Bending Properties of Lightweight Copper Specimens with Different Infill Patterns Produced by Material Extrusion Additive Manufacturing, Solvent Debinding and Sintering

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

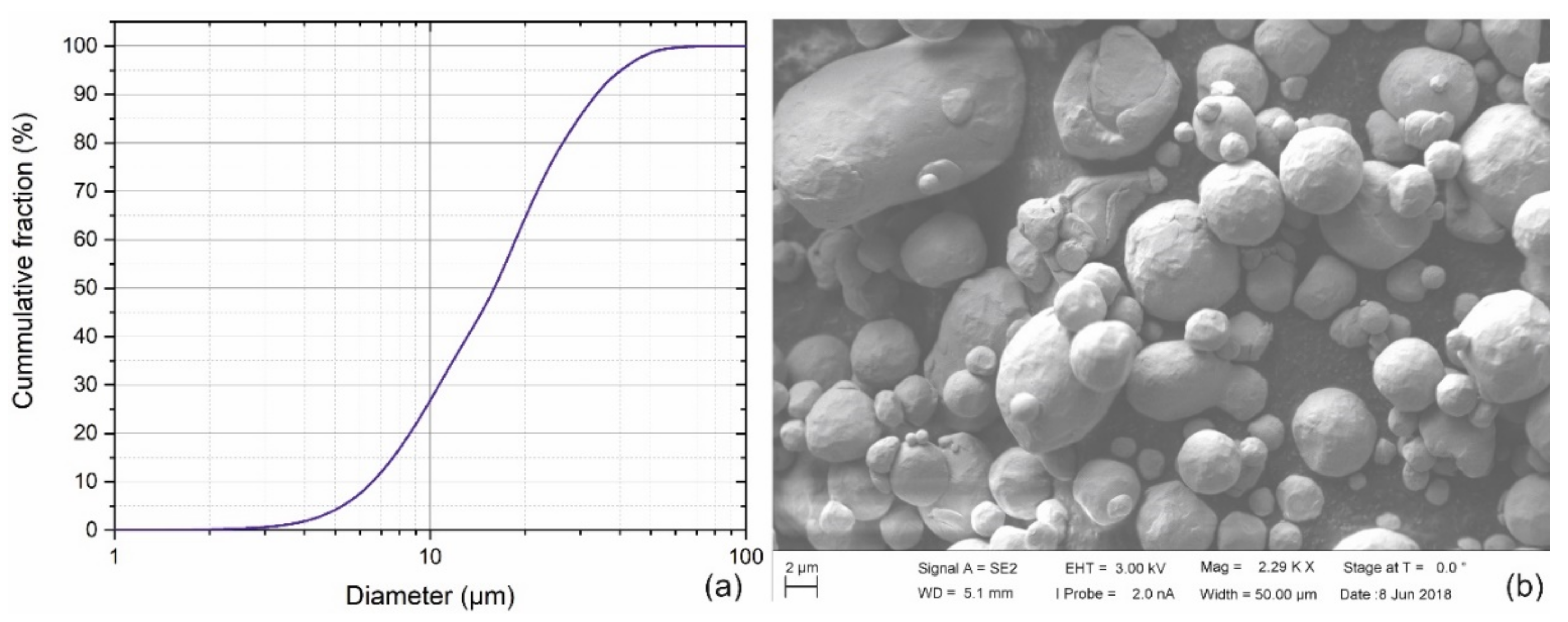

2.1. Materials

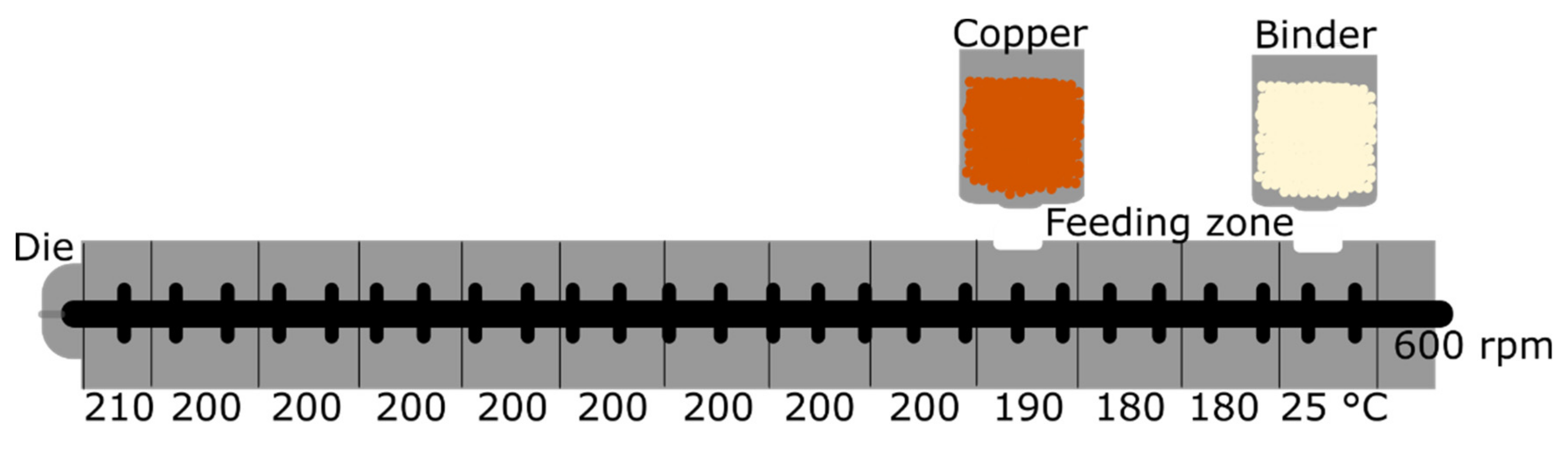

2.2. Feedstock and Filament Preparation

2.3. Material Extrusion Additive Manufacturing

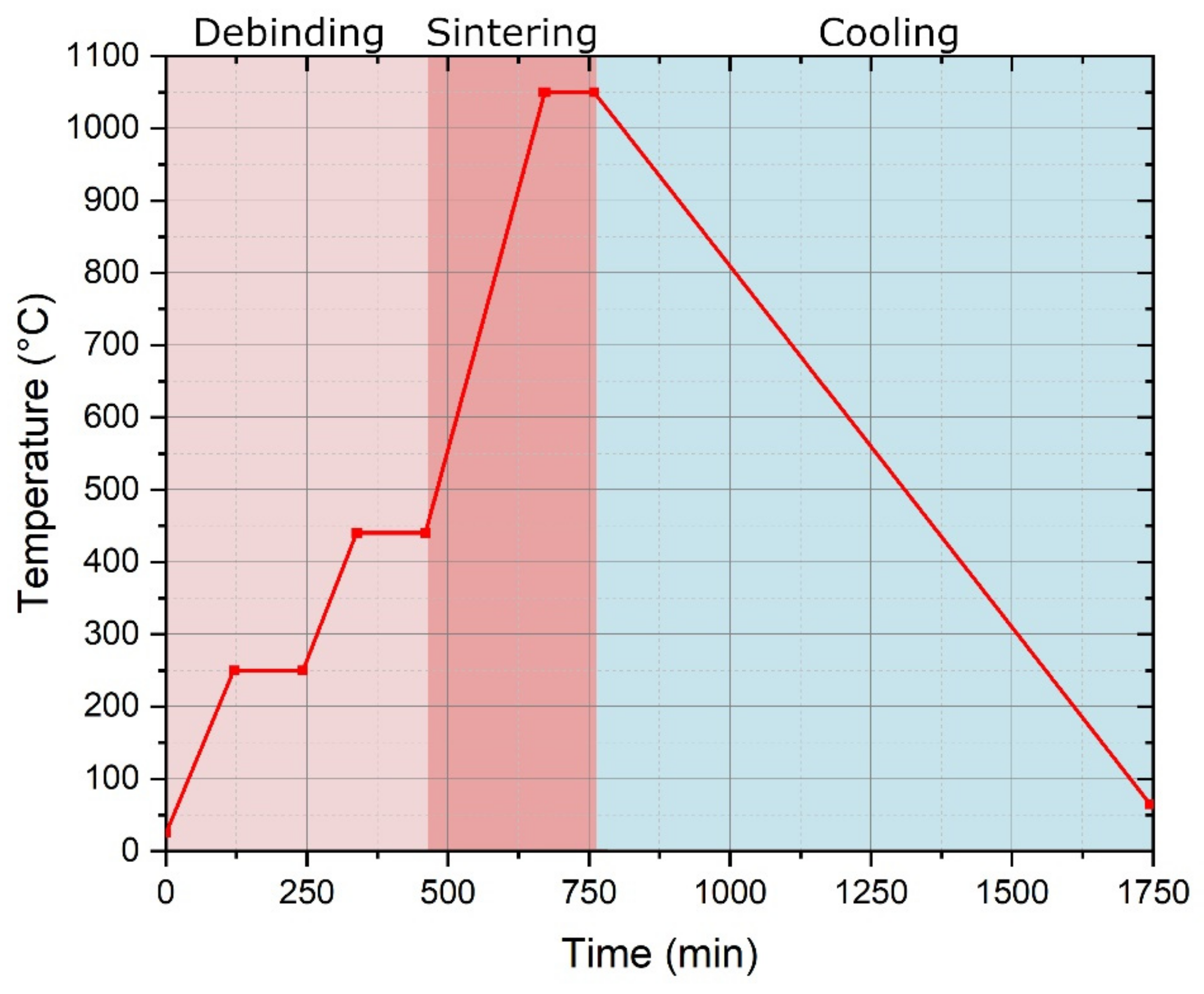

2.4. Debinding and Sintering

2.5. Bending Tests

3. Results

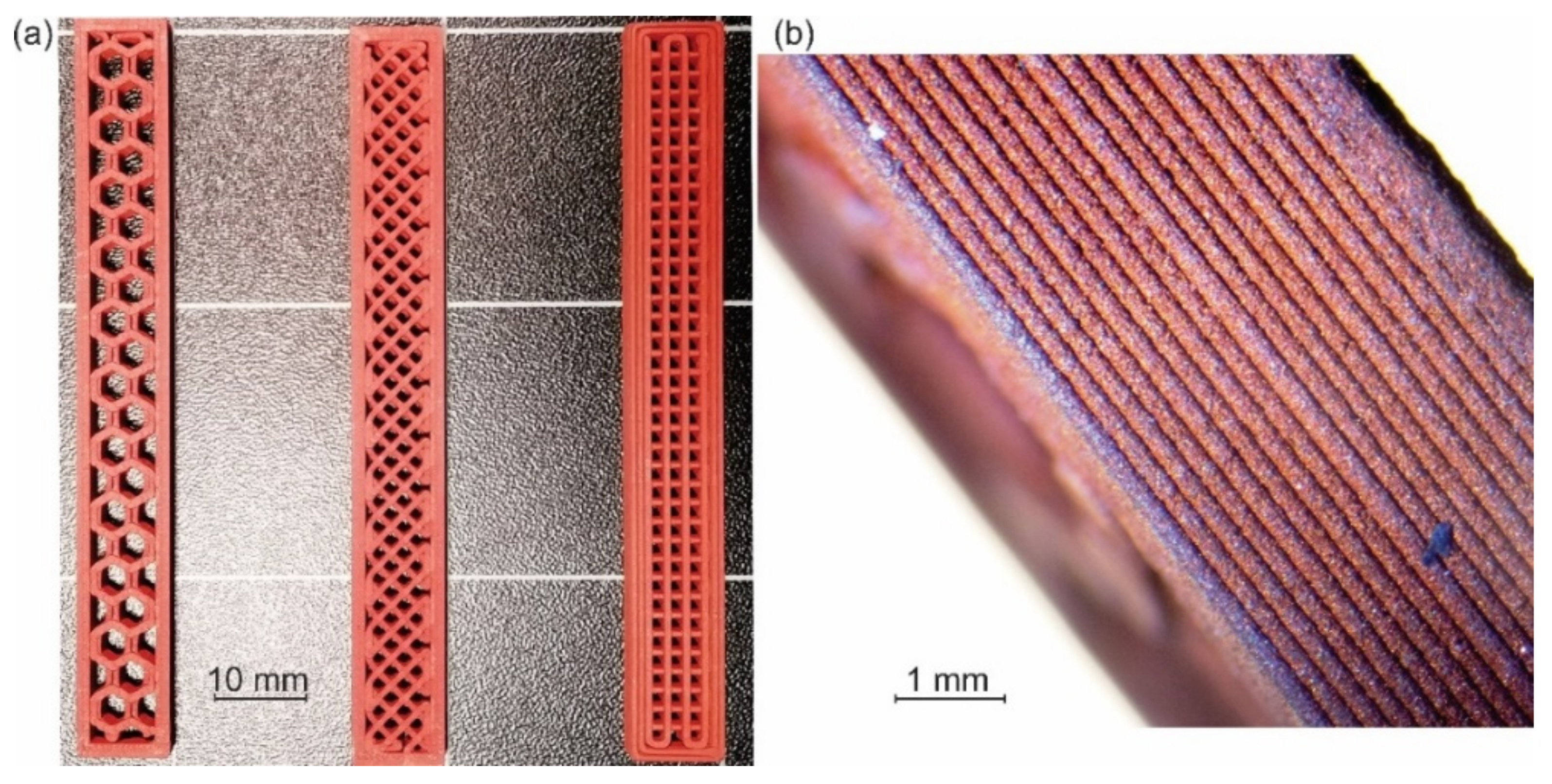

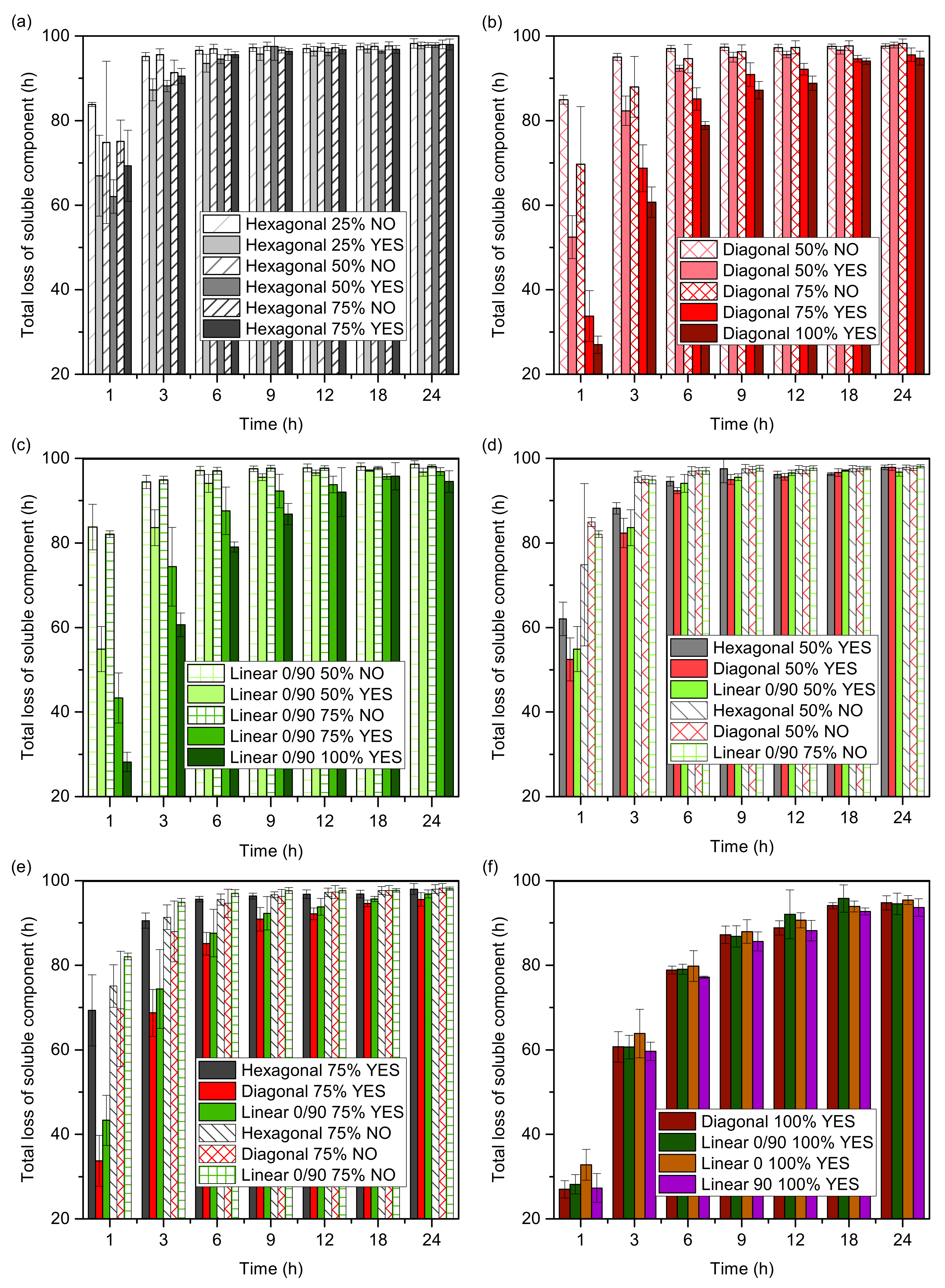

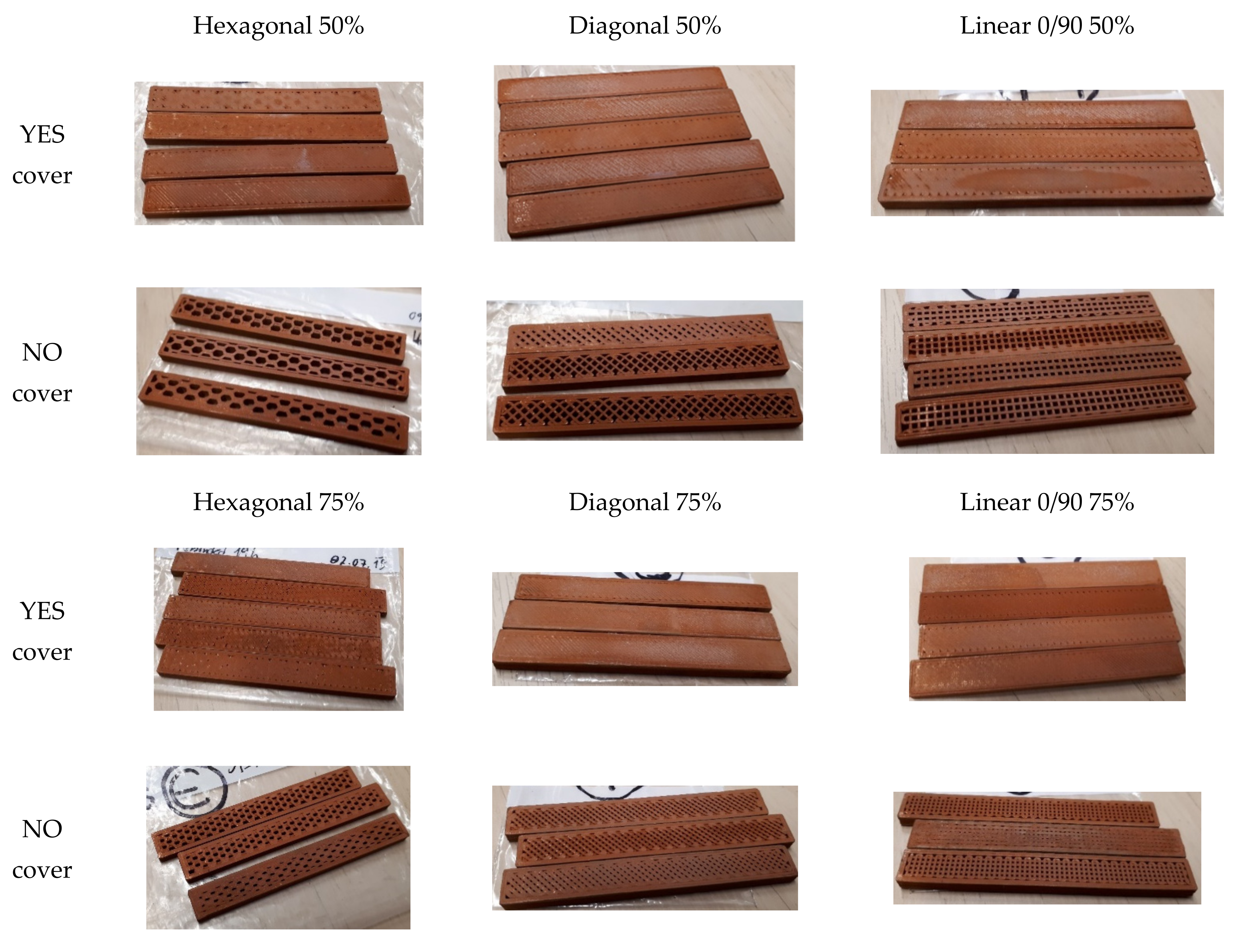

3.1. 3D Printing and Solvent Debinding

3.2. Thermal Debinding and Sintering

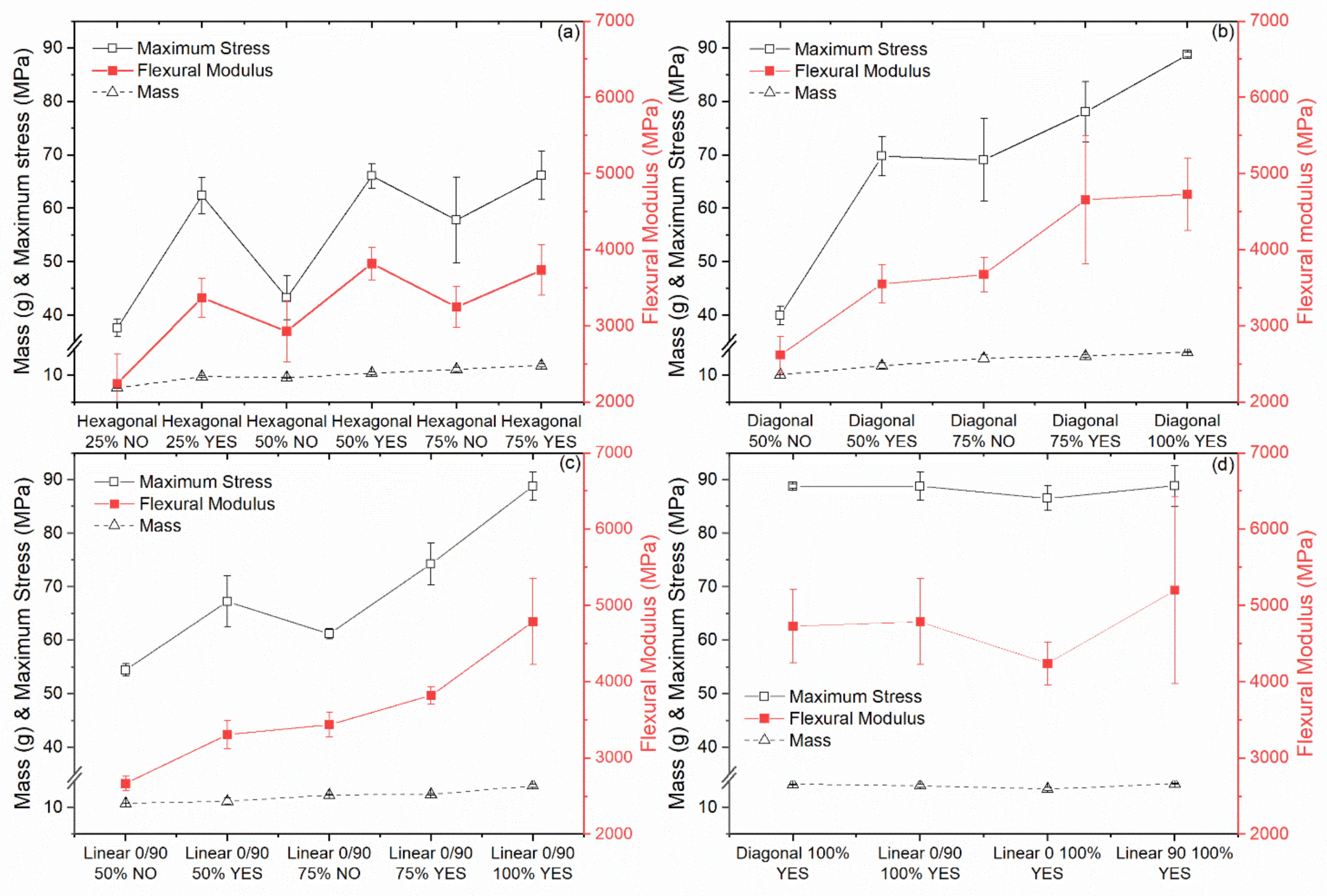

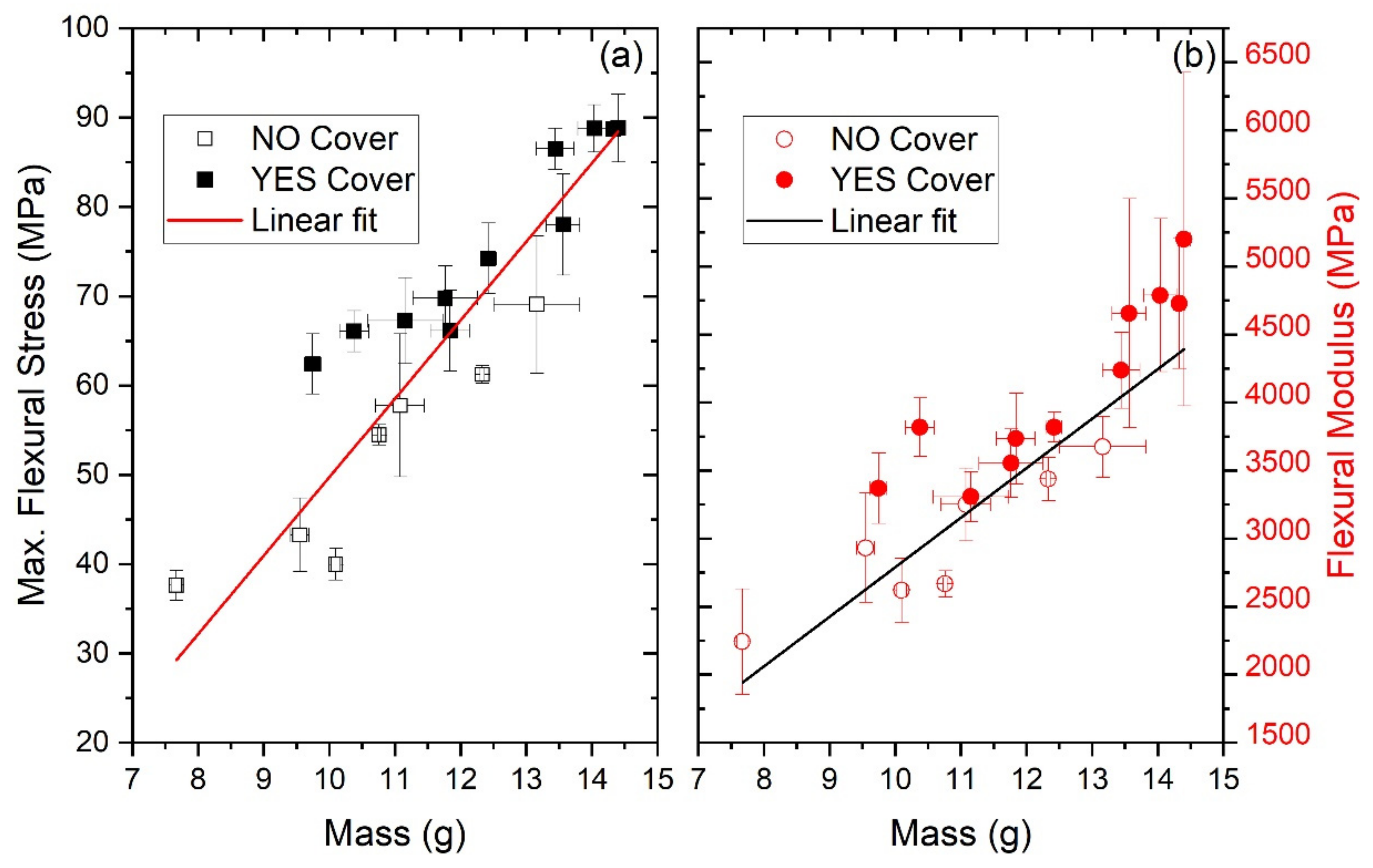

3.3. Properties of Sintered Specimens

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY, USA, 2015; ISBN 978-1-4939-2113-3. [Google Scholar]

- Wohlers, T.; Campbell, I.; Diegel, O.; Kowen, J.; Caffrey, T. Wohlers Report 2017: 3D Printing and Additive Manufacturing State of the Industry: Annual Worldwide Progress Report; Wohlers Associates, Inc.: Fort Collins, CO, USA, 2017; ISBN 978-0-9913332-3-3. [Google Scholar]

- Körner, C. Additive manufacturing of metallic components by selective electron beam melting—A review. Int. Mater. Rev. 2016, 61, 361–377. [Google Scholar] [CrossRef] [Green Version]

- Warnes, S.L.; Little, Z.R.; Keevil, C.W. Human coronavirus 229E remains infectious on common touch surface materials. MBio 2015, 6, e01697-15. [Google Scholar] [CrossRef] [Green Version]

- Scully, J. Editorial-THE COVID-19 pandemic, part 1: Can antimicrobial copper-based alloys help suppress infectious transmission of viruses originating from human contact with high-touch surfaces? Corrosion 2020, 76, 523–527. [Google Scholar] [CrossRef]

- Dai, D.; Gu, D. Thermal behavior and densification mechanism during selective laser melting of copper matrix composites: Simulation and experiments. Mater. Des. 2014, 55, 482–491. [Google Scholar] [CrossRef]

- Tran, T.Q.; Chinnappan, A.; Lee, J.K.Y.; Loc, N.H.; Tran, L.T.; Wang, G.; Kumar, V.V.; Jayathilaka, W.A.D.M.; Ji, D.; Doddamani, M.; et al. 3D printing of highly pure copper. Metals 2019, 9, 756. [Google Scholar] [CrossRef] [Green Version]

- Bogue, R. Lasers in manufacturing: A review of technologies and applications. Assem. Autom. 2015, 35, 161–165. [Google Scholar] [CrossRef]

- Lykov, P.A.; Safonov, E.V.; Akhmedianov, A.M. Selective laser melting of copper. Mater. Sci. Forum 2016, 843, 284–288. [Google Scholar] [CrossRef]

- Horn, T.J.; Gamzina, D. Additive manufacturing of copper and copper alloys. In ASM Handbook; Bourell, D.L., Frazier, W.E., Kuhn, H.A., Seifi, M., Eds.; ASM International: Materials Park, OH, USA, 2020; pp. 388–418. ISBN 978-1-62708-290-7. [Google Scholar]

- Gonzalez-Gutierrez, J. Indirect additive manufacturing techniques for metal parts: Binder-based additive manufacturing techniques. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Badrinarayan, B.; Barlow, J.W. Selective laser sintering of a Copper-PMMA system. In Solid Freeform Fabrication Symposium; Annual International Solid Freeform Fabrication Symposium: Austin, TX, USA, 1991; pp. 245–250. [Google Scholar]

- Klassen, A.; Bauereiß, A.; Körner, C. Modelling of electron beam absorption in complex geometries. J. Phys. D Appl. Phys. 2014, 47, 65307. [Google Scholar] [CrossRef]

- Lodes, M.A.; Guschlbauer, R.; Körner, C. Process development for the manufacturing of 99.94% pure copper via selective electron beam melting. Mater. Lett. 2015, 143, 298–301. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive manufacturing of metallic and ceramic components by the material extrusion of highly-filled polymers: A review and future perspectives. Materials 2018, 11, 840. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bai, Y.; Williams, C.B. An exploration of binder jetting of copper. Rapid Prototyp. J. 2015, 21, 177–185. [Google Scholar] [CrossRef] [Green Version]

- Bai, Y.; Wagner, G.; Williams, C.B. Effect of particle size distribution on powder packing and sintering in binder jetting additive manufacturing of metals. J. Manuf. Sci. Eng. 2017, 139. [Google Scholar] [CrossRef] [Green Version]

- Institute for Rare Earths and Metals AG. Ultrafine Copper Powder-Prices and Manufacture. Available online: https://en.institut-seltene-erden.de/ultrafeines-kupferpulver-preise-und-herstellung/ (accessed on 20 May 2021).

- Munsch, M.; Schmidt-Lehr, M.; Wycisk, E. Metal Additive Manufacturing with Sinter-Based Technologies; AM Power Insights No. 4, Hamburg, Germany. 2018. Available online: https://am-power.de/en/insights/additive-manufacturing-sinter-based-technologies/ (accessed on 23 April 2020).

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D printing and customized additive manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused filament fabrication of fiber-reinforced polymers: A review. Addit. Manuf. 2018, 21, 1–16. [Google Scholar] [CrossRef]

- Gibson, M.A.; Mykulowycz, N.M.; Shim, J.; Fontana, R.R.; Schmitt, P.; Roberts, A.; Ketkaew, J.; Shao, L.; Chen, W.; Bordeenithikasem, P.; et al. 3D printing metals like thermoplastics: Fused filament fabrication of metallic glasses. Mater. Today 2018, 21, 697–702. [Google Scholar] [CrossRef]

- Wu, G.; Langrana, N.A.; Sadanji, R.; Danforth, S.C. Solid freeform fabrication of metal components using fused deposition of metals. Mater. Des. 2002, 23, 97–105. [Google Scholar] [CrossRef]

- Bose, A.; Schuh, C.A.; Tobia, J.C.; Tuncer, N.; Mykulowycz, N.M.; Preston, A.; Barbati, A.C.; Kernan, B.; Gibson, M.A.; Krause, D.; et al. Traditional and additive manufacturing of a new Tungsten heavy alloy alternative. Int. J. Refract. Met. Hard Mater. 2018, 73, 22–28. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Arbeiter, F.; Schlauf, T.; Kukla, C.; Holzer, C. Tensile properties of sintered 17-4PH stainless steel fabricated by material extrusion additive manufacturing. Mater. Lett. 2019, 248, 165–168. [Google Scholar] [CrossRef]

- Thompson, Y.; Gonzalez-Gutierrez, J.; Kukla, C.; Felfer, P. Fused filament fabrication, debinding and sintering as a low cost additive manufacturing method of 316L stainless steel. Addit. Manuf. 2019, 30, 100861. [Google Scholar] [CrossRef]

- Damon, J.; Dietrich, S.; Gorantla, S.; Popp, U.; Okolo, B.; Schulze, V. Process porosity and mechanical performance of fused filament fabricated 316L stainless steel. Rapid Prototyp. J. 2019, 27, 1319–1327. [Google Scholar] [CrossRef]

- Singh, P.; Shaikh, Q.; Balla, V.K.; Atre, S.V.; Kate, K.H. Estimating powder-polymer material properties used in design for metal fused filament fabrication (DfMF3). JOM 2019, 11, 840. [Google Scholar] [CrossRef]

- Naranjo, J.A.; Berges, C.; Gallego, A.; Herranz, G. A novel printable high-speed steel filament: Towards the solution for wear-resistant customized tools by AM alternative. J. Mater. Res. Techol. 2021, 25, 185. [Google Scholar] [CrossRef]

- Wagner, M.A.; Sebastian, T.; Clemens, F.; Wheeler, J.M.; Rusch, A.; Ganz, R.; Spolenak, R. Feedstock development for fused deposition of 316L stainless steel and characterization of final materials properties. In Euro PM2020, Proceedings of the EuroPM 2020, Virtual Congress, Online, 5–7 October 2020; European Powder Metallurgy Association, Ed.; European Powder Metallurgy Association (EMPA): Chantilly, France, 2020; ISBN 9781899072538. [Google Scholar]

- Dehdari Ebrahimi, N.; Ju, Y.S. Thermal conductivity of sintered copper samples prepared using 3D printing-compatible polymer composite filaments. Addit. Manuf. 2018, 24, 479–485. [Google Scholar] [CrossRef] [Green Version]

- Cano, S.; Gonzalez-Gutierrez, J.; Sapkota, J.; Spoerk, M.; Arbeiter, F.; Schuschnigg, S.; Holzer, C.; Kukla, C. Additive manufacturing of zirconia parts by fused filament fabrication and solvent debinding: Selection of binder formulation. Addit. Manuf. 2019, 26, 117–128. [Google Scholar] [CrossRef]

- Gorjan, L.; Reiff, L.; Liersch, A.; Clemens, F. Ethylene-vinyl acetate as a binder for additive manufacturing of tricalcium phosphate bio-ceramics. Ceram. Inter. 2018, 44, 15817–15823. [Google Scholar] [CrossRef]

- Nötzel, D.; Eickhoff, R.; Hanemann, T. Fused filament fabrication of small ceramic components. Materials 2018, 11, 1463. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cano, S.; Lube, T.; Huber, P.; Gallego, A.; Naranjo, J.A.; Berges, C.; Schuschnigg, S.; Herranz, G.; Kukla, C.; Holzer, C.; et al. Influence of the infill orientation on the properties of zirconia parts produced by fused filament fabrication. Materials 2020, 13, 3158. [Google Scholar] [CrossRef] [PubMed]

- Conzelmann, N.A.; Gorjan, L.; Sarraf, F.; Poulikakos, L.D.; Partl, M.N.; Müller, C.R.; Clemens, F.J. Manufacturing complex Al 2 O 3 ceramic structures using consumer-grade fused deposition modelling printers. Rapid Prototyp. J. 2020, 26, 1035–1048. [Google Scholar] [CrossRef]

- Nötzel, D.; Hanemann, T. New feedstock system for fused filament fabrication of sintered alumina parts. Materials 2020, 13, 4461. [Google Scholar] [CrossRef] [PubMed]

- Orlovská, M.; Chlup, Z.; Bača, Ľ.; Janek, M.; Kitzmantel, M. Fracture and mechanical properties of lightweight alumina ceramics prepared by fused filament fabrication. J. Eur. Ceram. Soc. 2020, 40, 4837–4843. [Google Scholar] [CrossRef]

- Veteška, P.; Hajdúchová, Z.; Feranc, J.; Tomanová, K.; Milde, J.; Kritikos, M.; Bača, Ľ.; Janek, M. Novel composite filament usable in low-cost 3D printers for fabrication of complex ceramic shapes. Appl. Mater. Today 2021, 22, 100949. [Google Scholar] [CrossRef]

- Lengauer, W.; Duretek, I.; Fürst, M.; Schwarz, V.; Gonzalez-Gutierrez, J.; Schuschnigg, S.; Kukla, C.; Kitzmantel, M.; Neubauer, E.; Lieberwirth, C.; et al. Fabrication and properties of extrusion-based 3D-printed hardmetal and cermet components. Int. J. Refract. Met. Hard Mater. 2019, 82, 141–149. [Google Scholar] [CrossRef]

- Berger, C.; Abel, J.; Pötschke, J.; Moritz, T. Properties of additive manufactured hardmetal components produced by fused filament fabrication (FFF). In Proceedings of the Euro PM2018, Bilbao, Spain, 14–18 October 2018; EPMA, Ed.; European Powder Metallurgy Association (EMPA): Shrewsbury, UK, 2018; ISBN 978-1-899072-50-7. [Google Scholar]

- Coelho, S.; Magro, A.; Texeira, P.; Ferreira, N.; Pereira, P.; Rodrigues, F.; Jorge, H.; Sacramento, J. Development of formulations of WC-Co filament for Fused Filament Fabrication. In Euro PM2020 Proceedings of the EuroPM 2020, Virtual Congress, Online, 5–7 October 2020; European Powder Metallurgy Association, Ed.; European Powder Metallurgy Association (EMPA): Chantilly, France, 2020; ISBN 9781899072538. [Google Scholar]

- Kukla, C.; Cano, S.; Kaylani, D.; Schuschnigg, S.; Holzer, C.; Gonzalez-Gutierrez, J. Debinding behaviour of feedstock for material extrusion additive manufacturing of zirconia. Powder Met. 2019, 62, 196–204. [Google Scholar] [CrossRef]

- Rosnitschek, T.; Glamsch, J.; Lange, C.; Alber-Laukant, B.; Rieg, F. An Automated open-source approach for debinding simulation in metal extrusion additive manufacturing. Designs 2021, 5, 2. [Google Scholar] [CrossRef]

- Lieberwirth, C.; Harder, A.; Seitz, H. Extrusion based additive manufacturing of metal parts. J. Mech. Eng. Autom. 2017, 7. [Google Scholar] [CrossRef] [Green Version]

- Singh, G.; Missiaen, J.-M.; Bouvard, D.; Chaix, J.-M. Copper extrusion 3D printing using metal injection moulding feedstock: Analysis of process parameters for green density and surface roughness optimization. Addit. Manuf. 2021, 38, 101778. [Google Scholar] [CrossRef]

- de Calan, G. Benchmark of AM Technologies; Nanoe Webinar: Ballainvilliers, France, 2020; Available online: https://nanoe.com/ (accessed on 12 May 2020).

- Gonzalez-Gutierrez, J.; Thompson, Y.; Handl, D.; Cano, S.; Schuschnigg, S.; Felfer, P.; Kukla, C.; Holzer, C.; Burkhardt, C. Powder content in powder extrusion moulding of tool steel: Dimensional stability, shrinkage and hardness. Mater. Lett. 2021, 283, 128909. [Google Scholar] [CrossRef]

- Abel, J.; Scheithauer, U.; Janics, T.; Hampel, S.; Cano, S.; Müller-Köhn, A.; Günther, A.; Kukla, C.; Moritz, T. Fused filament fabrication (FFF) of metal-ceramic components. JoVE 2019. [Google Scholar] [CrossRef] [Green Version]

- Kukla, C.; Cano, S.; Moritz, T.; Müller-Köhn, A.; Courtney, P.; Hampel, S.; Holzer, C. Multimaterial Components by Material Extrusion-Fused Filament Fabrication (ME-FFF)-Production of an Infrared Heater. Ceram. Forum Int. 2019, 96, 22–27. [Google Scholar]

- Ultrafuse 316L-User Guidelines for 3D Printing Metal Parts. Available online: https://www.mholland.com/media/BASF_Ultrafuse_316L_User_Guidelines.pdf (accessed on 5 July 2021).

- Galati, M.; Minetola, P. Analysis of density, roughness, and accuracy of the atomic diffusion additive manufacturing (ADAM) Process for metal parts. Materials 2019, 12, 4122. [Google Scholar] [CrossRef] [Green Version]

- Gloeckle, C.; Konkol, T.; Jacobs, O.; Limberg, W.; Ebel, T.; Handge, U.A. Processing of highly filled polymer–metal feedstocks for fused filament fabrication and the production of metallic implants. Materials 2020, 13, 4413. [Google Scholar] [CrossRef] [PubMed]

- Mireles, J.; Espalin, D.; Roberson, D.; Zinniel, B.; Medina, F.R.; Wicker, R.B. Fused deposition modeling of metals. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2012; Laboratory for Freeform Fabrication, the University of Texas at Austin: Austin, TX, USA, 2012; pp. 836–845. [Google Scholar]

- Riecker, S.; Hein, S.B.; Studnitzky, T.; Andersen, O.; Kieback, B. 3D printing of metal parts by means of fused filament fabrication—A Non Beam-Based Approach. In Euro PM2017, Proceedings of the Euro PM2017 Congress & Exhibition, Milan, Italy, 1–5 October 2017; EPMA, Ed.; European Powder Metallurgy Association (EMPA): Bellstone, UK, 2017; ISBN 978-1-899072-49-1. [Google Scholar]

- Singh, P.; Balla, V.K.; Gokce, A.; Atre, S.V.; Kate, K.H. Additive manufacturing of Ti-6Al-4V alloy by metal fused filament fabrication (MF3): Producing parts comparable to that of metal injection molding. Prog. Addit. Manuf. 2021, 11, 840. [Google Scholar] [CrossRef]

- Tosto, C.; Tirillò, J.; Sarasini, F.; Cicala, G. Hybrid metal/polymer filaments for fused filament fabrication (FFF) to print metal parts. Appl. Sci. 2021, 11, 1444. [Google Scholar] [CrossRef]

- Zhang, Y.; Bai, S.; Riede, M.; Garratt, E.; Roch, A. A comprehensive study on Fused Filament Fabrication of Ti-6Al-4V structures. Addit. Manuf. 2020, 101256. [Google Scholar] [CrossRef]

- Gorjan, L.; Galusca, C.; Marwah, S.; Sebastian, T.; Clemens, F. Effect of stearic acid on rheological properties and printability of ethylene-vinyl acetate-based feedstocks for fused filament fabrication of alumina. Addit. Manuf. 2020, 101391. [Google Scholar] [CrossRef]

- Eickenscheidt, M.; Langenmair, M.; Dbouk, A.; Nötzel, D.; Hanemann, T.; Stieglitz, T. 3D-printed hermetic alumina housings. Materials 2021, 14, 200. [Google Scholar] [CrossRef] [PubMed]

- Fan, N.C.; Chen, Y.Y.; Wei, W.C.J.; Liu, B.H.; Wang, A.B.; Luo, R.C. Porous Al2O3 catalyst carrier by 3D additive manufacturing for syngas reforming. J. Ceram. Process. Res. 2017, 18, 676–682. [Google Scholar]

- Cano, S.; Cajner, H.; Gonzalez-Gutierrez, J.; Sapkota, J.; Kukla, C.; Arbeiter, F.; Schuschnigg, S.; Holzer, C. Optimization of material properties for highly-filled thermoplastic polymers used in fused filament fabrication of ceramics. AIP Conf. Proc. 2019, 2065. [Google Scholar] [CrossRef]

- Sadaf, M.; Bragaglia, M.; Nanni, F. A simple route for additive manufacturing of 316L stainless steel via Fused Filament Fabrication. J. Manuf. Process. 2021, 67, 141–150. [Google Scholar] [CrossRef]

- Li, T.; Gonzalez-Gutierrez, J.; Raguž, I.; Holzer, C.; Li, M.; Cheng, P.; Kitzmantel, M.; Shi, L.; Huang, L. Material extrusion additively manufactured alumina monolithic structures to improve the efficiency of plasma-catalytic oxidation of toluene. Addit. Manuf. 2021, 37, 101700. [Google Scholar] [CrossRef]

- Kim, S.W.; Lee, H.-W.; Song, H.; Kim, B.H. Pore structure evolution during solvent extraction and wicking. Ceram. Int. 1996, 22, 7–14. [Google Scholar] [CrossRef]

- Westcot, E.J.; Binet Andrandall, C.; German, R.M. In situ dimensional change, mass loss and mechanisms for solvent debinding of powder injection moulded components. Powder Metall. 2003, 46, 61–67. [Google Scholar] [CrossRef]

- Rolere, S.; Soupremanien, U.; Bohnke, M.; Dalmasso, M.; Delafosse, C.; Laucournet, R. New insights on the porous network created during solvent debinding of powder injection-molded (PIM) parts, and its influence on the thermal debinding efficiency. J. Mater. Process. Technol. 2021, 24, 117163. [Google Scholar] [CrossRef]

- Shivashankar, T.S.; German, R.M. Effective length scale for predicting solvent-debinding times of components produced by powder injection molding. J. Am. Ceram. Soc. 1999, 82, 1146–1152. [Google Scholar] [CrossRef]

- Oliveira, R.V.B.; Soldi, V.; Fredel, M.C.; Pires, A.T.N. Ceramic injection moulding: Influence of specimen dimensions and temperature on solvent debinding kinetics. J. Mater. Process. Technol. 2005, 160, 213–220. [Google Scholar] [CrossRef]

- Ecker, J.V.; Dobrezberger, K.; Gonzalez-Gutierrez, J.; Spoerk, M.; Gierl-Mayer, C.; Danninger, H. Additive manufacturing of steel and copper using fused layer modelling: Material and process development. Powder Metall. Progr. 2019, 19, 63–81. [Google Scholar] [CrossRef]

- Zavaliangos, A.; Missiaen, J.M.; Bouvard, D. Anisotropy in shrinkage during sintering. Sci. Sinter. 2006, 38, 13–25. [Google Scholar] [CrossRef]

- Tikare, V.; Braginsky, M.; Olevsky, E.; Johnson, D.L. Numerical simulation of anisotropic shrinkage in a 2D compact of elongated particles. J. Am. Ceram. Soc. 2005, 88, 59–65. [Google Scholar] [CrossRef]

| Infill Pattern | Degree of Infill (%) | Cover Layer (Yes/No) | Short Notation |

|---|---|---|---|

| Hexagonal | 25 | No | Hexagonal 25% NO |

| Hexagonal | 25 | Yes | Hexagonal 25% YES |

| Hexagonal | 50 | No | Hexagonal 50% NO |

| Hexagonal | 50 | Yes | Hexagonal 50% YES |

| Hexagonal | 75 | No | Hexagonal 75% NO |

| Hexagonal | 75 | Yes | Hexagonal 75% YES |

| Diagonal (±45°) | 50 | No | Diagonal 50% NO |

| Diagonal (±45°) | 50 | Yes | Diagonal 50% YES |

| Diagonal (±45°) | 75 | No | Diagonal 75% NO |

| Diagonal (±45°) | 75 | Yes | Diagonal 75% YES |

| Diagonal (±45°) | 100 | Yes | Diagonal 100% YES |

| Linear (0°/90°) | 50 | No | Linear 0/90 50% NO |

| Linear (0°/90°) | 50 | Yes | Linear 0/90 50% YES |

| Linear (0°/90°) | 75 | No | Linear 0/90 75% NO |

| Linear (0°/90°) | 75 | Yes | Linear 0/90 75% YES |

| Linear (0°/90°) | 100 | Yes | Linear 0/90 100% YES |

| Linear (0°) | 100 | Yes | Linear 0 100% YES |

| Linear (90°) | 100 | Yes | Linear 90 100% YES |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gonzalez-Gutierrez, J.; Cano, S.; Ecker, J.V.; Kitzmantel, M.; Arbeiter, F.; Kukla, C.; Holzer, C. Bending Properties of Lightweight Copper Specimens with Different Infill Patterns Produced by Material Extrusion Additive Manufacturing, Solvent Debinding and Sintering. Appl. Sci. 2021, 11, 7262. https://doi.org/10.3390/app11167262

Gonzalez-Gutierrez J, Cano S, Ecker JV, Kitzmantel M, Arbeiter F, Kukla C, Holzer C. Bending Properties of Lightweight Copper Specimens with Different Infill Patterns Produced by Material Extrusion Additive Manufacturing, Solvent Debinding and Sintering. Applied Sciences. 2021; 11(16):7262. https://doi.org/10.3390/app11167262

Chicago/Turabian StyleGonzalez-Gutierrez, Joamin, Santiago Cano, Josef Valentin Ecker, Michael Kitzmantel, Florian Arbeiter, Christian Kukla, and Clemens Holzer. 2021. "Bending Properties of Lightweight Copper Specimens with Different Infill Patterns Produced by Material Extrusion Additive Manufacturing, Solvent Debinding and Sintering" Applied Sciences 11, no. 16: 7262. https://doi.org/10.3390/app11167262

APA StyleGonzalez-Gutierrez, J., Cano, S., Ecker, J. V., Kitzmantel, M., Arbeiter, F., Kukla, C., & Holzer, C. (2021). Bending Properties of Lightweight Copper Specimens with Different Infill Patterns Produced by Material Extrusion Additive Manufacturing, Solvent Debinding and Sintering. Applied Sciences, 11(16), 7262. https://doi.org/10.3390/app11167262