1. Introduction

Carbon-fiber-reinforced plastic (CFRP) is used in various applications owing to its strength, heat resistance, and corrosion resistance, in addition to its weight advantage over other materials [

1,

2,

3,

4,

5]. A trend in aerospace applications is to increase the proportion of composite structural parts for aircraft weight reduction and corrosion resistance. In leisure and sporting goods industries, it is widely used in the production of golf shafts, tennis racquets, skis, and snowboards owing to the above advantages. However, despite these advantages, CFRP may not be suited for some structures exposed to large amplitude vibration, owing to its low damping capacity [

5]. Recently, various studies have been performed to improve the vibration damping ability of CFRP and studies on functional composite materials that can absorb vibration energy have been drawing more attention.

Recently, particles with nano and micro dimensions have been used as reinforcing materials to enhance the reinforcing effect; they have been added to the polymer matrix for composites to provide better performance. Multifunctional materials containing piezoelectric material such as lead zirconate titanate (PZT) and shape memory alloy (SMA) could increase the damping capacity by converting the vibration energy into heat energy. These materials, referred to as active materials, can convert a non-mechanical input into a mechanical output, or vice versa. The mechanical response of these materials to a non-mechanical input is several orders of magnitude larger than the thermal expansion. Piezoelectric material converts mechanical energy into electrical energy, and vice versa [

6]. Electrical energy is generated by deformation of piezoelectric ceramic particles during vibration of the composite material, which can lead to current flow if a proper resistance circuit is present [

7]. As Joule heat emerges from the generated current as it passes through the resistor, the vibration energy is converted into thermal energy, which increases the vibration damping ability of the material [

8].

Tanimoto [

9] demonstrated that the carbon-fiber-reinforced composite material itself can function as a proper resistor. Accordingly, the vibration damping mechanism of the piezoelectric ceramics can be applied to enhance the vibration damping. He applied a trial and error method to find the optimal content of piezoelectric ceramic particles. The vibration damping capability of composites increases with the introduction of piezoelectric ceramic particles owing to the electrical connections of the piezoelectric ceramic particles and carbon fibers, acting as resistors. Uchino [

10] enhanced the vibration damping ability of composite materials with piezoelectric ceramic particles, used as functional particles accelerating the loss of the vibration energy. Yazdani et al. investigated damping behavior of highly loaded PZT/Polyurethane particulate composite [

11]. They fabricated thermoplastic polyurethane elastomer (TPU) composites containing up to 70vol% PZT particles for increasing damping of composites. SMA is a type of hyperelastic material, which could restore its shape when a particular temperature is reached. When the shape of the material is deformed, its phase and crystal structure change, leading to a conversion of the mechanical energy into thermal energy [

12,

13,

14,

15,

16]. Studies have been performed to enhance vibration damping of composites utilizing SMA particles [

17,

18]. Piedboeuf and Gauvin investigated the damping behavior of SMA for various frequency and temperature conditions [

19]. Juan et al. demonstrated that nanoscale SMA particles are effective for ultra-high mechanical damping [

20].

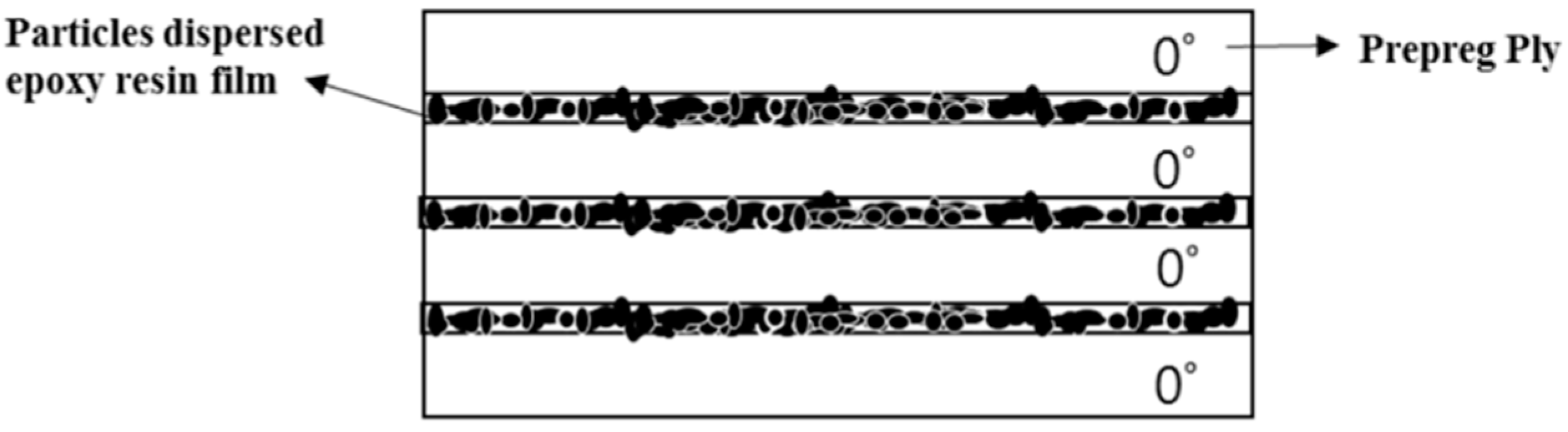

Kim et al. reported that with a dispersion of PZT ceramic particles on the prepreg in a single layer, the vibration damping ability was improved. Because the contact area between PZT and carbon fiber increases, electrical heat losses results in more efficiency [

8]. However, in their study, particles were applied directly on the carbon fiber prepreg surface resulting in poor control of dispersion and particle loading. If the particles are not well dispersed, they may act as defects and, thus, the dispersion of particles is a very important parameter in the overall performance of the finished structure. Quiroga et al. improved damping of composite structures by using piezoelectric filler-dispersed films [

21]. They made films dispersed piezoelectric and conductive particles in PA or PEKK for enhancing damping of the composite. In their study, the effect of particle dispersion on damping was not analyzed. In this investigation, we established a process to fabricate thin resin mixture films containing PZT and SMA particles within the composites with increased dispersion. By dispersing the particles evenly inside the mixture film and applying them to the carbon fiber reinforced composite material as interleaves, the vibration damping ability of the composite specimen increased.

In the research so far, there have been many studies to improve the vibration damping of composite materials by using PZT particles or SMA particles alone. Of course, there have also been attempts to apply PZT and SMA to composite materials at the same time. Dong et al. fabricated the thin SMA film deposited on PZT substrate composite by sputtering for enhancing damping property [

22]. However, devices fabricated in this way are very expensive and difficult to apply to large-area composite materials. In this study, PZT and SMA particles were applied separately to composite laminates to evaluate the vibration damping efficiency. In order to observe the effect of particle mixing, both PZT and SMA particles were mixed and applied to composite laminates to evaluate the effect. Particles are dispersed in large area films, so it is easy to apply to a large area and can be manufactured relatively inexpensively. The loss factor (tan

δ) was used as a parameter to indicate the vibration damping capability, measured using a dynamic mechanical analyzer (DMA). The change in vibration damping as a function of the particles loading was observed. In addition, flexural moduli of the interleaved specimens were evaluated to investigate the effect of the interleaved layers on the mechanical performance.

The structure of the paper is as follows: in

Section 2, materials and manufacturing methods for making specimens are introduced, and experiment methods to measure the physical properties of specimens are introduced.

Section 3, the loss factor according to the frequency of each specimen is examined, and the results are compared. The dispersion degree of the film in which the PZT particles were dispersed was confirmed through the EPMA results, and the loss factor and mechanical properties of the specimens in which the PZT particles and the SMA particles were simultaneously dispersed were confirmed through the experiments. Next, a discussion of the results obtained is provided.

Section 4 contains the final conclusions that summarize the most important achievements of the article.

3. Results and Discussion

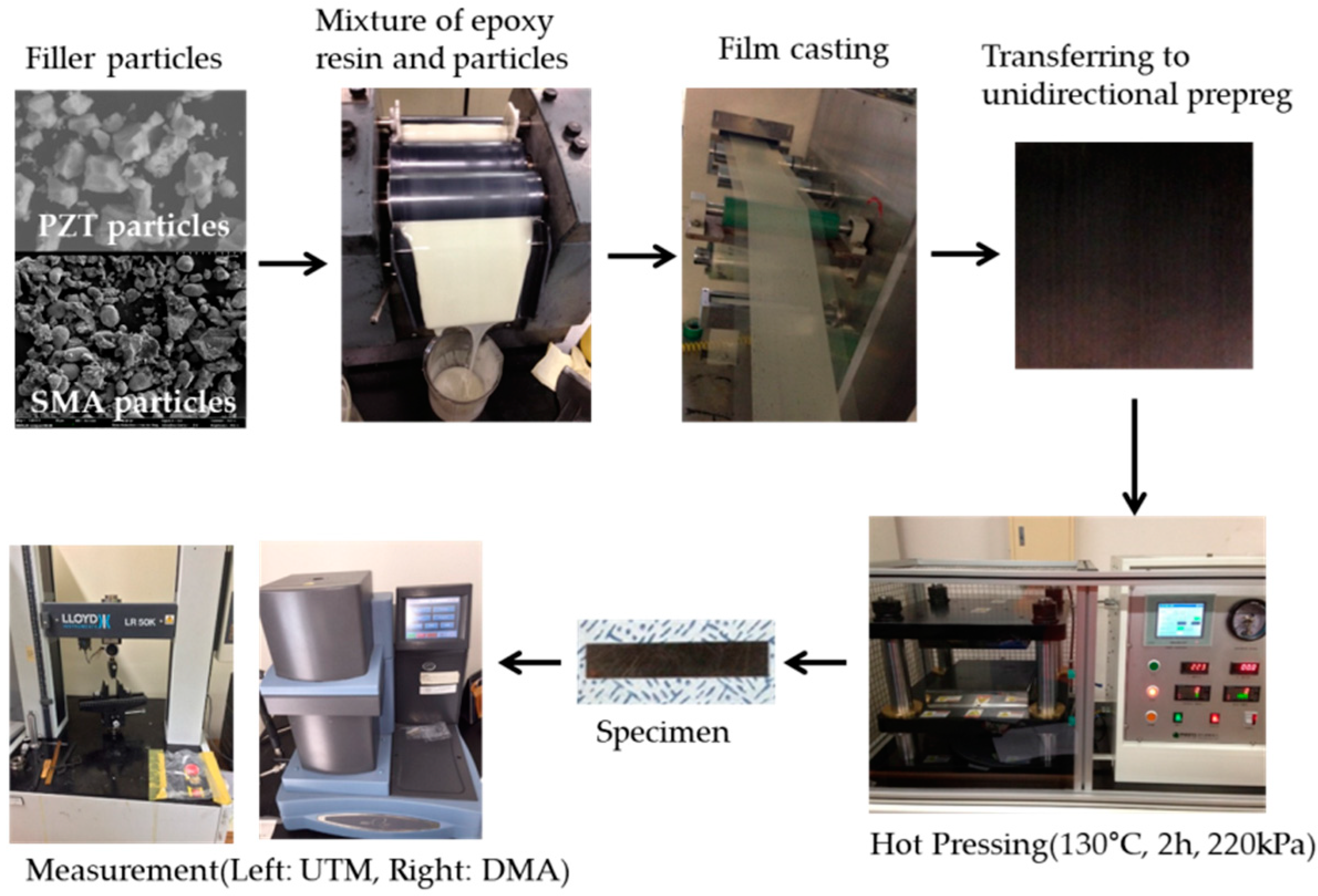

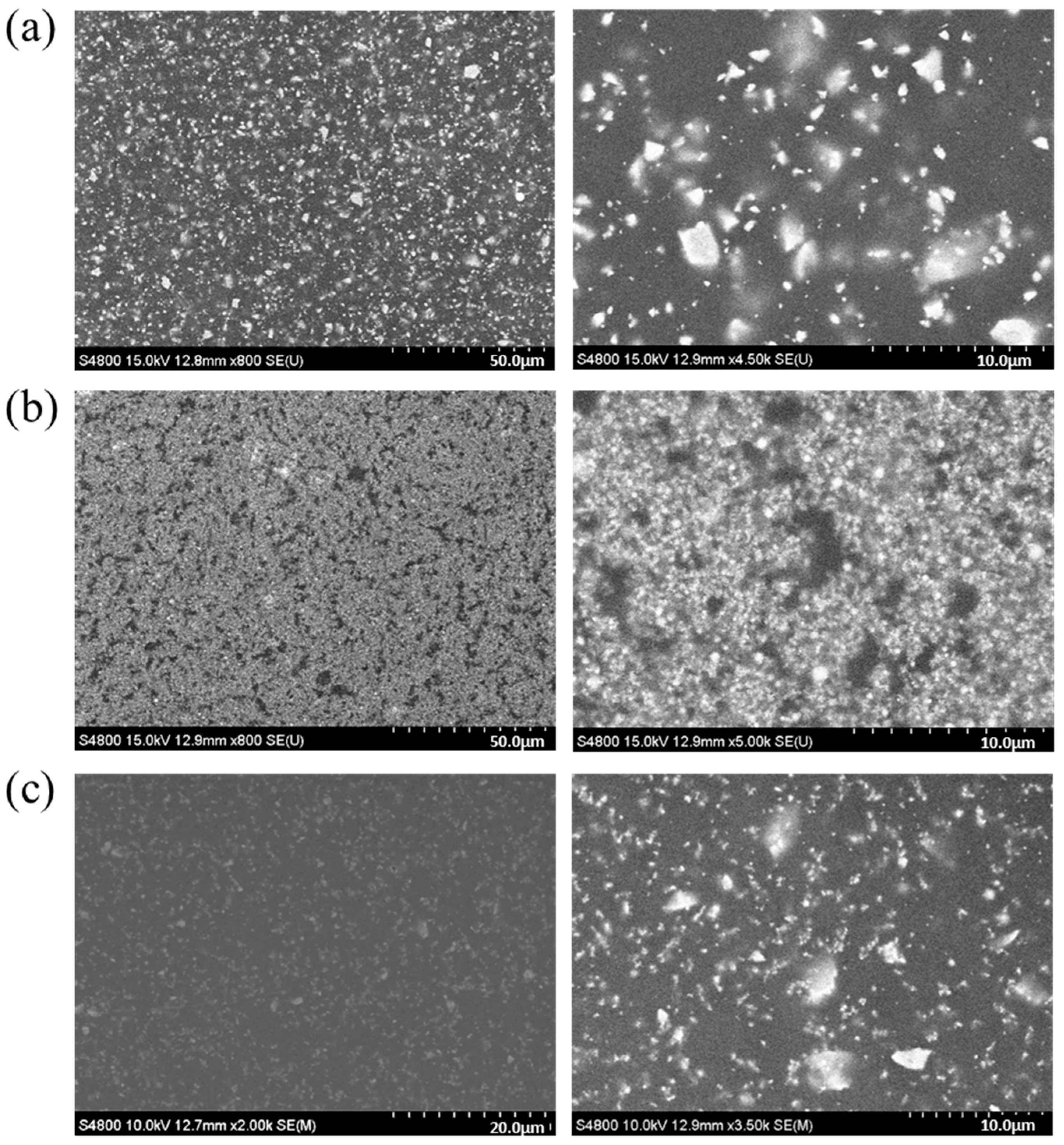

Figure 3 shows SEM images of the particle-dispersed epoxy film. The amount of dispersed PZT and SMA particles in the specimens were 20

. For the specimen in which both PZT and SMA particles were mixed together, each particle contains 10

to make the total amount of particles in the specimen also 20

. As can be seen, both PZT and SMA particles are uniformly distributed in the films. As the SMA particles have a smaller diameter than the PZT particles, the number of particles per unit area is larger for the SMA sample. However, as the densities of the two types of particles are similar, their masses per unit area are almost identical. The film specimen with a thickness of 20 μm was made with almost no void. It is noted that the films were casted on the substrate film by passing between two counter-rotating rollers with a gap of 20 μm. Therefore, better dispersion of the particles may be expected with thinner films with the thickness close to the particle diameter. Considering the voids and dispersion of the particles, the best performance was expected for the film with a thickness of 20 μm and all subsequent experiments were performed using 20 μm thickness mixture films.

Figure 4 shows the measured loss factors of the specimens interleaved with PZT-particle-dispersed mixture films as functions of frequency. As stated earlier, the amount of dispersed PZT particles in the mixture film was varied from 0

to 25

with an increment of 5

. The specimen denoted as “neat” was not interleaved with mixture films and served as a reference. As can be seen from

Figure 4, in general, the measured loss factor increases with the particle loading. For the PZT interleaved specimens, the frequency range where the loss factor increases most is approximately between 100 Hz and 150 Hz. The maximum loss factor peak was observed at 15

loading, and an improvement in loss factor can be observed up to 20

loading. In the case of 25

, the loss factor shows almost no enhancement over neat specimens. It is presumed that, in the case of 25

loading film, the particle content was too high to make a film in which particles were uniformly dispersed.

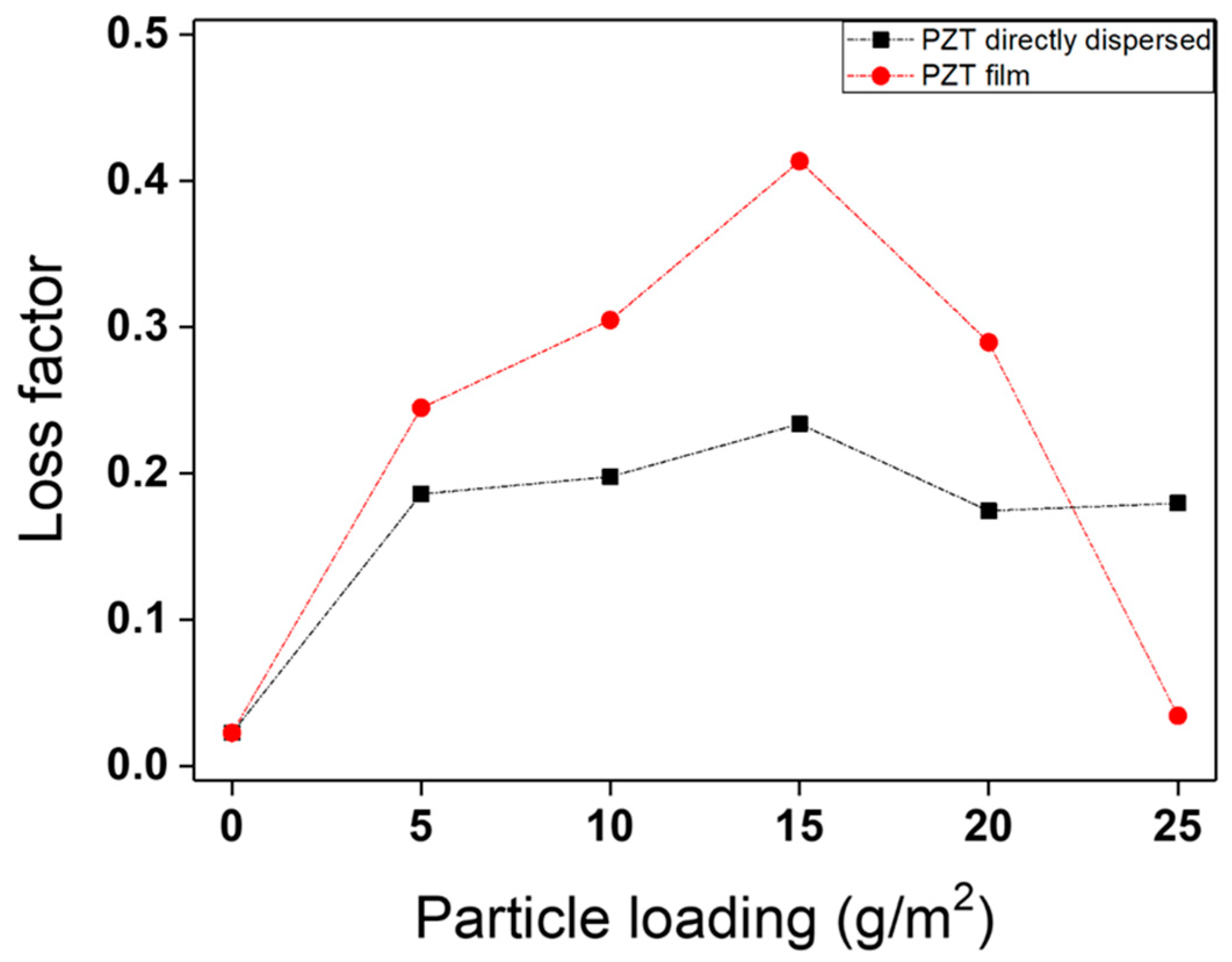

Figure 5 shows the loss factors of the CFRP samples with PZT particles directly dispersed with between the composite plies at 120 Hz frequency. In previous research, a study was conducted through a specimen of composite materials in which PZT particles were directly dispersed. Existing results show that loss factor values are maximized at 120 Hz for specimens with direct distribution of PZT particles [

25]. In this study, it was confirmed that the loss factor for different particle loadings was maximized in the range between 100 Hz and 150 Hz in a specimen using film-dispersed particles. However, in order to confirm the effect of particle dispersion on the loss factor through film dispersed particles, 120 Hz, which can confirm the most maximized effect by directly spraying particles, was compared. In the case of film-interleaved specimens with particle contents of 5

to 20

, the loss factor values are higher than those of directly dispersed specimens by up to two times or more. For the directly dispersed specimens, the improvement in the loss factors was observed up to the particle loading value of 15

. For higher particle loadings, the loss factor decreased due to poor dispersion of particles. On the other hand, when the mixture film was used, an improvement in the loss factor could be observed up to 20

. The method of using the mixture film rather than the direct application therefore can provide an improved damping capability through a better dispersion of particles. Kim et al. insisted that when using PZT particles dispersed by hand, it was revealed that the optimal content exists according to particle dispersion, and through this, the importance of particle dispersion was confirmed [

8].

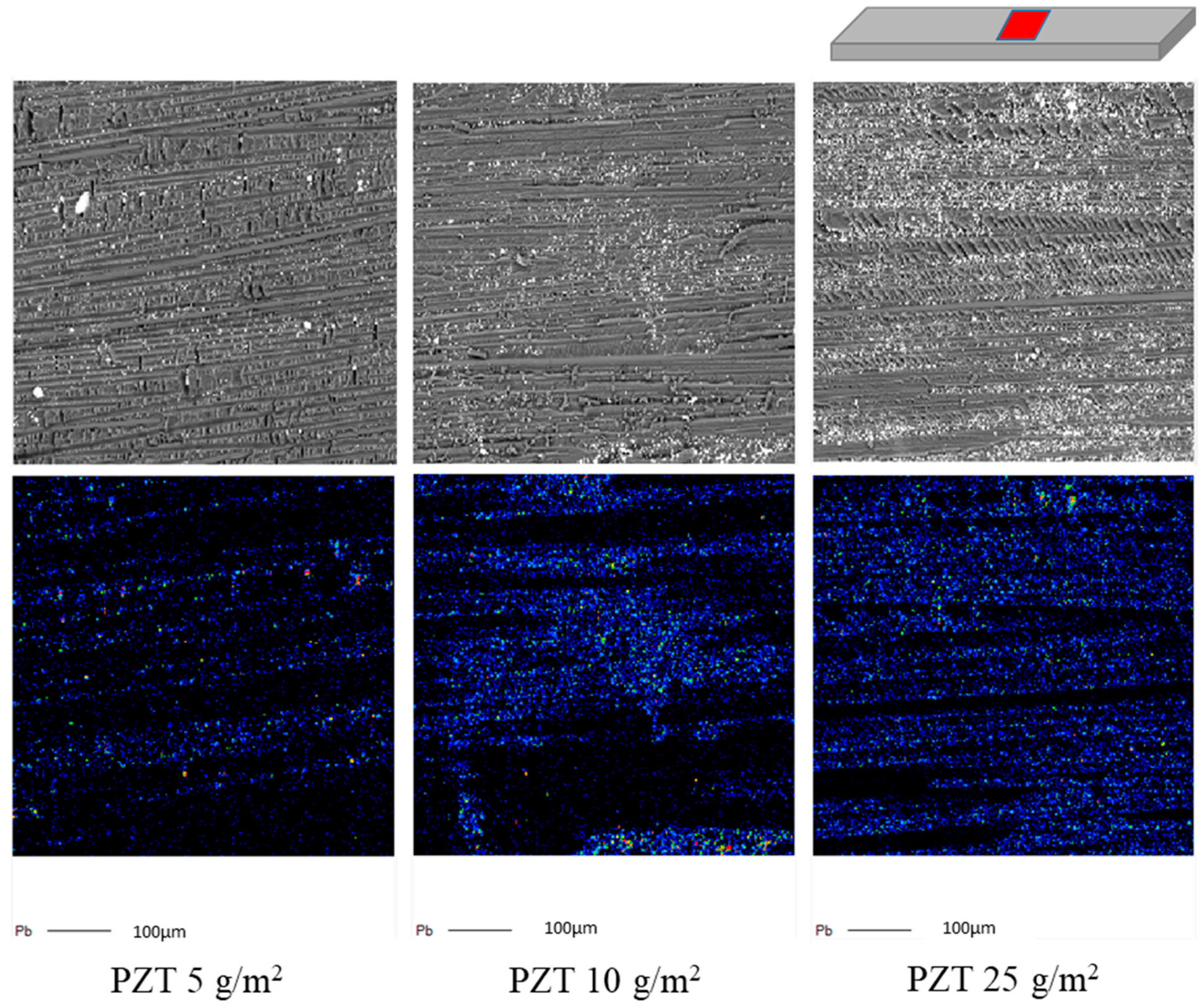

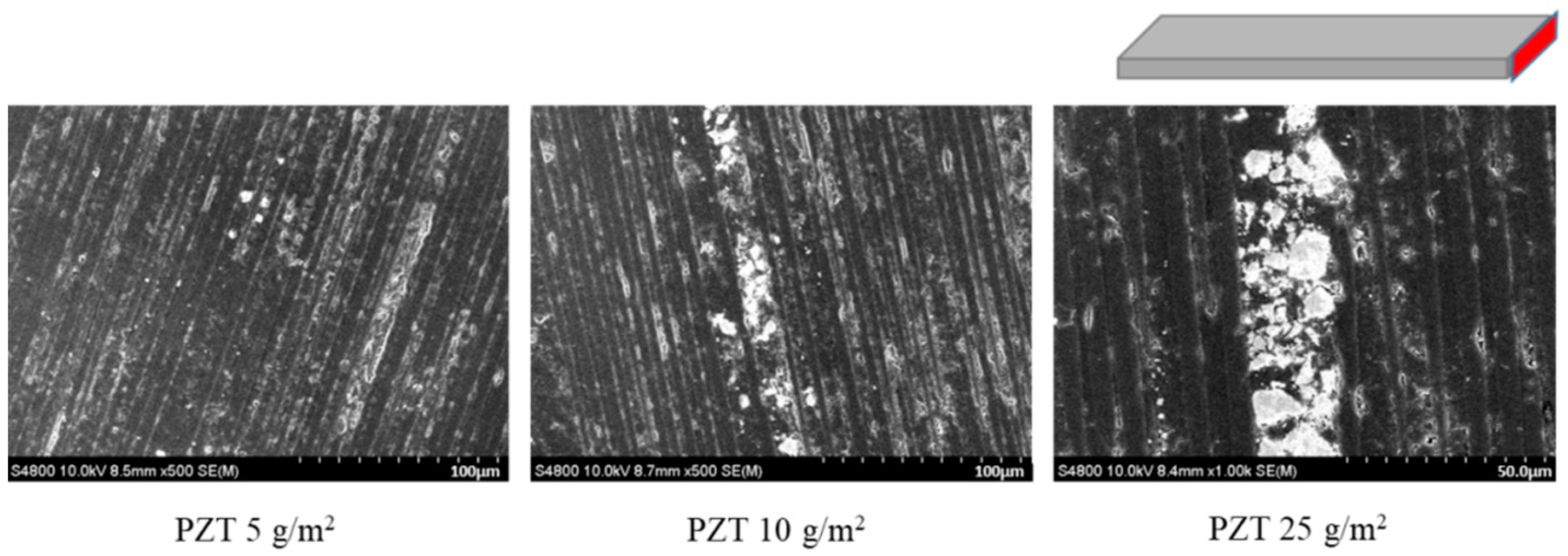

In order to confirm the improvement in particle dispersion by the use of the film, the cross-section of the specimen was further investigated using EPMA. Lead (Pb) contained in the PZT particles was traced and mapped using the EPMA. As shown in

Figure 6, good particle dispersion was confirmed. However, with the increase of the particle concentration, aggregations of the particles are formed, and the quality of dispersion deteriorates. Therefore, as described above, it is speculated that the cause of the decrease in loss factor for the particles loading at 25

is the deterioration in dispersion of particles in the film. SEM images of the cross-sections of the specimens are shown in

Figure 7, which clearly shows aggregations and thus confirms that high particle concentration may be detrimental to the dispersion of particles.

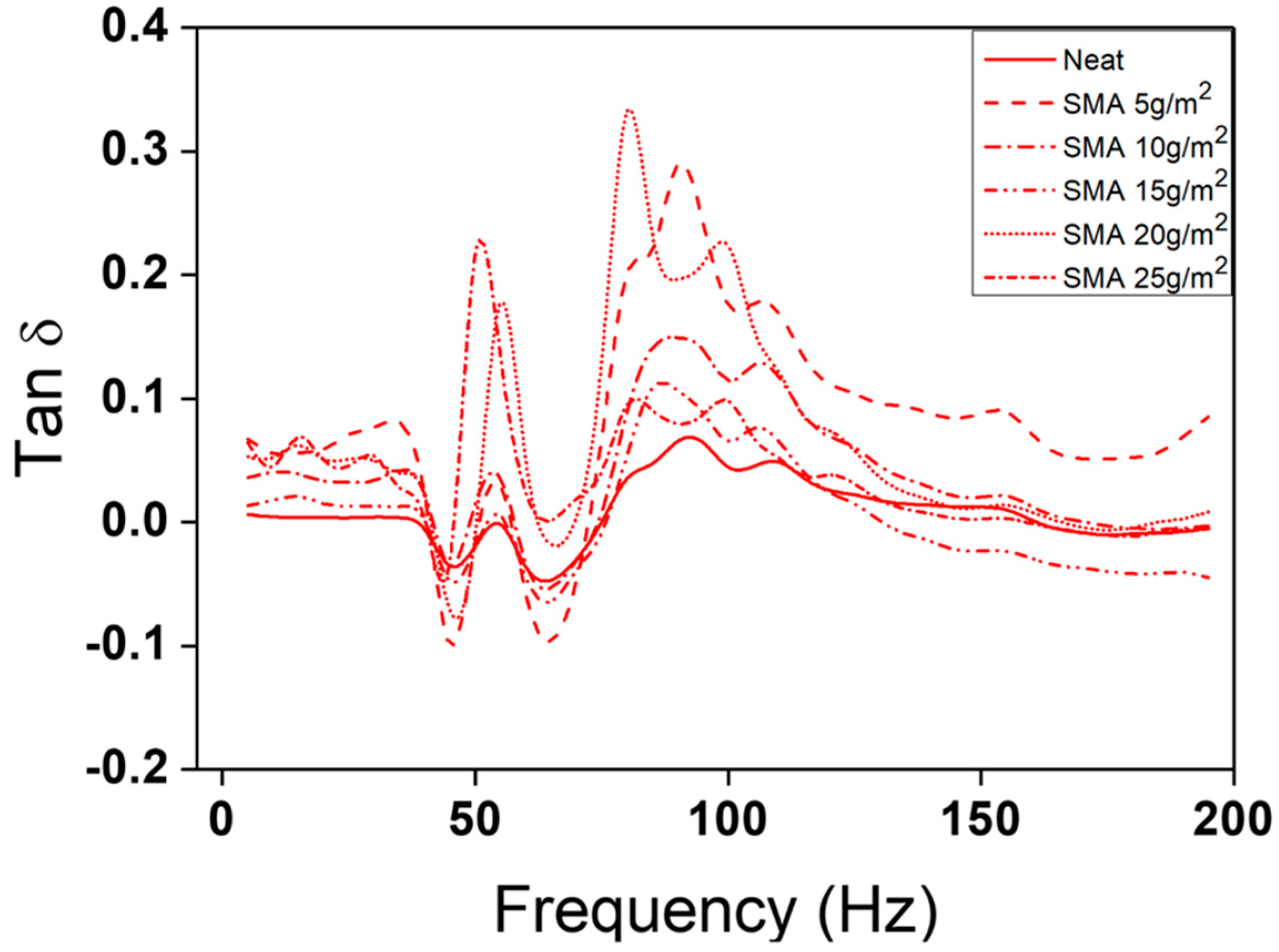

Figure 8 shows the measured loss factors of the specimens interleaved with SMA-particle-dispersed mixture films as functions of frequency. Again, the amount of SMA particles in the mixture film varied from 0

to 25

with an increment of 5

. As shown in

Figure 8, the measured loss coefficient usually increases with the particle load. Unlike the PZT-particle-dispersed specimen, the loss factor value for the SMA-particle-dispersed specimen is higher than the neat specimen under all particle loading conditions. This difference is due to the different mechanisms of PZT and SMA on improving vibration damping within the composite material. In the case of PZT, dispersion inside the composite materials is very important because each electrical circuit should be connected through contact with carbon fiber to convert vibration energy into heat energy. In the case of SMA, the dispersion inside the composite material is less critical because it has vibration damping characteristics on its own due to its hyper-elastic property. In contrast to the specimens with PZT-particle-dispersed mixture films, for SMA interleaved specimens, the frequency range where the loss factor increases most were lower at approximately 50 Hz to 100 Hz. A closer look at the results of

Figure 8 shows that the highest loss factor value was measured in a specimen containing 20

particles overall.

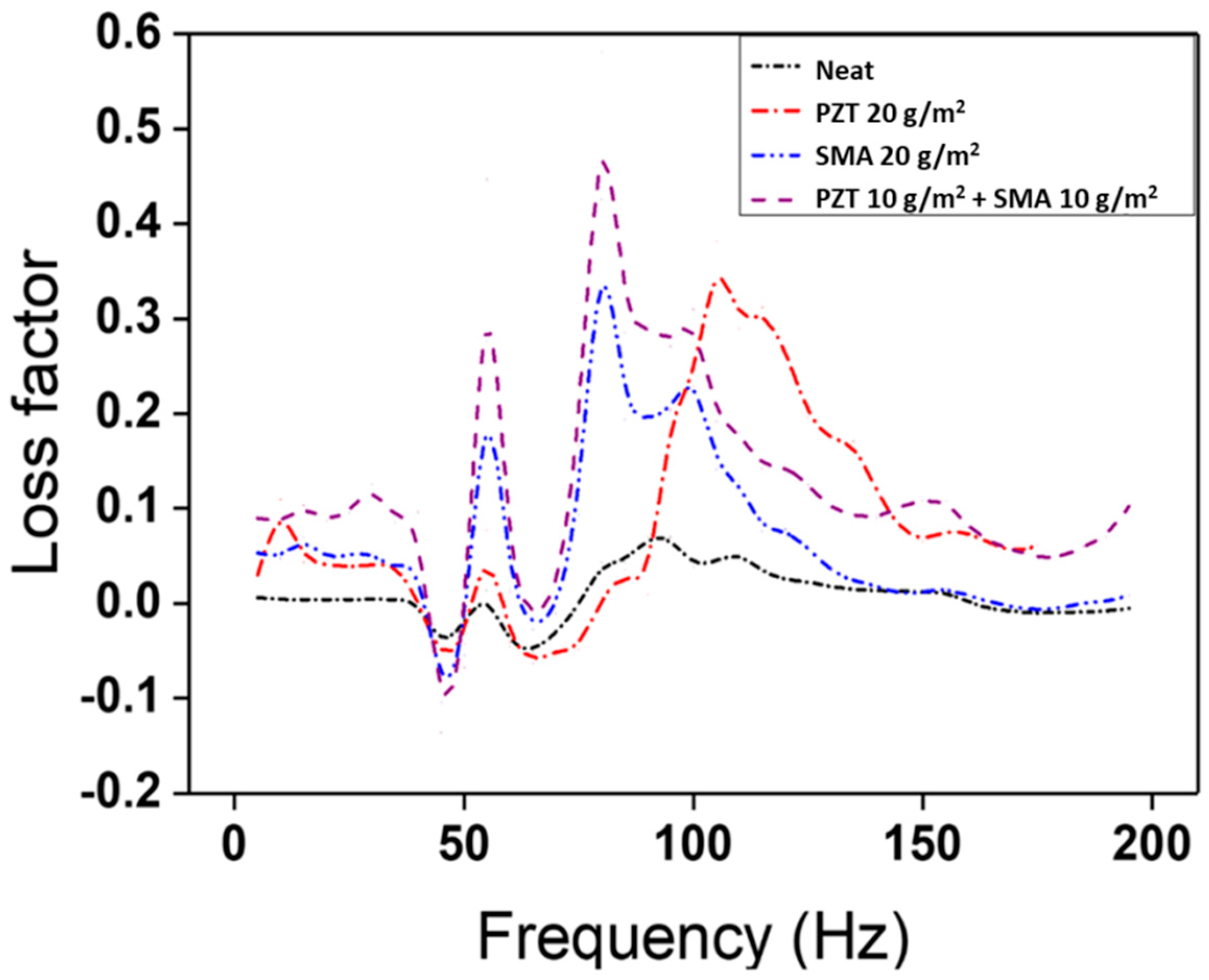

The DMA results of the carbon fiber composite material including mixed PZT and SMA-particle-dispersed mixture film (PZT + SMA) are shown in

Figure 9. The partial content of each kind of particles in the mixture film is 10

each to make the total particle content of the film 20

. In the figure, the loss factor values of PZT + SMA dispersed specimens are compared with those of PZT dispersed and SMA dispersed specimens. As mentioned above, the loss factor values of PZT + SMA dispersed specimens were measured to be larger than the loss factor of neat specimens in the whole frequency range.

It is interesting to note that the loss factor values of PZT + SMA dispersed specimens are higher than the specimens with SMA particles only in the whole frequency range. This is in contrast to the behavior of specimens with PZT particles; at 100–120 Hz, the PZT + SMA specimen had a lower loss factor value than the PZT particles specimen. Hartl et al. [

26] showed that it is necessary for SMA to reach a temperature condition that can cause phase change inside the material in order to exhibit pseudoelasticity. It was also shown that the higher the temperature, the greater the energy consumed by deformation. Therefore, in SMA, the higher the temperature is, the faster the vibration energy can be dissipated. The thermal energy generated from the deformation of the PZT accelerates the phase change of the SMA when the piezoelectric material and the shape memory alloy are used simultaneously.

Another point that can be seen from the above experimental results is that the loss factor value is negative at a specific frequency. This is due to the resonance phenomenon of the specimen, as the frequency range with negative loss factor is almost similar for all specimens. According to Menard et al., as the specimen is scanned across its frequency range, the specimen–instrument system, such as a guitar string, begins to resonate when it reaches a certain frequency. These frequencies are either the natural resonant frequencies or harmonics of the sample–instrument system. In this set of experimental conditions, the sample–instrument system vibrates as a guitar string does, obscuring the desired information about the sample. Since this resonant behavior is a physical property of the system and there is no way to change it, the experiment must be redesigned by changing the sample dimensions or shape to avoid problems [

27]. As mentioned above “Preparation of Specimens” section, all specimens used in this experiment have the same dimensions. Additionally, since the weight and elastic modulus are similar, it seems that resonance occurred at a similar frequency. The reason the negative value was measured can be seen as a calibration error of the measuring equipment or a calculation problem. However, before measuring the loss factor, the evaluation equipment should always be calibrated using a standard specimen before proceeding with the measurement. It seems that the direction of deflection of the specimen at the time of data measurement was measured as a negative number due to the resonance rather than the calibration of the measuring instrument, and the calculated value is considered to be negative. Normal values were output in the section over 100 Hz outside the resonance frequency, and since the section intensively analyzed for material properties in this study is the section over 100 Hz, it is not expected to have a significant impact on the validity of the experimental results.

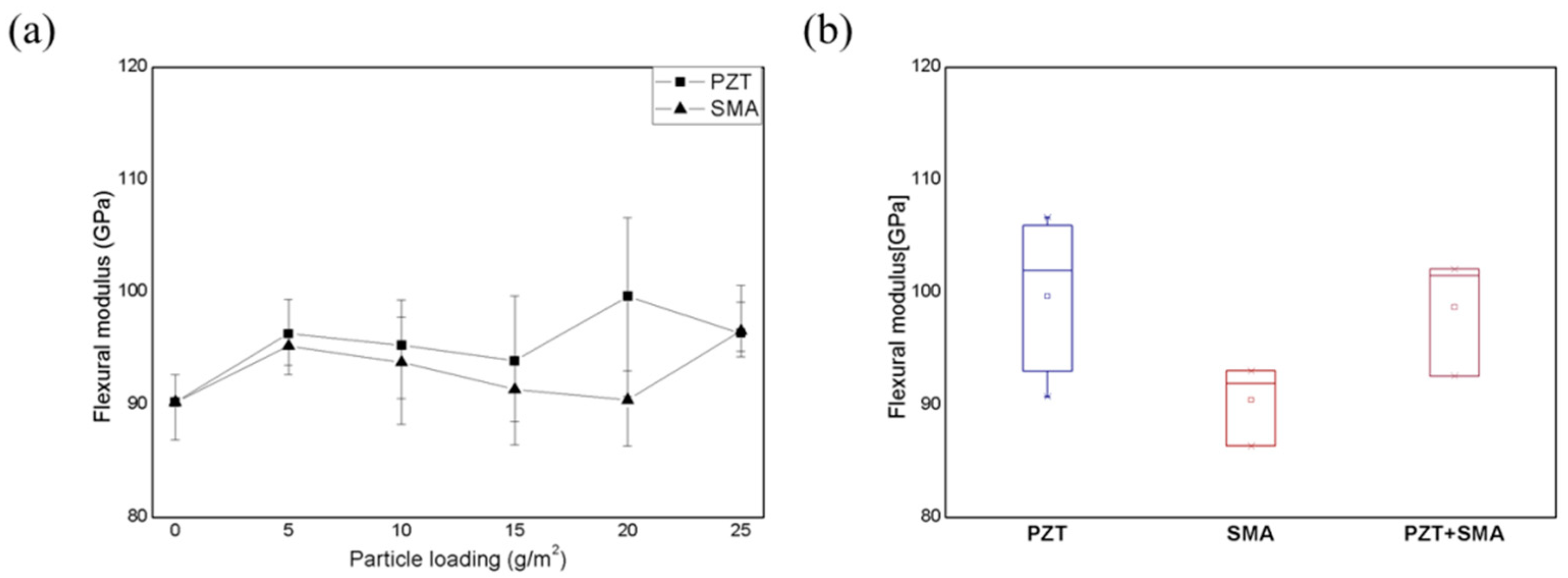

Figure 10 shows the flexural modulus of the CFRP samples interleaved with PZT-, SMA-, and mixed-particle-dispersed mixture films. The measured values showed no significant change as the content of the particles increases regardless of the type of material. This indicates that the interleaved mixture film does not act as a defect that degrades the mechanical properties of the material. It is safe to say, therefore, that interleaving PZT, SMA, and PZT + SMA particles mixture films in composite laminates can improve vibration damping capability without deteriorating the mechanical properties of the material.

4. Conclusions

In this study, functional particles such as piezoelectric (PZT) ceramic and shape memory alloy (SMA) particles have been incorporated in composite laminates to accelerate the loss of vibration energy. PZT ceramic particles and SMA particles are mixed with epoxy resin and rolled into a film shape before they are interleaved between prepreg plies for better distribution of the particles. In this study, 20 μm thickness epoxy resins film with well-dispersed particles was produced to improve particle dispersion inside composite materials. The loss factor (tan δ) was measured with various particle loadings to verify the effectiveness of interleaving in the vibration damping of laminate specimens. Therefore, dispersed particles used in this study increased the vibration damping capacity without reducing the mechanical properties.

Through SEM and EPMA, the degree of dispersion of particles inside the composite material was evaluated, and it was observed that the particles were well distributed between the composite interplies. However, in the case of the 25 specimen, PZT particles were found to form aggregates between the composite interplies. This confirmed that applying more than 25 of particles to a thin mixture film of 20 μm thickness would lead to a decrease in dispersion.

Mixture films were produced, where the content of PZT and SMA particles varied from 0 to 25 in an increment of 5 , to verify the vibration damping performance according to the content of the particles. To evaluate the vibration damping of the manufactured composite specimens, the loss factor was measured using DMA. It was recognized that there was an optimal particle content to improve vibration damping performance.

In order to verify the vibration damping effect when PZT and SMA particles are applied at the same time, a film containing 10 particles content of each material was produced. In this case, the loss factor was improved in all frequency ranges. In addition, when PZT and SMA are applied simultaneously, PZT is expected to enhance the vibration damping performance of SMA.

The flexural modulus was measured to confirm whether the introduction of interleaves between composite plies affects the mechanical properties of the material. Little change in flexural modulus with the content of the particles was observed. Therefore, dispersed particles used in this study increased the vibration damping capacity without reducing the mechanical properties.

This study demonstrates an effective way to improve the vibration damping of synthetic laminates through interleaving of particle/resin mixed films. We propose optimal conditions to improve the vibration damping capability of the composite by attempting various particles and particle loads.