Three-Dimensional Imaging of Metallic Grain by Stacking the Microscopic Images

Abstract

1. Introduction

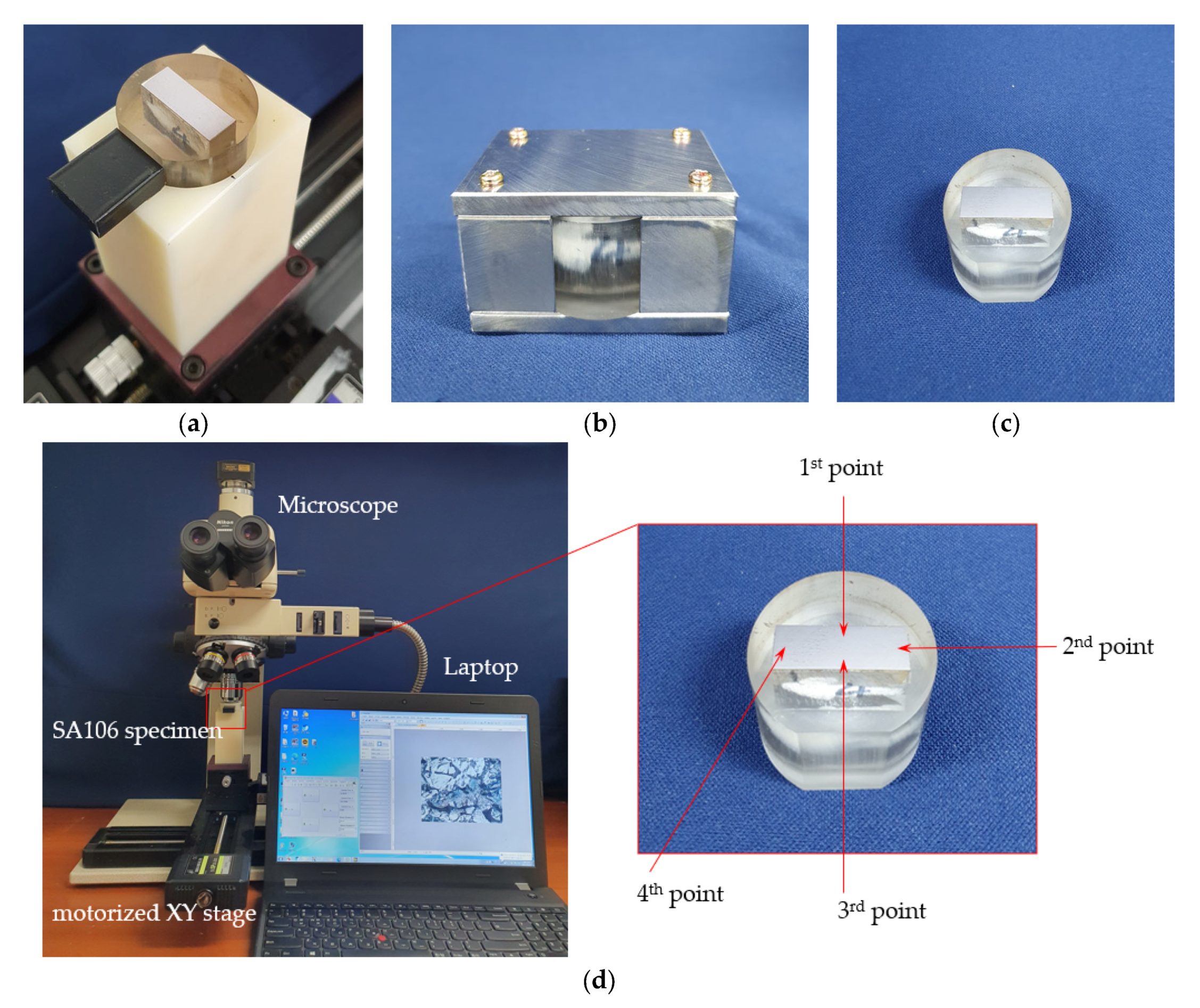

2. Specimen and Layer Capture

3. Algorithms for 3D Imaging of Grains and Results

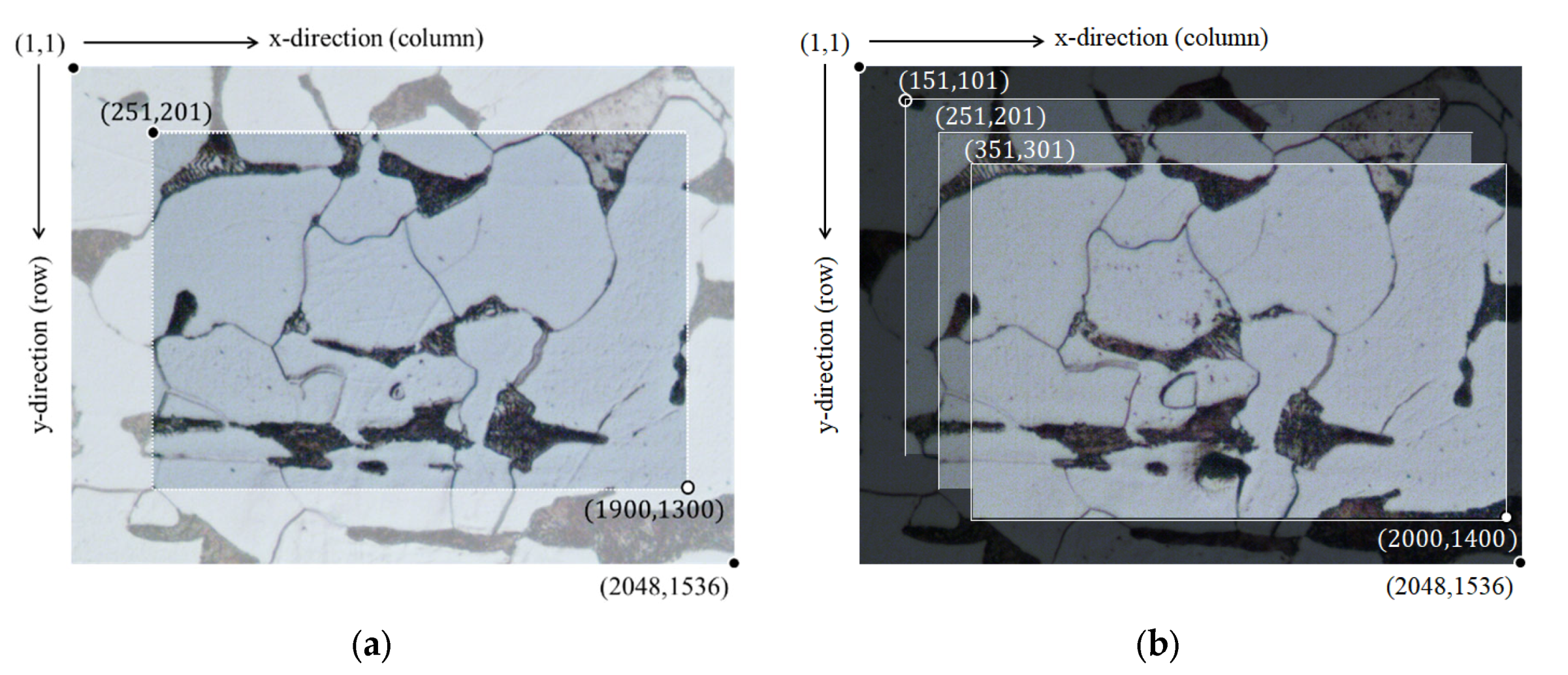

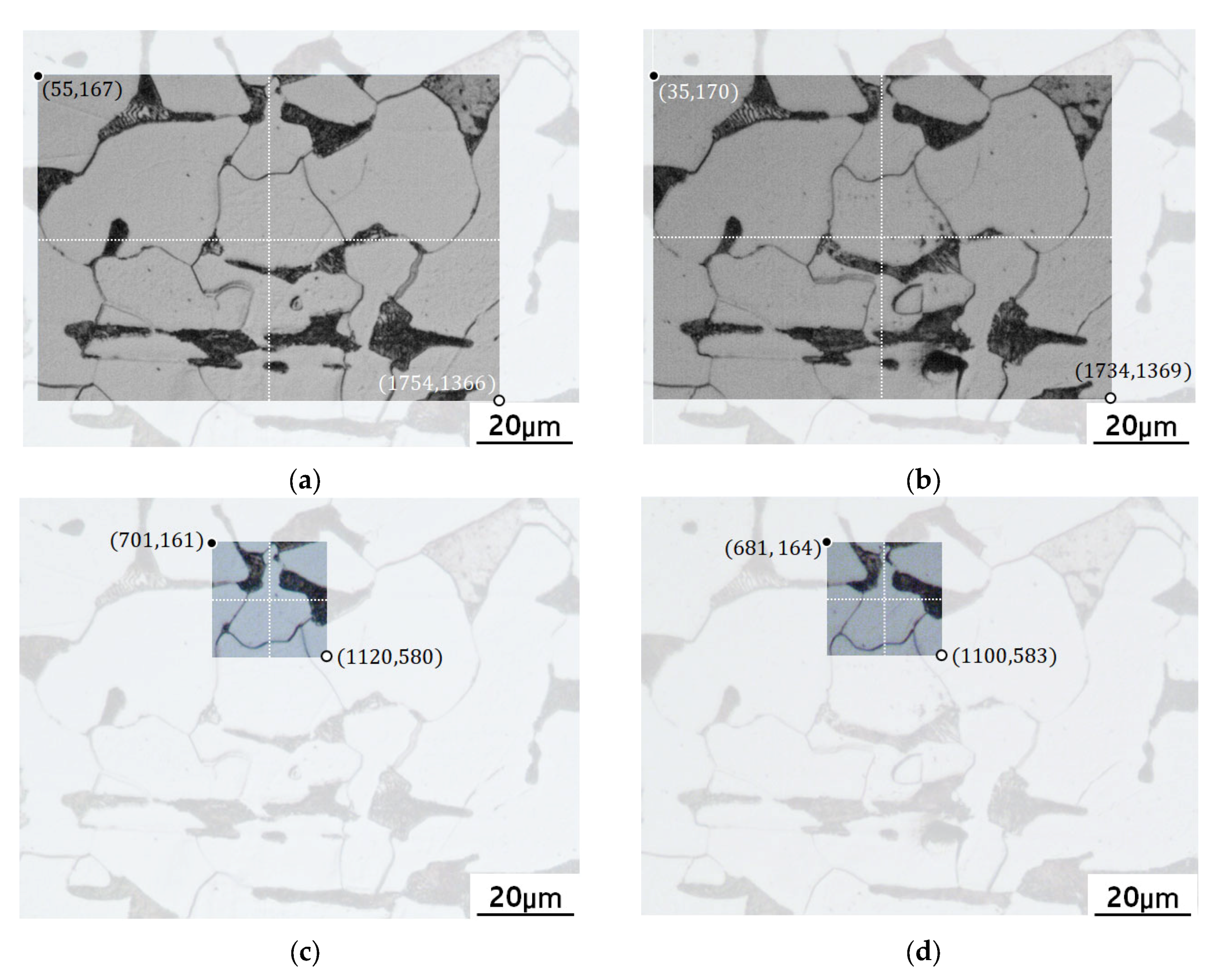

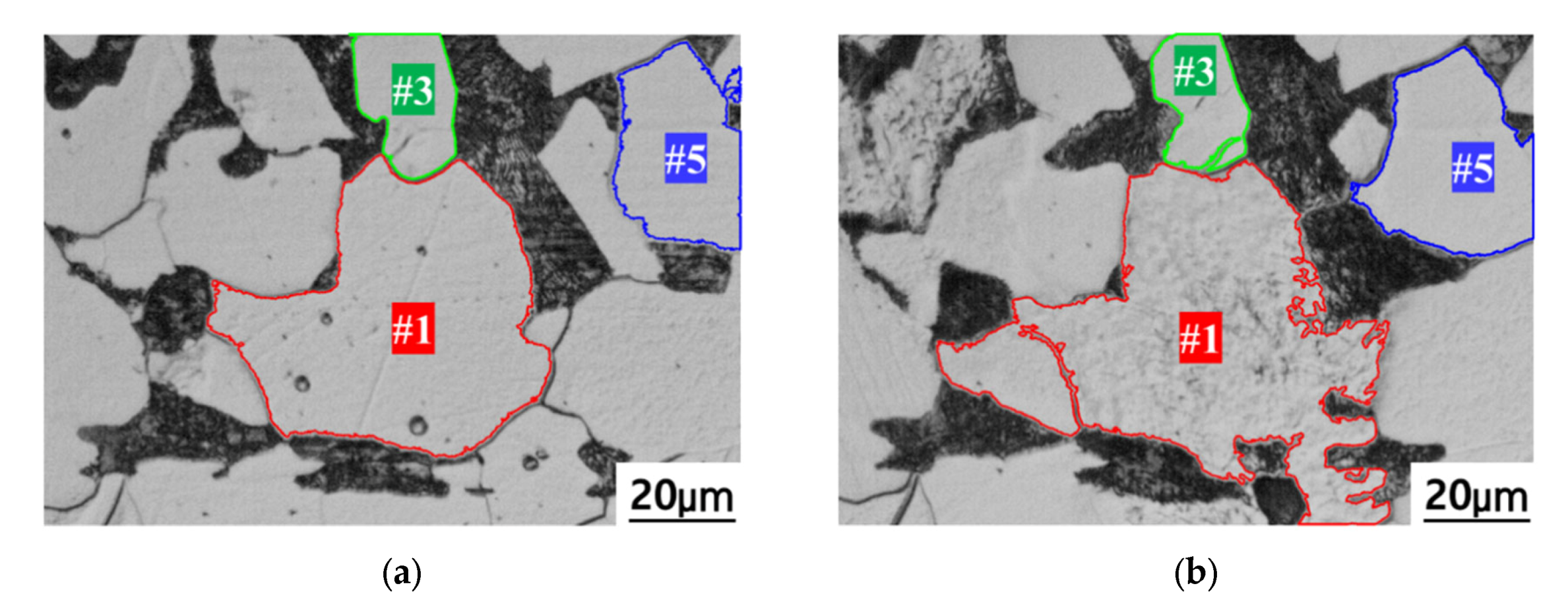

3.1. Local Positioning

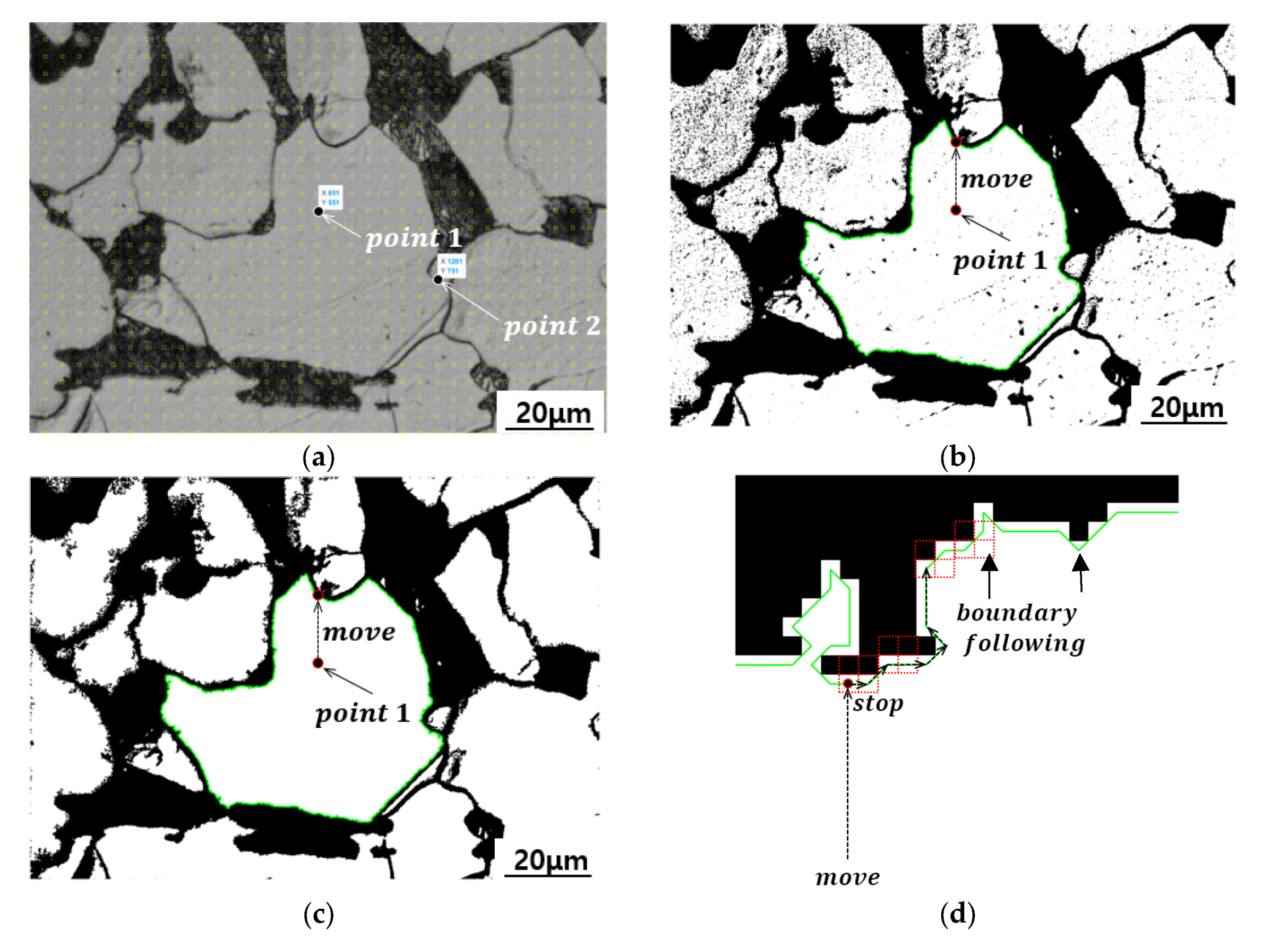

3.2. Selection and Binarization

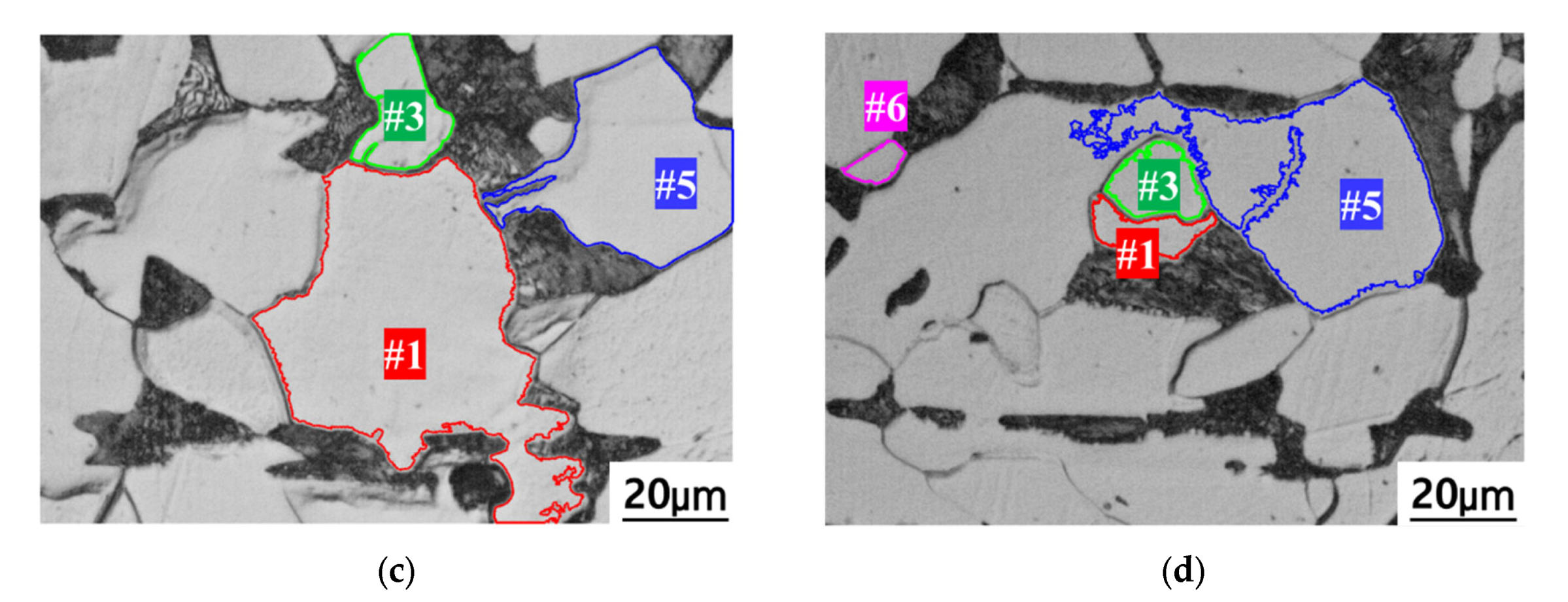

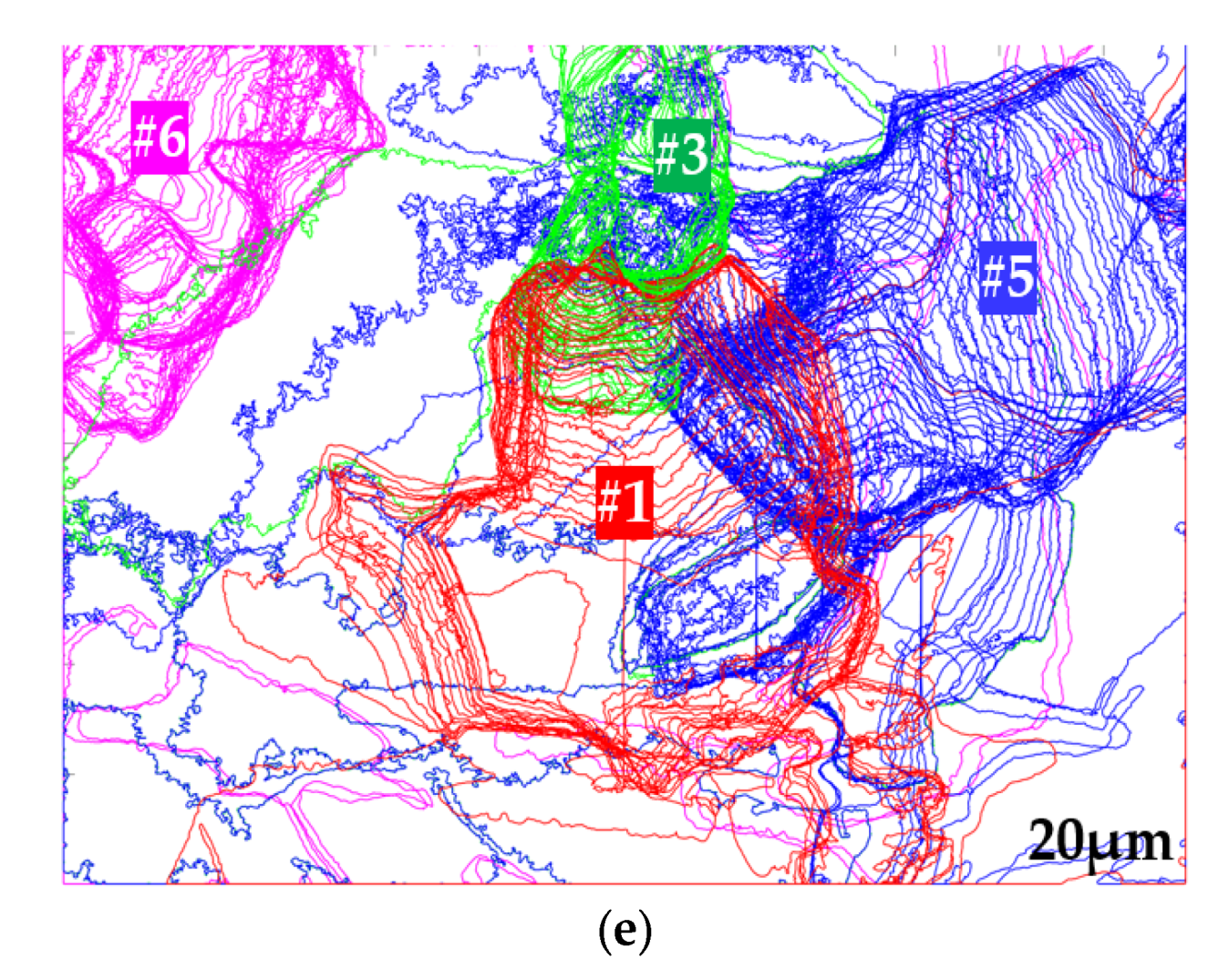

3.3. Nodes and Stacking

3.4. Post-Processing

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar, S.; Shahi, A. Effect of heat input on the microstructure and mechanical properties of gas tungsten arc welded AISI 304 stainless steel joints. Mater. Des. 2011, 32, 3617–3623. [Google Scholar] [CrossRef]

- Jang, D.; Kim, K.; Kim, H.C.; Jeon, J.B.; Nam, D.G.; Sohn, K.Y.; Kim, B.J. Evaluation of Mechanical Property for Welded Austenitic Stainless Steel 304 by Following Post Weld Heat Treatment. Korean J. Met. Mater. 2017, 55, 664–670. [Google Scholar] [CrossRef]

- Rabung, M.; Kopp, M.; Gasparics, A.; Vértesy, G.; Szenthe, I.; Uytdenhouwen, I.; Szielasko, K. Micromagnetic Characterization of Operation-Induced Damage in Charpy Specimens of RPV Steels. Appl. Sci. 2021, 11, 2917. [Google Scholar] [CrossRef]

- Berkache, A.; Lee, J.; Choe, E. Evaluation of Cracks on the Welding of Austenitic Stainless Steel Using Experimental and Numerical Techniques. Appl. Sci. 2021, 11, 2182. [Google Scholar] [CrossRef]

- Cook, R.D. Finite Element Modeling for Stress Analysis, 1st ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1995. [Google Scholar]

- Thomas, D.J. Using Finite Element Analysis to Assess and Prevent the Failure of Safety Critical Structures. J. Fail. Anal. Prev. 2016, 17, 1–3. [Google Scholar] [CrossRef][Green Version]

- Müzel, S.D.; Bonhin, E.P.; Guimarães, N.M.; Guidi, E.S. Application of the Finite Element Method in the Analysis of Composite Materials: A Review. Polymers 2020, 12, 818. [Google Scholar] [CrossRef] [PubMed]

- Xing, J.; Du, C.; He, X.; Zhao, Z.; Zhang, C.; Li, Y. Finite Element Study on the Impact Resistance of Laminated and Textile Composites. Polymers 2019, 11, 1798. [Google Scholar] [CrossRef]

- Raabe, D.; Sun, B.; Da Silva, A.K.; Gault, B.; Yen, H.-W.; Sedighiani, K.; Sukumar, P.T.; Filho, I.R.S.; Katnagallu, S.; Jägle, E.; et al. Current Challenges and Opportunities in Microstructure-Related Properties of Advanced High-Strength Steels. Met. Mater. Trans. A 2020, 51, 5517–5586. [Google Scholar] [CrossRef]

- Wu, Q.; Miao, W.-S.; Zhang, Y.-D.; Gao, H.-J.; Hui, D. Mechanical properties of nanomaterials: A review. Nanotechnol. Rev. 2020, 9, 259–273. [Google Scholar] [CrossRef]

- Estrada, N.; Oquendo, W.F. Microstructure as a function of the grain size distribution for packings of frictionless disks: Effects of the size span and the shape of the distribution. Phys. Rev. E 2017, 96, 042907. [Google Scholar] [CrossRef] [PubMed]

- Ashcroft, I.A.; Mubashar, A. Numerical Approach: Finite Element Analysis. In Handbook of Adhesion Technology; Springer: Berlin/Heidelberg, Germany, 2011; pp. 629–660. [Google Scholar] [CrossRef]

- Paknia, A.; Pramanik, A.; Dixit, A.R.; Chattopadhyaya, S. Effect of Size, Content and Shape of Reinforcements on the Behavior of Metal Matrix Composites (MMCs) Under Tension. J. Mater. Eng. Perform. 2016, 25, 4444–4459. [Google Scholar] [CrossRef]

- Takeo, K.; Aoki, Y.; Osada, T.; Nakao, W.; Ozaki, S. Finite Element Analysis of the Size Effect on Ceramic Strength. Materials 2019, 12, 2885. [Google Scholar] [CrossRef] [PubMed]

- Gad, S.; Attia, M.; Hassan, M.; El-Shafei, A. Predictive Computational Model for Damage Behavior of Metal-Matrix Composites Emphasizing the Effect of Particle Size and Volume Fraction. Materials 2021, 14, 2143. [Google Scholar] [CrossRef]

- Ebuchi, T.; Kitasaka, J.; Nagai, T. Non-Destructive Evaluation of Weld Structure Using Ultrasonic Imaging Technique. Mater. Trans. 2012, 53, 604–609. [Google Scholar] [CrossRef]

- Savin, A.; Craus, M.L.; Bruma, A.; Novy, F.; Malo, S.; Chlada, M.; Steigmann, R.; Vizureanu, P.; Harnois, C.; Turchenko, V.; et al. Microstructural Analysis and Mechanical Properties of TiMo20Zr7Ta15Six Alloys as Biomaterials. Materials 2020, 13, 4808. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Non-Destructive Testing: A Guidebook for Industrial Management and Quality Control Personnel; International Atomic Energy Agency (IAEA): Vienna, Austria, 1999; p. 296. [Google Scholar]

- Ono, K. A Comprehensive Report on Ultrasonic Attenuation of Engineering Materials, Including Metals, Ceramics, Polymers, Fiber-Reinforced Composites, Wood, and Rocks. Appl. Sci. 2020, 10, 2230. [Google Scholar] [CrossRef]

- Masumura, R.; Hazzledine, P.; Pande, C. Yield stress of fine grained materials. Acta Mater. 1998, 46, 4527–4534. [Google Scholar] [CrossRef]

- Kosoń-Schab, A.; Szpytko, J. Magnetic Metal Memory in the Assessment of the Technical Condition of Crane Girders for the Needs of Safety. J. Konbin 2019, 49, 49–73. [Google Scholar] [CrossRef]

- Kosoń-Schab, A.; Smoczek, J.; Szpytko, J. Magnetic Memory Inspection of an Overhead Crane Girder—Experimental Verification. J. KONES 2019, 26, 69–76. [Google Scholar] [CrossRef][Green Version]

- Murakami, K.; Ishimoto, K.; Senoo, T.; Ishikawa, M. Human Robot Hand Interaction with Plastic Deformation Control. Robotics 2020, 9, 73. [Google Scholar] [CrossRef]

- Rogovoy, A.A.; Stolbov, O.V.; Stolbova, O.S. The Microstructural Model of the Ferromagnetic Material Behavior in an External Magnetic Field. Magnetochemistry 2021, 7, 7. [Google Scholar] [CrossRef]

- Feinberg, B.; Gould, H. Placed in a steady magnetic field, the flux density inside a permalloy-shielded volume decreases over hours and days. AIP Adv. 2018, 8, 035303. [Google Scholar] [CrossRef]

- Cullity, B.D.; Graham, C.D. Introduction to Magnetic Materials, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011; p. 568. [Google Scholar]

- Nestleroth, J.; Davis, R.J. Application of eddy currents induced by permanent magnets for pipeline inspection. NDT E Int. 2007, 40, 77–84. [Google Scholar] [CrossRef]

- Xie, Y.; Li, J.; Tao, Y.; Wang, S.; Yin, W.; Xu, L. Edge Effect Analysis and Edge Defect Detection of Titanium Alloy Based on Eddy Current Testing. Appl. Sci. 2020, 10, 8796. [Google Scholar] [CrossRef]

- Grishina, D.A.; Harteveld, C.A.M.; Pacureanu, A.; Devashish, D.; Lagendijk, A.; Cloetens, P.; Vos, W.L. X-ray Imaging of Functional Three-Dimensional Nanostructures on Massive Substrates. ACS Nano 2019, 13, 13932–13939. [Google Scholar] [CrossRef] [PubMed]

- Yan, H.; Voorhees, P.W.; Xin, H.L. Nanoscale x-ray and electron tomography. MRS Bull. 2020, 45, 264–271. [Google Scholar] [CrossRef]

- Siodlak, D.; Lotter, U.; Kawalla, R.; Schwich, V. Modelling of the Mechanical Properties of Low Alloyed Multiphase Steels with Retained Austenite Taking into Account Strain-Induced Transformation. Steel Res. Int. 2008, 79, 776–783. [Google Scholar] [CrossRef]

- Kim, J.; Le, M.; Park, J.; Seo, H.; Jung, G.; Lee, J. Measurement of residual stress using linearly integrated GMR sensor arrays. J. Mech. Sci. Technol. 2018, 32, 623–630. [Google Scholar] [CrossRef]

- Suzuki, M.; Kim, K.-J.; Kim, S.; Yoshikawa, H.; Tono, T.; Yamada, K.T.; Taniguchi, T.; Mizuno, H.; Oda, K.; Ishibashi, M.; et al. Three-dimensional visualization of magnetic domain structure with strong uniaxial anisotropy via scanning hard X-ray microtomography. Appl. Phys. Express 2018, 11, 36601. [Google Scholar] [CrossRef]

- Kent, A.D.; Yu, J.; Rüdiger, U.; Parkin, S. Domain wall resistivity in epitaxial thin film microstructures. J. Phys. Condens. Matter 2001, 13, R461–R488. [Google Scholar] [CrossRef]

- D’Silva, G.J.; Feigenbaum, H.P.; Ciocanel, C. Visualization of Magnetic Domains and Magnetization Vectors in Magnetic Shape Memory Alloys Under Magneto-Mechanical Loading. Shape Mem. Superelasticity 2020, 6, 67–88. [Google Scholar] [CrossRef]

- Lebensohn, R.A.; Kanjarla, A.K.; Eisenlohr, P. An elasto-viscoplastic formulation based on fast Fourier transforms for the prediction of micromechanical fields in polycrystalline materials. Int. J. Plast. 2012, 32–33, 59–69. [Google Scholar] [CrossRef]

- Knezevic, M.; Drach, B.; Ardeljan, M.; Beyerlein, I.J. Three dimensional predictions of grain scale plasticity and grain boundaries using crystal plasticity finite element models. Comput. Methods Appl. Mech. Eng. 2014, 277, 239–259. [Google Scholar] [CrossRef]

- Tasan, C.; Hoefnagels, J.; Diehl, M.; Yan, D.; Roters, F.; Raabe, D. Strain localization and damage in dual phase steels investigated by coupled in-situ deformation experiments and crystal plasticity simulations. Int. J. Plast. 2014, 63, 198–210. [Google Scholar] [CrossRef]

- Ardeljan, M.; Knezevic, M.; Nizolek, T.; Beyerlein, I.J.; Mara, N.; Pollock, T.M. A study of microstructure-driven strain localizations in two-phase polycrystalline HCP/BCC composites using a multi-scale model. Int. J. Plast. 2015, 74, 35–57. [Google Scholar] [CrossRef]

- Zhang, D.; Prasad, A.; Bermingham, M.J.; Todaro, C.J.; Benoit, M.J.; Patel, M.N.; Qiu, D.; StJohn, D.H.; Qian, M.; Easton, M.A. Grain Refinement of Alloys in Fusion-Based Additive Manufacturing Processes. Met. Mater. Trans. A 2020, 51, 4341–4359. [Google Scholar] [CrossRef]

- Todaro, C.J.; Easton, M.A.; Qiu, D.; Zhang, D.; Bermingham, M.J.; Lui, E.W.; Brandt, M.; StJohn, D.H.; Qian, M. Grain structure control during metal 3D printing by high-intensity ultrasound. Nat. Commun. 2020, 11, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Qayyum, F.; Guk, S.; Kawalla, R.; Prahl, U. On Attempting to Create a Virtual Laboratory for Application-Oriented Microstructural Optimization of Multi-Phase Materials. Appl. Sci. 2021, 11, 1506. [Google Scholar] [CrossRef]

- Darbandi, P.; Bieler, T.R.; Pourboghrat, F.; Lee, T.-K. The Effect of Cooling Rate on Grain Orientation and Misorientation Microstructure of SAC105 Solder Joints Before and After Impact Drop Tests. J. Electron. Mater. 2014, 43, 2521–2529. [Google Scholar] [CrossRef]

- Liu, W.; Lianbc, J.; Aravasde, N.; Münstermanna, S. A strategy for synthetic microstructure generation and crystal plasticity parameter calibration of fine-grain-structured dual-phase steel. Int. J. Plast. 2020, 126, 102614. [Google Scholar] [CrossRef]

- Rolchigo, M.R.; Mendoza, M.Y.; Samimi, P.; Brice, D.A.; Martin, B.; Collins, P.C.; Lesar, R. Modeling of Ti-W Solidification Microstructures Under Additive Manufacturing Conditions. Met. Mater. Trans. A 2017, 48, 3606–3622. [Google Scholar] [CrossRef]

- Mendoza, M.Y.; Samimi, P.; Brice, D.A.; Martin, B.W.; Rolchigo, M.R.; Lesar, R.; Collins, P.C. Microstructures and Grain Refinement of Additive-Manufactured Ti-xW Alloys. Met. Mater. Trans. A 2017, 48, 3594–3605. [Google Scholar] [CrossRef]

- Wong, S.L.; Madivala, M.; Prahl, U.; Roters, F.; Raabe, D. A crystal plasticity model for twinning- and transformation-induced plasticity. Acta Mater. 2016, 118, 140–151. [Google Scholar] [CrossRef]

- Qayyum, F.; Guk, S.; Prüger, S.; Schmidtchen, M.; Saenko, I.; Kiefer, B.; Kawalla, R.; Prahl, U. Investigating the local deformation and transformation behavior of sintered X3CrMnNi16-7-6 TRIP steel using a calibrated crystal plasticity-based numerical simulation model. Int. J. Mater. Res. 2020, 111, 392–404. [Google Scholar] [CrossRef]

| Layer | Height of Layer (mm) | ||||

|---|---|---|---|---|---|

| 1st Point | 2nd Point | 3rd Point | 4th Point | Average | |

| 1 | 22.49370 | 22.47870 | 22.50430 | 22.51340 | 22.49753 |

| 2 | 22.49280 | 22.47680 | 22.50210 | 22.51190 | 22.49590 |

| 3 | 22.49160 | 22.47510 | 22.50000 | 22.50910 | 22.49395 |

| 4 | 22.48980 | 22.47290 | 22.49850 | 22.50800 | 22.49230 |

| 5 | 22.48820 | 22.47130 | 22.49740 | 22.50620 | 22.49078 |

| 6 | 22.48680 | 22.47090 | 22.49660 | 22.50440 | 22.48968 |

| 7 | 22.48510 | 22.46850 | 22.49450 | 22.50240 | 22.48763 |

| 8 | 22.48300 | 22.46730 | 22.49240 | 22.50030 | 22.48575 |

| 9 | 22.48160 | 22.46550 | 22.49120 | 22.49910 | 22.48435 |

| 10 | 22.48020 | 22.46410 | 22.48900 | 22.49700 | 22.48258 |

| 11 | 22.47910 | 22.46330 | 22.48750 | 22.49540 | 22.48133 |

| 12 | 22.47680 | 22.46140 | 22.48580 | 22.49320 | 22.47933 |

| 13 | 22.47570 | 22.46040 | 22.48330 | 22.49090 | 22.47758 |

| 14 | 22.47400 | 22.45810 | 22.48170 | 22.48880 | 22.47565 |

| 15 | 22.47220 | 22.45700 | 22.47990 | 22.48750 | 22.47415 |

| 16 | 22.47120 | 22.45550 | 22.47790 | 22.48630 | 22.47273 |

| 17 | 22.46920 | 22.45340 | 22.47640 | 22.48510 | 22.47103 |

| 18 | 22.46730 | 22.45250 | 22.47560 | 22.48420 | 22.46990 |

| 19 | 22.46586 | 22.45088 | 22.43980 | 22.48258 | 22.46828 |

| 20 | 22.46448 | 22.44918 | 22.47228 | 22.44048 | 22.46660 |

| 21 | 22.46338 | 22.44788 | 22.47038 | 22.47948 | 22.46528 |

| 22 | 22.46188 | 22.44578 | 22.46938 | 22.47798 | 22.46375 |

| 23 | 22.46088 | 22.44368 | 22.46688 | 22.47718 | 22.46215 |

| 24 | 22.45918 | 22.44238 | 22.46528 | 22.47568 | 22.46063 |

| 25 | 22.45788 | 22.44028 | 22.46358 | 22.47368 | 22.45885 |

| 26 | 22.45588 | 22.43848 | 22.46218 | 22.47188 | 22.45710 |

| 27 | 22.45398 | 22.43748 | 22.46038 | 22.47048 | 22.45558 |

| 28 | 22.45198 | 22.43548 | 22.45778 | 22.46968 | 22.45373 |

| 29 | 22.45038 | 22.43368 | 22.45578 | 22.46858 | 22.45210 |

| 30 | 22.44878 | 22.43258 | 22.45408 | 22.46608 | 22.45038 |

| 31 | 22.44728 | 22.43068 | 22.45258 | 22.46518 | 22.44893 |

| 32 | 22.44608 | 22.42948 | 22.45168 | 22.46338 | 22.44765 |

| 33 | 22.44498 | 22.42728 | 22.45008 | 22.46098 | 22.44583 |

| 34 | 22.44388 | 22.42518 | 22.44868 | 22.45968 | 22.44435 |

| 35 | 22.44278 | 22.42288 | 22.44748 | 22.45868 | 22.44295 |

| 36 | 22.44158 | 22.42188 | 22.44638 | 22.45618 | 22.44150 |

| 37 | 22.44008 | 22.42038 | 22.44368 | 22.45528 | 22.43985 |

| 38 | 22.44385 | 22.41880 | 22.44210 | 22.45370 | 22.43827 |

| 39 | 22.44364 | 22.41560 | 22.44090 | 22.45230 | 22.43630 |

| 40 | 22.43470 | 22.41440 | 22.43880 | 22.45090 | 22.43470 |

| 41 | 22.43230 | 22.41230 | 22.4376 | 22.44950 | 22.43292 |

| 42 | 22.43120 | 22.41070 | 22.43620 | 22.44720 | 22.43132 |

| 43 | 22.43000 | 22.40960 | 22.43550 | 22.44580 | 22.43022 |

| 44 | 22.42920 | 22.40870 | 22.43350 | 22.44460 | 22.42900 |

| 45 | 22.42830 | 22.40780 | 22.43150 | 22.44270 | 22.42757 |

| 46 | 22.42650 | 22.40620 | 22.42990 | 22.44030 | 22.42572 |

| 47 | 22.42570 | 22.40530 | 22.42900 | 22.43870 | 22.42467 |

| 48 | 22.42390 | 22.40380 | 22.42770 | 22.43740 | 22.42320 |

| 49 | 22.42210 | 22.40170 | 22.42670 | 22.43560 | 22.42152 |

| 50 | 22.42070 | 22.40070 | 22.42500 | 22.43430 | 22.42017 |

| 51 | 22.41910 | 22.39980 | 22.42350 | 22.43340 | 22.41895 |

| 52 | 22.41860 | 22.39840 | 22.42180 | 22.43210 | 22.41772 |

| 53 | 22.41700 | 22.39700 | 22.42000 | 22.43030 | 22.41607 |

| 54 | 22.41580 | 22.39510 | 22.41860 | 22.42880 | 22.41457 |

| 55 | 22.41420 | 22.39300 | 22.41670 | 22.42680 | 22.41267 |

| 56 | 22.41300 | 22.39160 | 22.41520 | 22.42550 | 22.41132 |

| 57 | 22.41230 | 22.39080 | 22.41340 | 22.42340 | 22.40997 |

| 58 | 22.41070 | 22.38880 | 22.41170 | 22.42150 | 22.40817 |

| 59 | 22.40860 | 22.38680 | 22.41050 | 22.42000 | 22.40650 |

| 60 | 22.40660 | 22.38590 | 22.40890 | 22.41850 | 22.40497 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Berkache, A.; Wang, D.; Hwang, Y.-H. Three-Dimensional Imaging of Metallic Grain by Stacking the Microscopic Images. Appl. Sci. 2021, 11, 7787. https://doi.org/10.3390/app11177787

Lee J, Berkache A, Wang D, Hwang Y-H. Three-Dimensional Imaging of Metallic Grain by Stacking the Microscopic Images. Applied Sciences. 2021; 11(17):7787. https://doi.org/10.3390/app11177787

Chicago/Turabian StyleLee, Jinyi, Azouaou Berkache, Dabin Wang, and Young-Ha Hwang. 2021. "Three-Dimensional Imaging of Metallic Grain by Stacking the Microscopic Images" Applied Sciences 11, no. 17: 7787. https://doi.org/10.3390/app11177787

APA StyleLee, J., Berkache, A., Wang, D., & Hwang, Y.-H. (2021). Three-Dimensional Imaging of Metallic Grain by Stacking the Microscopic Images. Applied Sciences, 11(17), 7787. https://doi.org/10.3390/app11177787