Microbially Induced Desaturation and Carbonate Precipitation through Denitrification: A Review

Abstract

:1. Introduction

2. The Denitrification Mechanism

2.1. The Intermediates of Denitrification

2.2. Stoichiometry of Complete Denitrification

2.3. Inducing Calcium Carbonate Precipitation through Denitrification

3. Advantages of Denitrification Metabolism in MICP

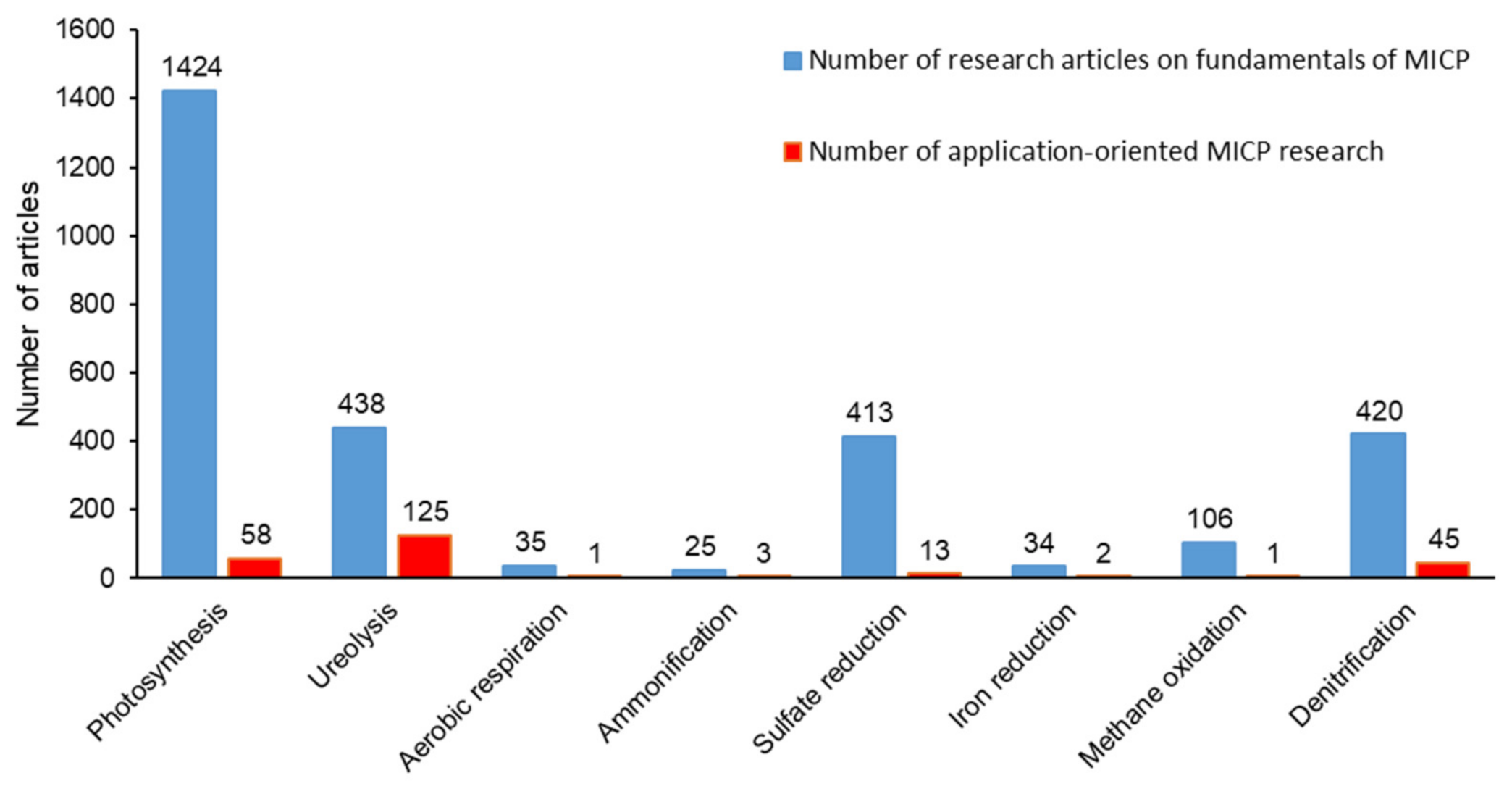

4. Potential Applications of Denitrification-Based MICP Biotechnology

4.1. MICP-Driven Applications

4.1.1. Soil Reinforcement

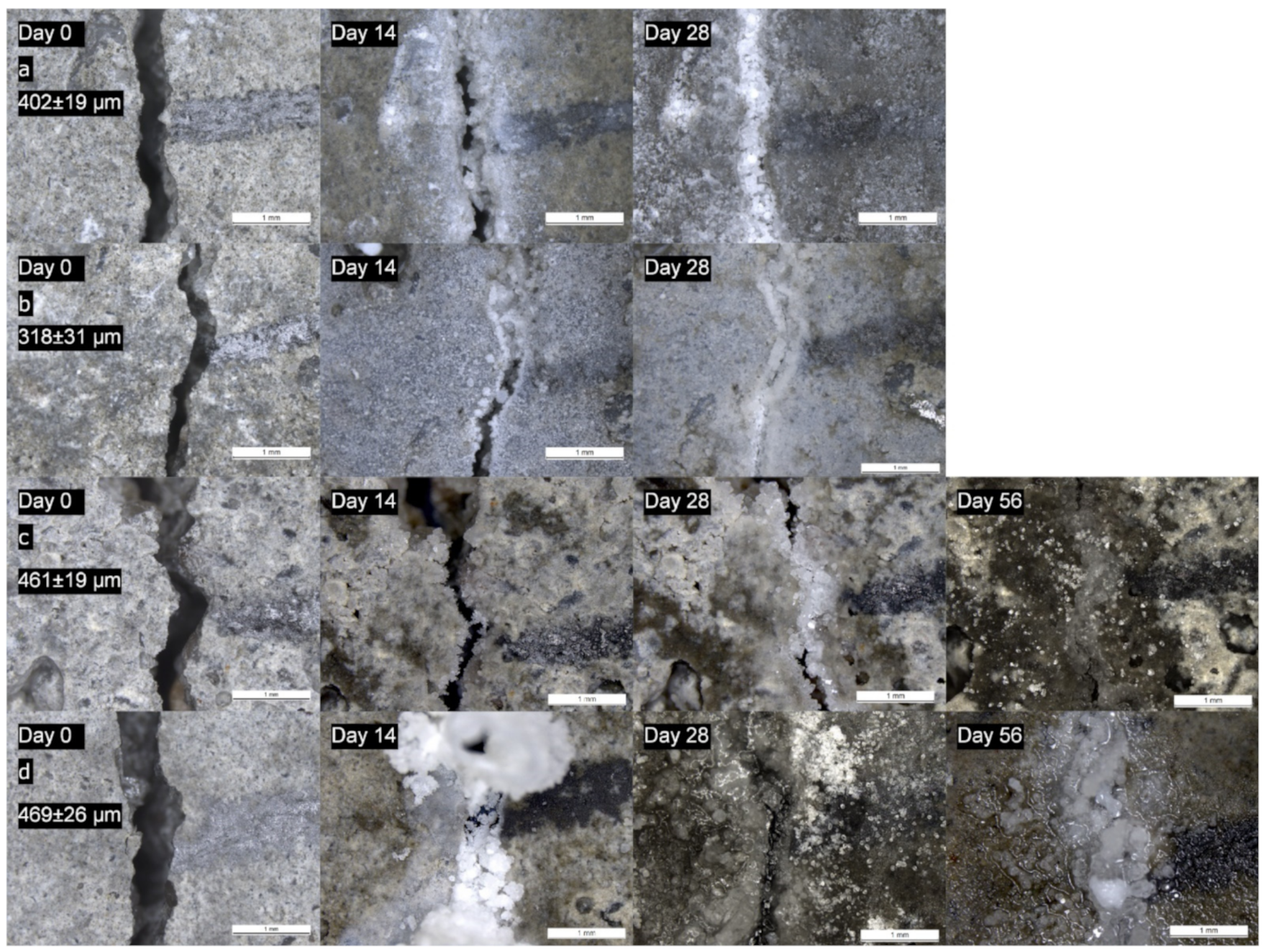

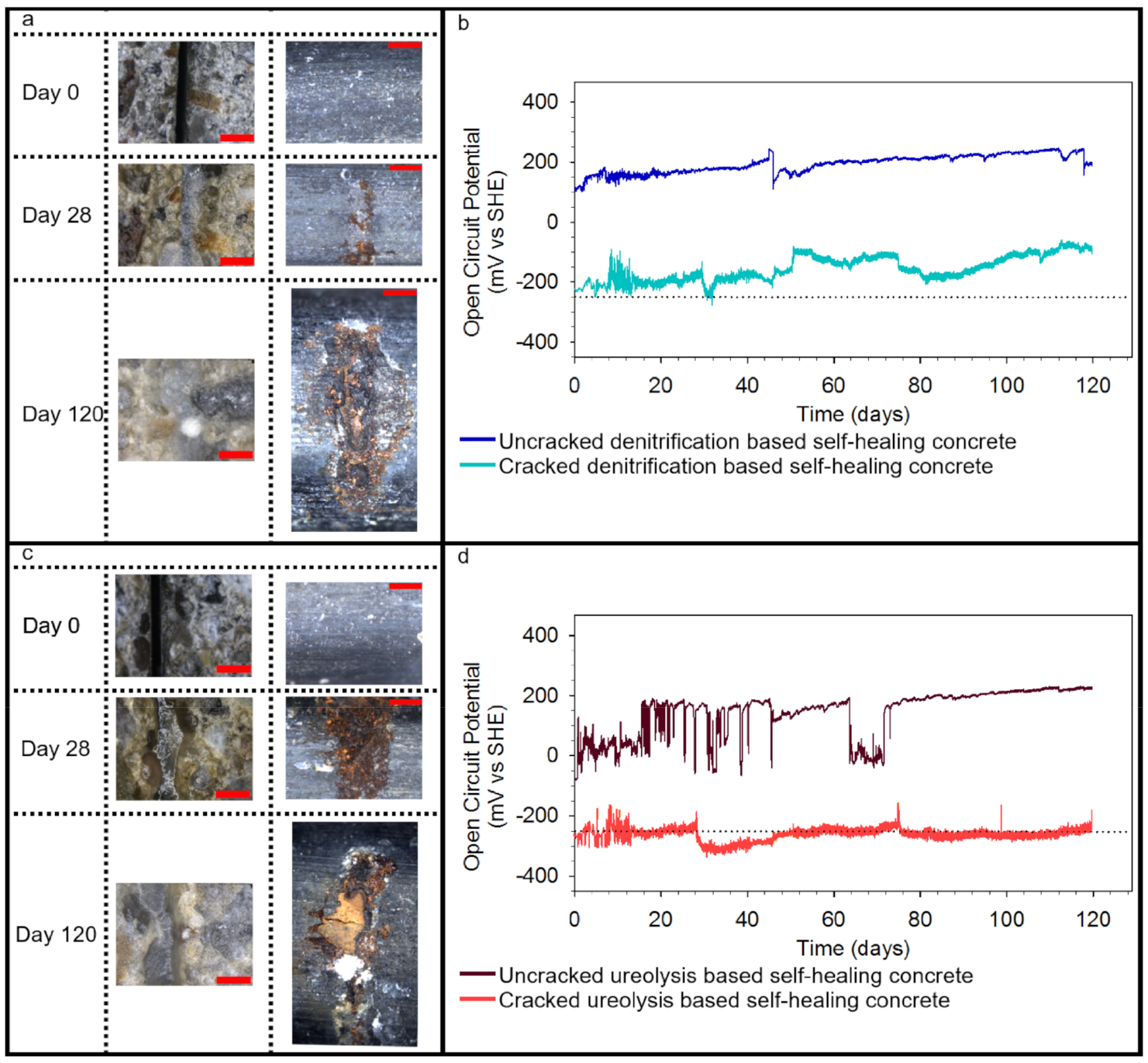

4.1.2. Remediation of Cracks and Inhibition of Steel Corrosion in Reinforced Concrete

4.1.3. Nitrate and Calcium Removal from Industrial Streams

4.1.4. Remediation of Artwork and Historical Monuments

4.1.5. Heavy Metal and Metalloid Immobilization

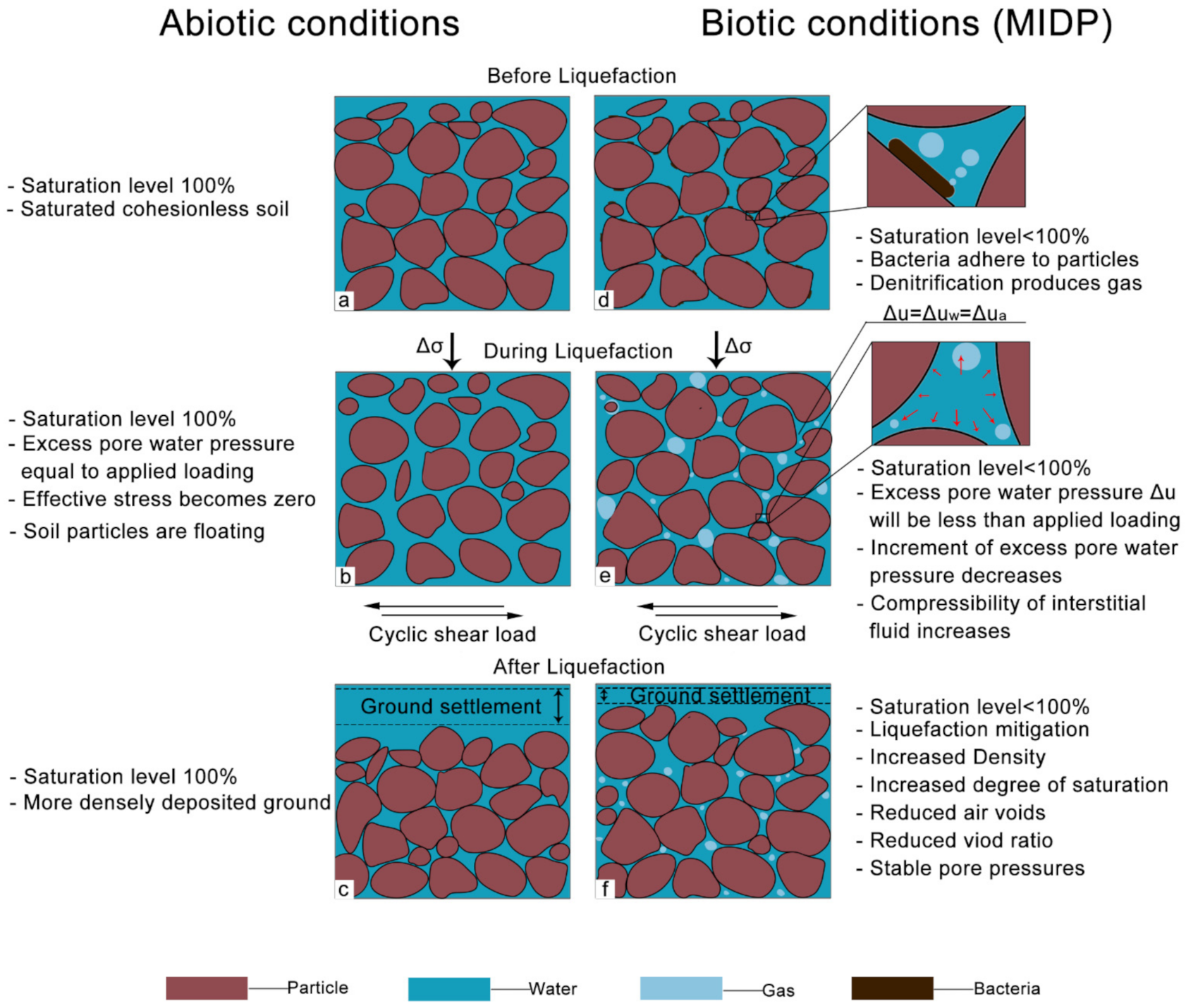

4.2. MIDP-Driven Applications

Liquefaction Mitigation

5. Challenges in Denitrification-Based MICP/MIDP Biotechnology

6. Suggestions for Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lowenstam, H.A.; Weiner, S. On Biomineralization; Oxford University Press: New York, NY, USA, 1990. [Google Scholar]

- Ersan, Y.C. Overlooked strategies in exploitation of microorganisms in the field of building materials. In Ecological Wisdom Inspired Restoration Engineering; Springer: Berlin/Heidelberg, Germany, 2019; pp. 19–45. [Google Scholar]

- Dupraz, C.; Visscher, P.T.; Baumgartner, L.K.; Reid, R.P. Microbe-mineral interactions: Early carbonate precipitation in a hypersaline lake (eleuthera island, bahamas). Sedimentology 2004, 51, 745–765. [Google Scholar] [CrossRef]

- Baumgartner, L.K.; Reid, R.P.; Dupraz, C.; Decho, A.W.; Buckley, D.H.; Spear, J.R.; Przekop, K.M.; Visscher, P.T. Sulfate reducing bacteria in microbial mats: Changing paradigms, new discoveries. Sediment. Geol. 2006, 185, 131–145. [Google Scholar] [CrossRef]

- Ganendra, G.; De Muynck, W.; Ho, A.; Arvaniti, E.C.; Hosseinkhani, B.; Ramos, J.A.; Rahier, H.; Boon, N.; Kostka, J.E. Formate oxidation-driven calcium carbonate precipitation by methylocystis parvus obbp. Appl. Environ. Microbiol. 2014, 80, 4659–4667. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- González-Muñoz, M.T.; Rodriguez-Navarro, C.; Martínez-Ruiz, F.; Arias, J.M.; Merroun, M.L.; Rodriguez-Gallego, M. Bacterial biomineralization: New insights from myxococcus-induced mineral precipitation. Geol. Soc. Spec. Publ. 2010, 336, 31–50. [Google Scholar] [CrossRef]

- Van Paassen, L.A.; Daza, C.M.; Staal, M.; Sorokin, D.Y.; van der Zon, W.; van Loosdrecht, M.C.M. Potential soil reinforcement by biological denitrification. Ecol. Eng. 2010, 36, 168–175. [Google Scholar] [CrossRef]

- Whiffin, V.S.; van Paassen, L.A.; Harkes, M.P. Microbial carbonate precipitation as a soil improvement technique. Geomicrobiol. J. 2007, 24, 417–423. [Google Scholar] [CrossRef]

- Van Paassen, L.A. Bio-mediated ground improvement: From laboratory experiment to pilot applications. In Geo-Frontiers Congress 2011; ASCE Geotechnical Special Publication: Dallas, TX, USA, 2011; Volume 2011, pp. 4099–4108. [Google Scholar]

- De Muynck, W.; Verbeken, K.; De Belie, N.; Verstraete, W. Influence of temperature on the effectiveness of a biogenic carbonate surface treatment for limestone conservation. Appl. Microbiol. Biotechnol. 2013, 97, 1335–1347. [Google Scholar] [CrossRef]

- Li, M.; Cheng, X.; Guo, H. Heavy metal removal by biomineralization of urease producing bacteria isolated from soil. Int. Biodeter. Biodegr. 2013, 76, 81–85. [Google Scholar] [CrossRef]

- Zhu, T.; Dittrich, M. Carbonate precipitation through microbial activities in natural environment, and their potential in biotechnology: A review. Front. Bioeng. Biotechnol. 2016, 4, 4. [Google Scholar] [CrossRef] [Green Version]

- Raveh-Amit, H.; Tsesarsky, M. Biostimulation in desert soils for microbial-induced calcite precipitation. Appl. Sci. 2020, 10, 2905. [Google Scholar] [CrossRef] [Green Version]

- He, J.; Chu, J.; Gao, Y.; Liu, H. Research advances and challenges in biogeotechnologies. Geotech. Res. 2019, 6, 144–155. [Google Scholar] [CrossRef] [Green Version]

- De Muynck, W.; De Belie, N.; Verstraete, W. Microbial carbonate precipitation in construction materials: A review. Ecol. Eng. 2010, 36, 118–136. [Google Scholar] [CrossRef]

- Pham, V.P. Bio-Based Ground Improvement through Microbial Induced Desaturation and Precipitation (midp). Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2017. [Google Scholar]

- Phillips, A.J.; Gerlach, R.; Lauchnor, E.; Mitchell, A.C.; Cunningham, A.B.; Spangler, L. Engineered applications of ureolytic biomineralization: A review. Biofouling 2013, 29, 715–733. [Google Scholar] [CrossRef] [Green Version]

- Randall, D.J.; Tsui, T.K. Ammonia Toxicity in Fish. Mar. Pollut. Bull. 2002, 45, 17–23. [Google Scholar] [CrossRef]

- O’Donnell, S.T.; Hamdan, N.; Rittmann, B.E.; Kavazanjian, E., Jr. A stoichiometric model for biogeotechnical soil improvement. In Geo-Chicago 2016; American Society of Civil Engineers: Reston, VA, USA, 2016. [Google Scholar]

- Gamble, T.N.; Betlach, M.R.; Tiedje, J.M. Numerically dominant denitrifying bacteria from world soils. Appl. Environ. Microbiol. 1977, 33, 926–939. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tiedje, J.M.; Sexstone, A.J.; Myrold, D.D.; Robinson, J.A. Denitrification: Ecological niches, competition and survival. Anton. Leeuw. Int. J. G. 1982, 48, 569–583. [Google Scholar] [CrossRef]

- Zumft, W.G. The denitrifying prokaryotes. In The Prokaryotes; Balows, A., Ed.; Springer: New York, NY, USA, 1992. [Google Scholar]

- Karatas, I. Microbiological Improvement of the Physical Properties of Soils. Ph.D. Thesis, Arizona State University, Tempe, AZ, USA, 2008. [Google Scholar]

- Pham, V.P.; Nakano, A.; van der Star, W.R.L.; Heimovaara, T.J.; van Paassen, L.A. Applying MICP by denitrification in soils: A process analysis. Environ. Geotech. 2018, 5, 79–93. [Google Scholar] [CrossRef] [Green Version]

- Heijnen, J.J.; van Loosdrecht, M.C.M.; Tijhuis, L. A black box mathematical model to calculate auto- and heterotrophic biomass yields based on gibbs energy dissipation. Biotechnol. Bioeng. 1992, 40, 1139–1154. [Google Scholar] [CrossRef]

- Heijnen, J.J.; Kleerebezem, R. Bioenergetics of microbial growth. In Encyclopedia of Industrial Biotechnology: Bioprocess, Bioseparation, and Cell Technology; Flickinger, M.C., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Gerlach, R.; Cunningham, A. Influence of microbial biofilms on reactive transport in porous media. AIP Conf. Proc. 2012, 1453, 276–283. [Google Scholar]

- Martin, D.; Dodds, K.; Butler, I.B.; Ngwenya, B.T. Carbonate precipitation under pressure for bioengineering in the anaerobic subsurface via denitrification. Environ. Sci. Technol. 2013, 47, 8692–8699. [Google Scholar] [CrossRef]

- Ersan, Y.Ç.; Belie, N.d.; Boon, N. Microbially induced CaCO3 precipitation through denitrification: An optimization study in minimal nutrient environment. Biochem. Eng. J. 2015, 101, 108–118. [Google Scholar] [CrossRef]

- Hamdan, N. Carbonate Mineral Precipitation for Soil Improvement through Microbial Denitrification. Master’s Thesis, Arizona State University, Tempe, AZ, USA, 2013. [Google Scholar]

- Hamdan, N.; Kavazanjian, E.; Rittmann, B.E.; Karatas, I. Carbonate mineral precipitation for soil improvement through microbial denitrification. Geomicrobio. J. 2017, 34, 139–146. [Google Scholar] [CrossRef] [Green Version]

- Pham, V.P.; van Paassen, L.A.; van der Star, W.R.L.; Heimovaara, T.J. Evaluating strategies to improve process efficiency of denitrification-based micp. J. Geotech. Geoenviron. Eng. 2018, 144. [Google Scholar] [CrossRef]

- Ersan, Y.C.; Van Tittelboom, K.; Boon, N.; De Belie, N. Nitrite producing bacteria inhibit reinforcement bar corrosion in cementitious materials. Sci. Rep. 2018, 8, 14092. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ersan, Y.C.; Palin, D.; Yengec, T.S.B.; Tasdemir, K.; Jonkers, H.M.; Boon, N.; De Belie, N. Volume fraction, thickness, and permeability of the sealing layer in microbial self-healing concrete containing biogranules. Front. Built Environ. 2018, 4. [Google Scholar] [CrossRef]

- Ersan, Y.Ç. Self-healing performance of biogranule containing microbial self-healing concrete under intermittent wet/dry cycles. J. Polytech. 2021, 24, 323–332. [Google Scholar]

- Song, Y.; Chetty, K.; Garbe, U.; Wei, J.; Bu, H.; O’moore, L.; Li, X.; Yuan, Z.; McCarthy, T.; Jiang, G. A novel granular sludge-based and highly corrosion-resistant bio-concrete in sewers. Sci. Total Environ. 2021, 791, 148270. [Google Scholar] [CrossRef] [PubMed]

- Ersan, Y.Ç.; Verbruggen, H.; De Graeve, I.; Verstraete, W.; De Belie, N.; Boon, N. Nitrate reducing CaCO3 precipitating bacteria survive in mortar and inhibit steel corrosion. Cem. Concr. Res. 2016, 83, 19–30. [Google Scholar] [CrossRef]

- Fernandez-Nava, Y.; Maranon, E.; Soons, J.; Castrillon, L. Denitrification of wastewater containing high nitrate and calcium concentrations. Bioresour. Technol. 2008, 99, 7976–7981. [Google Scholar] [CrossRef] [PubMed]

- Aoki, M.; Noma, T.; Araki, N.; Yamaguchi, T.; Masataka, K.; Hayashi, K. Isolation of Acinetobacter sp. Strain WKDN with capacity of aerobic denitrification and CaCO3 biomineralization and its potential application in dissolved Zn removal. Desalin. Water Treat. 2020, 194, 172–179. [Google Scholar] [CrossRef]

- Fan, Y.; Su, J.; Wang, Z.; Deng, L.; Zhang, H. Impact of C/N ratio on the fate of simultaneous Ca2+ precipitation, F− removal, and denitrification in quartz sand biofilm reactor. Chemosphere 2021, 273, 129667. [Google Scholar] [CrossRef]

- Liu, J.; Amhaj, A.; Su, J.; Wu, Z.; Zhang, R.; Xiong, R. Simultaneous removal of calcium, fluoride, nickel and nitrate using microbial induced calcium precipitation in a biological immobilization reactor. J. Hazard. Mater. 2021, 416, 125776. [Google Scholar] [CrossRef]

- Su, J.; Wu, Z.; Huang, T.; Zhang, H.; Li, J. A new technology for simultaneous calcium–nitrate and fluoride removal in the biofilm reactor. J. Hazard. Mater. 2020, 399, 122846. [Google Scholar] [CrossRef]

- Castanier, S.; Le Métayer-Levrel, G.; Orial, G.; Loubière, J.-F.; Perthuisot, J.-P. Bacterial carbonatogenesis and applications to preservation and restoration of historic property. In Of Microbes and Art; Ciferri, O., Mastromei, G., Tiano, P., Eds.; Springer: Boston, MA, USA, 2000; pp. 203–218. [Google Scholar]

- Ranalli, G.; Chiavarini, M.; Guidetti, V.; Marsala, F.; Matteini, M.; Zanardini, E.; Sorlini, C. In The use of microorganisms for the removal of nitrates and organic substances on artistic stoneworks. In Proceedings of the 8th International Congress on Deterioration and Conservation of Stone, Berlin, Germany, 30 September–4 October 1996; pp. 1415–1420. [Google Scholar]

- Ranalli, G.; Chiavarini, M.; Tosini, I.; Zanardini, E.; Sorlini, C. Bioremediation on cultural heritage: Removal of sulphates, nitrates and organic substances. In Of Microbes and Art: The Role of Microbial Communities in the Degradation and Protection of Cul-tural Heritage; Ciferri, O., Tiano, P., Mastromei, G., Eds.; Kluwer Academic-Plenum: New York, NY, USA, 2000; pp. 231–245. [Google Scholar]

- Ranalli, G.; Alfano, G.; Belli, C.; Lustrato, G.; Colombini, M.P.; Bonaduce, I.; Zanardini, E.; Abbruscato, P.; Cappitelli, F.; Sorlini, C. Biotechnology applied to cultural heritage: Biorestoration of frescoes using viable bacterial cells and enzymes. J. Appl. Microbiol. 2005, 98, 73–83. [Google Scholar] [CrossRef]

- Roig, P.B.; Regidor Ros, J.L.; Estellés, R.M. Biocleaning of nitrate alterations on wall paintings by pseudomonas stutzeri. Int. Biodeterior. Biodegrad. 2013, 84, 266–274. [Google Scholar] [CrossRef] [Green Version]

- Alfano, G.; Lustrato, G.; Belli, C.; Zanardini, E.; Cappitelli, F.; Mello, E.; Sorlini, C.; Ranalli, G. The bioremoval of nitrate and sulfate alterations on artistic stonework: The case-study of matera cathedral after six years from the treatment. Int. Biodeterior. Biodegrad. 2011, 65, 1004–1011. [Google Scholar] [CrossRef]

- Daskalakis, M.I.; Magoulas, A.; Kotoulas, G.; Catsikis, I.; Bakolas, A.; Karageorgis, A.P.; Mavridou, A.; Doulia, D.; Rigas, F. Pseudomonas, pantoea and cupriavidus isolates induce calcium carbonate precipitation for biorestoration of ornamental stone. J. Appl. Microbiol. 2013, 115, 409–423. [Google Scholar] [CrossRef]

- Rebata-Landa, V.; Santamarina, J.C. Mechanical effects of biogenic nitrogen gas bubbles in soils. J. Geotech. Geoenviron. Eng. 2012, 138, 128–137. [Google Scholar] [CrossRef]

- He, J.; Chu, J.; Ivanov, V. Mitigation of liquefaction of saturated sand using biogas. Géotechnique 2013, 63, 267–275. [Google Scholar] [CrossRef]

- He, J.; Chu, J.; Wu, S.; Peng, J. Mitigation of soil liquefaction using microbially induced desaturation. J. Zhejiang Univ. Sci. A 2016, 17, 577–588. [Google Scholar] [CrossRef] [Green Version]

- He, J.; Chu, J. Undrained responses of microbially desaturated sand under monotonic loading. J. Geotech. Geoenviron. Eng. 2014, 140, 04014003. [Google Scholar] [CrossRef]

- O’Donnell, S.T.; Rittmann, B.E.; Kavazanjian, E. MIDP: Liquefaction mitigation via microbial denitrification as a two-stage process. I: Desaturation. J. Geotech. Geoenviron. Eng. 2017, 143, 04017094. [Google Scholar] [CrossRef]

- O’Donnell, S.T.; Kavazanjian, E.; Rittmann, B.E. MIDP: Liquefaction mitigation via microbial denitrification as a two-stage process. II: MICP. J. Geotech. Geoenviron. Eng. 2017, 143, 04017095. [Google Scholar] [CrossRef]

- Ivanov, V.; Chu, J. Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil in situ. Rev. Environ. Sci. Biol. 2008, 7, 139–153. [Google Scholar] [CrossRef]

- Ersan, Y.Ç.; Hernandez-Sanabria, E.; Boon, N.; de Belie, N. Enhanced crack closure performance of microbial mortar through nitrate reduction. Cem. Concr. Comp. 2016, 70, 159–170. [Google Scholar] [CrossRef]

- Ersan, Y.Ç.; Da Silva, F.B.; Boon, N.; Verstraete, W.; De Belie, N. Screening of bacteria and concrete compatible protection materials. Constr. Build. Mater. 2015, 88, 196–203. [Google Scholar] [CrossRef]

- Ersan, Y.C.; Gruyaert, E.; Louis, G.; Lors, C.; De Belie, N.; Boon, N. Self-protected nitrate reducing culture for intrinsic repair of concrete cracks. Front. Microbiol. 2015, 6, 1228. [Google Scholar] [CrossRef] [Green Version]

- Grantham, M.G.; Sonmez, M.; Ersan, Y.C.; Mircea, C. Production of concrete compatible biogranules for self-healing concrete applications. MATEC Web Conf. 2019, 289. [Google Scholar] [CrossRef]

- Park, J.Y.; Yoo, Y.J. Biological nitrate removal in industrial wastewater treatment: Which electron donor we can choose. Appl. Microbiol. Biotechnol. 2009, 82, 415–429. [Google Scholar] [CrossRef]

- Shrimali, M.; Singh, K.P. New methods of nitrate removal from water. Environ. Pollut. 2001, 112, 351–359. [Google Scholar] [CrossRef]

- Soares, M.I.M. Biological denitrification of groundwater. In Water, Air, and Soil Pollution; Springer Nature: Dordrecht, The Netherlands, 2000; Volume 123, pp. 183–193. [Google Scholar]

- Rezvani, F.; Sarrafzadeh, M.H.; Ebrahimi, S.; Oh, H.M. Nitrate removal from drinking water with a focus on biological methods: A review. Environ. Sci. Pollut. Res. Int. 2019, 26, 1124–1141. [Google Scholar] [CrossRef] [PubMed]

- Archna; Sharma, S.K.; Sobti, R.C. Nitrate removal from ground water: A review. E-J. Chem. 2012, 9, 1667–1675. [Google Scholar] [CrossRef]

- Saiz-Jimenez, C. Biodeterioration vs. biodegradation: The role of microorganisms in the removal of pollutants deposited on historic buildings. Int. Biodeterior. Biodegrad. 1997, 40, 225–232. [Google Scholar] [CrossRef] [Green Version]

- Webster, A.; May, E. Bioremediation of weathered-building stone surfaces. Trends Biotechnol. 2006, 24, 255–260. [Google Scholar] [CrossRef]

- Tiano, P.; Biagiotti, L.; Mastromei, G. Bacterial bio-mediated calcite precipitation for monumental stones conservation: Methods of evaluation. J. Microbiol. Methods 1999, 36, 139–145. [Google Scholar] [CrossRef]

- Li, M.; Cheng, X.; Guo, H.; Yang, Z. Biomineralization of carbonate by terrabacter tumescens for heavy metal removal and biogrouting applications. J. Environ. Eng. 2016, 142. [Google Scholar] [CrossRef]

- Qian, X.; Fang, C.; Huang, M.; Achal, V. Characterization of fungal-mediated carbonate precipitation in the biomineralization of chromate and lead from an aqueous solution and soil. J. Clean. Prod. 2017, 164, 198–208. [Google Scholar] [CrossRef]

- Tamayo-Figueroa, D.P.; Castillo, E.; Brandao, P.F.B. Metal and metalloid immobilization by microbiologically induced carbonates precipitation. World J. Microbiol. Biotechnol. 2019, 35, 58. [Google Scholar] [CrossRef] [PubMed]

- Dhami, N.K.; Quirin, M.E.C.; Mukherjee, A. Carbonate biomineralization and heavy metal remediation by calcifying fungi isolated from karstic caves. Ecol. Eng. 2017, 103, 106–117. [Google Scholar] [CrossRef]

- Andrus, R.D.; Chung, R.M. Ground Improvement Techniques for Liquefaction Remediation Near Existing Lifelines; Technical Report NISTIR 5714; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1995. [Google Scholar]

- Kim, H.; Lee, K.; Jamin, J.; Mission, J. Stochastic cost optimization of ground improvement with prefabricated vertical drains and surcharge preloading. Geomech. Eng. 2014, 7, 525–537. [Google Scholar] [CrossRef]

- Durukan, Z.; Tezcan, S.S. Cost analysis of reinforced soil walls. Geotext. Geomembr. 1992, 11, 29–43. [Google Scholar] [CrossRef]

- Tsukamoto, Y.; Ishihara, K.; Nakazawa, H.; Kamada, K.; Huang, Y. Resistance of partly saturated sand to liquefaction with reference to longitudinal and shear wave velocities. Soils Found. 2002, 42, 93–104. [Google Scholar] [CrossRef] [Green Version]

- Li, Y. Mitigation of Sand Liquefaction Using in situ Production of Biogas with Biosealing. Master’s Thesis, Iowa State University, Ames, IA, USA, 2014. [Google Scholar]

- Yang, J.; Savidis, S.; Roemer, M. Evaluating liquefaction strength of partially saturated sand. J. Geotech. Geoenviron. Eng. 2004, 130, 975–979. [Google Scholar] [CrossRef]

- Okamura, M.; Soga, Y. Effects of pore fluid compressibility on liquefaction resistance of partially saturated sand. Soils Found. 2006, 46, 695–700. [Google Scholar] [CrossRef] [Green Version]

- Yegian, M.K.; Eseller-Bayat, E.; Alshawabkeh, A.; Ali, S. Induced-partial saturation for liquefaction mitigation: Experimental investigation. J. Geotech. Geoenviron. Eng. 2007, 133, 372–380. [Google Scholar] [CrossRef] [Green Version]

- Arab, A.; Shahrour, I.; Lancelot, L. Estudio en laboratorio sobre licuefacción de arena parcialmente saturada. J. Iber. Geol. 2011, 37, 29–36. [Google Scholar] [CrossRef] [Green Version]

- Eseller-Bayat, E.; Yegian, M.K.; Alshawabkeh, A.; Gokyer, S. Liquefaction response of partially saturated sands. II: Empirical model. J. Geotech. Geoenviron. Eng. 2013, 139, 872–879. [Google Scholar] [CrossRef]

- Fredlund, D.G.; Rahardjo, H. Soil Mechanics for Unsaturated Soils; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1993. [Google Scholar]

- Eseller-Bayat, E.E. Seismic Response and Prevention of Liquefaction Failure of Sands Partially Saturated Through Introduction of Gas Bubbles. Ph.D. Thesis, Northeastern University, Boston, MA, USA, 2009. [Google Scholar]

- Zhai, Q.; Rahardjo, H.; Satyanaga, A.; Priono; Dai, G. Role of the pore-size distribution function on water flow in unsaturated soil. J. Zhejiang Univ. Sci. A 2019, 20, 10–20. [Google Scholar] [CrossRef]

- Rahardjo, H.; Kim, Y.; Satyanaga, A. Role of Unsaturated Soil Mechanics in Ge-otechnical Engineering. Int. J. Geo-Eng. 2019, 10, 8. [Google Scholar] [CrossRef] [Green Version]

- Baird, A.J.; Waldron, S. Shallow horizontal groundwater flow in peatlands is reduced by bacteriogenic gas production. Geophys. Res. Lett. 2003, 30, 2043–2046. [Google Scholar] [CrossRef]

- Mahabadi, N.; Dai, S.; Seol, Y.; Yun, T.; Jang, J. The water retention curve and relative permeability for gas production from hydrate-bearing sediments: Pore-network model simulation. Geochem. Geophys. Geosyst. 2016, 17, 3099–3110. [Google Scholar] [CrossRef]

- Chu, J.; Stabnikov, V.; Ivanov, V. Microbially induced calcium carbonate precipitation on surface or in the bulk of soil. Geomicrobiol. J. 2012, 29, 544–549. [Google Scholar] [CrossRef]

- Yang, Z.; Cheng, X. A performance study of high-strength microbial mortar produced by low pressure grouting for the reinforcement of deteriorated masonry structures. Constr. Build. Mater. 2013, 41, 505–515. [Google Scholar] [CrossRef]

- Amen, T.W.M.; Eljamal, O.; Khalil, A.M.E.; Matsunaga, N. Biochemical methane potential enhancement of domestic sludge digestion by adding pristine iron nanoparticles and iron nanoparticles coated zeolite compositions. J. Environ. Chem. Eng. 2017, 5, 5002–5013. [Google Scholar] [CrossRef]

- Eljamal, O.; Shubair, T.; Tahara, A.; Sugihara, Y.; Matsunaga, N. Iron based nanoparticles-zeolite composites for the removal of cesium from aqueous solutions. J. Mol. Liq. 2019, 277, 613–623. [Google Scholar] [CrossRef]

- Eljamal, O.; Thompson, I.P.; Maamoun, I.; Shubair, T.; Eljamal, K.; Lueangwattanapong, K.; Sugihara, Y. Investigating the design parameters for a permeable reactive barrier consisting of nanoscale zero-valent iron and bimetallic iron/copper for phosphate removal. J. Mol. Liq. 2020, 299. [Google Scholar] [CrossRef]

- O’Donnell, S.T.; Hall, C.A.; Kavazanjian, E.; Rittmann, B.E. Biogeochemical model for soil improvement by denitrification. J. Geotech. Geoenviron. Eng. 2019, 145, 04019091. [Google Scholar] [CrossRef]

| Metabolisms | Microorganisms | Reactions | Author and Ref |

|---|---|---|---|

| Oxygenic photosynthesis | Cyanobacteria algae | + Ca2+ → CH2O + CaCO3 + O2 | Dupraz et al. [3] |

| Aerobic respiration | Aerobic heterotroph | + 4H2O 6CaCO3 + 6H2O + 2OH− | Ersan [2] |

| Ureolysis | Ureolytic bacteria | → CaCO3 | Whiffin et al. [9] |

| Ammonification | Myxobacteria | Amino acids + O2 → NH3 + CO2 + H2O NH3 + H2O →+OH− OH− + CO2 → +OH− → CaCO3 + H2O | González-Muñoz et al. [7] |

| Nitrate reduction/denitrification | Denitrifying bacteria | + 2.6H+ → 0.8N2 + 2.8H2O + 2CO2 CO2 + H2O ⇆+ H+ + 2OH− → CaCO3 + H2O | Van Paassen et al. [8] |

| Sulfate reduction | Sulfate-reducing bacteria | CaSO4+ 2CH2O + OH− → CaCO3 + H2O + 2CO2 + HS− | Baumgartner et al. [4] |

| Iron reduction | Iron-reducing bacteria | + 7H+ → 8FeCO3 + 20H2O | DeJong et al. [6] |

| Methane oxidation | Methanotroph | CH3OH + H2O CHOH 2HCOO− + H2O HCOO− + H2O ⇆ HCOOH + OH− CO2 Ca2+ + CO2 + 2OH− ⇆ CaCO3 + H2O | Ganendra et al. [5] |

| Applications | Process | Microorganisms | Author and Ref | Country/Region |

|---|---|---|---|---|

| Soil reinforcement | MICP | Pseudomonas denitrificans | Karatas [24]; Hamdan [31]; O’Donnell [20]; Hamdan et al. [32] | Netherlands UK USA |

| Castellaniella denitrificans | Van Paassen et al. [8] | |||

| Halomonas halodenitrificans | Martin et al. [29] | |||

| Denitrifiers from natural soil | Pham [17]; Pham et al. [25,33] | |||

| Self-healing concrete | MICP | Nitrate reducing biogranules | Ersan et al. [30,34,35]; Ersan [36] | Belgium Turkey |

| Diaphorobacter nitroreducens | ||||

| Pseudomonas aeruginosa | ||||

| Sewer corrosion resistant concrete | MICP | Nitrate and sulfate reducing biogranules | Song et al. [37] | Australia |

| Corrosion inhibition of steel in reinforced concrete | MICP | Nitrate reducing biogranules | Ersan et al. [34,38] | Belgium |

| Diaphorobacter nitroreducens | ||||

| Pseudomonas aeruginosa | ||||

| Treatment of industrial wastewater (calcium, nitrate, zinc, nickel, fluoride removal) | MICP | Diaphorobacter nitroreducens | Ersan et al. [30] | Belgium China Japan Spain |

| Pseudomonas aeruginosa | ||||

| Sludge from the biological treatment of leachate | Fernandez-Nava et al. [39] | |||

| Sludge from a Sewage Treatment Plant | ||||

| Acinetobacter sp. | Aoki et al. [40], Fan et al. [41], Liu et al. [42], Su et al. [43] | |||

| Remediation of artwork and historical monuments | MICP | Bacillus cereus | Castanier et al. [44] | France Greece Italy Spain |

| Ranalli et al. [45,46,47]; Bosch-Roig et al. [48] | ||||

| Pseudomonas stutzeri | ||||

| Pseudomonas aeruginosa | Ranalli et al. [45,47] | |||

| Pseudomonas pseudoalcaligenes | Alfano et al. [49] | |||

| Pseudomonas chlororaphis | Daskalakis et al. [50] | |||

| Liquefaction mitigation of soils | MIDP | Paracoccus denitrificans | Rebata-Landa et al. [51] | China USA |

| Acidovorax sp. | He et al. [52,53]; He and Chu [54] | |||

| Mixed culture of bacteria from natural sand | O’Donnell [20]; O’Donnell et al. [55,56] |

| Author and Ref | Electron Donor (Concentration) | NO3− Consumed (mM) | Initial Ca2+ Concentrate (mM) | CaCO3 (by Weight%) Range Reported | Time (Days) |

|---|---|---|---|---|---|

| Karatas [24] | NB* (16.7 g/L) Acetate (75 mM) L-glutamic acid (50/75 mM) | 8 12 15 25 | 20–100 | ND* | 2–40 |

| Van Paassen et al. [8] | Acetate (24 mM) Acetate (60 mM) Acetate (120 mM) Acetate (240 mM) | 16 40 80 160 | 20 50 100 200 | Less than 1% at the bottom to 10% at the top of the sand column | 100 |

| Martin et al. [29] | Acetate (45 mM) | 50 | 100 | 6% at the top to 42% at the bottom | 1.5 |

| Hamdan et al. [32] | NB* (20 g/L) L-glutamic acid (75 mM) | 17.6 | 20 | ≈0.01% | 7 |

| Pham et al. [25] | Acetate (160 mM, first three flushes) Acetate (130 mM, fourth to ninth flush) | 100 (first three flushes)–120 (fourth to ninth flush) | 130 (first three flushes)–120 (fourth to ninth flush) | Average 1.1% | 65 |

| Pham et al. [33] | Acetate (120 mM, three flushes) Acetate (24 mM, 15 flushes) | 100 (three flushes)20 (15 flushes) | 110 (three flushes) 22 (15 flushes) | 0.28% by weight 0.65% by weight | 35 |

| Liquefaction Mitigation Methods | Mechanisms | Costs | Negative Effects | Limitations | Author and Ref |

|---|---|---|---|---|---|

| Densification | Densifying the existing soil, increasing the strength and stiffness of soil | The cost of labor and grout materials start at about 20/m3 of improved soil | Making the soil more dilatant, producing ground settlement, and disrupting nearby existing structures and utilities | Limited in finer grained liquefiable soils | O’Donnell [20]; Andrus and Chung [74]; |

| Solidification | Injecting or mixing cementitious materials (e.g., Portland cement or polymers) into the soil to solidify the soil mass. | The cost of injection labor and grout materials varies from 100/m3 to 320/m3 of improved soil | Environmentally unfriendly | Limited by the ability of grout to pass through pore spaces and relatively uniformly permeate the soil | O’Donnell [20]; Andrus and Chung [74]; |

| Drainage | Installation of free draining materials to mitigate the buildup of excess pore pressures during cyclic loading | 2.5/m for prefabricated vertical drains and 10/m3 for preloading | Excessive vibrations leading to producing ground settlement, and disrupting nearby existing structures and utilities | When using gravel drains and prefabricated vertical drains, they do nothing to mitigate seismic settlement | O’Donnell [20]; Andrus and Chung [74]; Kim et al. [75] |

| Reinforcement | Installation of reinforcing elements to improve the strength and stiffness of a soil mass | 118/m2 to 134/m2 for geotextile reinforced soil | Environmentally unfriendly, and excessive vibrations leading to producing ground settlement, and disrupting nearby existing structures and utilities | Can be affected by a variety of factors, including the soil type, ground water conditions, grout mix, injection rate, jet pressure, withdrawal rates, etc. | O’Donnell [20]; Andrus and Chung [74]; Durukan and Tezcan [76] |

| Desaturation | Inclusion of a small amounts of gas in the soil can add considerable compressibility to the pore fluid, mitigating the buildup of excess pore pressures | The estimated cost of electron donor and acceptor for 10% (volume of gas/volume of water) desaturation of soil with porosity 50% is from 0.25 to 0.31/m3 of saturated soil. | Traditional desaturation methods, such as dewatering or lowering of the groundwater table through continuous pumping may causing slightly settlement | May not lead to long term desaturation in clean sands or gravel | Tsukamoto et al. [77]; He et al. [52]; Li et al. [78] |

| Challenges in In-Situ Applications | Strategies to Mitigate Those Challenges |

|---|---|

| Generation of harmful intermediates | Avoid by ensuring the completeness of reactions (i.e., proper substrate concentration) Use for other applications (nitrite can be utilized as a commercial anodic rebar corrosion inhibitor) Treat the harmful intermediates on site or collection after the application is done |

| Environmental factors | Stimulation of inactive cells in the field by providing appropriate nutritional conditions Incorporation of a functional isolate or a non-axenic microbial community into the application field to enumerate the number of functional microorganisms Combined ureolysis and denitrification process |

| CaCO3 precipitation rate | Proper substrate concentration Applying an optimized substrate regime and residence time Isolate and select more appropriate strains Adding iron nanoparticles |

| Controlling of gas generation | Control the generation, distribution, and persistence of the gas Applying an optimized substrate regime and residence time Proper substrate concentration |

| Obtaining homogeneous treatment | Uniform distribution of microorganisms and solution chemistry Applying an optimized substrate regime and spatial distribution |

| Monitoring | Mathematical model |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, W.; Lin, W.; Cheng, X.; Chen, G.; Ersan, Y.C. Microbially Induced Desaturation and Carbonate Precipitation through Denitrification: A Review. Appl. Sci. 2021, 11, 7842. https://doi.org/10.3390/app11177842

Lin W, Lin W, Cheng X, Chen G, Ersan YC. Microbially Induced Desaturation and Carbonate Precipitation through Denitrification: A Review. Applied Sciences. 2021; 11(17):7842. https://doi.org/10.3390/app11177842

Chicago/Turabian StyleLin, Wenbin, Wei Lin, Xiaohui Cheng, Guozhou Chen, and Yusuf Cagatay Ersan. 2021. "Microbially Induced Desaturation and Carbonate Precipitation through Denitrification: A Review" Applied Sciences 11, no. 17: 7842. https://doi.org/10.3390/app11177842

APA StyleLin, W., Lin, W., Cheng, X., Chen, G., & Ersan, Y. C. (2021). Microbially Induced Desaturation and Carbonate Precipitation through Denitrification: A Review. Applied Sciences, 11(17), 7842. https://doi.org/10.3390/app11177842