Monitoring of Preload Variation of Linear Guide Positioning Stage Using Artificial Neural Network

Abstract

:1. Introduction

2. Preload and Rigidity of Linear Guide

2.1. Preload Amount

2.2. Static Radial Compressive Tests

2.3. Rigidity of Linear Guide

3. Dynamic Characteristics of Positioning Stage

3.1. Structure Rigidity of the Stage

3.2. Fundamental Vibration Modes of Stage

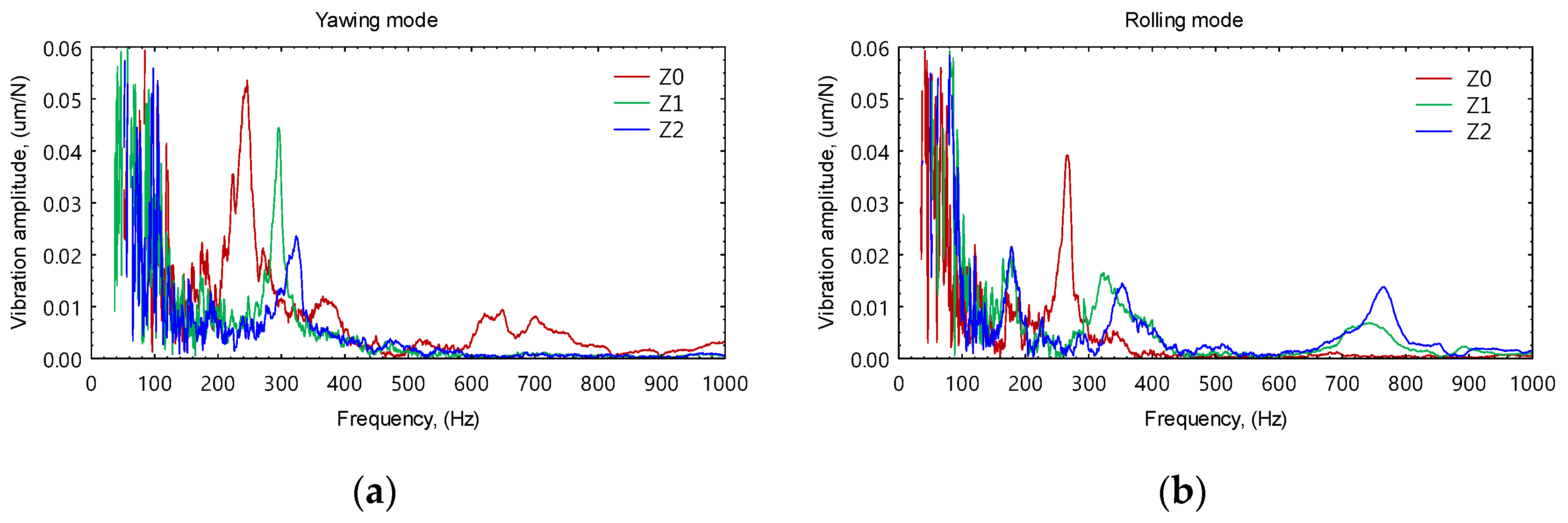

3.3. Variation of Modal Frequency with Preload

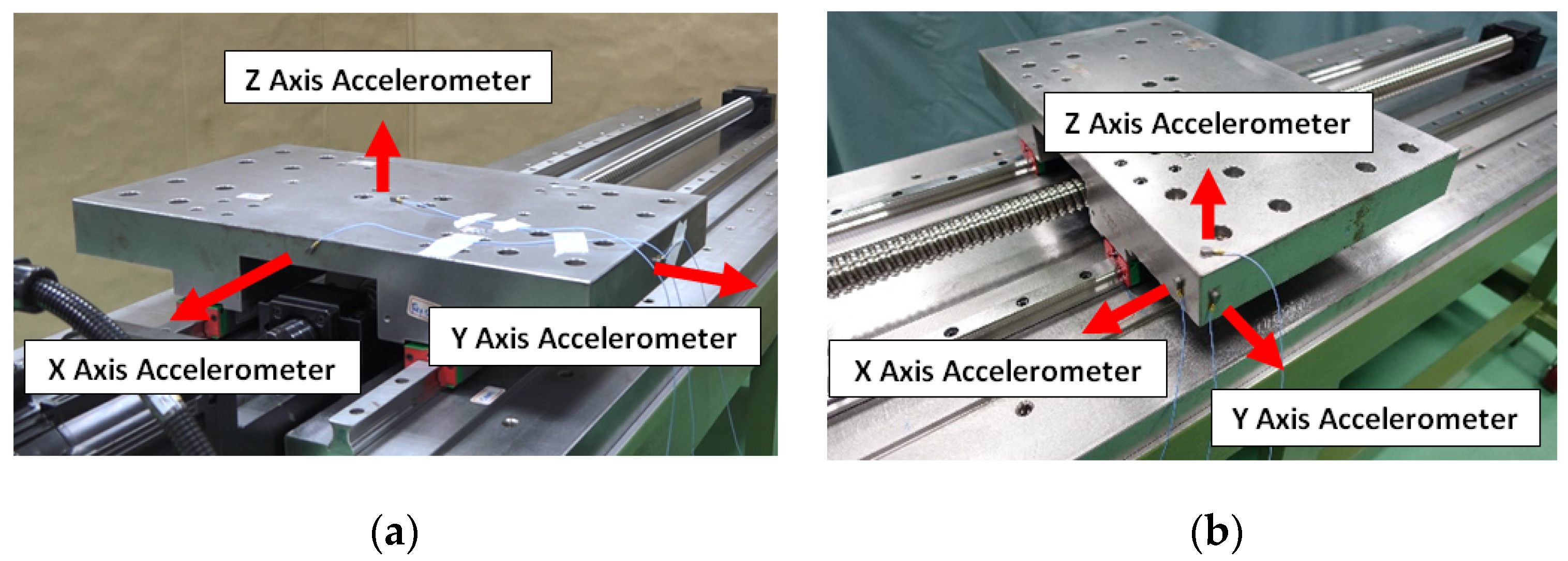

3.4. Vibration of Stage in Motion

3.5. Relationship between Stage Rigidity and Vibration Level

3.6. Stage Vibration against Linear Guide Preload and Feed Rate

4. Prediction of Linear Guide Preload—ANN Modeling

4.1. Preload Variation of Linear Guide

- (1)

- Case I: Stage assembled with four sliding blocks or carriages preloaded at heavy or high levels. Essentially, the interference at the rolling interface was about 8 μm for achieving high preload and the initial positioning stage rigidity was 2020 N/μm.

- (2)

- Case II: Stage with four sliding carriages preloaded at the medium level, which was generated by making an interference of 5 μm in the ball grooves of the linear guide. The stage rigidity was rated as 1696 N/μm.

- (3)

- Case III: Stage with four sliding carriages with low or light preloads. A light preload linear guide could be achieved by reducing the interference at the rolling interface to 1–2 μm. The structural rigidity of the stage was rated as 1176 N/μm.

4.2. Artificial Neural Network Model

4.2.1. ANN Architecture

4.2.2. Determination of the Effectiveness of Prediction Models

4.3. ANN Predictive Models

4.4. Evaluation of ANN Model

- (1)

- Case IV: Stage with three high preload and one low preload sliding blocks. This condition simulated one of the linear guide blocks subjected to severe wear at the rolling interfaces, and hence the preload decreased owing to the reduction of interference. This was also regarded as a moderate abnormal state, and the overall rigidity of the stage was 1809 N/μm, which was reduced by approximately 10% from an initially high preloaded stage.

- (2)

- Case V: Stage with two high preload and two low preload sliding blocks. This condition simulated two linear guides in a severe failure state with uneven wear at the rolling interface, which greatly reduced the preload of the two carriages from high to low values. In this severely abnormal state, the overall rigidity of the stage was 1598 N/μm, which was reduced by approximately 21%, from an initially high preloaded stage.

- (3)

- Case VI: Stage with three sliding blocks at medium preload and one low preload. This was intended to simulate the failure of the linear guide blocks subjected to severe wear at the rolling interfaces, yielding a preload loss of approximately 10%. In this case, in a moderately abnormal state, the overall rigidity of the stage was 1566 N/μm, which was reduced by approximately 10% from an initially medium preloaded stage.

4.5. Application Scenario of ANN Model

- (1)

- Scenario 1, a normal preload condition is predicted for the X axis linear guide with green signs. The ANN models predict the rigidity at the value of 2020 N/um without preload decay in a short-term operation.

- (2)

- Scenario 2, a moderate preload degradation of the Y axis linear guide is predicted based on the measured vibration features. In this case, the linear guide is preloaded at the medium level (Z1), as in case (II), which is also considered to have a preload loss of 18% from the highest preload stage with a yellow sign.

- (3)

- Scenario 3, a severe preload degradation of the Z axis linear guide is predicted based on the measured vibration features, with a red sign. In this case, the linear guide is preloaded at a low level (Z0), as in case (III), which can be caused by the surface wear of the rolling elements or ball grooves. The decrease in the interference at the rolling interface reduces the preload by 30% or 42% from the initial medium (Z1) or the highest preload state (Z2).

5. Conclusions

- The vibration characteristics of the positioning stage structure in the static state and in motion are closely related to the linear guide preload. This shows that the vibration level of the high preload positioning stage is higher than that of the low preload positioning stage. The variation in the linear guide preload was determined and affected by the change in the interference between the rolling balls and the raceway. Basically, interference can be reduced by wearing out the rolling interface, which further causes a preload loss in linear guides with service time. This concept provides the basic knowledge for monitoring the degradation of a linear guide preload.

- The ANN predictive models were shown to have good prediction performance in all training datasets collected from experiments, with an accuracy of 96.5%. This implies that the ANN models perform well in predicting the preload conditions of linear guides with consistent sliding blocks. In the verification dataset, the average percentage prediction error of the stage rigidity is approximately 8.54–11.23%, which is slightly higher than that in the training phase. This can be ascribed to the fact that the stage with an unevenly distributed preload in the sliding blocks easily induces vibration with more fluctuation, which ultimately affects the prediction accuracy.

- The results of this study can provide a reference basis for the future development of a positioning stage preload intelligent monitoring system. The monitoring system output display was established using GUI from an SQL Server. In the current study, a monitoring system has been designed so that the prediction results from the ANN and the rest of the process are easily interpreted by the user to maintain the positioning stage in optimum performance. Future work in this field would entail incorporating online monitoring concepts to obtain real-time prediction values, that are updated and displayed quickly.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Datta, J.; Farhang, K. A nonlinear model for structural vibrations in rolling element bearings: Part I—Derivation of governing equations. J. Tribol. 1997, 119, 323–331. [Google Scholar] [CrossRef]

- Ohta, H.; Hayashi, E. Vibration of linear guideway type recirculating linear ball bearings. J. Sound Vib. 2000, 235, 847–861. [Google Scholar] [CrossRef]

- Chang, J.C.; Wu, J.S.S.; Hung, J.P. Characterization of the dynamic behavior of a linear guideway mechanism. Struct. Eng. Mech. 2007, 25, 1–10. [Google Scholar] [CrossRef]

- Sun, W.; Kong, X.; Wang, B.; Li, X. Statics modeling and analysis of linear rolling guideway considering rolling balls contact. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2015, 229, 168–179. [Google Scholar] [CrossRef]

- Hung, J.P.; Lai, Y.L.; Lin, C.Y.; Lo, T.L. Modeling the machining stability of a vertical milling machine under the influence of the preloaded linear guide. Int. J. Mach. Tools Manuf. 2011, 51, 731–739. [Google Scholar] [CrossRef]

- Hung, J.P.; Lin, W.Z.; Chen, Y.J.; Luo, T.L. Investigation of the machining stability of a milling machine with hybrid guideway systems. Appl. Sci. 2016, 6, 76. [Google Scholar] [CrossRef] [Green Version]

- Deng, C.; Yin, G.; Fang, H.; Meng, Z. Dynamic characteristics optimization for a whole vertical machining center based on the configuration of joint stiffness. Int. J. Adv. Manuf. Technol. 2015, 76, 1225–1242. [Google Scholar] [CrossRef]

- Tao, W.; Zhong, Y.; Feng, H.; Wang, Y. Model for wear prediction of roller linear guides. Wear 2013, 305, 260–266. [Google Scholar] [CrossRef]

- Zou, H.T.; Wang, B.L. Investigation of the contact stiffness variation of linear rolling guides due to the effects of friction and wear during operation. Tribol. Int. 2015, 92, 472–484. [Google Scholar] [CrossRef]

- Wang, X.Y.; Zhou, C.G.; Ou, Y. Experimental analysis of the wear coefficient for the rolling linear guide. Adv. Mech. Eng. 2019, 11. [Google Scholar] [CrossRef]

- Zhou, C.G.; Ren, S.H.; Feng, H.T.; Shen, J.W.; Zhang, Y.S.; Chen, Z.T. A new model for the preload degradation of linear rolling guide. Wear 2021, 482–483, 203963. [Google Scholar]

- Wei, W.; Yimin, Z.; Changyou, L.; Hao, W.; Yanxun, Z. Effects of wear on dynamic characteristics and stability of linear guides. Meccanica 2017, 52, 2899–2913. [Google Scholar] [CrossRef]

- Li, C.; Xu, M.; He, G.; Zhang, H.; Liu, Z.; He, D.; Zhang, Y. Time-dependent nonlinear dynamic model for linear guideway with crowning. Tribol. Int. 2020, 151, 106413. [Google Scholar] [CrossRef]

- Wang, W.; Shen, G.; Zhang, Y.; Zhu, Z.; Li, C.; Lu, H. Dynamic reliability analysis of mechanical system with wear and vibration failure modes. Mech. Mach. Theory 2021, 163, 104385. [Google Scholar] [CrossRef]

- Lee, J.; Wu, F.; Zhao, W.; Ghaffari, M.; Liao, L.; Siegel, D. Prognostics and health management design for rotary machinery systems—reviews, methodology and applications. Mech. Syst. Signal Process. 2014, 42, 314–334. [Google Scholar] [CrossRef]

- Pellegrino, J.; Justiniano, M.; Raghunathan, A.; Weiss, B.A. Measurement science road map for prognostics and health management for smart manufacturing systems. In NIST Advanced Manufacturing Seriess (AMS); National Institute of Standards and Technology: Gaithersburg, MD, USA, 2016. [Google Scholar]

- Vogl, G.W.; Weiss, B.A.; Helu, M. A review of diagnostic and prognostic capabilities and best practices for manufacturing. J. Intell. Manuf. 2019, 30, 79–95. [Google Scholar] [CrossRef] [PubMed]

- Bin, G.F.; Gao, J.J.; Li, X.J.; Dhillon, B.S. Early fault diagnosis of rotating machinery based on wavelet packets—Empirical mode decomposition feature extraction and neural network. Mech. Syst. Signal Process. 2012, 27, 696–711. [Google Scholar] [CrossRef]

- Peng, Z.K.; Peter, W.T.; Chu, F.L. A comparison study of improved Hilbert–Huang transform and wavelet transform: Application to fault diagnosis for rolling bearing. Mech. Syst. Signal Process. 2005, 19, 974–988. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, J. Multi-fault diagnosis for rolling element bearings based on ensemble empirical mode decomposition and optimized support vector machines. Mech. Syst. Signal Process. 2013, 41, 127–140. [Google Scholar] [CrossRef]

- Ali, J.B.; Fnaiech, N.; Saidi, L.; Chebel-Morello, B.; Fnaiech, F. Application of empirical mode decomposition and artificial neural network for automatic bearing fault diagnosis based on vibration signals. Appl. Acoust. 2015, 89, 16–27. [Google Scholar]

- Lawbootsa, S.; Chommaungpuck, P.; Srisertpol, J. Linear bearing fault detection in operational condition using artificial neural network. In ITM Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 24, p. 01004. [Google Scholar]

- Samanta, B.; Al-Balushi, K.R.; Al-Araimi, S.A. Artificial neural networks and genetic algorithm for bearing fault detection. Soft Comput. 2006, 10, 264–271. [Google Scholar] [CrossRef]

- Wang, H.; Chen, P. Intelligent diagnosis method for rolling element bearing faults using possibility theory and neural network. Comput. Ind. Eng. 2011, 60, 511–518. [Google Scholar] [CrossRef]

- Zarei, J.; Tajeddini, M.A.; Karimi, H.R. Vibration analysis for bearing fault detection and classification using an intelligent filter. Mechatronics 2014, 24, 151–157. [Google Scholar] [CrossRef]

- Rai, A.; Upadhyay, S.H. A review on signal processing techniques utilized in the fault diagnosis of rolling element bearings. J. Tribol. 2016, 96, 289–306. [Google Scholar] [CrossRef]

- Hung, J.P.; Lin, C.Y.; Luo, T.L. Fault detection of linear guide preload of a positioning stage with vibration–acoustic analysis. J. Fail. Anal. Prev. 2011, 11, 684–692. [Google Scholar] [CrossRef]

- Jin, W.; Chen, Y.; Lee, J. Methodology for ball screw component health assessment and failure analysis. In International Manufacturing Science and Engineering Conference; American Society of Mechanical Engineers: New York, NY, USA, 2013; Volume 55461, p. V002T02A031. [Google Scholar]

- Bianchini, C.; Immovilli, F.; Cocconcelli, M.; Rubini, R.; Bellini, A. Fault diagnosis of linear bearings in brushless ac linear motors. In Proceedings of the 2009 IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Cargese, France, 31 August–3 September 2009; pp. 1–6. [Google Scholar]

- Chommaungpuck, P.; Lawbootsa, S.; Srisertpol, J. Fault detection of linear bearing in auto core adhesion mounting machine using artificial neural network. WSEAS Trans. Syst. Control 2019, 14, 31–42. [Google Scholar]

- Chommuangpuck, P.; Wanglomklang, T.; Srisertpol, J. Fault detection and diagnosis of linear bearing in auto core adhesion mounting machines based on condition monitoring. Syst. Sci. Control Eng. 2021, 9, 290–303. [Google Scholar] [CrossRef]

- Feng, H.; Chen, R.; Wang, Y. Feature extraction for fault diagnosis based on wavelet packet decomposition: An application on linear rolling guide. Adv. Mech. Eng. 2018, 10. [Google Scholar] [CrossRef] [Green Version]

- Sharma, A.; Amarnath, M.; Kankar, P.K. Feature extraction and fault severity classification in ball bearings. J. Vib. Control 2016, 22, 176–192. [Google Scholar] [CrossRef]

- Cui, L.; Jin, Z.; Huang, J.; Wang, H. Fault severity classification and size estimation for ball bearings based on vibration mechanism. IEEE Access 2019, 7, 56107–56116. [Google Scholar] [CrossRef]

- Kankar, P.K.; Sharma, S.C.; Harsha, S.P. Fault diagnosis of ball bearings using machine learning methods. Expert Syst. Appl. 2011, 38, 1876–1886. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, Y.; Zhou, J. A novel bearing fault diagnosis model integrated permutation entropy, ensemble empirical mode decomposition and optimized SVM. Measurement 2015, 69, 164–179. [Google Scholar] [CrossRef]

- Sakai, Y.; Tanaka, T. Influence of lubricant on nonlinear vibration characteristics of linear rolling guideway. J. Tribol. 2020, 144, 106124. [Google Scholar] [CrossRef]

- Hiwin Technologies Corp. Linear Guideway Technical Information. Available online: https://www.hiwin.com/pdf/linear_guid.eway.pdf (accessed on 15 January 2020).

- Brewe, D.E.; Hamrock, B.J. Simplified solution for elliptical-contact deformation between two elastic solid. J. Lubr. Technol. 1997, 99, 485–487. [Google Scholar] [CrossRef]

- Greenwood, J.A. Analysis of elliptical Herztian contacts. Tribol. Int. 1997, 30, 235–237. [Google Scholar] [CrossRef]

- Chang, J.C.; Hung, J.P. Analytical and finite element modeling of the dynamic characteristics of a linear feeding stage with different arrangements of rolling guides. Math. Probl. Eng. 2014, 2014, 454156. [Google Scholar] [CrossRef]

- Pedley, M. Tilt sensing using a three-axis accelerometer. Free. Semicond. Appl. Note 2013, 1, 2012–2013. [Google Scholar]

- TIBCO Software Inc. TIBCO Statistica. Available online: http://www.statsoft.com/Products/STATISTICA/Automated-Neural-Networks (accessed on 11 November 2018).

| Item | Description |

|---|---|

| Contact configuration | DB type |

| The size of block (length, width, height) | 61 × 48 × 34 mm |

| Nominal diameter of steel ball, Db | 4.76 mm |

| Contact angle, β | 45° |

| Number of grooves | 4 |

| Dynamic load capacity, C | 34.96 kN |

| Light preload, Z0 | (0–0.02 C) |

| Medium preload, Z1 | (0.05–0.07 C) |

| Heavy preload, Z2 | (0.10–0.12 C) |

| Static load capacity, Co | 43.94 kN |

| Preload Level | Preload Amount (N) | Radial Rigidity (kN/µm) | ||

|---|---|---|---|---|

| Hertz Theory | Experiments | |||

| Low, Z0 | 0.02 C | 699 | 295 | 308 |

| Medium, Z1 | 0.07 C | 2447 | 448 | 472 |

| High, Z2 | 0.12 C | 4195 | 536 | 536 |

| Vibration Mode | Stage Modal Frequency (Hz) | |||||

|---|---|---|---|---|---|---|

| Low Preload | Medium Preload | High Preload | ||||

| FEM | Experiment | FEM | Experiment | FEM | Experiment | |

| Yawing | 249 | 246 | 314 | 295 | 345 | 323 |

| Rolling | 279 | 266 | 354 | 323 | 393 | 352 |

| Pitching | 501 | 626 | 653 | 671 | 730 | 781 |

| Stage Condition | Stage Rigidity (N/μm) | Preload Amount of the Sliding Blocks |

|---|---|---|

| Case I | 2020 | All the four blocks were preloaded at highest level (Z2) |

| Case II | 1696 | All the four blocks were preloaded at medium level (Z1) |

| Case III | 1176 | All the four blocks were preloaded at medium level (Z0) |

| Case IV | 1809 | Three blocks with high preload and one with low preload |

| Case V | 1598 | Two blocks with high preload and the other two with low preload |

| Input Variables | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| X-RMS | Y-RMS | Z-RMS | XYZ -RMS | Pitching RMS | Rolling RMS | Yawing RMS | Feed Rate | Stage Rigidity | Initial STATE * |

| 0.0328 | 0.0298 | 0.0334 | 0.0555 | 0.5887 | 0.5492 | 0.5931 | 4000 | 2020 | Case I |

| 0.0309 | 0.0286 | 0.0334 | 0.0537 | 0.5773 | 0.5469 | 0.6063 | 2000 | 1696 | Case II |

| 0.0401 | 0.0435 | 0.0651 | 0.0879 | 0.5032 | 0.5160 | 0.6932 | 6000 | 1696 | Case II |

| 0.0440 | 0.0534 | 0.0314 | 0.0760 | 0.5718 | 0.6612 | 0.4856 | 8000 | 1176 | Case III |

| ANN Model | X-RMS | Y-RMS | Z-RMS | XYZ -RMS | Pitching RMS | Rolling RMS | Yawing RMS | Feed Rate |

|---|---|---|---|---|---|---|---|---|

| MLP 8-16-1 | 3.975 | 6.674 | 4.272 | 2.988 | 2.703 | 3.584 | 4.015 | 2.456 |

| MLP 8-18-1 | 3.425 | 2.482 | 5.324 | 2.976 | 2.875 | 1.802 | 1.976 | 1.422 |

| MLP 8-28-1 | 3.113 | 9.626 | 6.590 | 8.392 | 2.737 | 5.653 | 5.212 | 2.737 |

| MLP 8-30-1 | 10.115 | 5.696 | 24.056 | 2.057 | 3.712 | 2.568 | 5.927 | 3.712 |

| Dataset | Training Dataset | Testing Dataset | Validation Dataset | ||||||

|---|---|---|---|---|---|---|---|---|---|

| ANN Model | R | RMSE | MAPE | R | RMSE | MAPE | R | RMSE | MAPE |

| MLP 8-16-1 | 0.975 | 69.4 | 2.19% | 0.959 | 88.2 | 2.95% | 0.971 | 77.4 | 2.65% |

| MLP 8-18-1 | 0.967 | 78.5 | 2.74% | 0.964 | 82.8 | 2.68% | 0.962 | 86.3 | 2.95% |

| MLP 8-28-1 | 0.981 | 59.5 | 2.38% | 0.959 | 87.4 | 3.40% | 0.970 | 76.2 | 3.50% |

| MLP 8-30-1 | 0.971 | 74.3 | 2.56% | 0.967 | 78.9 | 2.64% | 0.964 | 90.0 | 2.91% |

| ANN Model | Test Cases of Stage | |||||

|---|---|---|---|---|---|---|

| Case IV | Case V | Case VI | ||||

| RMSE | MAPE | RMSE | MAPE | RMSE | MAPE | |

| MLP 8-16-1 | 122.5 | 5.96% | 257.8 | 15.0% | 133.9 | 6.83% |

| MLP 8-18-1 | 140.6 | 7.55% | 326.9 | 15.4% | 138.6 | 7.37% |

| MLP 8-28-1 | 117.0 | 5.74% | 326.9 | 16.8% | 180.8 | 9.68% |

| MLP 8-30-1 | 181.0 | 8.6% | 333.0 | 16.8% | 180.8 | 7.78% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shih, W.-C.; Furqanuddin, F.; Lee, P.-L.; Hung, J.-P. Monitoring of Preload Variation of Linear Guide Positioning Stage Using Artificial Neural Network. Appl. Sci. 2021, 11, 7902. https://doi.org/10.3390/app11177902

Shih W-C, Furqanuddin F, Lee P-L, Hung J-P. Monitoring of Preload Variation of Linear Guide Positioning Stage Using Artificial Neural Network. Applied Sciences. 2021; 11(17):7902. https://doi.org/10.3390/app11177902

Chicago/Turabian StyleShih, Wei-Cheng, Furqan Furqanuddin, Po-Lin Lee, and Jui-Pin Hung. 2021. "Monitoring of Preload Variation of Linear Guide Positioning Stage Using Artificial Neural Network" Applied Sciences 11, no. 17: 7902. https://doi.org/10.3390/app11177902

APA StyleShih, W.-C., Furqanuddin, F., Lee, P.-L., & Hung, J.-P. (2021). Monitoring of Preload Variation of Linear Guide Positioning Stage Using Artificial Neural Network. Applied Sciences, 11(17), 7902. https://doi.org/10.3390/app11177902