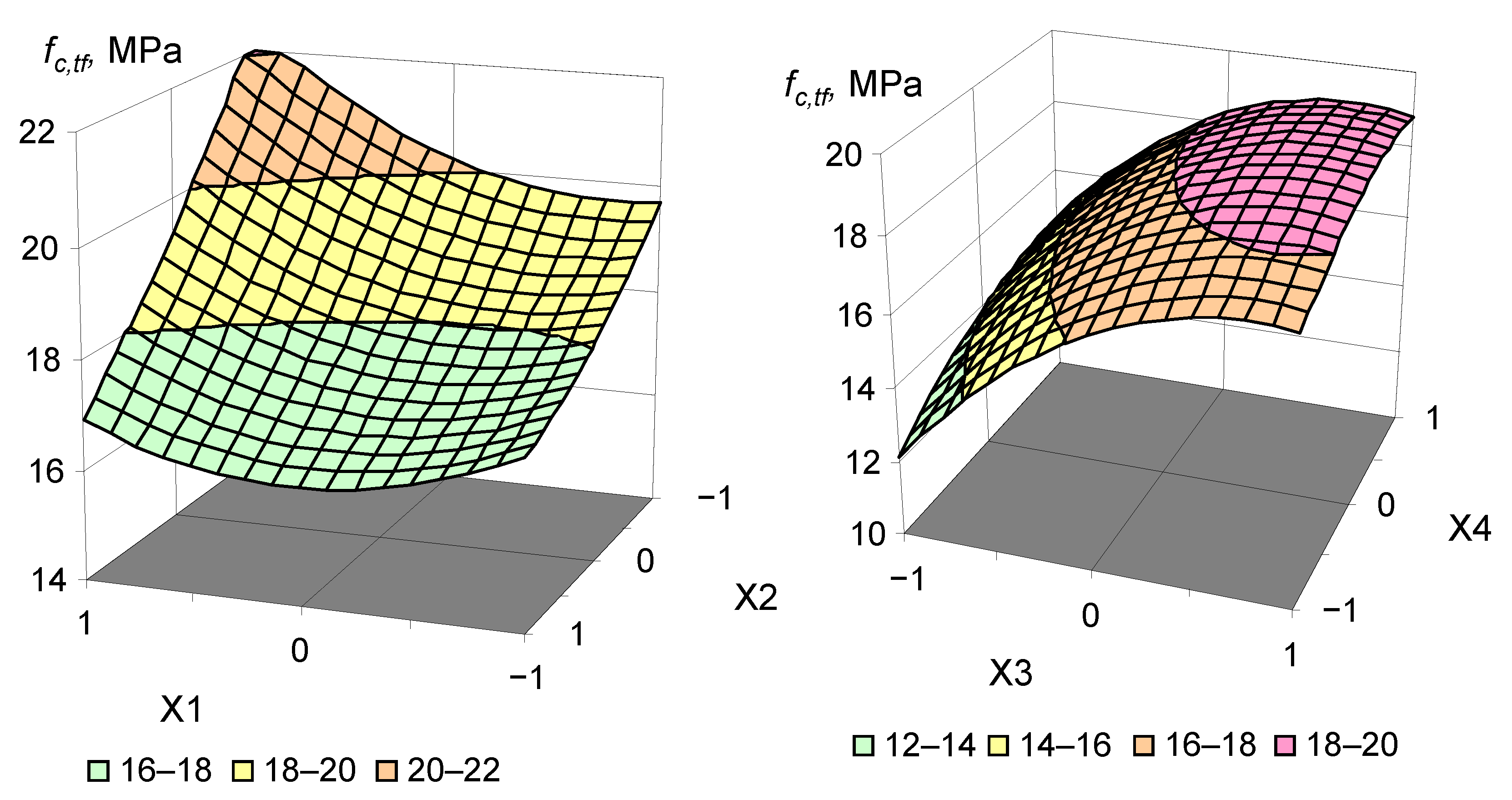

4.3. Influence of Composition Factors on HFRC Strength

5. Design of HFRC Composition

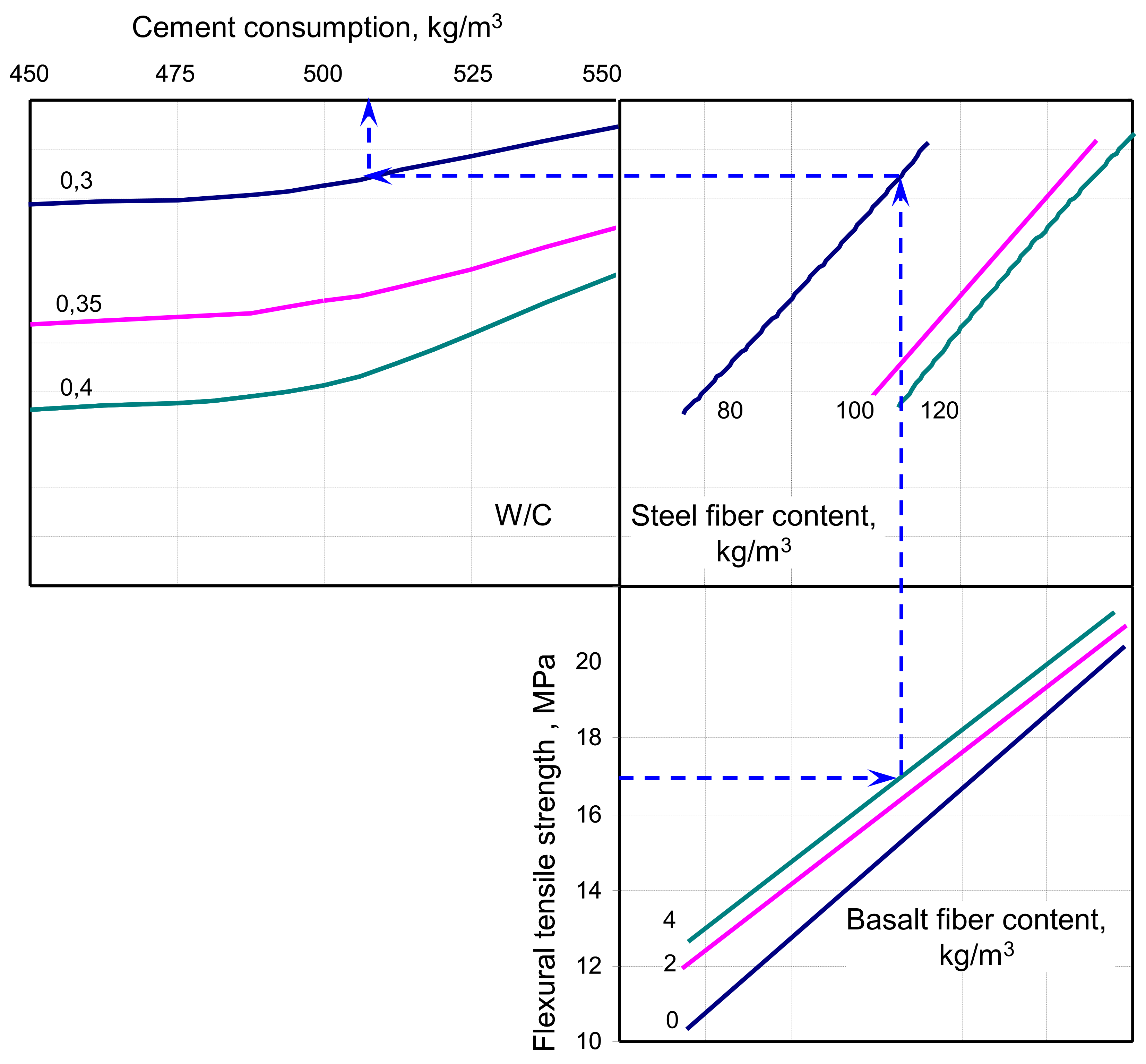

6. Numerical Example

- Selecting the fiber content and W/C for concrete with given strength values (Table 6). In our case SF = 80 to 120 kg/m3, BF = 0 to 4 kg/m3, W/C = 0.3 to 0.4;

- Assuming minimal SF content (80 kg/m3), the required water-cement ratio and cement content, yielding the desired concrete strengths, are found using the nomogram (blue line in Figure 9);

- Translating the obtained values (W/C = 0.3, C = 507 kg/m3, SF = 80 kg/m3, BF = 4 kg/m3) in coded form:

- Substituting of the coded values in the regression equation (Table 6), calculating the concrete compressive strength

- Calculating the water demand, corresponding to W/C and cement content using Equation (3):

- Calculating the superplasticizer content for known composition parameters:

- Calculating the aggregates content using Equations (4)–(7):

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shah, A.A.; Ribakov, Y. Recent trends in steel fibered high-strength concrete. Mater. Des. 2011, 32, 4122–4151. [Google Scholar] [CrossRef]

- Thomas, J.; Ramaswamy, A. Mechanical Properties of Steel Fiber-Reinforced Concrete. J. Mater. Civ. Eng. 2007, 19, 385–392. [Google Scholar] [CrossRef]

- Holschemacher, K.; Mueller, T.; Ribakov, Y. Effect of steel fibres on mechanical properties of high-strength concrete. Mater. Des. 2010, 31, 2604–2615. [Google Scholar] [CrossRef]

- Dong, S.; Han, B.; Yu, X.; Ou, J. Dynamic impact behaviors and constitutive model of super-fine stainless wire reinforced reactive powder concrete. Constr. Build. Mater. 2018, 184, 602–616. [Google Scholar] [CrossRef]

- Şahin, Y.; Köksal, F. The influences of matrix and steel fibre tensile strengths on the fracture energy of high-strength concrete. Constr. Build. Mater. 2011, 25, 1801–1806. [Google Scholar] [CrossRef]

- Suksawang, N.; Wtaife, S.; Alsabbagh, A. Evaluation of Elastic Modulus of Fiber-Reinforced Concrete. ACI Mater. J. 2018, 115. [Google Scholar] [CrossRef] [Green Version]

- Iskhakov, I.; Ribakov, Y. Two-layer concrete bridge beams as composite elements. Struct. Concr. 2013, 14, 271–277. [Google Scholar] [CrossRef]

- Iskhakov, I.; Ribakov, Y.; Holschemacher, K. Experimental investigation of continuous two-layer reinforced concrete beams. Struct. Concr. 2017, 18, 205–215. [Google Scholar] [CrossRef] [Green Version]

- Zorla, E.; Ipbuker, C.; Gulik, V.; Kovaljov, S.; Kiisa, M.; Biland, A.; Tkaczyk, A.H. Optimization of Basalt Fiber in Concrete Composite for Industrial Application in Estonia. Fresenius Environ. Bull. 2016, 25, 355–364. [Google Scholar]

- Ayub, T.; Shafiq, N.; Nuruddin, M.F. Mechanical Properties of High-performance Concrete Reinforced with Basalt Fibers. Procedia Eng. 2014, 77, 131–139. [Google Scholar] [CrossRef] [Green Version]

- Ayub, T.; Shafiq, N.; Khan, S.U. Compressive Stress-Strain Behavior of HSFRC Reinforced with Basalt Fibers. J. Mater. Civ. Eng. 2016, 28, 6015014. [Google Scholar] [CrossRef]

- Nihal, P.P.; Shinu, S. Experimental Studies on Steel and Basalt Fiber Reinforced Concrete. Int. J. Innov. Res. Sci. Eng. Technol. 2017, 6, 6753–6761. [Google Scholar]

- Kumar, M.V.; Niveditha, K.; Anusha, B.; Sudhakar, B. Comparison Study of Basalt Fiber and Steel Fiber as Additives to Concrete. IJRASET 2017, 5, 6–14. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Taweel, M. Compressive strength and failure behaviour of fibre reinforced concrete at elevated temperatures. Adv. Concr. Constr. 2015, 3, 283–293. [Google Scholar] [CrossRef]

- Manu, P.P.; Eldhose, C. Flexural Behavior of Hybrid Steel Basalt Fibre Reinforced Concrete. Int. Res. J. Eng. Technol. 2019, 6, 760–764. [Google Scholar]

- Li, Z.-X.; Li, C.-H.; Shi, Y.-D.; Zhou, X.-J. Experimental investigation on mechanical properties of Hybrid Fibre Reinforced Concrete. Constr. Build. Mater. 2017, 157, 930–942. [Google Scholar] [CrossRef]

- Chakravarthy, R.; Venkatesan, S.; Patnaikuni, I. Review on Hybrid Fiber Reinforced High Performance High Volume Flyash Concrete. IJSCER 2016, 5, 39–43. [Google Scholar] [CrossRef]

- EN 14889-1:2006. Fibres for Concrete—Part 1: Steel Fibres-Definitions, Specifications and Conformity; British Standards Institution: London, UK, 2006. [Google Scholar]

- ASTM C78/C78M-18. Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Dvorkin, L.I.; Dvorkin, O.; Ribakov, Y. Mathematical Experiments Planning in Concrete Technology; Nova Science Publishers: New York, NY, USA, 2012; ISBN 9781621002833. [Google Scholar]

- Box, G.E.P.; Hunter, J.S.; Hunter, W.G. Statistics for Experimenters: Design, Innovation, and Discovery, 2nd ed.; Wiley: Hoboken, NJ, USA, 2005; ISBN 9780471718130. [Google Scholar]

- Han, J.; Zhao, M.; Chen, J.; Lan, X. Effects of steel fiber length and coarse aggregate maximum size on mechanical properties of steel fiber reinforced concrete. Constr. Build. Mater. 2019, 209, 577–591. [Google Scholar] [CrossRef]

- Dvorkin, L.; Bordiuzhenko, O.; Zhitkovsky, V.; Marchuk, V. Mathematical modeling of steel fiber reinforced concrete properties and selecting its effective composition. IOP Conf. Ser. Mater. Sci. Eng. 2019, 708, 12085. [Google Scholar] [CrossRef]

| Ingredients | Amount (kg/m3) |

|---|---|

| Portland cement CEM 42.5 | 500 |

| Water | 175 |

| Sand (2–5 mm) | 990 |

| Fine sand (fineness modulus of 2.1) | 810 |

| SF | 80 and 120 |

| BF | 0 to 6 |

| PF | 0 to 2 |

| Melflux 2651F superplasticizer | Varied to achieve 13–15 cm slump |

| SF, kg/m3 | BF, kg/m3 | Total Fibers Content by Volume, μ, % | BF Part in the Fiber Volume, n | Compressive Strength at 7 Days fcm7, MPa | Flexural Tensile Strength at 7 Days fc,tf 7, MPa |

|---|---|---|---|---|---|

| BF (l = 12 mm) | |||||

| 80 | 0 | 1.03 | 0.00 | 64.5 | 10.3 |

| 2 | 1.10 | 0.07 | 65.2 | 12.1 | |

| 4 | 1.18 | 0.13 | 67.1 | 12.4 | |

| 6 | 1.25 | 0.18 | 66.2 | 10.2 | |

| 120 | 0 | 1.54 | 0.00 | 66.8 | 13.3 |

| 2 | 1.61 | 0.05 | 66.5 | 14.8 | |

| 4 | 1.69 | 0.09 | 69.2 | 14.9 | |

| 6 | 1.76 | 0.13 | 65.4 | 11.5 | |

| BF (l = 24 mm) | |||||

| 80 | 0 | 1.03 | 0.00 | 64.5 | 10.3 |

| 2 | 1.10 | 0.07 | 67.2 | 11.0 | |

| 4 | 1.18 | 0.13 | 63.1 | 9.6 | |

| 6 | 1.25 | 0.18 | 62.8 | 6.5 | |

| 120 | 0 | 1.54 | 0.00 | 66.8 | 13.3 |

| 2 | 1.61 | 0.05 | 68.6 | 13.5 | |

| 4 | 1.69 | 0.09 | 63.1 | 11.9 | |

| 6 | 1.76 | 0.13 | 61.7 | 7.9 | |

| SF, kg/m3 | PF, kg/m3 | Total Fibers Content by Volume, μ, % | PF Part in the Fiber Volume, n | Compressive Strength at 7 Days fcm7, MPa | Flexural Tensile Strength at 7 Days fc,tf 7, MPa |

|---|---|---|---|---|---|

| PF (l = 12 mm) | |||||

| 80 | 0 | 1.03 | 0.00 | 64.5 | 10.3 |

| 1 | 1.14 | 0.10 | 64.2 | 10.1 | |

| 2 | 1.25 | 0.18 | 64.6 | 9.4 | |

| 120 | 0 | 1.54 | 0.00 | 66.8 | 13.3 |

| 1 | 1.65 | 0.07 | 67.2 | 12.7 | |

| 2 | 1.76 | 0.13 | 67.3 | 12.1 | |

| PF (l = 18 mm) | |||||

| 80 | 0 | 1.03 | 0.00 | 64.5 | 10.3 |

| 1 | 1.14 | 0.03 | 63.2 | 9.8 | |

| 2 | 1.25 | 0.06 | 62.9 | 8.6 | |

| 120 | 0 | 1.54 | 0.00 | 66.8 | 13.3 |

| 1 | 1.65 | 0.07 | 65.3 | 10.6 | |

| 2 | 1.76 | 0.13 | 65.9 | 7.8 | |

| No. | Factors | Variation Levels | Variation Interval | |||

|---|---|---|---|---|---|---|

| Code | Natural Value | −1 | 0 | +1 | ||

| 1 | X1 | Cement content, kg/m3 (C) | 450 | 500 | 550 | 50 |

| 2 | X2 | W/C | 0.3 | 0.35 | 0.4 | 0.05 |

| 3 | X3 | SF, kg/m3 | 80 | 100 | 120 | 20 |

| 4 | X4 | BF, kg/m3 | 0 | 2 | 4 | 2 |

| No | Coded Factors Values | Components Content, kg/m3 | W/C | SP, % | fcm1, MPa | fc,tf1, MPa | fcm7, MPa | fc,tf7, MPa | fcm28, MPa | fc,tf28, MPa | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X1 | X2 | X3 | X4 | C | S | CS | W | SF | BF | |||||||||

| 1 | + | + | + | + | 550 | 732 | 895 | 220 | 120 | 4 | 0.4 | 0.25 | 27.4 | 7.1 | 55.2 | 14.2 | 64.9 | 16.7 |

| 2 | + | + | + | - | 550 | 732 | 895 | 220 | 120 | 0 | 0.4 | 0.20 | 28.6 | 6.2 | 54.7 | 11.1 | 67.2 | 13.8 |

| 3 | + | + | - | + | 550 | 732 | 895 | 220 | 80 | 4 | 0.4 | 0.13 | 30.2 | 6.3 | 57.1 | 12.4 | 67.3 | 12.1 |

| 4 | + | + | - | - | 550 | 732 | 895 | 220 | 80 | 0 | 0.4 | 0.05 | 28.2 | 5.0 | 55.8 | 10.0 | 66.6 | 9.0 |

| 5 | + | - | + | + | 550 | 799 | 977 | 165 | 120 | 4 | 0.3 | 1.18 | 40.5 | 9.4 | 76.9 | 17.9 | 95.9 | 20.9 |

| 6 | + | - | + | - | 550 | 799 | 977 | 165 | 120 | 0 | 0.3 | 1.10 | 40.9 | 8.8 | 78.1 | 15.9 | 96.0 | 19.9 |

| 7 | + | - | - | + | 550 | 799 | 977 | 165 | 80 | 4 | 0.3 | 0.87 | 41.6 | 8.9 | 80.3 | 18.3 | 96.4 | 17.8 |

| 8 | + | - | - | - | 550 | 799 | 977 | 165 | 80 | 0 | 0.3 | 0.80 | 40.3 | 7.7 | 79.7 | 15.5 | 95.2 | 15.2 |

| 9 | - | + | + | + | 450 | 820 | 1002 | 180 | 120 | 4 | 0.4 | 0.44 | 24.1 | 7.2 | 49.2 | 15.2 | 55.9 | 16.2 |

| 10 | - | + | + | - | 450 | 820 | 1002 | 180 | 120 | 0 | 0.4 | 0.40 | 23.8 | 6.6 | 49.1 | 13.9 | 57.3 | 14.9 |

| 11 | - | + | - | + | 450 | 820 | 1002 | 180 | 80 | 4 | 0.4 | 0.26 | 24.5 | 6.1 | 49.6 | 10.8 | 57.1 | 11.4 |

| 12 | - | + | - | - | 450 | 820 | 1002 | 180 | 80 | 0 | 0.4 | 0.20 | 23.0 | 5.2 | 48.0 | 8.2 | 56.9 | 9.5 |

| 13 | - | - | + | + | 450 | 875 | 1069 | 135 | 120 | 4 | 0.3 | 1.14 | 33.9 | 8.3 | 69.9 | 16.9 | 83.8 | 19.8 |

| 14 | - | - | + | - | 450 | 875 | 1069 | 135 | 120 | 0 | 0.3 | 1.05 | 34.1 | 7.5 | 71.0 | 15.2 | 83.9 | 17.0 |

| 15 | - | - | - | + | 450 | 875 | 1069 | 135 | 80 | 4 | 0.3 | 0.34 | 34.3 | 7.2 | 72.2 | 12.8 | 84.8 | 13.7 |

| 16 | - | - | - | - | 450 | 875 | 1069 | 135 | 80 | 0 | 0.3 | 1.00 | 33.8 | 6.3 | 70.4 | 10.3 | 83.3 | 11.8 |

| 17 | + | 0 | 0 | 0 | 550 | 766 | 936 | 193 | 100 | 2 | 0.35 | 0.48 | 32.3 | 8.3 | 67.1 | 16.9 | 79.9 | 19.2 |

| 18 | - | 0 | 0 | 0 | 450 | 847 | 1036 | 158 | 100 | 2 | 0.35 | 0.32 | 29.9 | 7.6 | 64.2 | 15.6 | 75.1 | 18.3 |

| 19 | 0 | + | 0 | 0 | 500 | 776 | 948 | 200 | 100 | 2 | 0.4 | 0.33 | 24.2 | 7.7 | 53.0 | 14.7 | 65.0 | 16.3 |

| 20 | 0 | - | 0 | 0 | 500 | 837 | 1023 | 150 | 100 | 2 | 0.3 | 0.56 | 39.5 | 8.8 | 77.9 | 17.4 | 92.9 | 20.1 |

| 21 | 0 | 0 | + | 0 | 500 | 806 | 986 | 175 | 120 | 2 | 0.35 | 0.34 | 31.7 | 7.5 | 68.1 | 14.2 | 77.2 | 16.4 |

| 22 | 0 | 0 | - | 0 | 500 | 806 | 986 | 175 | 80 | 2 | 0.35 | 0.13 | 32.3 | 6.8 | 62.3 | 11.5 | 78.5 | 12.1 |

| 23 | 0 | 0 | 0 | + | 500 | 806 | 986 | 175 | 100 | 4 | 0.35 | 0.27 | 32.0 | 8.7 | 65.2 | 15.7 | 76.4 | 18.9 |

| 24 | 0 | 0 | 0 | - | 500 | 806 | 986 | 175 | 100 | 0 | 0.35 | 0.20 | 31.6 | 7.5 | 66.0 | 14.6 | 78.1 | 17.1 |

| Output Parameter | Mathematical Models | |

|---|---|---|

| Compressive strength at | 1 day | fcm1 = 31.7 + 2.7X1 − 5.8X2 − 0.2X3 + 0.2X4 − 0.6X12 + 0.1X22 + 0.3X32 − 0.5X1X2 − 0.3X1X3 − 0.4 X3X4 |

| 7 days | fcm7= 66.1 + 3.6X1 − 11.3X2 − 0.2X3 + 0.2X4 −0.7X22− 2.4X42 − 0.4X1X2 − 0.5X1X3 + 0.2X2X3 + 0.3X2X4 − 0.4X3X4 | |

| 28 days | fcm28 = 78.4 + 5X1 − 14.2X2 − 0.1X3 + X4 − 1.1X12 − 0.6X22 − 0.7X32− 1.3X42 − 0.1X1X2 + 0.2X1X3 − 0.35X2X3 | |

| Flexural tensile strength at | 1 day | fc,tf 1 = 7.47 + 0.31X1 − 0.82X2 + 0.46X3 + 0.43X4 − 0.18X12 − 0.33X32 + 0.12X42 − 0.36X1X2 − 0.1X1X4 −0.1X3X4 |

| 7 days | fc,tf 7 = 15.56 + 0.74X1 − 1.66X2 + 1.38X3 + 1.1X4 + 0.67X12 + 0.47X22 − 1.43X32 − 0.43X42 − 0.8X1X2 − X1X3 + 0.14X1X4 + 0.25X2X3 − 0.14X3X4 | |

| 28 days | fc,tf 28 = 17.85 + 0.66X1 − 2.03X2 + 2.32X3 + X4 + 0.88X12 + 0.33X22 − 1.62X32 − 0.57X42 − 0.75X1X2 − 0.18X1X3 − 0.1X1X4 − 0.19X3X4 | |

| Melflux 2651Fcontent | SP = 0.41 + 0.095X1 − 0.33X2 + 0.12X3 + 0.11X4 − 0.06X12 + 0.2X22 − 0.03X32 − 0.02X42 − 0.07X1X2 −0.02X1X3 + 0.04X1X4 − 0.05X2X3 + 0.04X2X4 + 0.04X3X4 | |

| BF, kg/m3 | SF, kg/m3 | W/C | fc,tf28, MPa | fcm28, MPa |

|---|---|---|---|---|

| 0–2 | 80–100 | 0.3–0.35 | 14.2–17.8 | 70.3–95.3 |

| 0.35–0.4 | 10.5–17.8 | 55.8–81.2 | ||

| 100–120 | 0.3–0.35 | 16.7–20.9 | 68.9–94.4 | |

| 0.35–0.4 | 16.7–18.5 | 54.2–79.1 | ||

| 2–4 | 80–100 | 0.3–0.35 | 16.2–20.5 | 71.1–94.8 |

| 0.35–0.4 | 12.1–17.2 | 55.9–82.0 | ||

| 100–120 | 0.3–0.35 | 18.2–23.5 | 69.3–96.3 | |

| 0.35–0.4 | 17.8–18.8 | 55.8–79.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dvorkin, L.; Bordiuzhenko, O.; Tekle, B.H.; Ribakov, Y. A Method for the Design of Concrete with Combined Steel and Basalt Fiber. Appl. Sci. 2021, 11, 8850. https://doi.org/10.3390/app11198850

Dvorkin L, Bordiuzhenko O, Tekle BH, Ribakov Y. A Method for the Design of Concrete with Combined Steel and Basalt Fiber. Applied Sciences. 2021; 11(19):8850. https://doi.org/10.3390/app11198850

Chicago/Turabian StyleDvorkin, Leonid, Oleh Bordiuzhenko, Biruk Hailu Tekle, and Yuri Ribakov. 2021. "A Method for the Design of Concrete with Combined Steel and Basalt Fiber" Applied Sciences 11, no. 19: 8850. https://doi.org/10.3390/app11198850

APA StyleDvorkin, L., Bordiuzhenko, O., Tekle, B. H., & Ribakov, Y. (2021). A Method for the Design of Concrete with Combined Steel and Basalt Fiber. Applied Sciences, 11(19), 8850. https://doi.org/10.3390/app11198850