Digital Denture Fabrication: A Technical Note

Abstract

:1. Introduction

2. Advantages of Digital Denture

- More AccurateThe CAD/CAM fabrication process is a more accurate and reproducible denture fabrication technique in comparison to the conventional method;

- More EfficientThe CAD/CAM fabrication process needs a reduced total number of appointments (two or three visits) in comparison to the conventional protocol (more than five visits) and a significantly reduced clinical treatment time for the digital fabrication process (approximately 3.5 h less compared to the conventional protocol);

- Improved Retention

- Teeth ArrangementIn the digital denture workflow, the teeth are arranged on the digital denture design software, and the digital preview of the teeth setup of complete dentures is reviewed and easily modified;

- Remake DenturesThe most beneficial feature of CAD/CAM dentures in comparison to conventional dentures is the stored digital files that allow the fabrication of new prostheses when dentures are lost or damaged. Therefore, the electronic achieving of all clinical data from the patient along with the design of the manufactured prostheses enables making spare or new dentures, in case of breakage or loss, without clinical appointments [16];

- Better Fracture ResistanceThe material used for digital denture fabrication was significantly improved in its properties [17,18]. Increased toughness, ultimate strength, and higher elastic modulus provide clinical benefits regarding the denture base design with minimal thickness, without the common occurrence of denture fractures.

3. Digital Denture Fabrication Procedure

3.1. Step 1. Trial Denture Fabrication

- (1)

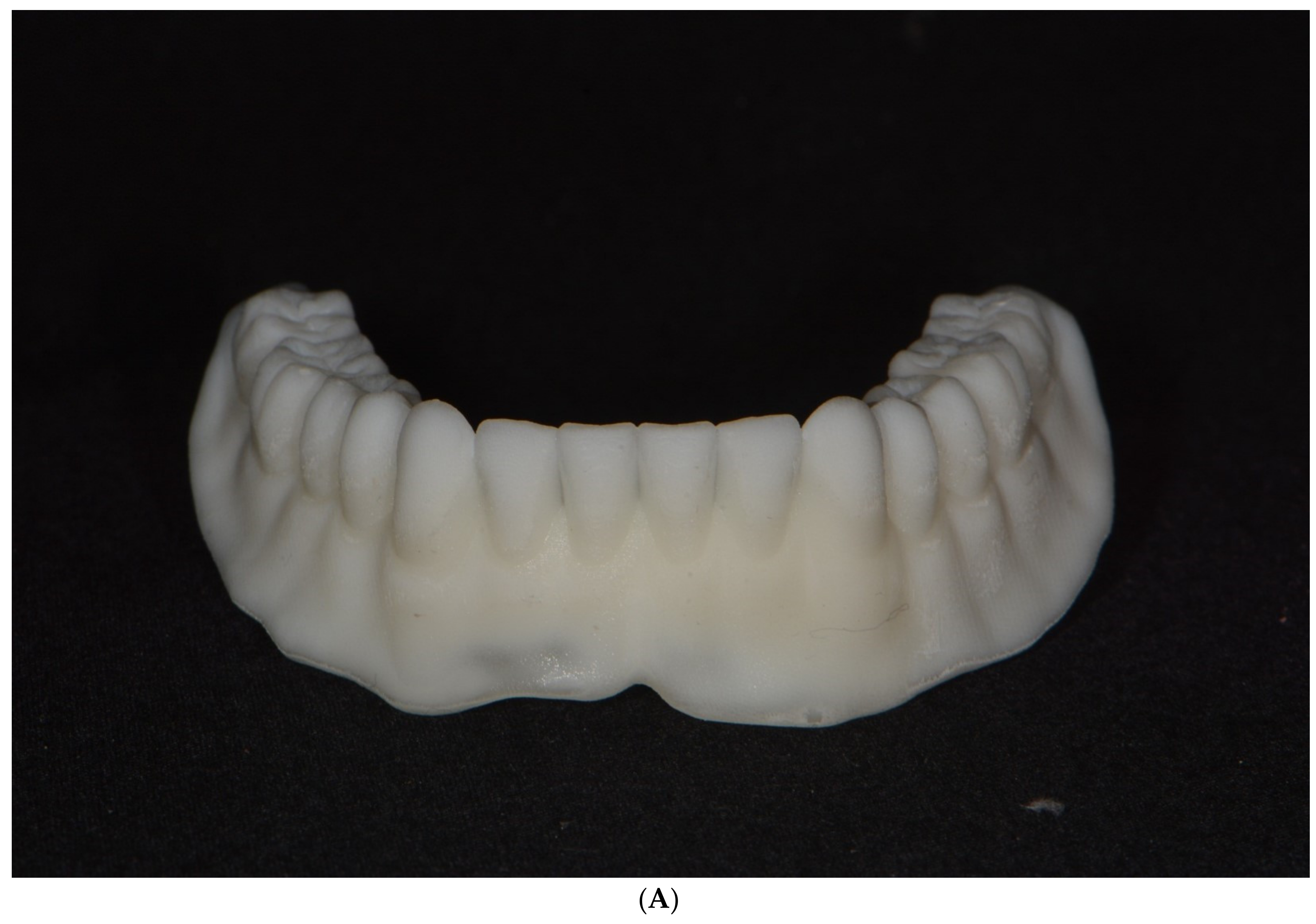

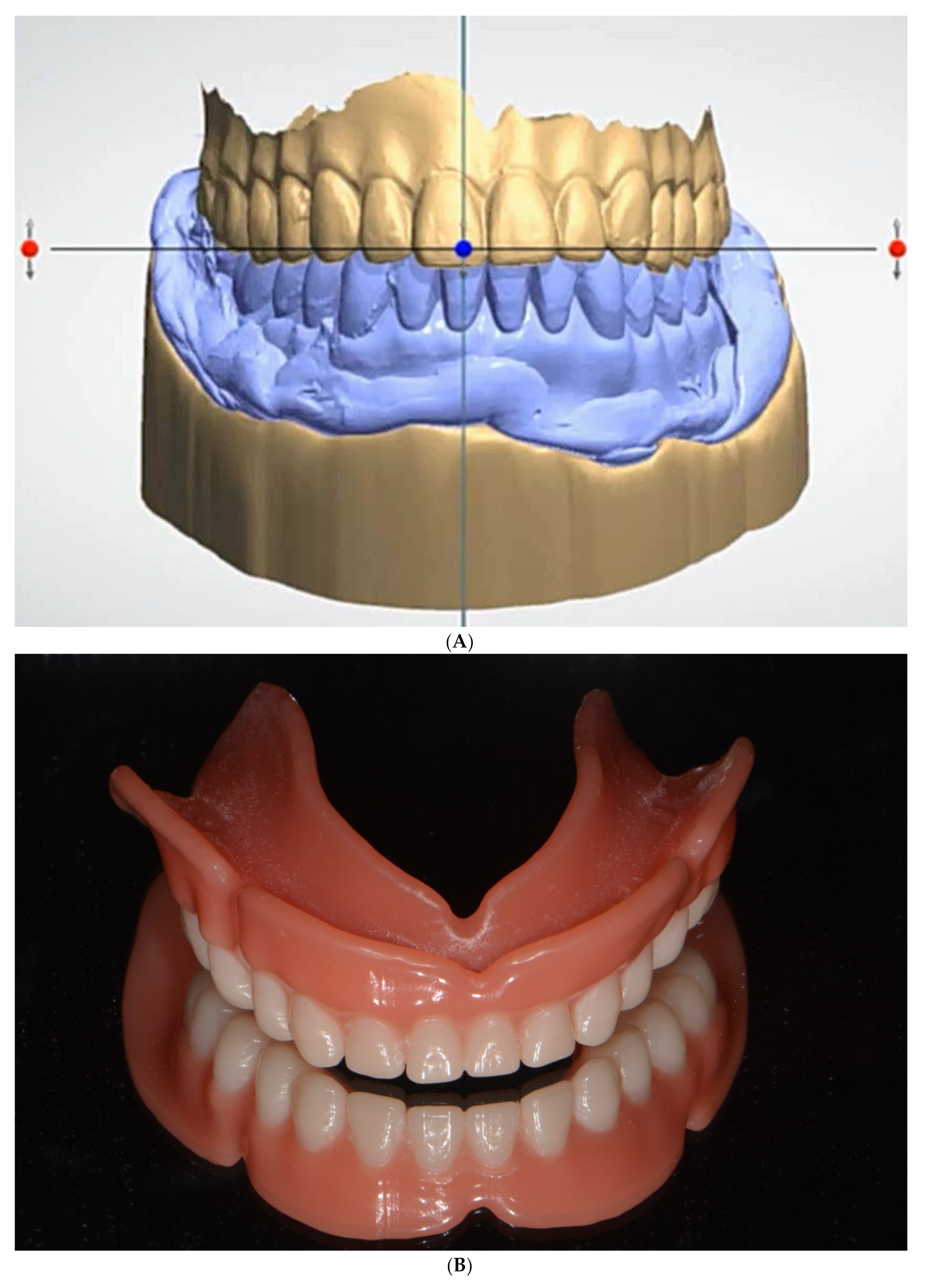

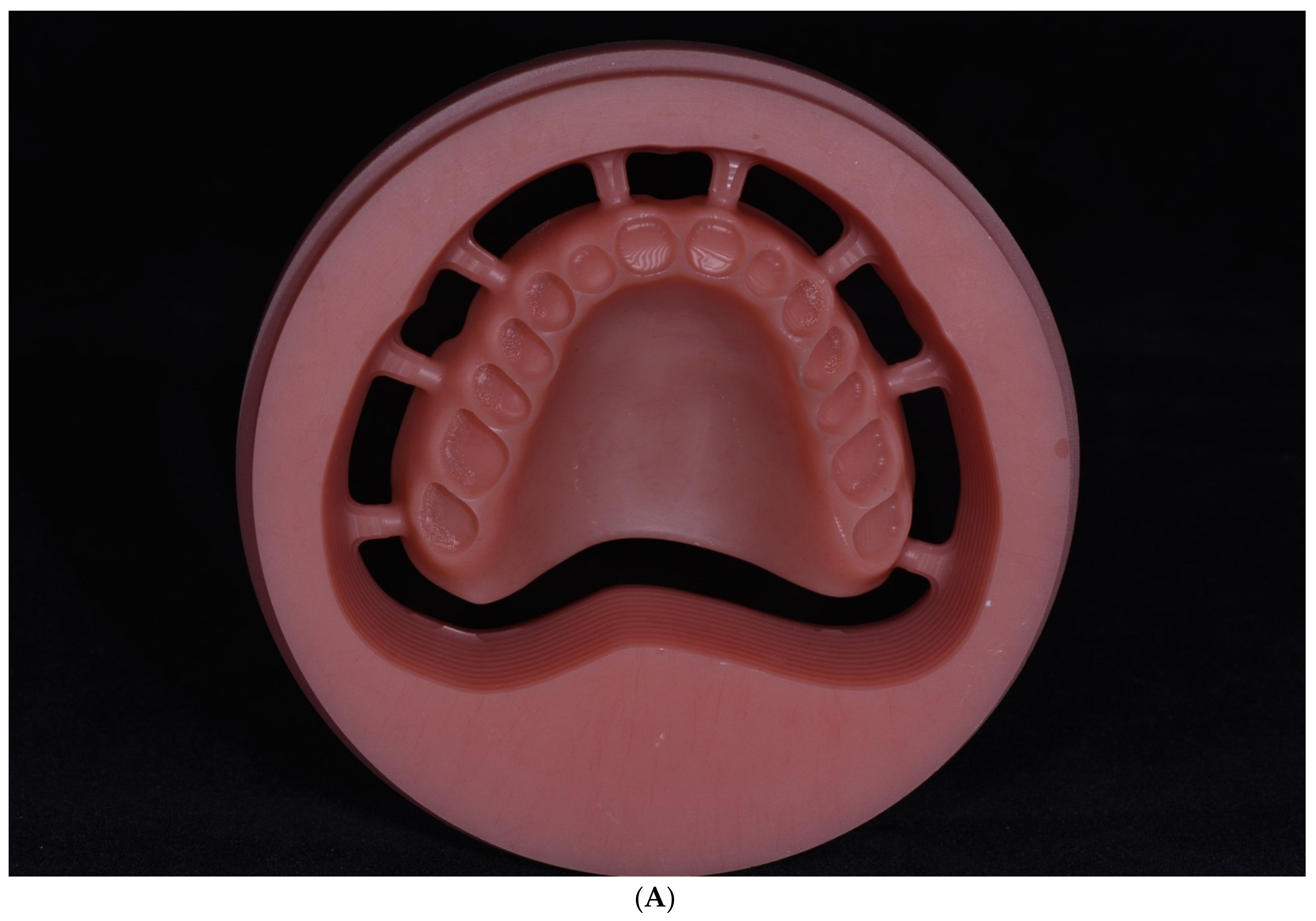

- Trial denture designAfter the images of the edentulous ridge and opposite teeth with the interarch relationship are obtained by recording the digital impression and all the jaw relationships are recorded using an intraoral scanner, trial denture designing begins using the 3Shape Dental software (3Shape, Copenhagen, Denmark). Anatomic structures (incisal papilla, retro-molar pad, and tuberosities) are identified on the edentulous image to correctly place the teeth (Figure 1A). Thereafter, the limit of the future denture base is drawn (Figure 1B). The occlusal plane is determined by considering the jaw relationships, the curve of Spee, and the curve of Wilson. Subsequently, denture teeth are arranged using the denture designing software (Figure 1C). The software contains a library of teeth of different brands and shapes and a function with an automatic setup of tooth position, axis, and height that are matched with the arches and the occlusal plane (Figure 1D);

- (2)

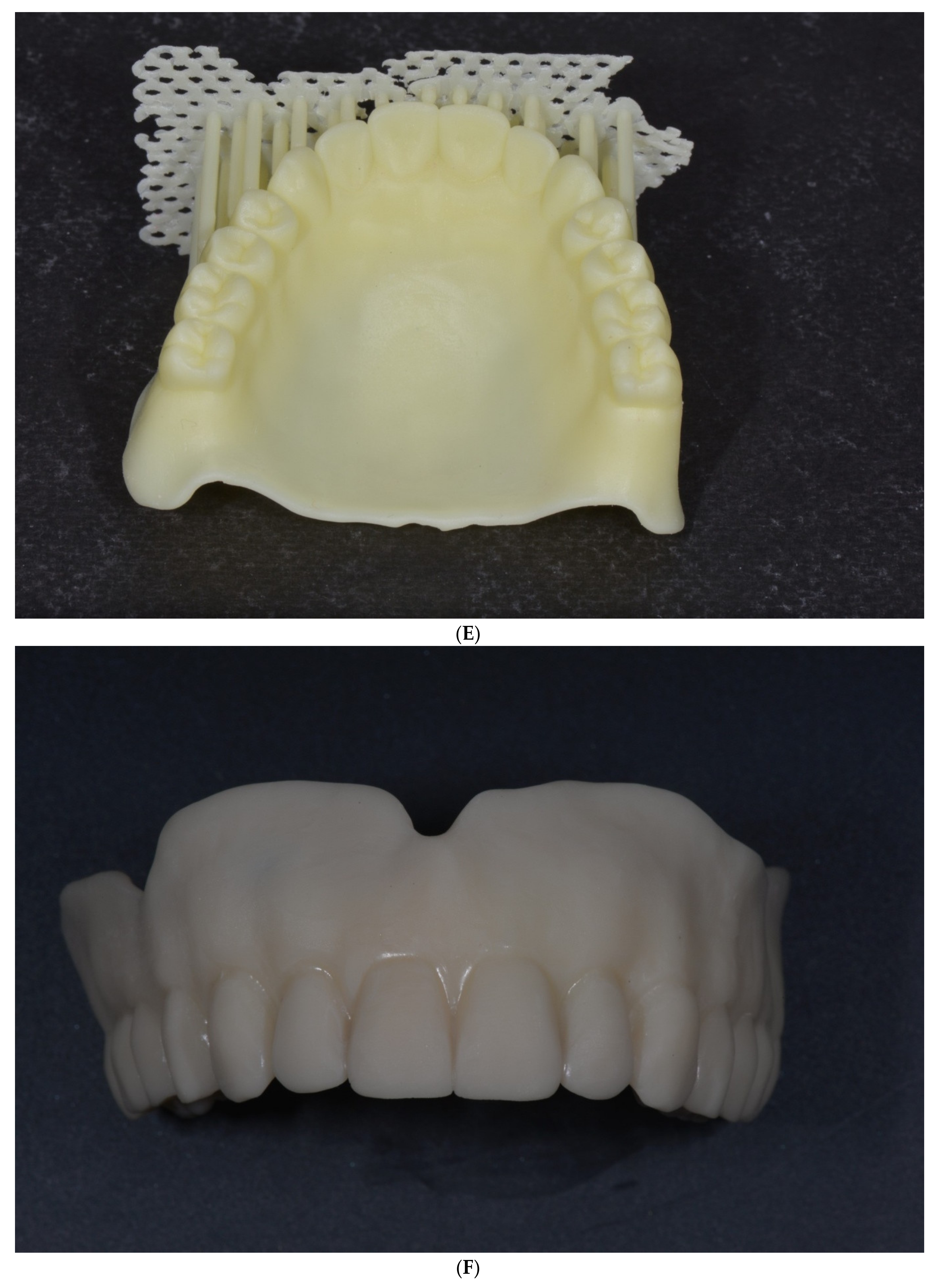

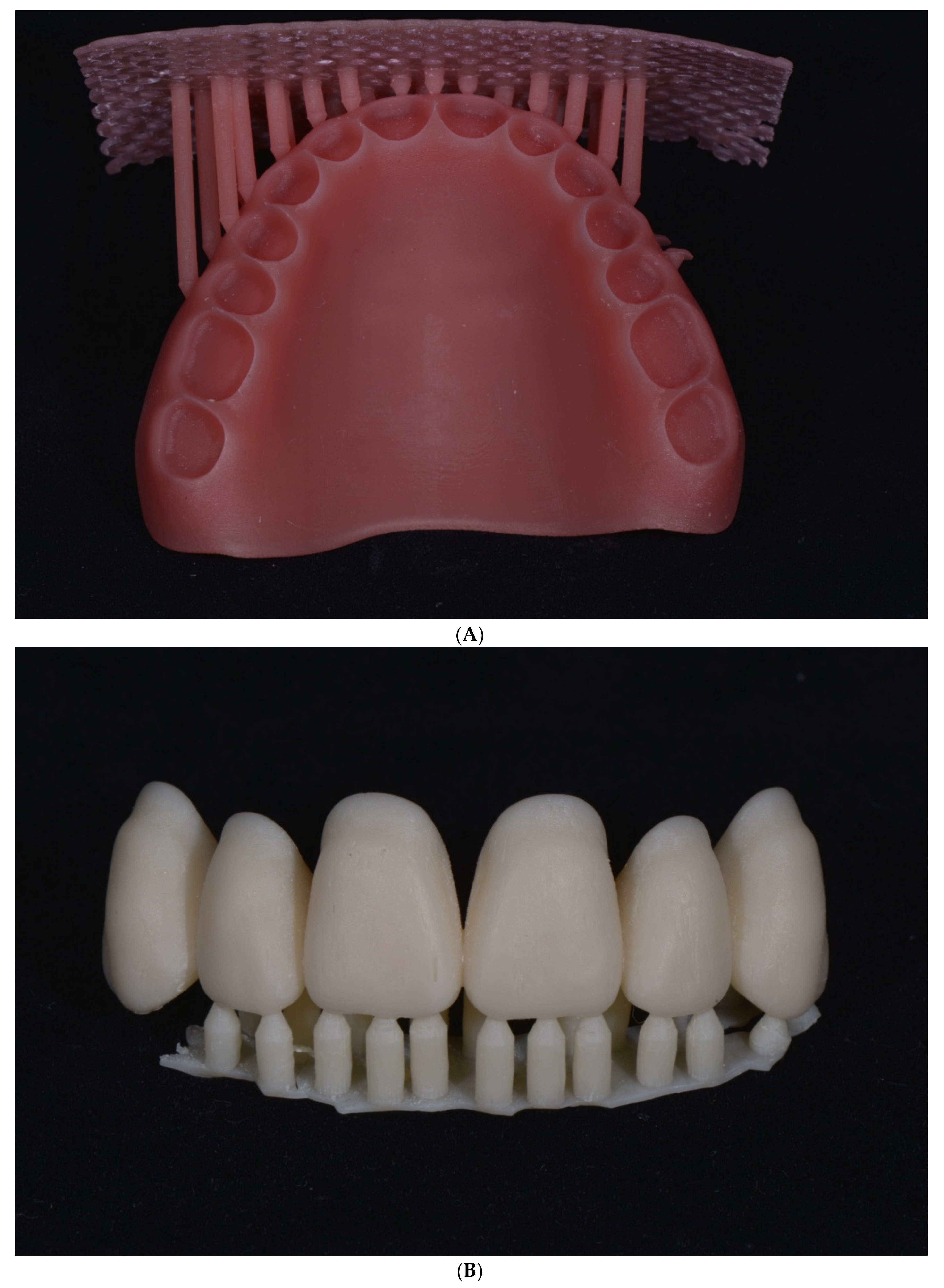

- Fabricating trial dentureAfter the design is finalized, the digital STL files are sent to the three-dimensional (3D) printing machine. The trial denture is 3D printed as a monolithic denture, teeth, and base in one unit (Figure 1E,F);

- (3)

- Verifying jaw relation with trial dentureAt the trial placement, the horizontal and vertical jaw relationships are evaluated with the trial denture.

- -

- Midline regarding the maxillary midline being aligned with the center of the nose;

- -

- Resting interocclusal distance;

- -

- Phonetics and esthetic appearance;

- -

- Vertical dimension at the rest position;

- -

- Facial measurements;

- -

- Lip length in relation to the teeth;

- -

- Lip support;

- -

- Smile line;

- -

- Occlusal plane parallel to the interpupillary line.

- (4)

- Occlusal adjustmentAfter confirming the CR, occlusal adjustment is carried out to achieve a bilateral balanced occlusion.

3.2. Step 2. Final Impression

- (1)

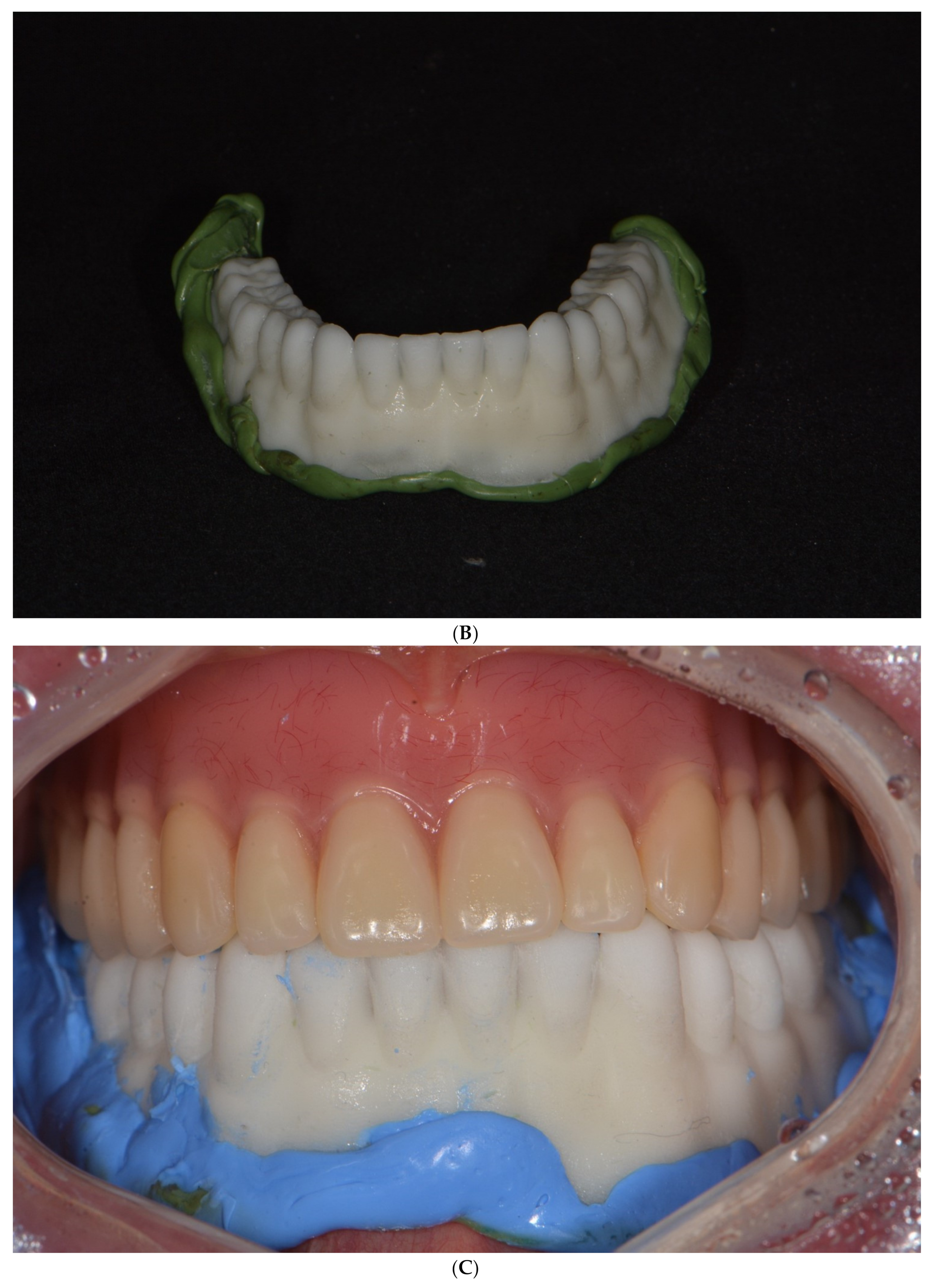

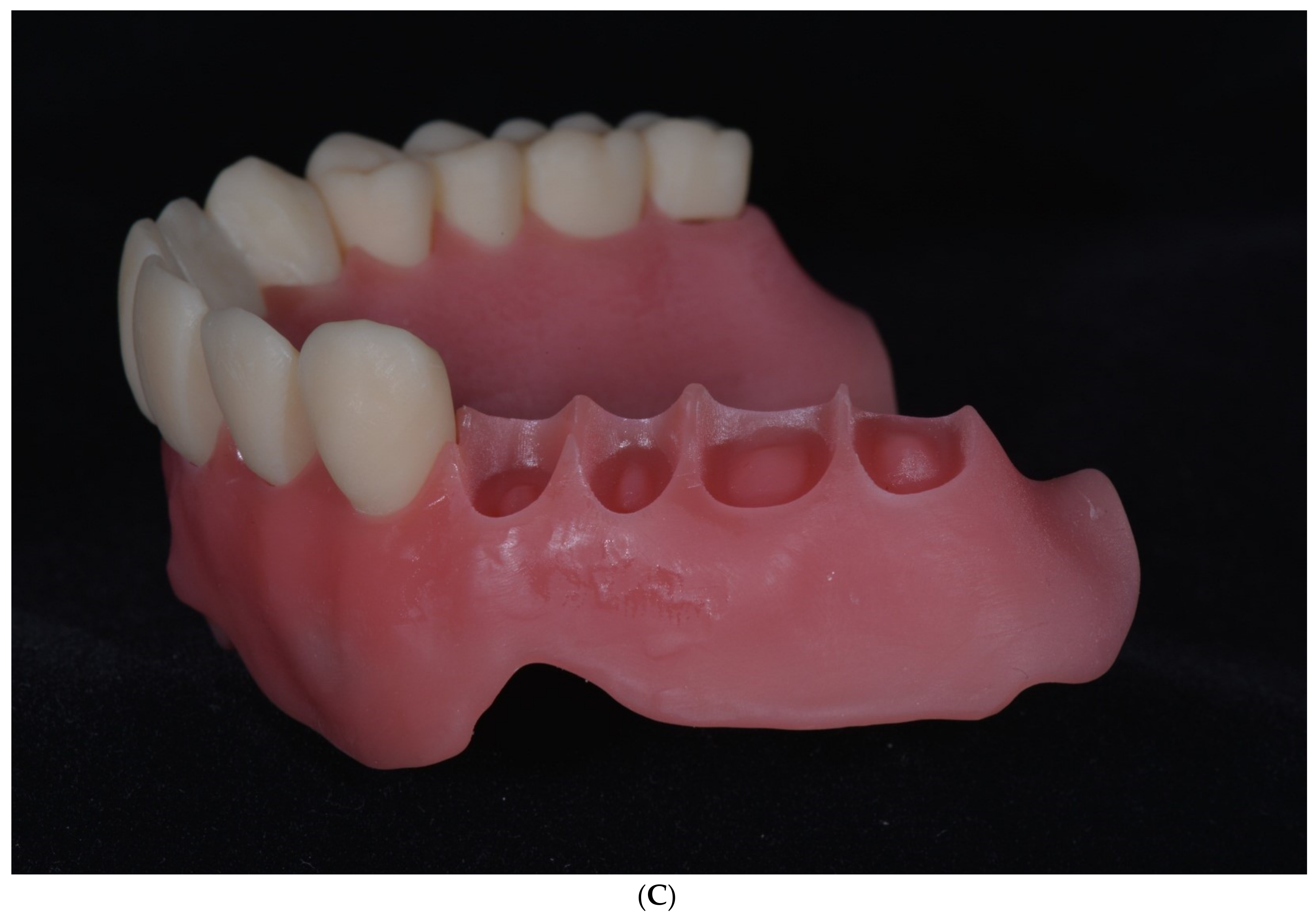

- Border moldingThe trial denture is checked in the mouth to ascertain that the borders are approximately 2 mm short of the vestibular reflections. Border molding is performed by adding a modeling compound to the trial denture borders and moving the tongue, lips, and cheeks for adjustment (Figure 2A,B). The trial denture is adapted closely to the tissues of the vestibule before making the final impression;

- (2)

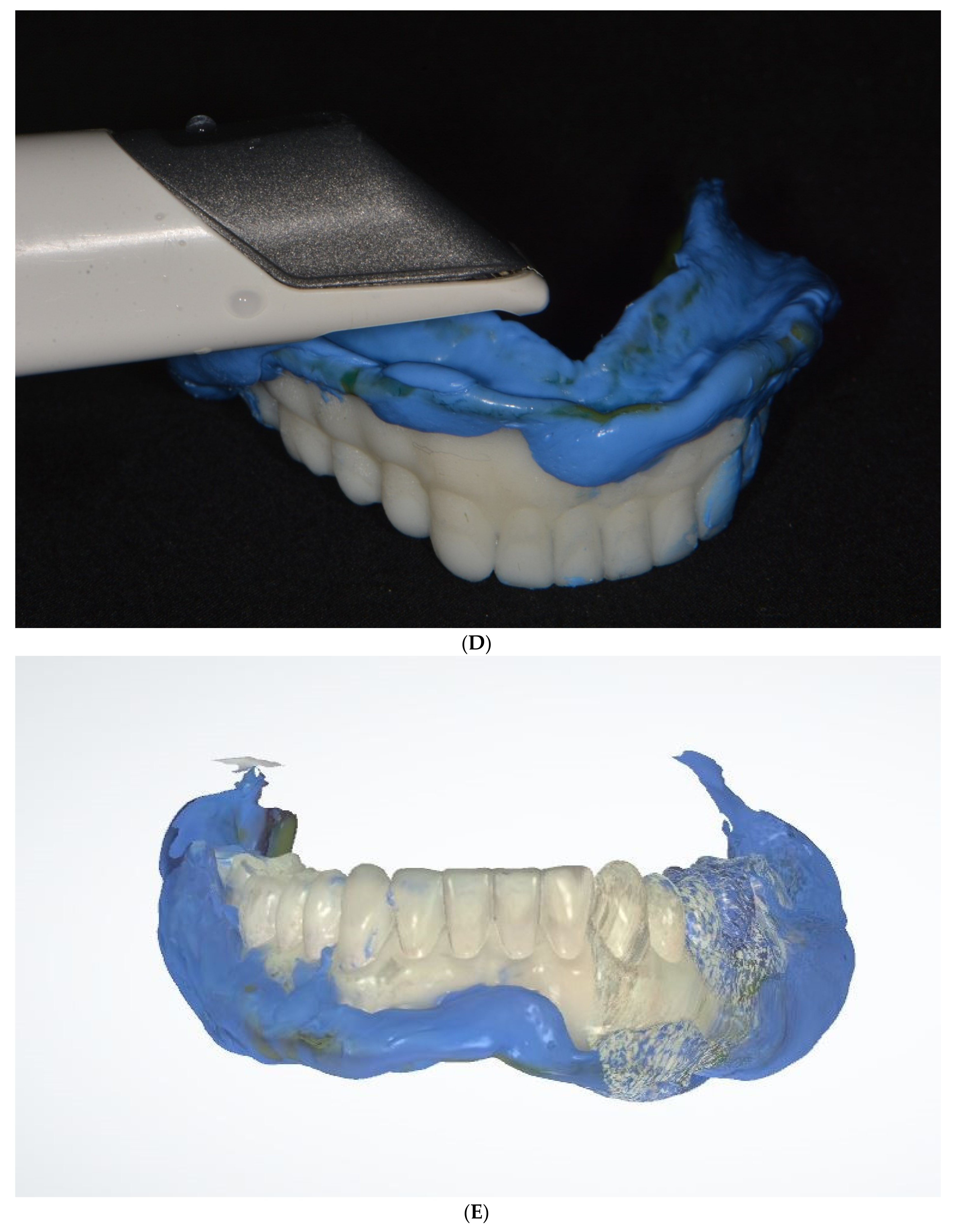

- Recording final impressionThe final impression is made with the border-molded trial denture (Figure 2C). After obtaining the impression, the denture is removed from the mouth and is scanned using an intraoral scanner (Figure 2D). The denture scanning area should include all areas of the denture, such as the denture base, border, teeth, and palate (Figure 2E).

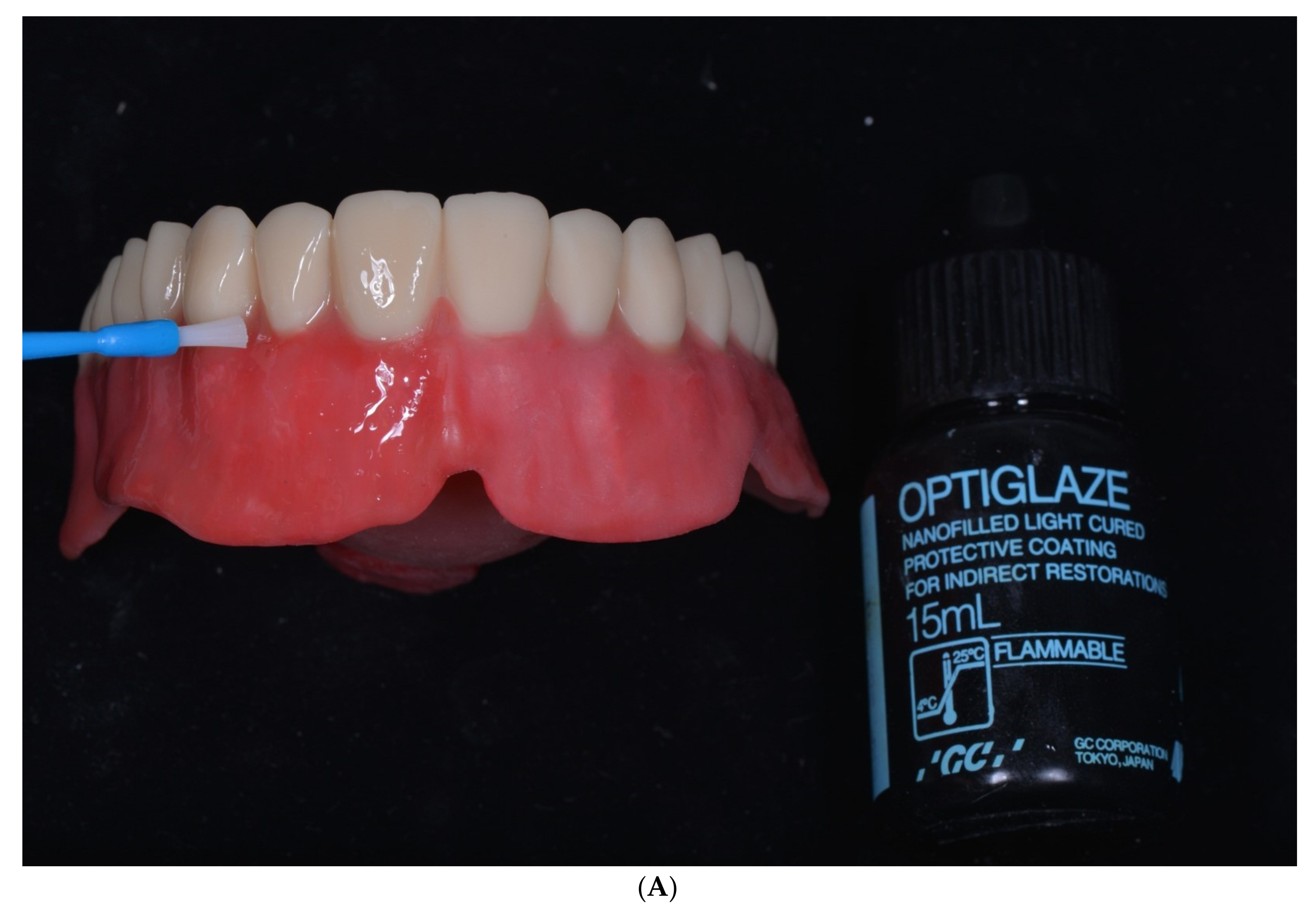

3.3. Step 3. Final Denture Fabrication

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Neumeier, T.T.; Neumeier, H. Digital immediate dentures treatment: A clinical report of two patients. J. Prosthet. Dent. 2016, 116, 314–319. [Google Scholar] [CrossRef] [PubMed]

- Kanazawa, M.; Inokoshi, M.; Minakuchi, S.; Ohbayashi, N. Trial of a CAD/CAM system for fabricating complete dentures. Dent. Mater. J. 2011, 30, 93–96. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goodacre, C.J.; Garbacea, A.; Naylor, W.P.; Daher, T. CAD/CAM fabricated complete dentures: Concepts and clinical methods of obtaining required morphological data. J. Prosthet. Dent. 2012, 107, 34–46. [Google Scholar] [CrossRef]

- Miyazaki, T.; Hotta, Y.; Kunii, J.; Kuriyama, S.; Tamaki, Y. A review of dental CAD/CAM: Current status and future perspectives from 20 years of experience. Dent. Mater. J. 2009, 28, 44–56. [Google Scholar] [CrossRef] [Green Version]

- Alghazzawi, T.F. Advancements in CAD/CAM technology: Options for practical implementation. J. Prosthodont. Res. 2016, 60, 72–84. [Google Scholar] [CrossRef]

- Christensen, G.J. Impressions are changing: Deciding on conventional, digital or digital plus in-offlce milling. J. Am. Dent. Assoc. 2009, 140, 1301–1304. [Google Scholar] [CrossRef] [PubMed]

- Ting-Shu, S.; Jian, S. Intraoral digital impression technique: A review. J. Prosthodont. 2015, 24, 313–321. [Google Scholar] [CrossRef]

- Christensen, G.J. The challenge to conventional impressions. J. Am. Dent. Assoc. 2008, 139, 347–349. [Google Scholar] [CrossRef] [PubMed]

- Pereira, A.L.C.; de Medeiros, A.K.B.; de Sousa Santos, K.; de Almeida, É.O.; Barbosa, G.A.S.; Carreiro, A.D.F.P. Accuracy of CAD-CAM systems for removable partial denture framework fabrication: A systematic review. J. Prosthet. Dent. 2021, 125, 241–248. [Google Scholar] [CrossRef]

- Goodacre, B.J.; Goodacre, C.J.; Baba, N.Z.; Kattadiyil, M.T. Comparison of denture base adaptation between CAD-CAM and conventional fabrication techniques. J. Prosthet. Dent. 2016, 116, 249–256. [Google Scholar] [CrossRef] [PubMed]

- Kattadiyil, M.T.; Goodacre, C.J.; Baba, N.Z. CAD/CAM complete dentures: A review of two commercial fabrication systems. J. Calif. Dent. Assoc. 2013, 41, 407–416. [Google Scholar]

- Artopoulos, A.; Juszczyk, A.S.; Rodriquez, J.M.; Clark, R.K.; Radford, D.R. Three-dimensional processing deformation of three denture base materials. J. Prosthet. Dent. 2013, 110, 481–487. [Google Scholar] [CrossRef]

- Soltanzadeh, P.; Suprono, M.S.; Kattadiyil, M.T.; Goodacre, C.; Gregorius, W. An in vitro investigation of accuracy and fit of conventional and CAD/CAM removable partial denture frameworks. J. Prosthet. Dent. 2019, 28, 547–555. [Google Scholar] [CrossRef]

- Lee, C.; Dusmukhamedov, S.; Fang, Y.Q.; Jeong, S.M.; Choi, B.H. Accuracy of the provisional prosthesis scanning technique versus a conventional impression technique on completely edentulous arches. Appl. Sci. 2021, 11, 7182. [Google Scholar] [CrossRef]

- AlHelal, A.; AlRumaih, H.S.; Kattadiyil, M.T.; Baba, N.Z.; Goodacre, C.J. Comparison of retention between maxillary milled and conventional denture bases: A clinical study. J. Prosthet. Dent. 2017, 117, 233–238. [Google Scholar] [CrossRef]

- Lo, R.L.; Salamini, A. Removable complete digital dentures: A workflow that integrates open technologies. J. Prosthet. Dent. 2018, 119, 727–732. [Google Scholar]

- Lee, D.H.; Lee, J.S. Comparison of flexural strength according to thickness between CAD/CAM denture base resins and conventional denture base resins. J. Dent. Rehabil. Appl. Sci. 2020, 36, 183–195. [Google Scholar] [CrossRef]

- Sun, Y.; Tian, W.; Zhang, T.; Chen, P.; Li, M. Strength and toughness enhancement in 3D printing via bioinspired tool path. Mater. Des. 2020, 185, 108239. [Google Scholar] [CrossRef]

- Gilboa, I.; Cardash, H.S. An alternative approach to the immediate overdenture. J. Prosthodont. 2009, 18, 71–75. [Google Scholar] [CrossRef]

- Shah, F.K.; Gebreel, A.; Elshokouki, A.H.; Habib, A.A.; Porwal, A. Comparison of immediate complete denture, tooth and implant-supported overdenture on vertical dimension and muscle activity. J. Adv. Prosthodont. 2012, 4, 61–71. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Caputi, S.; Murmura, G.; Ricci, L.; Varvara, G.; Sinjari, B. Immediate denture fabrication: A clinical report. Ann. Di Stomatol. 2014, 4, 273–277. [Google Scholar]

- Soni, A. Use of loose fitting copper bands over extremely mobile teeth while making impressions for immediate dentures. J. Prosthet. Dent. 1999, 81, 638–639. [Google Scholar] [CrossRef]

- Fang, J.H.; An, X.; Jeong, S.M.; Choi, B.H. Digital immediate denture: A clinical report. J. Prosthet. Dent. 2018, 119, 698–701. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dusmukhamedov, S.; Lee, C.-N.; Jeong, S.-M.; Choi, B.-H. Digital Denture Fabrication: A Technical Note. Appl. Sci. 2021, 11, 8093. https://doi.org/10.3390/app11178093

Dusmukhamedov S, Lee C-N, Jeong S-M, Choi B-H. Digital Denture Fabrication: A Technical Note. Applied Sciences. 2021; 11(17):8093. https://doi.org/10.3390/app11178093

Chicago/Turabian StyleDusmukhamedov, Shavkat, Chu-Nui Lee, Seung-Mi Jeong, and Byung-Ho Choi. 2021. "Digital Denture Fabrication: A Technical Note" Applied Sciences 11, no. 17: 8093. https://doi.org/10.3390/app11178093

APA StyleDusmukhamedov, S., Lee, C.-N., Jeong, S.-M., & Choi, B.-H. (2021). Digital Denture Fabrication: A Technical Note. Applied Sciences, 11(17), 8093. https://doi.org/10.3390/app11178093