1. Introduction

It is well-known that rotary dryers are the main dehydration equipment used for many different types of processing such as food industry [

1], agriculture [

2], and tobacco production [

3]. The rotary dryers can remove water from the material through heat exchange, the greatest advantage of rotary dryers is that they can process more material in a more efficient way than other kinds of dryers [

4]. Usually, the wet material is dried by hot air pumped into the rotating drum of the dryer [

5]. At the same time, the drum needs to keep rotating all the time to increase the contact area between the wet material and the hot air.

However, traditional dryers usually operate at low thermal efficiency, because of the inconsistent control of temperature originating from the human factor or overheating [

6]. For example, during regular operation, incorrect or delayed correction of temperature in process points can lead to significant variations of the outlet moisture content, resulting in a decline of the product quality.

At present, the application of automation control technology to the industrial rotary dryer is a highly effective way to improve operation, safety, and efficiency. The core implementation of automation control technology is the fuzzy control strategy, which has been already used in various industrial applications [

7]. Tsourveloudis and Kiralakis [

8] have designed a system with two controllers, a fuzzy controller (FC) and a neuro-fuzzy controller (NFC), for an industrial rotary dryer applied to olive stones. The FC was based on some operators’ experience and knowledge. The NFC, on the other hand, was constructed by applying the adaptive neuro-fuzzy inference system to the data collected from an empirical model of a rotary dryer. Yliniemi et al. [

9] applied a hybrid fuzzy controller and the proportional-integral (PI) controller for a rotary dryer to a laboratory-scale pilot plant. Modesto et al. [

10] designed a fuzzy multivariable controller for an industrial rotary dryer applied to fertilizers. In their study, they described in detail the process of constructing a fuzzy controller, including variables, membership functions, and rules.

Among the aforementioned studies, a common drawback of the control approaches is how human involvement works. The human factor is not easy to quantify in this case [

11], while the exact amount of moisture content is pivotal in the tobacco drying process and requires very precise control. In such cases, mathematical modeling and experimental validation have played an important role [

12]. At least two reasons for the use of mathematical models should be mentioned: (1) it avoids dependence on human agents, who, in some cases, could be unable to perform their tasks or even be in danger. (2) the models in question can efficiently simulate the drying behavior and provide information for operation optimization, which is the real key to improve the accuracy of the control system.

As a matter of fact, following this understanding, Hosseinabadi et al. [

13] developed a computerized mathematical model of a closed-loop triple-pass concurrent rotary dryer to simulate the drying behavior of poplar wood particles within the dryer drums. Moreover, Xu and Pang [

14] developed a mathematical model to simulate the drying of the woody biomass as chips in a rotary dryer, based on energy and mass balance and transfer, experimental drying kinetics of the wood chips, and using literature correlations for the residence time. Iguaz et al. [

15] developed a dynamic model to simulate the dehydration process of vegetable wastes in a rotary dryer.

Besides, several studies applied mathematical models and simulators to industrial rotary dryers. For example, a Grey-box Neural Model (GNM) in a nonlinear model predictive control scheme (NMPC) of a direct rotary dryer was developed by Francisco et al. [

16]. The latter scholars tested two types of behavior of NMPC control strategies applied on a simulated industrial fishmeal drying process. Paiva et al. [

17] designed a PI controller based on online monitoring to regulate the temperature of the fishmeal at the outlet of the dryer.

Therefore, it is necessary to see more in detail how rotary drying has been successfully applied so far in the tobacco industry due to its high uniform processing quality compared to that of fluidized drying [

18,

19]. In particular, Zhou et al. [

20] obtained a set of optimal setting curves of the input variables based on a multi-sampling-rate RBF-ARX (MSR-RBF-ARX) model which was, once again, tested only by simulation studies. Other researchers, Chen et al. [

21], applied an L1-Norm model predictive controller with a dead zone to cut tobacco dryers. Such controller was used in an L1-Norm moving horizon estimator to provide state and parameter estimation. The same study [

22] proposed a two-layer model predictive control strategy for a non-square system of the nonlinear cut tobacco drying process. But these researches are mainly based on simulations, they do not consider several practical real-situation issues. Zhu et al. [

23] took the practical application of mathematical models one step forward, carrying out their research in a laboratory-scale rotary dryer.

The drawback in the above literature is quite evident because problems that occur on a real plant floor, such as unusual operations of control, are neglected. Only a few studies have discussed and analyzed control applications for rotary dryers in a real industrial environment [

10]. Consequently, there is a lack of specific research dedicated to the implementation of intelligent controllers in a real industrial rotary dryer.

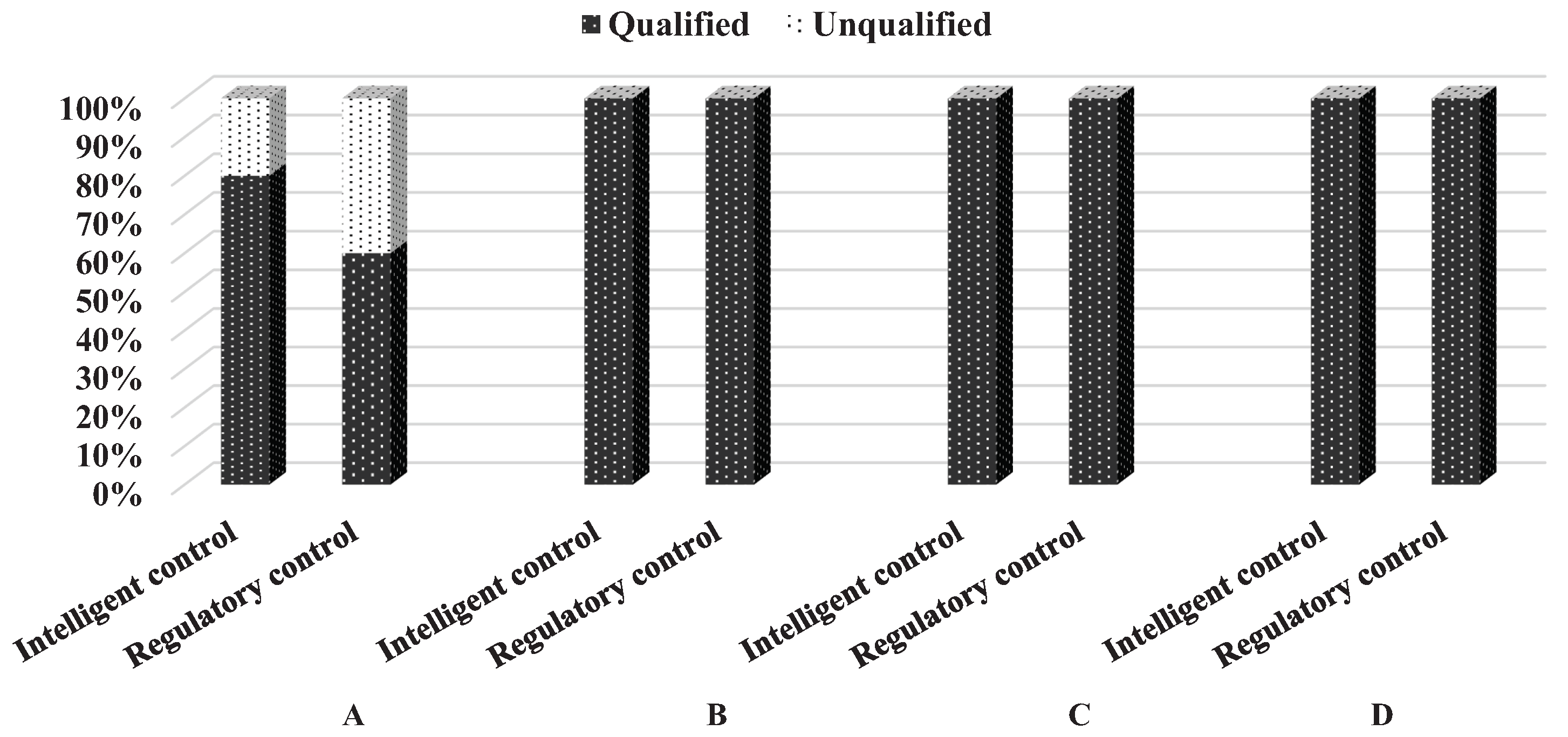

The main purpose of this paper is to describe and examine the design, as well as the applications, of a new control strategy to an industrial rotary dryer. We will illustrate the practical aspects and details to design our controller based on the rotary dryers used to dry cut tobacco. Actually, our proposed controller operates in a layer above one of the basic regulatory control which is already in place in the plant. This study will further show that the new controller can maintain the same quality the product, as already provided by manual operation, with an increase in the reduction of over-dried cut tobacco.

The paper is organized as follows:

Section 2 deals with the description of the cut tobacco drying process; as well as the current regulatory control system.

Section 3 illustrates the proposed intelligent control system.

Section 4 explains the experimental setup and the result analysis.

Section 5 shows the conclusions.

2. The Rotary Dryer System

This section describes the rotary dryers for cut tobacco, existing regulatory controls, and how operators process variables in manual programs.

2.1. The Rotary Dryer Process Description

The proposed controller was developed and applied in an industrial tobacco plant in Zhejiang, China. In this factory, cut tobacco is dried to remove impurities and some free alkali.

For this study, a cut tobacco dryer system with a production capacity of 4000 kg/h was used. The dryer is a new generation Hauni KLD rotary dryer [

24]. The cut tobacco is dried in batches, generally lasting two hours for each batch. After a drying process is completed, the operator carries out the essential maintenance work of the relevant machines involved. After that, the next batch is processed.

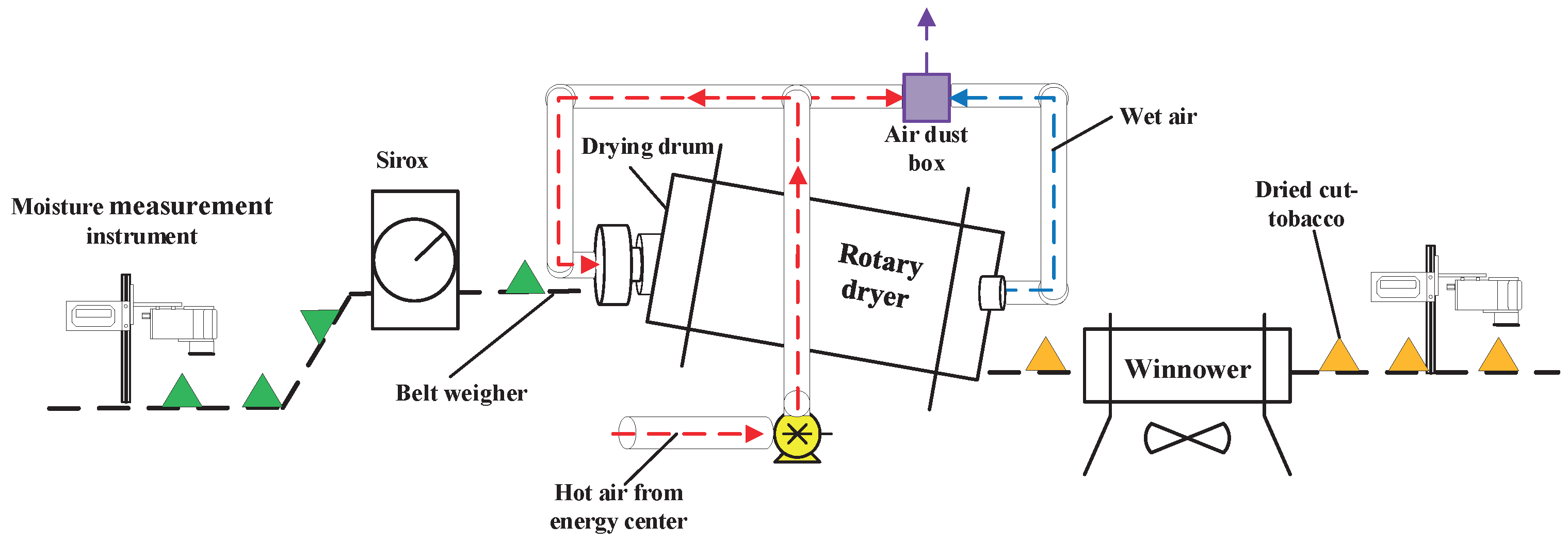

The process of drying tobacco is entirely shown in

Figure 1. However, a full description of such a process is beyond the purpose of this paper. To understand how the proposed operating control works, it is necessary to give a succinct description of two machines involved in the whole process: the Sirox conditioner [

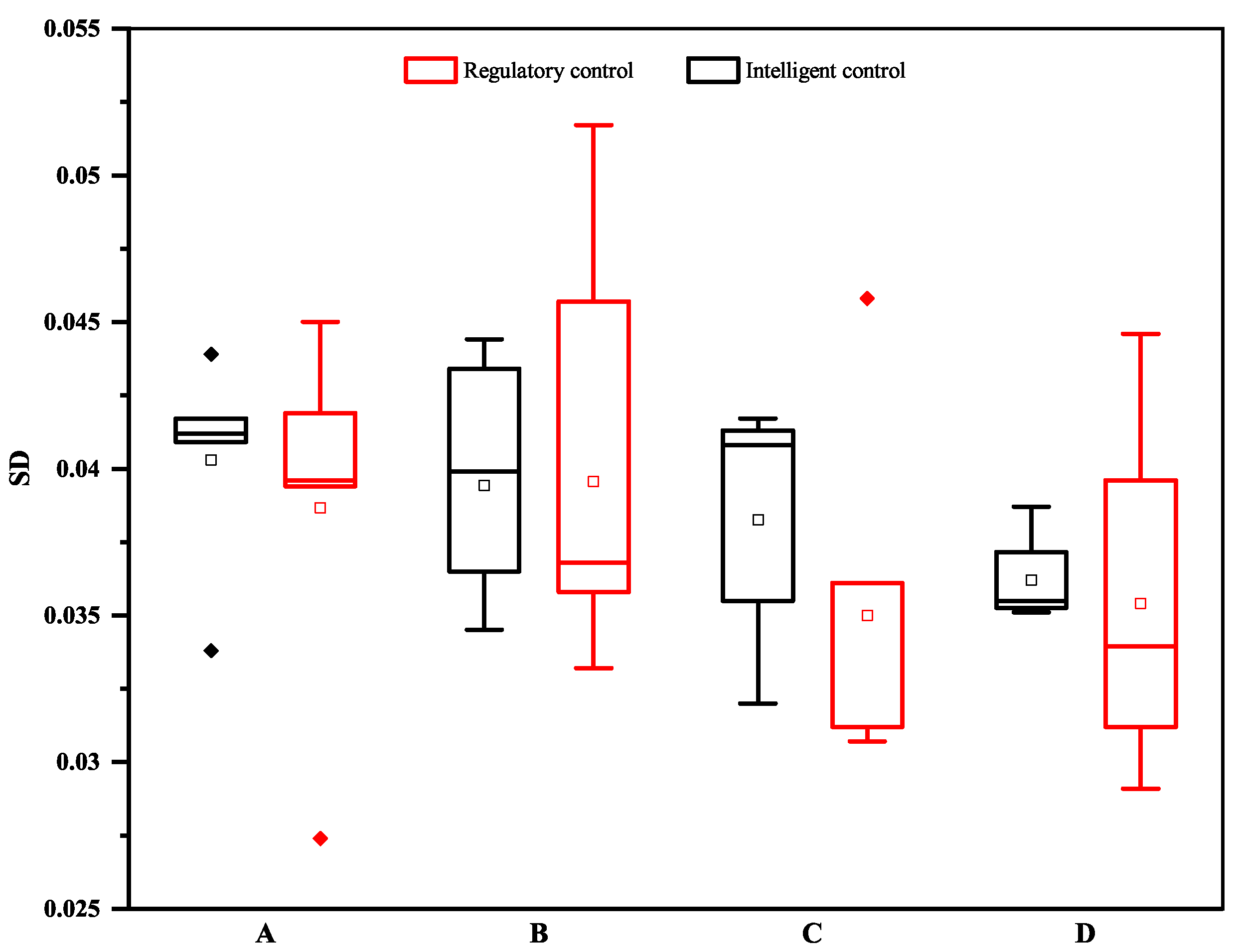

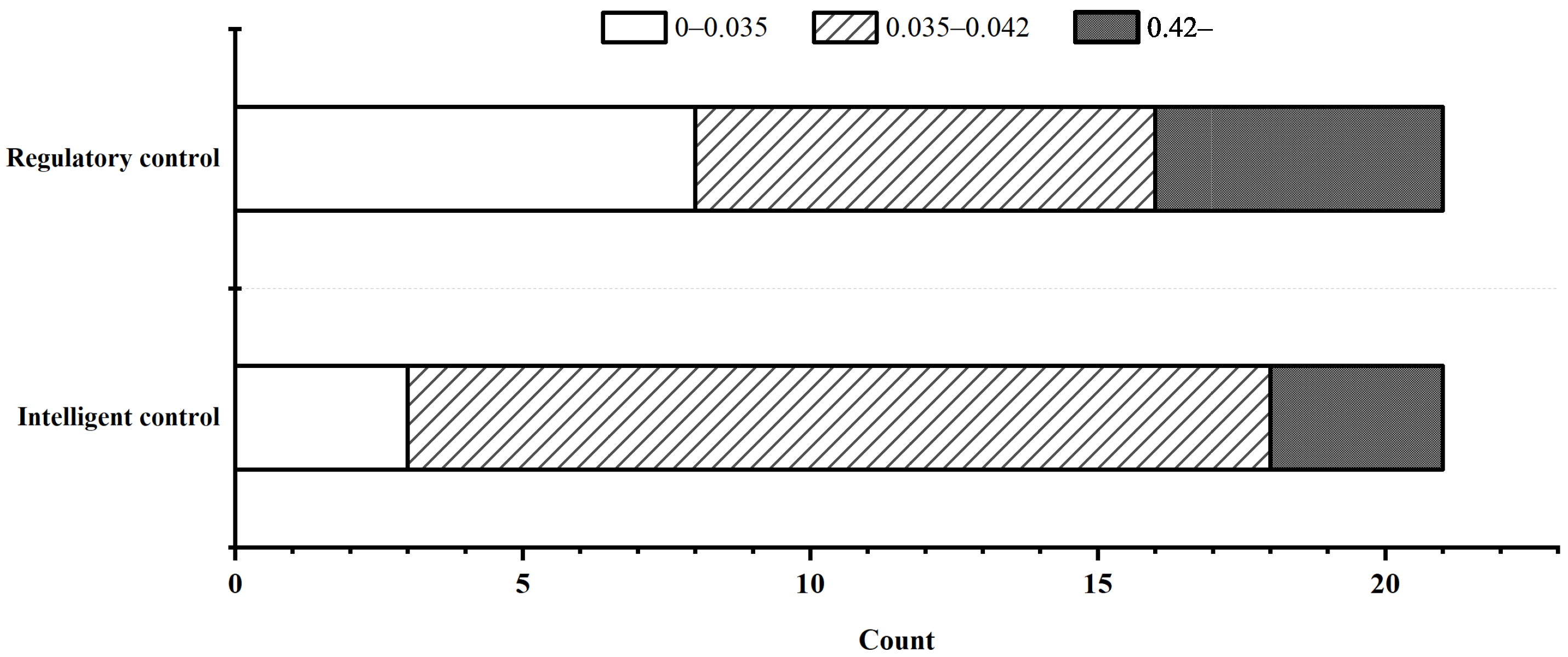

25] and the rotary drier. It is important to remember that in this plant, they produce two varieties of tobacco that have a different moisture content, respectively, 12.00% and 12.10%. In addition to this, the processed cut tobacco must have a standard deviation of moisture content of less than 0.042 in each batch.

Figure 1 shows the dryer process under study. In the aforementioned figure, you can see the cut tobacco which is going to be fed into a rotating cylinder that in reality has a length of 9 m and a diameter of 1.9 m. The rotating drum, called the rotary drier in the figure, has a speed of 11 revolutions per minute (RPM). The dryer uses steam as heating energy. Although in the drum both mixed conduction and convection heating operate, conduction is the principal source of heat. The cylinder’s external surface is warmed by the steam supply system. The cut tobacco is fed by a vibrating conveyor into the continuously rotating dryer and directly contacts the drum walls. Simultaneously, the hot air and cut tobacco are conveyed in the same direction. The hot air directly contacts the cut tobacco and transfers heat to cut tobacco by convection. The moisture on the surface of the cut tobacco vaporizes and diffuses into the hot air as the cut tobacco absorbs heat from the drum walls and the hot air. The hot air turns into hot and humid air while drives water vapor and enters the dust box from the discharge end of the dryer. When the exhaust gas comes out of the dryer, it must pass through a dust box which collects the entrained products to meet the waste emission regulations. After that, the dried cut tobacco is sent to the winnower for cooling and screening.

Before the tobacco is dried, it passes through a Sirox conditioner. This is used for conditioning and warming the whole batch. Apart from the two machines mentioned above, it is important to bear in mind that at the inlet of dryer, there is an online moisture measurement instrument.

Normally, the temperature is controlled by the human operator. The mass feed rate, the rotation speed of the drum, and the inclination of the dryer usually follow preset parameters. Moreover, the water increase provoked by SIROX is always the same independently of the type of cut tobacco that they want to produce [

26].

In the dryer, the heat exchange between the steam flow and the cut tobacco varies depending on the opening of the steam valve. The overall temperature of dryer depends on the steam pressure which, in its turn, depends on the opening of the steam valve, to be further examined later. For the system under study, it is empirically assumed that dryer temperature within the range of 130∼133 °C, the speed of the hot air flow is in the range of 0.348∼0.351 m/s, and the temperature of the hot air is in the range of 105.00∼105.10 °C. The cut tobacco at the inlet of the dryer has a moisture content between 18% and 19%.

2.2. The Regulatory Control System

Rotary dryers are an important type of equipment for drying cut tobacco. Although there are many process parameters in the dryer control system, in real case scenarios, the operator only controls the temperature of dryer according to the intended process. In the plant where we studied the tobacco drying process, the Assessment of the entire procedure is mainly based on the control of the moisture content of the product. Therefore, from the financial side, achieving the intended level of moisture is considered the riskiest part of the business.

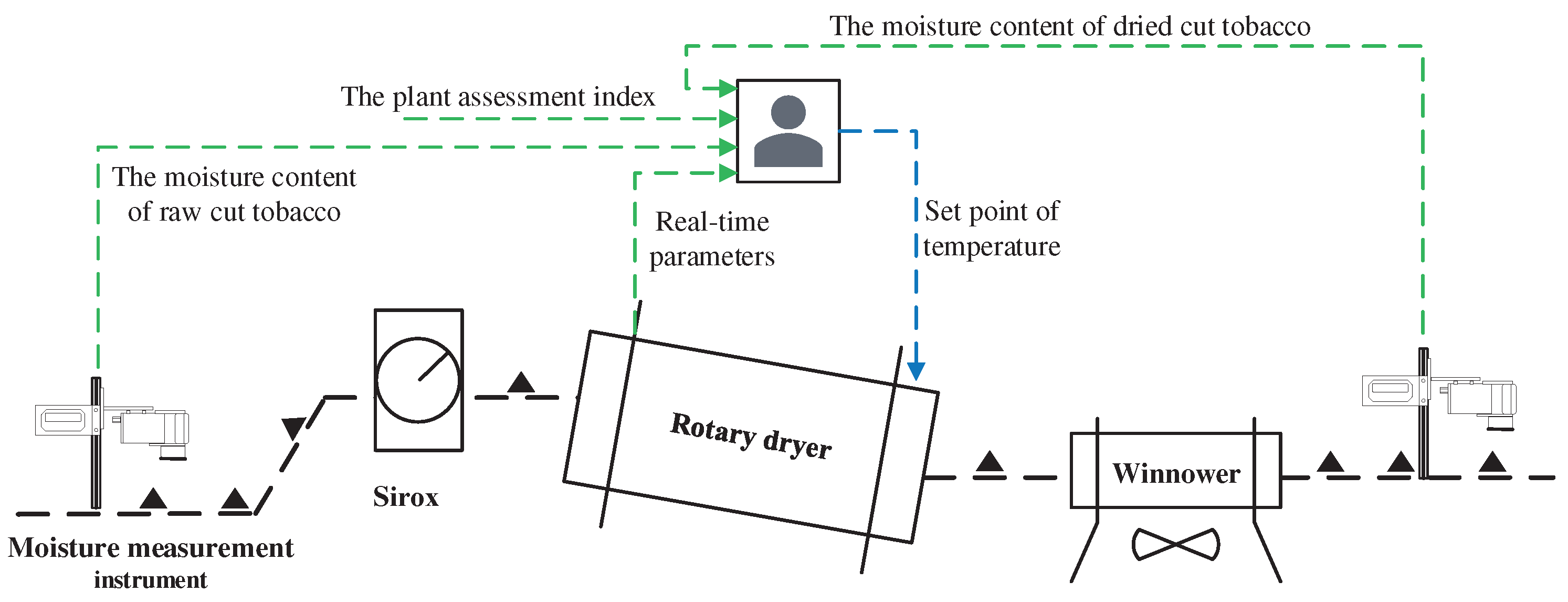

The regulatory control system of the plant is shown in the

Figure 2 below. The regulatory control system is based on the dryer proportional–integral–derivative (PID) control system, which contains feedforward control, PID moisture controller, and PID temperature controller. Before starting the production, the dryer needs to reach a temperature of 124 °C and keep it for 20 min.

In the first stage of drying process, the belt keeps feeding the drum, consequently the amount of cut tobacco varies and it will stay inside the dryer few minutes. The operator sets the temperature value based on several parameters (as shown by

Figure 2) such as inlet moisture, the value of the previous batch, and the target value of outlet moisture. At this stage, the temperature control of the dryer is mainly a feedforward control.

In the central stage of drying process, the online outlet moisture measurement instrument detects cut tobacco. Consequently, the PID temperature controller considers the results of the feedforward control operation and the PID moisture controller as input parameters. As a matter of fact, the moisture content control relies mainly on the PID controller at this stage. In this phase, the operator pays attention to the mean and SD of the outlet moisture content of cut tobacco, and carries out appropriate intervention to meet the assessment target.

In the last stage of the drying process, the steam valve is closed. The cut tobacco is mainly dried through the residual heat of the dryer without manual intervention.

This is the regulatory control system already existing in the plant. The main role of our proposed controller is to replace operator and achieve intelligent control, to be described in the following section.

3. Proposed Intelligent Control System

The nonlinear behavior of the process, long-time delays, and large input disturbances make the control of rotary dryer difficult [

10]. Due to the complex process dynamics, human-sourced mistakes are usually made in the operation process of rotary dryer. Therefore, an intelligent controller is designed to overcome these problems.

The main role of our proposed controller is to replace the operator and achieve intelligent control. Indeed, the proposed control system aims to keep the content of moisture at the dryer outlet as close as possible to the optimal value and improve the homogeneity of the product without operator interventions. Consequently, it is possible to obtain an efficient operation of the rotary dryer, and prevent human mistakes.

The proposed controller was developed using the Simulink from MATLAB [

27]. This piece of software includes a library of components from which the model can be developed.Simulink is widely used in automatic control for multidomain simulation and model-based design. Furthermore, the software has an interface that allows the industrial internet of things (IIoTs) to communicate. For this research, Thingworx [

28] from PTC was mainly used. The data template for an intelligent controller, devices and regulatory control in the IIoT are: Remote thing, plant thing, and regulatory thing.

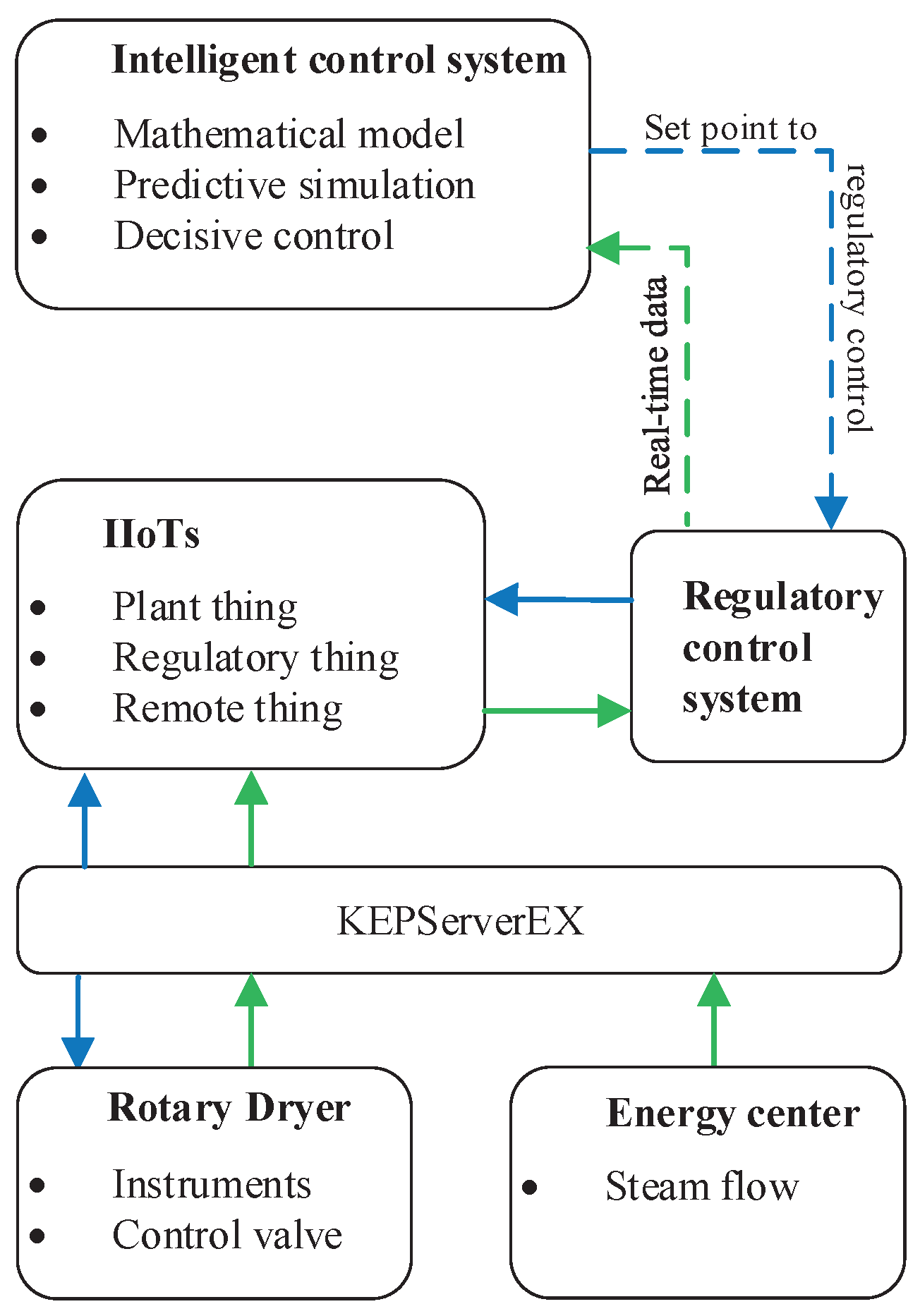

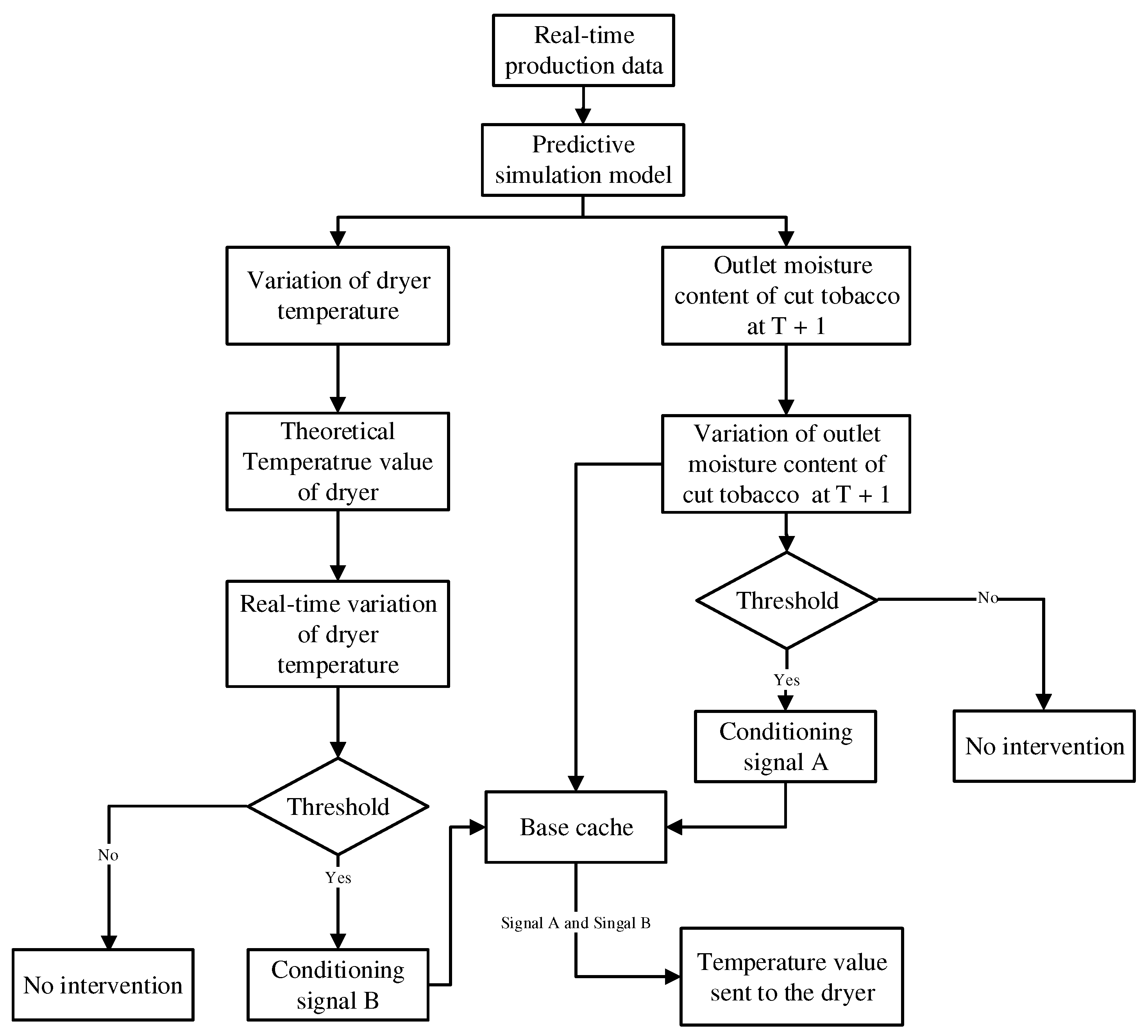

A schematic representation of the advanced control system is depicted in

Figure 3. The intelligent control system uses data from IIoTs to evaluate the operating condition of the dryer and monitor the outlet moisture content of the cut tobacco. KEPServerEX leverages OPC (OLE for Process Control which is the automation industry’s standard for interoperability) and IT-centric communication protocols (such as SNMP, ODBC, and web services) to provide Thingworx with a single source for industrial data.

The regulatory control system has two modes, an automatic mode and a manual mode. In automatic mode, the dryer is completely controlled by the intelligent controller without manual intervention. In the manual mode, on the other hand, the dryer is completely controlled by the operator without any intelligent control system support. It should be emphasized here that in manual mode, the intelligent control system continues working, it still outputs a setpoint to the regulatory control system which will not be sent to the dryer. The two modes can be easily interchanged at any time. In other words, if the automatic mode, for whatever reason, is not satisfactory it is always possible to switch to the control operator.

The intelligent control system includes three main modules:

The mathematical model, which a mathematical model for the control of the dryer, and this is the basis for creating a predictive simulation model of the dryer;

The predictive simulation mainly simulates the control state of the dryer and predicts the outlet moisture content of cut tobacco at the moment T + 1;

The decisive control handles the process variable: set point of the dryer temperature.

In the flowing sections, the mathematical model, predictive simulation and decisive control of the intelligent controller are described.

3.1. Mathematical Model

The cut-tobacco dryer is in the first stage before the cut tobacco reaches the outlet moisture meter. The actual outlet moisture content of cut tobacco cannot be measured because there is no cut tobacco at the outlet; thus, the actual moisture feedback cannot be formed. The temperature control of the dryer was achieved using the feed-forward mathematical model. Thus, the accuracy of the feed-forward mathematical model is key for determining the accuracy of the cut-tobacco drying control. Indeed, the operator can intervene and adjust the temperature during the entire process.

We set

as the tobacco mass flow at the inlet [kg/h], and

as the inlet moisture content of cut tobacco (lsb%). The mass flow of dry-cut tobacco is the flow of water changes, the mass flow of dry-cut tobacco

(moisture content of 0%) is given as:

We set the value of moisture increase at the Sirox as

. Therefore, the mass flow after Sirox [kg/h],

, is given as:

We set

as the outlet moisture content of cut tobacco (lrb%) because there is no tobacco at the outlet at this time. The theoretical value of mass flow after the winnower [kg/h] is given by

as:

Equations (

4) and (

5) are used to obtain the dryer moisture reduction (kg/h)

as:

We set the target moisture reduction (kg/h) in the process recipe as

. The variation in the dryer moisture reduction (kg/h) is denoted by

and is given as:

We can define the dry factor as

[°C /(kg/h)]; then, the variation of the dryer temperature according to the feedforward control

[°C] is given as:

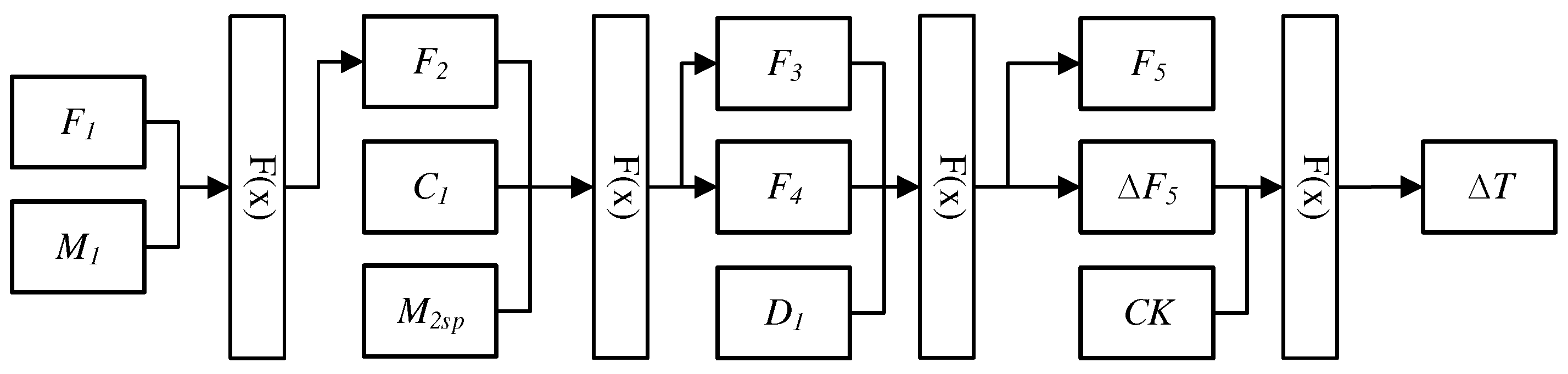

The feedforward control data flow diagram is shown in

Figure 4:

When the moisture detected by the detector deviates from the target value after passing through the winnower, there is a deviation between the actual outlet value of the cut tobacco flow and the expected value. That is, the deviation is equivalent to that between the actual value of the dryer moisture reduction flow and the expected value. However, the flow deviation can be converted into temperature, and the formula is calculated and applied to the control system immediately. The variation in the dryer temperature based on feedback control is

, where

represents the outlet moisture content of the cut tobacco.

The dryer calculates the actual temperature value based on steam pressure. The saturated steam pressure used by the dryer is 0–1 MPa (approximately 99–183 °C). The program can be realized using look-up tables or empirical formulas. Although the amount of calculation required when using look-up tables is small, the control accuracy is directly affected by the amount of data in the table. The amount of data must be increased to improve accuracy. To this end, an optimized empirical formula is adopted for determining the relationship between steam pressure and temperature [

29].

As shown in

Figure 5, the set point of temperature T consists of four values: the manual setting value

, the feedback control temperature variation

, the actual dryer temperature

and the feed forward control variation

. The temperature is then converted into steam pressure and sent to dryer which is achieved by the steam valve.

T is given as:

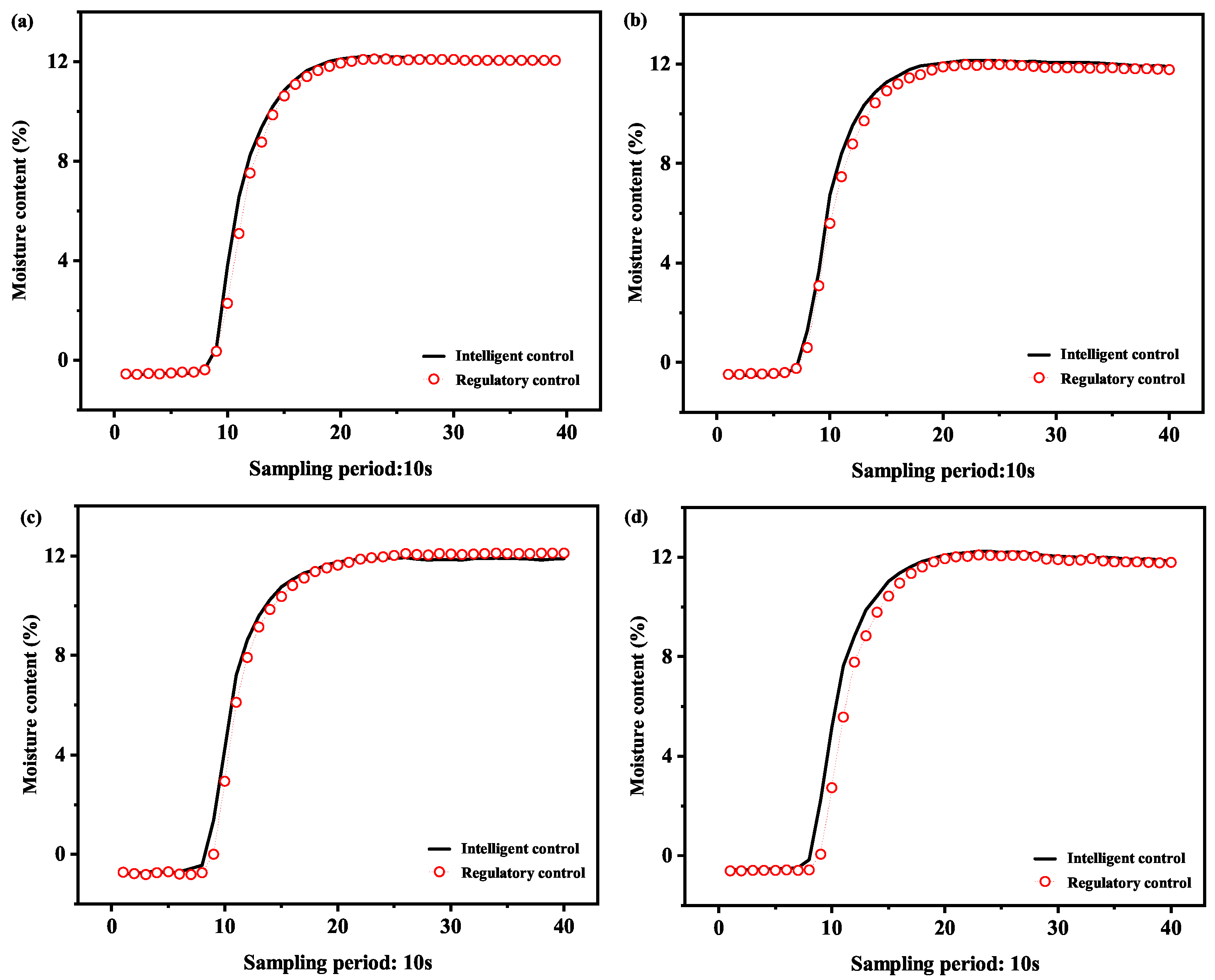

During the different stages, IIoTs collected the data and the mathematical model was validated. Experimental results of the proposed model are summarized in

Table 1 and

Table 2. Specifically,

Table 2 results were calculated using

Table 1 data an Equations (

1)–(

9). The reason why

T and

actualT are not identical is that there is some stochastic deviation in system control process.

3.2. Predictive Simulation Module

Since we proved the correctness of the mathematical model, we created a predictive control module to simulate the virtual environment of the system. The predictive model was based on:

The aforementioned mathematical model;

The transfer function of the black box system;

The identification of the state space model; In the flowing sections, the mathematical model, predictive simulation and decisive control of the intelligent controller are described.

The predictive module foresees the key parameter values, such as outlet moisture content and the opening of the steam valve (the opening is related to the amount of steam, and the amount of steam is related to the temperature) to solve the time delay in the control and improvement of the accuracy.

Figure 6 shows that real-time production data are divided into controllable and uncontrollable variables. Controllable variables refer to manually sett values, process calculated values, partial sensor data, etc. Uncontrollable variables refer to immutable input factors such as inlet moisture content and inlet cut tobacco mass flow; they are computed using the joint probability density function. Controllable and uncontrollable variables are stored together in the base buffer. The data in the base buffer are smoothed and denoised using Butterworth low-pass filtering. Finally, the obtained data were substituted into the stream data computing model. The stream data computing model contains two major categories: Equations (

1)–(

9), and the transfer function of the black box system and identification of the state space model. Further, we added perturbation errors to make the virtual environment realistic. The virtual environment outputs important parameters such as steam valve opening, outlet moisture content prediction, and analog quantities. These analog quantities are substituted into the previous stream data computing model to fill in the vacant inputs (this part of the input can only be obtained through a virtual environment).

3.3. Decisive Control Module

The predictive simulation module receives real-time production data as shown in

Figure 7. The values of the outlet moisture content are forecasted at

T + 1 with a time interval of 360 s (this time interval is derived from data analysis and actual production testing). Therefore, we obtain the moisture deviation at time

T + 1, and we accumulate this value. If it is greater than the set threshold, the adjustable signal A (this signal is a rising edge pulse and does not accumulate) is triggered and stored in the base buffer.

The variable quantity of the dryer temperature can be calculated (computed by formula). The desired value of the dryer temperature is the sum of the set value and the variation in the dryer temperature. Therefore, the real-time deviation of the dryer temperature is the difference between the desired and actual temperatures. If this deviation is greater than the set threshold, the adjustable signal B will be triggered and stored in the base buffer. When signals A and B are satisfied simultaneously, the sum of the set value and real-time deviation of the dryer temperature is output.