Visioning the Future of Smart Fashion Factories Based on Media Big Data Analysis

Abstract

:1. Introduction

2. Theoretical Background

2.1. Maturity of Smart Fashion Factory

2.2. Technologies of Smart Fashion Factory

3. Methods

4. Results

4.1. Semantic Analysis Finding 1: Issue Networks

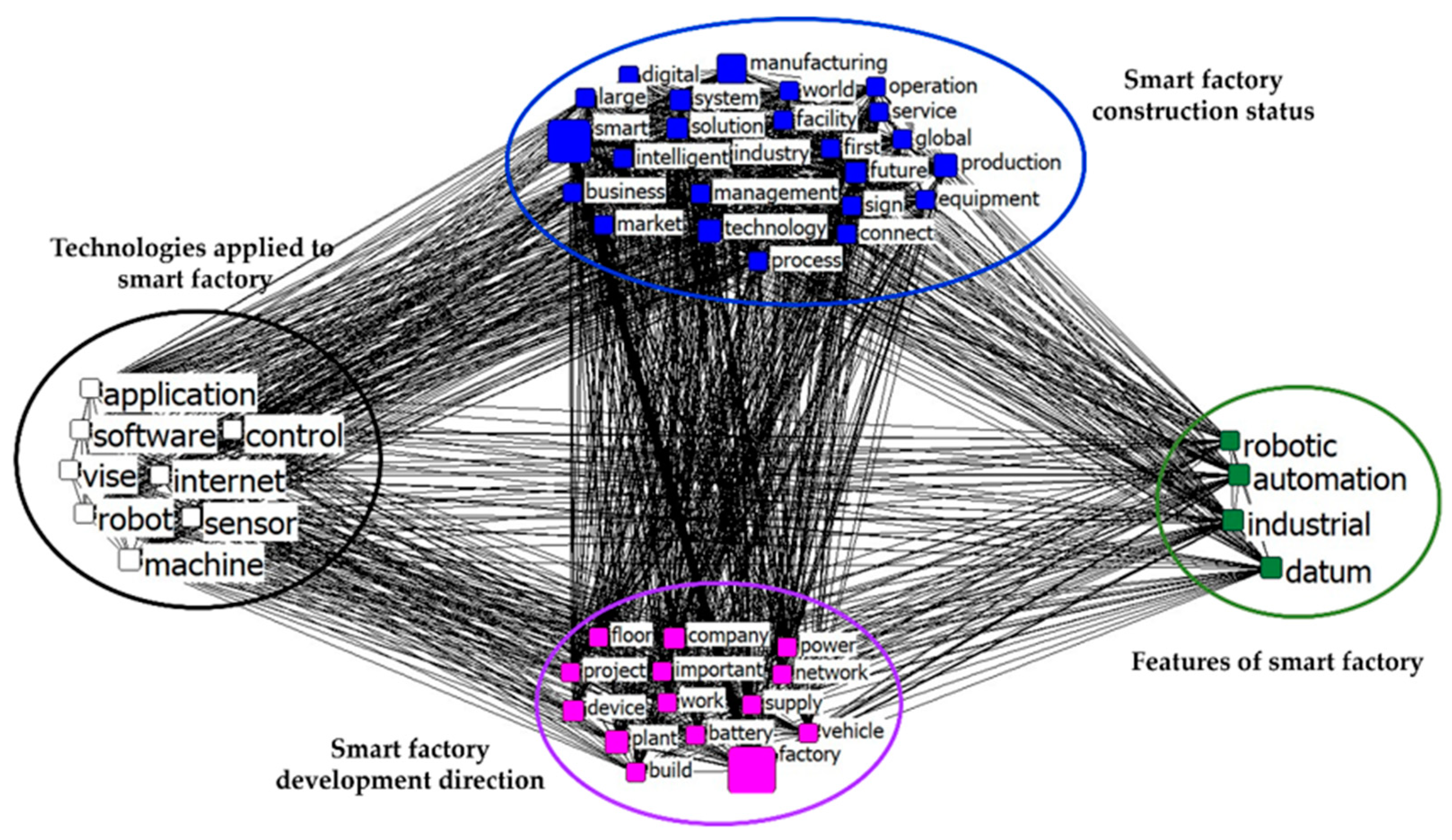

4.2. Semantic Analysis Finding 2: CONCOR Analysis of News Articles Related to Fashion Smart Factory

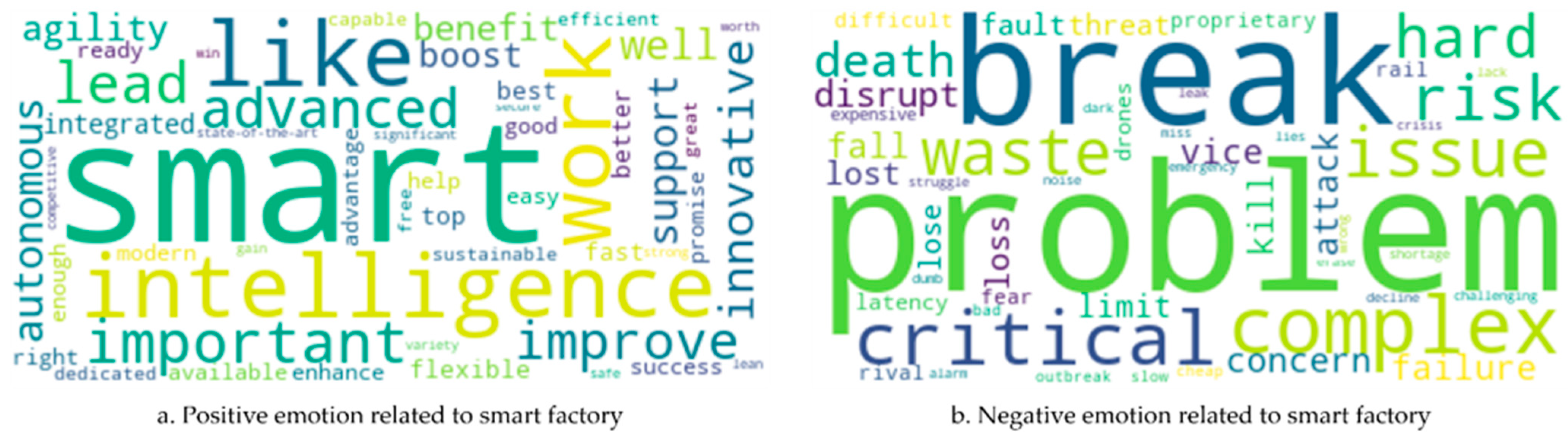

4.3. Semantic Analysis Finding 3: Opinion Mining

5. Conclusion and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Why Smart Factory is Important in the 4th Industrial Revolution Era. 2018.02.18. Available online: http://industrynews.co.kr/news/articleView.html?idxno=21427 (accessed on 18 February 2018).

- Antunes, J.; Pinto, A.; Reis, P.; Henriques, C. Industry 4.0: A challenge of competition. Mille.–J. Edu. Tech. Helth 2018, 6, 89–97. [Google Scholar] [CrossRef]

- Choi, S.K. The 4th industrial revolution and the future of manufacturing. In Proceedings of the Korean Society of Mechanical Engineers, Seoul, Korea, 29 June 2018. [Google Scholar]

- Smart Factories Will Deliver $500B in Value by 2022. Available online: http://www.forbes.com/sites/louiscolumbus/2017/07/30/smart-factoies-will-deliver-500b-in-value-by-2022/?sh=44e5afeed22 (accessed on 23 June 2021).

- 2021 Smart Factory Market Prospect: Smart Manufacturing Solution, Maintaining Growth…. As a New Technology Convergence Task. Available online: http://www.industrynews.co.kr/news/articleView.html?idxno=40535 (accessed on 23 June 2021).

- Amazon (AMZN) Has Patented an Automated On-Demand Clothing Factory. Available online: http://qz.com/963381/amazon-has-patented-an-automated-on-demand-clothing-factory (accessed on 23 June 2021).

- Softwear Automation Sewbots: The Future of Apparel Manufacturing? Available online: http://whattheythink.com/video/102677-softwear-automation-sewbots-the-future-of-apparel-manufacturing/ (accessed on 23 June 2021).

- Lee, S.; Rho, S.H.; Lee, S.; Lee, J.; Lee, S.W.; Lim, D.; Jeong, W. Implementation of an Automated Manufacturing Process for Smart Clothing: The Case Study of a Smart Sports Bra. Processes 2021, 9, 289. [Google Scholar] [CrossRef]

- Seoul Design Foundation Promotes Smart Fashion Manufacturing Business. Available online: http://www.apparelnews.co.kr/news_view/?idx=18060321 (accessed on 23 June 2021).

- China Is Ahead of the 4th Industrial Revolution, What Will KOREA Do? Available online: http://www.hani.co.kr/arti/economy/economy_general/846760.html (accessed on 23 June 2021).

- Kim, J.C.; Moon, I.Y. A Study on Smart Factory Construction Method for Efficient Production Management in Sewing Industry. J. Inform. Commu. Conver. Eng. 2020, 18, 61–68. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing smart factory of industries 4.0: An outlook. Int. J. Distrib. Sens. Net. 2016, 12, 3159805. [Google Scholar] [CrossRef] [Green Version]

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart factory of industry 4.0: Key technologies, application case, and challenges. IEEE Access 2017, 6, 6505–6519. [Google Scholar] [CrossRef]

- Radziwon, A.; Bilberg, A.; Bogers, M.; Madsen, E.S. The smart factory: Exploring adaptive and flexible manufacturing solutions. Procedia Eng. 2014, 69, 1184–1190. [Google Scholar] [CrossRef] [Green Version]

- Büchi, G.; Cugno, M.; Castagnoli, R. Smart factory performance and Industry 4.0. Technol. Forecast. Soc. Chang. 2020, 150, 119790. [Google Scholar] [CrossRef]

- Jung, Y.S.; Chang, T. Text mining based online news analysis about smart factory. ICIC Express Lett. Part B Appl. Int. J. Res. Surv. 2018, 9, 559–565. [Google Scholar]

- Kwon, J.H.; Lee, H. A Study on Trends and Perceptions in Smart Factory: News Network Analysis. J. Knowl. Inf. Technol. Syst. 2019, 14, 605–614. [Google Scholar] [CrossRef]

- Yang, H.L.; Chang, T.W.; Choi, Y. Exploring the research trend of smart factory with topic modeling. Sustainability 2018, 10, 2779. [Google Scholar] [CrossRef] [Green Version]

- McCombs, M.; Reynolds, A. News influence on our pictures of the world. In Media Effects: Advances in Theory and Research; Bryant, J., Zillmann, D., Eds.; Lawrence Erlbaum Associates Publishers: Mahwah, NJ, USA, 2002; pp. 1–18. [Google Scholar]

- Price, V.; Nir, L.; Cappella, J. Framing public discussion of gay civil unions. Public Opin. Quart. 2005, 69, 179–212. [Google Scholar] [CrossRef] [Green Version]

- Kim, L.; Ju, J. Can media forecast technological progress? A text-mining approach to the on-line newspaper and blog’s representation of prospective industrial technologies. Inform. Process. Manag. 2019, 56, 1506–1525. [Google Scholar] [CrossRef]

- Jasanoff, S. (Ed.) States of Knowledge: The Co-Production of Science and the Social Order; Routledge: London, UK, 2004. [Google Scholar]

- Jung, W.K.; Kim, D.R.; Lee, H.; Lee, T.H.; Yang, I.; Youn, B.D.; Zontar, D.; Brockmann, M.; Brecher, C.; Ahn, S.H. Appropriate Smart Factory for SMEs: Concept, Application and Perspective. Int. J. Precis. Eng. Manuf. 2021, 22, 201–215. [Google Scholar] [CrossRef]

- Chonsawat, N.; Sopadang, A. Smart SMEs 4.0 maturity model to evaluate the readiness of SMEs implementing industry 4.0. CMUJ Nat. Sci. 2021, 20, e2021027. [Google Scholar] [CrossRef]

- Grieco, A.; Caricato, P.; Gianfreda, D.; Pesce, M.; Rigon, V.; Tregnaghi, L.; Voglino, A. An industry 4.0 case study in fashion manufacturing. Procedia Manuf. 2017, 11, 871–877. [Google Scholar] [CrossRef]

- Textile & Fashion Industrial Skills Council. Manpower Development for Textile & Fashion Industry in the 4th Industrial Revolution; Korea Federation of Textile Industries: Seoul, Korea, 2019; p. 20. [Google Scholar]

- Yoon, H.J.; Yoon, J.W.; Ahn, J.S. Development of intelligent flexible sewing system for domestic production. In Proceedings of the 2nd Korea Fashion & Costume Design Association, Seoul, Korea, 12 December 2020. [Google Scholar]

- Zahra, A.M.; Dhewanto, W.; Utama, A.A. Boosting Emerging Technology Adoption in SMEs: A Case Study of the Fashion Industry. Int. J. Appl. Bus. Res. 2021, 3, 81–96. [Google Scholar] [CrossRef]

- Bertola, P.; Teunissen, J. Fashion 4.0. Innovating fashion industry through digital transformation. Res. J. Text. Appar. 2018, 22, 352–369. [Google Scholar] [CrossRef]

- Agrawal, T.K.; Sharma, A.; Kumar, V. Blockchain-based secured traceability system for textile and clothing supply chain. In Artificial Intelligence for Fashion Industry in the Big Data Era; Thomassey, S., Zeng, X., Eds.; Springer: Singapore, 2018; pp. 197–208. [Google Scholar] [CrossRef]

- Seoul Design Foundation. A Study on Ways to Revitalize Innovative Growth of Fashion and Apparel Manufacturing Companies; Seoul Design Foundation: Seoul, Korea, 2020; p. 139. [Google Scholar]

- Sjödin, D.R.; Parida, V.; Leksell, M.; Petrovic, A. Smart Factory Implementation and Process Innovation: A Preliminary Maturity Model for Leveraging Digitalization in Manufacturing. Res.-Technol. Manag. 2018, 61, 22–31. [Google Scholar]

- Baronchelli, A.; Ferrer-i-Cancho, R.; Pastor-Satorras, R.; Chater, N.; Christiansen, M.H. Networks in cognitive science. Trends Cogn. Sci. 2013, 17, 348–360. [Google Scholar] [CrossRef] [Green Version]

- Siew, C.S.; Wulff, D.U.; Beckage, N.M.; Kenett, Y.N. Cognitive network science: A review of research on cognition through the lens of network representations, processes, and dynamics. Complexity 2019, 2019, 1–24. [Google Scholar] [CrossRef]

- Rice, R.E.; Danowski, J. Comparing comments and semantic networks about voice mail. In Proceedings of the Asis Annual Meeting, Washington, DC, USA, 27–31 October 1991; American Society for Information Science: Washington, DC, USA, 1991; Volume 28, pp. 134–138. [Google Scholar]

- Schindler, P. The Google News Initiative: Building a Stronger Future for News. Google Blog. Available online: https://blog.google/outreach-initiatives/google-newsinitiative/announcing-google-news-initiative/ (accessed on 10 June 2021).

- Helmore, E. Google Made $4.7bn from News Sites in 2018, Study Claims. Theguardian.com. Available online: https://www.theguardian.com/technology/2019/jun/10/googlenews-revenue-2018-new-study (accessed on 10 June 2021).

- Chen, H.; Zimbra, D. AI and opinion mining. IEEE Intell. Syst. 2010, 25, 74–80. [Google Scholar] [CrossRef]

- Chung, W.J.; Kim, D.W.; Yoon, H.Y.; Lee, H.M.; Park, J.W.; Kim, D.S.; Shon, Y.K.; Cheon, H.S.; Cheon, Y.S.; Jung, Y.M.; et al. Big Data Research Methods and Applications; Hakjisa: Seoul, Korea, 2019. [Google Scholar]

- Suvarna, M.; Büth, L.; Hejny, J.; Mennenga, M.; Li, J.; Ng, Y.T.; Herrmann, C.; Wang, X. Smart manufacturing for smart cities—overview, insights, and future directions. Adv. Intell. Syst. 2020, 2, 2000043. [Google Scholar] [CrossRef]

- Kiel, D.; Müller, J.M.; Arnold, C.; Voigt, K.I. Sustainable industrial value creation: Benefits and challenges of industry 4.0. Digit. Disruptive Innov. 2020, 1740015, 231–270. [Google Scholar] [CrossRef]

- Peukert, B.; Benecke, S.; Clavell, J.; Neugebauer, S.; Nissen, N.F.; Uhlmann, E.; Lang, K.-D.; Finkbeiner, M. Addressing sustainability and flexibility in manufacturing via smart modular machine tool frames to support sustainable value creation. Procedia CIRP 2015, 29, 514–519. [Google Scholar] [CrossRef]

- Gabriel, M.; Pessel, E. Industry 4.0 and sustainability impacts: Critical discussion of sustainability aspects with a special focus on future of work and ecological consequences. Annals of Faculty Engineering Hunedoara. Int. J. Eng. 2016, 1, 131–136. [Google Scholar]

- Henning, K. Recommendations for Implementing the Strategic Initiative Industrie 4.0: Final Report of the Industrie 4.0 Working Group; Frankfurt am Main: Forschungsunion, Germany, 2013. [Google Scholar]

- Otles, S.; Sakalli, A. Industry 4.0: The Smart Factory of the Future in Beverage Industry. In Production and Management of Beverages; Woodhead Publishing: Sawstone, UK, 2019; pp. 439–469. [Google Scholar]

- Zivic, N. Distributed Ledger Technologies for Car Industry 4.0. In Proceedings of the 2020 ICCIS, Ho Chi Minh, Vietnam, 1 August 2020; Association for Computing Machinery: New York, NY, USA; pp. 45–51. [Google Scholar]

- Vargas, D.G.M.; Vijayan, K.K.; Mork, O.J. Augmented Reality for Future Research Opportunities and Challenges in the Shipbuilding Industry: A Literature Review. Procedia Manuf. 2020, 45, 497–503. [Google Scholar] [CrossRef]

| Value Chain | Maturity | Effect | Example |

|---|---|---|---|

| Development (fashion brand business): plan, design/development | Level 3 or 4 | Satisfy customer needs

| 3D CAD, CLO, VR/AR mirror, 3D virtual fitting, Design custom system, Smart pattern coordination service Product traceability system Algorithm of forecasting |

| Manufacturing (fashion manufacturing business): sourcing/preproduction/production | Level 1 or 5 | Improve productivity

| Automatic sewing machine (pocket, numbering, folding, iron, barcode attachment, inspector, button, hanging, grinding, etc.) Smart production system (IoT and modular sewing system, SewBot, gripper robot arm) |

| Reduce lead time | Made-to-measure service, On-demand apparel manufacturing system | ||

| Supply chain (fashion retail business): delivery/distribution/CS | Level 5 | Increase distribution efficiency

| Logistics data in machine learning Remote monitoring service |

| Rank | Word | Frequency | Rank | Word | Frequency |

|---|---|---|---|---|---|

| 1 | Factory | 11,319 | 26 | Business | 562 |

| 2 | Smart | 10,473 | 27 | Process | 540 |

| 3 | Manufacturing | 3866 | 28 | Worker | 525 |

| 4 | Industry | 1941 | 29 | Software | 513 |

| 5 | Plant | 1886 | 30 | Sensor | 510 |

| 6 | New | 1748 | 31 | Vehicle | 497 |

| 7 | Technology | 1638 | 32 | Part | 487 |

| 8 | Company | 1412 | 33 | World | 480 |

| 9 | Automation | 1220 | 34 | Global | 459 |

| 10 | Production | 1206 | 35 | City | 449 |

| 11 | System | 1154 | 36 | Floor | 447 |

| 12 | Car | 894 | 37 | Facility | 446 |

| 13 | Device | 890 | 38 | Connected | 247 |

| 14 | Future | 878 | 39 | IoT | 415 |

| 15 | Datum | 877 | 40 | Network | 413 |

| 16 | Machine | 846 | 41 | Power | 408 |

| 17 | Solution | 807 | 42 | Vision | 408 |

| 18 | First | 721 | 43 | Job | 405 |

| 19 | Robot | 703 | 44 | Way | 404 |

| 20 | Manufacturer | 668 | 45 | Digital | 400 |

| 21 | Internet | 666 | 46 | Big | 390 |

| 22 | Product | 625 | 47 | Intelligent | 390 |

| 23 | Robotic | 611 | 48 | Service | 382 |

| 24 | Thing | 606 | 49 | Application | 375 |

| 25 | Market | 565 | 50 | Operation | 372 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-E.; Ju, N.; Lee, K.-H. Visioning the Future of Smart Fashion Factories Based on Media Big Data Analysis. Appl. Sci. 2021, 11, 7549. https://doi.org/10.3390/app11167549

Lee S-E, Ju N, Lee K-H. Visioning the Future of Smart Fashion Factories Based on Media Big Data Analysis. Applied Sciences. 2021; 11(16):7549. https://doi.org/10.3390/app11167549

Chicago/Turabian StyleLee, Sae-Eun, Naan Ju, and Kyu-Hye Lee. 2021. "Visioning the Future of Smart Fashion Factories Based on Media Big Data Analysis" Applied Sciences 11, no. 16: 7549. https://doi.org/10.3390/app11167549

APA StyleLee, S.-E., Ju, N., & Lee, K.-H. (2021). Visioning the Future of Smart Fashion Factories Based on Media Big Data Analysis. Applied Sciences, 11(16), 7549. https://doi.org/10.3390/app11167549