Effects of Process Parameters on Surface Straightness of Variable-Section Conical Parts during Hot Power Spinning

Abstract

:1. Introduction

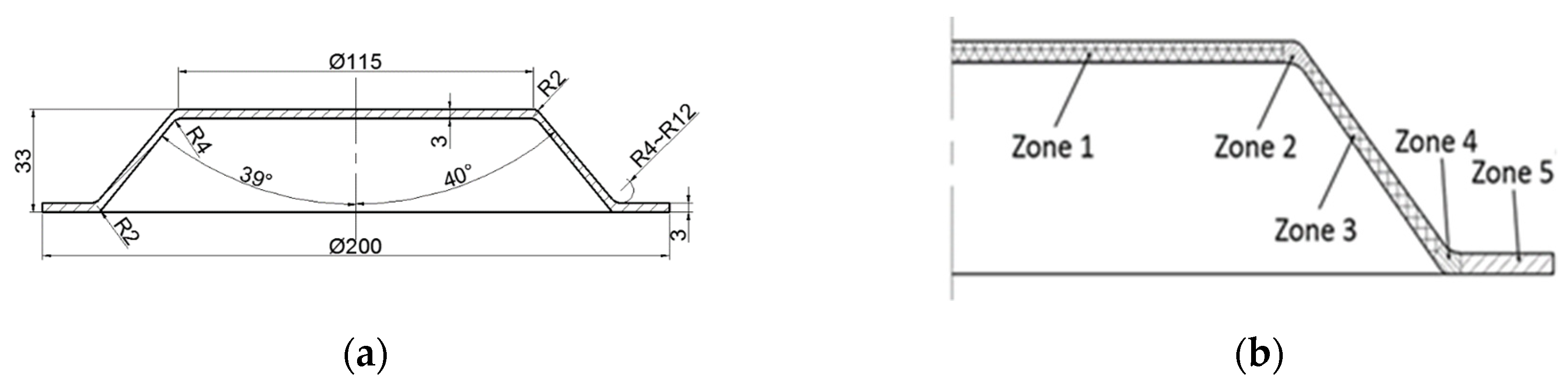

2. Establishment of Finite Element Model

2.1. Material Properties of GH4169 Superalloy

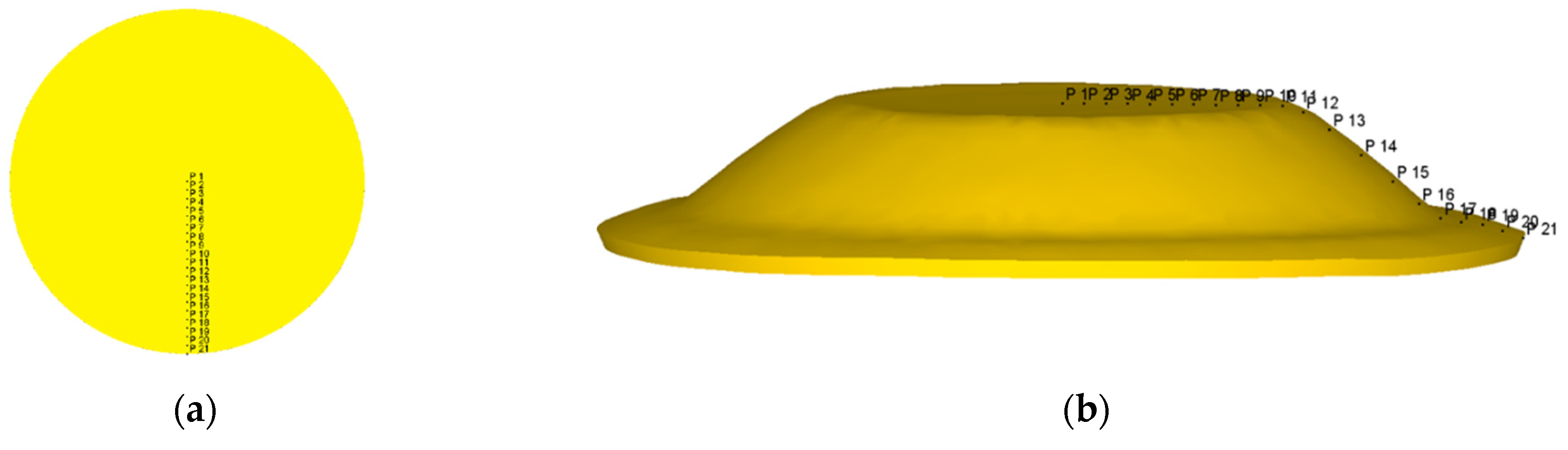

2.2. Establishment of 3D Finite Element Model (FEM)

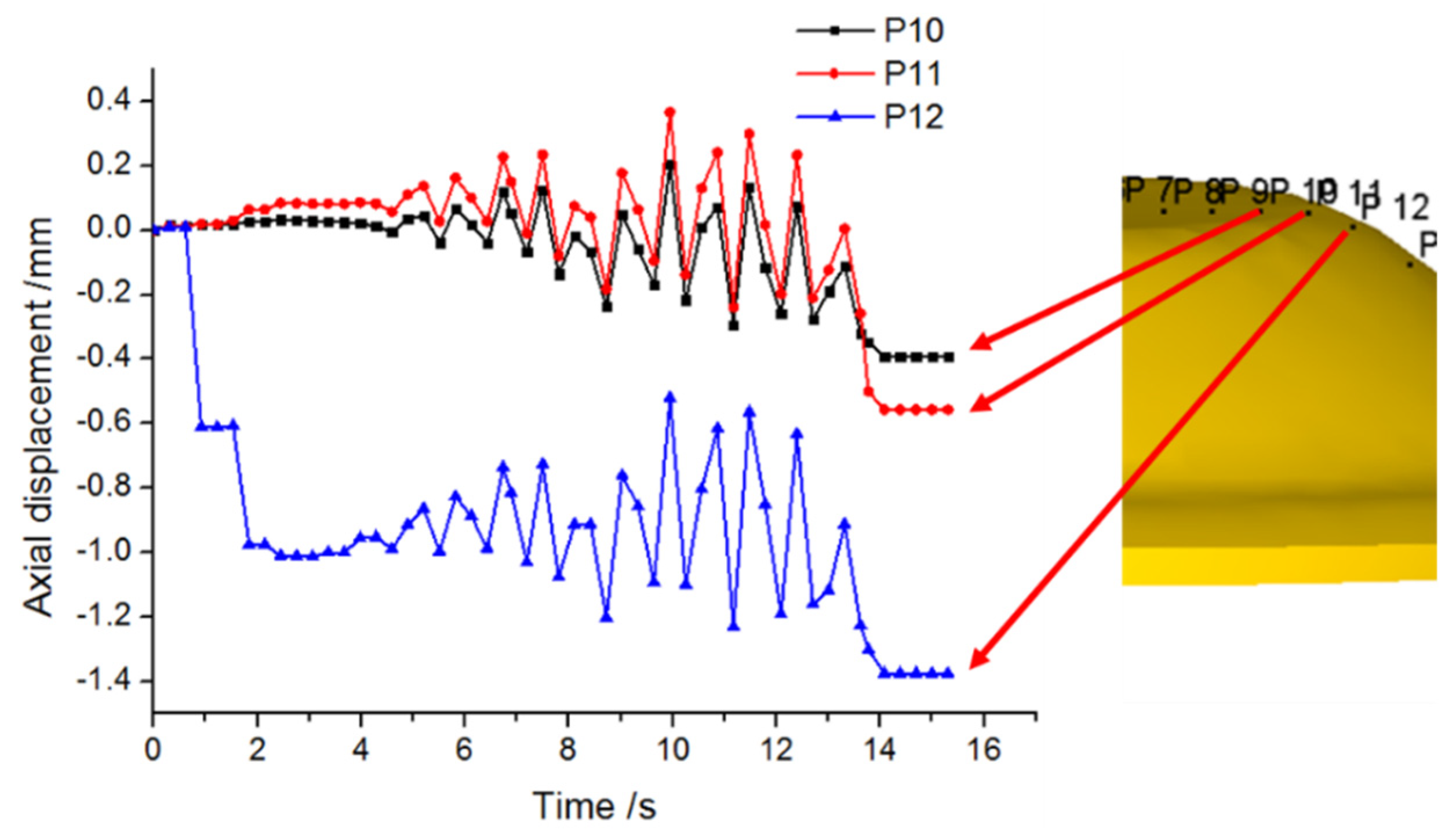

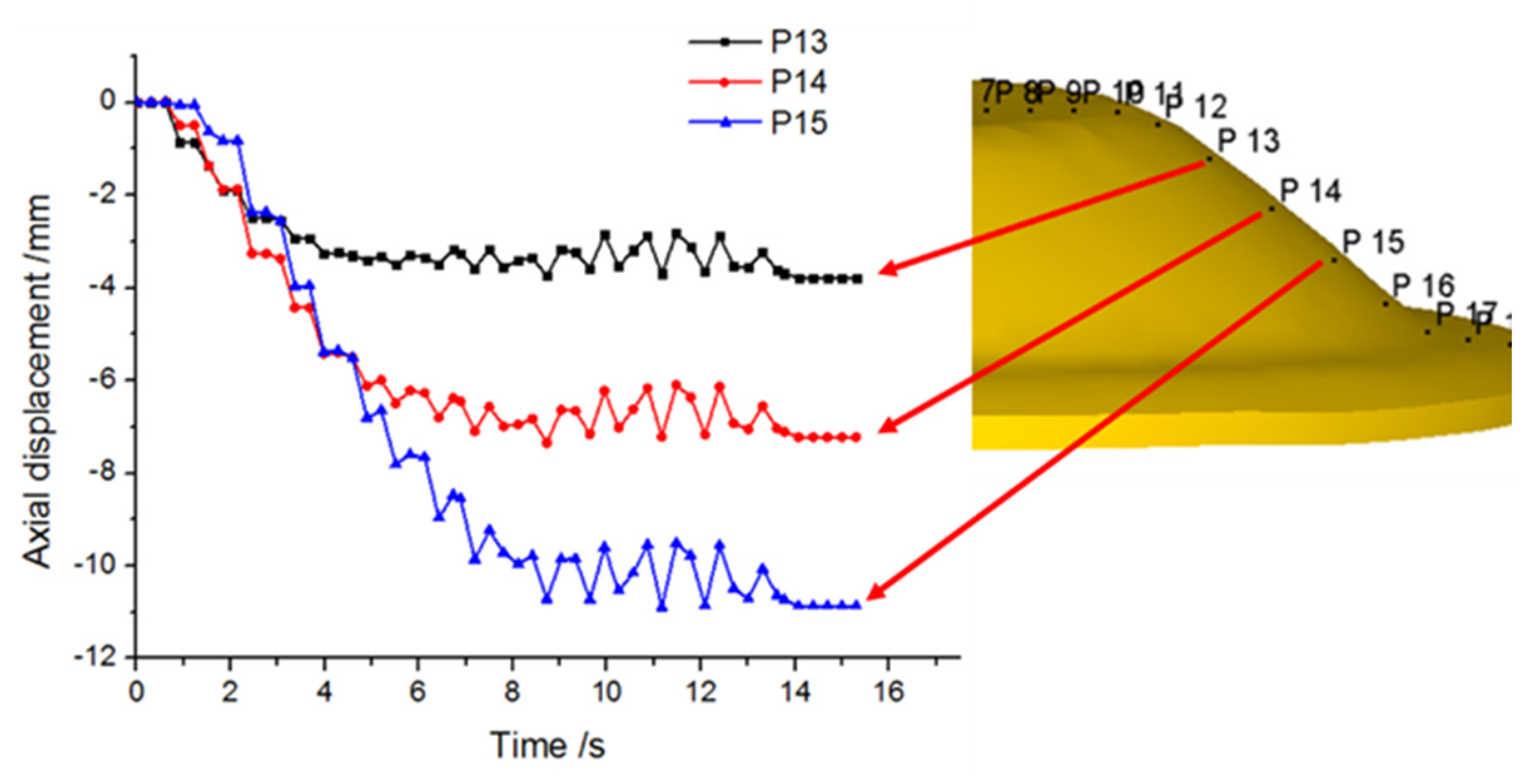

2.3. Finite Element Analysis of Material Flow Law

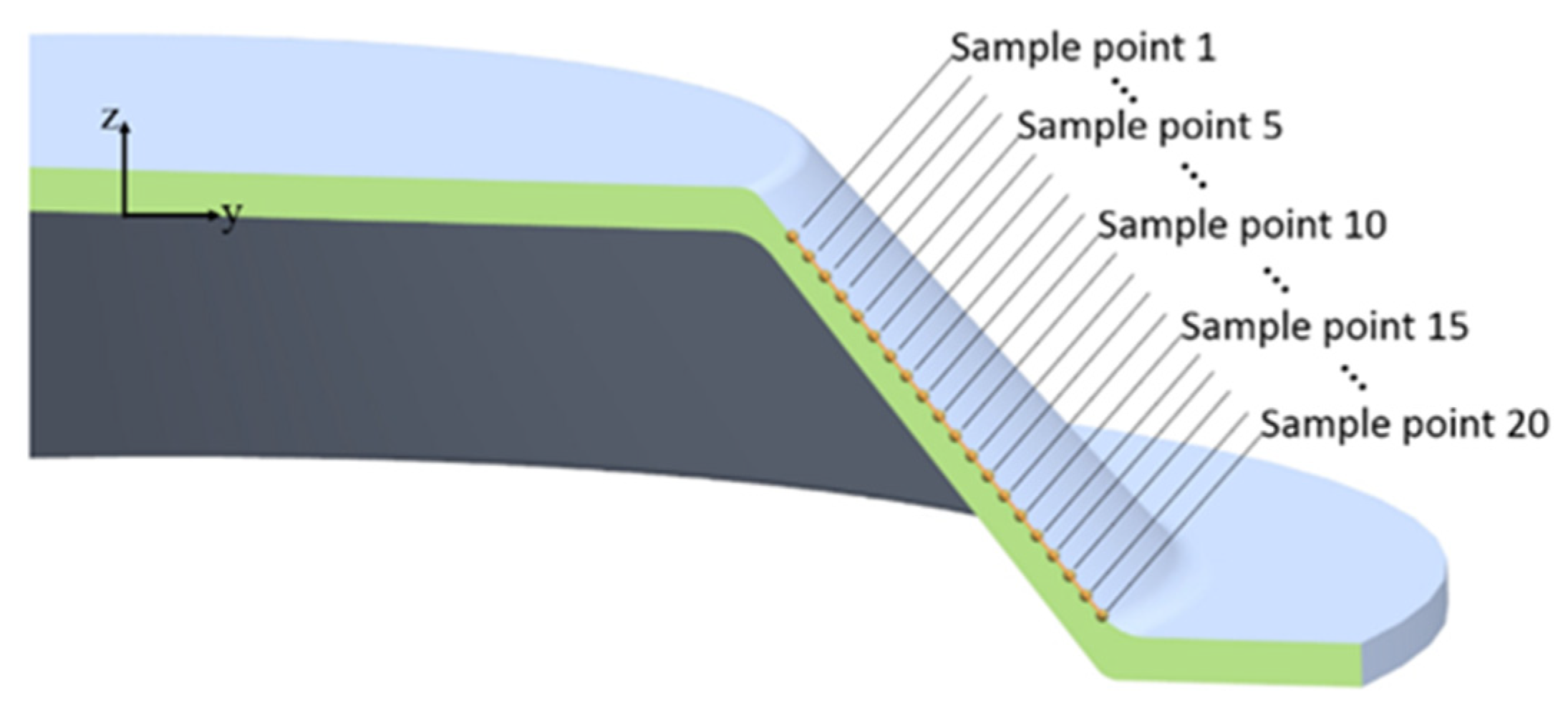

3. Effects of Process Parameters on Surface Straightness

3.1. Single Factor Experiment Design

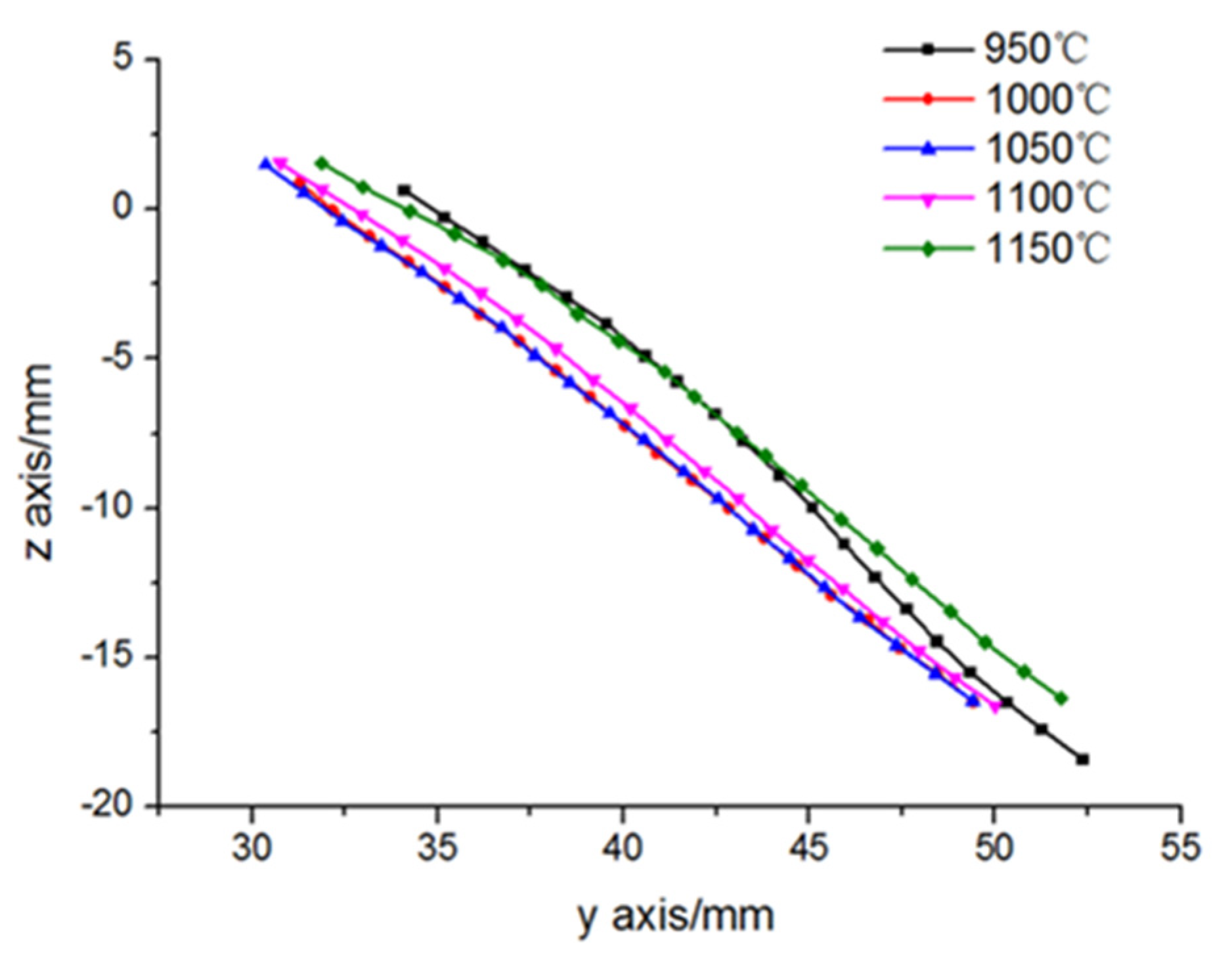

3.1.1. Effect of Spinning Temperature on Surface Straightness

3.1.2. Effect of Mandrel Rotation Rate on Surface Straightness

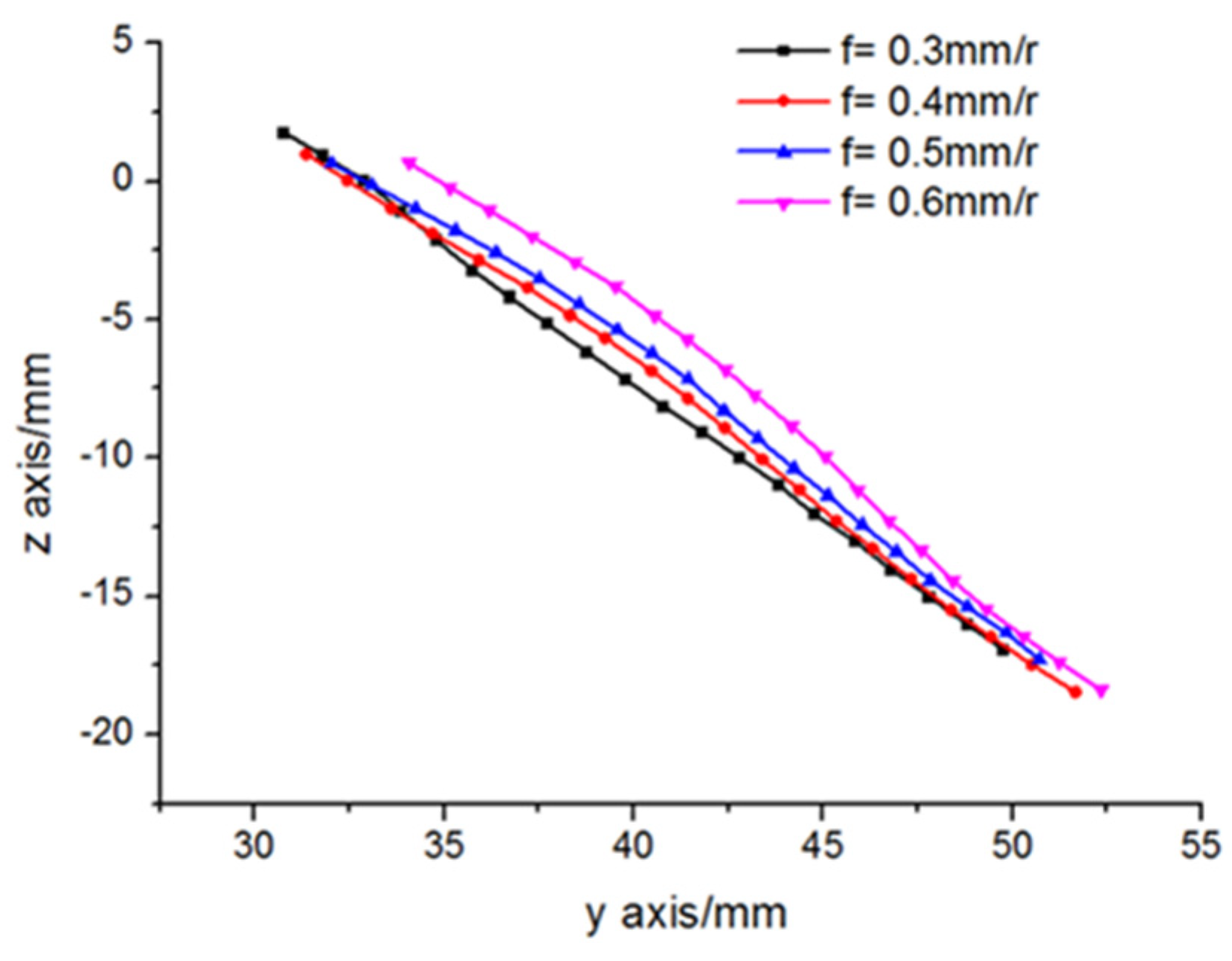

3.1.3. Effect of Roller Feed Ratio on Surface Straightness

3.2. Design and Analysis of Orthogonal Experiment

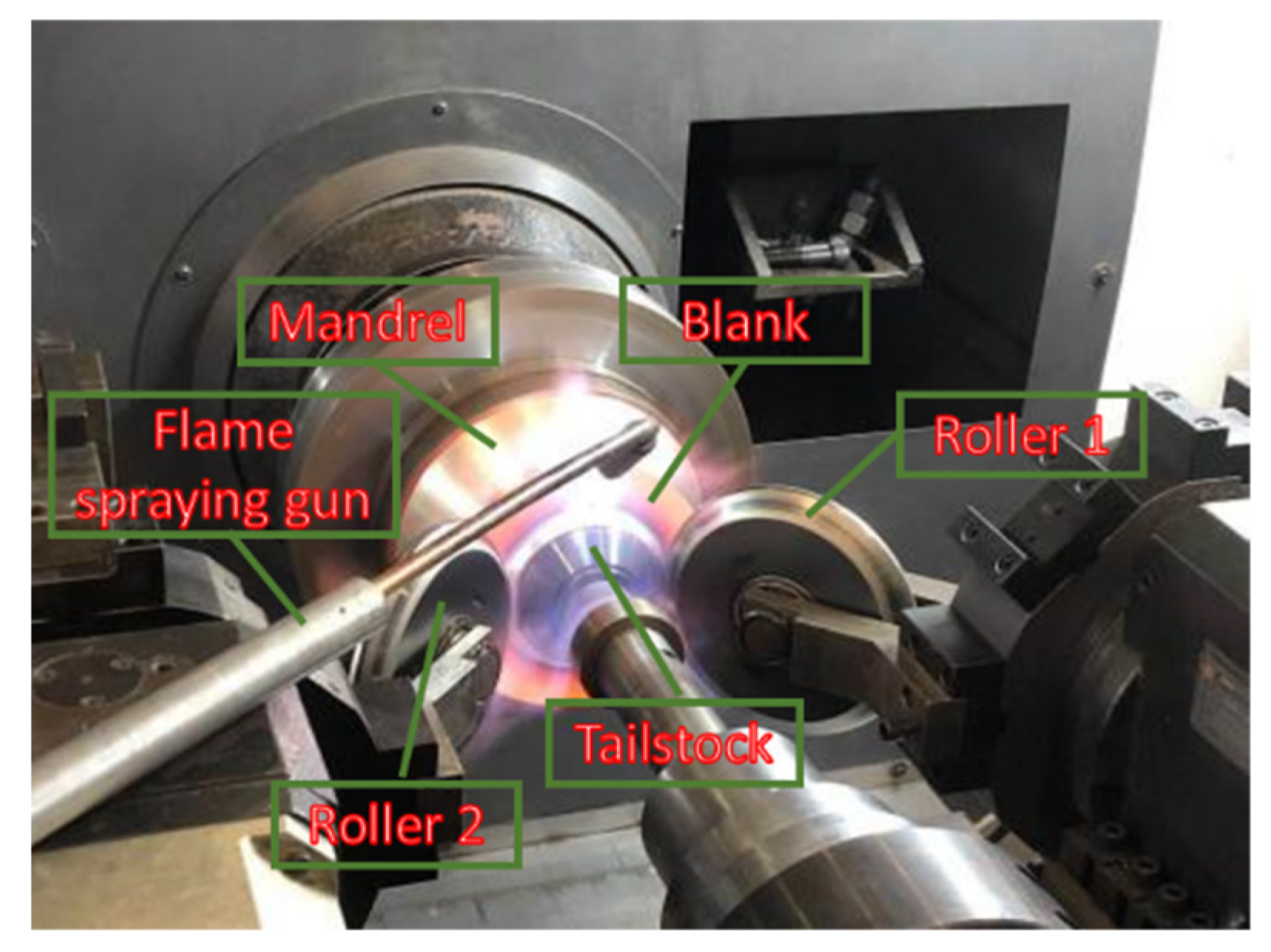

4. Spinning Experiment and Analysis

4.1. Spinning Experiment

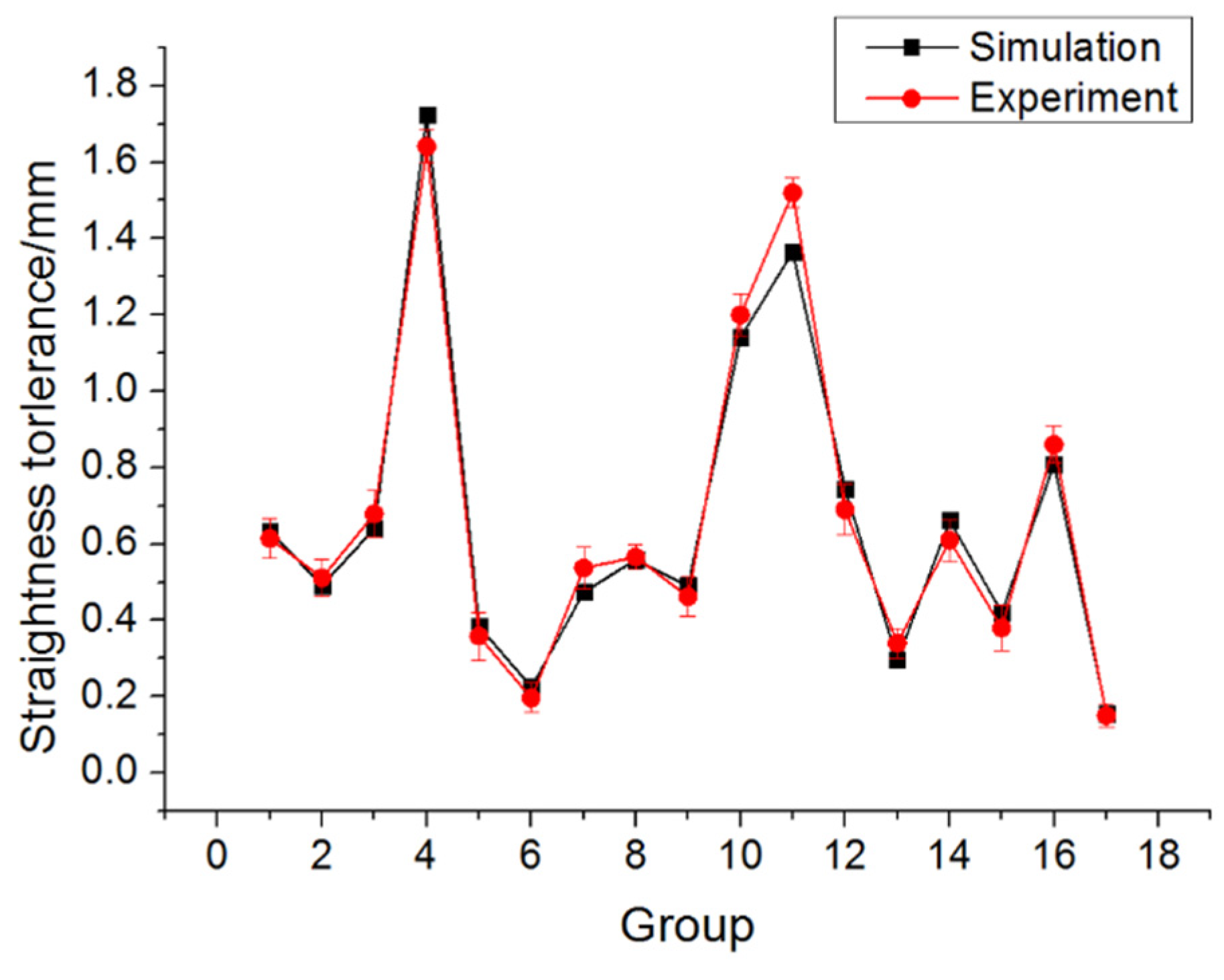

4.2. Comparison Analysis

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wong, C.; Dean, T.; Lin, J. A review of spinning, shear forming and flow forming processes. Int. J. Mach. Tools Manuf. 2003, 43, 1419–1435. [Google Scholar] [CrossRef]

- Music, O.; Allwood, J.; Kawai, K.-I. A review of the mechanics of metal spinning. J. Mater. Process. Technol. 2010, 210, 3–23. [Google Scholar] [CrossRef]

- Xia, Q.; Xiao, G.; Long, H.; Cheng, X.; Sheng, X. A review of process advancement of novel metal spinning. Int. J. Mach. Tools Manuf. 2014, 85, 100–121. [Google Scholar] [CrossRef]

- Zhan, M.; Yang, H.; Guo, J.; Wang, X.-X. Review on hot spinning for difficult-to-deform lightweight metals. Trans. Nonferrous Met. Soc. China 2015, 25, 1732–1743. [Google Scholar] [CrossRef]

- Jahazi, M.; Ebrahimi, G. The influence of flow-forming parameters and microstructure on the quality of a D6ac steel. J. Mater. Process. Technol. 2000, 103, 362–366. [Google Scholar] [CrossRef]

- Xia, Q.-X.; Long, J.-C.; Zhu, N.-Y.; Xiao, G.-F. Research on the microstructure evolution of Ni-based superalloy cylindrical parts during hot power spinning. Adv. Manuf. 2019, 7, 52–63. [Google Scholar] [CrossRef]

- Xiao, G.; Xia, Q.; Long, J.; Chen, W. Research on the forming quality and mechanical properties of cylindrical spun parts with ultrafine-grained structure during power spinning. Int. J. Adv. Manuf. Technol. 2018, 97, 2979–2986. [Google Scholar] [CrossRef]

- Li, Z.-X.; Shu, X.-D. Numerical and experimental analysis on multi-pass conventional spinning of the cylindrical part with GH3030. Int. J. Adv. Manuf. Technol. 2019, 103, 2893–2901. [Google Scholar] [CrossRef]

- Essa, K.; Hartley, P. Numerical simulation of single and dual pass conventional spinning processes. Int. J. Mater. Form. 2009, 2, 271–281. [Google Scholar] [CrossRef]

- Essa, K.; Hartley, P. Optimization of conventional spinning process parameters by means of numerical simulation and statistical analysis. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 1691–1705. [Google Scholar] [CrossRef] [Green Version]

- Song, X.; Fong, K.S.; Oon, S.R.; Tiong, W.R.; Li, P.F.; Korsunsky, A.M.; Danno, A. Diametrical growth in the forward flow forming process: Simulation, validation, and prediction. Int. J. Adv. Manuf. Technol. 2013, 71, 207–217. [Google Scholar] [CrossRef]

- Kuss, M.; Buchmayr, B. Analytical, numerical and experimental investigations of a ball spinning expansion process. J. Mater. Process. Technol. 2015, 224, 213–221. [Google Scholar] [CrossRef]

- Xu, W.; Zhao, X.; Ma, H.; Shan, D.; Lin, H. Influence of roller distribution modes on spinning force during tube spinning. Int. J. Mech. Sci. 2016, 113, 10–25. [Google Scholar] [CrossRef]

- Wang, X.-K.; Xia, Q.-X.; Cheng, X.-Q. Deformation behavior of haynes230 superalloy during backward flow forming. Int. J. Precis. Eng. Manuf. 2017, 18, 77–83. [Google Scholar] [CrossRef]

- Fazeli, A.R.; Ghoreishi, M. Investigation of effective parameters on surface roughness in thermomechanical tube spinning process. Int. J. Mater. Form. 2009, 2, 261–270. [Google Scholar] [CrossRef]

- Wang, L.; Long, H. A study of effects of roller path profiles on tool forces and part wall thickness variation in conventional metal spinning. J. Mater. Process. Technol. 2011, 211, 2140–2151. [Google Scholar] [CrossRef]

- Wang, L.; Long, H. Investigation of material deformation in multi-pass conventional metal spinning. Mater. Des. 2011, 32, 2891–2899. [Google Scholar] [CrossRef]

- Rentsch, B.; Manopulo, N.; Hora, P. Numerical modelling, validation and analysis of multi-pass sheet metal spinning processes. Int. J. Mater. Form. 2016, 10, 641–651. [Google Scholar] [CrossRef]

- Gan, T.; Yu, Z.-Q.; Zhao, Y.-X.; Evsyukov, S.; Lai, X.-M. Effects of backward path parameters on formability in conventional spinning of aluminum hemispherical parts. Trans. Nonferrous Met. Soc. China 2018, 28, 328–339. [Google Scholar] [CrossRef]

- Zhang, H.-R.; Zhan, M.; Guo, J.; Wang, X.-X.; Gao, P.; Ma, F. Forming the transverse inner rib of a curved generatrix part through power spinning. Adv. Manuf. 2019, 7, 105–115. [Google Scholar] [CrossRef]

- Wang, L.; Long, H.; Ashley, D.; Roberts, M.; White, P. Effects of the roller feed ratio on wrinkling failure in conventional spinning of a cylindrical cup. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 1991–2006. [Google Scholar] [CrossRef]

- Watson, M.; Long, H.; Lu, B. Investigation of wrinkling failure mechanics in metal spinning by Box-Behnken design of ex-periments using finite element method. Int. J. Adv. Manuf. Technol. 2015, 78, 981–995. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.; Gao, P.; Zhan, M.; Ma, F.; Zhang, H.; Xu, R. Determination of formability considering wrinkling defect in first-pass conventional spinning with linear roller path. J. Mater. Process. Technol. 2019, 265, 44–55. [Google Scholar] [CrossRef]

- Mohebbi, M.S.; Pour, M.R. Effects of temperature, initial conditions, and roller path on hot spinnability of AZ31 alloy. Int. J. Adv. Manuf. Technol. 2019, 103, 377–388. [Google Scholar] [CrossRef]

- Ma, J.; Shen, J.L.; Li, M.M.; Liang, Y. Effect of chemical composition on microstructure and mechanical properties of GH4169 alloy. Heat Treat. Met. 2020, 45, 197–204. [Google Scholar]

- Wang, H.Y.; Zhao, W.; Dong, J.X.; Zhang, M.C.; Yao, Z.H. Research on optimization of GH4169 turbine disc hot die forging technique based on Deform-3D and orthogonal experimental method. Forg. Stamp. Technol. 2013, 38, 13–19. [Google Scholar]

| C | Si | Mn | Cr | B | Al | Mo | Fe | Ti | Nb | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.05 | 0.30 | 0.20 | 19.0 | 0.006 | 0.5 | 3.0 | 18.0 | 1.0 | 5.3 | others |

| T (℃) | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

|---|---|---|---|---|---|---|---|---|

| E (GPa) | 205 | 201 | 196 | 189 | 183 | 176 | 169 | 164 |

| T (℃) | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

|---|---|---|---|---|---|---|---|---|

| μ | 0.3 | 0.3 | 0.3 | 0.3 | 0.31 | 0.31 | 0.32 | 0.34 |

| No | Temperature TC/℃ | Mandrel Rotation Rate n/rpm | Roller Feed Ratio f/mm∙r−1 |

|---|---|---|---|

| 1 | 1050 | 180 | 0.6 |

| 2 | 1050 | 240 | 0.6 |

| 3 | 1050 | 300 | 0.6 |

| 4 | 1050 | 360 | 0.6 |

| 5 | 1050 | 420 | 0.6 |

| 6 | 1050 | 300 | 0.3 |

| 7 | 1050 | 300 | 0.4 |

| 8 | 1050 | 300 | 0.5 |

| 9 | 950 | 300 | 0.6 |

| 10 | 1000 | 300 | 0.6 |

| 11 | 1100 | 300 | 0.6 |

| 12 | 1150 | 300 | 0.6 |

| No | Spinning Temperature Tc (℃) | Roller Nose Radius R (mm) | Mandrel Rotation Rate n (r/min) | Roller Feed Ratio f (mm/r) | Null Columns | Straightness Tolerance ΔY (mm) |

|---|---|---|---|---|---|---|

| A | B | C | D | |||

| 1 | 1 (950) | 1 (4) | 1 (240) | 1 (0.3) | 1 | 0.634 |

| 2 | 1 | 2 (6) | 2 (300) | 2 (0.4) | 2 | 0.491 |

| 3 | 1 | 3 (8) | 3 (360) | 3 (0.5) | 3 | 0.641 |

| 4 | 1 | 4 (10) | 4 (420) | 4 (0.6) | 4 | 1.723 |

| 5 | 2 (1000) | 1 | 2 | 3 | 4 | 0.384 |

| 6 | 2 | 2 | 1 | 4 | 3 | 0.225 |

| 7 | 2 | 3 | 4 | 1 | 2 | 0.474 |

| 8 | 2 | 4 | 3 | 2 | 1 | 0.559 |

| 9 | 3 (1050) | 1 | 3 | 4 | 2 | 0.490 |

| 10 | 3 | 2 | 4 | 3 | 1 | 1.140 |

| 11 | 3 | 3 | 1 | 2 | 4 | 1.365 |

| 12 | 3 | 4 | 2 | 1 | 3 | 0.745 |

| 13 | 4 (1100) | 1 | 4 | 2 | 3 | 0.296 |

| 14 | 4 | 2 | 3 | 1 | 4 | 0.662 |

| 15 | 4 | 3 | 2 | 4 | 1 | 0.419 |

| 16 | 4 | 4 | 1 | 3 | 2 | 0.809 |

| Factor | A | B | C | D |

|---|---|---|---|---|

| T1 | 3.489 | 1.804 | 3.033 | 2.515 |

| T2 | 1.642 | 2.518 | 2.039 | 2.711 |

| T3 | 3.740 | 2.899 | 2.352 | 2.974 |

| T4 | 2.186 | 3.836 | 3.633 | 2.857 |

| t1 | 0.872 | 0.451 | 0.758 | 0.629 |

| t2 | 0.411 | 0.630 | 0.510 | 0.678 |

| t3 | 0.935 | 0.725 | 0.588 | 0.744 |

| t4 | 0.547 | 0.959 | 0.908 | 0.714 |

| Level | 2 | 1 | 2 | 1 |

| R | 2.098 | 2.032 | 1.594 | 0.459 |

| Order | ABCD | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Shu, X.; Cen, Z.; Li, Z.; Ye, B. Effects of Process Parameters on Surface Straightness of Variable-Section Conical Parts during Hot Power Spinning. Appl. Sci. 2021, 11, 8187. https://doi.org/10.3390/app11178187

Liu Y, Shu X, Cen Z, Li Z, Ye B. Effects of Process Parameters on Surface Straightness of Variable-Section Conical Parts during Hot Power Spinning. Applied Sciences. 2021; 11(17):8187. https://doi.org/10.3390/app11178187

Chicago/Turabian StyleLiu, Yanli, Xuedao Shu, Zewei Cen, Zixuan Li, and Bohai Ye. 2021. "Effects of Process Parameters on Surface Straightness of Variable-Section Conical Parts during Hot Power Spinning" Applied Sciences 11, no. 17: 8187. https://doi.org/10.3390/app11178187

APA StyleLiu, Y., Shu, X., Cen, Z., Li, Z., & Ye, B. (2021). Effects of Process Parameters on Surface Straightness of Variable-Section Conical Parts during Hot Power Spinning. Applied Sciences, 11(17), 8187. https://doi.org/10.3390/app11178187