Effect of Water-Based Acrylic Acid Microcapsules on the Properties of Paint Film for Furniture Surface

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Method

2.3. Testing and Characterization

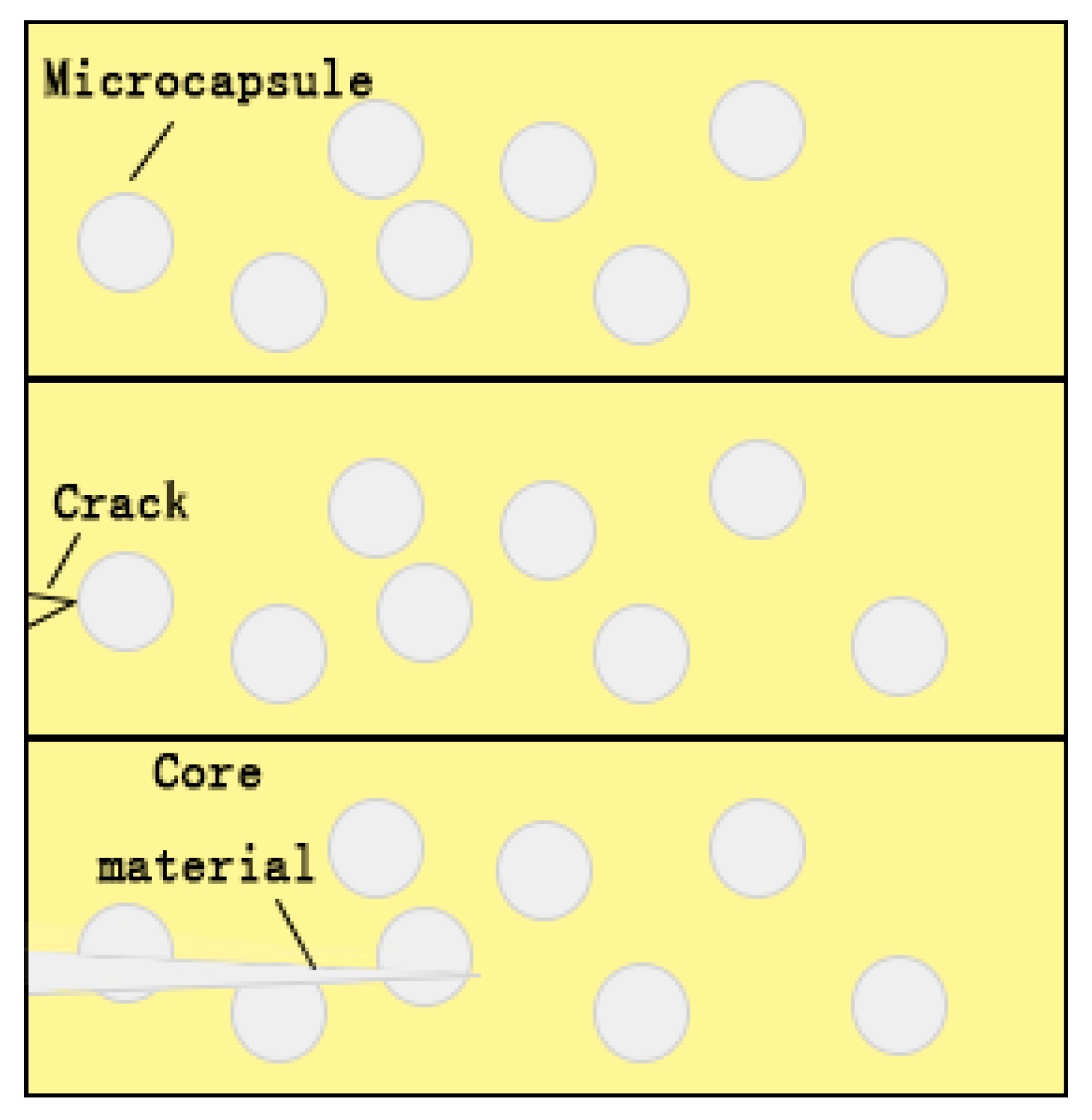

3. Results and Discussion

3.1. Variation of Optical Performances of Water-Based Topcoat Paint Film

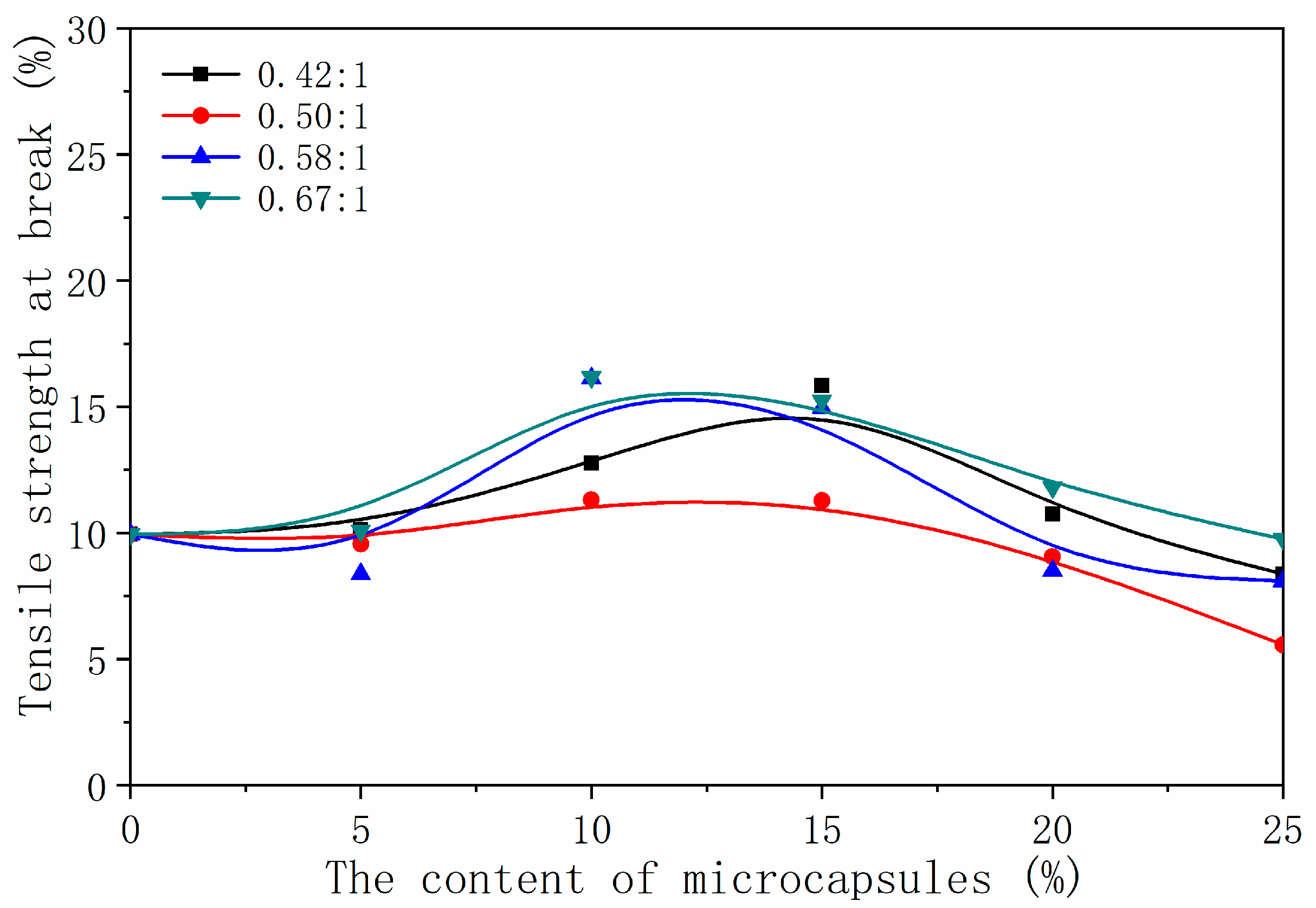

3.2. Variation of Mechanical Performances of Water-Based Topcoat Paint Film

3.3. Variation of Self-Healing Microcapsules on Liquid Resistance of Water-Based Topcoat Paint Film

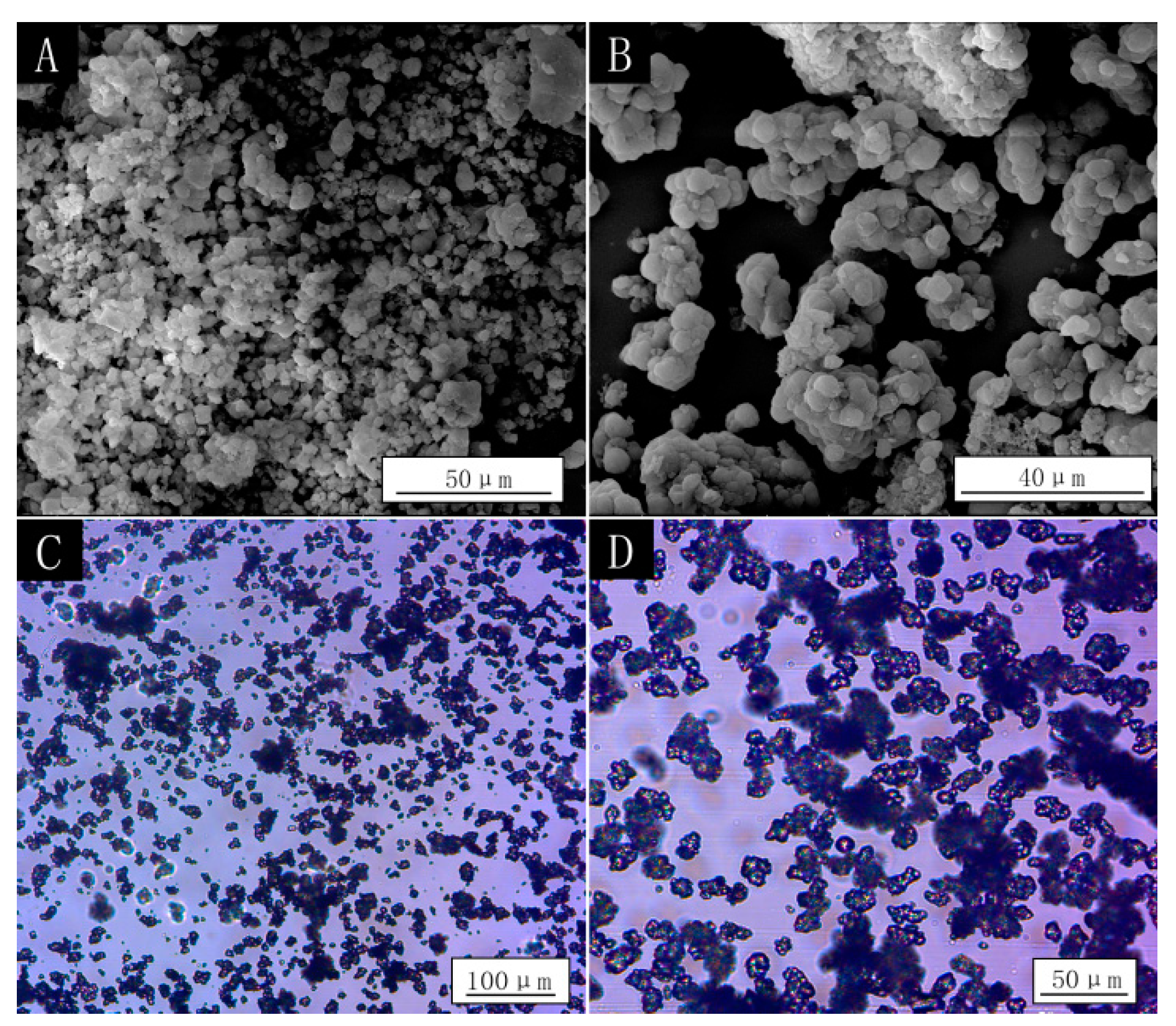

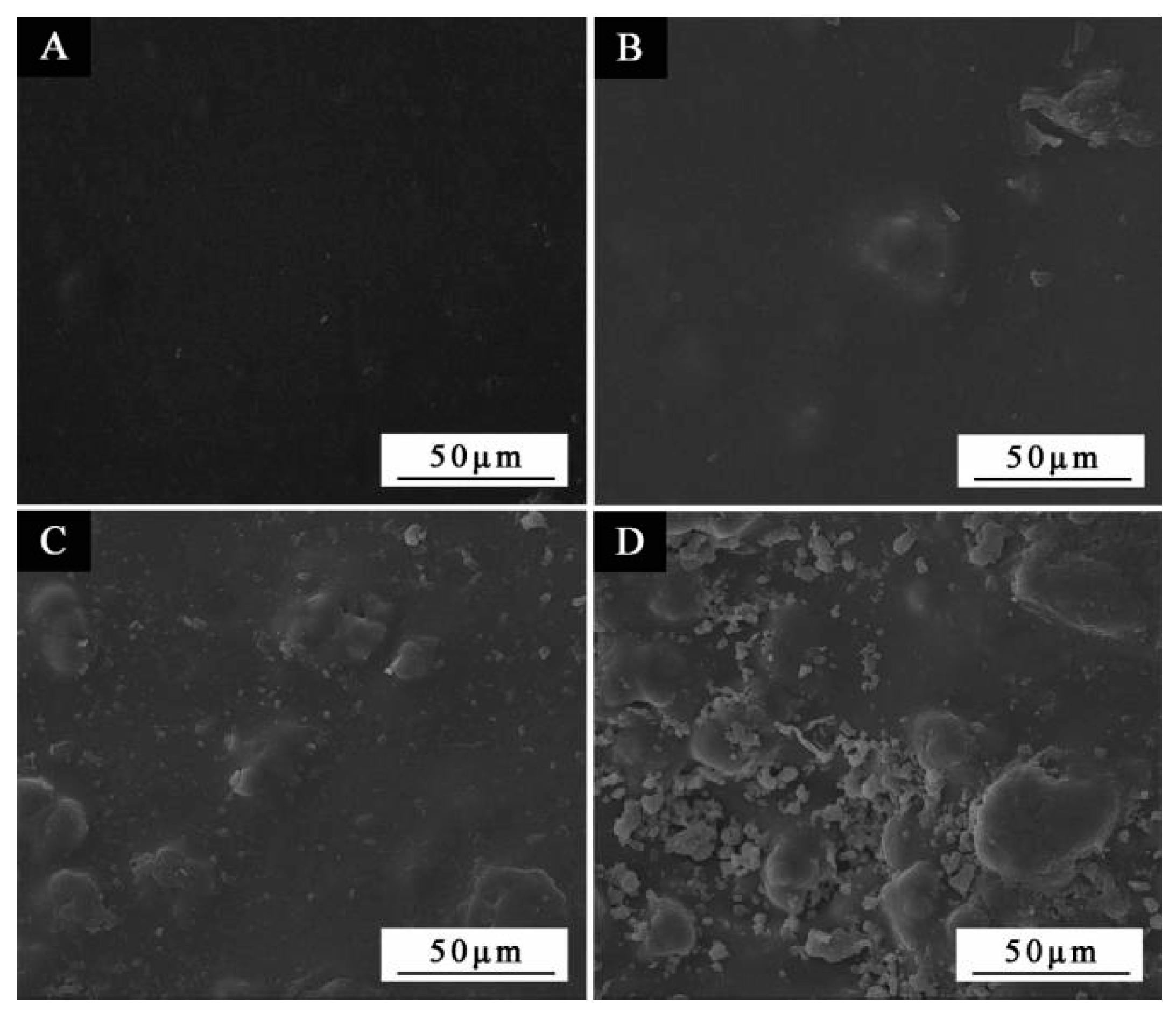

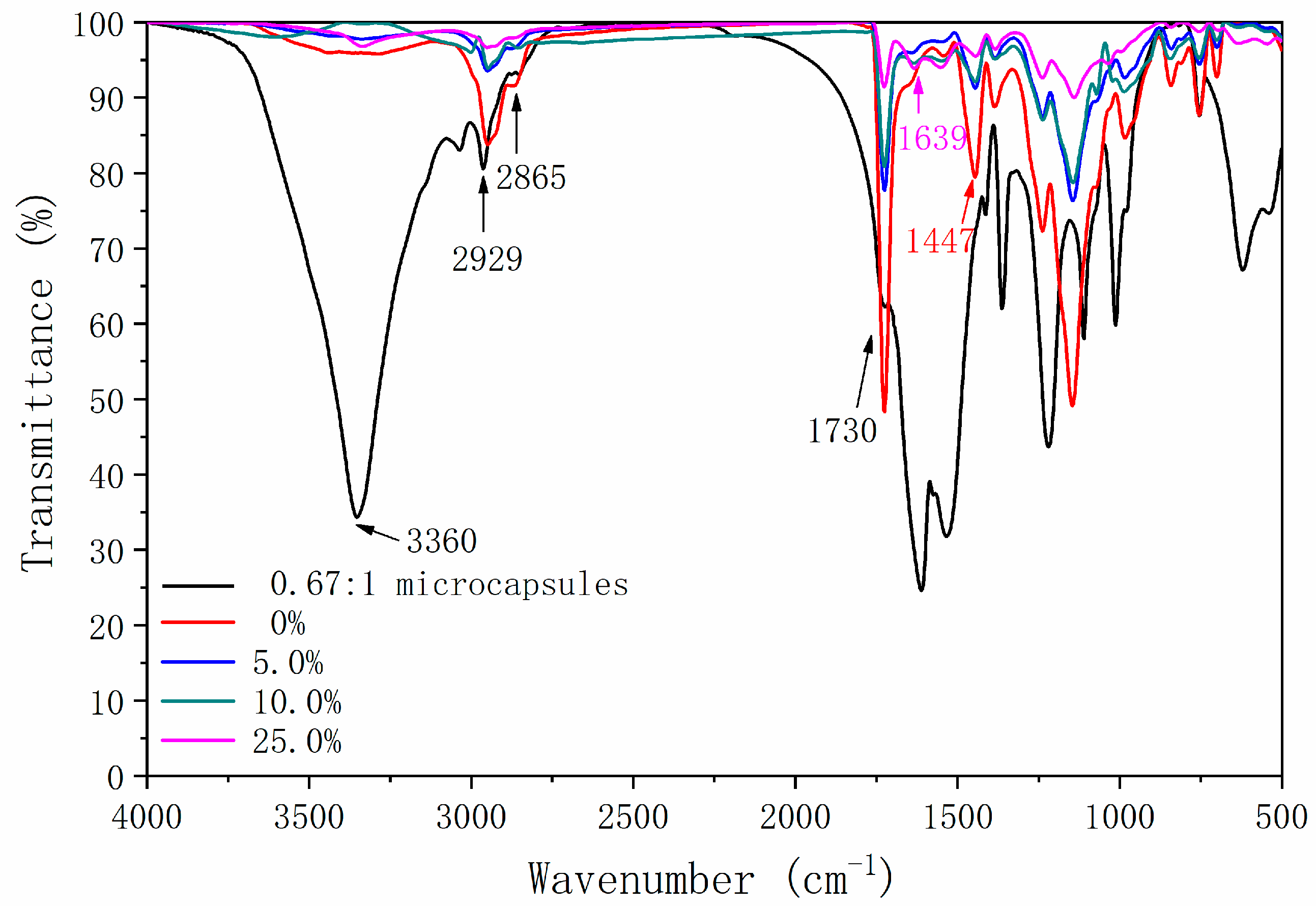

3.4. Structure Analysis

3.5. Composition Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, X.X.; Wang, L. Preparation of shellac resin microcapsules coated with urea formaldehyde resin and properties of waterborne paint films for Tilia amurensis rupr. Membranes 2020, 10, 278. [Google Scholar] [CrossRef]

- Jiang, W.J.; Zhou, G.; Duan, J.J.; Liu, D.; Zhang, Q.T.; Tian, F.C. Synthesis and characterization of a multifunctional sustained-release organic-inorganic hybrid microcapsule with self-healing and flame-retardancy properties. ACS Appl. Mater. Interfaces 2021, 13, 15668–15679. [Google Scholar] [CrossRef] [PubMed]

- Parsaee, S.; Mirabedini, S.M.; Farnood, R.; Alizadegan, F. Development of self-healing coatings based on urea-formaldehyde/polyurethane microcapsules containing epoxy resin. J. Appl. Polym. Sci. 2020, 137, e49663. [Google Scholar] [CrossRef]

- Jeong, H.; Lim, H.; Lee, D.Y.; Song, Y.S.; Kim, B.Y. Preparation and drug release behavior of nifedipine-loaded poly (lactic acid) /polyethylene glycol microcapsules. J. Nanosci. Nanotechnol. 2021, 21, 3735–3741. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.L.; Zhou, J.L.; Che, X.G.; Zhao, R.Y.; Gao, Q. One-step synthesis of core shell cellulose-silica/n-octadecane microcapsules and their application in waterborne self-healing multiple protective fabric coatings. J. Colloid Interface Sci. 2020, 566, 401–410. [Google Scholar] [CrossRef] [PubMed]

- Nesterova, T.; Dam-Johansen, K.; Pedersen, L.T.; Kiil, S. Microcapsule-based self-healing anticorrosive coatings: Capsule size, coating formulation, and exposure testing. Prog. Org. Coat. 2012, 75, 309–318. [Google Scholar] [CrossRef]

- Njoku, C.N.; Bai, W.C.; Arukalam, I.O.; Yang, L.H.; Hou, B.R.; Njoku, D.I.; Li, Y. Epoxy-based smart coating with self-repairing polyurea-formaldehyde microcapsules for anticorrosion protection of aluminum alloy AA2024. J. Coat. Technol. Res. 2020, 17, 797–813. [Google Scholar] [CrossRef]

- Yan, X.X.; Zhao, W.T.; Qian, X.Y. Effect of urea-formaldehyde (UF) with waterborne emulsion microcapsules on properties of waterborne acrylic coatings based on coating process for American lime. Appl. Sci. 2020, 10, 6341. [Google Scholar] [CrossRef]

- Liu, M.; Xu, G.L.; Wang, J.A.; Tu, X.W.; Liu, X.Y.; Wu, Z.H.; Lv, J.F.; Xu, W. Effects of shellac treatment on wood hygroscopicity, dimensional stability and thermostability. Coatings 2020, 10, 881. [Google Scholar] [CrossRef]

- Peng, X.R.; Zhang, Z.K. Improvement of paint adhesion of environmentally friendly paint film on wood surface by plasma treatment. Prog. Org. Coat. 2019, 134, 255–263. [Google Scholar] [CrossRef]

- Li, R.R.; Chen, J.J.; Wang, X.D. Prediction of the color variation of moso bamboo during CO2 laser thermal modification. BioResources 2020, 15, 5049–5057. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Gao, D.; Xu, W. Effect of sanding processes on the surface properties of modified Poplar coated by primer compared with Mahogany. Coatings 2020, 10, 856. [Google Scholar] [CrossRef]

- Yu, F.; Feng, H.Y.; Xiao, L.H.; Liu, Y. Fabrication of graphene oxide microcapsules based on Pickering emulsions for self-healing water-borne epoxy resin coatings. Prog. Org. Coat. 2021, 155, 106221. [Google Scholar] [CrossRef]

- Xiong, X.Q.; Yuan, Y.Y.; Niu, Y.T.; Zhang, L.T. Development of a cornstarch adhesive for laminated veneer lumber bonding for use in engineered wood flooring. Int. J. Adhes. Adhes. 2020, 98, 102534. [Google Scholar]

- Zhang, T.X.; Ting, G.; Wu, Z.H.; Sun, T. Reinforced strength evaluation of binding material for the restoration of Chinese ancient lacquer furniture. BioResources 2019, 14, 7182–7192. [Google Scholar]

- Abbaspoor, S.; Ashrafi, A.; Salehi, M. Cathodic disbonding of self-healing composite coatings: Effect of ethyl cellulose micro/nanocapsules. Corros. Eng. Sci. Technol. 2021. [Google Scholar] [CrossRef]

- Han, T.L.; Wang, X.F.; Li, D.W.; Li, D.F.; Xing, F.; Han, N.X. Influence of strain rate on mechanical characteristic and pore structure of self-healing cementitious composites with epoxy/urea-formaldehyde microcapsules. Constr. Build. Mater. 2021, 268, 121138. [Google Scholar] [CrossRef]

- Xu, W.; Fang, X.Y.; Han, J.T.; Wu, Z.H.; Zhang, J.L. Effect of coating thickness on sound absorption property of four wood species commonly used for piano soundboards. Wood Fiber. Sci. 2020, 52, 28–43. [Google Scholar] [CrossRef] [Green Version]

- Liu, Q.Q.; Gao, D.; Xu, W. Influence of the bottom color modification and material color modification process on the performance of modified Poplar. Coatings 2021, 11, 660. [Google Scholar] [CrossRef]

- Wu, S.S.; Tao, X.; Xu, W. Thermal conductivity of Poplar wood veneer impregnated with graphene/polyvinyl alcohol. Forests 2021, 12, 777. [Google Scholar] [CrossRef]

- Zhang, B.D.; Huang, C.X.; Zhang, L.Y.; Wang, J.; Huang, X.Q.; Zhao, Y.; Liu, Y.; Li, C.C. Application of chlorine dioxide microcapsule sustained-release antibacterial films for preservation of mangos. J. Food Sci. Technol. Mys. 2019, 56, 1095–1103. [Google Scholar] [CrossRef]

- Ebrahimnezhad-Khaljiri, H.; Eslami-Farsani, R. The tensile properties and interlaminar shear strength of microcapsules-glass fibers/epoxy self-healable composites. Eng. Fract. Mech. 2020, 230, 106937. [Google Scholar] [CrossRef]

- Ji, X.P.; Li, J.; Hua, W.L.; Hu, Y.L.; Si, B.T.; Chen, B. Preparation and performance of microcapsules for asphalt pavements using interfacial polymerization. Constr. Build. Mater. 2021, 289, 123179. [Google Scholar] [CrossRef]

- Li, K.K.; Liu, Z.J.; Wang, C.J.; Fan, W.H.; Liu, F.T.; Li, H.Y.; Zhu, Y.J.; Wang, H.Y. Preparation of smart coatings with self-healing and anti-wear properties by embedding PU-fly ash absorbing linseed oil microcapsules. Prog. Org. Coat. 2020, 145, 105668. [Google Scholar] [CrossRef]

- Pan, S.H.; Cao, H.C.; Li, B.X.; Zhang, D.X.; Mu, W.; Liu, F. Improving the efficacy against crop foliage disease by regulating fungicide adhesion on leaves with soft microcapsules. Pest Manag. Sci. 2021. [Google Scholar] [CrossRef]

- Shi, S.S.; Netravali, A.N. Bacterial cellulose integrated irregularly shaped microcapsules enhance self-healing efficiency and mechanical properties of green soy protein resins. J. Mater. Sci. 2021, 56, 12030–12047. [Google Scholar] [CrossRef]

- Santana, J.J.; Mena, V.F.; Betancor-Abreu, A.; Rodriguez-Raposo, R.; Izquierdo, J.; Souto, R.M. Use of alumina sludge arising from an electrocoagulation process as functional mesoporous microcapsules for active corrosion protection of aluminum. Prog. Org. Coat. 2021, 151, 106044. [Google Scholar] [CrossRef]

- Zhang, S.N.; Ye, T.T. Preparation of natural composite microcapsules containing orchid black currant fragrance and its sustained-release properties on hair bundle. J. Polym. Environ. 2021. [Google Scholar] [CrossRef]

- Adibzadeh, E.; Mirabedini, S.M.; Behzadnasab, M.; Farnood, R.R. A novel two-component self-healing coating comprising vinyl ester resin-filled microcapsules with prolonged anticorrosion performance. Prog. Org. Coat. 2021, 154, 106220. [Google Scholar] [CrossRef]

- Yan, X.X.; Peng, W.W. Effect of microcapsules of a waterborne core material on the properties of a waterborne primer coating on a wooden surface. Coatings 2021, 11, 657. [Google Scholar] [CrossRef]

- Rao, Y.S.; Kumari, P.V.K.; Chowdary, K.P.R. Ethylene vinyl acetate microcapsules of nifedipine: Characterization, release kinetics and pharmacokinetic evaluation. Indian J. Pharm. Sci. 2020, 82, 6. [Google Scholar] [CrossRef]

- Lee, J.; Jo, B. Surfactant-free synthesis protocol of robust and sustainable molten salt microcapsules for solar thermal energy storage. Sol. Energy Mater. Sol. Cells 2021, 222, 110954. [Google Scholar] [CrossRef]

| Content of Microcapsules (%) | Color Difference | ||||||

|---|---|---|---|---|---|---|---|

| 0.42:1 | 0.50:1 | 0.58:1 | 0.67:1 | 0.75:1 | 0.83:1 | 0.92:1 | |

| 0 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| 5.0 | 1.8 | 1.5 | 1.5 | 1.6 | 1.3 | 1.2 | 1.6 |

| 10.0 | 2.8 | 2.2 | 2.3 | 2.0 | 1.5 | 2.1 | 2.9 |

| 15.0 | 3.6 | 3.2 | 2.8 | 2.4 | 2.4 | 2.7 | 4.1 ± 0.1 |

| 20.0 | 4.4 | 3.3 | 3.2 | 3.5 | 4.4 | 3.4 | 4.4 ± 0.1 |

| 25.0 | 5.1 | 5.5 | 5.0 ± 0.2 | 4.8 ± 0.1 | 4.7 ± 0.1 | 3.9 ± 0.1 | 5.3 ± 0.2 |

| Content of Microcapsules (%) | Gloss (%) | ||||||

|---|---|---|---|---|---|---|---|

| 0.42:1 | 0.50:1 | 0.58:1 | 0.67:1 | 0.75:1 | 0.83:1 | 0.92:1 | |

| 0 | 29.4 ± 0.8 | 29.4 ± 0.8 | 29.4 ± 0.8 | 29.4 ± 0.8 | 29.4 ± 0.8 | 29.4 ± 0.8 | 29.4 ± 0.8 |

| 5.0 | 15.3 ± 0.8 | 8.9 ± 0.2 | 10.2 ± 0.2 | 17.9 ± 0.7 | 13.6 ± 0.6 | 11.2 ± 0.9 | 11.8 ± 0.3 |

| 10.0 | 9.4 ± 0.1 | 7.1 ± 0.1 | 9.1 ± 0.1 | 11.9 ± 0.2 | 10.4 ± 0.2 | 8.6 ± 0.2 | 10.6 ± 0.1 |

| 15.0 | 4.0 ± 0.1 | 4.6 ± 0.1 | 7.3 ± 0.2 | 6.7 ± 0.1 | 5.2 ± 0.1 | 3.4 ± 0.1 | 5.0 ± 0.1 |

| 20.0 | 2.6 | 3.6 ± 0.1 | 2.9 ± 0.1 | 5.5 | 3.2 | 2.8 ± 0.1 | 3.3 ± 0.1 |

| 25.0 | 2.4 ± 0.1 | 3.3 | 2.3 | 3.2 | 2.1 ± 0.1 | 2.1 ± 0.1 | 3.2 |

| Content of Microcapsules (%) | Hardness | ||||||

|---|---|---|---|---|---|---|---|

| 0.42:1 | 0.50:1 | 0.58:1 | 0.67:1 | 0.75:1 | 0.83:1 | 0.92:1 | |

| 0 | HB | HB | HB | HB | HB | HB | HB |

| 5.0 | H | 2H | 2H | 2H | 2H | 2H | 2H |

| 10.0 | 2H | 2H | 2H | 3H | 2H | 2H | 2H |

| 15.0 | 2H | 2H | 2H | 3H | 2H | 2H | 3H |

| 20.0 | 2H | 2H | 3H | 3H | 2H | 3H | 3H |

| 25.0 | 2H | 2H | 3H | 3H | 2H | 3H | 3H |

| Content of Microcapsules (%) | Adhesion (Grade) | ||||||

|---|---|---|---|---|---|---|---|

| 0.42:1 | 0.50:1 | 0.58:1 | 0.67:1 | 0.75:1 | 0.83:1 | 0.92:1 | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 5.0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| 10.0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 |

| 15.0 | 1 | 2 | 1 | 1 | 1 | 2 | 2 |

| 20.0 | 2 | 2 | 1 | 1 | 2 | 2 | 2 |

| 25.0 | 2 | 2 | 2 | 2 | 2 | 3 | 3 |

| Content of Microcapsules (%) | Impact Resistance (kg·cm) | ||||||

|---|---|---|---|---|---|---|---|

| 0.42:1 | 0.50:1 | 0.58:1 | 0.67:1 | 0.75:1 | 0.83:1 | 0.92:1 | |

| 0 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| 5.0 | 8 | 8 | 8 | 10 | 10 | 9 | 9 |

| 10.0 | 9 | 12 | 9 | 13 | 13 | 12 | 12 |

| 15.0 | 13 | 12 | 13 | 13 | 13 | 12 | 13 |

| 20.0 | 15 | 12 | 11 | 13 | 11 | 10 | 10 |

| 25.0 | 15 | 13 | 11 | 13 | 11 | 10 | 10 |

| Core-Wall Ratio | Content (%) | Color Difference | Gloss (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| NaCl | Ethanol | Detergent | Red Ink | NaCl | Ethanol | Detergent | Red Ink | ||

| 0.42:1 | 0 | 0.4 | 1.2 | 0.4 | 2.3 | 29.1 ± 1.2 | 29.0 ± 1.0 | 29.4 ± 1.3 | 29.6 ± 1.5 |

| 5.0 | 0.6 | 0.4 | 0.4 | 0.3 | 15.1 ± 0.6 | 15.4 ± 0.5 | 15.0 ± 0.5 | 15.1 ± 0.9 | |

| 10.0 | 0.3 | 0.6 | 0.8 | 0.9 | 9.1 ± 0.3 | 9.2 ± 0.3 | 9.2 ± 0.3 | 9.0 ± 0.6 | |

| 15.0 | 0.4 | 0.8 | 0.5 | 1.5 | 4.0 ± 0.1 | 3.9 ± 0.1 | 3.8 ± 0.1 | 3.3 ± 0.2 | |

| 20.0 | 1.0 | 1.2 | 1.0 | 2.9 | 2.4 | 2.4 | 2.6 ± 0.1 | 2.0 | |

| 25.0 | 0.8 | 3.3 | 0.8 | 2.0 | 2.2 | 2.2 | 2.3 | 2.0 | |

| 0.50:1 | 0 | 0.4 | 1.2 | 0.4 | 2.3 | 29.1 ± 1.2 | 29.0 ±1.0 | 29.4 ± 1.3 | 29.6 ± 1.5 |

| 5.0 | 1.1 | 1.0 | 1.1 | 1.8 | 8.4 ± 0.3 | 8.3 ± 0.2 | 8.5 ± 0.3 | 8.3 ± 0.7 | |

| 10.0 | 1.1 | 0.7 | 1.0 | 0.9 | 7.0 ± 0.2 | 7.1 ± 0.1 | 6.9 ± 0.2 | 6.6 ± 0.5 | |

| 15.0 | 1.0 | 1.0 | 1.0 | 2.4 | 4.3 ± 0.1 | 4.3 | 4.4 ± 0.2 | 4.0 ± 0.2 | |

| 20.0 | 0.9 | 1.9 | 0.9 | 6.2 ± 0.1 | 3.4 ± 0.1 | 3.7 ± 0.3 | 3.6 ± 0.1 | 3.2 ± 0.2 | |

| 25.0 | 0.9 | 1.8 | 1.1 | 3.0 | 3.3 ± 0.1 | 3.4 ± 0.1 | 3.2 ± 0.1 | 2.8 ± 0.1 | |

| 0.58:1 | 0 | 0.4 | 1.2 | 0.4 | 2.3 | 29.1 ± 1.0 | 29 ± 1.0 | 29.4 ± 1.3 | 29.6 ± 1.5 |

| 5.0 | 1.0 | 1.1 | 1.1 | 0.8 | 9.7 ± 0.3 | 9.8 ± 0.2 | 10.0 ± 0.4 | 9.1 ± 0.3 | |

| 10.0 | 0.7 | 1.0 | 0.6 | 1.3 | 8.8 ± 0.2 | 8.9 ± 0.1 | 8.6 ± 0.5 | 8.3 ± 0.2 | |

| 15.0 | 0.7 | 1.3 | 0.3 | 0.7 | 7.2 ± 0.1 | 7.3 ± 0.2 | 7.2 ± 0.3 | 6.9 ± 0.2 | |

| 20.0 | 1.0 | 1.8 | 1.1 | 2.4 | 2.7 | 2.8 | 2.7 | 2.6 ± 0.1 | |

| 25.0 | 0.5 | 1.3 | 0.7 | 4.2 ± 0.1 | 2.5 ± 0.1 | 2.3 | 2.1 | 2.0 | |

| 0.67:1 | 0 | 0.4 | 1.2 | 0.4 | 2.3 | 29.1 ± 1.2 | 29.0 ±1.0 | 29.4 ± 1.3 | 29.6 ± 1.5 |

| 5.0 | 0.9 | 1.1 | 0.7 | 0.8 | 13.5 ± 0.6 | 13.5 ± 0.8 | 13.6 ± 0.6 | 13.1 ± 0.9 | |

| 10.0 | 0.7 | 1.1 | 0.8 | 0.8 | 11.9 ± 0.5 | 11.4 ± 0.7 | 11.7 ± 0.7 | 11.2 ± 0.6 | |

| 15.0 | 1.1 | 0.6 | 1.1 | 0.9 | 6.4 ± 0.1 | 6.4 ± 0.6 | 6.6 ± 0.4 | 6.2 ± 0.4 | |

| 20.0 | 1.0 | 0.9 | 1.0 | 2.7 | 5.4 ± 0.1 | 5.3 ± 0.2 | 5.4 ± 0.2 | 5.0 ± 0.3 | |

| 25.0 | 1.1 | 1.1 | 1.1 | 3.2 | 3.2 | 3.2 ± 0.1 | 3.0 ± 0.1 | 2.8 ± 0.1 | |

| 0.75:1 | 0 | 0.4 | 1.2 | 0.4 | 2.3 | 29.1 ± 1.2 | 29 ± 1.0 | 29.4 ± 1.3 | 29.6 ± 1.5 |

| 5.0 | 1.2 | 1.0 | 0.7 | 1.2 | 17.5 ± 0.4 | 17.5 ± 0.4 | 17.3 ± 0.8 | 16.8 ± 0.9 | |

| 10.0 | 0.7 | 1.0 | 0.3 | 0.7 | 10.3 ± 0.2 | 10.2 ± 0.3 | 10.0 ± 0.4 | 9.9 ± 0.8 | |

| 15.0 | 0.6 | 0.9 | 0.7 | 1.8 | 5.1 ± 0.1 | 5.2 ± 0.2 | 5.3 ± 0.1 | 5.0 ± 0.3 | |

| 20.0 | 1.0 | 0.8 | 1.9 | 1.2 | 3.1 | 3.2 ± 0.1 | 3.2 ± 0.1 | 2.8 | |

| 25.0 | 0.3 | 1.0 | 1.9 | 3.5 | 2.0 | 2.1 | 2.1 | 1.9 | |

| 0.83:1 | 0 | 0.4 | 1.2 | 0.4 | 2.3 | 29.1 ± 1.2 | 29.0 ± 1.0 | 29.4 ± 1.3 | 29.6 ± 1.5 |

| 5.0 | 1.5 | 0.7 | 0.9 | 1.6 | 11.1 ± 0.4 | 11.2 ± 0.3 | 11.2 ± 0.4 | 11.0 ± 0.5 | |

| 10.0 | 0.5 | 1.0 | 0.7 | 1.8 | 8.4 ± 0.3 | 8.3 ± 0.3 | 8.5 ± 0.3 | 8.0 ± 0.4 | |

| 15.0 | 0.9 | 2.5 | 1.1 | 2.3 | 3.2 | 3.4 ± 0.1 | 3.4 ± 0.1 | 2.9 ± 0.1 | |

| 20.0 | 1.3 | 3.0 ± 0.1 | 1.9 | 2.6 | 2.5 | 2.4 ± 0.1 | 2.7 ± 0.1 | 2.5 | |

| 25.0 | 1.5 | 3.3 ± 0.1 | 1.5 | 2.1 | 2.1 | 2.0 | 2.1 ± 0.1 | 2.0 | |

| 0.92:1 | 0 | 0.4 | 1.2 | 0.4 | 2.3 | 29.1 ± 1.2 | 29.0 ±1.0 | 29.4 ± 1.3 | 29.6 ± 1.5 |

| 5.0 | 0.6 | 1.1 | 0.9 | 1.8 | 11.3 ± 0.3 | 11.8 ± 0.5 | 11.6 ± 0.4 | 10.8 ± 0.5 | |

| 10.0 | 0.7 | 1.3 | 0.4 | 0.9 | 10.3 ± 0.2 | 10.4 ± 0.3 | 10.4 ± 0.6 | 10.2 ± 0.7 | |

| 15.0 | 1.1 | 1.5 | 0.7 | 2.2 | 4.9 ± 0.1 | 4.9 ± 0.2 | 4.8 ± 0.2 | 4.5 ± 0.2 | |

| 20.0 | 0.7 | 2.1 | 1.0 | 2.6 ± 0.1 | 3.2 ± 0.1 | 3.3 ± 0.2 | 3.3 ± 0.1 | 3.2 ± 0.1 | |

| 25.0 | 0.8 | 1.7 | 1.3 | 8.8 ± 0.3 | 3.0 | 3.1 ± 0.1 | 3.2 ± 0.1 | 2.9 ± 0.1 | |

| Core-Wall Ratio | Content of Microcapsules (%) | Liquid Resistance (Level) | |||

|---|---|---|---|---|---|

| NaCl | Ethanol | Detergent | Red Ink | ||

| 0.42:1 | 0 | 1 | 1 | 1 | 2 |

| 5.0 | 1 | 1 | 1 | 1 | |

| 10.0 | 1 | 1 | 1 | 1 | |

| 15.0 | 1 | 1 | 1 | 1 | |

| 20.0 | 1 | 1 | 1 | 3 | |

| 25.0 | 1 | 3 | 1 | 2 | |

| 0.50:1 | 0 | 1 | 1 | 1 | 2 |

| 5.0 | 1 | 1 | 1 | 1 | |

| 10.0 | 1 | 1 | 1 | 1 | |

| 15.0 | 1 | 1 | 1 | 2 | |

| 20.0 | 1 | 1 | 1 | 3 | |

| 25.0 | 1 | 1 | 1 | 3 | |

| 0.58:1 | 0 | 1 | 1 | 1 | 2 |

| 5.0 | 1 | 1 | 1 | 1 | |

| 10.0 | 1 | 1 | 1 | 1 | |

| 15.0 | 1 | 1 | 1 | 1 | |

| 20.0 | 1 | 1 | 1 | 2 | |

| 25.0 | 1 | 1 | 1 | 3 | |

| 0.67:1 | 0 | 1 | 1 | 1 | 2 |

| 5.0 | 1 | 1 | 1 | 1 | |

| 10.0 | 1 | 1 | 1 | 1 | |

| 15.0 | 1 | 1 | 1 | 1 | |

| 20.0 | 1 | 1 | 1 | 2 | |

| 25.0 | 1 | 1 | 1 | 3 | |

| 0.75:1 | 0 | 1 | 1 | 1 | 2 |

| 5.0 | 1 | 1 | 1 | 1 | |

| 10.0 | 1 | 1 | 1 | 1 | |

| 15.0 | 1 | 1 | 1 | 1 | |

| 20.0 | 1 | 1 | 1 | 1 | |

| 25.0 | 1 | 1 | 1 | 3 | |

| 0.83:1 | 0 | 1 | 1 | 1 | 2 |

| 5.0 | 1 | 1 | 1 | 1 | |

| 10.0 | 1 | 1 | 1 | 1 | |

| 15.0 | 1 | 2 | 1 | 3 | |

| 20.0 | 1 | 3 | 1 | 3 | |

| 25.0 | 1 | 3 | 1 | 3 | |

| 0.92:1 | 0 | 1 | 1 | 1 | 2 |

| 5.0 | 1 | 1 | 1 | 1 | |

| 10.0 | 1 | 1 | 1 | 1 | |

| 15.0 | 1 | 1 | 1 | 2 | |

| 20.0 | 1 | 2 | 1 | 2 | |

| 25.0 | 1 | 1 | 1 | 3 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, X.; Peng, W.; Qian, X. Effect of Water-Based Acrylic Acid Microcapsules on the Properties of Paint Film for Furniture Surface. Appl. Sci. 2021, 11, 7586. https://doi.org/10.3390/app11167586

Yan X, Peng W, Qian X. Effect of Water-Based Acrylic Acid Microcapsules on the Properties of Paint Film for Furniture Surface. Applied Sciences. 2021; 11(16):7586. https://doi.org/10.3390/app11167586

Chicago/Turabian StyleYan, Xiaoxing, Wenwen Peng, and Xingyu Qian. 2021. "Effect of Water-Based Acrylic Acid Microcapsules on the Properties of Paint Film for Furniture Surface" Applied Sciences 11, no. 16: 7586. https://doi.org/10.3390/app11167586

APA StyleYan, X., Peng, W., & Qian, X. (2021). Effect of Water-Based Acrylic Acid Microcapsules on the Properties of Paint Film for Furniture Surface. Applied Sciences, 11(16), 7586. https://doi.org/10.3390/app11167586